Patents

Literature

135results about How to "High voltage resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

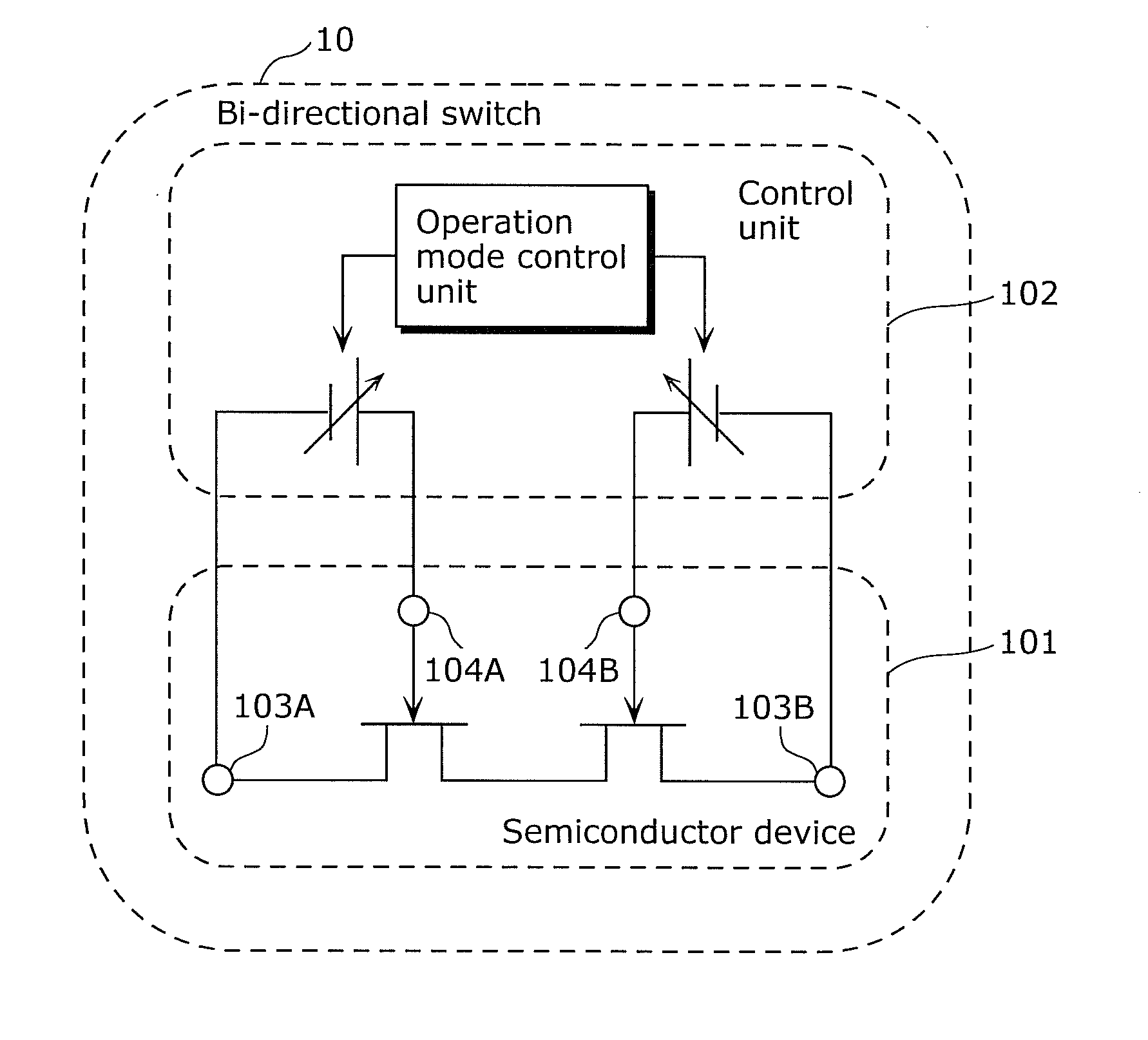

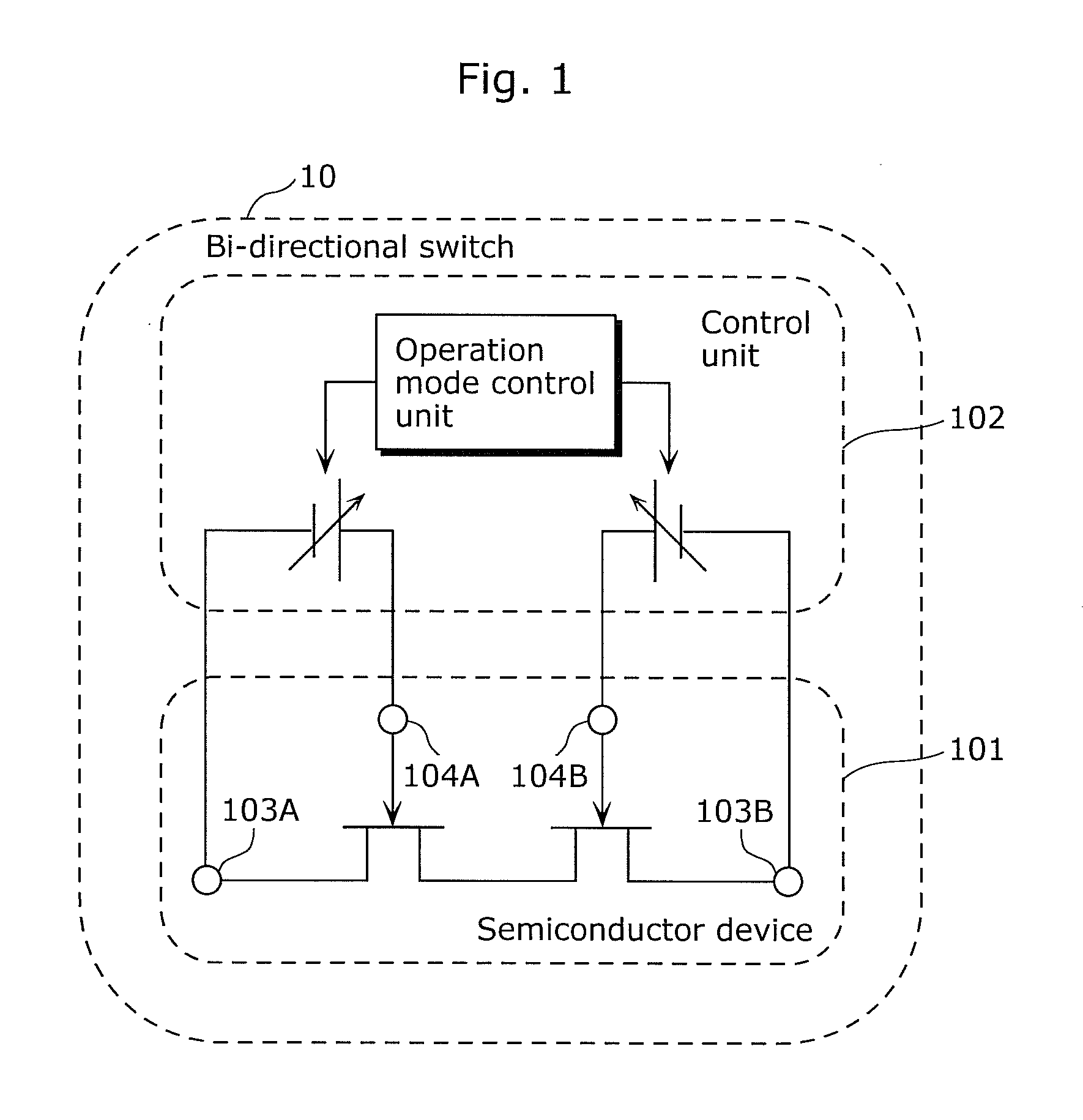

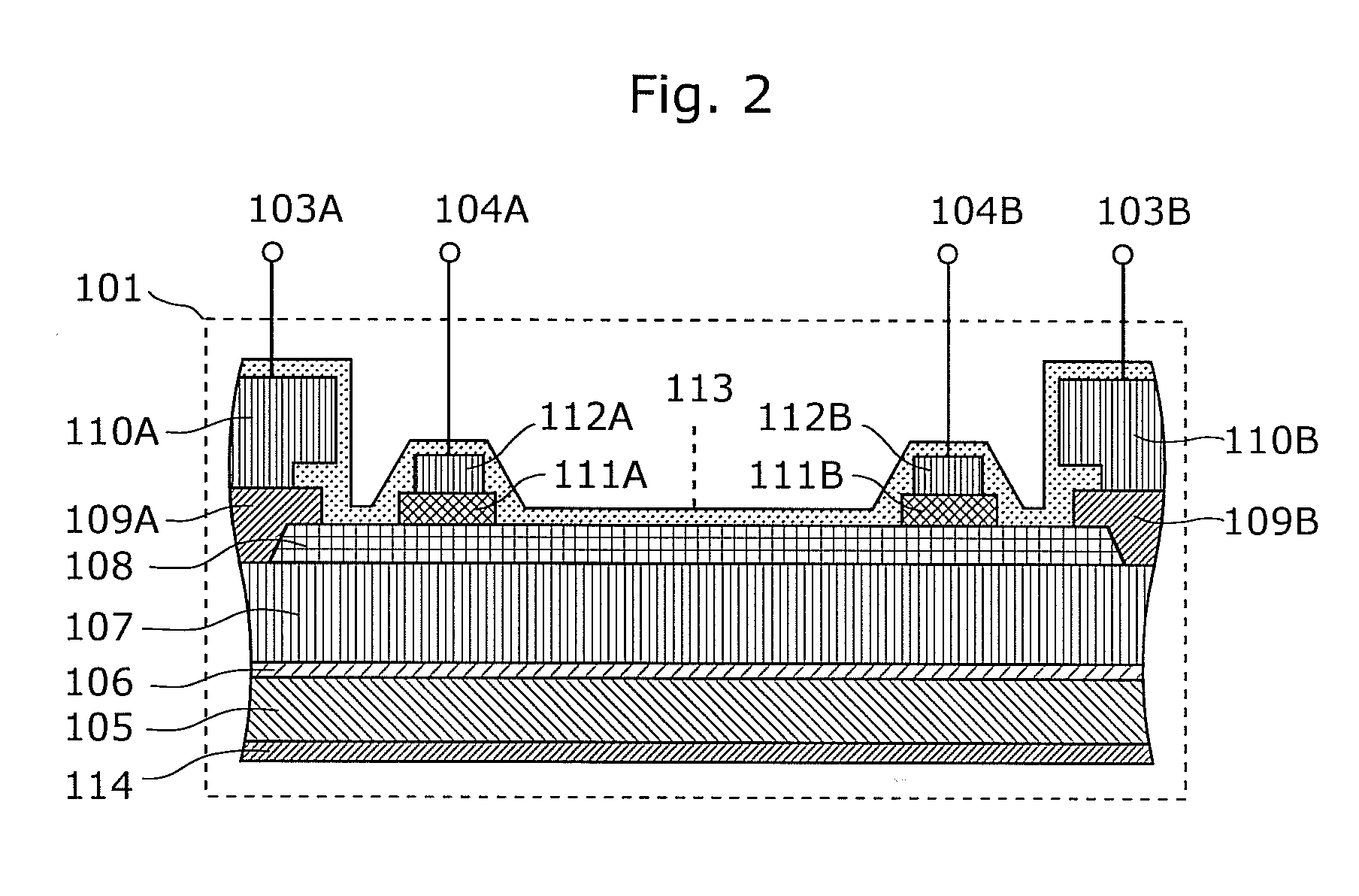

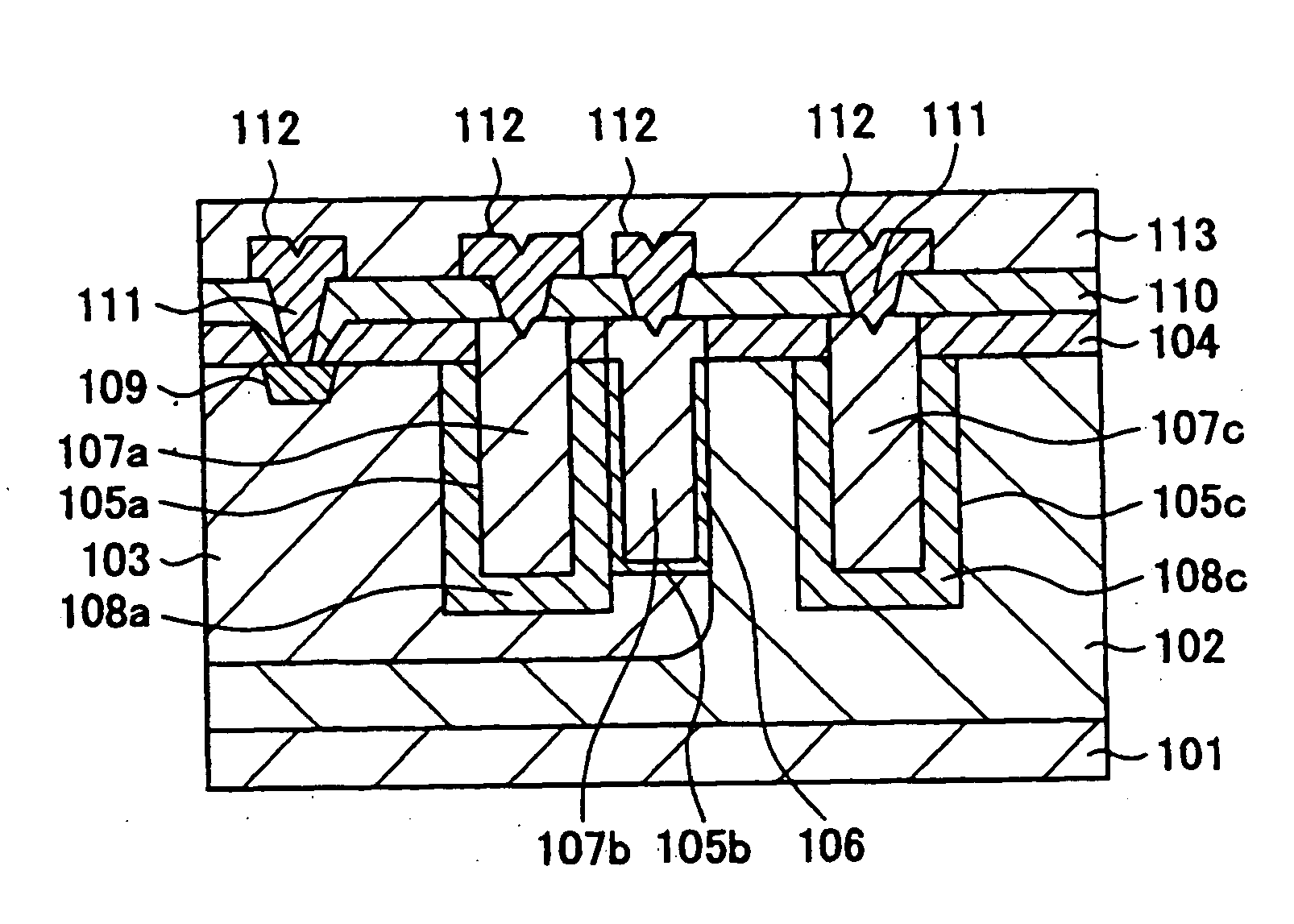

Bi-directional switch, alternating-current two-wire switch, switching power source circuit, and method of driving bi-directional switch

ActiveUS20110305054A1Reduce conduction lossLower on-resistanceAc-dc conversion without reversalElectronic switchingAlternating currentSemiconductor

A semiconductor device 101 in a bi-directional switch includes: a first electrode 109A, a second electrode 109B, a first gate electrode 112A, and a second gate electrode 112B. In a transition period: when the potential of the first electrode 109A is higher than the potential of the second electrode 109B, a voltage lower than the first threshold voltage is applied to the first gate electrode 112A and a voltage higher than the second threshold value voltage is applied to the second gate electrode 112B; and otherwise, a voltage higher than the first threshold value voltage is applied to the first gate electrode, and a voltage lower than the second threshold value voltage is applied to the second gate electrode.

Owner:PANASONIC CORP

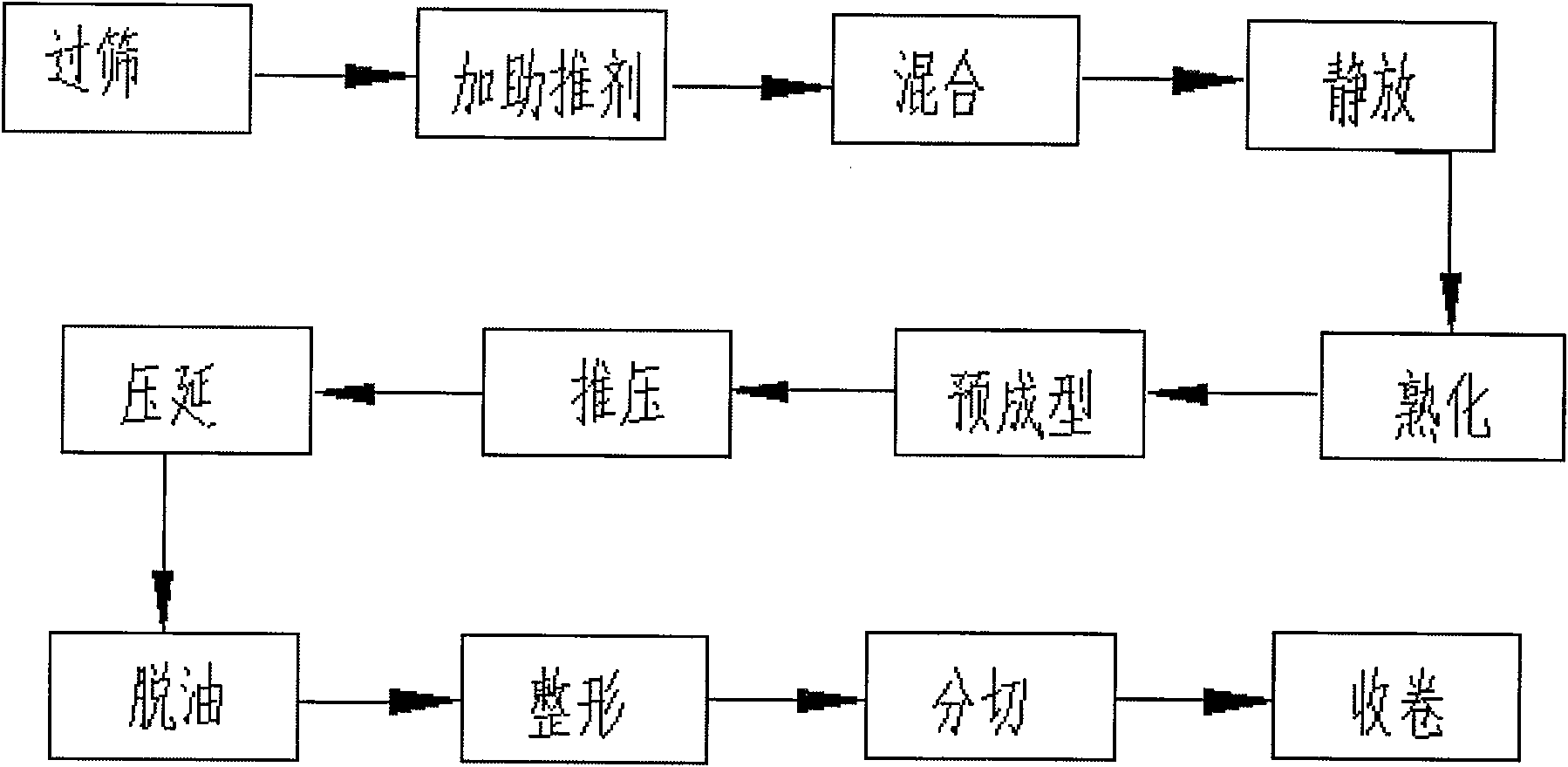

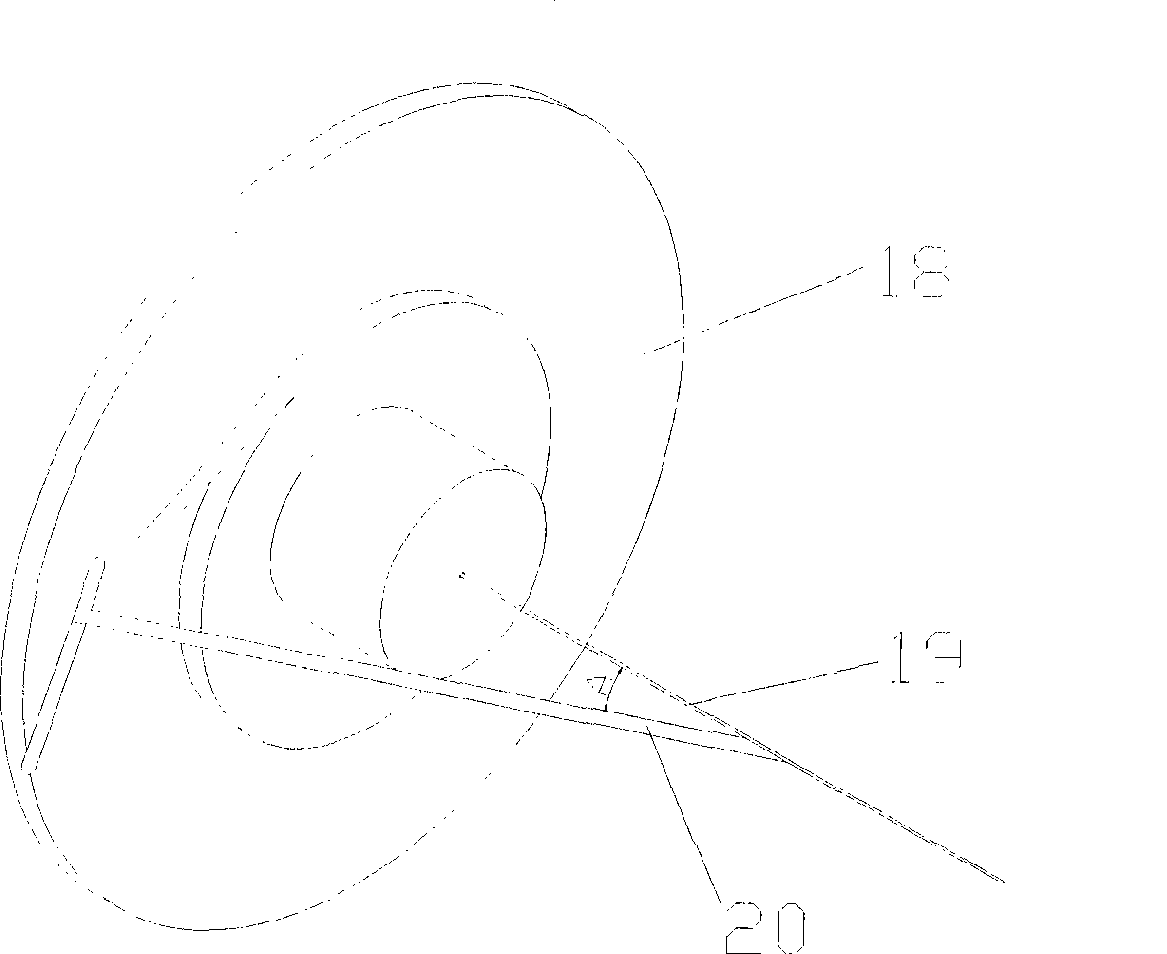

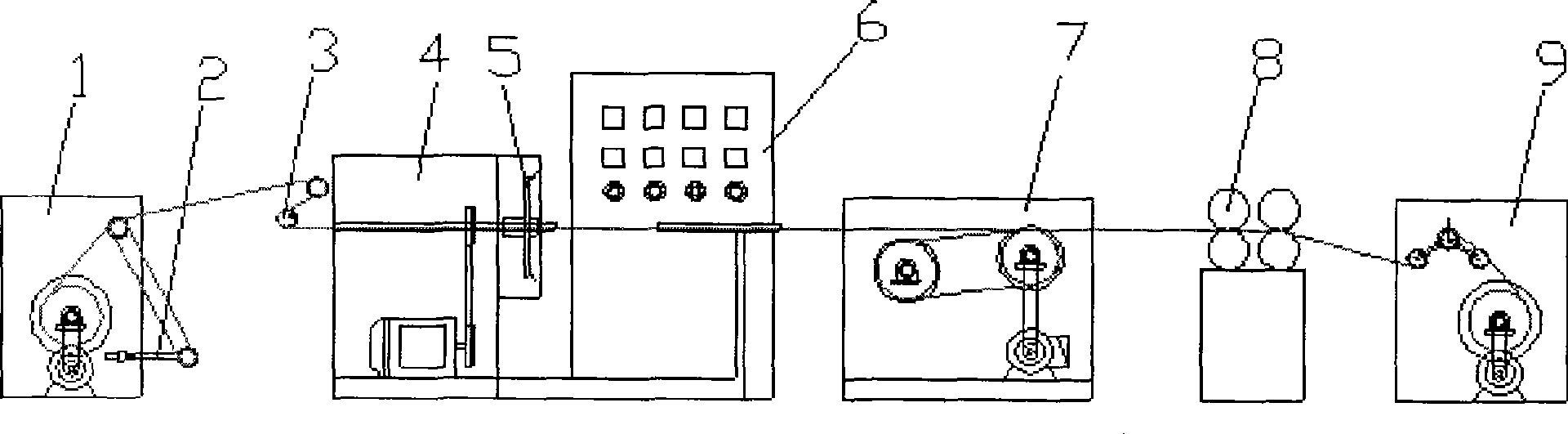

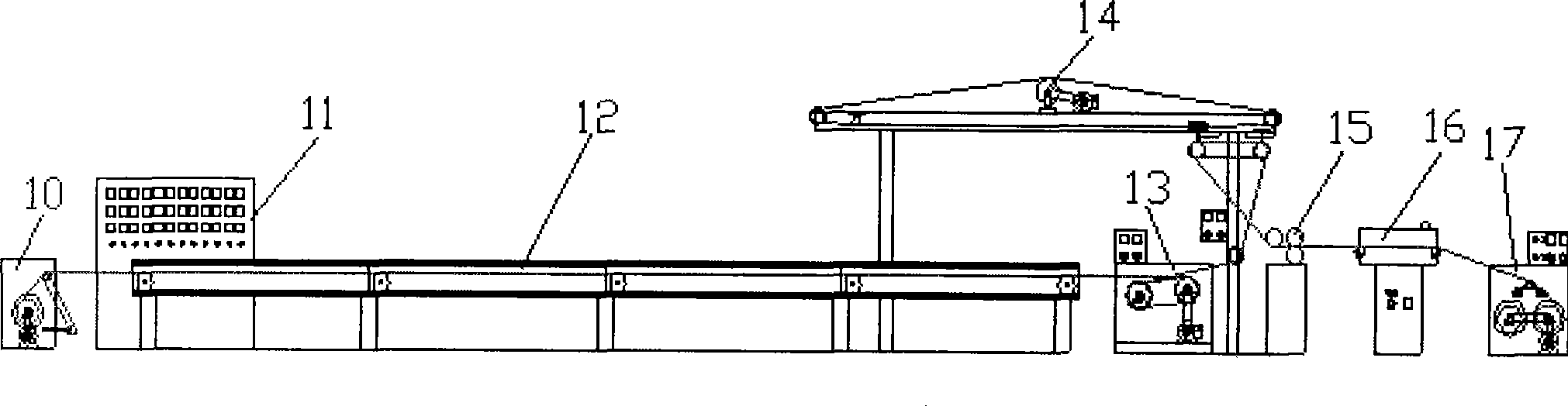

Manufacturing method of colored polytetrafluoroethylene (PTFE) thread seal tape for winding and sintering

ActiveCN101597379AImprove performanceHigh voltage resistancePlastic/resin/waxes insulatorsManufacturing technologyMixed materials

The invention provides a manufacturing method of a colored polytetrafluoroethylene (PTFE) thread seal tape for winding and sintering, comprising the following steps: sifting polytetrafluoroethylene (PTFE) dispersion resins, adding a propellant for mixing, curing the mixed materials after standing for 24 hours, prepressing to squeeze out a molded blank, calendering the blank by two rolls, removing the propellant, after shaping, slitting and rolling, finally obtaining the colored PTFE thread seal tape for winding and sintering. The colored PTFE thread seal tape for winding and sintering prepared in the invention is a major breakthrough of the manufacturing technology of ordinary thread seal tapes; the compactness, electric insulation and voltage resistance are enhanced dramatically; manufacturing electric wires by the winding and sintering method is also a major breakthrough in the electric wire manufacturing techniques; easy operation and lower cost ensure the possibility of popularizing the high-end product fluoroplastics electric wires for civil use.

Owner:四会市生料带厂有限公司

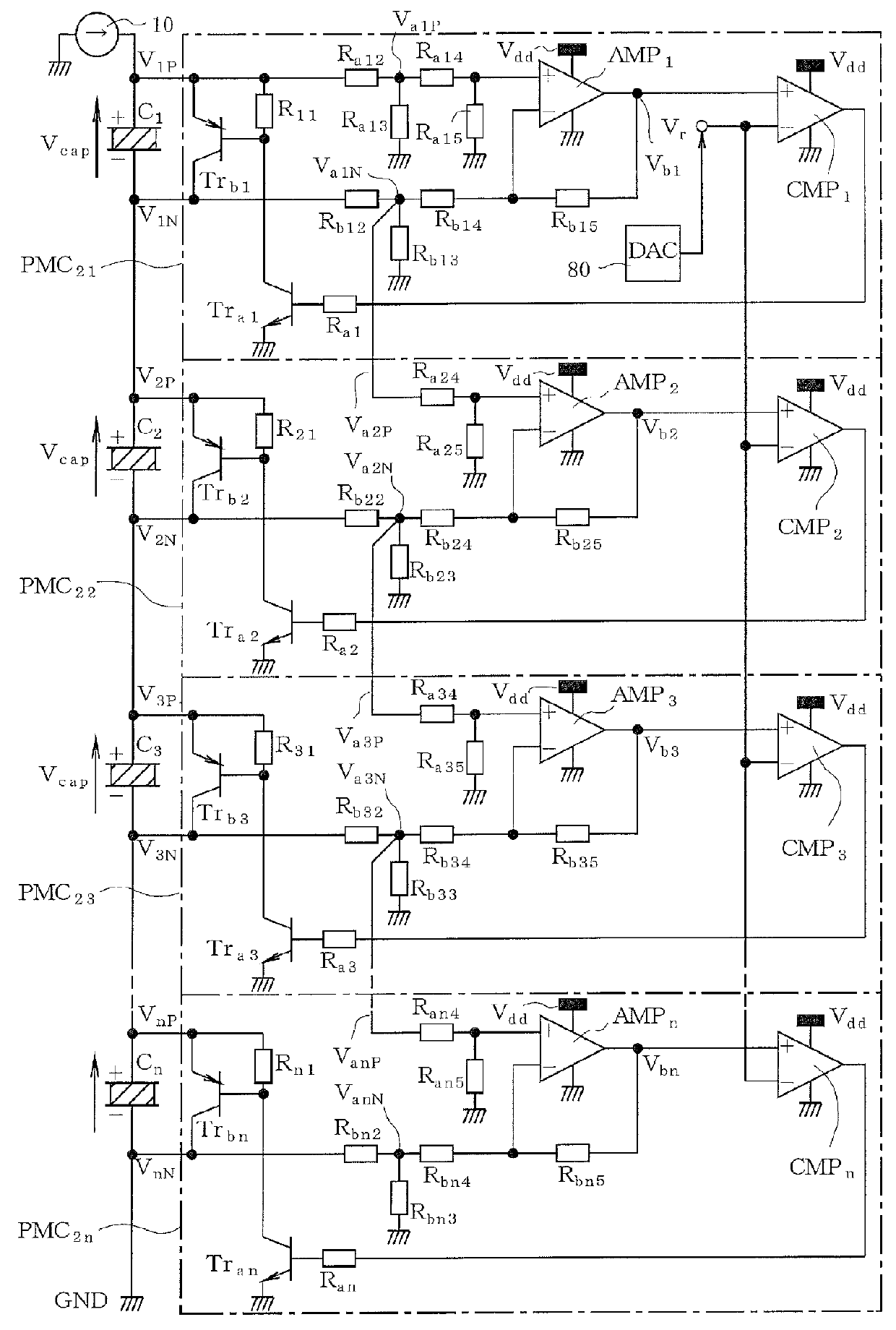

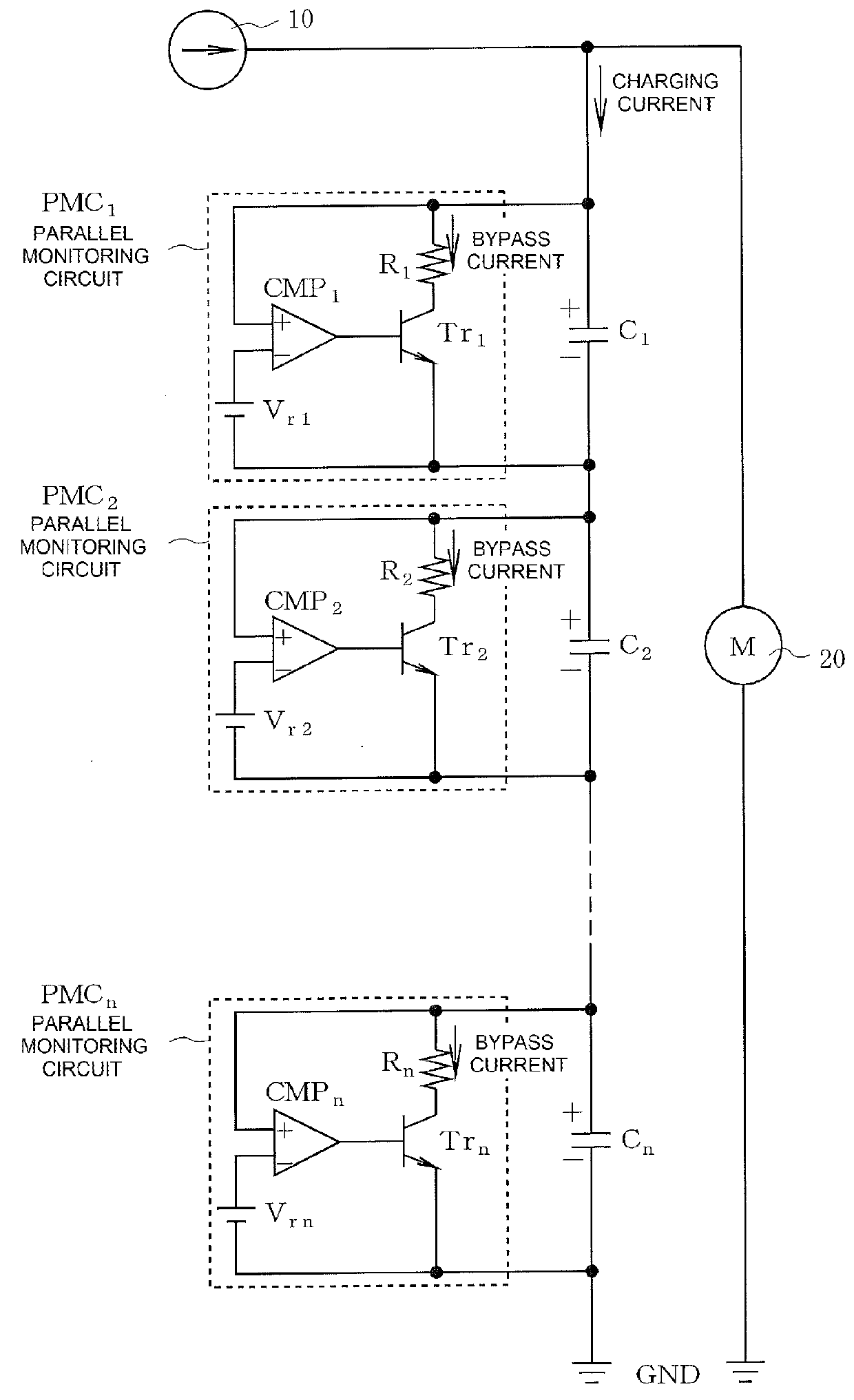

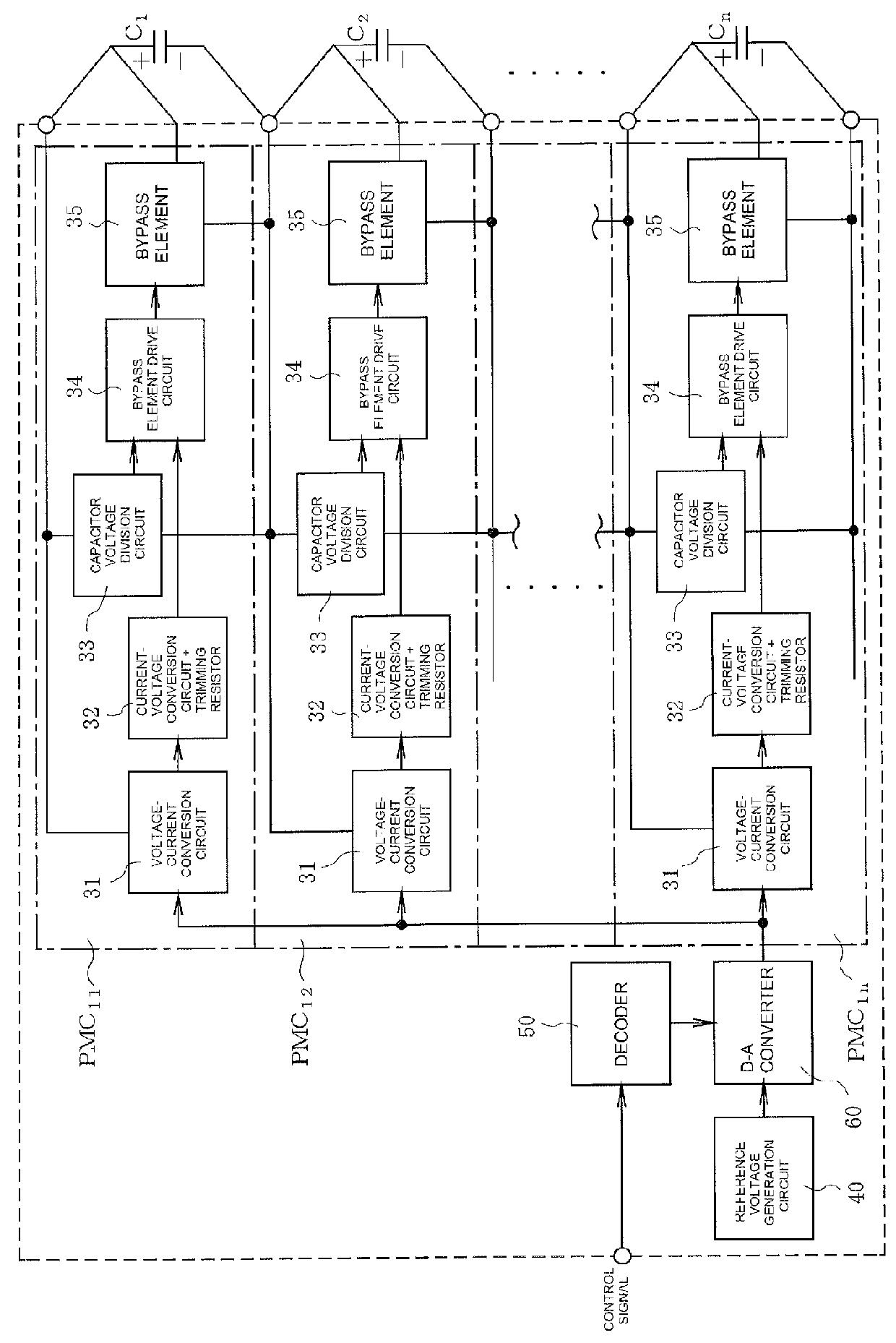

Parallel monitoring circuit for capacitor

InactiveUS20160036248A1High voltage resistanceCharge equalisation circuitCircuit monitoring/indicationElectrical resistance and conductanceCharge current

A capacitor charging-discharging system, including a plurality of serially connected capacitors, a voltage source for setting an equalization potential, and a plurality of parallel monitoring circuit. Each parallel monitoring circuit is connected to the two ends electrodes of one capacitor, and includes: a voltage dividing circuit configured to resistively divide and attenuate two voltages respectively on the two end electrodes of the one capacitor, a differential amplifier configured to amplify a difference between the two divided voltages to thereby detecting a charge potential of the one capacitor, a comparator configured to compare the charge potential with the equalization potential, and a charge current bypass circuit configured to control charge current of the one capacitor, based on an output of the comparator, so that the charge potential of the one capacitor matches the equalization potential.

Owner:FUJI ELECTRIC CO LTD

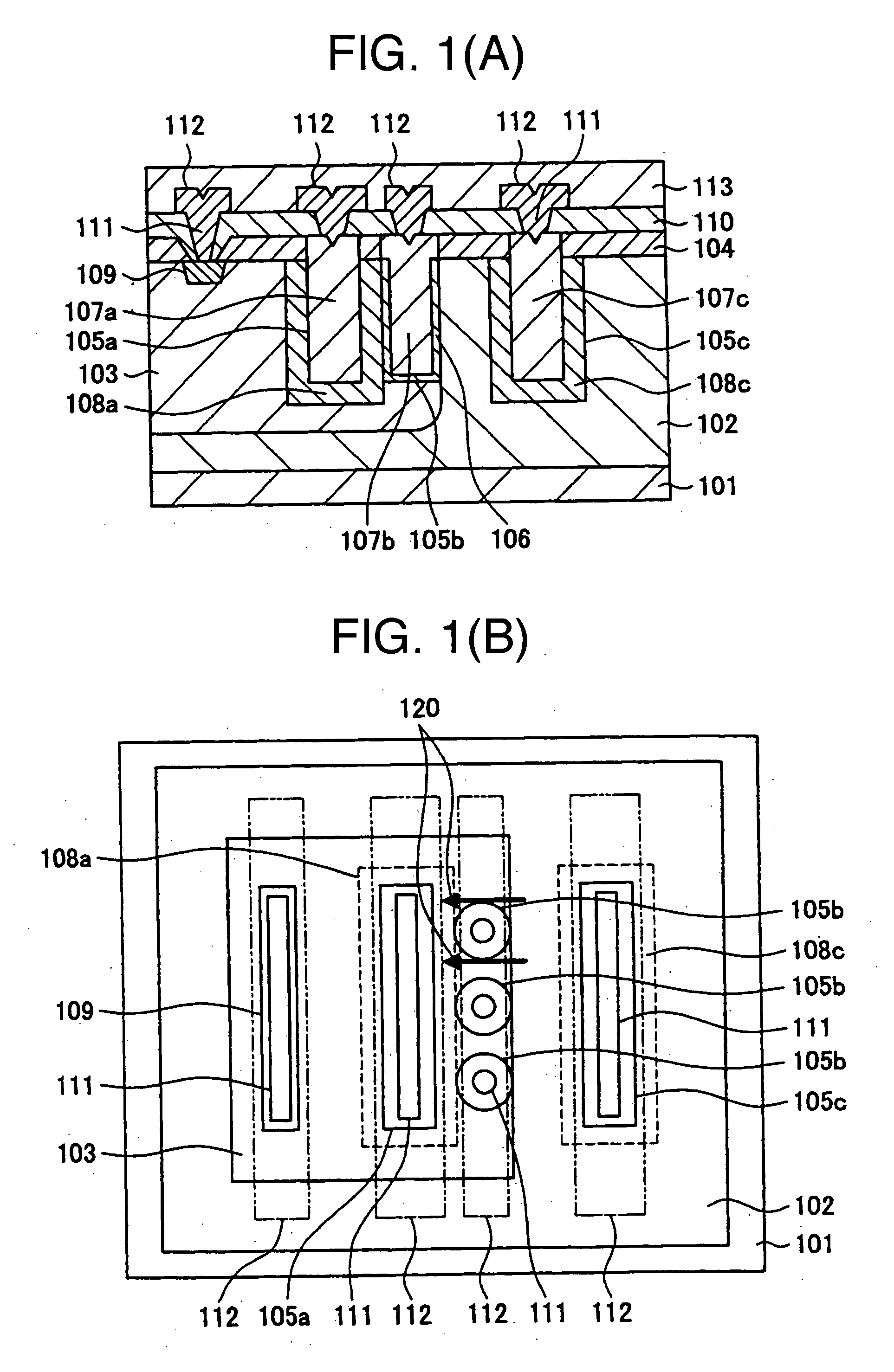

A structure of a lateral diffusion mos transistor in widespread use as a power control device

InactiveUS20050093060A1High currentShort pathTransistorSolid-state devicesDevice materialHigh pressure

There is provided a semiconductor device structured so as to be mounted jointly with other devices on one chip, and capable of controlling a large current in spite of a small device area while having small on-resistance, thereby enabling a high voltage resistance to be obtained. In the case of NLDMOS, the semiconductor device comprises an N well layer, formed on a p-type semiconductor substrate, a P well layer formed in the N well layer, a source electrode formed in a source trench cavity within the P well layer, a gate electrode formed in at least one of gate trench cavities within the P well layer, through the intermediary of an oxide film, and a drain electrode formed in a drain trench cavity within the N well layer, and further, N+ diffused layers are formed around the source trench cavity, the drain trench cavity, respectively.

Owner:LAPIS SEMICON CO LTD

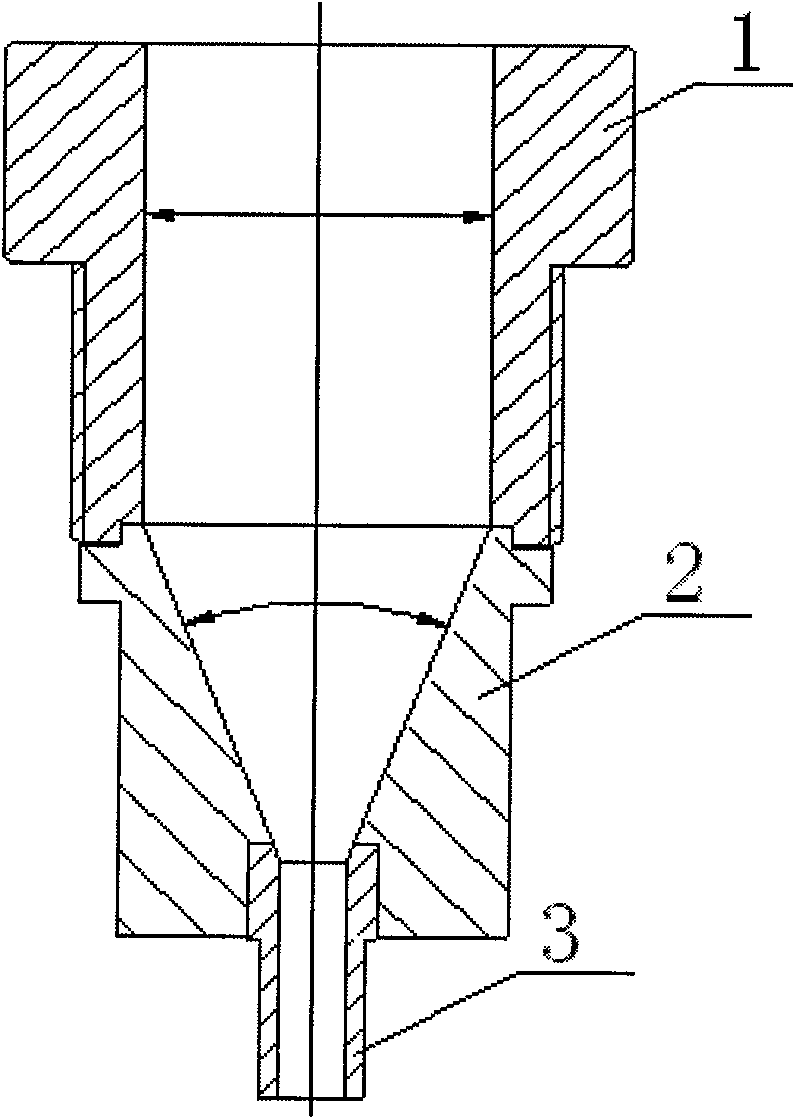

Sealed switching connector

InactiveCN101707310AImprove pressure resistanceImprove high-pressure sealing performanceCoupling device detailsEngineeringHigh pressure

The invention discloses a sealed switching connector, which is characterized in that ceramic tubes are sleeved on the excircles on contact elements of the contactor, and at least one end of the excircles is positioned at the end openings of contact pin channels; glass sealing members are integrally sintered between the inner walls of the channels at the inner end openings of the ceramic tubes in the contact pin channels and the contact elements, between the outer walls of the ceramic tubes and the inner walls of the contact pin channels as well as between the inner walls of the ceramic tubes and the contact elements; and the ceramic tubes, a metal shell and sealing-in pins are solidified into a whole by the integrally sintered glass sealing members. The invention greatly improves the high pressure sealing property of the connector by or above 140MPa, so that the connector can completely bear the hydraulic pressure of the special high-pressure vessels and ensure overall sealing of the high-pressure fluid vessels not to be affected while finishing signal transmission.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

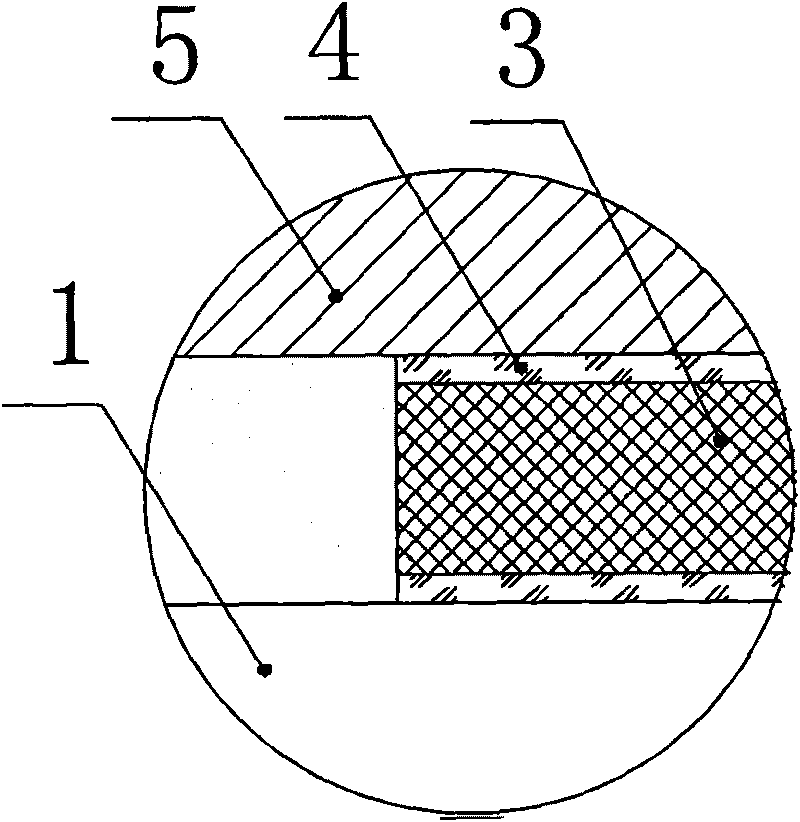

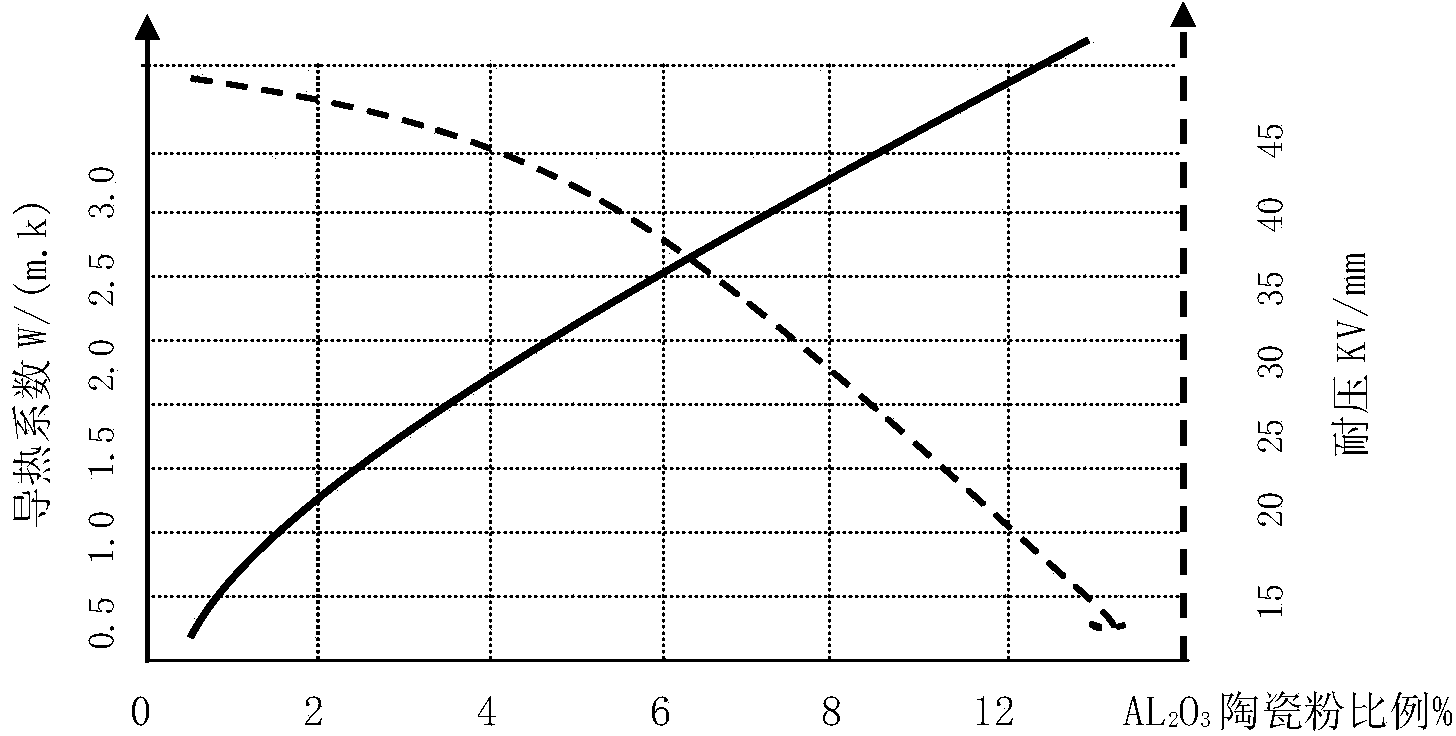

Copper-clad plate with aluminum substrate and media filled with ceramics and method for manufacturing copper-clad plate

ActiveCN104363697AImprove cooling effectHigh voltage resistanceSynthetic resin layered productsPrinted circuit manufactureEpoxyAluminum substrate

The invention provides a copper-clad plate with an aluminum substrate and media filled with ceramics and a method for manufacturing the copper-clad plate. The copper-clad plate with the aluminum substrate and the media filled with the ceramics comprises an aluminum-base bottom plate, an insulating layer and a conducting circuit layer. The insulating layer is stacked between the aluminum-base bottom plate and the conducting circuit layer and comprises epoxy resin and alpha-Al<2>O<3> ceramic powder, the alpha-Al<2>O<3> ceramic powder is dispersed in the epoxy resin, and the mass percent of the alpha-Al<2>O<3> ceramic powder in the insulating layer ranges from 3% to 9%. The copper-clad plate and the method have the advantages that the insulating layer of the copper-clad plate with the aluminum substrate and the media filled with the ceramics comprises the alpha-Al<2>O<3> ceramic powder and the epoxy resin, alpha-Al<2>O<3> is high heat conductivity and voltage withstand property and is added into the insulating layer, and accordingly the problem of degradation of voltage withstand property due to ceramic powder filling can be effectively solved.

Owner:嘉兴庆春电子科技有限公司

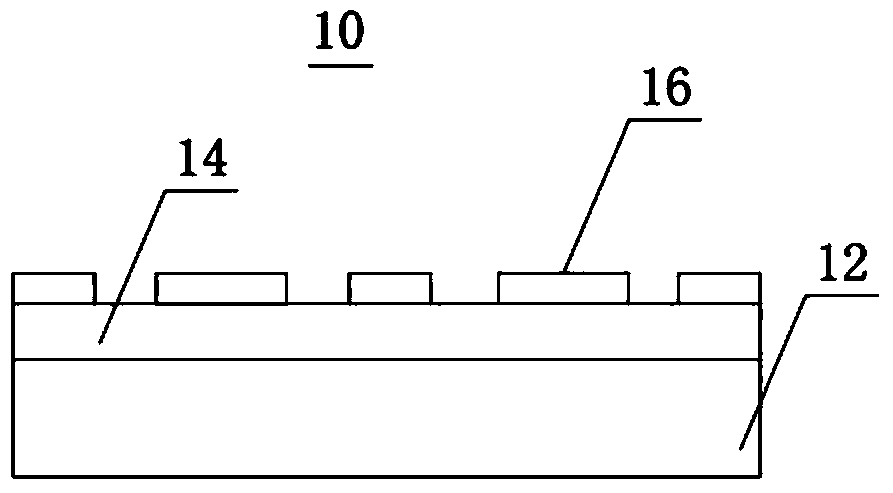

Schottky diode with diamond rod and method for manufacturing the same

InactiveUS20110297962A1Excellent on/off characteristicCost of productionSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky diodeMaterials science

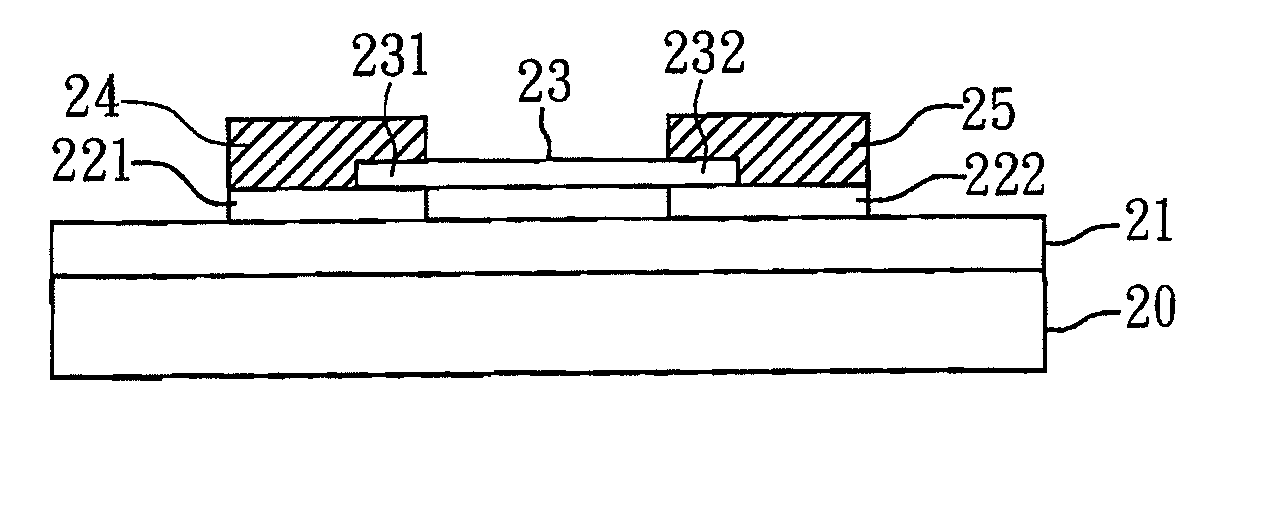

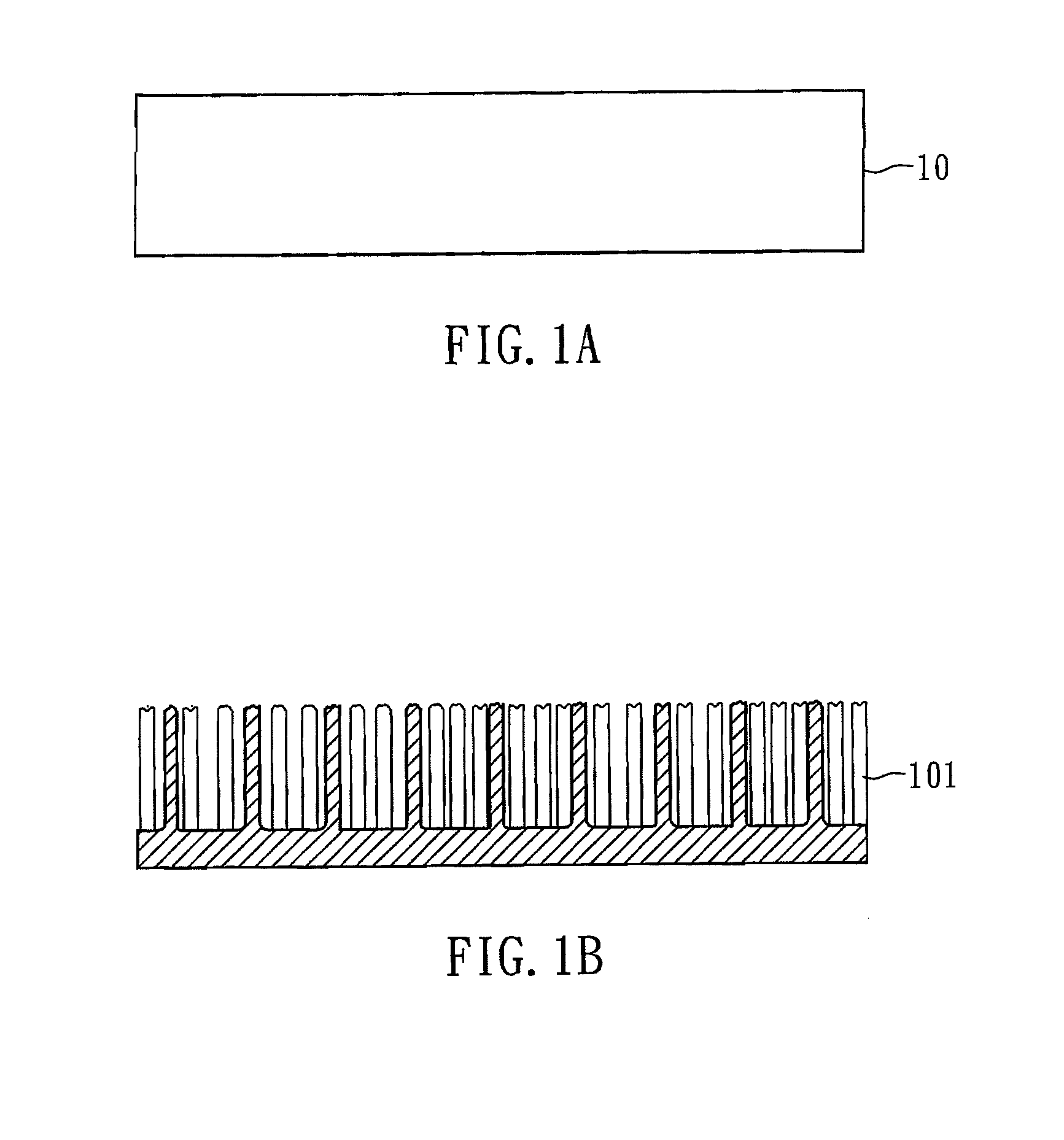

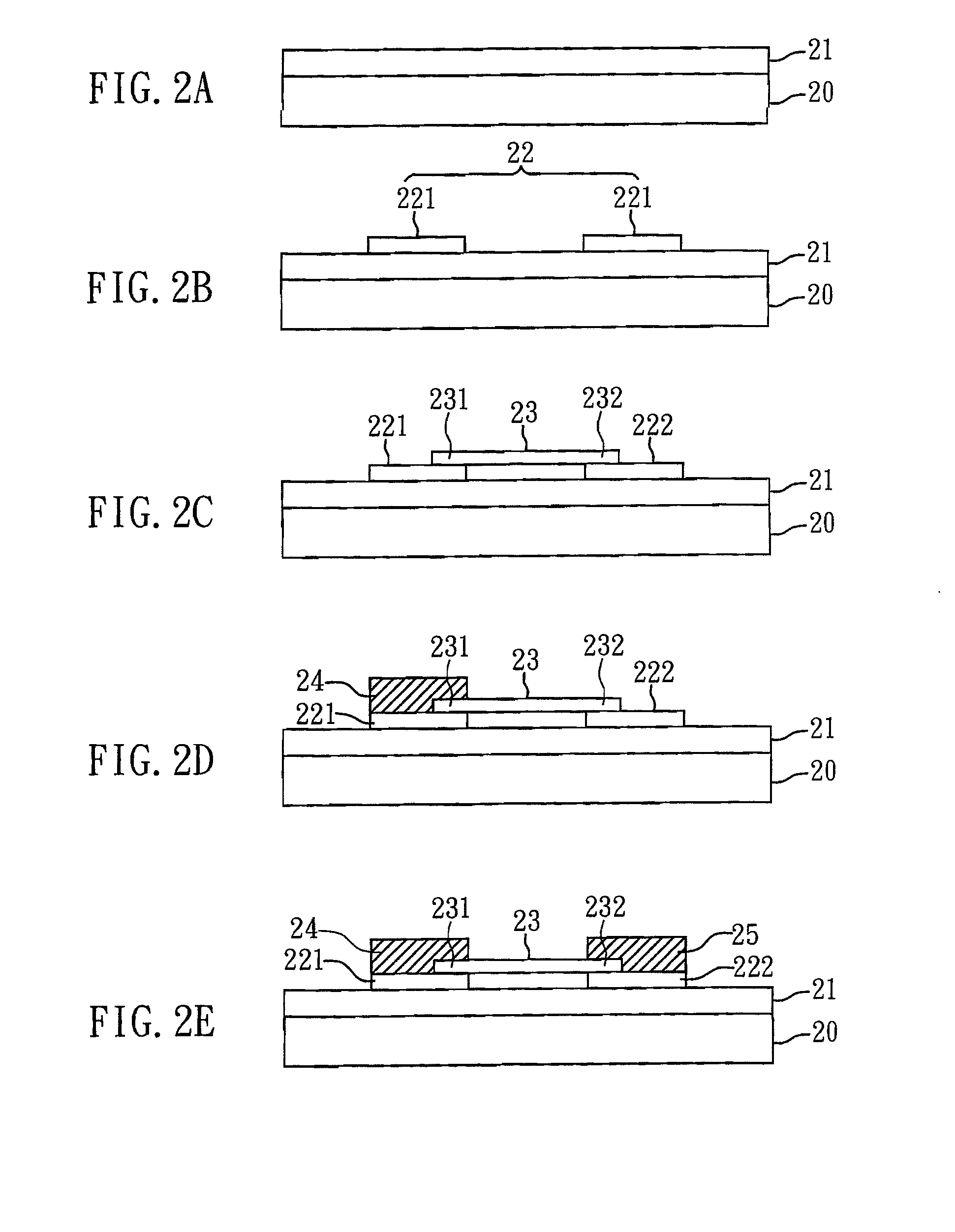

The present invention relates to a Schottky diode with a diamond rod, which comprises: a substrate with a gate layer formed thereon; a patterned insulating layer disposed on the gate layer, wherein the patterned insulating layer comprises a first contact region and a second contact region; a diamond rod disposed on the patterned insulating layer, wherein a first end of the diamond rod connects to the first contact region, and a second end of the diamond rod connects to the second contact region; a first electrode corresponding to the first contact region of the patterned insulating layer, and covering the first end of the diamond rod; and a second electrode corresponding to the second contact region of the patterned insulating layer, and covering the second end of the diamond rod, and a method for manufacturing the same.

Owner:NATIONAL TSING HUA UNIVERSITY

Method for manufacturing smokeless incombustible temperature-resistant tetrafluoroethylene electric wire

InactiveCN101533688AUniform apparent densityHigh apparent densityPlastic/resin/waxes insulatorsInsulated cablesStrong acidsOxygen

The invention provides a method for manufacturing smokeless incombustible temperature-resistant tetrafluoroethylene electric wire, comprising the steps of uniformly and seamlessly winding tetrafluoroethylene colour raw material belt for winding and sintering on nickel plated copper stranded wire according to a certain winding angle, improving the apparent density of winding belt by a shaping technology, and finally sintering so as to obtain the smokeless incombustible temperature-resistant tetrafluoroethylene electric wire. The invention has the advantages that 1. the thickness is uniform, the surface is smooth, and the compactness is high; 2. the manufacturing process is simple and the operation is simple and convenient; 3. the manufacturing cost is reduced by 50% compared with the manufacturing method in a paste extrusion manner; and 4. the breakdown resistant voltage can be 6000-8000V, the used rated voltage is 600V, the temperature range for long term usage is -65 to 260 DEG C, the limited oxygen index is more than 95, and the electric wire is incombustible and resistant to strong acids, strong alkalis and aging.

Owner:四会市生料带厂有限公司

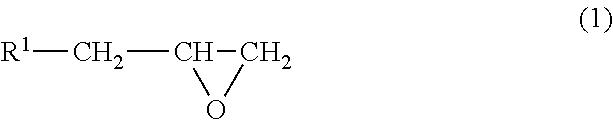

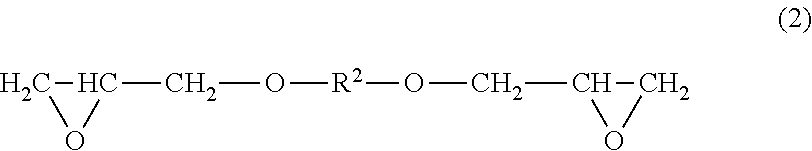

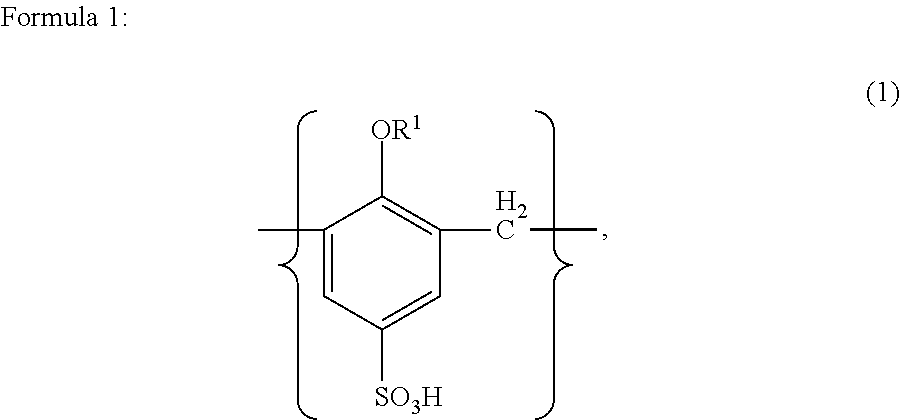

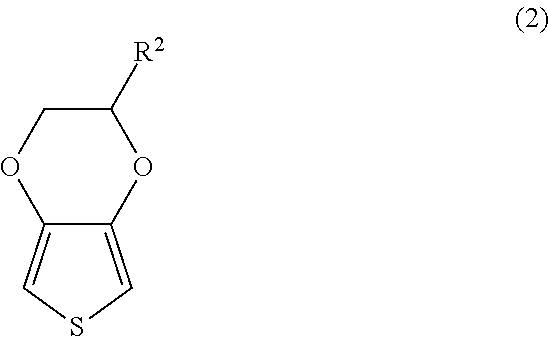

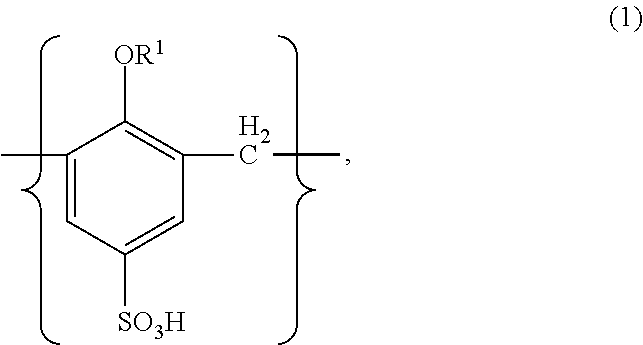

Oxidant and dopant solution for conductive polymer production, a conductive polymer and a solid electrolyte capacitor

ActiveUS20120165488A1High voltage resistanceFavorably useSolid electrolytic capacitorsOther chemical processesOxidizing agentGlycylxylidide

There is provided an oxidant and dopant which can produce a conductive polymer. The conductive polymer can be used in a solid electrolyte capacitor as solid electrolyte. The solid electrolyte capacitor can be provided with improved breakdown voltage and voltage resistance, as well as less generation of the defects due to leak current. There is provided an oxidant and dopant solution for conductive polymer production including an oxidant and dopant for an organic ferric sulfonate, and an alcohol with a carbon number of 1 to 4. The oxidant and dopant solution further includes a compound with a glycidyl group, or its ring-opened compound. Faborably, a polyalcohol is further added. Using the oxidant and dopant solution, a thiophene or its derivative is subject to an oxidation polymerization to prepare a conductive polymer, which can be used as solid electrolyte of a solid electrolyte capacitor.

Owner:TAYCA CORP

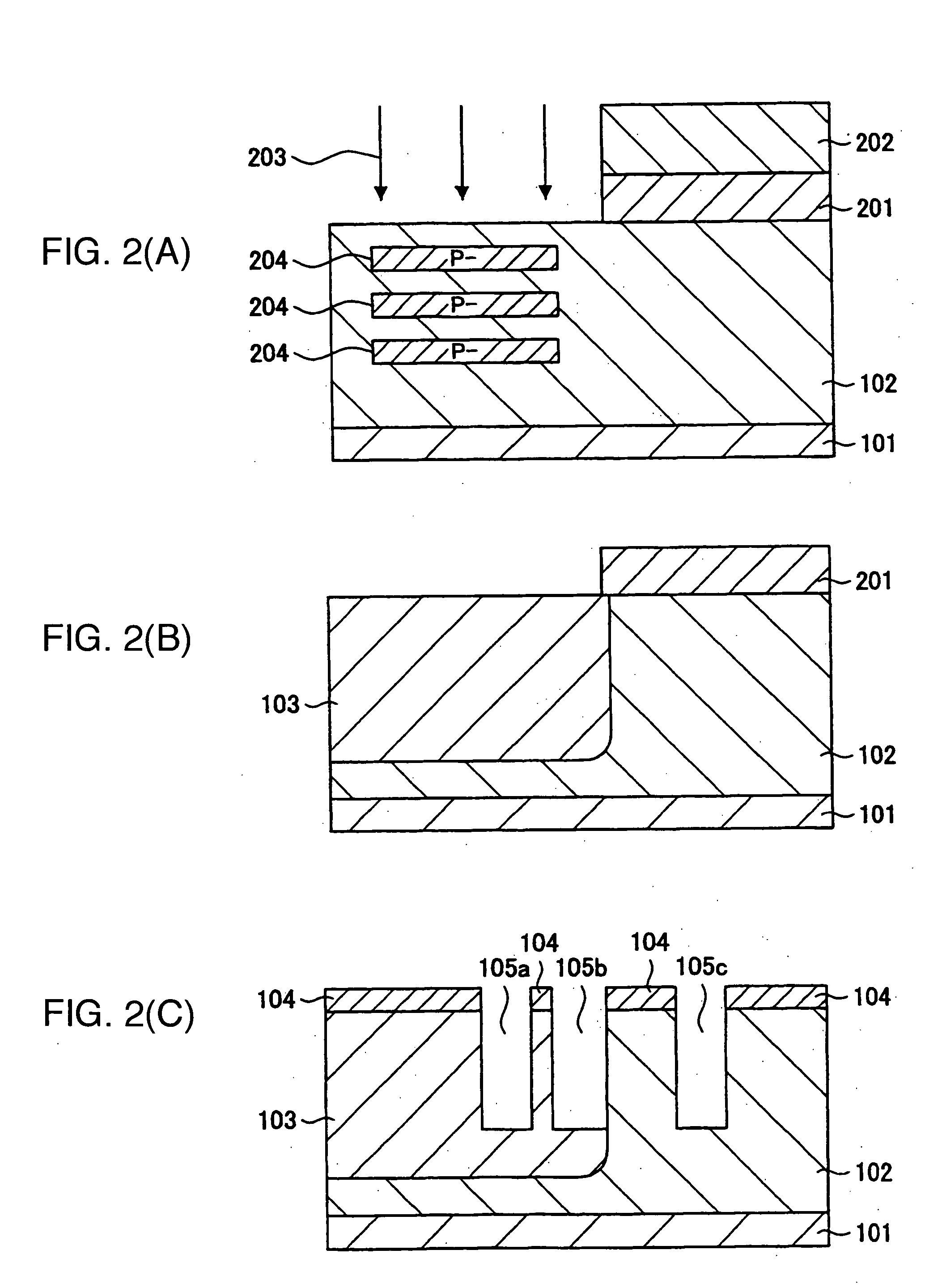

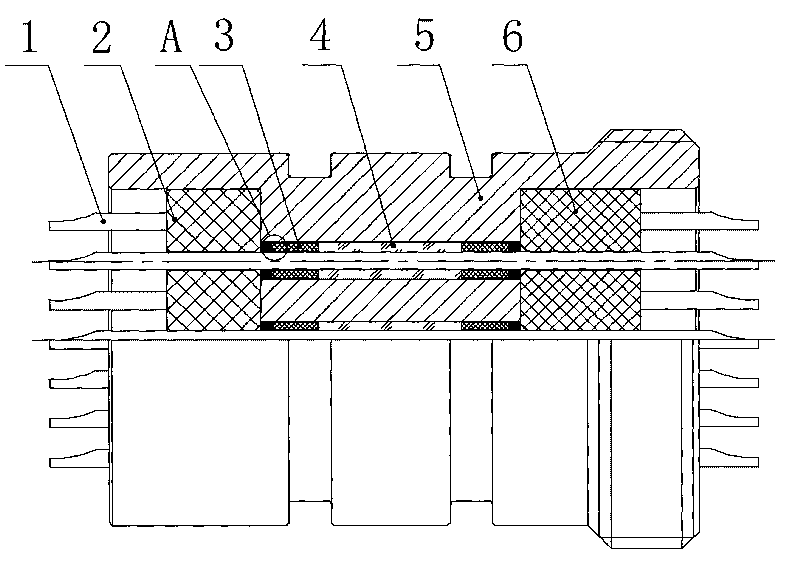

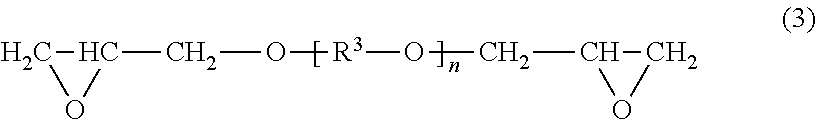

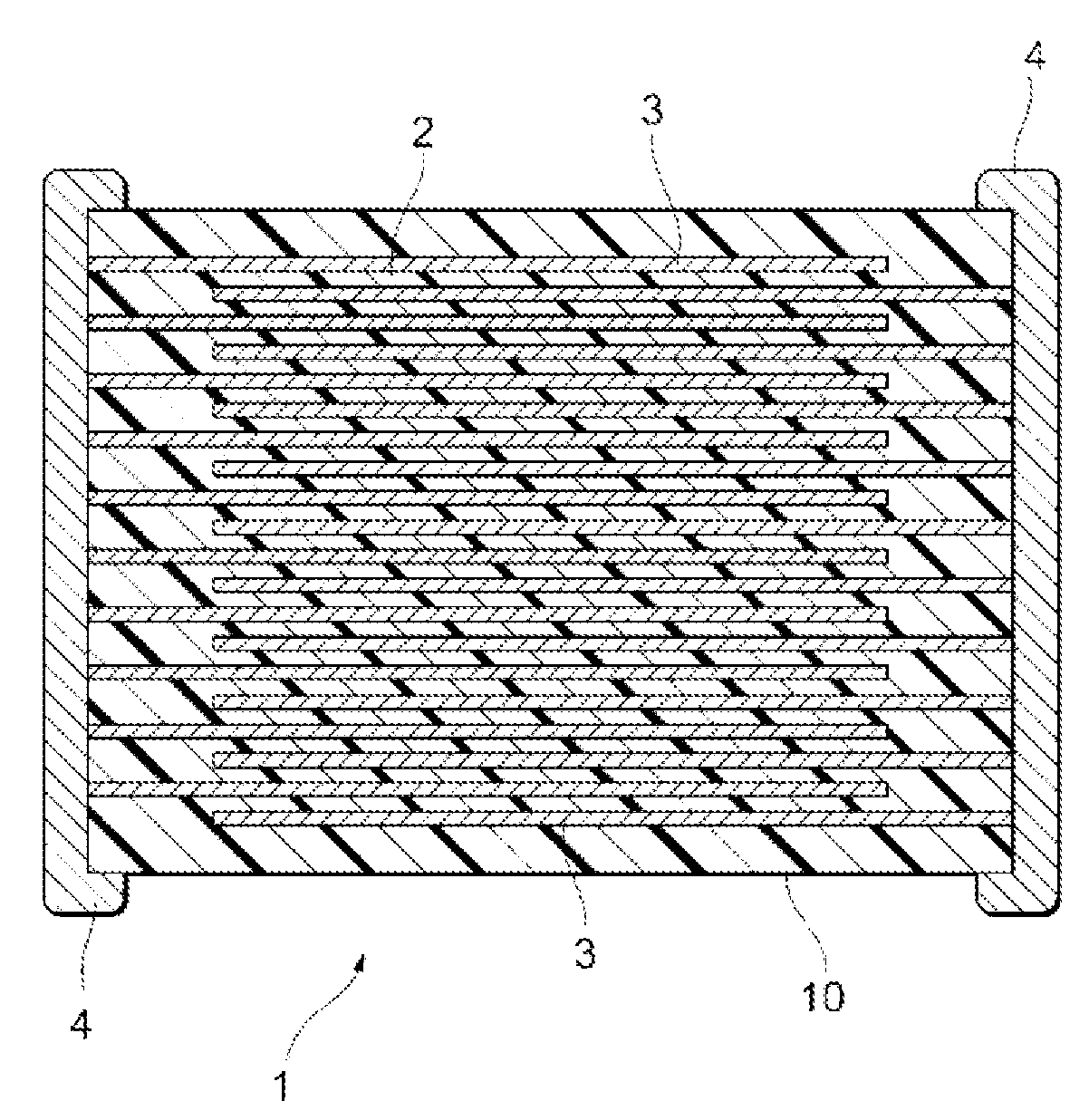

Electrostatic chuck device

ActiveCN103443914AImprove corrosion resistanceGood flexibilitySleeve/socket jointsSemiconductor/solid-state device manufacturingElectrostatic adsorptionElectrical and Electronics engineering

This electrostatic chuck device (1) comprises an electrostatic chuck part (2), which has one primary surface as a supporting surface for supporting plate-shaped samples and in which internal electrodes for electrostatic adsorption are housed, and a cooling base part (3) for cooling the electrostatic chuck part (2), wherein a heating member (5) is adhered, via a first adhesive member layer (4), to the other primary surface of the electrostatic chuck part (2) on the side opposite the supporting surface; the electrostatic chuck part (2) and heating member (5), and the cooling base part (3) are integrally adhered via an acrylic adhesive agent layer (9) having flexibility and insulating properties performance.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Graphene lithium ion battery electrolyte

InactiveCN105098239AImprove withstand voltage performanceReduce hydrogen evolutionSecondary cellsOrganic electrolytesLithium electrodePrecipitation

The invention relates to graphene lithium ion battery electrolyte, which comprises a lithium salt, a non-aqueous organic solvent and an additive, wherein the additive is prepared from the following components: 5%-6.5% of hexamethyl disilazane, 0.5%-3.5% of octamethylcyclotetrasiloxane, 4.5%-8.5% of graphene and 0.3%-5.3% of vitamin E on the basis of total weight of the electrolyte. The graphene is added to the lithium ion battery electrolyte, so that the voltage resistance of the electrolyte can be greatly improved; the electrolyte is not easy to decompose at high pressure; corrosive substances in an electrolyte system and the corrosive substances dissociating on the surface of a positive electrode can be effectively removed by the octamethylcyclotetrasiloxane; a lead electrode surface is adsorbed in the charging and discharging process due to the addition of the hexamethyl disilazane; equivalently, the deposition potential of hydrogen is improved; precipitation of hydrogen can be reduced; the lithium ion battery is stored in a high-temperature state; the capacity retention ratio and the capacity recovery rate are high; and the cycle performance is excellent.

Owner:NINGBO POLYTECHNIC

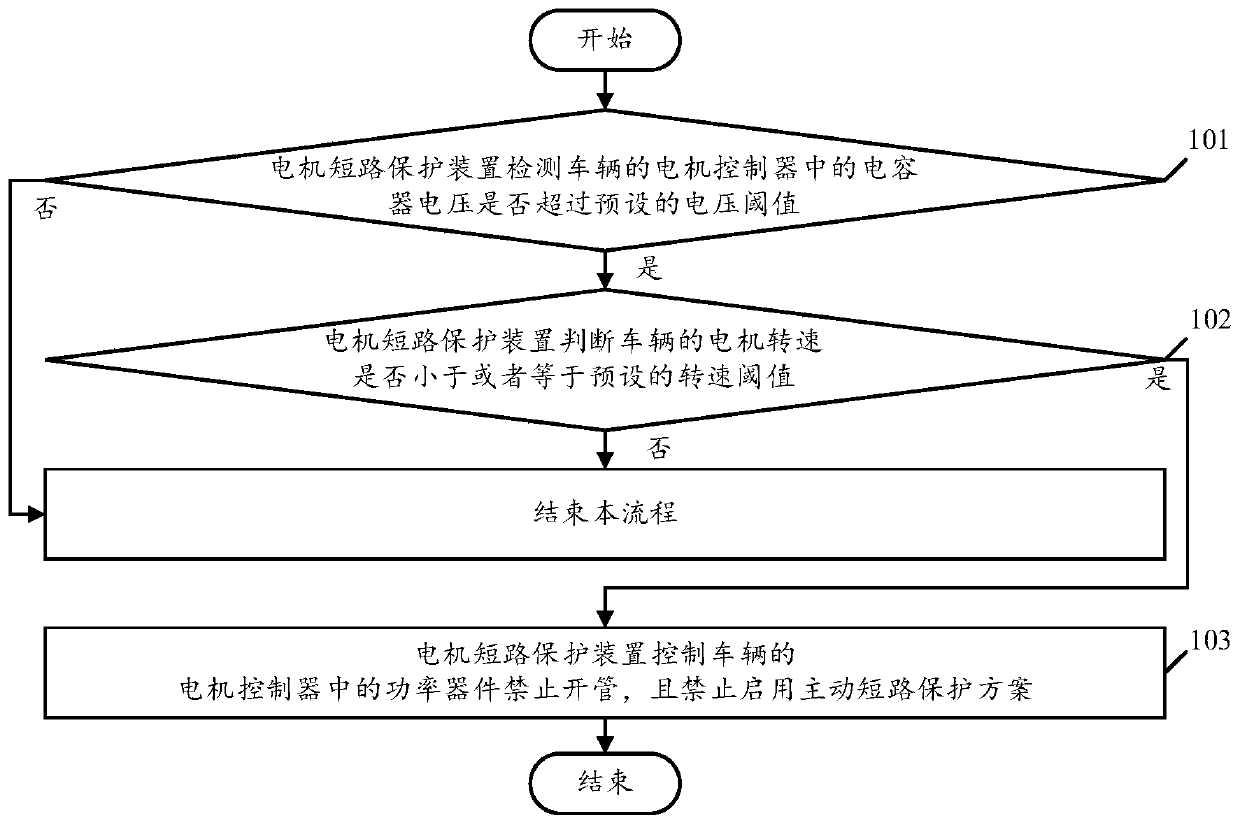

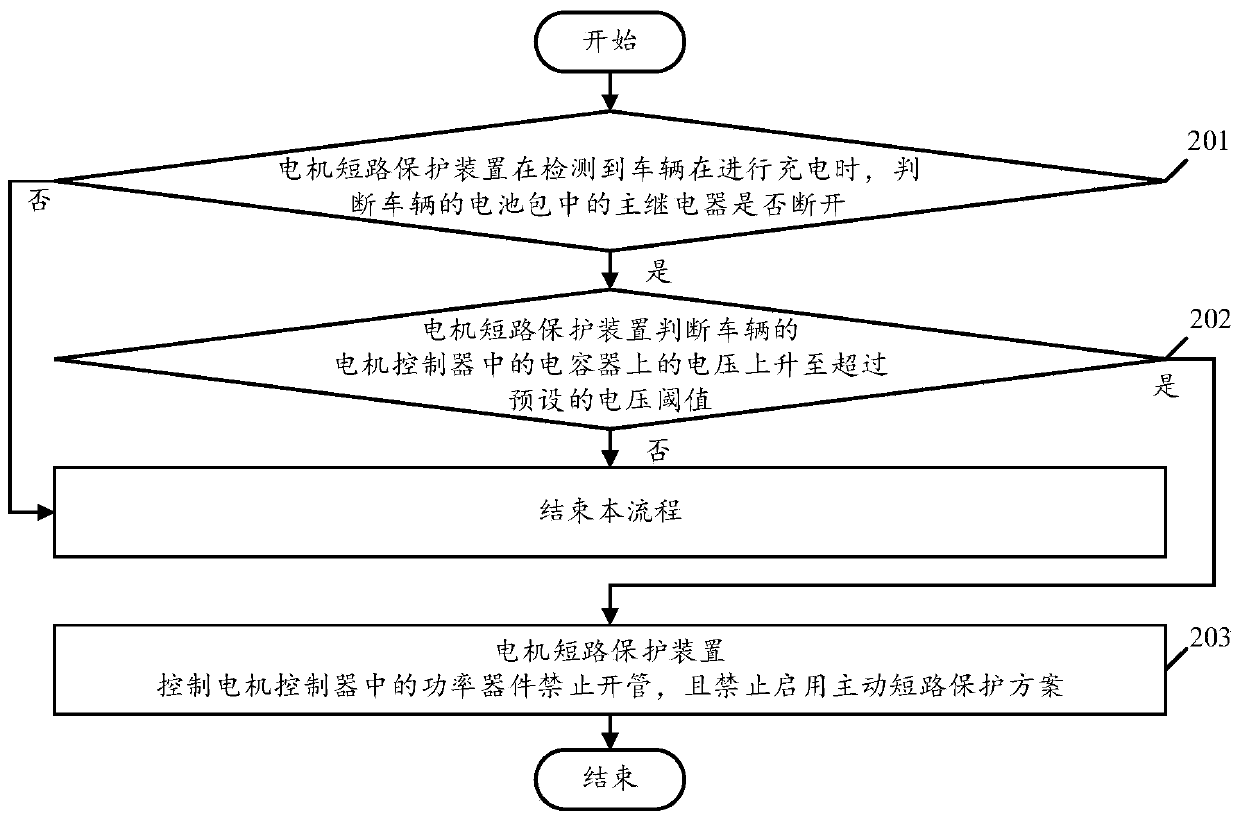

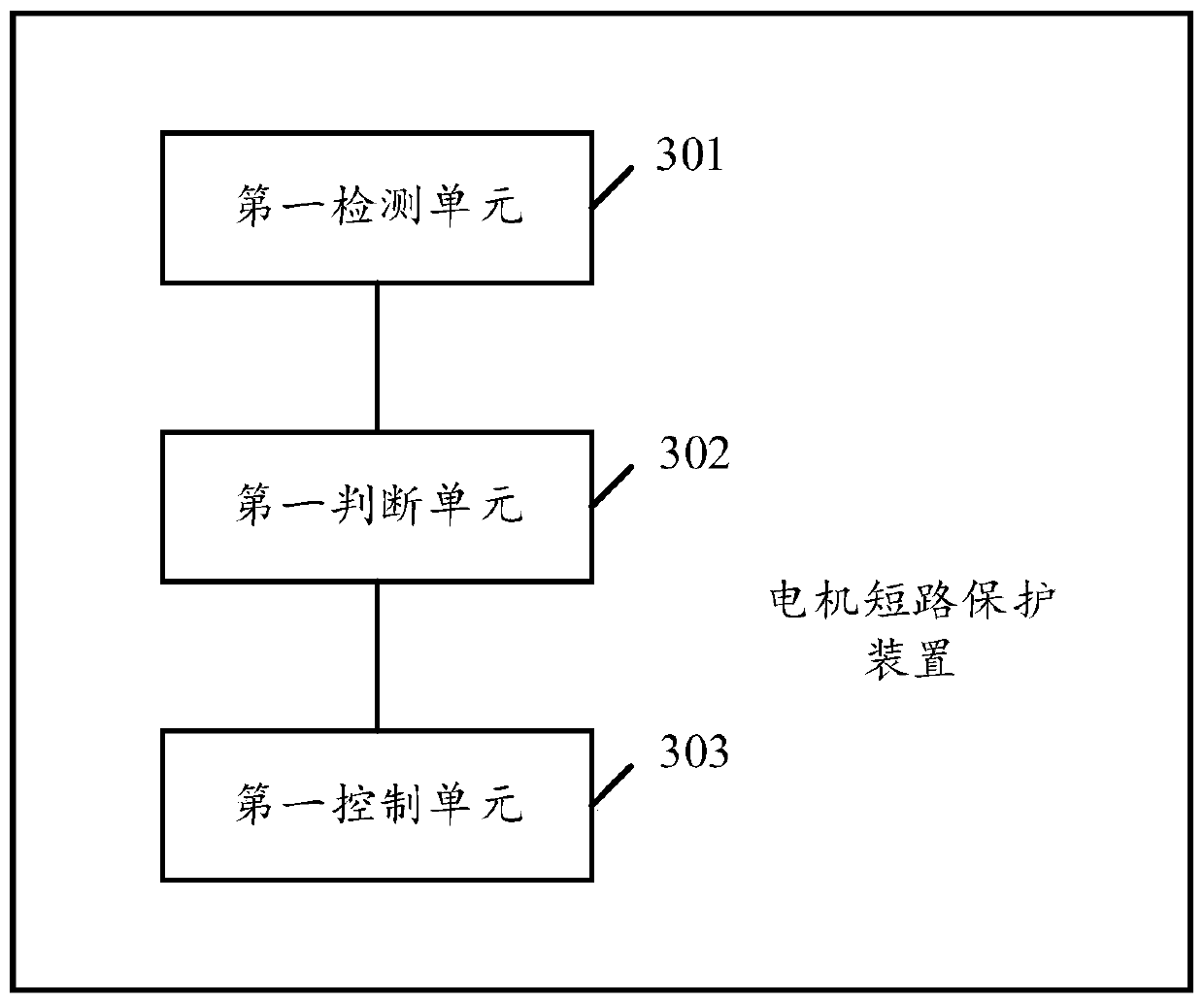

Motor short-circuit protection method and device

ActiveCN110011278AAvoid damageImprove withstand voltage performanceEmergency protective circuit arrangementsOvervoltageCapacitor voltage

The embodiment of the invention relates to the technical field of overvoltage protection, and discloses a motor short-circuit protection method and device. The method comprises the steps of: detectinga voltage of a capacitor in a motor controller of a vehicle exceeds a preset voltage threshold value or not, if yes, determining the rotation speed of the motor of the vehicle is smaller than or equal to a preset rotation speed threshold value, and if yes, controlling a power device in the motor controller to forbid tube opening and forbid starting of an active short-circuit protection scheme. According to the embodiment of the invention, the probability of failure or even damage of the power device or the motor controller can be reduced.

Owner:GUANGZHOU XIAOPENG MOTORS TECH CO LTD

Method for producing DTX carbon fibre cable protecting and leading pipes

InactiveCN101463159AImprove toughnessHigh voltage resistanceInsulating bodiesTubular articlesFiberHigh pressure

The invention relates to a preparation method for a DTX carbon fiber protect lead tubular product. The product uses HDPE high density polyene and modification carbon elements as raw materials. The mould extrusion forming and the unique rotational forming technique are used for setting and producing the protect lead tube which takes on helix tube shape. As the invention uses the rotational technique, the cast has thin walls, saves materials and has light weight, and is convenient for transportation and construction. The helix shape is used in the method, which increases ring stiffness and has strong rigidity. Tough elasticity, namely, deflexion, effectively undertakes loading and is not out of shape. The ring extrusion technique is used in the method, which causes that the tubular product has excellent bending property, can bend at will, can avoid barriers, and is suitable for different topography and landform, constructed in an optimizing and reelability way. In addition, as the tubular product has longer length, has few adapters, thus saving a large number of labor power, physical resources, and financial resources. The tubular product has strong quake-proof capability, corrosion-resistance, high pressure-proof performance, good flame retarding effect and is convenient for installation and construction.

Owner:李立才 +2

Method for manufacturing solid electrolytic capacitor

ActiveUS20140078645A1High voltage resistanceImprove discharge characteristicsSolid electrolytic capacitorsCapacitor electrolytes/absorbentsSimple Organic CompoundsDopant

There is provided a method to provide a capacitor element including a porous body of a valve metal, and a dielectric layer of an oxide layer of the valve metal. The method includes a first sequential process, and a second sequential process. The first sequential process includes: immersing the capacitor element in a first liquid of dispersion of a conductive polymer obtained by means of oxidation polymerization of thiophene or its derivative in the presence of a dopant of a polymer anion; taking out the capacitor element from the first liquid; and drying the capacitor element. Subsequent second sequential process includes: immersing the capacitor element in a second liquid which dissolves a cyclic organic compound having at least one hydroxyl group; taking out the capacitor element from the second liquid; and drying the capacitor element.

Owner:TAYCA CORP

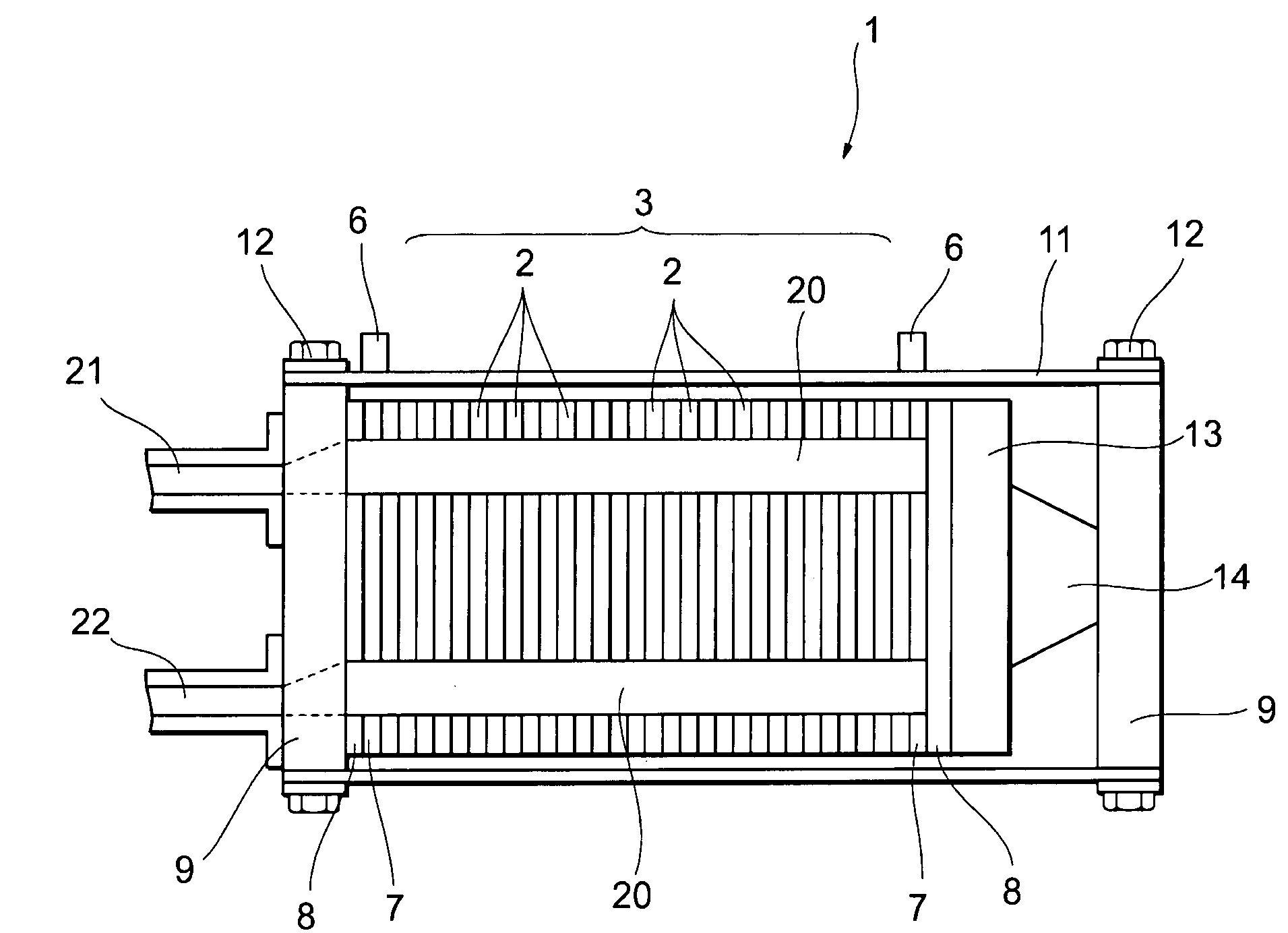

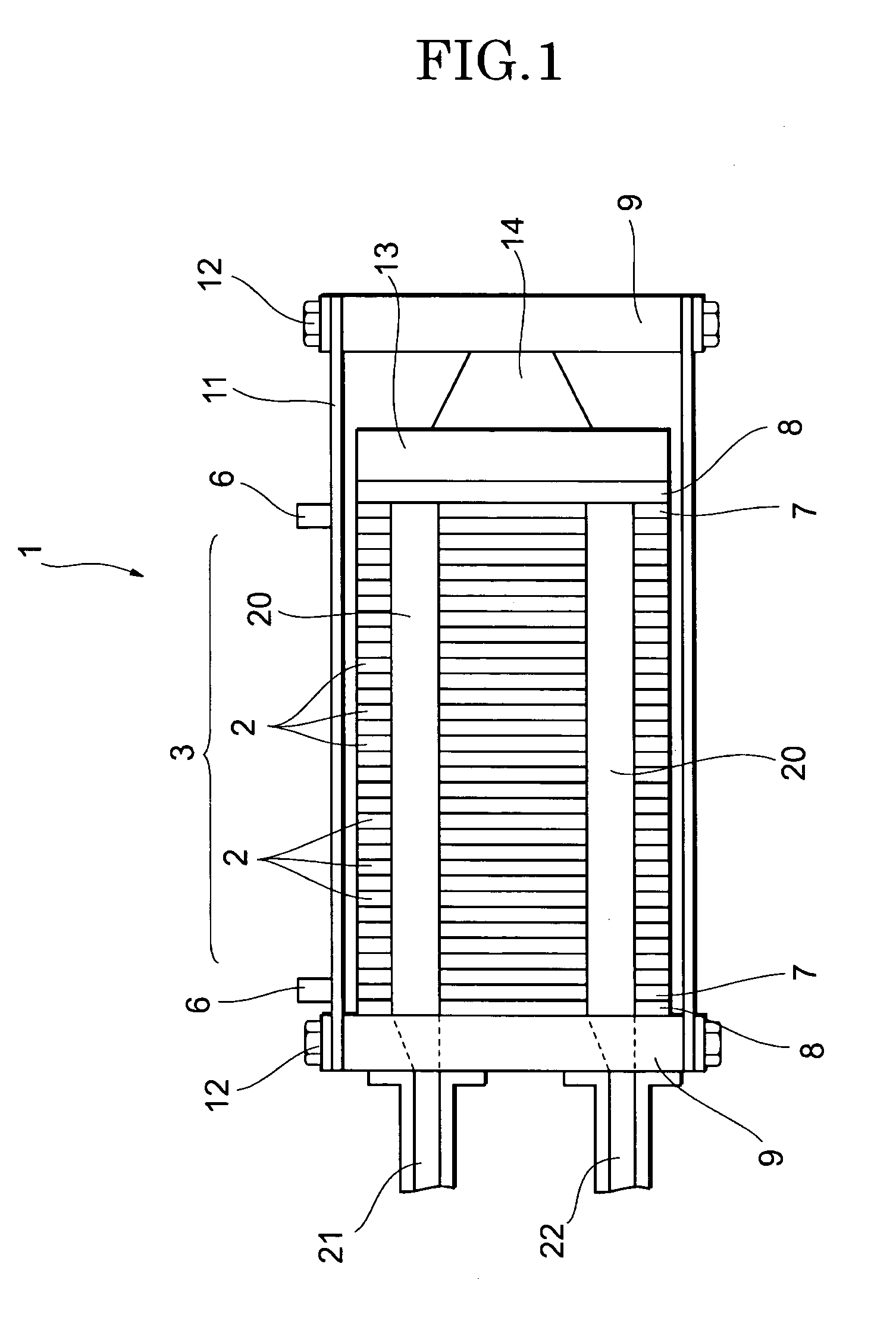

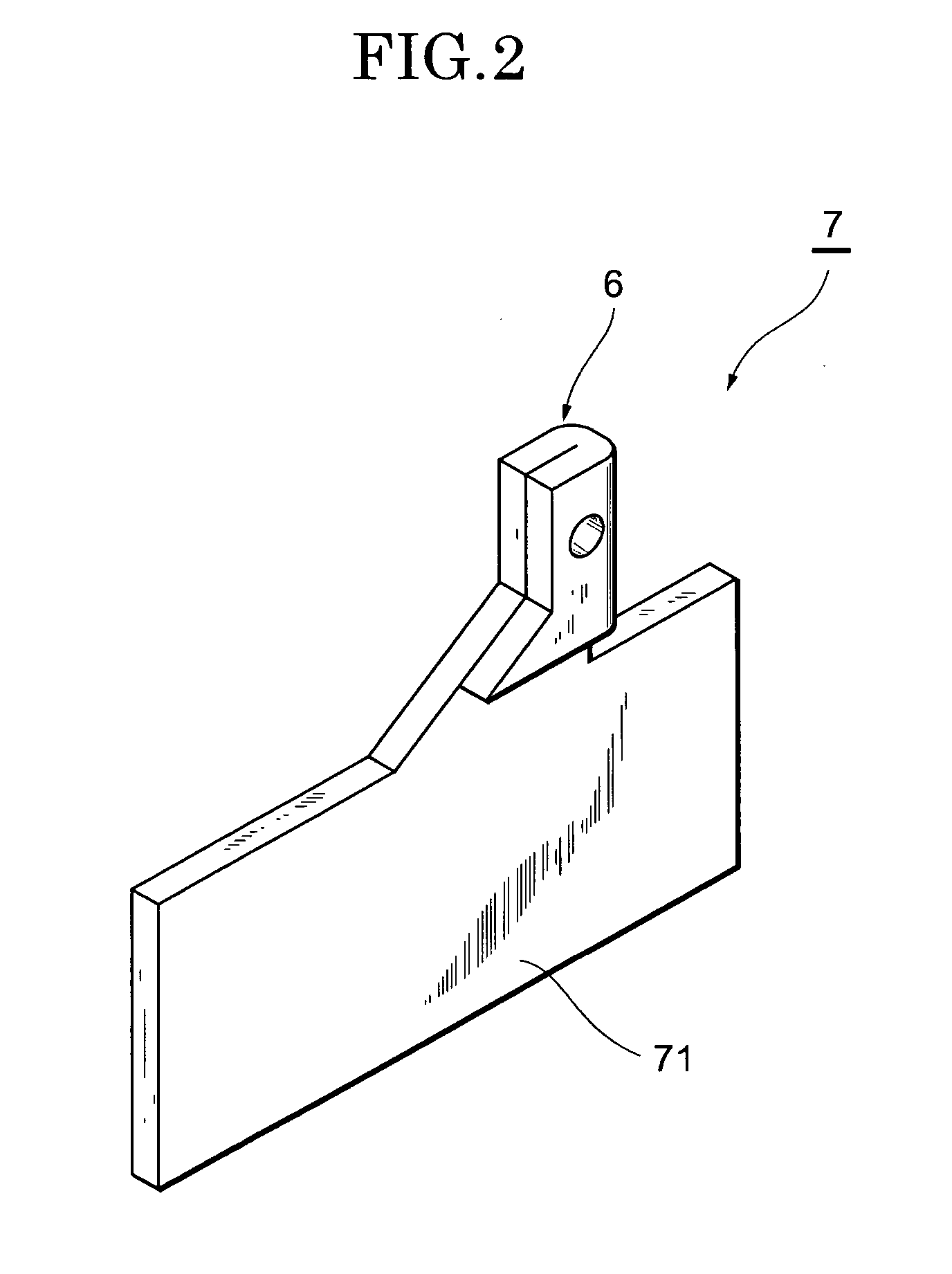

Collecting Plate, Fuel Cell, and Method for Manufacturing Same

InactiveUS20070287053A1Improve rigidityReduce weightWave amplification devicesFuel cells groupingFuel cellsElectrical and Electronics engineering

The collecting plate of the present invention is used in a stacked fuel cell, and comprises a collecting section and an output terminal that is electrically connected to the collecting section and has a thickness that is greater than the thickness of the collecting section. For example, the output terminal is formed by bending at least part of an output terminal forming portion that is extended from the collecting section, at least one time.

Owner:TOYOTA JIDOSHA KK

Dielectric composition, dielectric element, electronic component, and multilayer electronic component

ActiveUS20190256425A1Low dielectric lossHigh voltage resistanceFixed capacitor electrodesFixed capacitor dielectricComposite oxideMaterials science

A dielectric composition with high voltage resistance and favorable reliability, and an electronic component using the dielectric composition. The dielectric composition contains, as a main component, a tungsten bronze type composite oxide represented by a chemical formula (Sr1.00-(s+t)BasCat)6.00-xRx(Ti1.00-aZra)x+2.00(Nb1.00-bTab)8.00-xO30.00, in which the R is at least one element selected from Y, La, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu, and s, t, x, a, and b satisfy 0.50≤s≤1.00, 0≤t≤0.30, 0.50≤s+t≤1.00, 1.50<x≤3.00, 0.20≤a≤1.00, and 0≤b≤1.00. At least one selected from Mn, Mg, Co, V, W, Mo, Si, Li, B, and Al is contained as a sub component in 0.10 mol or more and 20.00 mol or less with respect to 100 mol of the main component.

Owner:TDK CORPARATION

High-voltage-resistant PTC (positive temperature coefficient) ceramic and preparation method thereof

The invention relates to a high-voltage-resistant PTC (positive temperature coefficient) ceramic and a preparation method thereof. The high-voltage-resistant PTC ceramic comprises the following main component and donor doping components in percentage by weight: 36-42% of BaCO3, 28-33% of Pb3O4, 26-29% of TiO2, 0.6-1.8% of CaCO3, 0.05-0.13% of Sb2O5 and 0.001-0.003% of Nd2O3. The donor doping components Sb2O5 and Nd2O3 are added compositely; the radius of Sb<5+> ions is approximate to that of titanium ions, and thus, the Sb<5+> can substitute Ti<4+> as the donor; the radius of Nd<3+> ions is approximate to that of Ba<2+>, and thus, the Nd<3+> can substitute Ba<2+> as a donor impurity; the effect of Sb<5+> and Nd<3+> on inhibiting grain growth is much better than that of the traditional Nb<5+> or Y<3+>; and the double-component composite doping can maximally reduce the grain size and enhance the voltage resistance of the PTC ceramic.

Owner:SUZHOU XINYE ELECTRONICS

Process to Produce Electrode Sheet

InactiveUS20090233171A1Improve electrochemical stabilityIncrease capacityNon-aqueous electrolyte accumulatorsHybrid capacitor electrodesSlurrySolvent

This invention provides a method to produce an electrode sheet adaptable to high-temperature drying and to charge and discharge under high voltage, by coating a collector with a slurry which comprises electrode active material, electroconductive agent, binder and solvent, and then drying the same, wherein meta-aramid is used as binder, and wherein thus dried electrode sheet is compressed.

Owner:DUPONT TEIJIN ADVANCED PAPERS JAPAN

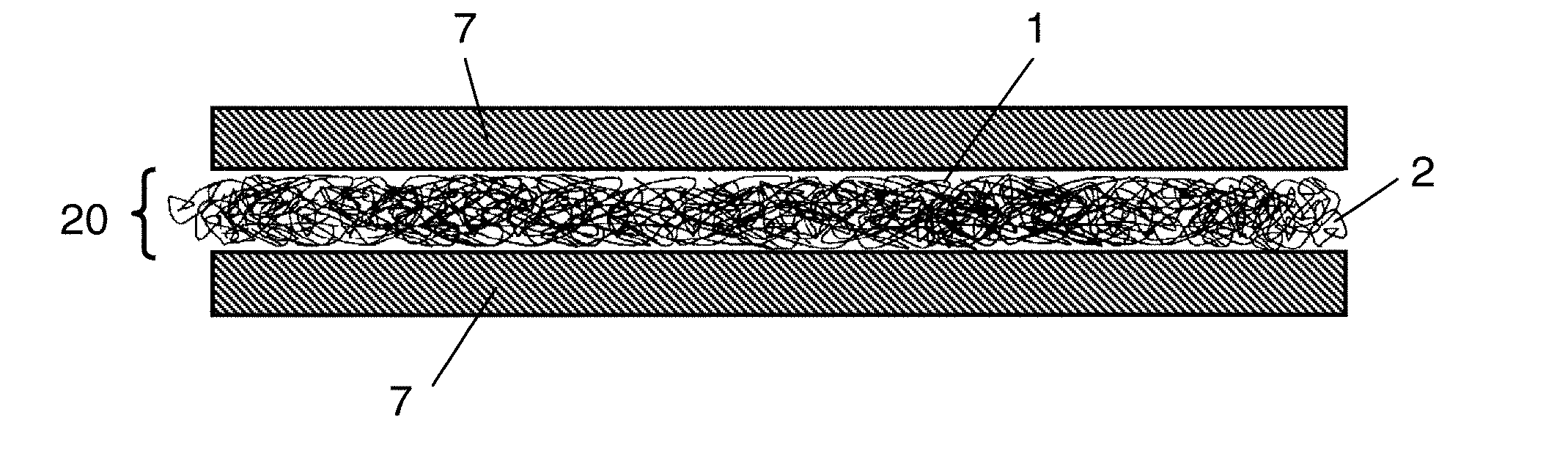

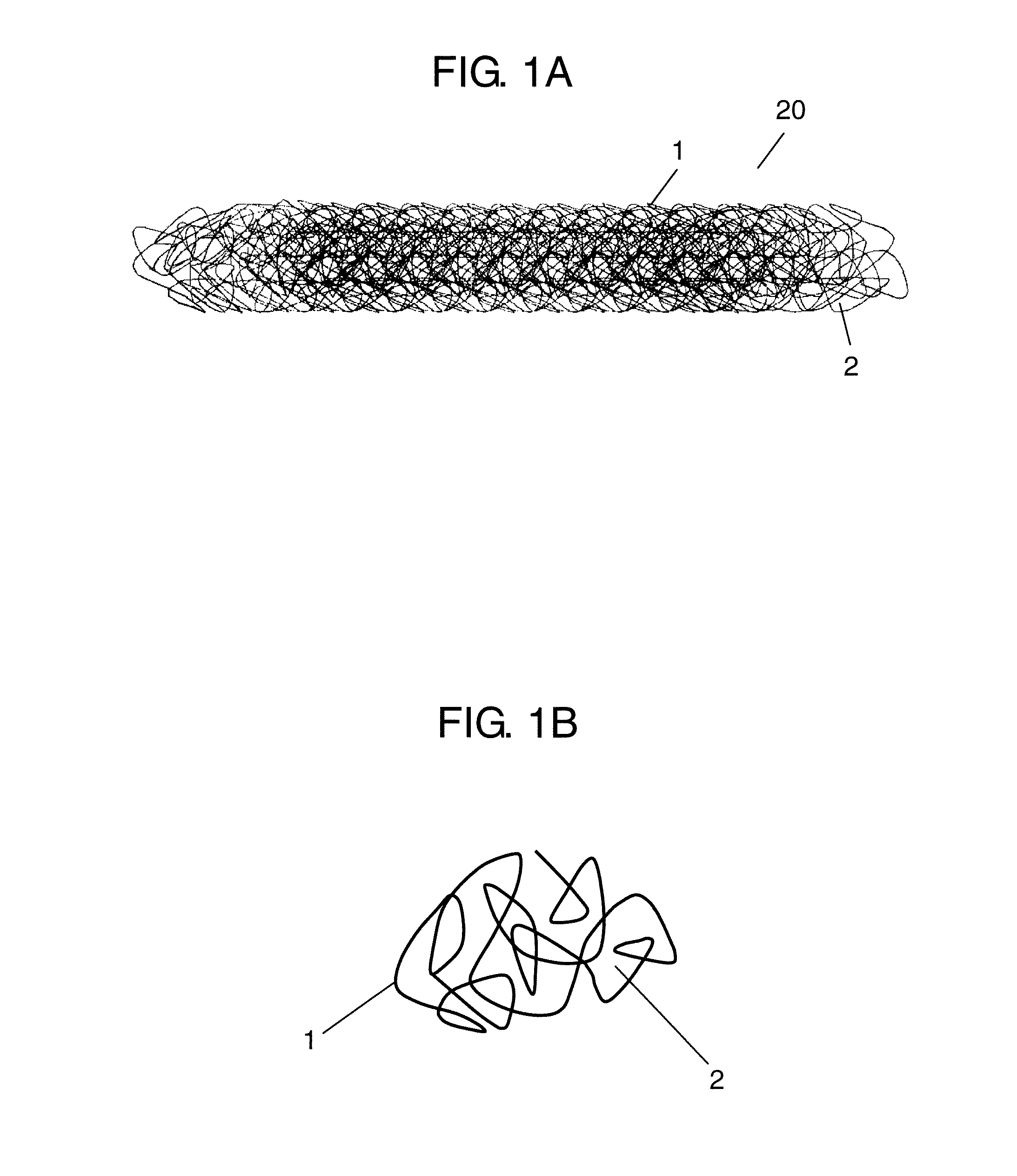

Sheet-like fiber structure, and battery, heat insulation material, waterproof sheet, scaffold for cell culture, and holding material each using the sheet-like fiber structure

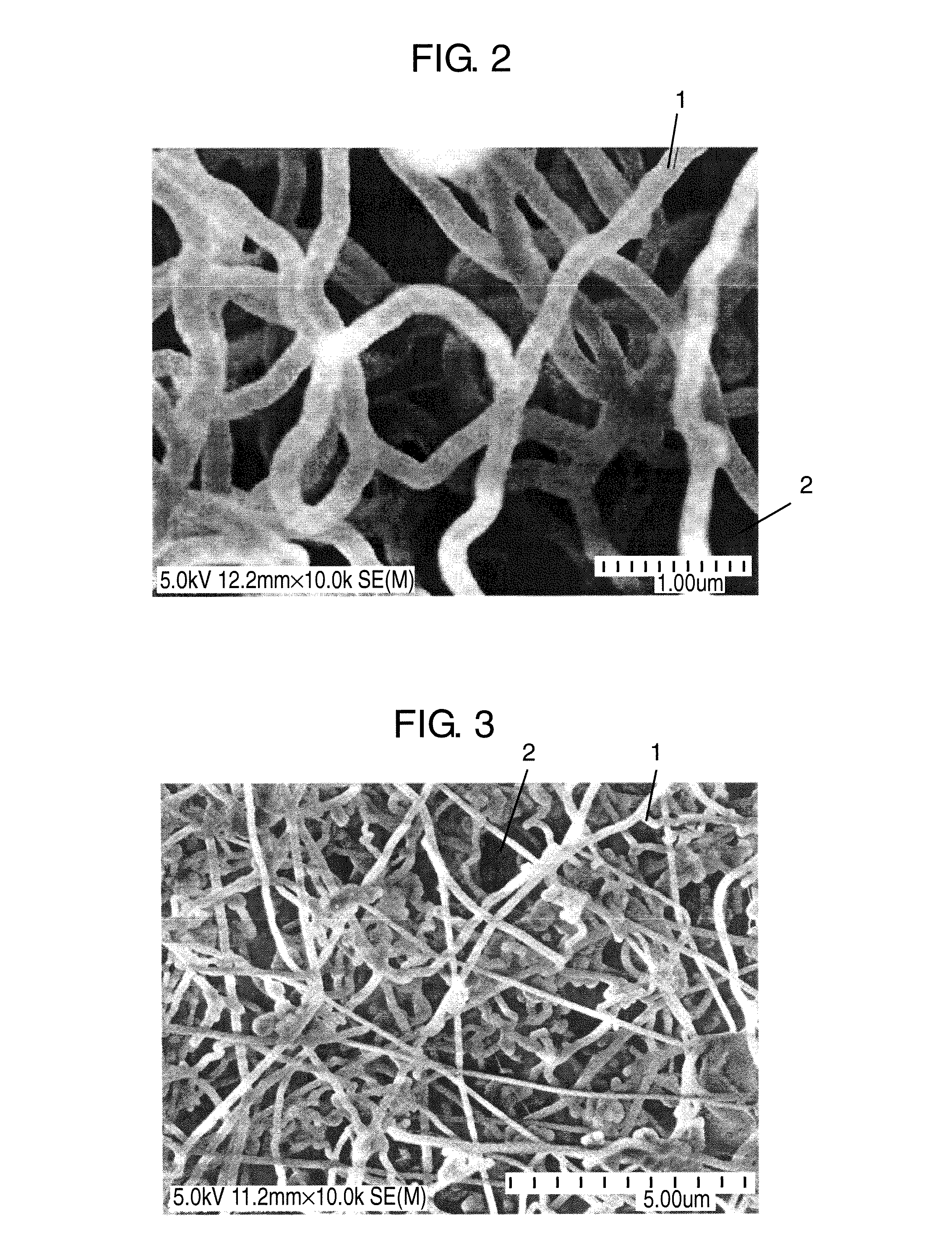

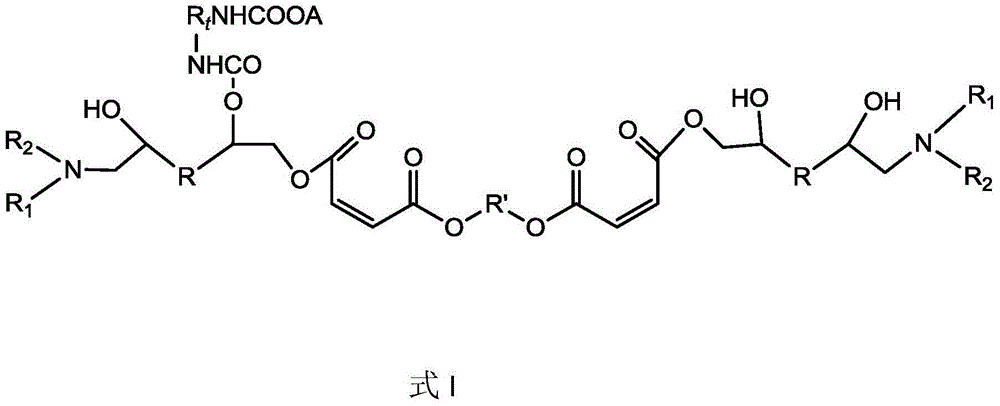

ActiveUS20130017450A1Increase flexibilityHigh currentMaterial nanotechnologyNatural cellulose pulp/paperHeat resistanceOptoelectronics

A sheet-like fiber structure including a plurality of fibers made of amorphous silicon dioxide. The plurality of fibers are intertwined with each other and thus connected to each other, thereby forming void portions. Consequently, the sheet-like fiber structure has not only liquid permeability and voltage resistance but also high heat resistance and chemical resistance. The sheet-like fiber structure is therefore applicable to a separator for preventing a short circuit between electrodes, a scaffold for cell culture, to holding a biomolecule, or the like.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Epoxy resin used for cathode electrophoretic coating and independent of circulation and preparation method of epoxy resin

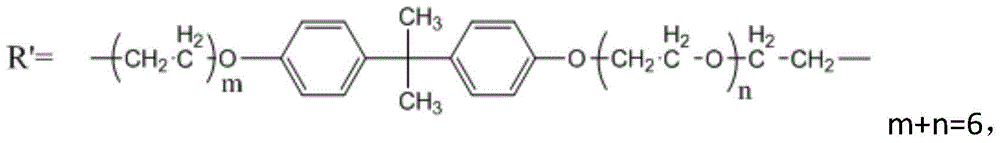

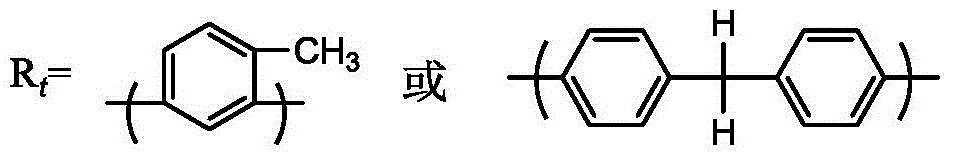

ActiveCN104803885AEasy to wrapReduce sedimentation velocityCarbamic acid derivatives preparationOrganic compound preparationLeveling effectSide chain

The invention relates to the technical field of cathode electrophoretic coatings, in particular to epoxy resin used for a cathode electrophoretic coating and capable of guaranteeing normal use without dependence of circulation as well as a preparation method of the epoxy resin. According to the epoxy resin, bisphenol A polyoxyethylene ether resin participates in chain extension and is modified by amine, meanwhile, semi-closed isocyanate is introduced on a side chain, and a side group comprises inclusion and a highly toughening main chain. The epoxy resin has a good appearance leveling effect and throwing power; the filler and pigment settling speed is greatly decreased when the coating stops circulating, and the coating after the circulation is stopped can be used normally when the circulation is performed again.

Owner:HAOLISEN COATING SHANGHAI

High-temperature and high-voltage-resistance copper alloy conductive material

InactiveCN103343259AImprove temperature resistanceHigh densityConductive materialsMechanical property

The invention discloses a high-temperature and high-voltage-resistance copper alloy conductive material. The high-temperature and high-voltage-resistance copper alloy conductive material comprises the following major ingredients in percentage by mass: 3.5-3.8% of C, 0.9-1.1% of Cr, 0.25-0.35% of Zr, 0.4-0.6% of Co, 3.5-3.8% of Fe, 0.8-1.0% of Ni, and the following minor constituents in percentage by mass: 0.1-0.3% of W, 0.1-0.3% of Mo, 0.3-0.4% of Ta, 0.2-0.4% of Nb, 0.05-0.08% of Ce, and the balance of Cu. Via the mode aforementioned, the high-temperature and high-voltage-resistance copper alloy conductive material disclosed by the invention is capable of improving the temperature-resistant performance of an alloy material, refining crystalline grains, homogenizing each ingredient in alloy, improving the compactness of the alloy material, improving the voltage-resistant performance of the alloy material, decreasing a conductivity coefficient, and reinforcing the mechanical properties of the alloy material.

Owner:KUSN QIAORUI METAL PRODS

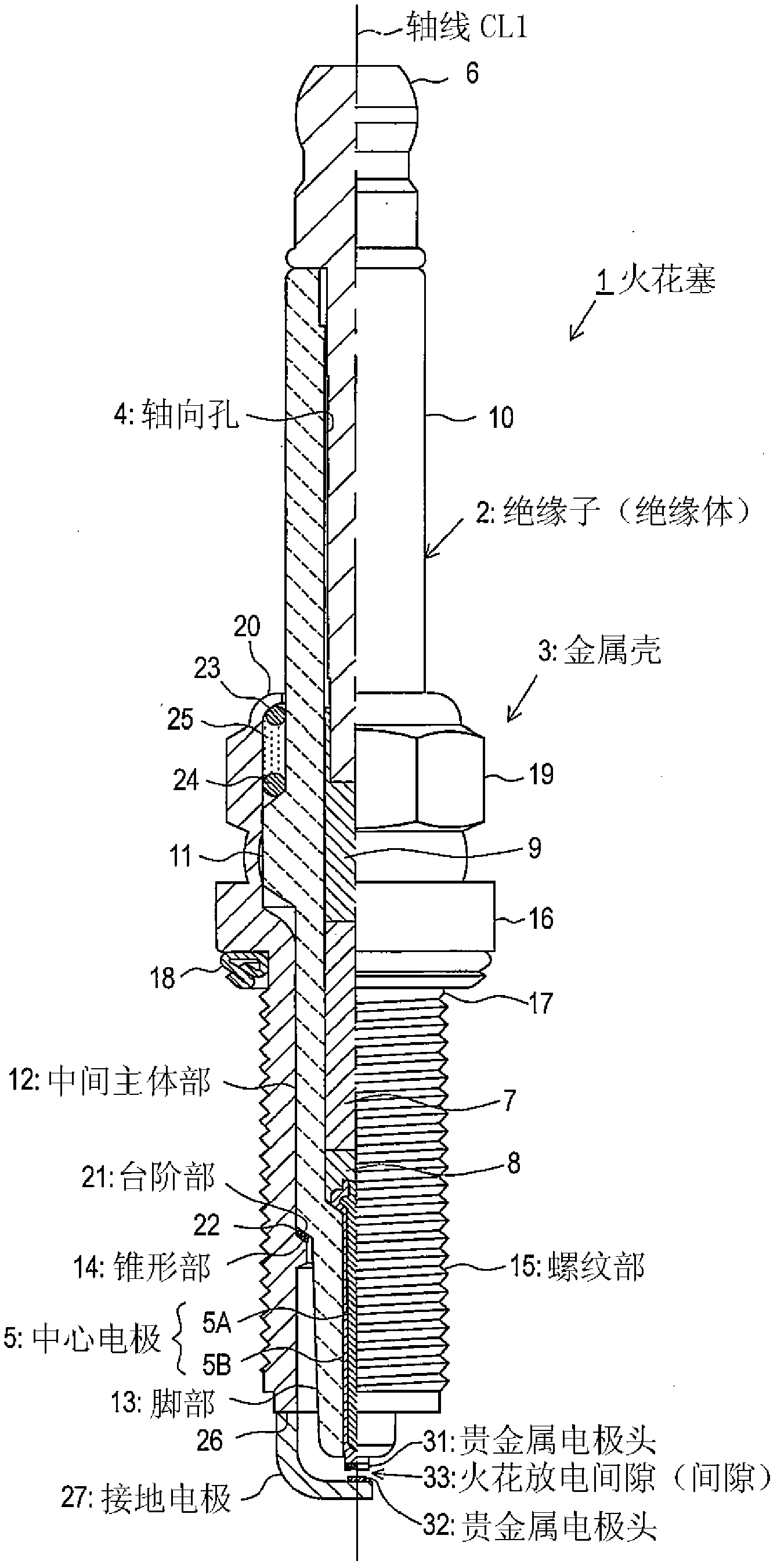

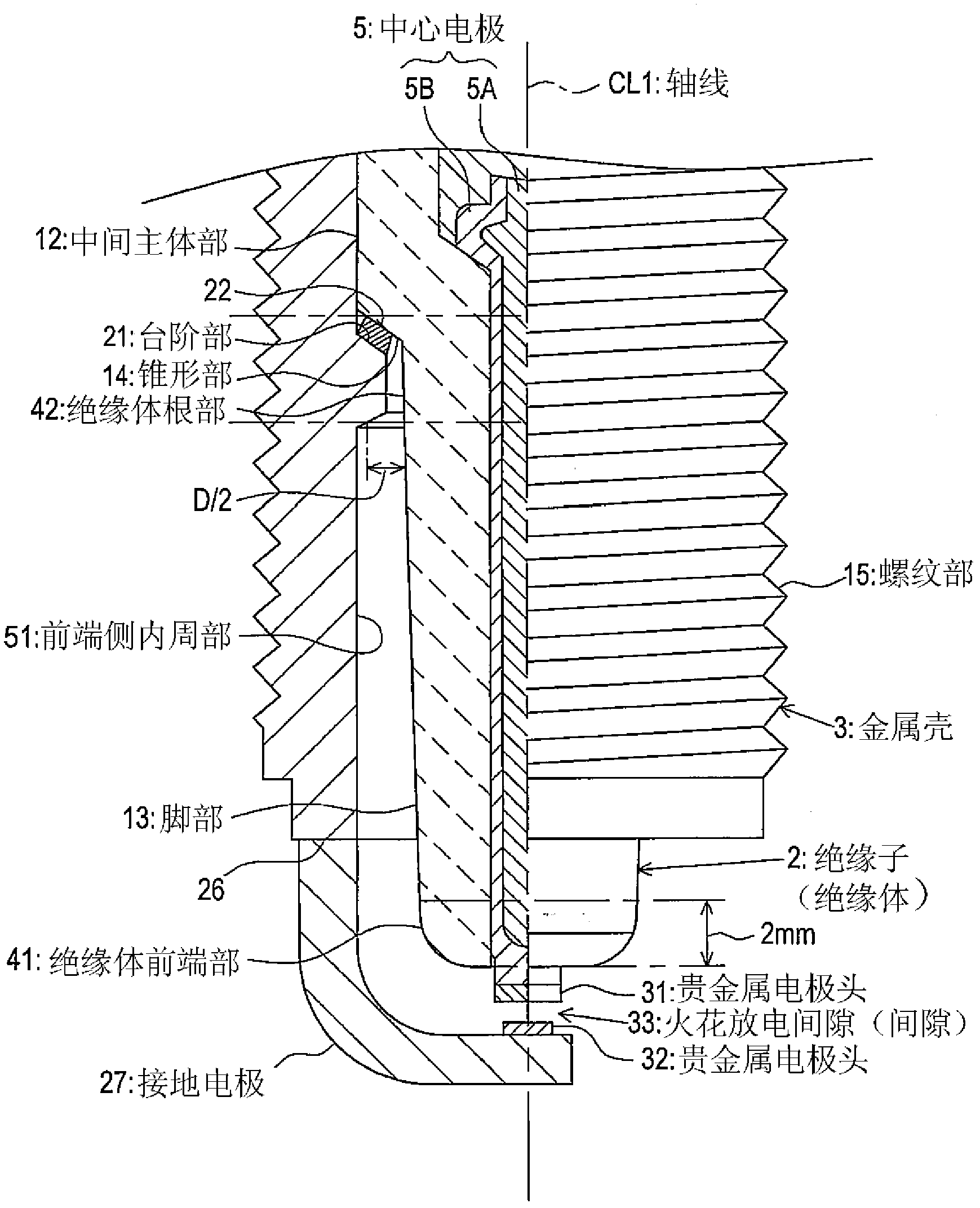

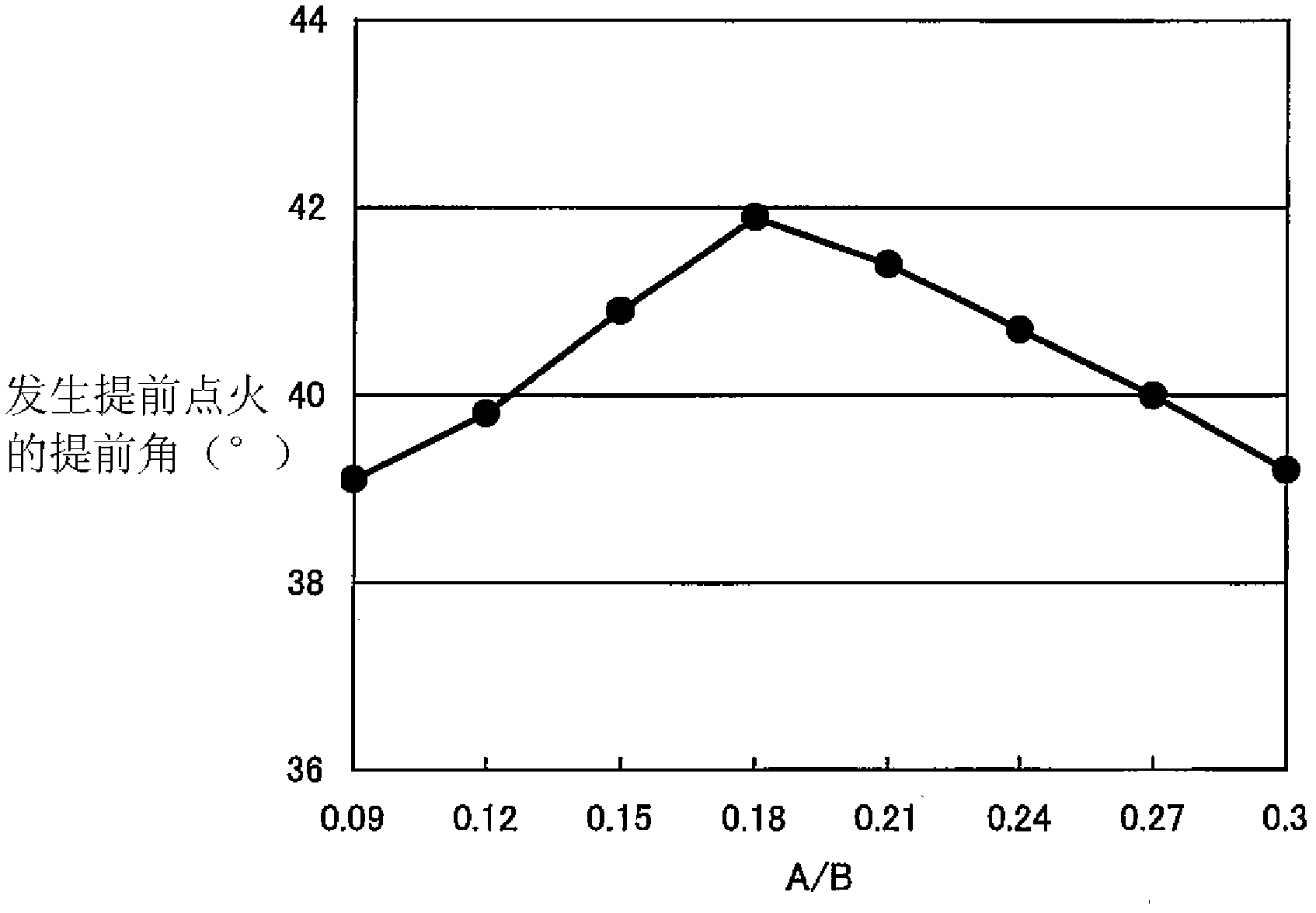

Spark plug

ActiveCN102576984AMaintain voltage resistanceImprove heat resistanceSparking plugsMachines/enginesHeat resistanceEngineering

Provided is a spark plug with a center electrode that has the diameter thereof made thinner, wherein stain-resistant and heat-resistant characteristics are improved. The spark plug (1) is provided with a center electrode (5), an insulator (2), and a main metal-part (3), and the insulator (2) is provided with a long-leg section (13), a tapered section (14), and a mid-body section (12). The maximumouter-diameter of a portion of the center electrode (5) to be arranged within the long-leg section (13) is to be 3.0 mm or shorter. A step section (21) and a front-tip-side inner circumference section (51) are formed on the inner circumference of the main metal part (3), and the tapered section (14) is latched together to the step section (21). An inequality 0.12<= A / B<= 0.24 is satisfied, when the volume of a portion of the insulator (2) existing along the axis (CL1) direction, from the tip of the insulator (2) to a place 2 mm from the rear-end side, is assumed to be A (mm3), and the volume of a portion of the tapered section (14) located at the front tip side of the rear end of the portion to be latched together with the step section (21), and which portion has the difference in the diameters of the front-tip side inner circumference section (51) and the outer circumference part of itself to be 1.5 mm or less, is assumed to be B (mm3).

Owner:NGK SPARK PLUG CO LTD

Starched agent and glass powder for forming dielectric for plasma display board

InactiveCN1448960AHigh transparencyHigh voltage resistanceGas discharge electrodesQuartz/glass/vitreous enamelsPlasma displayParticle-size distribution

PROBLEM TO BE SOLVED: To provide a dielectric formation paste for a plasma display panel excellent in transparency, and capable of forming a dielectric layer having a high breakdown voltage. ŽSOLUTION: This paste has a particle size distribution wherein the maximum particle diameter D<SB>MAX< / SB>is 15μm or less, D<SB>90< / SB>is 7μm or less, D<SB>75< / SB>is 4μm or less, D<SB>50< / SB>is 3μm or less, and D<SB>25< / SB>is 2μm or less, and contains glass powder having a specific surface area of 1.0-4.0 m<SP>2< / SP> / g. Ž

Owner:NIPPON ELECTRIC GLASS CO LTD

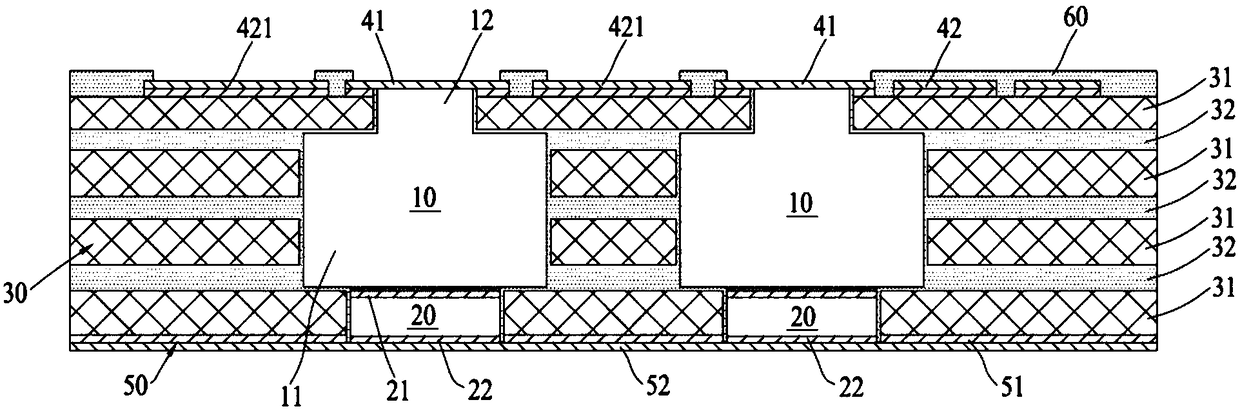

Heat dissipation substrate and preparation method thereof

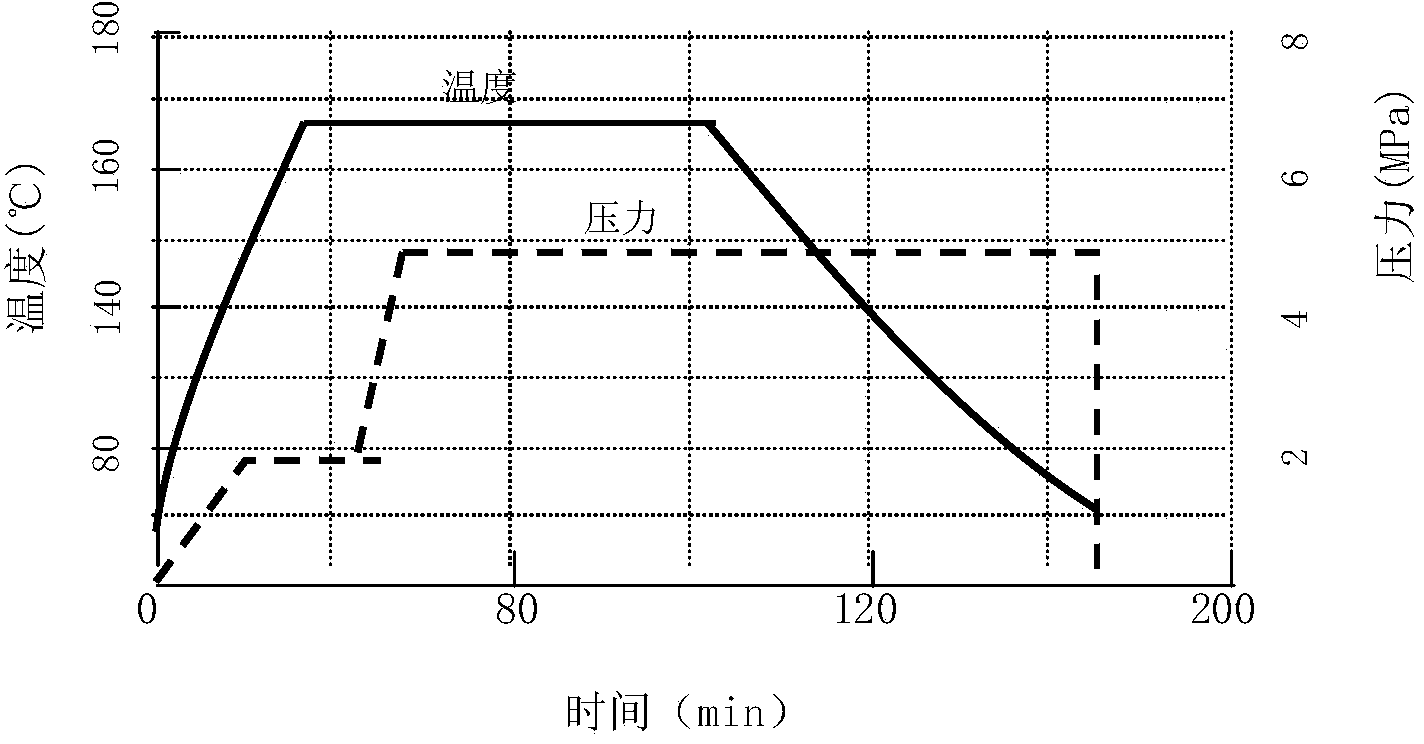

ActiveCN109148411AReduced wiring areaMiniaturizationSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceMetal

The invention relates to a heat dissipation substrate and a preparation method thereof. The heat dissipation substrate comprises an insulating substrate, a metal conductive member embedded in the insulating substrate, a patterned conductive layer formed on the upper surface of the insulating substrate and a metal heat dissipation layer formed on the lower surface of the heat dissipation substrate.A power device mounting pad exposed to an insulating substrate is formed on an upper surface of the metal conductive member, and a ceramic heat conductive member is disposed between the metal conductive member and the metal heat dissipation layer. As that heat dissipation substrate can simultaneously carry power devices and non-power device, the heat dissipation substrate is convenient to realizeminiaturization, and has good heat dissipation performance and voltage withstand performance. The preparation method comprises the steps of molding an insulating substrate by hot pressing and embedding a metal conductive member and a ceramic heat dissipation member in the insulating substrate, the preparation process is simple and the cost is low.

Owner:RAYBEN TECH ZHUHAI

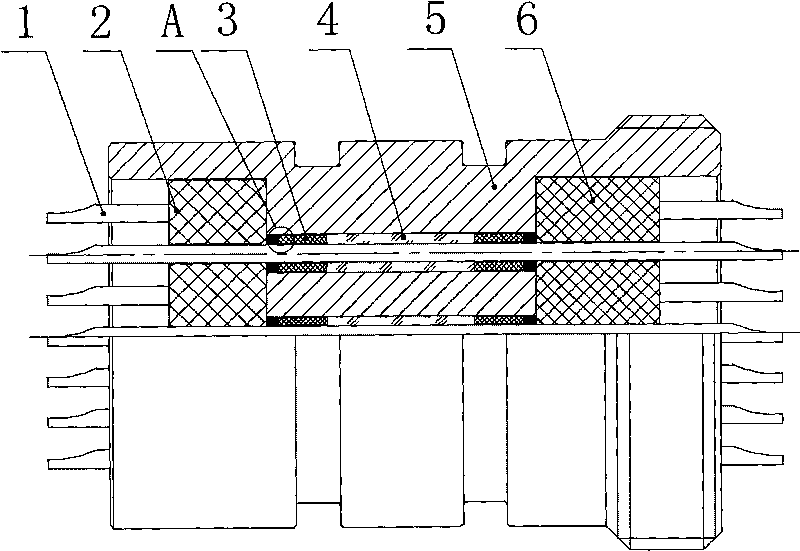

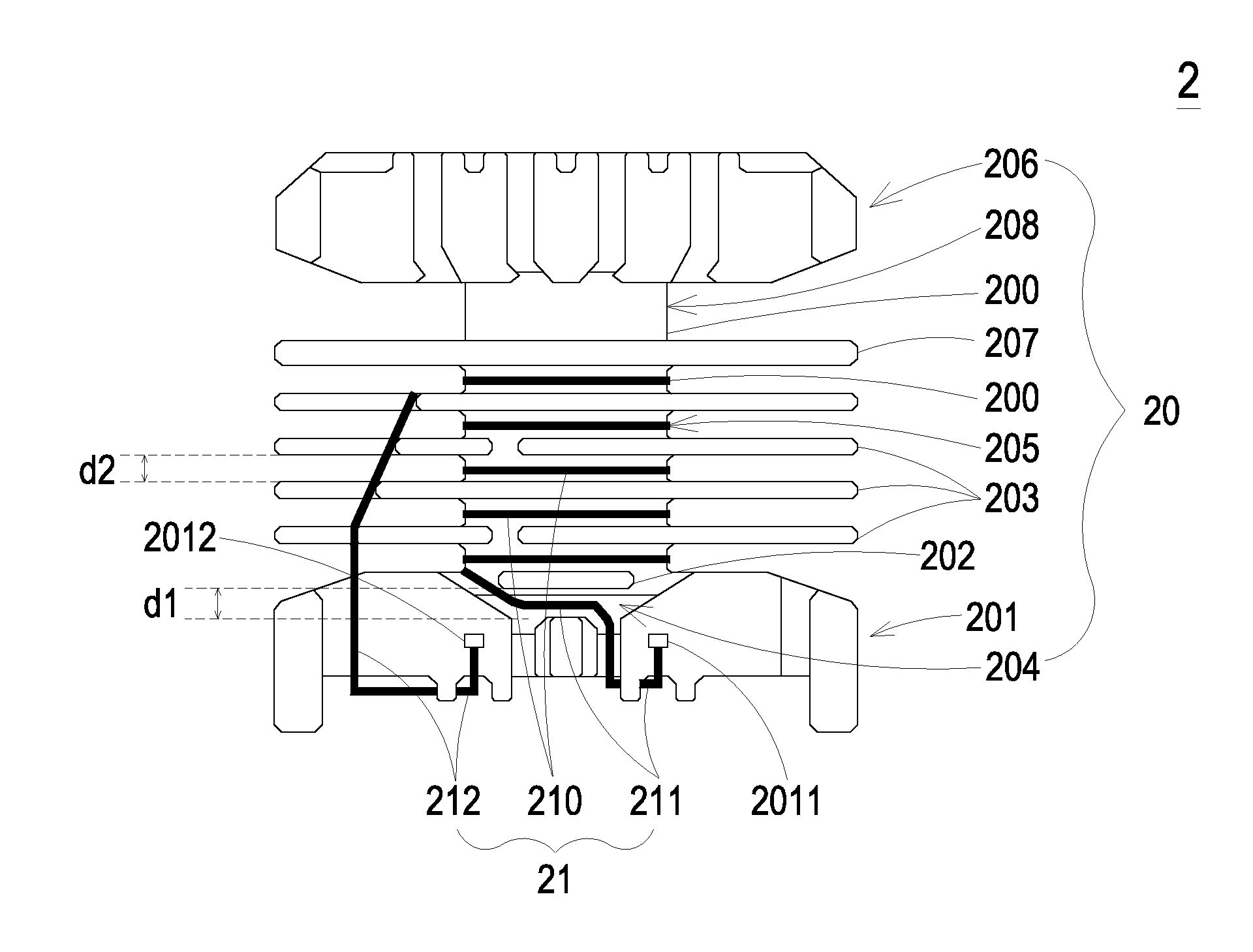

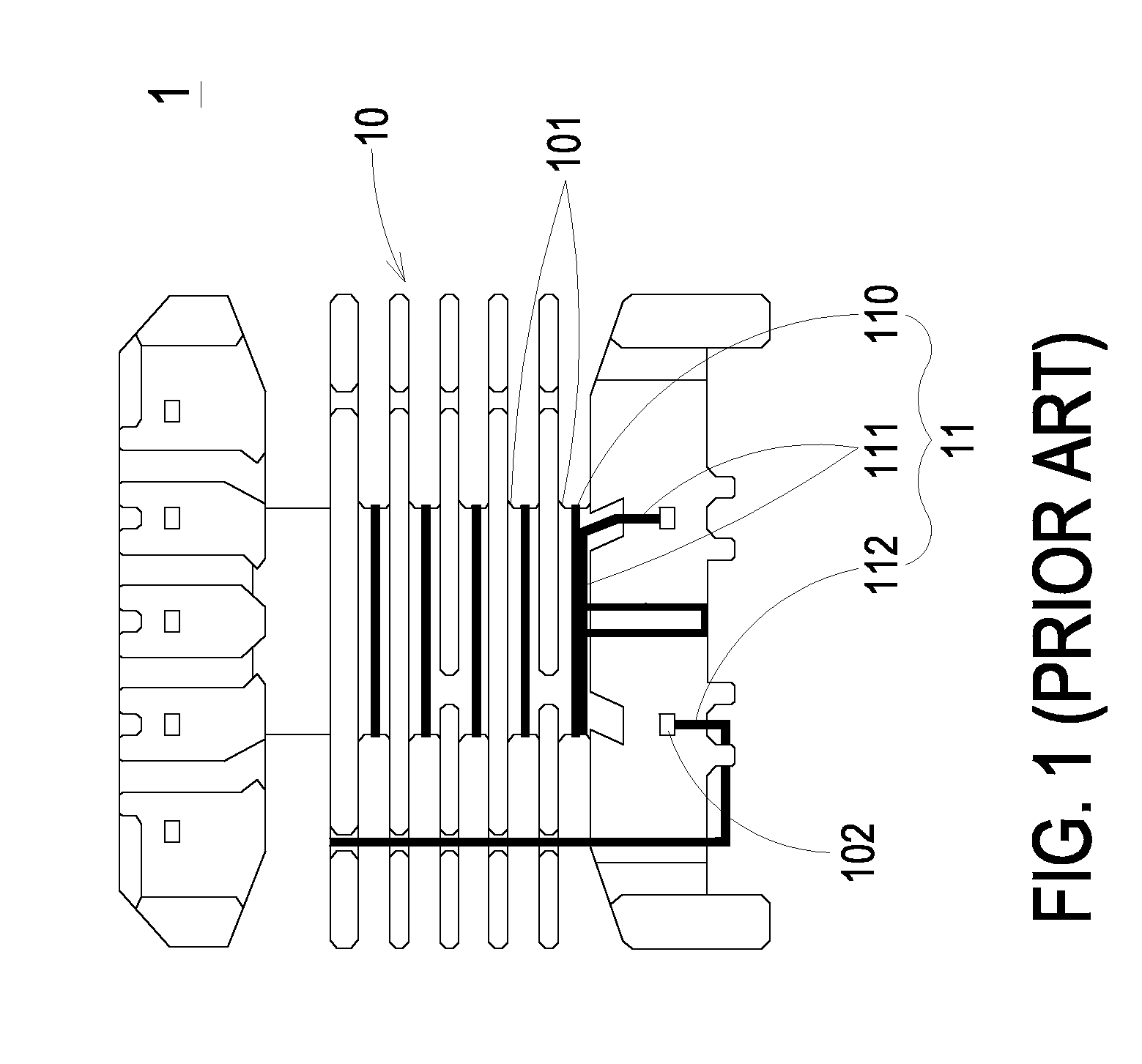

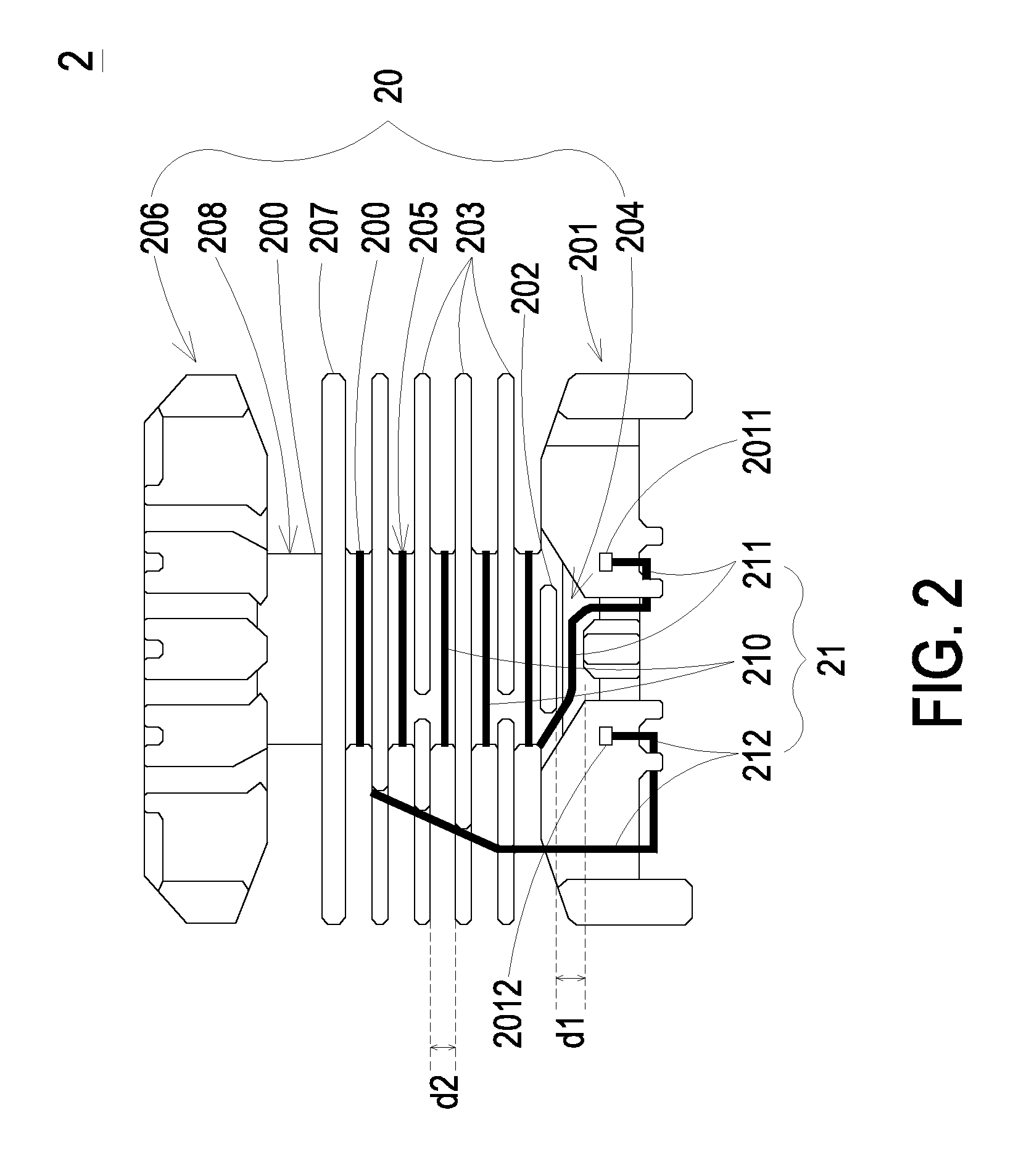

Inverter and bobbin thereof

InactiveUS20150194257A1Drawback can be obviatedReduce withstand voltagePipe supportsTransformers/inductances coils/windings/connectionsFrequency changerBobbin

An inverter includes a bobbin and a first insulated wire. The bobbin includes a main body, a first base disposed on one side of the main body and connected with the main body, a first plate disposed between the main body and the first base, among which a wire groove is formed between the first plate and the first base, and a plurality of second plates disposed on the main body for forming a plurality of first winding grooves on the main body. The first insulated wire has a winding portion disposed in the first winding grooves and a first outlet partially disposed in the wire groove, such that the first outlet is staggered with the winding portion, thereby avoiding the short circuit phenomena of the first insulated wire caused by the tear abrasion, avoiding the arc burn phenomena, and having high voltage-resistance.

Owner:DELTA ELECTRONICS INC

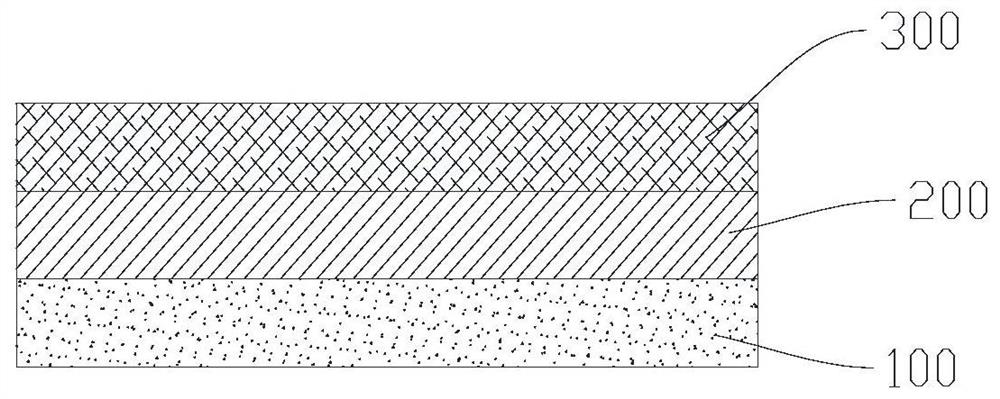

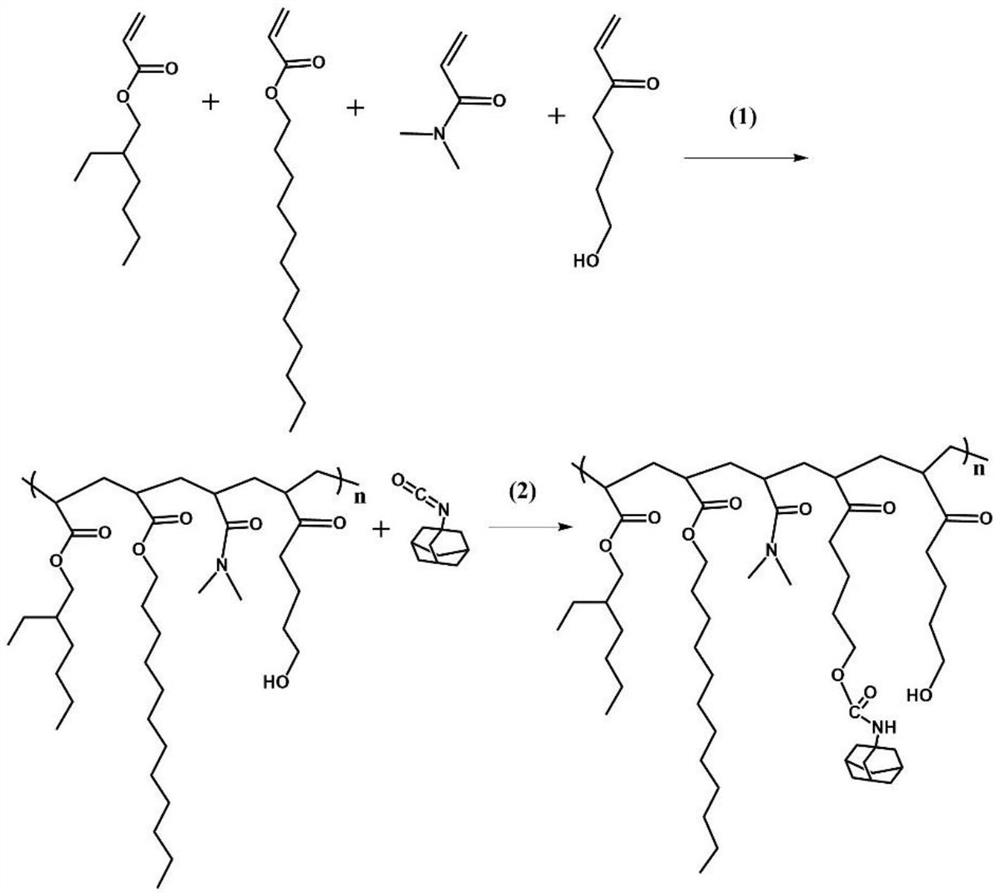

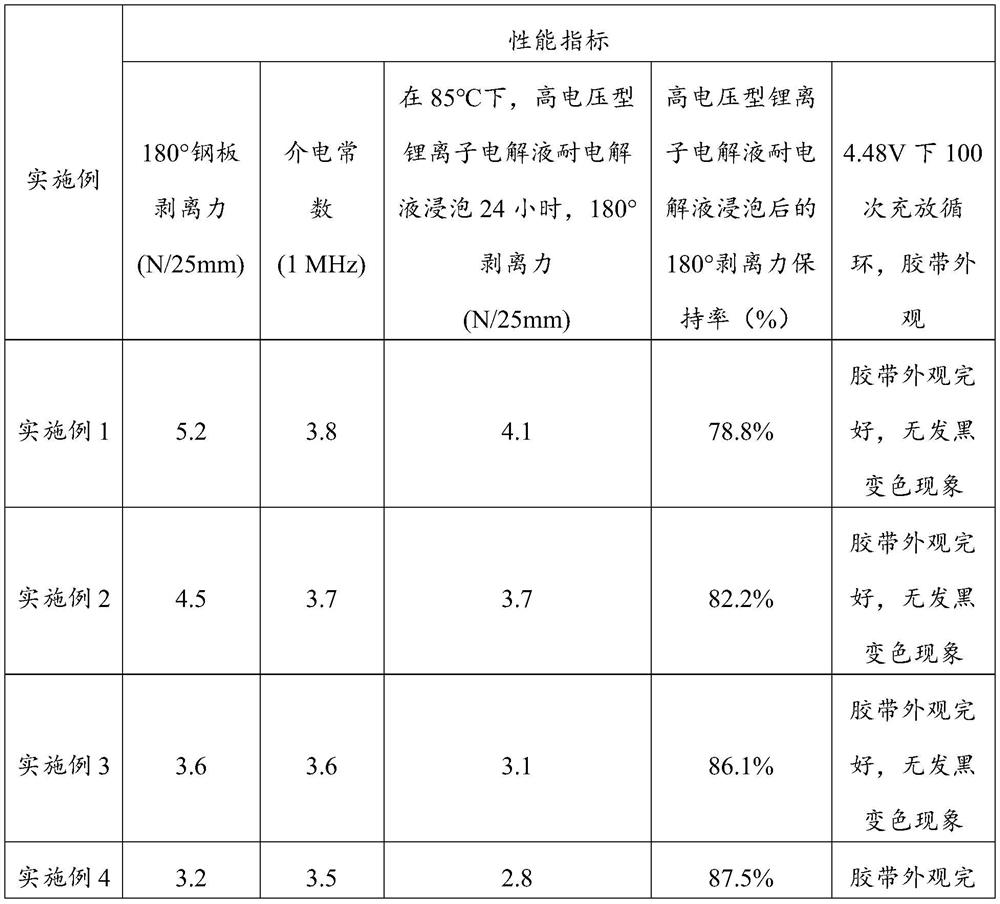

Voltage-resistant electrolyte-resistant termination adhesive tape and copolymer for termination adhesive tape

ActiveCN114057929AReduce polarityReduce movementNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerElectrolytic agent

The invention discloses a voltage-resistant electrolyte-resistant termination adhesive tape and a copolymer used for the termination adhesive tape. The structure of the copolymer is poly(octadecylacrylate / random 2-ethylhexyl acrylate / random 4-hydroxybutyl acrylate / random 4-((adamantan-1-ylcarbamoyl)oxy)butyl acrylate / random-N,N-dimethylacrylamide). According to the invention, 4-((adamantan-1-ylcarbamoyl)oxy)butyl acrylate is introduced into a side chain of a polyacrylate colloid, so the polarity of a polyacrylate molecular chain is effectively reduced, a free volume is increased, charge movement among molecules is reduced, and voltage resistance is improved; the copolymer is cross-linked with a hydroxyl-containing elastomer and a polyfunctional isocyanate curing agent to form an interpenetrating-polymer-network three-dimensional cross-linked structure, so an obtained adhesive maintains the same good adhesive force as a polyacrylate system and also shows excellent voltage resistance and electrolyte resistance; and the termination adhesive tape prepared from the adhesive can be suitable for high-energy-density lithium ion batteries.

Owner:佛山市顺德区永创翔亿电子材料有限公司

Aluminum substrate binding agent and aluminum substrate with same

InactiveCN109575858AGood flexibilityLow costNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesInsulation layerNitrile rubber

The invention relates to the technical field of LED aluminum substrates, in particular to an aluminum substrate binding agent and an aluminum substrate with the same. The aluminum substrate binding agent comprises, by weight, 40-80 parts of polyurethane modified epoxy resin, 30-50 parts of tung oil modified phenolic resin, 10-20 parts of high-functionality polyurethane modified acrylate, 100-200 parts of inorganic powder, 20-40 parts of nitrile rubber, 5-15 parts of organosilicon compounds, 1-2 parts of imidazole and 1-5 parts of curing agents. The aluminum substrate binding agent and the aluminum substrate have the advantages that the aluminum substrate prepared from the aluminum substrate binding agent is high in Tg and voltage resistance and excellent in heat conductivity and has a lowdielectric constant; the aluminum substrate is good in flexibility and excellent in machining property and can resist bending, insulation layers are free of cracking after the aluminum substrate is bent, base materials are free of leaking after the aluminum substrate is bent, and hole edges are free of breaking after holes are drilled in plates.

Owner:DONGGUAN XIANGSI ELECTRONICS TECH CO LTD

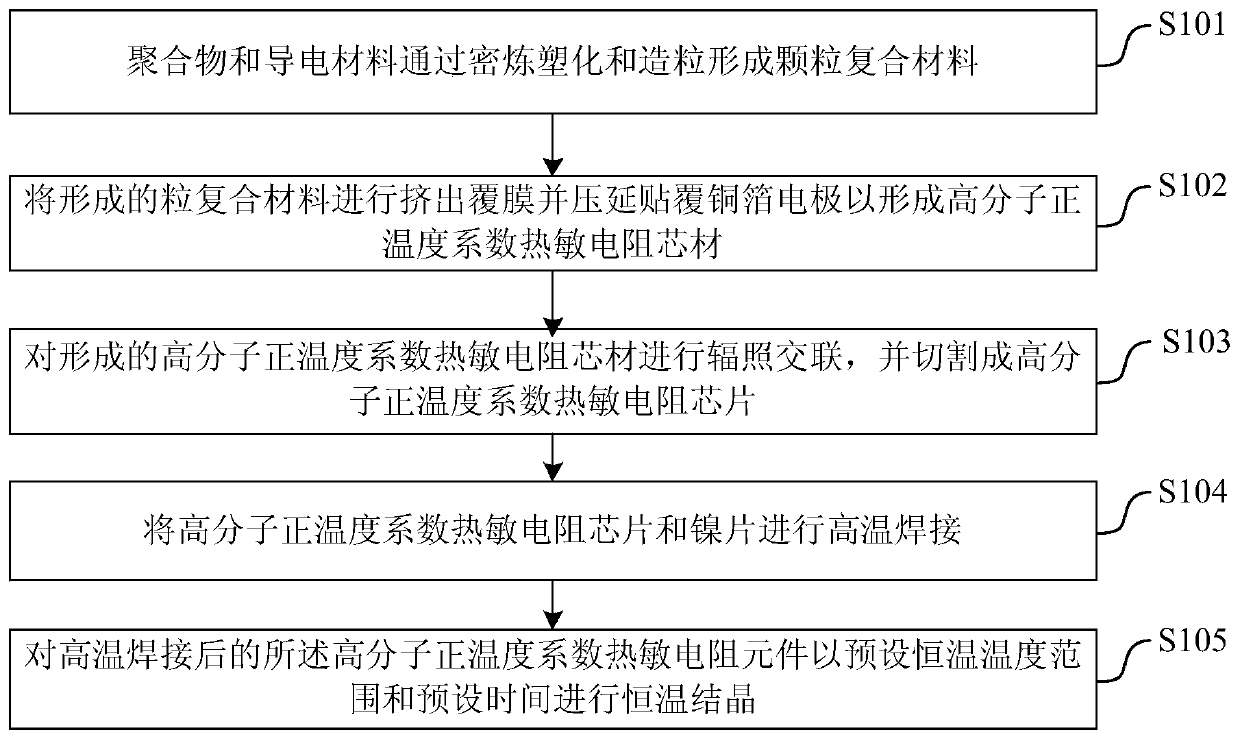

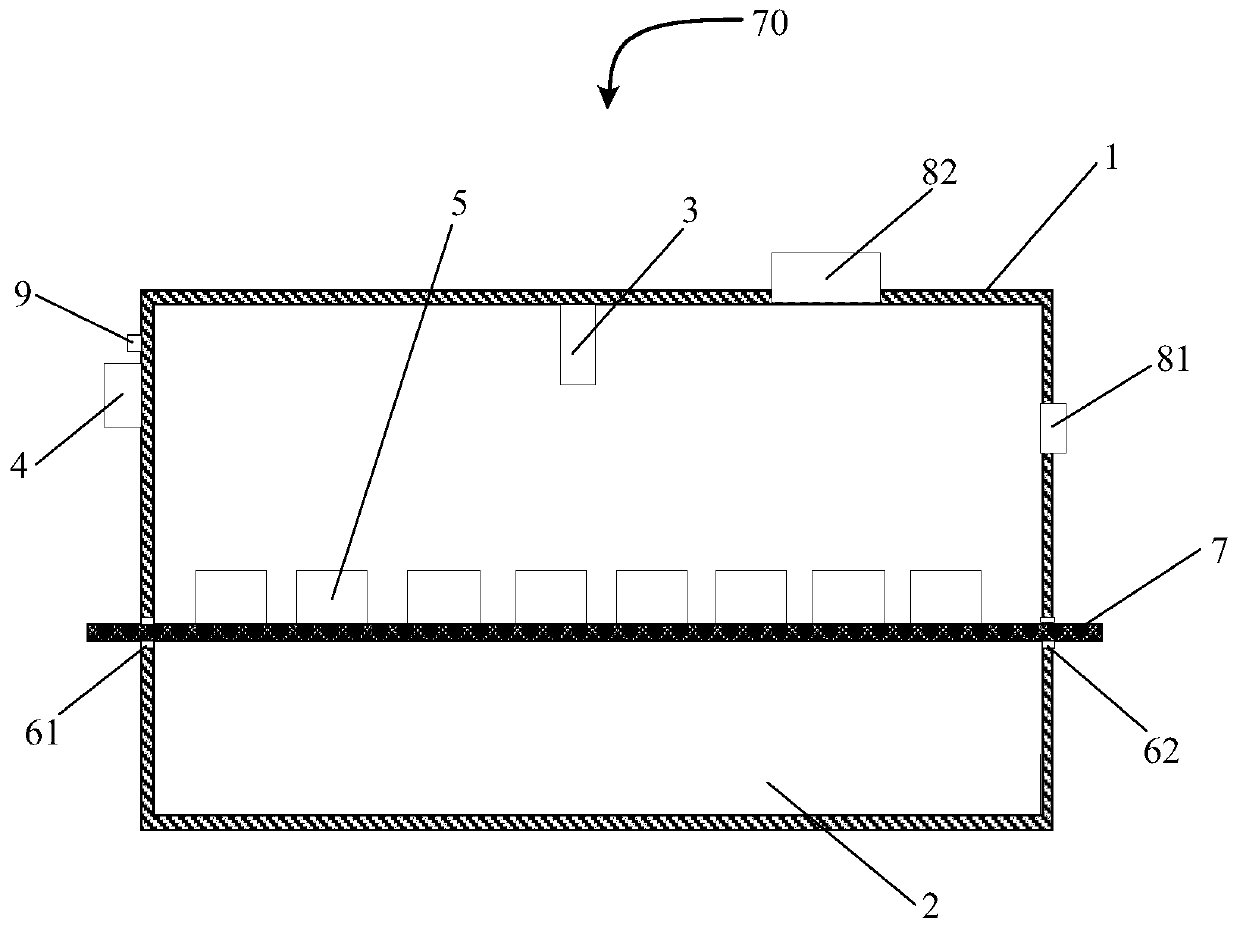

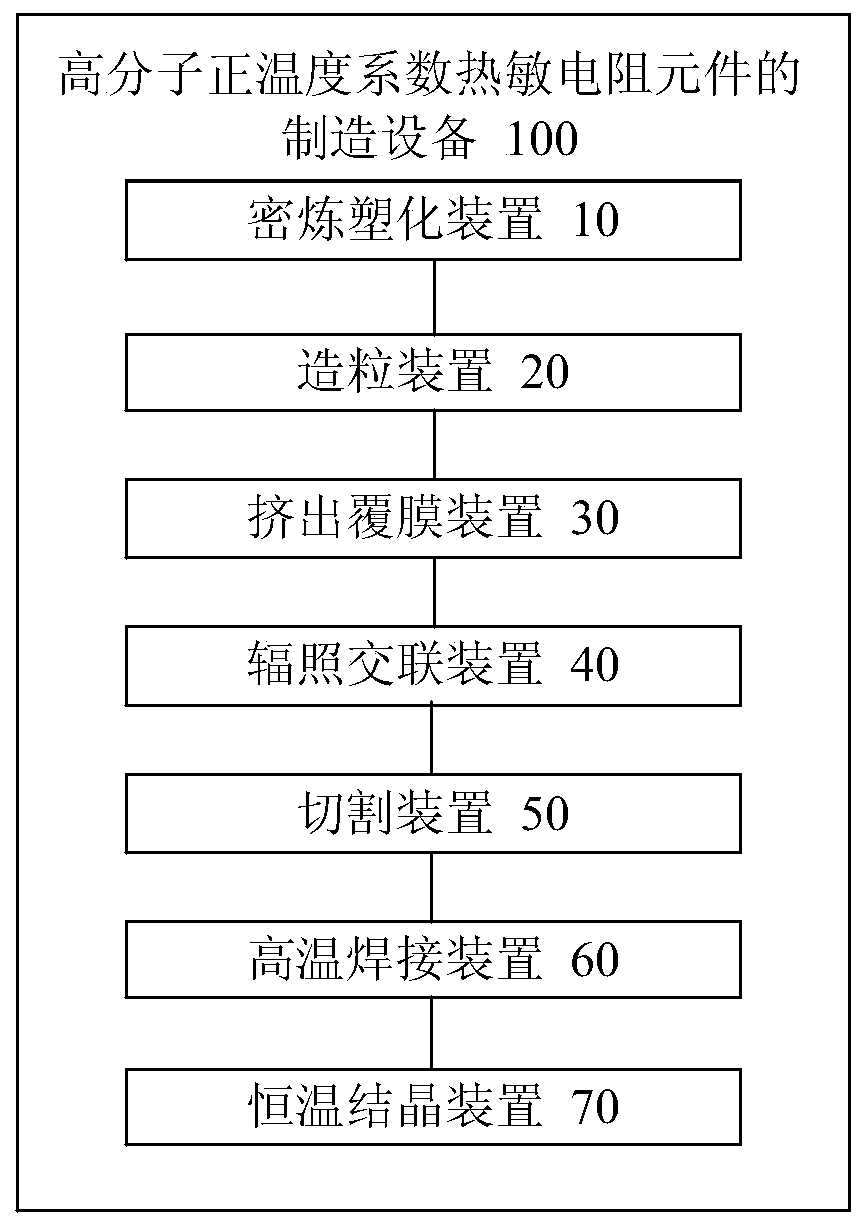

Method of manufacturing polymer positive temperature coefficient thermistor element and crystallization device

InactiveCN109859918ASolving Consistency IssuesSolving Dispersion ProblemsResistor manufacturePolymer scienceInternal resistance

The invention relates to the technical field of thermistors, and discloses a method of manufacturing a polymer positive temperature coefficient thermistor element and a crystallization device. The method of manufacturing the polymer positive temperature coefficient thermistor element comprises steps: a polymer and a conductive material form a granular composite material through mixed plasticization and granulation; extrusion coating and copper foil electrode rolling coating are carried out to form a polymer positive temperature coefficient thermistor chip material; the chip material is subjected to radiation crosslinking and is cut into a chip; the polymer positive temperature coefficient thermistor chip and a pole piece are subjected to high temperature welding; and the polymer positive temperature coefficient thermistor element after high temperature welding is subjected to constant temperature crystallization at a preset constant temperature range and a preset time. The crystallizable part in the polymer can be fully crystallized through constant temperature crystallization, and the polymer material and the conductive material form a stable network structure, thereby solving theproblem of poor resistance consistency and internal resistance dispersion, and improving the voltage withstanding performance.

Owner:SHENZHEN JINRUI ELECTRONICS MATERIAL

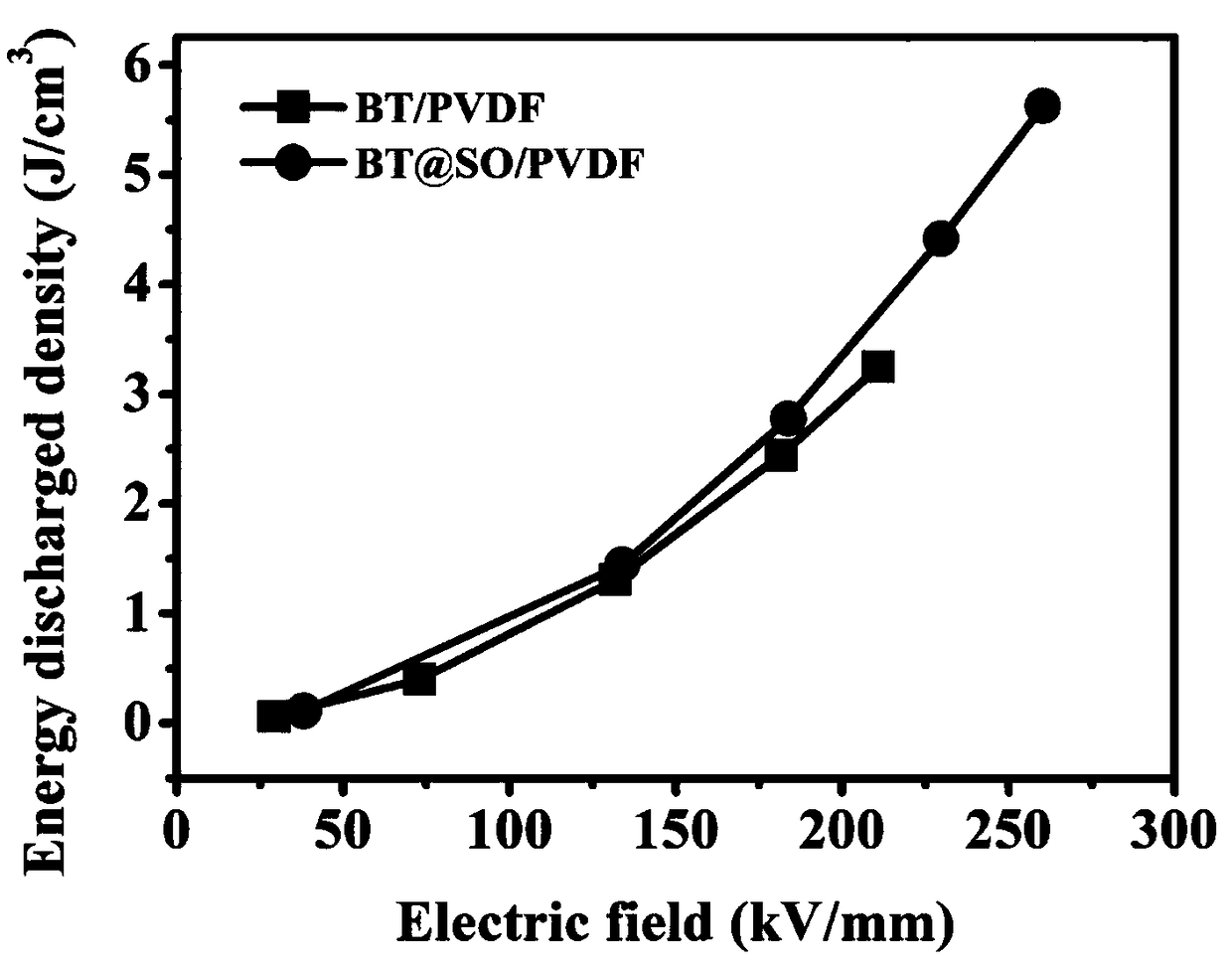

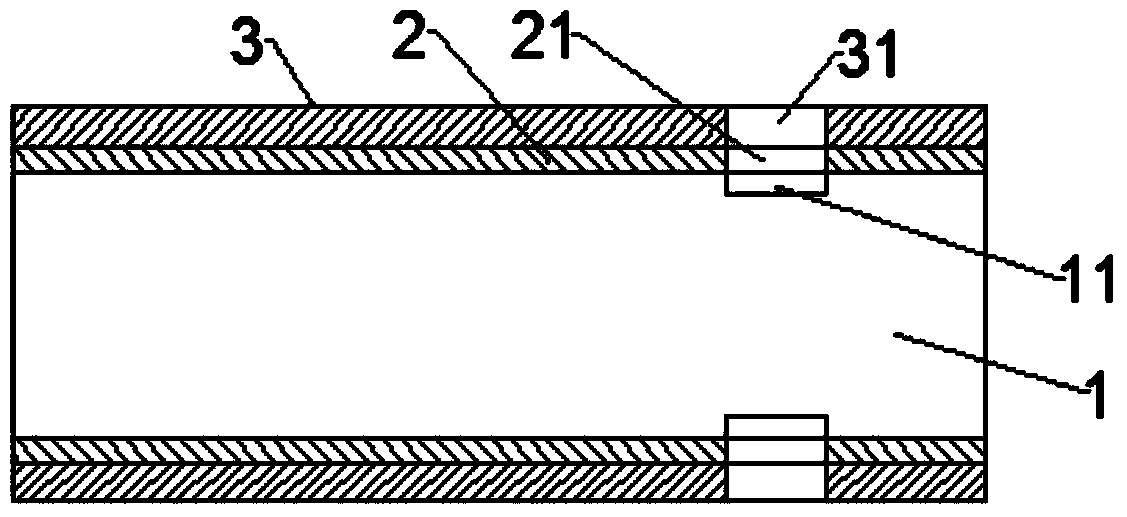

Compound material with high energy density and preparation method thereof

The invention relates to the technical field of high polymer compound materials, in particular to a compound material with high energy density and a preparation method thereof. The compound material with high energy density is mainly obtained by mixing titanate particles of a core-shell structure with a high polymer; the titanate particles of the core-shell structure is obtained by coating silicondioxide on the surface of the titanate particles. According to the compound material with the high energy density and the preparation method thereof, the silicon dioxide serving as an insulating layer is coated on the surface of ultra-fine barium titanate particles to form the titanate of the core-shell structure, the local electric field concentration and electric charge accumulation can be effectively weakened, the formation of a leakage current passage is prevented, the dielectric loss is reduced, the voltage resistant performance of the material is wholly improved, and the homogeneous dispersion of titanate and high-interface compatibility brought by a silicon dioxide layer can improve the puncture of thin film; the titanate of the core-shell structure compounds with the high polymer,and the compound material with excellent energy storage performance can be obtained under the condition of lower filling quantity.

Owner:BEIJING UNIV OF POSTS & TELECOMM

High-voltage-resistant structure of mutual induction coil printed circuit board

InactiveCN103826385AHigh voltage resistanceMeet high voltage insulation testPrinted electric component incorporationCopperHigh pressure

The invention discloses a high-voltage-resistant structure of a mutual induction coil printed circuit board. A wet film type solder-resistant ink layer with the thickness of 0.035mm-0.01mm covers the surface of a circuit on the outmost layer of the mutual induction coil printed circuit board; a copper-free baseplate with the thickness of 0.05mm-0.15mm is fixedly attached onto the surface of the wet film type solder-resistant ink layer; the wet film type solder-resistant ink layer and the copper-free baseplate are respectively provided with a windowing part and a grooving part corresponding to plug-in holes of the circuit on the outmost layer, and the plug-in holes are exposed out of the windowing parts and the grooving parts. Due to the adoption of the structure, the voltage resistance of the mutual induction coil printed circuit board is enhanced, and the requirement of a high-voltage insulation test under the conditions of DC1500V, 60sec and 2mA can be met.

Owner:竞陆电子(昆山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com