Compound material with high energy density and preparation method thereof

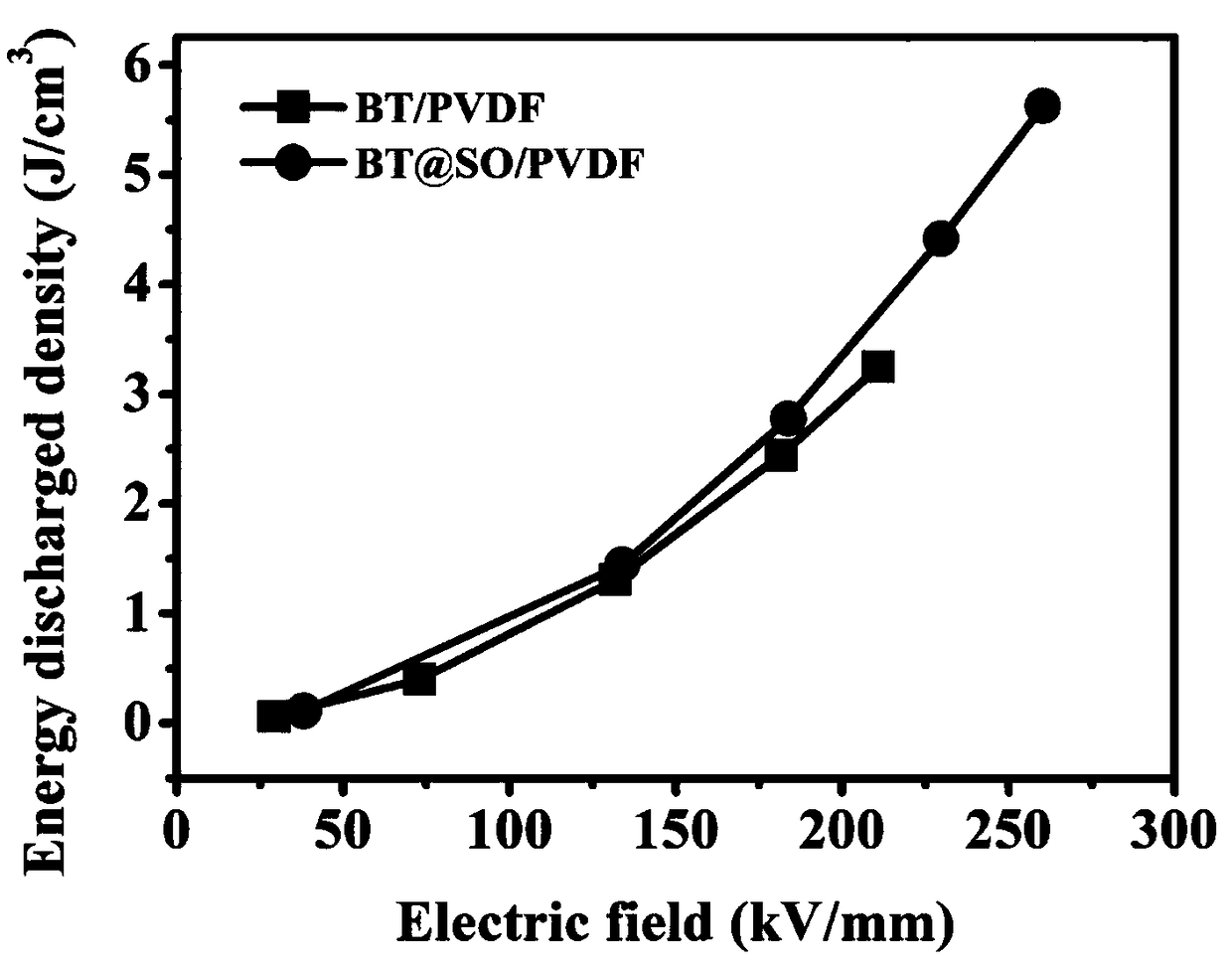

A technology of high energy storage density and composite materials, applied in the field of high energy storage density composite materials and their preparation, can solve the problems of microscopic inhomogeneity, dielectric mismatch, and large film brittleness, and achieve excellent uniform dispersion and excellent storage capacity. performance, the effect of eliminating pores and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a preparation method of a high energy storage density composite material, comprising the following steps:

[0068] Coating silicon dioxide on the surface of the titanate to obtain titanate particles with a core-shell structure, which is mixed with a high polymer to obtain the composite material with high energy storage density.

[0069] In a preferred embodiment of the present invention, the method for preparing titanate particles with a core-shell structure includes: dispersing titanate in a solvent, adding tetraethyl silicate to react under alkaline conditions, centrifuging the reacted solution and cleaning to obtain titanate particles with a core-shell structure.

[0070] In a preferred embodiment of the present invention, in the titanate particles with a core-shell structure, the mass fraction of silicon dioxide in the titanate with a core-shell structure is 1-50%, preferably 2-30%, more preferably 2-10%, most preferably 6%.

[...

Embodiment 1

[0083] The preparation method of the high energy storage density composite material described in this embodiment is as follows:

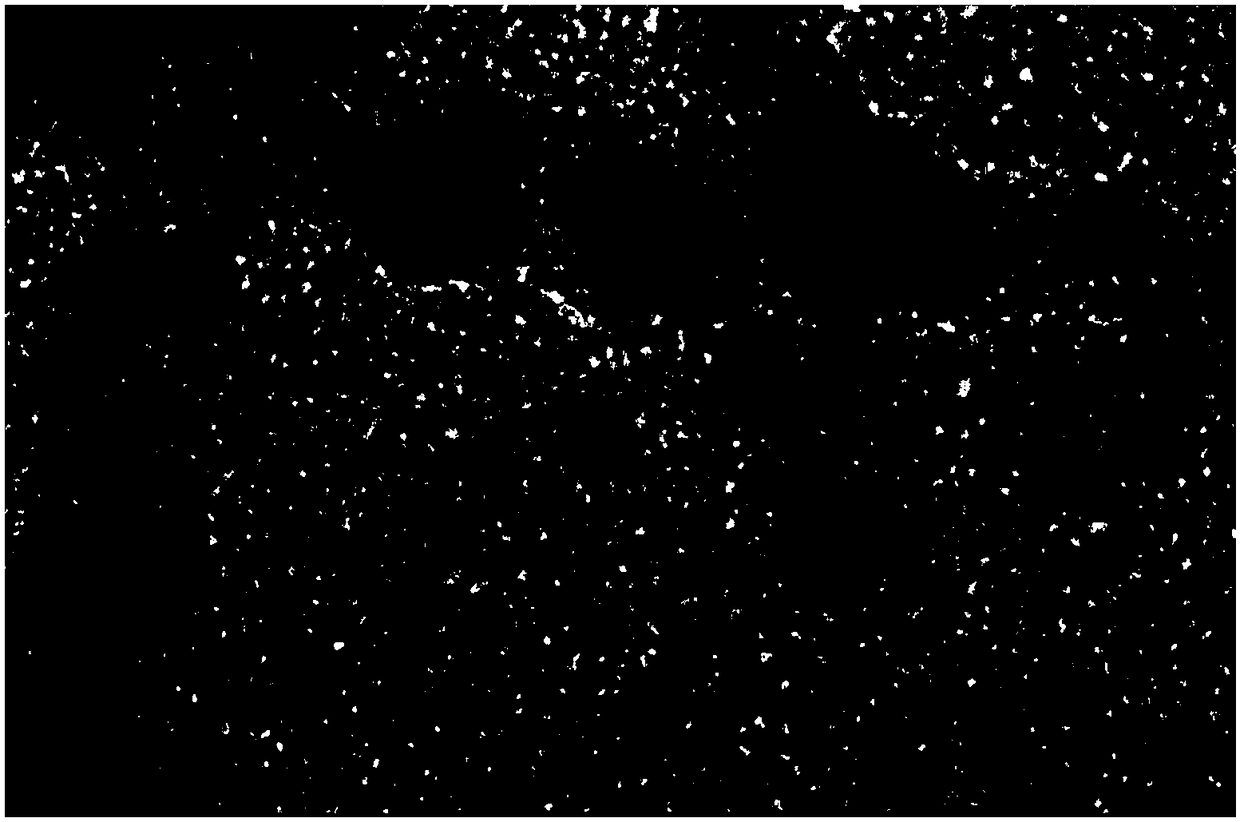

[0084] (1) Ultrafine 0.37g barium titanate (average particle size 6-8nm) is ultrasonically dispersed in absolute ethanol, tetraethyl silicate is used as silicon source, and ammonia water is used as catalyst to hydrolyze tetraethyl silicate to form diethyl silicate Silicon oxide was coated on the surface of barium titanate. After the reaction, the solution was centrifuged and washed with absolute ethanol to obtain barium titanate particles with a core-shell structure (BT@SO). The amount of silica coating on the surface of BT@SO was 6wt% to form a silicon dioxide layer with a thickness of 0.2nm; ultrasonically disperse the obtained BT@SO in 8mL of N,N-dimethylacetamide, so that BT@SO is uniformly dispersed in the solvent to form a uniform dispersion ;

[0085] (2) Add 1 g of polyvinylidene fluoride and 10 mL of N,N-dimethylacetamide into the containe...

Embodiment 2

[0089] The preparation method of the high energy storage density composite material described in this embodiment is as follows:

[0090](1) ultrasonically disperse 0.18g of ultrafine barium titanate (average particle size 6-8nm) in absolute ethanol, use tetraethyl silicate as silicon source, and ammonia water as catalyst to hydrolyze tetraethyl silicate to form di Silicon oxide was coated on the surface of barium titanate. After the reaction, the solution was centrifuged and washed with absolute ethanol to obtain barium titanate particles with a core-shell structure (BT@SO). The amount of silica coating on the surface of BT@SO was 2wt% to form a silicon dioxide layer with a thickness of 0.07nm; ultrasonically disperse the obtained BT@SO in 4mL of N,N-dimethylacetamide, so that BT@SO is uniformly dispersed in the solvent to form a uniform dispersion ;

[0091] (2) Add 1 g of polyvinylidene fluoride and 10 mL of N,N-dimethylacetamide into the container, and magnetically stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com