High-voltage-resistant structure of mutual induction coil printed circuit board

A technology of mutual inductance coils and printed boards, which is applied in directions including printed electrical components, can solve problems such as poor withstand voltage and achieve the effect of enhancing withstand voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

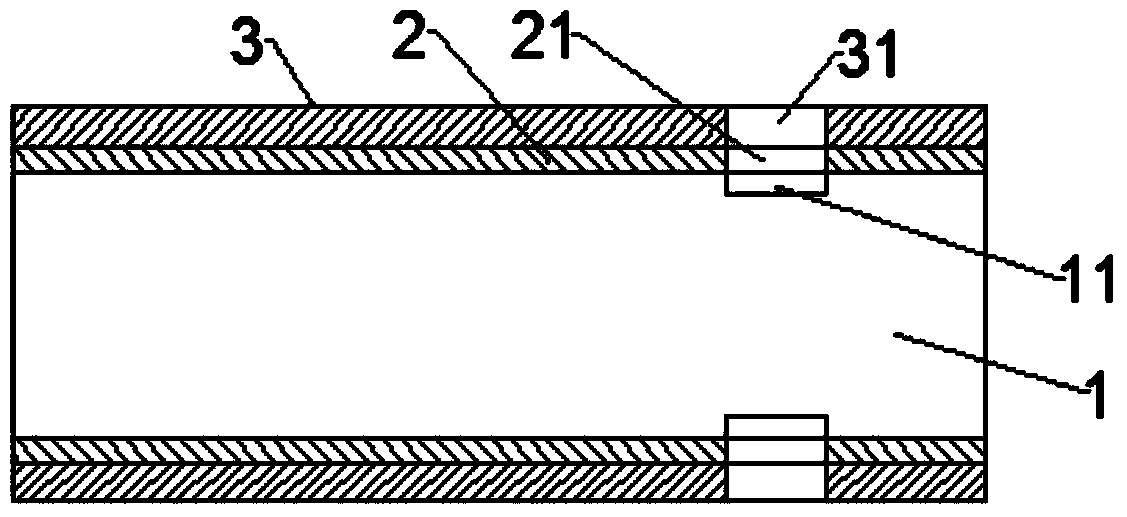

[0011] Embodiment: a high-voltage resistant structure of a mutual induction coil printed board, the outermost circuit surface of the mutual induction coil printed board 1 is covered with a wet film type solder resist ink layer 2 (made of synthetic resin, photoinitiator, color materials, surfactants, fillers and solvents), the outermost circuit of the mutual induction coil printed board has a plug-in hole 11, and the wet film type solder resist ink layer has an opening corresponding to the position of the plug-in hole The window part 21, the plug-in hole of the outermost circuit is exposed to the outside at the window part of the wet film type solder resist ink layer, and the surface of the wet film type solder resist ink layer is fixedly attached with a copper-free substrate 3 , the copper-free substrate has a grooved portion 31 corresponding to the plug-in hole and the window portion, the plug-in hole is exposed to the outside at the grooved portion of the copper-free substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com