Patents

Literature

110results about How to "Improve withstand voltage performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of cryogenic direct-welding polyurethane envelope without pinhole

InactiveCN101029203AReduce direct soldering temperatureImprove adhesionPolyurea/polyurethane coatingsEngineeringPolyurethane

A low-temperature straight-welding polyurethane wire enamel without pin hole is carried out by preparing hydroxide radical component, preparing enclosed component and formulating wire enamel. It can be used for extended or bended zero pin hole below 340degree.

Owner:DANYANG STAR CHEM

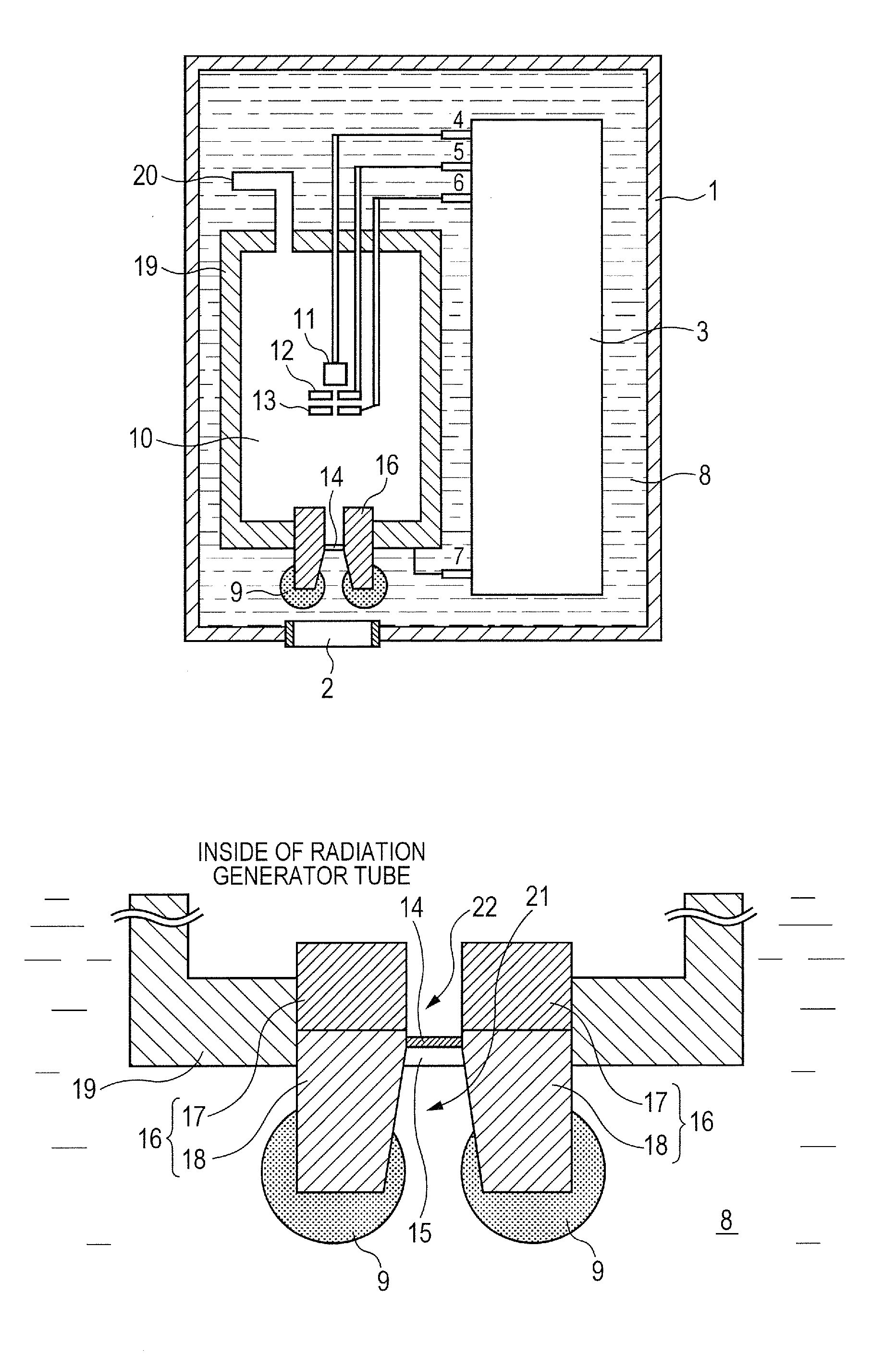

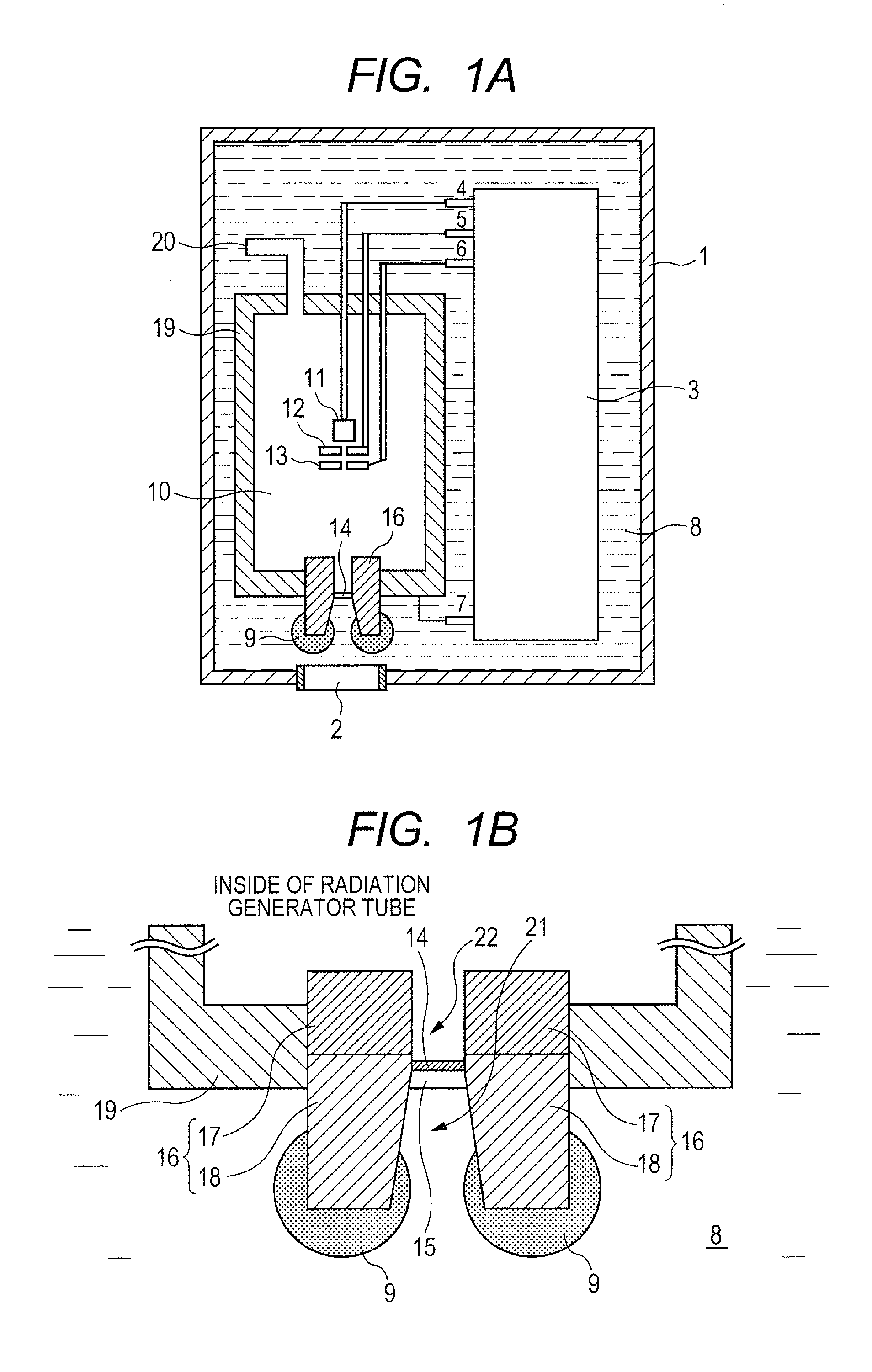

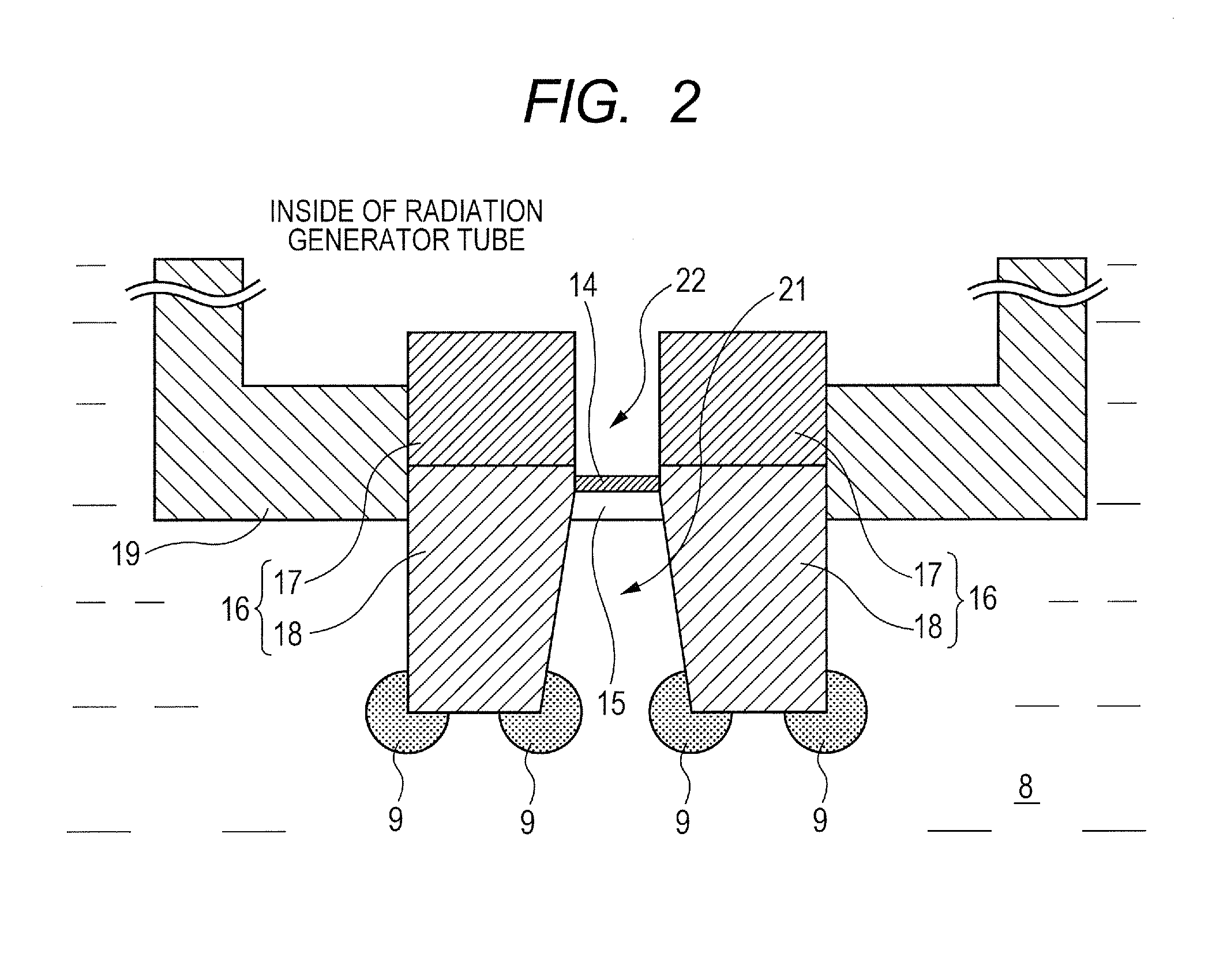

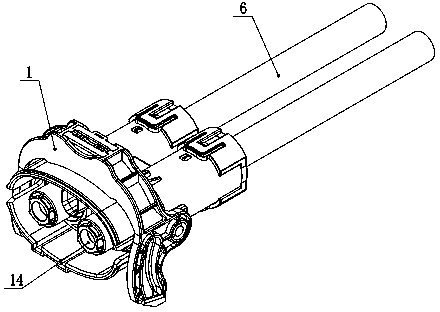

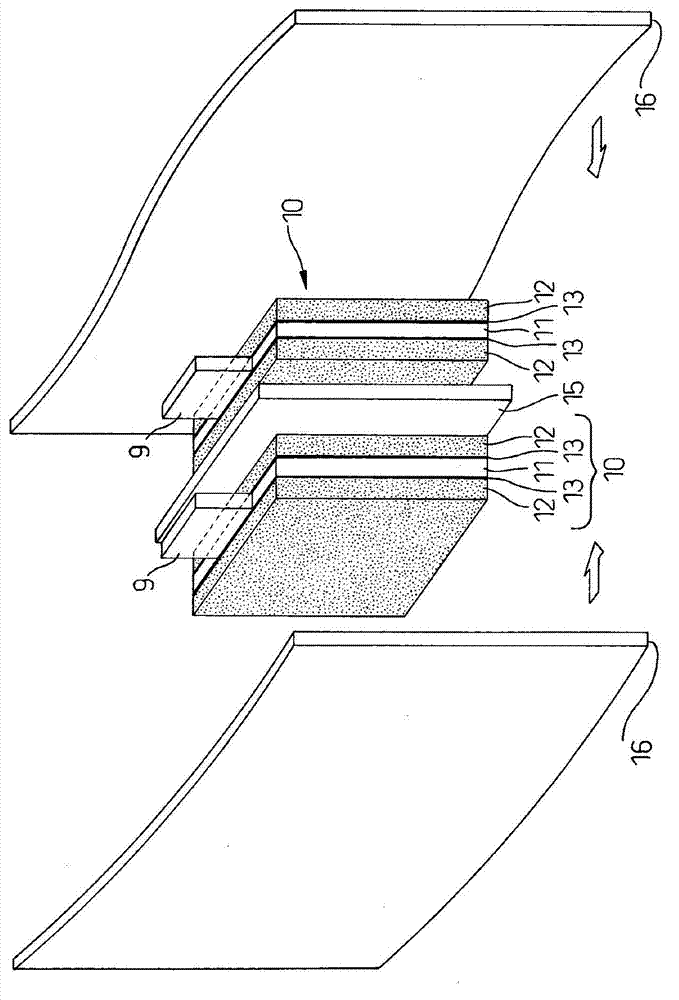

Radiation generating apparatus and radiation imaging apparatus using the same

InactiveUS20130016812A1Improve electrostatic performanceReduce distanceX-ray tube electrodesCathode ray concentrating/focusing/directingRadiation imagingPhysics

A radiation generating apparatus 30 according to the present invention including: a radiation generating tube 10 having a target 14, a tubular shielding member 18 that shields a part of a radiation generated from the target 14 and also has an aperture 21 through which the radiation generated from the target 14 passes, and an envelope 1 that has the target 14 so as to be brought into contact with the internal space thereof and also has the tubular shielding member 18 so as to protrude toward an external space thereof; a storage container 1 for storing the radiation generating tube 3 therein; and an insulating liquid 8 that comes in contact with the tubular shielding member 18 and the storage container 1, wherein the tubular shielding member 18 has a protruding portion P, and the protruding portion P is covered with a solid insulating member 9.

Owner:CANON KK

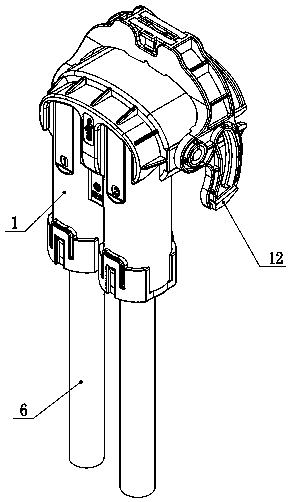

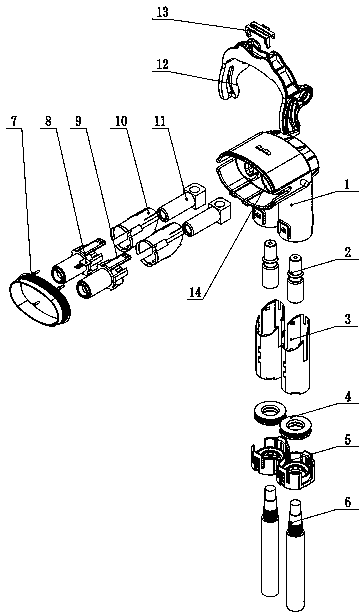

Electric connector for high-voltage electric equipment

InactiveCN103427259AIncrease carrying capacityImprove withstand voltage performanceCoupling contact membersCouplings bases/casesElectricityElectromagnetic shielding

The invention relates to an electric connector for high-voltage electric equipment. The electric connector comprises a plug and a socket, wherein the plug comprises a plug body, at least two through holes are formed in the plug body in a penetrating mode, an inserting sleeve for being electrically connected with a contact pin of the socket is arranged in one end of one through hole, a conversion terminal for being electrically connected with a connection cable is arranged in the other end of the through hole, the plug body is of a turning structure, and the turning curvature of the through holes are equal to that of the plug body. The electric connector has the advantages of having drawing and bending resistance, high-loading capability, high voltage-resisting capability, excellent impact resistance, vibration capability and electromagnetic shielding performance of the existing connectors, being suitable for being installed in narrow inside spaces of electric automobiles, and meeting using requirements of installation in small-dimensional spaces and various wiring modes.

Owner:SUZHOU CHILYE GREEN TECH

Method for producing positive temperature coefficient thermistor for surge suppressor

InactiveCN101429020ASatisfy Absorption Inhibition CapacityImprove withstand voltage performanceElectrical resistance and conductanceSuppressor

The invention relates to a method for producing a positive temperature coefficient thermistor for a surge suppressor. The compositions of raw materials in molar ratio are as follows: 1.011 percent of TiO2, 0.755 to 0.764 percent of BaCO3, 0.140 to 0.155 percent of CaCO3, 0.090 to 0.096 percent of SrCO3, 0.006 percent of Y2O3, 0.017 percent of SiO2, and 0.0008 percent of MnO2. When the diameter of the positive temperature coefficient thermistor prepared by the method is less than 6 millimeters, the voltage withstanding capacity is more than AC700V, and the resistivity is between 180 and 220 omega.Cm, thus the method can fully meet and adapt to the use requirements of the surge suppressor.

Owner:DANDONG GUOTONG ELECTRONICS COMPONENTS

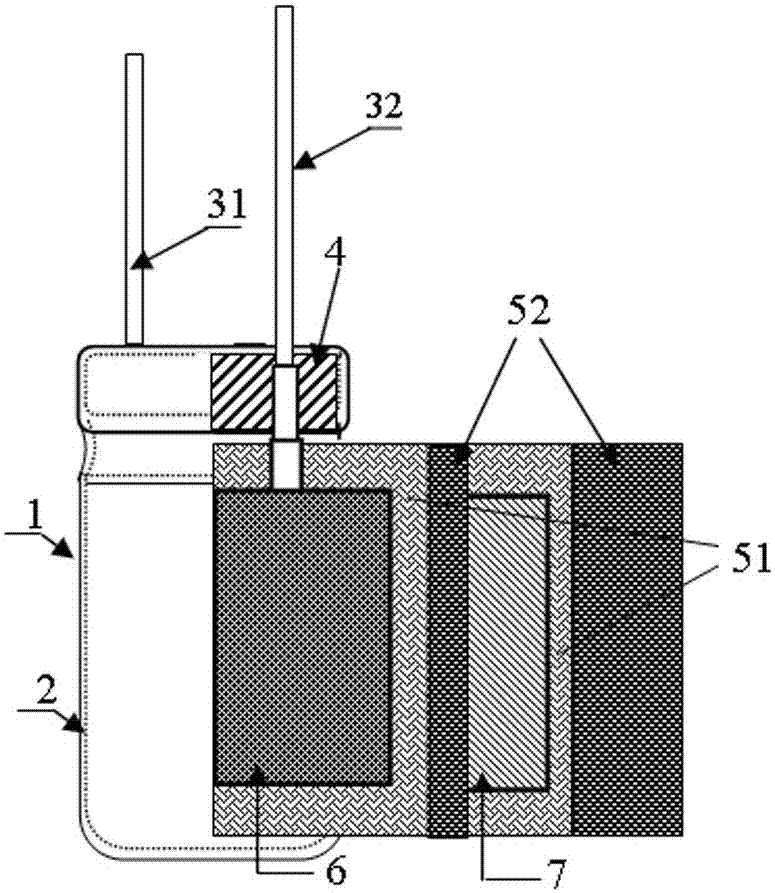

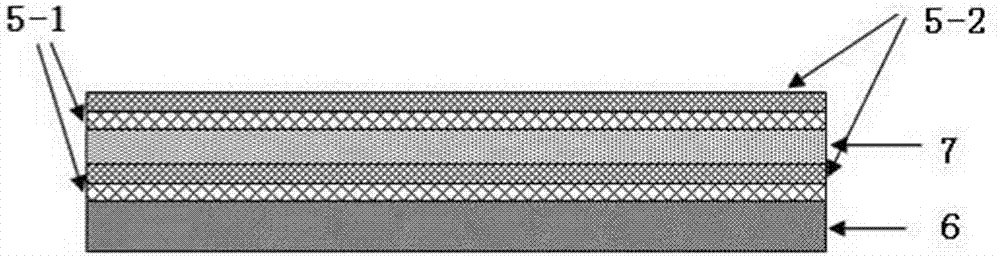

Novel lightning-stroke protection aluminium electrolytic capacitor and preparation method therefor

ActiveCN107195460AImproving the ability to withstand instantaneous high pressureImprove securityCapacitor housing/encapsulationWinding capacitor machinesLightning strokesEngineering

The invention provides a novel lightning-stroke protection aluminium electrolytic capacitor and a preparation method therefor. A core is immersed with an electrolyte with a break-down voltage of 490V or above; the core is formed by a pieces of positive electrode foil, a piece of negative electrode foil and electrolytic paper in an overlapping and winding manner, wherein the electrolytic paper used as a substrate is arranged on the same sides of the negative electrode foil and the positive electrode foil separately; a positive electrode conductive pin in nail joint with the positive electrode foil and a negative electrode conductive pin in nail joint with the negative electrode foil are arranged in a manner of running through a packaging layer; the electrolytic paper comprises inner layer electrolytic paper and outer layer electrolytic paper; the inner layer electrolytic paper is positioned on the inner side of the corresponding negative electrode foil or positive electrode foil; and the inner layer electrolytic paper and outer layer electrolytic paper are consistent in tightness. The overall voltage withstand capacity of the product is improved effectively, and the instantaneous voltage withstand of the aluminium electrolytic capacitor is improved to 2.2KV; and in addition, the aluminium electrolytic capacitor has high impact resistance, high safety and an effect of ensuring the service life.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Voltage-resistant insulating flame-retardant reinforced nylon 66 engineering plastic

InactiveCN102924917AImprove flame retardant performanceImprove mechanical propertiesHalloysiteAlkali free

The invention relates to voltage-resistant insulating flame-retardant reinforced nylon 66 engineering plastic. The engineering plastics comprise the following components in percentage by weight: 30-60% of PA 66 resin, 1.5-9% of PPO resin, 2-5% of compatilizer, 10-20% of red phosphorus flame retardant masterbatch, 2-10% of voltage-resistant insulating modified filler particles, 0.01-35% of alkali-free chopped glass fiber, and 1-2% of other auxiliaries. The voltage-resistant insulating modified filler particles include at least one of calcined kaolin, mica and halloysite carbon nanotube, the other auxiliaries comprise aminosilane coupling agent, and the filler particles are treated by the aminosilane coupling agent, which accounts for 5 wt% of the filler particles. The nylon 66 engineering plastic has excellent voltage-resistant insulating property, good mechanical performance and flame retardancy; and can be used for preparing electrical and electronic components with voltage-resistant and flame retardancy requirements.

Owner:惠州市华聚塑化科技有限公司

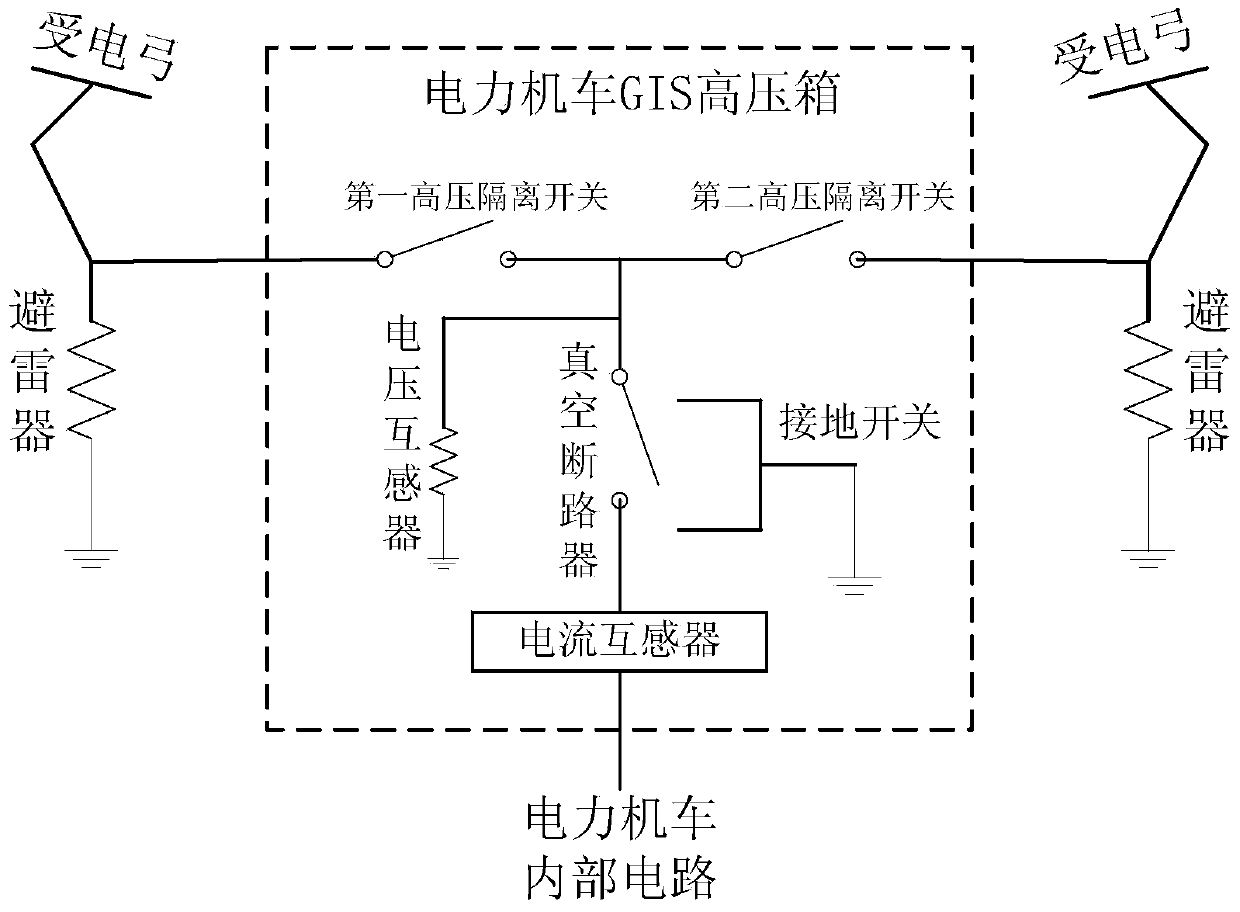

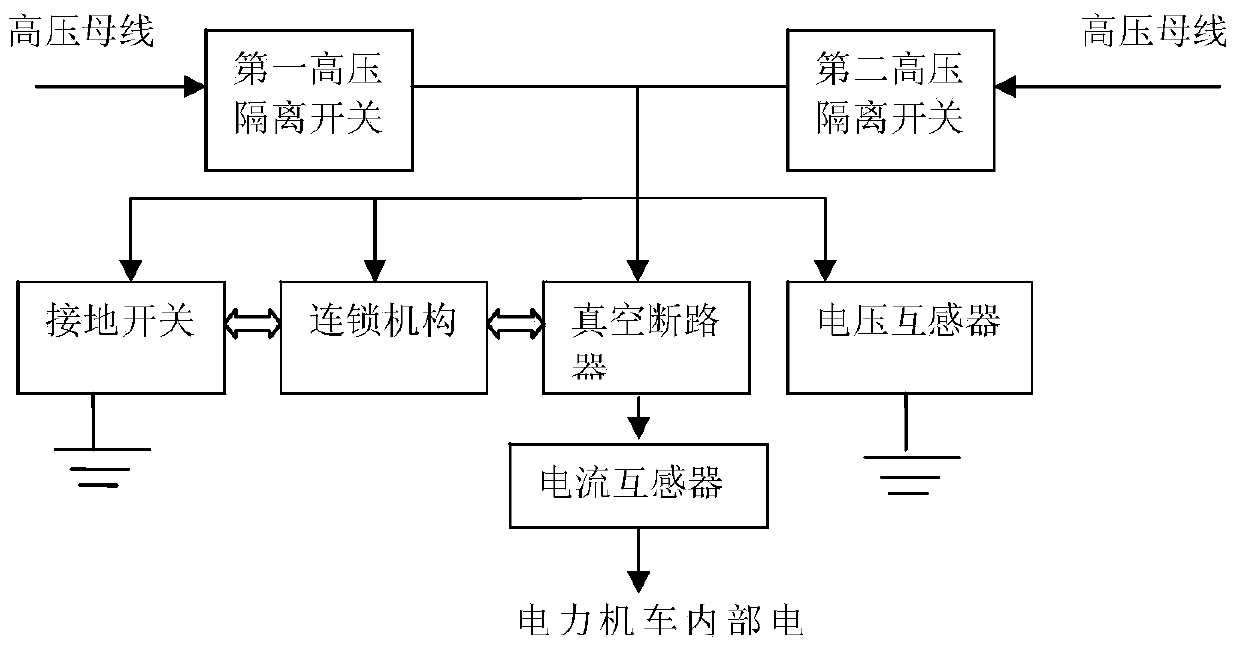

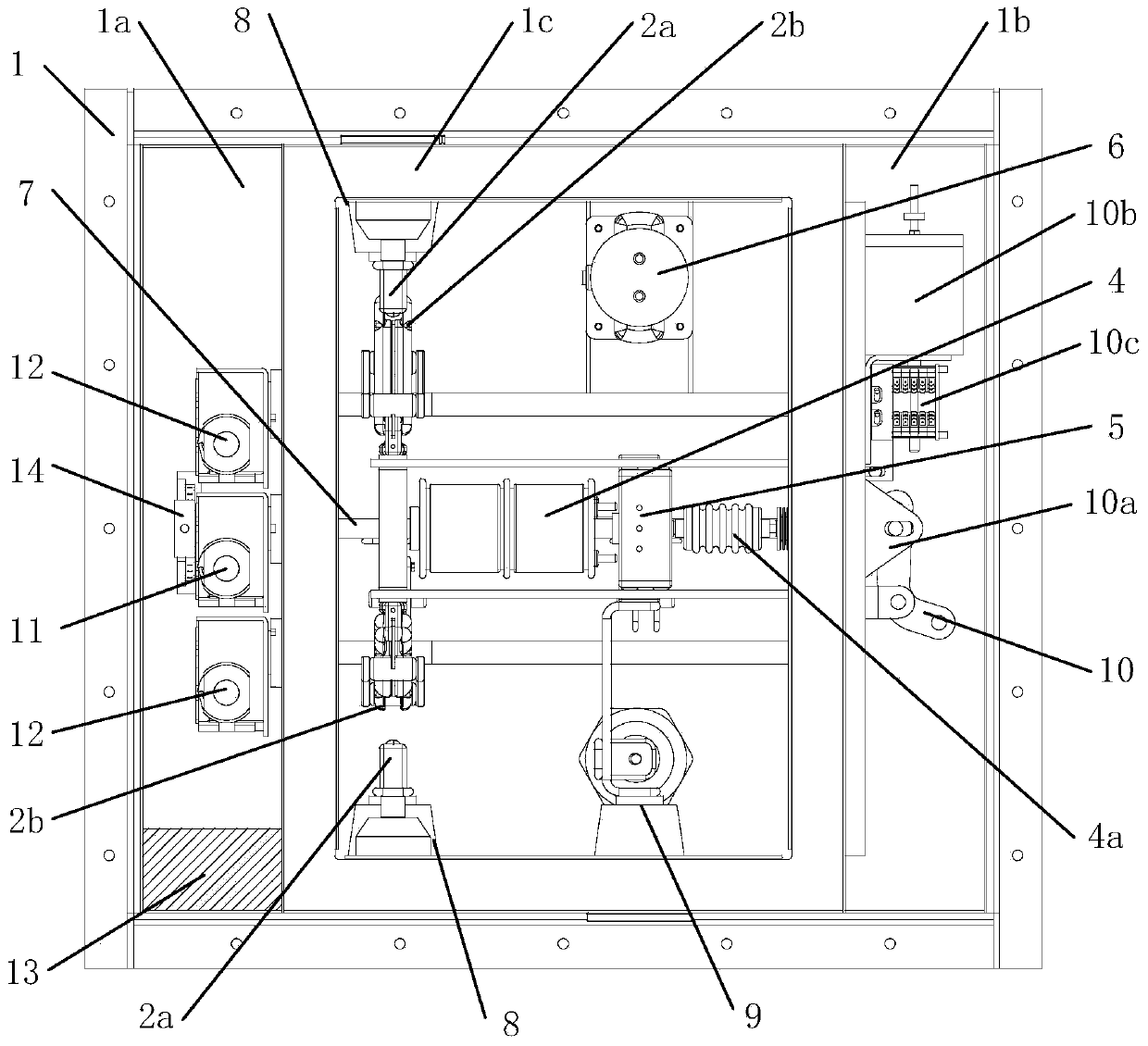

GIS (Gas Insulated Swtichgear) high-voltage box of electric locomotive

ActiveCN103594953ANo electrical interferenceReduce volumeSwitchgear arrangementsElectricitySulfur hexafluoride

The invention discloses a GIS high-voltage box of an electric locomotive. The high-voltage box comprises high-voltage disconnecting switches, a vacuum circuit breaker 4, a current transformer 5, a voltage transformer 6 and a grounding switch 7 which are arranged in a middle seal box 1c, and the internal of the middle seal box 1c is filled with sulfur hexafluoride gas; a cable inlet end 8 and a cable outlet end 9 are arranged in the middle seal box 1c; the high-voltage disconnecting switches are electrically connected with a pantograph via the cable inlet end 8; the current transformer 5 is electrically connected with an internal circuit of the electric locomotive via the cable outlet end 9; a vacuum circuit breaker operation mechanism 10 is connected with the vacuum circuit breaker 4; a grounding switch operating mechanism 11 is connected with the grounding switch 7; and high-voltage disconnecting switch operating mechanisms 12 are respectively connected with the high-voltage disconnecting switches. The GIS high-voltage box of the electric locomotive can effectively avoid ground discharge of high-voltage components, reduce the space, which is occupied by the high-voltage components, at the top of the electric locomotive, and improve the mounting and dismounting efficiency.

Owner:BEIJING CED RAILWAY ELECTRIC TECH +1

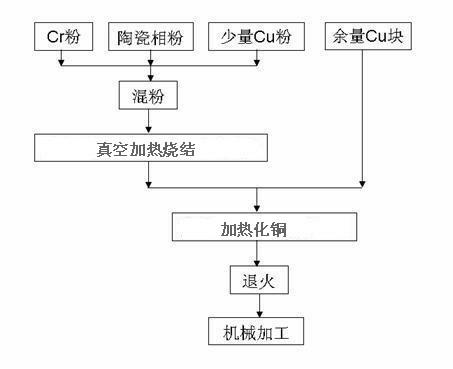

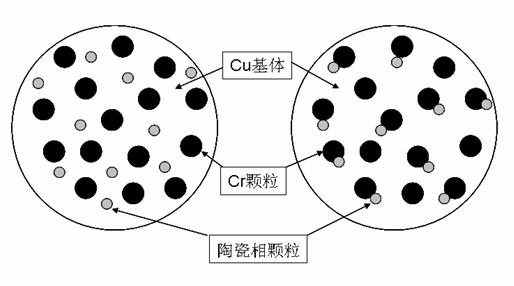

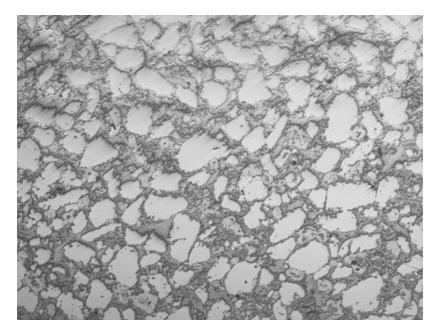

Vacuum copper-based electrical contact composite material containing ceramic phase and preparation method of vacuum copper-based electrical contact composite material

InactiveCN102628114AHigh mechanical strengthImprove withstand voltage performanceContactsElectricityRoom temperature

The invention relates to the field of powder metallurgy, in particular to a vacuum copper-based electrical contact composite material containing a ceramic phase and a preparation method of the vacuum copper-based electrical contact composite material. According to the invention, the vacuum copper-based electrical contact composite material containing the ceramic phase comprises the following chemical components in percentage by mass: 5-50% of Cr, 1-10.5% of B4C and Cu in balancing amount. The preparation method comprises the following steps: uniformly mixing Cr powder, B4C powder and Cu powder so as to obtain mixed powder; adding a copper rod and putting the copper rod in a vacuum heating furnace; after the temperature rises to 1350 DEG C, beginning to smelt the copper; after the copper is smelted, reducing the temperature of the smelted copper rod to 1100-1200 DEG C; preserving the heat of the smelted copper rod for 20-60 minutes; cooling the smelted copper rod to room temperature so as to obtain a composite material blank; and annealing the composite material blank so as to obtain the vacuum copper-based electrical contact composite material containing the ceramic phase. The vacuum copper-based electrical contact composite material containing the ceramic phase, provided by the invention, has the advantages of higher mechanical strength, higher voltage resistance and higher breaking capacity and can be used for medium and high voltage vacuum switches after being appropriately machined.

Owner:NORTHEASTERN UNIV LIAONING +1

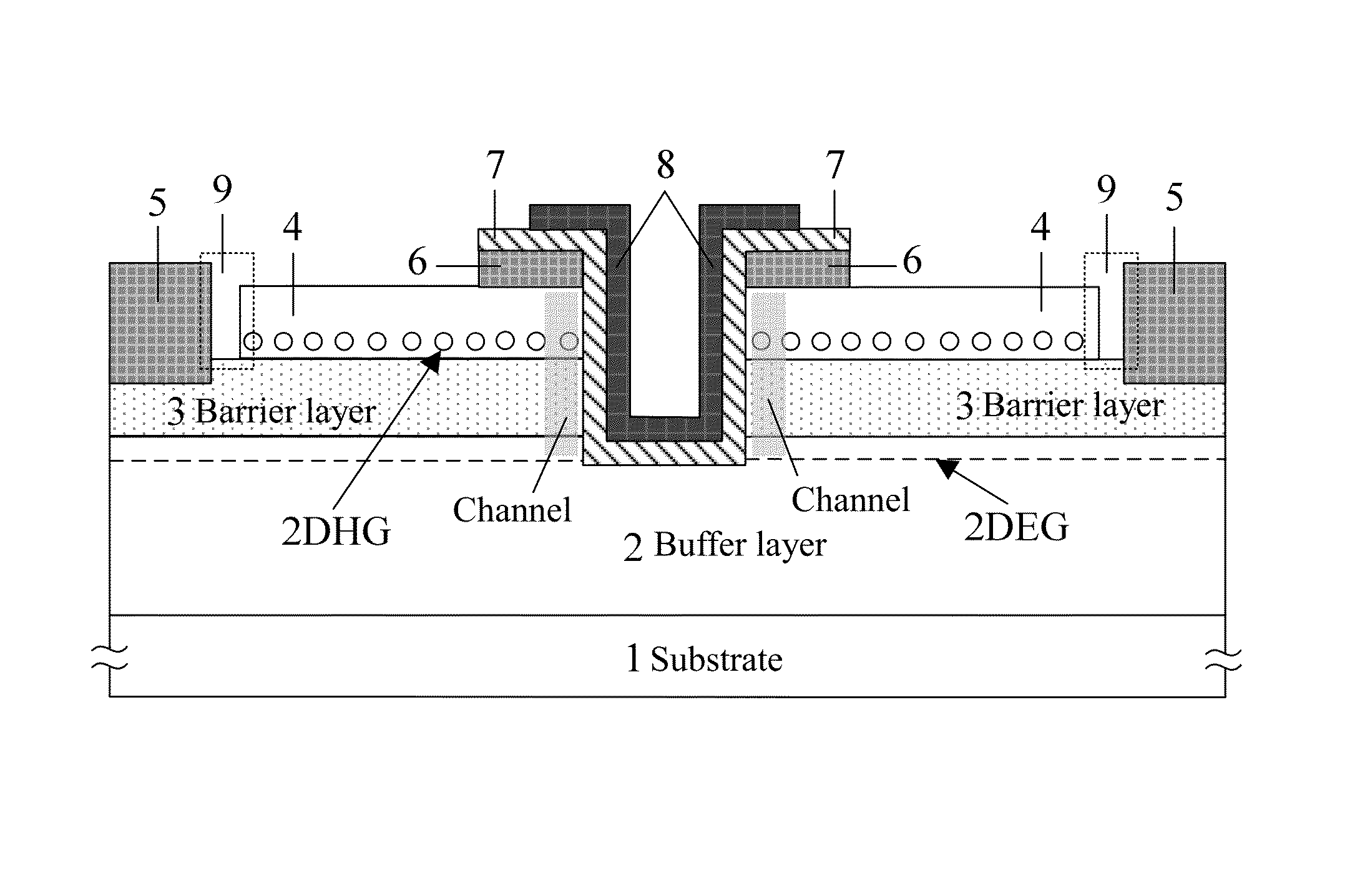

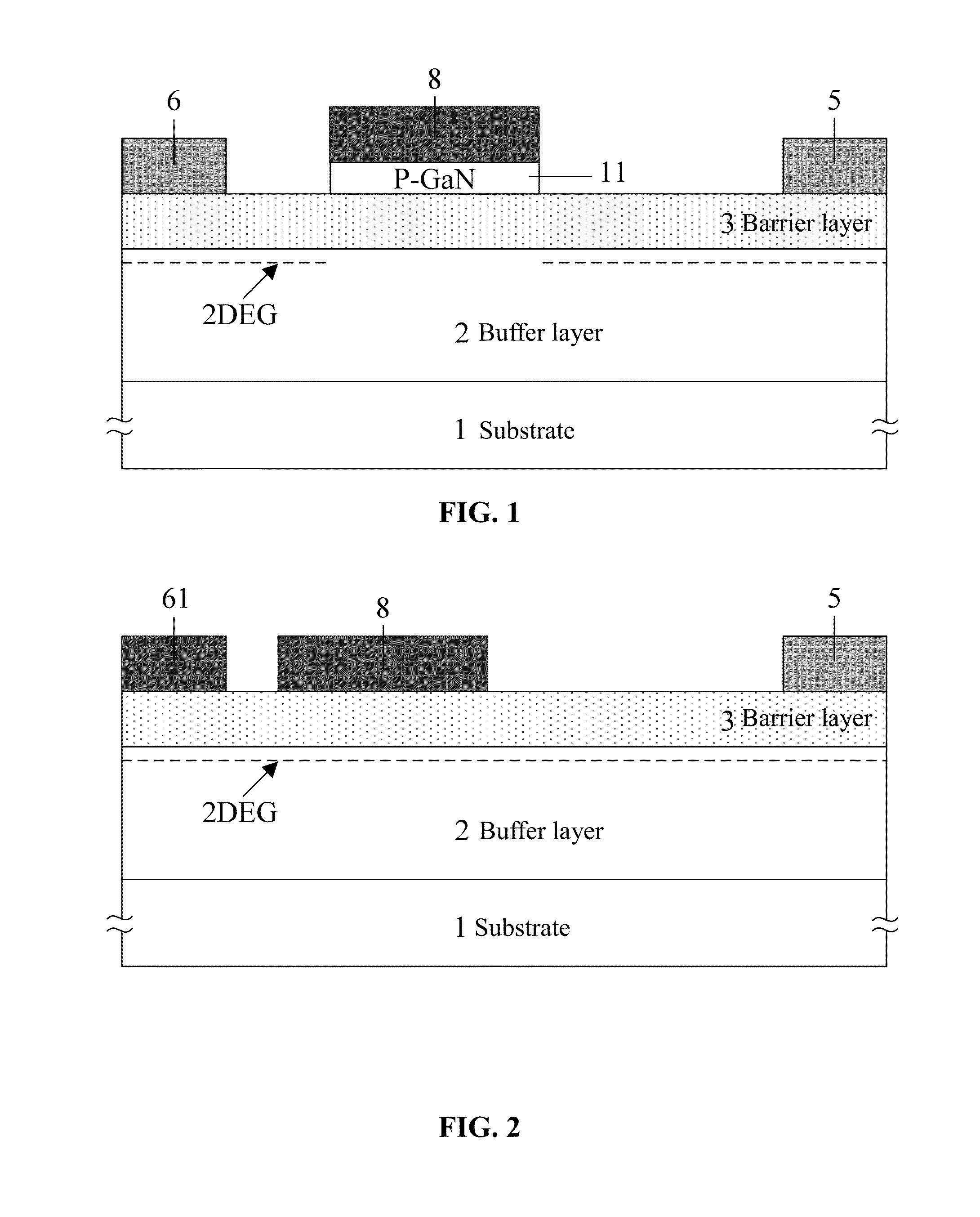

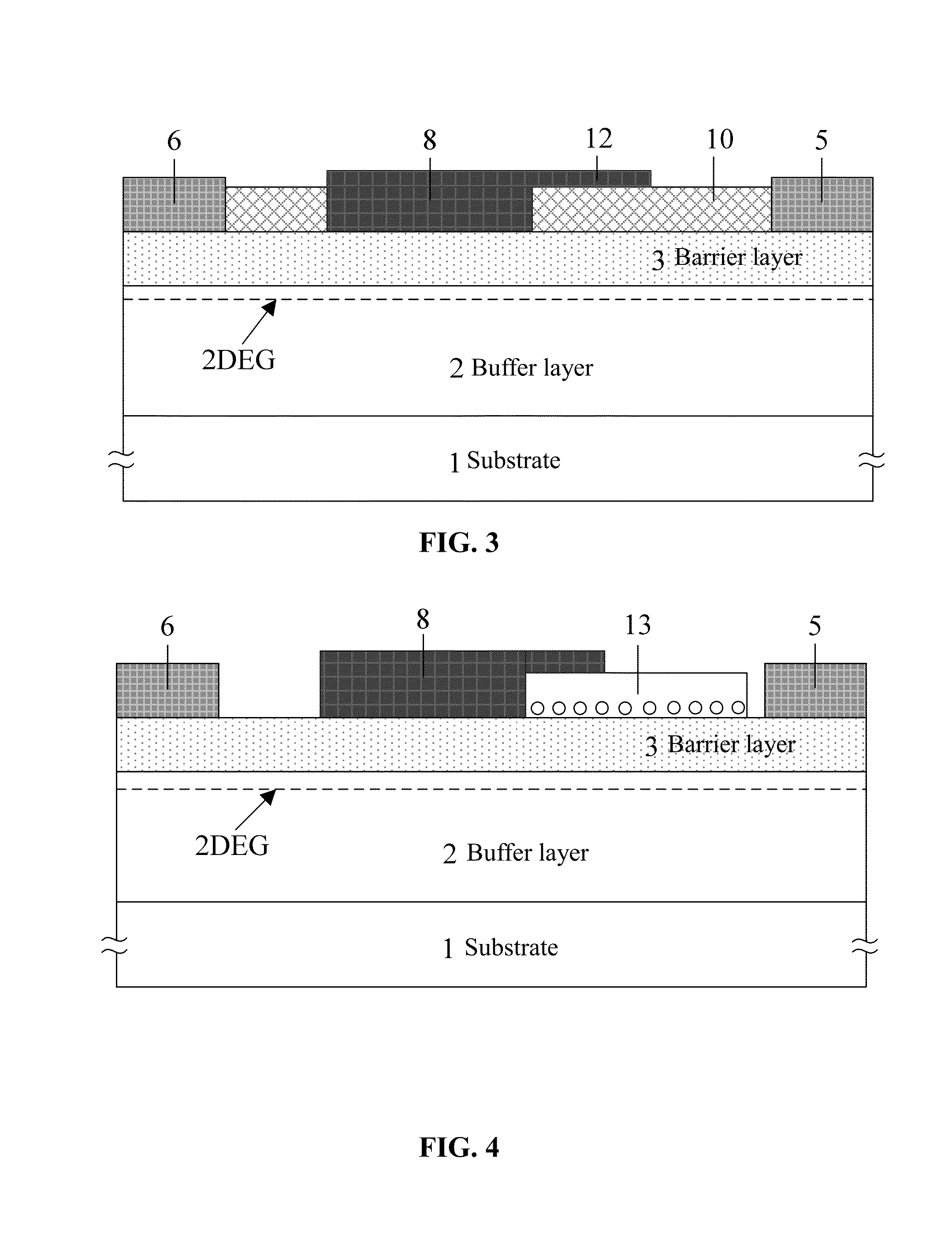

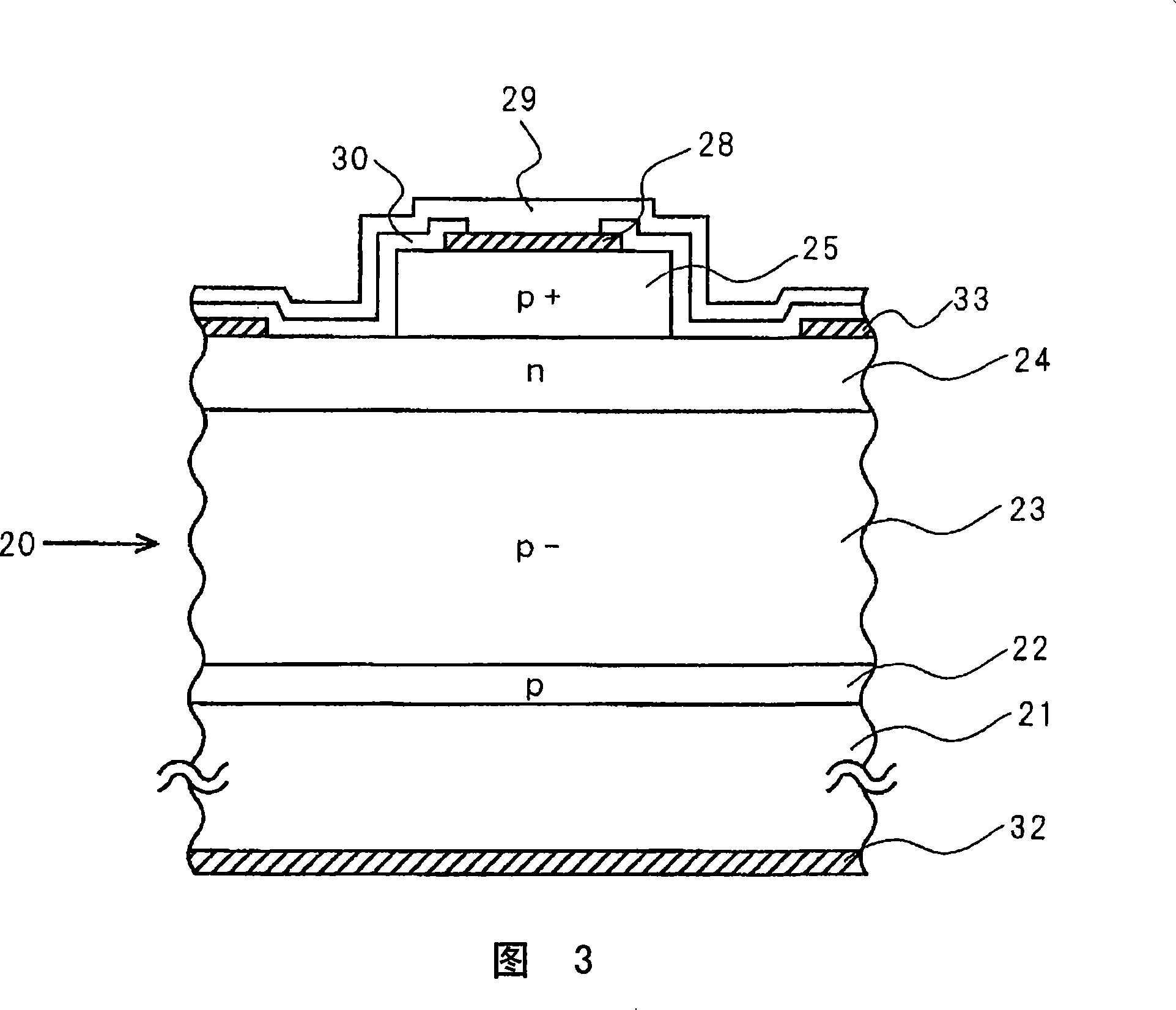

Enhancement mode high electron mobility transistor

InactiveUS9431527B1Improve breakdown voltageImprove withstand voltage performanceSemiconductor devicesHeterojunctionElectron mobility

An enhancement mode HEMT, including: a substrate layer; a buffer layer; barrier layers; drain electrodes; reverse polarization semiconductor layers; source electrodes; an insulated gate dielectric; and a metal gate electrode The buffer layer is disposed on the substrate layer, and the barrier layers are disposed on the buffer layer. Interfaces between the buffer layer and the barrier layers are provided with first heterojunctions having a two-dimensional electron gas (2DEG) channel. The drain electrodes are disposed at one end of the upper surfaces of the barrier layers and form Ohmic contact with the barrier layers. The reverse polarization semiconductor layers are disposed on the upper surfaces of the barrier layers and are able to produce inversed polarization with the barrier layers. The interfaces between reverse polarization semiconductor layers and barrier layers are provided with second heterojunctions having two-dimensional hole gas (2DHG).

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

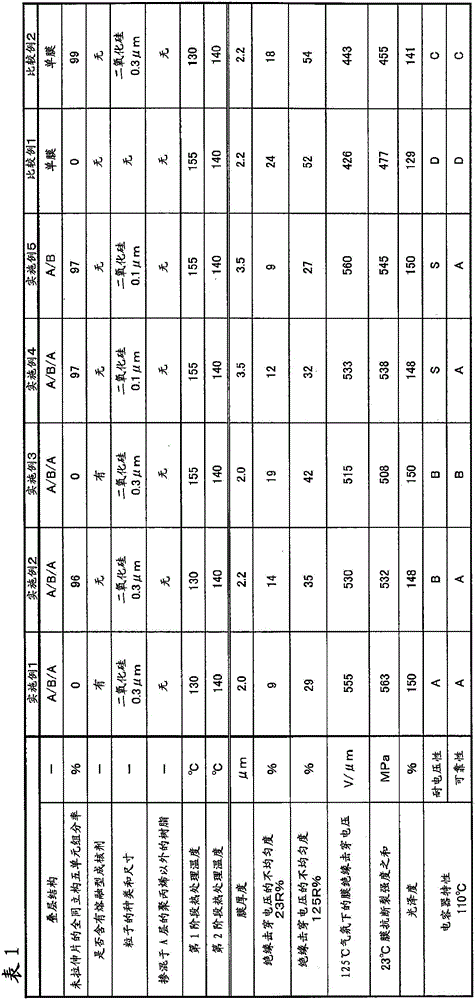

Polypropylene film and film capacitor

ActiveCN106574061ALess insulation defectsImprove withstand voltage performancePlastic/resin/waxes insulatorsThin/thick film capacitorDielectricHigh voltage capacitors

A polypropylene film wherein, a percentage (125R%) calculated by measuring the dielectric breakdown voltage (V / [mu]m) of the film at 30 points in a 125 DEG C atmosphere, and dividing the difference between the maximum value and the minimum value among 20 points obtained by respectively excluding the 5 points having the greatest breakdown voltage and the 5 points having the lowest, by the average value of these 20 points is less than 50%; and a percentage (23R%) calculated by measuring the dielectric breakdown voltage (V / [mu]m) of the film at 30 points in a 23 DEG C atmosphere, and dividing the difference between the maximum value and the minimum value among 20 points obtained by respectively excluding the 5 points having the greatest breakdown voltage and the 5 points having the lowest, by the average value of these 20 points is less than 20%. The present invention relates to a polypropylene film having few insulation defects and minimal variance of dielectric breakdown voltage in high-temperature environments, and in particular there is provided a polypropylene film that exhibits high withstand voltage and reliability in high-voltage capacitor applications.

Owner:TORAY IND INC

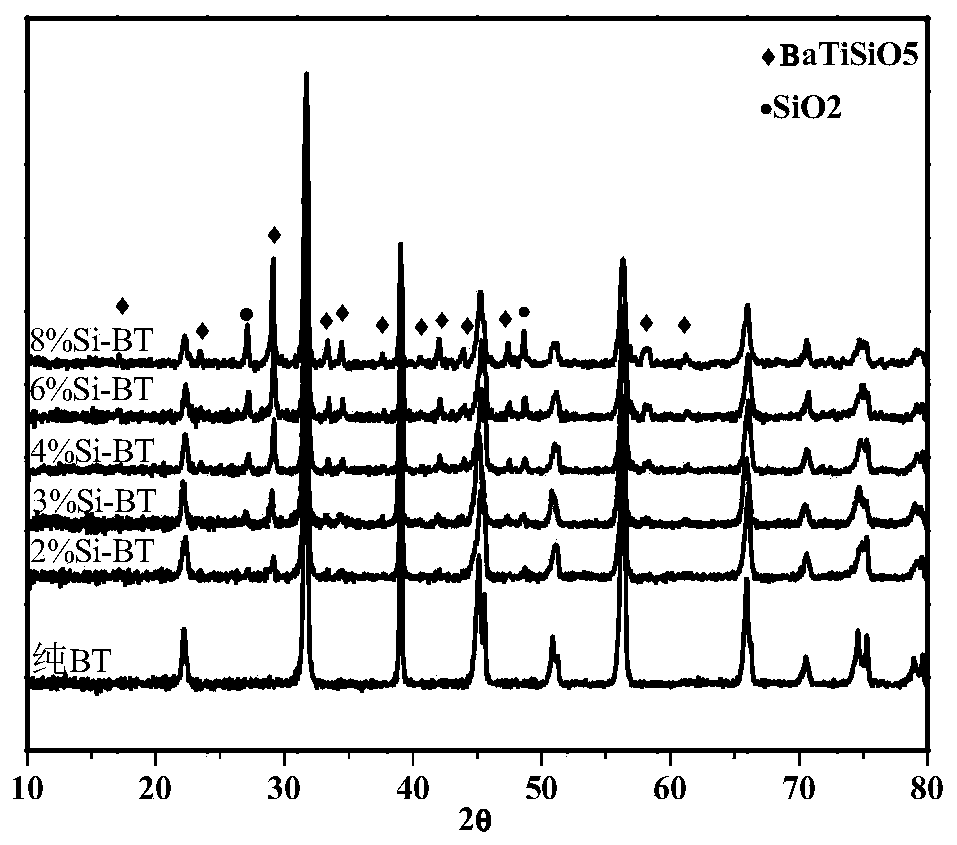

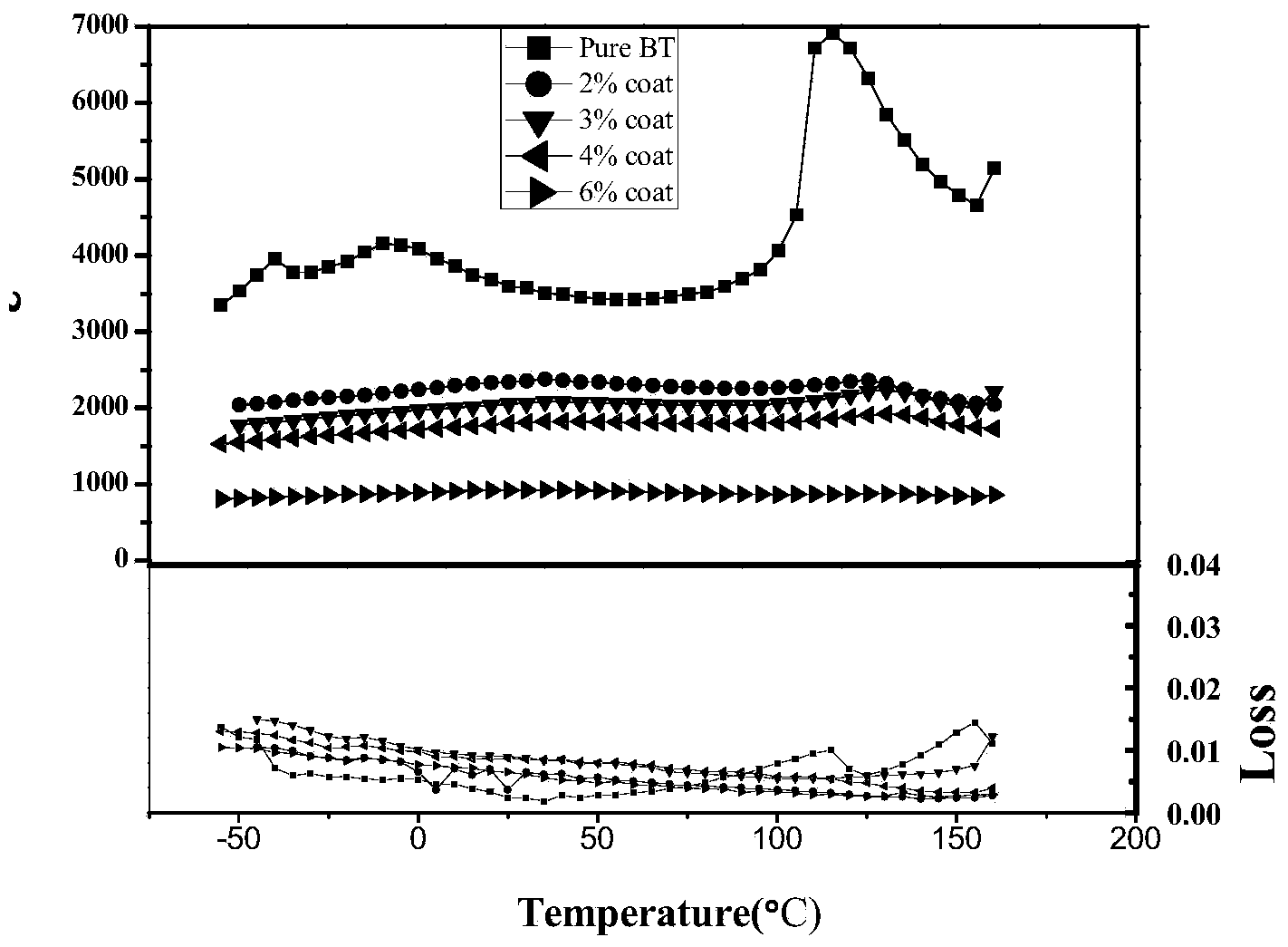

Preparation method of wide-temperature, high-pressure-resistant and high-energy-density ceramic dielectric material

InactiveCN103864435AImprove withstand voltage performanceExcellent dielectric propertiesDielectricWater baths

The invention relates to a preparation method of a wide-temperature, high-pressure-resistant and high-energy-density BaTiO3 ceramic dielectric material. The preparation method comprises the following steps: (1) putting ceramic powder into a mixture solution of ethanol and glacial acetic acid, and carrying out water-bath stirring and ultrasonic dispersion, so as to obtain a turbid liquid; (2) adding metal alkoxide into the turbid liquid, stirring to uniformly distribute the metal alkoxide into the ethanol and on the surface of the ceramic powder; (3) continuously stirring, simultaneously dropwise adding ammonium hydroxide, and carrying out hydrolysis, so as to obtain thick slurry; (4) stirring and washing to obtain pulp, adding deionized water or absolute ethyl alcohol, stirring to obtain a uniformly-mixed turbid liquid, and carrying out centrifugal separation; and (5) carrying out presintering, pelleting, sieving and precipitation, pressing to obtain a ceramic green body, carrying out rubber discharging and sintering, and maintaining the temperature to obtain the ceramic dielectric material. The preparation method has the advantages that the cost is low, the preparation process is concise, the repeatability is good, the large-scale production can be realized, and the preparation of a large-size energy-storage dielectric material is facilitated; and the original grain size can be maintained, and the preparation of a nanometer energy-storage dielectric ceramic can be well assisted.

Owner:WUHAN UNIV OF TECH

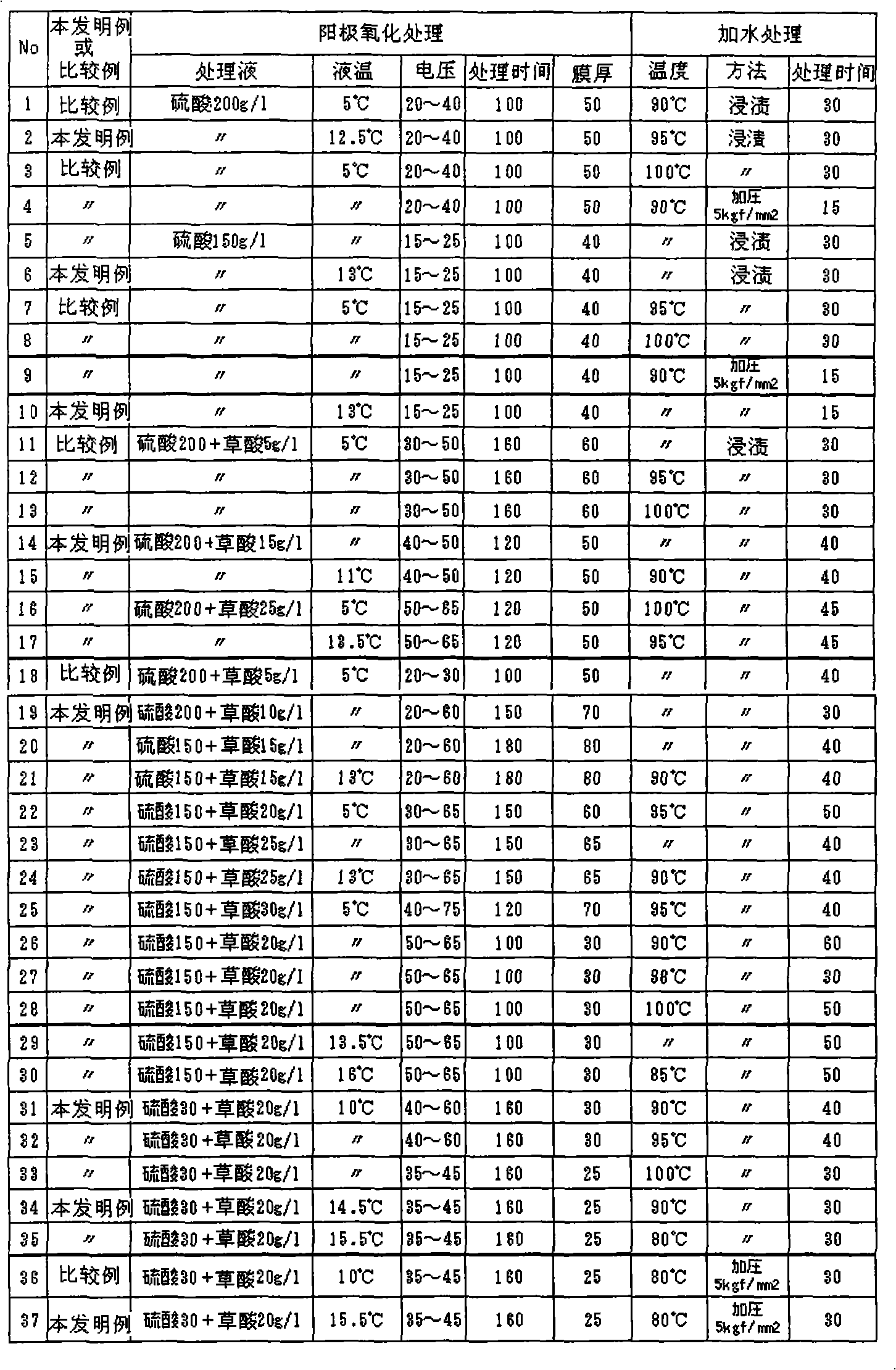

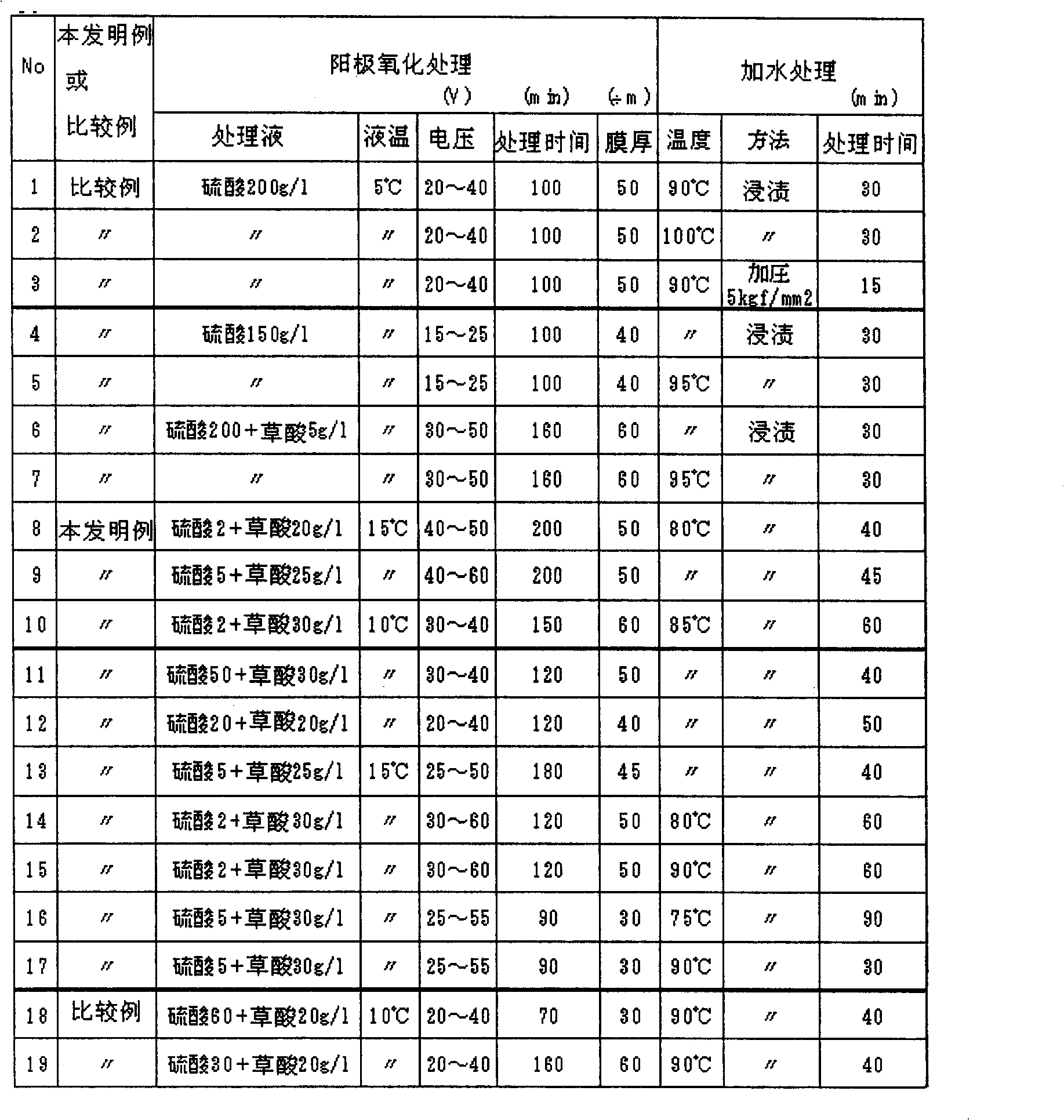

Aluminum member or aluminum alloy member with excellent corrosion resistance

InactiveCN101287861AImprove corrosion resistanceAccelerated corrosionAnodisationSemiconductor/solid-state device manufacturingHardnessElectrical impedance

An aluminum member or aluminum alloy member which has, formed thereon, an anodized coating excellent not only in gas corrosion resistance and plasma resistance but in adhesion; and a member for vacuum apparatus which comprises the aluminum member or aluminum alloy member having such excellent corrosion resistance. Also provided is the member having sufficient withstand voltage characteristics which is useful in stably maintaining a plasma state in a process utilizing a plasma. The member is (1) an aluminum member or aluminum alloy member in which the anodized coating has an impedance as determined at a frequency of 10<-2> Hz of 10<7> O or higher and has a hardness of 400 or higher in terms of Vickers hardness (Hv) or (2) an aluminum member or aluminum alloy member in which the anodized coating has an impedance as determined at a frequency of 10<-2> Hz of 10<8> O or higher and has a hardness of 350 or higher in terms of Vickers hardness (Hv).

Owner:KOBE STEEL LTD

Graphene lithium ion battery electrolyte

InactiveCN105098239AImprove withstand voltage performanceReduce hydrogen evolutionSecondary cellsOrganic electrolytesLithium electrodePrecipitation

The invention relates to graphene lithium ion battery electrolyte, which comprises a lithium salt, a non-aqueous organic solvent and an additive, wherein the additive is prepared from the following components: 5%-6.5% of hexamethyl disilazane, 0.5%-3.5% of octamethylcyclotetrasiloxane, 4.5%-8.5% of graphene and 0.3%-5.3% of vitamin E on the basis of total weight of the electrolyte. The graphene is added to the lithium ion battery electrolyte, so that the voltage resistance of the electrolyte can be greatly improved; the electrolyte is not easy to decompose at high pressure; corrosive substances in an electrolyte system and the corrosive substances dissociating on the surface of a positive electrode can be effectively removed by the octamethylcyclotetrasiloxane; a lead electrode surface is adsorbed in the charging and discharging process due to the addition of the hexamethyl disilazane; equivalently, the deposition potential of hydrogen is improved; precipitation of hydrogen can be reduced; the lithium ion battery is stored in a high-temperature state; the capacity retention ratio and the capacity recovery rate are high; and the cycle performance is excellent.

Owner:NINGBO POLYTECHNIC

Ceramic positive temperature coefficient (PTC) thermistor of variable-frequency air conditioner starter and manufacturing method thereof

InactiveCN102649641ASimple manufacturing processReasonable matchPositive temperature coefficient thermistorsElectrical resistance and conductanceSynthesis methods

The invention relates to a ceramic positive temperature coefficient (PTC) thermistor of a variable-frequency air conditioner starter and a manufacturing method thereof. The ceramic PTC thermistor belongs to the (Ba1-xCaX) TiO3+TiO2+Y2O3+SiO2+Mn(NO3)2 series. The ceramic PTC thermistor is prepared by 1.022 mol of TiO2, 0.790 to 0.810 mol of BaCO3, 0.179 to 0.185 mol of CaCO3, 0.022 to 0.023 mol ofSiO2, 0.0021 to 0.0022 mol of Y2O3 and 50 mass percent of Mn(NO3)2 solution at the concentration of 0.005 ml per weight percent by a one-step synthesis method. The raw materials are reasonable; the production process is simple; in the product, the Curie temperature is between 125 and 135 DEG C, the voltage resistance is more than AC800V, and the resistivity at room temperature is 190 to 480 Omegacm; and the ceramic PTC thermistor is particularly suitable for the variable-frequency air conditioner starter.

Owner:DANDONG GUOTONG ELECTRONICS COMPONENTS

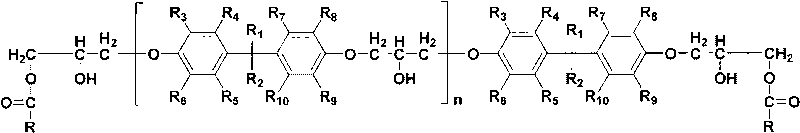

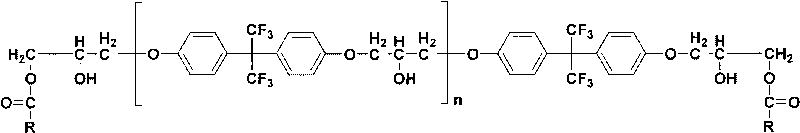

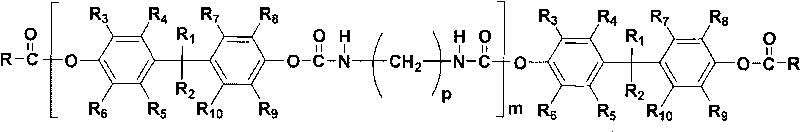

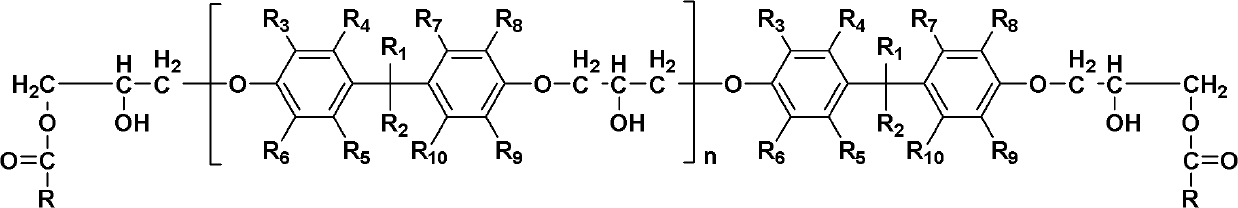

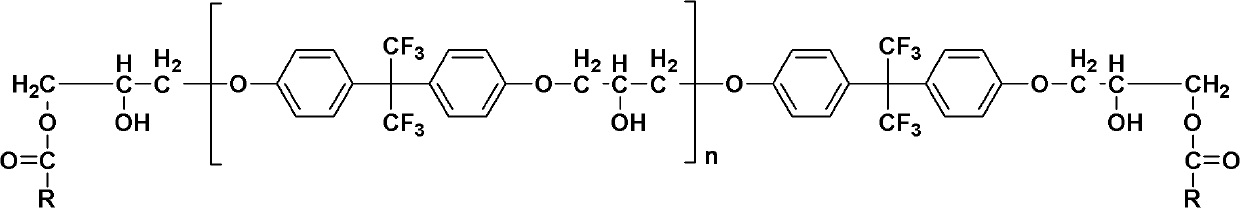

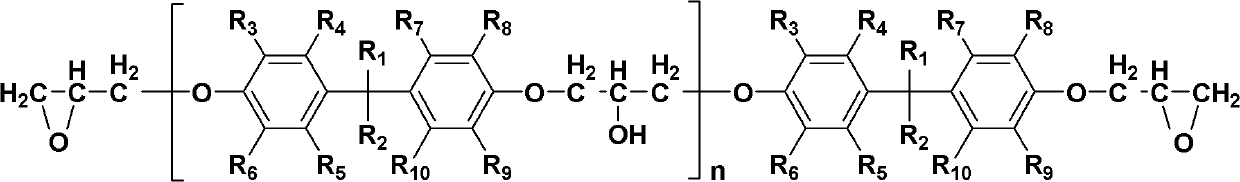

Fluorine-containing resin and preparation method thereof, conformal coating and printed circuit board

ActiveCN101747490AHigh activityHigh degree of curingPolyurea/polyurethane coatingsEpoxy resin coatingsCycloadditionDouble bond

The invention provides a fluorine-containing resin of which the molecular structure contains multiple carbon-carbon double bonds in which at least two are spaced by a methylene. The invention also provides a preparation method of the fluorine-containing resin, comprising the step of performing condensation reaction and / or ring-opening addition reaction on the precursor of the fluorine-containing resin and the unsaturated fatty acid under the action of catalyst, wherein, the molecular structure of the unsaturated fatty acid contains in which at least two are spaced by a methylene. The invention further provides a conformal coating and printed circuit board containing the fluorine-containing resin. The adhesive attraction of the coating layer formed by curing the conformal coating containing the fluorine-containing resin to the printed circuit board reaches 5B, the rigidity reaches B level, the flexibility is 0.5mm, the surface energy is 16.56-17.51 mJ / cm<2>, the voltage resistance capacity is higher than 10000V; the completely cured printed circuit board coated with the conformal coating of the invention can not bubble in 50 circulations after being soaked in the water of 50 DEG C.

Owner:BYD CO LTD

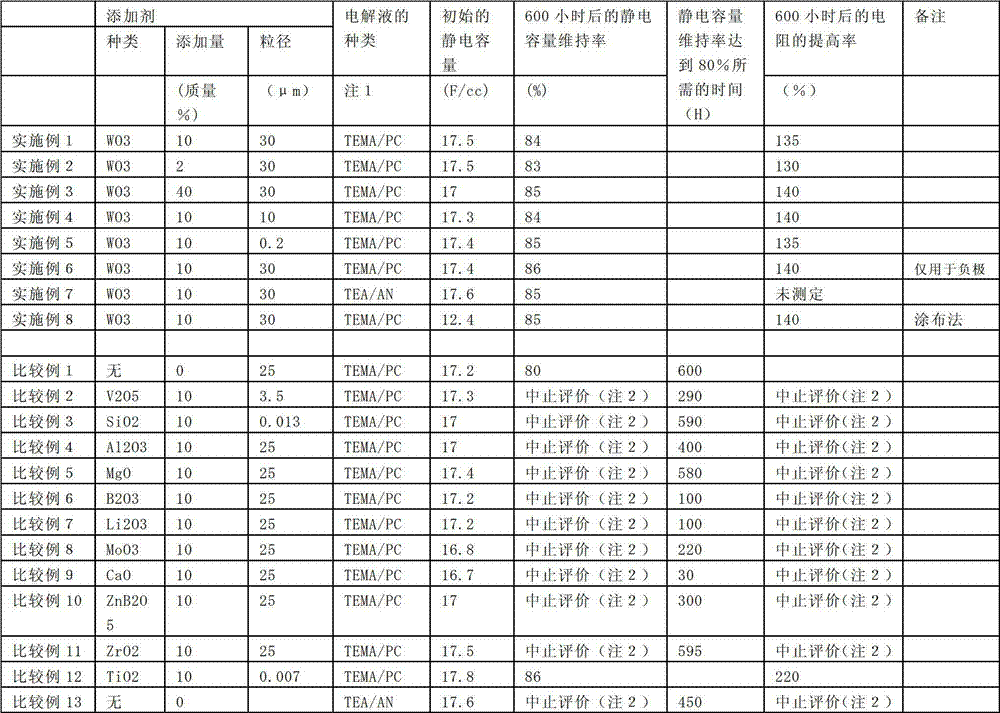

Polarizable electrode material for electric double layer capacitor having improved withstand voltage, and electric double layer capacitor using same

ActiveCN102893352AIncrease energy densityImprove withstand voltage performanceElectrolytic capacitorsHybrid capacitor electrodesCapacitancePorous carbon

Owner:W L GORE & ASSOC GK

Inorganic nanoparticle containing organic electrolyte solution of super capacitor

InactiveCN104701029AImprove high temperature resistanceImprove withstand voltage performanceHybrid capacitor electrolytesOrganic solventInorganic compound

The invention relates to the technical field of super capacitors, and specifically relates to an inorganic nanoparticle containing organic electrolyte solution of a super capacitor. The electrolyte solution is prepared from an organic solvent, electrolyte salt and inorganic compound nanoparticles. The electrolyte solution has the advantages that the high temperature resistance of the super capacitor can be improved, the service life can be prolonged, and the safety of the super capacitor can be improved.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

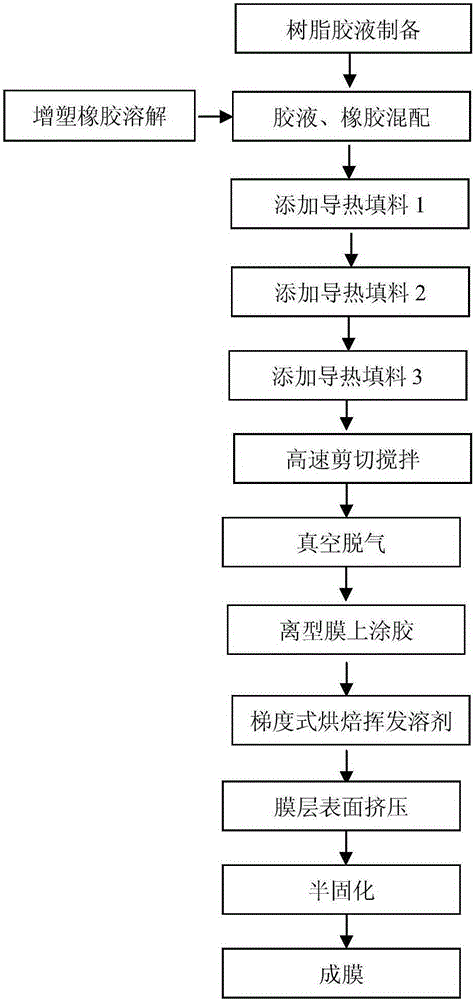

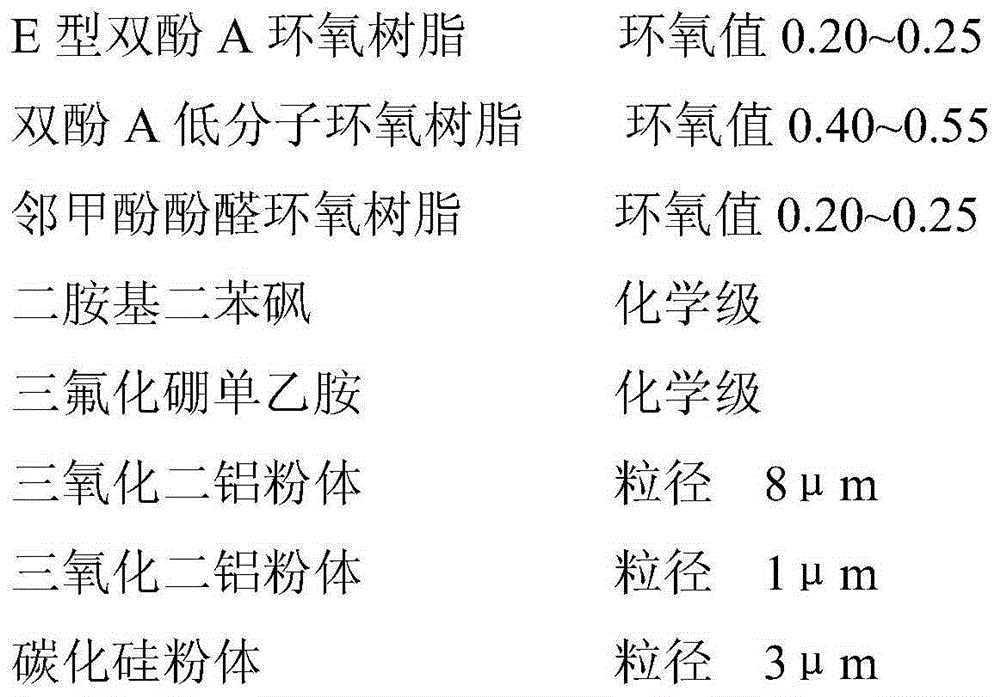

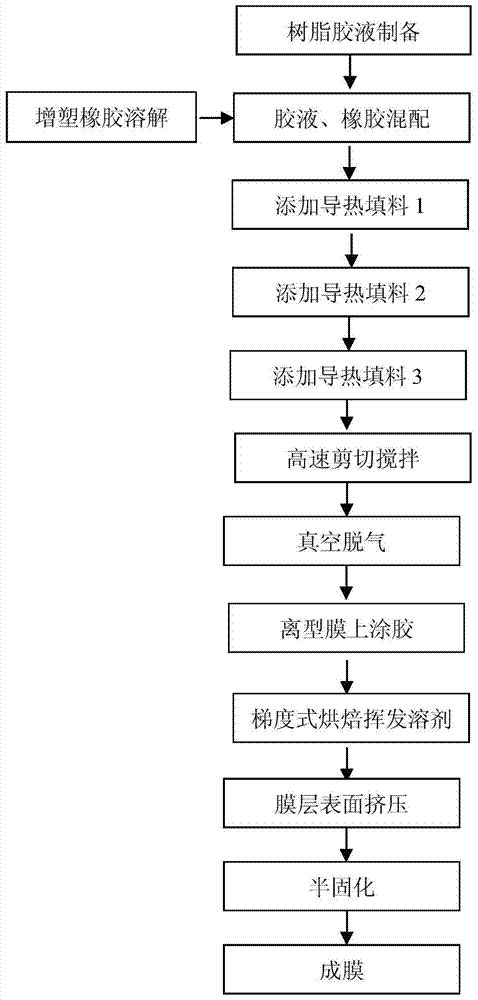

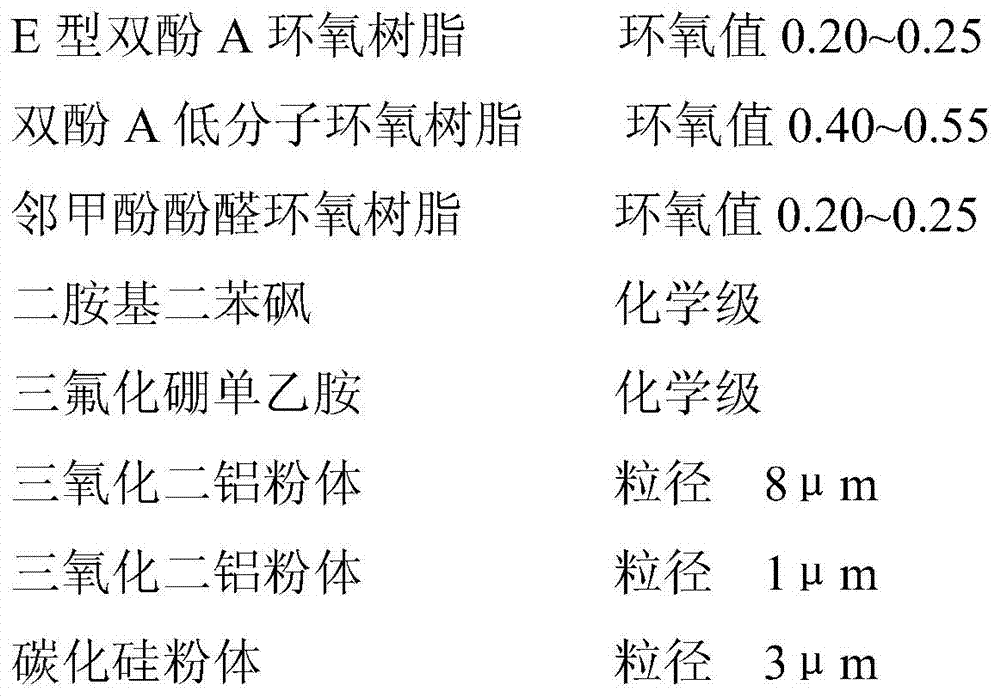

Method for preparing high-thermal-conductivity coating for aluminum-based copper-clad plate

ActiveCN105199619AIncrease elasticitySmall microbubblesNon-macromolecular adhesive additivesFilm/foil adhesivesMicrobubblesBoiling point

The invention discloses a method for preparing a high-thermal-conductivity coating for an aluminum-based copper-clad plate. According to the method, the heat conductivity coefficient of the coating is made to be larger than 3.0 W / K.m by adding composite thermal conducting filler; meanwhile, various solvent systems with different boiling points are adopted, solvents volatilize in a gradient mode during drying of the coating, the number of microbubbles in the coating is reduced, and the electric insulation performance and voltage resistance of the coating are improved; furthermore, organic elastic resin and micromolecule resin are introduced into a resin system, so that the elasticity of the coating is improved, and the coating performance and wettability of resin on inorganic filler are improved.

Owner:GOLDENMAX INTERNATIONAL TECHNOLOGY (ZHUHAI) LTD

High-thermal conductivity weather-resistant packaging material for microprocessors, and preparation method thereof

InactiveCN107163529AImprove wear resistanceImprove heat resistanceHeat-exchange elementsBoron nitrideUnsaturated polyester

The invention discloses a high-thermal conductivity weather-resistant packaging material for microprocessors. The high-thermal conductivity weather-resistant packaging material for microprocessors comprises, by weight, 50-60 parts of unsaturated polyester resin, 12-18 parts of an ethylene-methacrylic acid copolymer, 5-7 parts of nano-oxide, 4-8 parts of ethylene glycol, 10-14 parts of silicone oil, 10-14 parts of a flame-retardant additive, 8-10 parts of a synergist aid, 1-3 parts of boron nitride, 4-6 parts of silicon carbide, 6-8 parts of graphene and 3-5 parts of a coupling agent. The packaging material has the advantages of good thermal conduction and thermal dissipation effects, low thermal impedance, good weather resistance, good flame retardation property and good sealing effect; and a preparation method of the packaging material has the advantages of low material cost, easily available raw materials, simple process, high use values and good application prospect.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

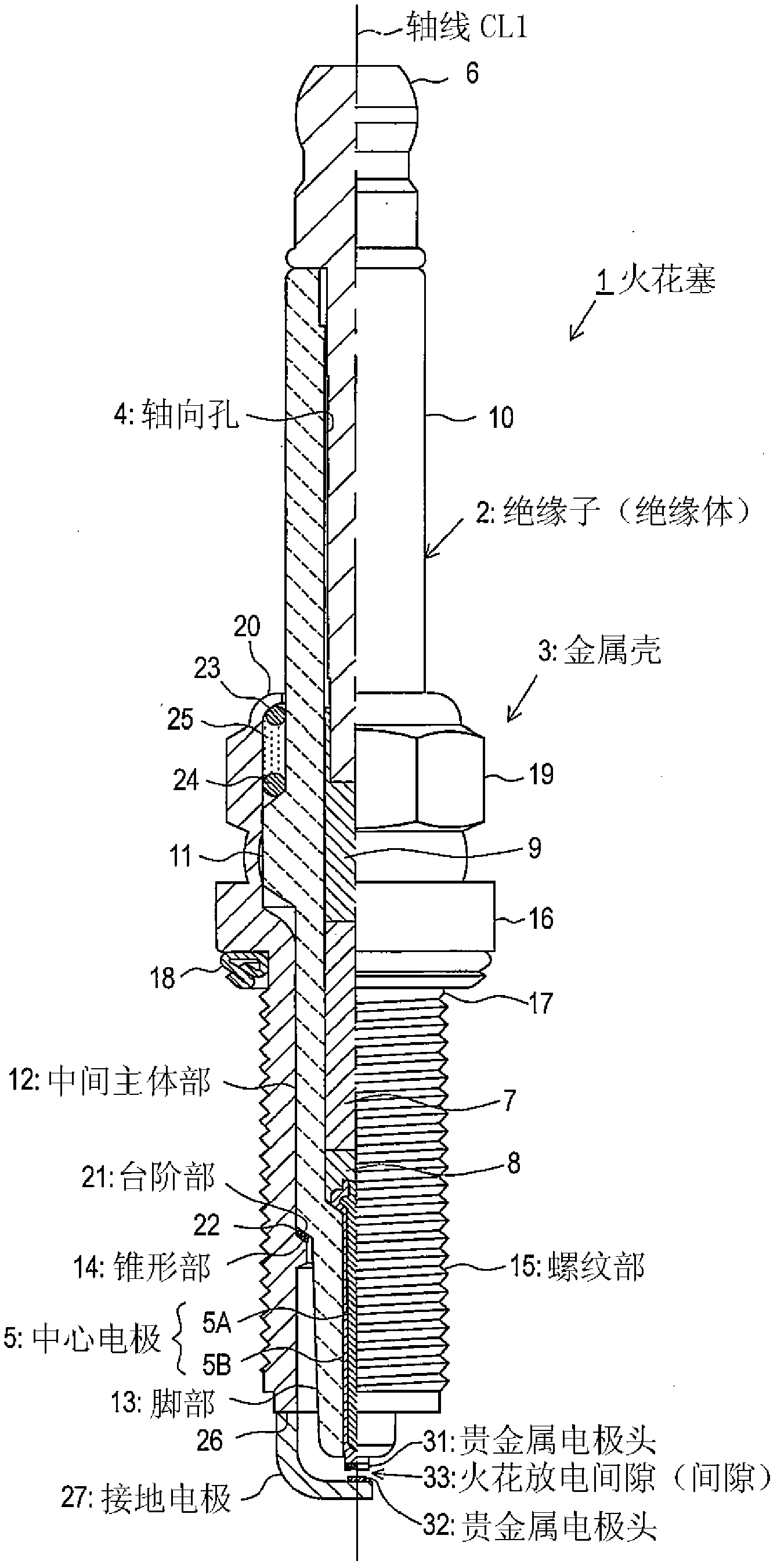

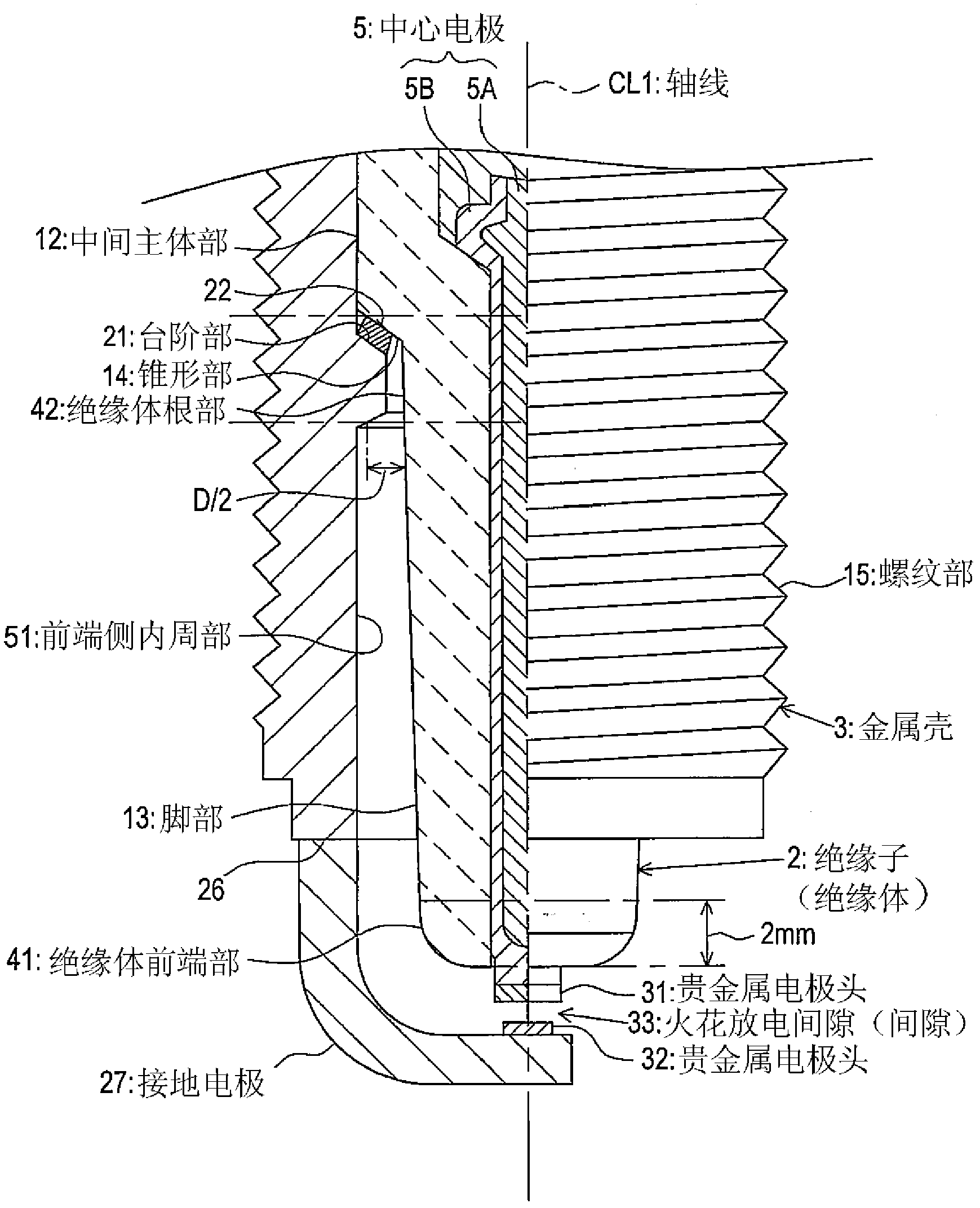

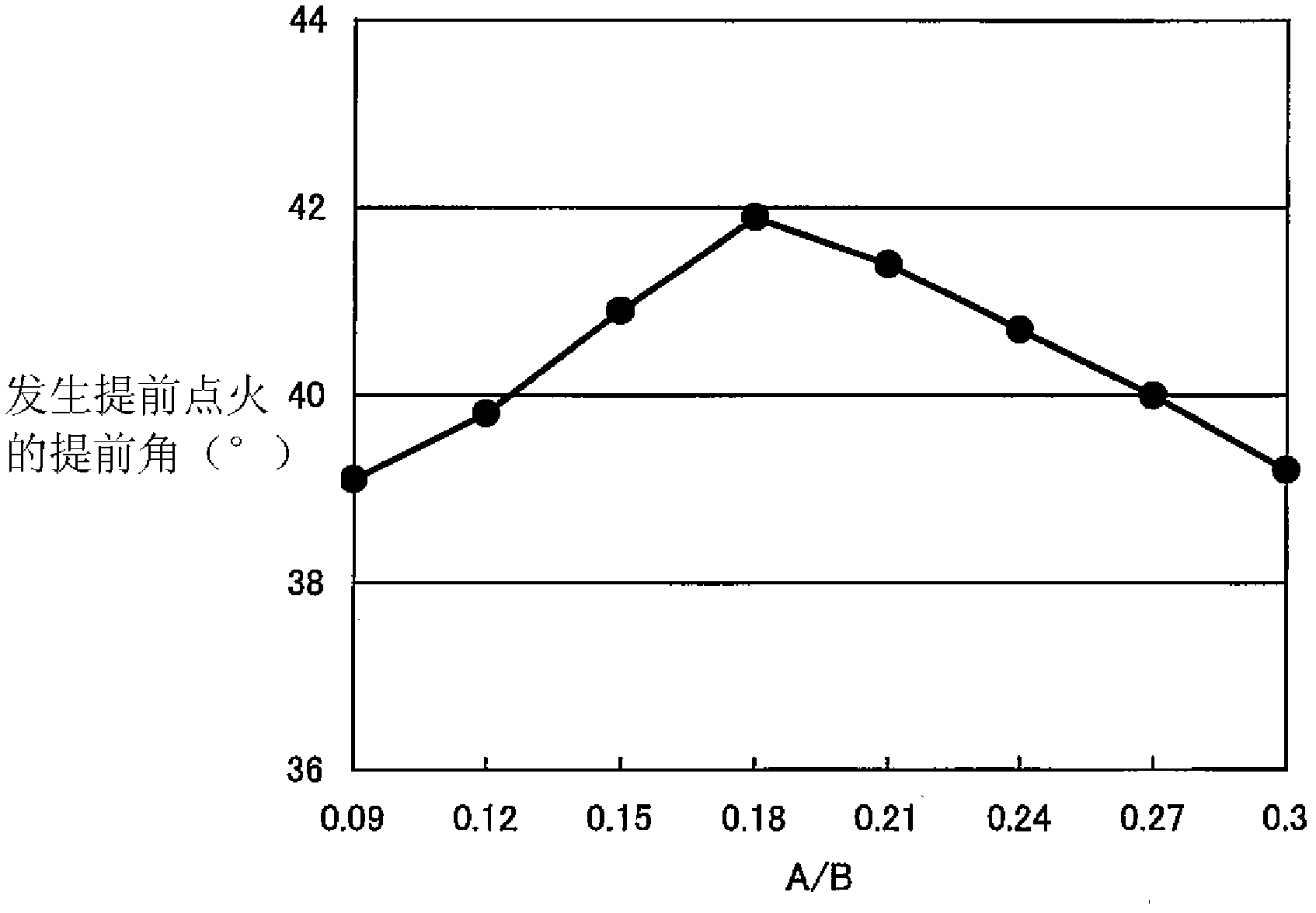

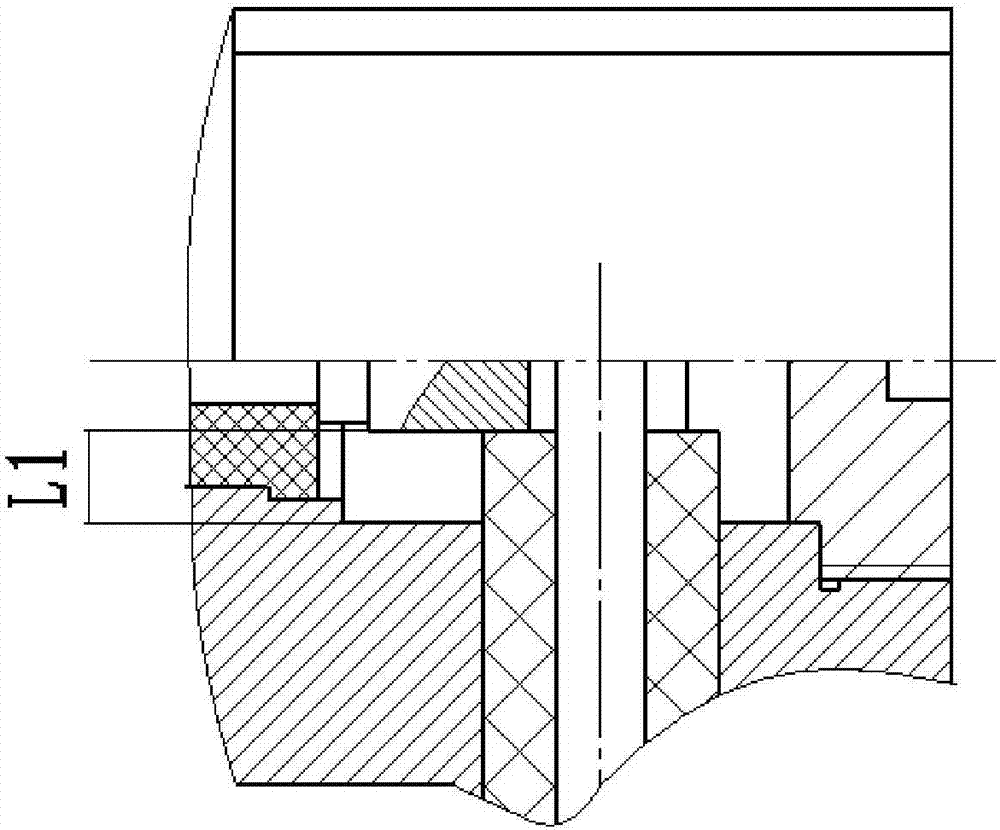

Spark plug

ActiveCN102576984AMaintain voltage resistanceImprove heat resistanceSparking plugsMachines/enginesHeat resistanceEngineering

Provided is a spark plug with a center electrode that has the diameter thereof made thinner, wherein stain-resistant and heat-resistant characteristics are improved. The spark plug (1) is provided with a center electrode (5), an insulator (2), and a main metal-part (3), and the insulator (2) is provided with a long-leg section (13), a tapered section (14), and a mid-body section (12). The maximumouter-diameter of a portion of the center electrode (5) to be arranged within the long-leg section (13) is to be 3.0 mm or shorter. A step section (21) and a front-tip-side inner circumference section (51) are formed on the inner circumference of the main metal part (3), and the tapered section (14) is latched together to the step section (21). An inequality 0.12<= A / B<= 0.24 is satisfied, when the volume of a portion of the insulator (2) existing along the axis (CL1) direction, from the tip of the insulator (2) to a place 2 mm from the rear-end side, is assumed to be A (mm3), and the volume of a portion of the tapered section (14) located at the front tip side of the rear end of the portion to be latched together with the step section (21), and which portion has the difference in the diameters of the front-tip side inner circumference section (51) and the outer circumference part of itself to be 1.5 mm or less, is assumed to be B (mm3).

Owner:NGK SPARK PLUG CO LTD

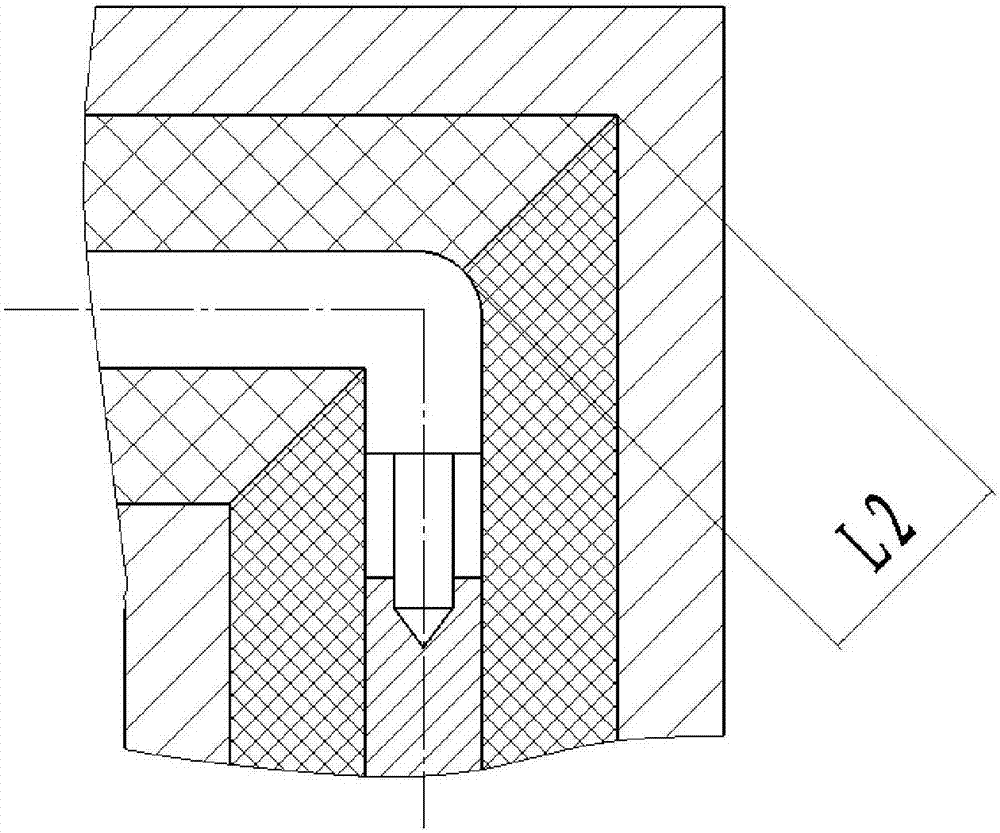

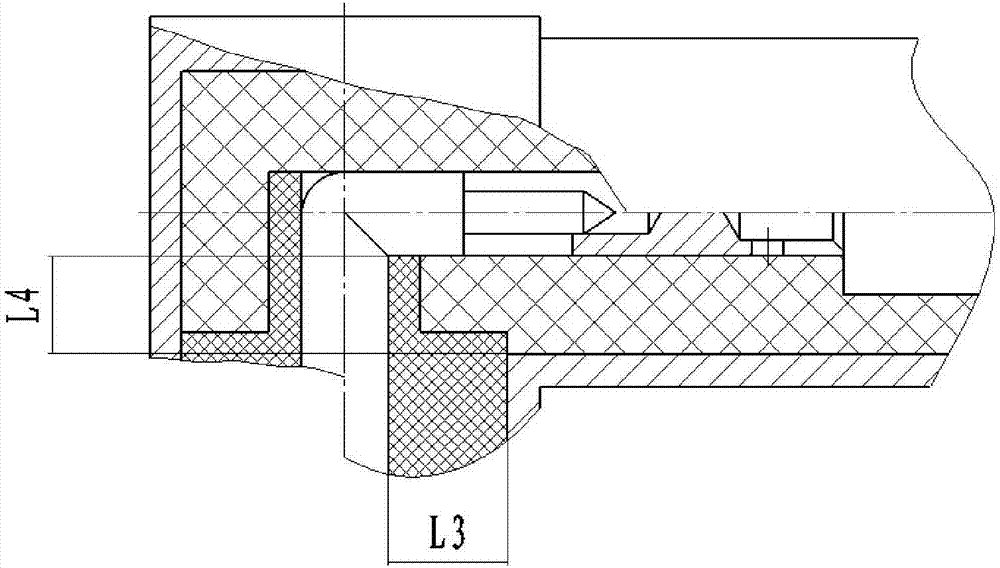

Bent type high voltage-resisting radio frequency coaxial connector structure

ActiveCN106972330AImprove withstand voltage performanceIncrease axial lengthSecuring/insulating coupling contact membersTwo-part coupling devicesElectrical conductorElectrical connection

The invention discloses a bent type high voltage-resisting radio frequency coaxial connector structure, and belongs to the technical field of radio frequency coaxial electric connectors. The objective of the invention is to solve a problem of failure to resist high voltage in the current radio frequency coaxial connector is solved. The connector comprises a housing, an inner conductor assembly, a first insulator and a second insulator. The housing comprises two blind holes which are perpendicular to each other and communicate with each other. The inner side walls of an included angle of the two blind holes communicate with each other to form an installation slit. The inner conductor assembly is an injection piece with a right angle structure. The plastic part of the injection piece is polyphenylene sulfide materials. The inner conductor assembly is arranged in the housing through the installation slit. The first insulator is inserted between the housing and the inner conductor assembly through a blind hole. The second insulator is inserted between the housing and the inner conductor assembly through another blind hole. The first port of the first insulator is in contact with the first port of the second insulator. Each of the first port of the first insulator and the first port of the second insulator is at an angle of 45 degrees. An included angle between the first insulator and the second insulator is a right angle.

Owner:SHAANXI HUADA SCI TECH

Preparation method of high thermal conductivity adhesive film for aluminum base copper clad laminate

ActiveCN105199619BIncrease elasticitySmall microbubblesNon-macromolecular adhesive additivesFilm/foil adhesivesThermal adhesiveInorganic filler

The invention discloses a method for preparing a high thermal conductivity adhesive film for aluminum-based copper-clad laminates, mainly by adding composite thermal conductive fillers to make the thermal conductivity of the adhesive film greater than 3.0W / K m; at the same time, using a variety of solvent systems with different boiling points. During the film drying process, the solvent is volatilized in a gradient manner, reducing the micro-bubbles in the film layer, improving the electrical insulation performance and voltage resistance of the film layer; and introducing organic elastic resin and sub-resin into the resin system to increase the elasticity of the film and resin Coating and wettability of inorganic fillers.

Owner:GOLDENMAX INTERNATIONAL TECHNOLOGY (ZHUHAI) LTD

Fluorine-containing resin, preparation method thereof, conformal coating and printed circuit board

ActiveCN102516497AHigh activityHigh degree of curingOrganic compound preparationCarboxylic acid esters preparationEpoxyCycloaddition

The invention provides a fluorine-containing resin. The molecular structure of the fluorine-containing resin contains a plurality of carbon-carbon double bonds, a methylene group is between at least two carbon-carbon double bonds in all the carbon-carbon double bonds, and the fluorine-containing resin is a fluorine-containing epoxy resin. The invention also provides a preparation method of the fluorine-containing resin. According to the method, a fluorine atom-containing epoxy resin precursor and an unsaturated fatty acid with the molecular structure containing a plurality of the carbon-carbon double bonds and the methylene group between at least two carbon-carbon double bonds in all the carbon-carbon double bonds undergo a condensation reaction and / or a ring-opening addition reaction. The invention further provides a conformal coating containing the fluorine-containing resin of the invention, and a printed circuit board containing the fluorine-containing resin of the invention. The adhesion force of a coating layer formed after the curing of the conformal coating containing the fluorine-containing resin of the invention to the printed circuit board reaches 5B, the hardness reaches a B grade, the flexibility is 0.5mm, the surface energy is 16.56-17.51mJ / cm<2>, and the voltage resistance is higher than 10,000V; and no foaming appears after fifty cycles when the printed circuit board which is sprayed with the conformal coating of the invention and is completely cured is immersed in 50DEG C water.

Owner:BYD CO LTD

Process for producing high temperature and pressure resistant PTC (Positive Temperature Coefficient) thermistor ceramics

The invention relates to the technical field of preparation of electronic components and devices and particularly relates to high temperature and pressure resistant PTC (Positive Temperature Coefficient) thermistor ceramics for heating and a production process thereof. The process comprises the steps of preparing a material A from BaCO3, TiO2, Y2O3 and CaCO3 through the processes of material preparation, pre-stirring, filtering for iron removal, cyclic stirring and grinding, filtering for iron removal, pressure-filtration dehydration, calcining synthesis and the like, preparing a material B from Pb3O4, TiO2 and Nb2O5 through the processes of material preparation, pre-stirring, filtering for iron removal, cyclic stirring and grinding, filtering for iron removal, pressure-filtration dehydration, calcining synthesis and the like, and preparing the high temperature and pressure resistant PTC thermistor ceramics from a mixture of the material A, the material B, SiO2 and adjuvants through the processes of material preparation, ball-milling material mixing, filtering for iron removal, cyclic stirring and grinding, filtering for iron removal, spray granulating and the like. The high temperature and pressure resistant PTC thermistor ceramics disclosed by the invention have the characteristics of uniform ingredient dispersion, uniform crystal grain size, higher voltage resistance, lower attenuation performance, higher alpha coefficient and the like.

Owner:HAINING YONGLI ELECTRONICS CERAMICS

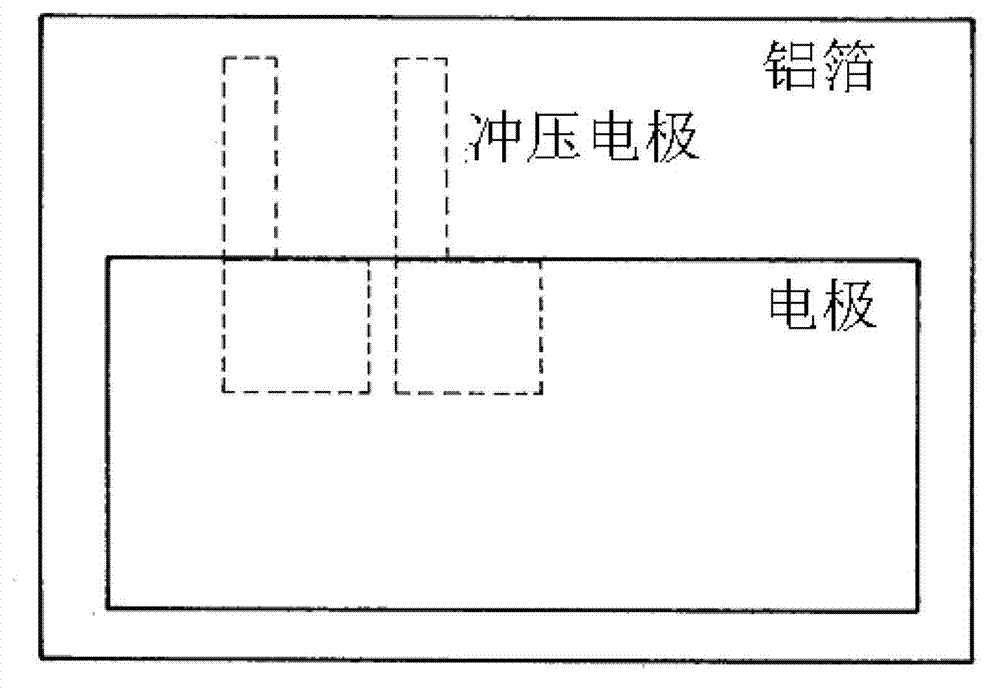

Graphene electrode sheet and manufacturing method, and method for manufacturing supercapacitor by using graphene electrode sheet

InactiveCN108470636AHuge specific surface areaReduce resistance lossHybrid capacitor electrodesHybrid/EDL manufactureWater contentGraphene electrode

The invention relates to a graphene electrode sheet and a manufacturing method, and a method for manufacturing a high specific-energy and ultra-high-power graphene supercapacitor by using the grapheneelectrode sheet and belongs to the new energy storage device technology field. The graphene electrode sheet comprises a current collector and a graphene electrode slurry. The graphene electrode slurry comprises, by weight, 75-93% of graphene, 2-10% of conductive agent, and 5-15% binder. The current collector is a foamed aluminum current collector. The specific surface area of graphene is 1000 to1500 m<2> / g, a tap density is 0.2 to 0.5 g / cm<3>, an aperture is 2 to 10 nm, a particle size is 7 to 10 micron, and a carbon content is greater than 99.8%. The content of an oxygen-containing functional group is less than 0.35 meq / g, a water content is less than 0.40%, and a total metal content is less than 100 ppm. The energy density of the graphene supercapacitor manufactured by the electrode sheet is 12 Wh / kg and a power density is 30.14 kW / kg.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

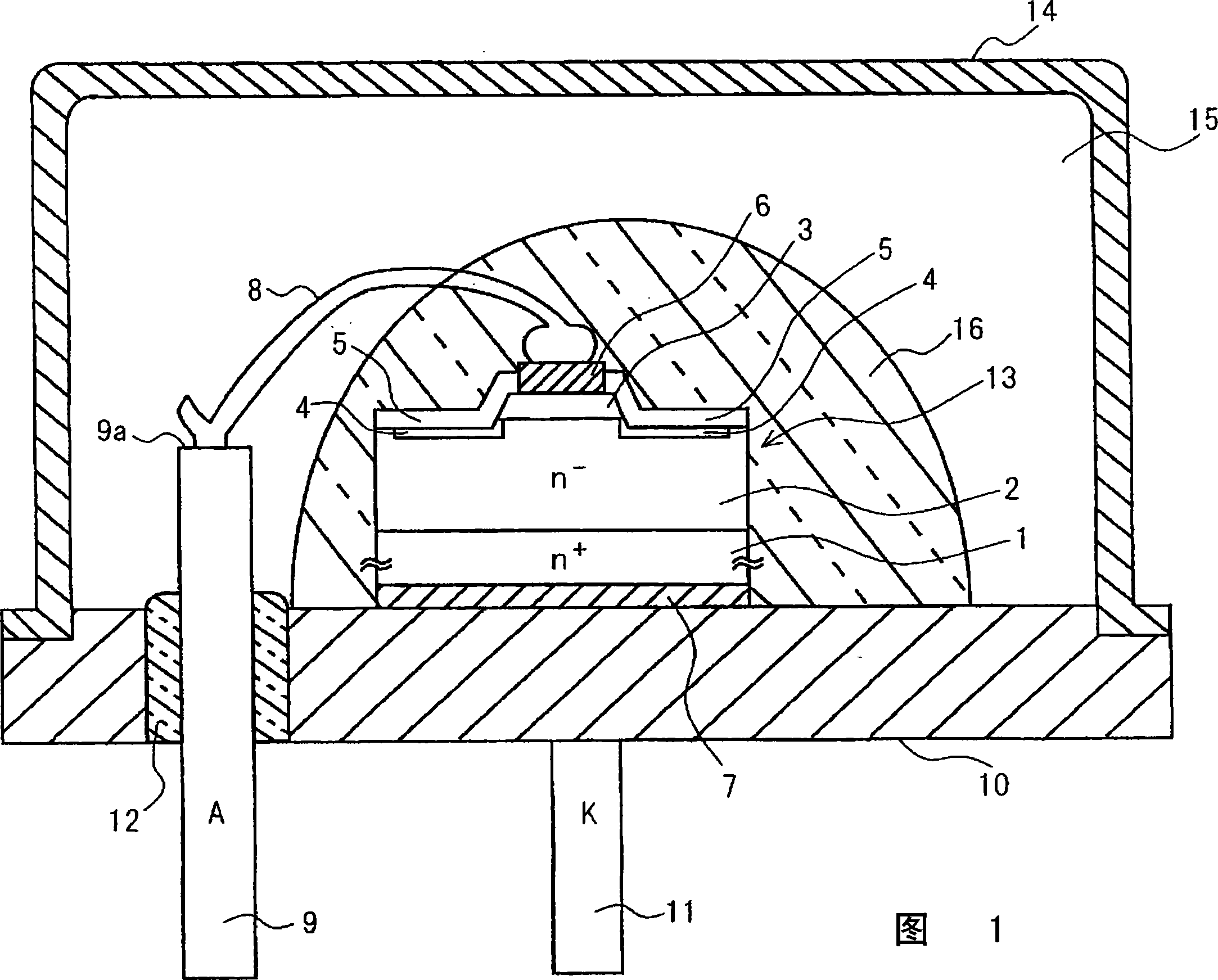

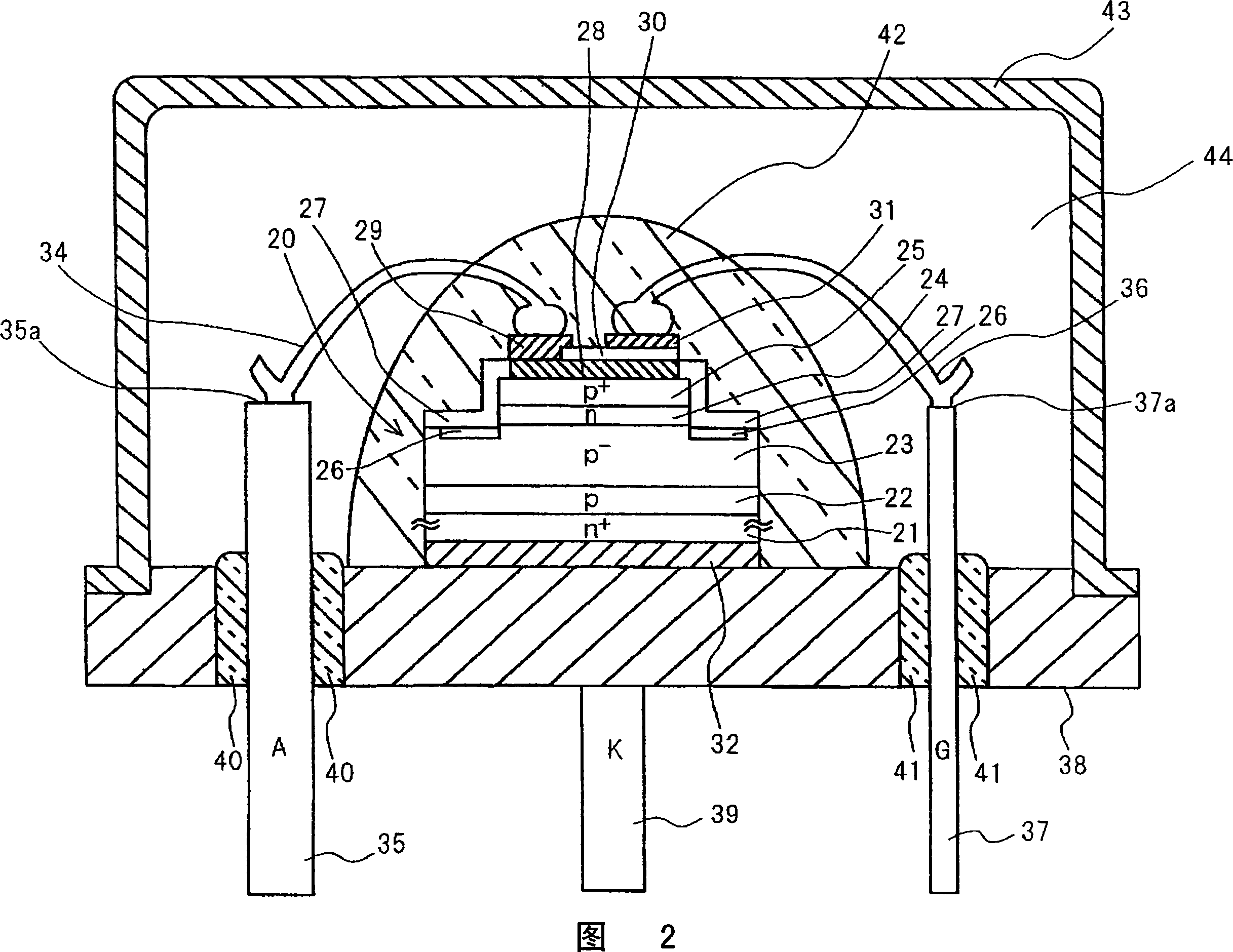

Highly heat-resistant synthetic polymer compound and high withstand voltage semiconductor device

InactiveCN101107293AImprove heat resistanceFast heat conductionSemiconductor/solid-state device detailsSolid-state devicesMicroparticleSynthetic Polymeric Macromolecules

The outer surface of a wide-gap semiconductor device is covered with a synthetic polymer compound. The synthetic polymer compound is formed by linking a plurality of third organosilicon polymers through covalent bonding which is formed by addition reaction, and has a three-dimensional steric structure. The third organosilicon polymers are obtained by linking one or more kinds of first organosilicon polymers having a bridge structure formed by siloxane bonds (Si-O-Si bonds) with one or more kinds of second organosilicon polymers having a linear structure formed by siloxane bonds. Insulating ceramic fine particles having high heat conductivity are preferably mixed with the synthetic polymer compound.

Owner:THE KANSAI ELECTRIC POWER CO +1

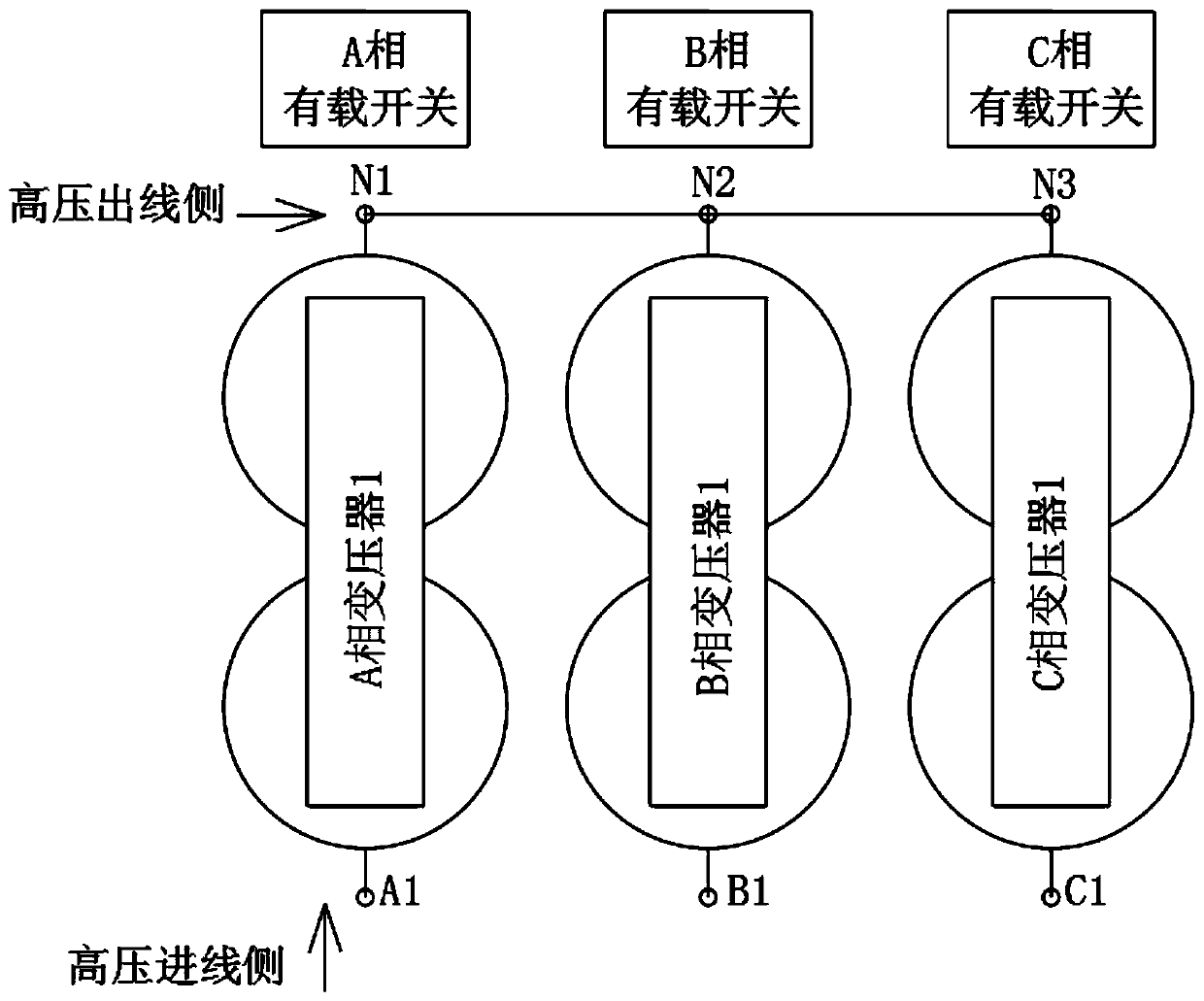

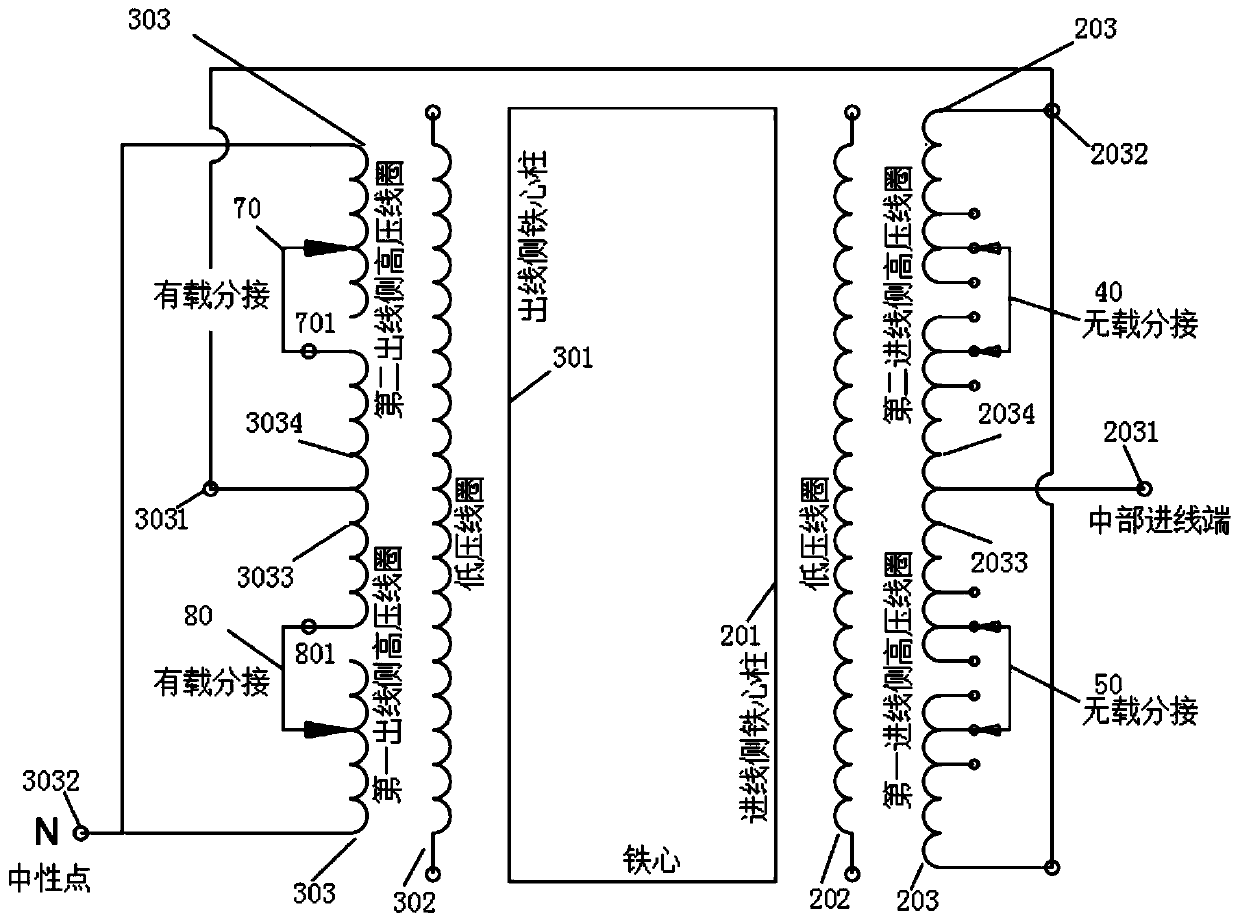

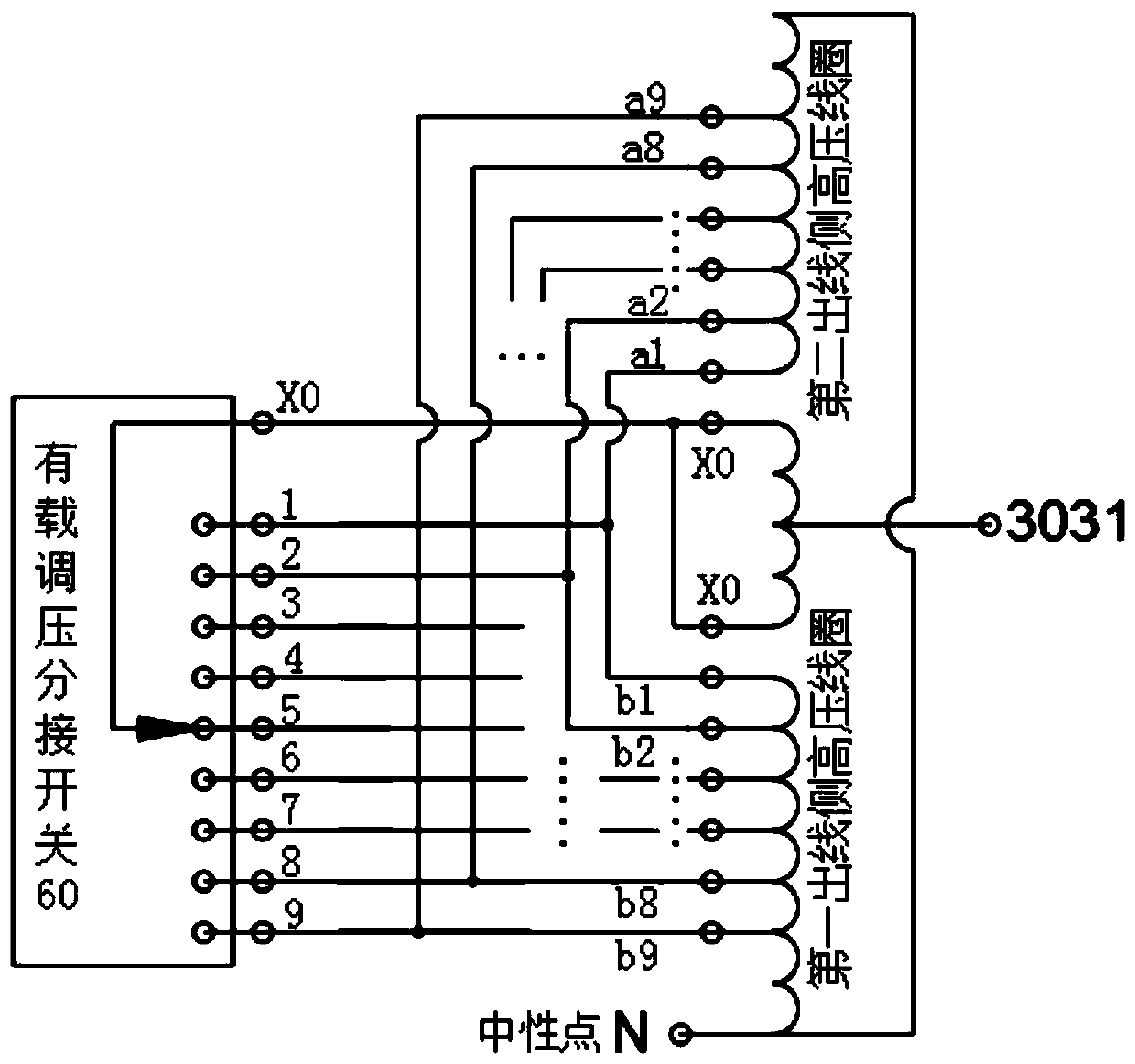

110kV three-phase dry-type transformer

PendingCN109935455ASolve the problem of voltage withstand capability requirementsImprove withstand voltage performanceTransformers/inductances coils/windings/connectionsVariable inductancesLightning impulse voltageTransformer

The embodiment of the invention provides a 110kV three-phase dry-type transformer, and the 110kV three-phase dry-type transformer comprises three connected single-phase dry-type transformers, whereineach single-phase transformer comprises a wire inlet side high-voltage coil and a wire outlet side high-voltage coil; the wire inlet side high-voltage coil is provided with a wire inlet end and a wireoutlet end, and the wire outlet side high-voltage coil is provided with a wire inlet end and a wire outlet end; the wire outlet end of the wire inlet side high-voltage coil is connected with the wireinlet end of the wire outlet side high-voltage coil, and the wire inlet side high-voltage coil is in series connection with the wire outlet side high-voltage coil. According to the invention, the wire inlet ends are arranged at the middles of the high-voltage coils at all sides, so the lightning impulse voltage resistance of the wire inlet ends of the high-voltage coils at all sides is improved,the lightning impulse voltage resistance of the whole three-phase dry type transformer is further improved, and the requirement for the voltage resistance of insulation of the three-phase dry type transformer under the 110kV voltage level is met.

Owner:JIANGSU HUAPENG TRANSFORMER

Cascaded structure capacitor core

InactiveCN103779074AImprove withstand voltage performanceReduced fluctuations in capacity deviationFixed capacitor electrodesThin/thick film capacitorMetallurgyHigh pressure

The invention discloses a cascaded structure capacitor core. The cascaded structure capacitor core comprises an aluminum foil, a metallization polypropylene film and a dielectric layer. The core is formed by winding the aluminum foil and the dielectric layer. The metallization polypropylene film winds the dielectric layer in sequence, the two ends of the aluminum foil extend outwards, and the middle of the aluminum foil is hollow. The cascaded structure capacitor core overcomes the defects in the prior art, and is simple in design and reasonable in structure. The capacitor core has high-pressure resistant performance and large-current resistant performance and is small in size and suitable for an electronic rectifier.

Owner:铜陵市佳龙飞电容器有限公司

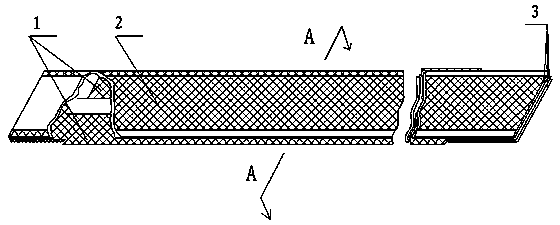

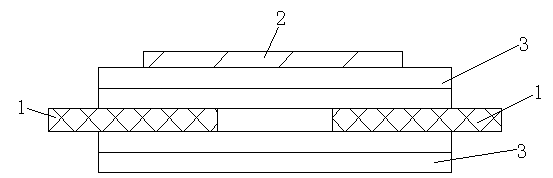

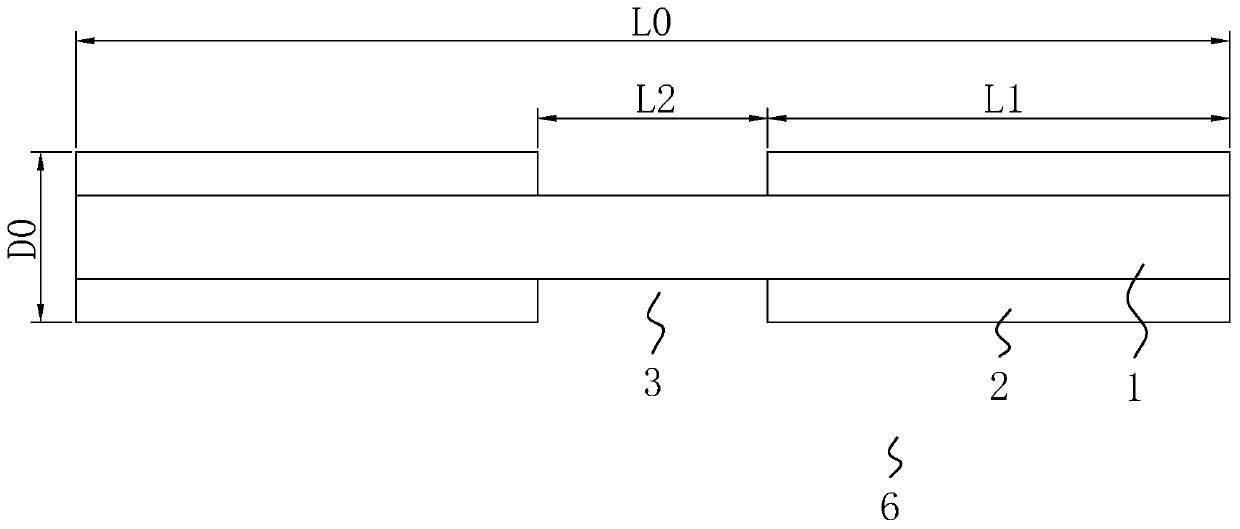

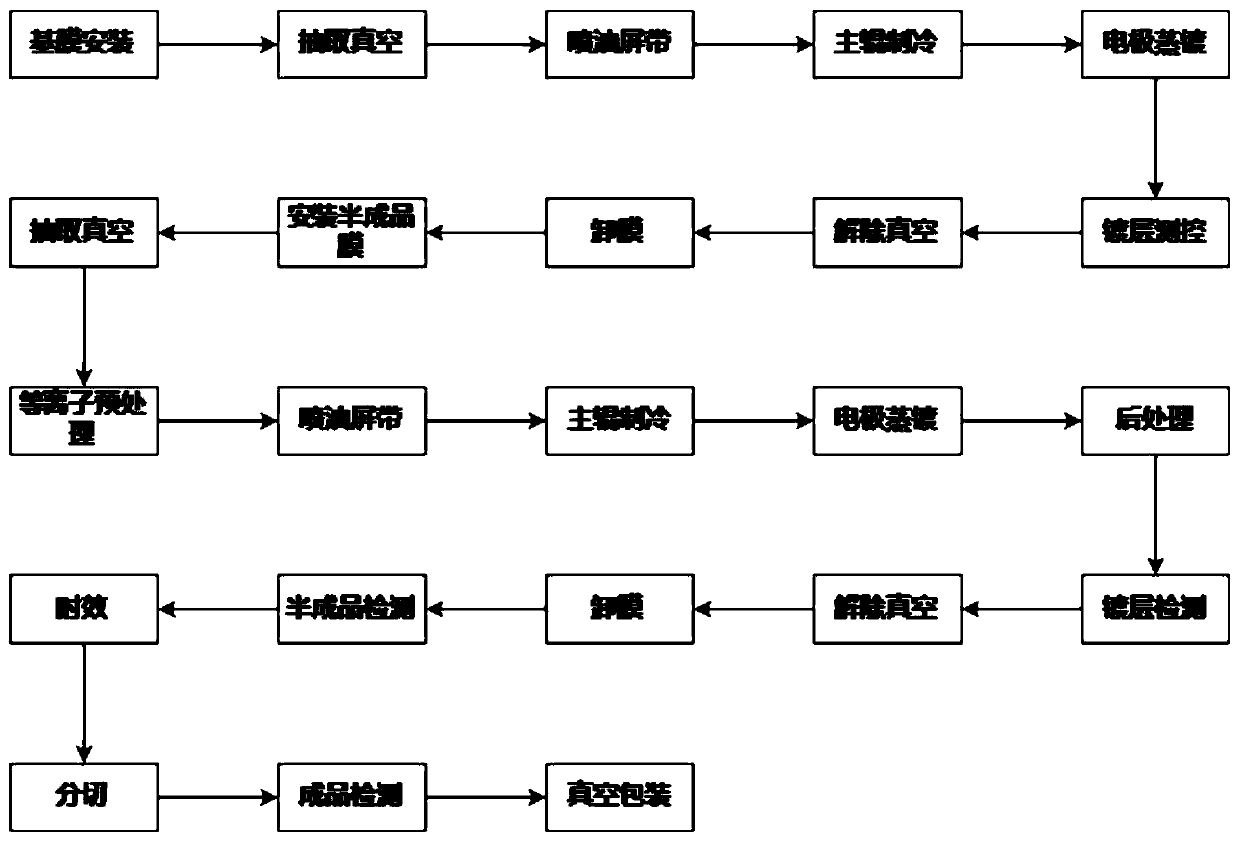

Double-sided aluminum metallized polypropylene film and preparation method thereof and capacitor core

InactiveCN110684944AImprove withstand voltage performanceUniform vapor depositionThin/thick film capacitorFixed capacitor dielectricPolymer scienceThin membrane

The invention relates to a double-sided aluminum metallized polypropylene film and a preparation method thereof and a capacitor core. The double-sided aluminum metallized polypropylene film includes apolypropylene base film and two pairs of aluminum metallized layers. The preparation method of the double-sided aluminum metallized polypropylene film includes the steps of first vacuum evaporation,non-corona surface corona, second vacuum evaporation and post-treatment. The capacitor core includes a pair of single-sided metallized polypropylene film, a polypropylene light film and the double-sided aluminum metallized polypropylene film. The double-sided aluminum metallized polypropylene film has the advantage of improving the voltage resistance of the film; in addition, the preparation method has the advantage of uniformly vaporizing the aluminum metallized layers on both surfaces of the polypropylene film; and the capacitor core has the advantage of improving the thermal polymerizationeffect.

Owner:ZHEJIANG QIXING CAPACITOR

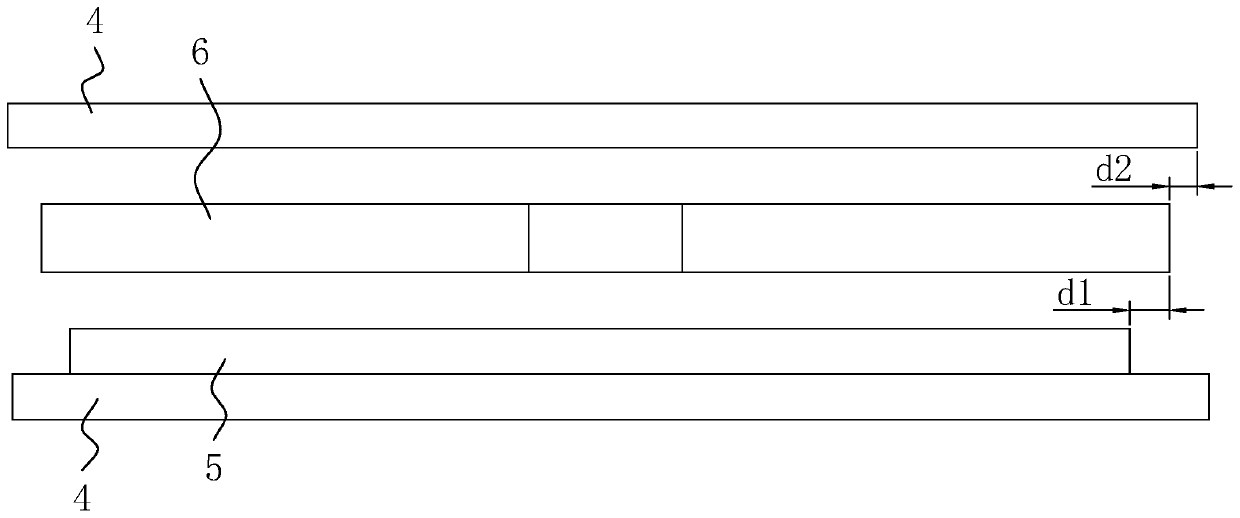

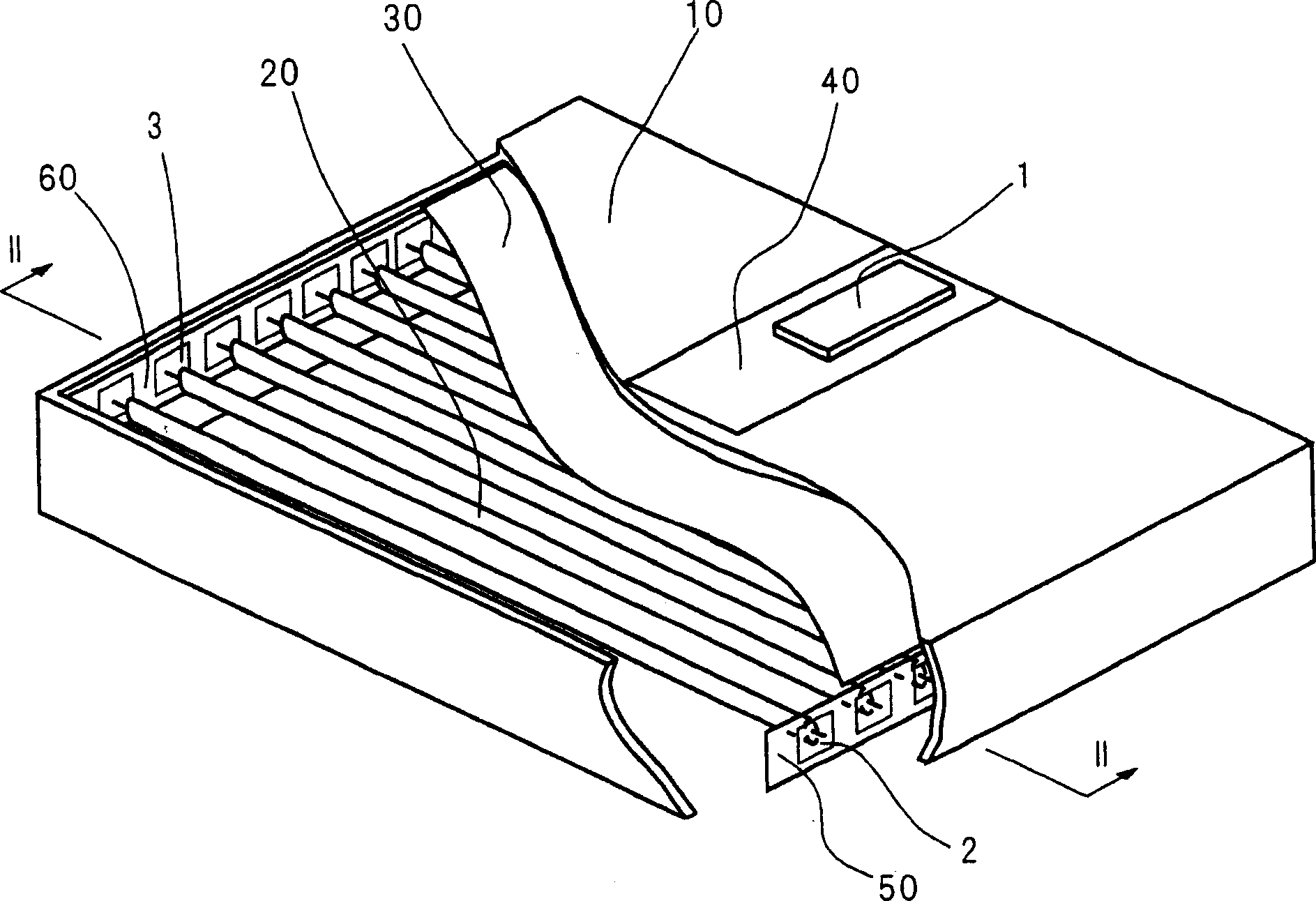

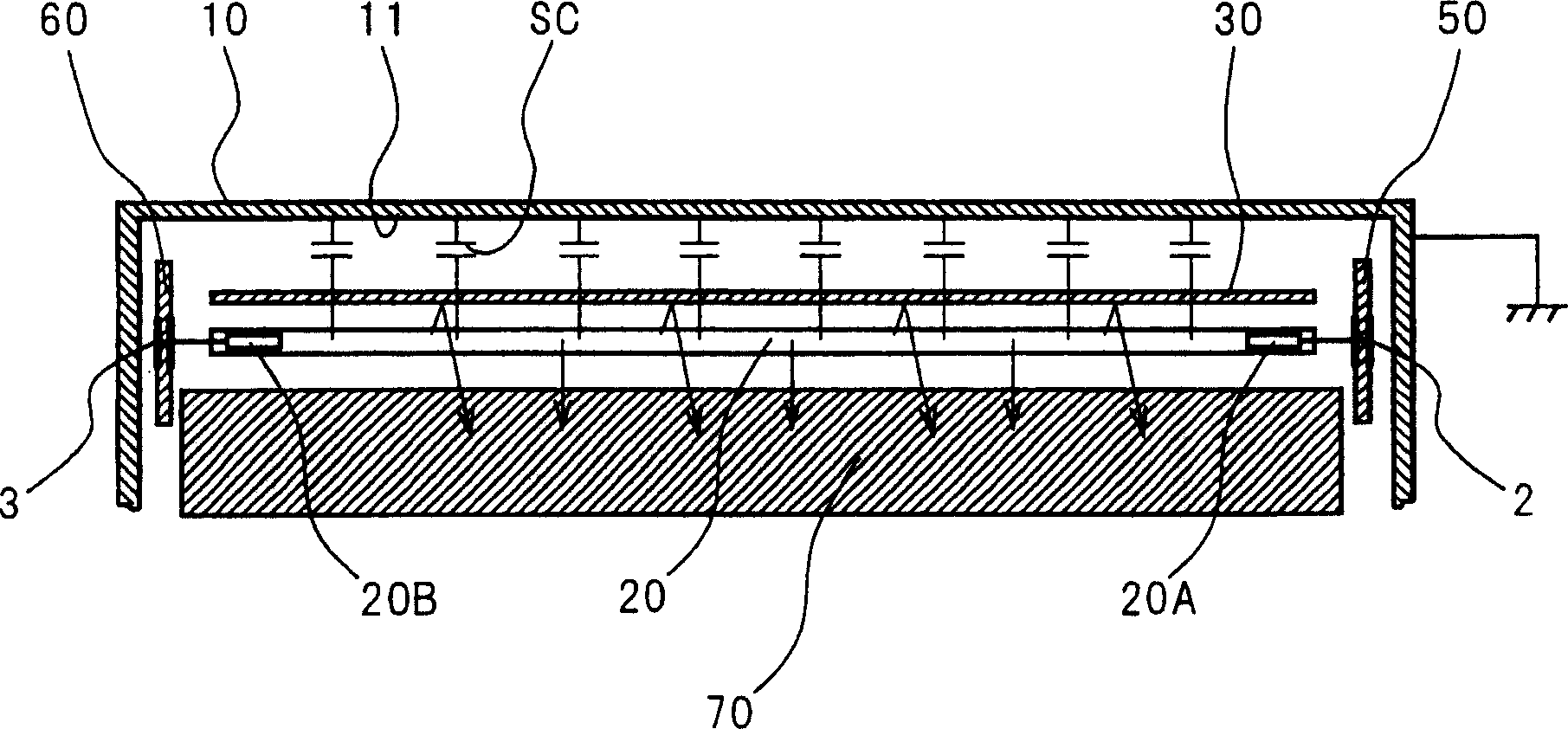

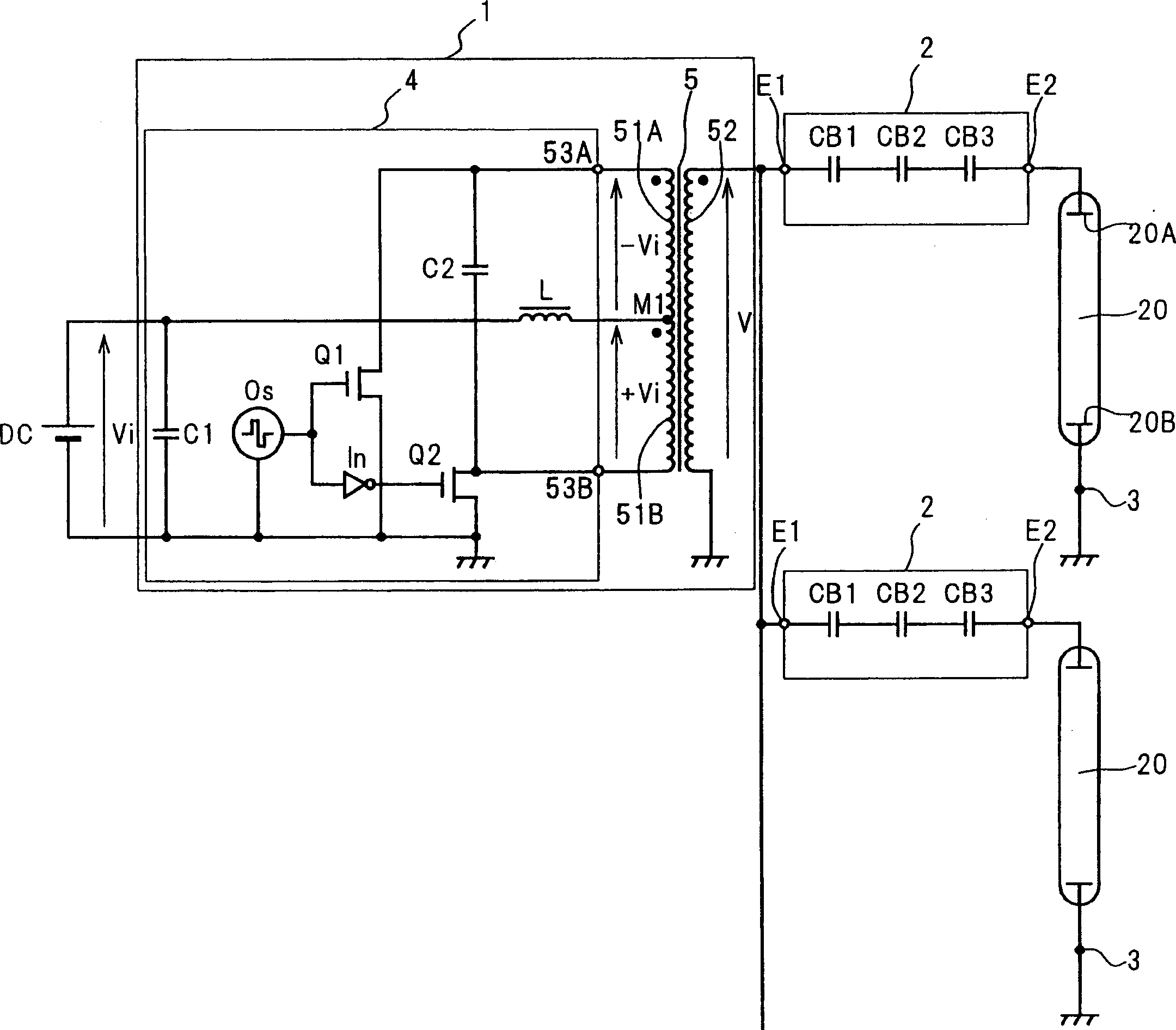

Cold-cathode tube lighting device

InactiveCN1898998AImprove heat resistanceImprove withstand voltage performanceTransformersElongate light sourcesElectrical conductorCold cathode

The inveniton provides a cold-cathode tube lighting device which uniformly lights up a plurality of cold-cathode tubes with a common power supply and is downsized effectively by using a ballast capacitor. A substrate (50) is divided into as many blocks (2) as the number of cold-cathode tubes (20). Two conductor layers in each block (2) respectively include two foils (21A and 21B, 24A and 24B). The first foil (21A) in the first conductor layer is connected with a common low-impedance power supply. Between the two conductor layers, an area where the first foils (21A and 24A) overlap each other forms a first ballast capacitor (CB1), an area where the first foil (24A) and the second foil (21B) overlap each other forms a second ballast capacitor (CB2), and an area where the second foils (21B and 24B) overlap each other forms a third ballast capacitor (CB3). The second foils (21B and 24B) are connected to the first electrode (21) of a cold-cathode tube (20).

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com