Fluorine-containing resin, preparation method thereof, conformal coating and printed circuit board

A technology of fluorine-containing resin and conformal coating, which is applied in the direction of epoxy resin coating, printed circuit secondary treatment, carboxylate preparation, etc., and can solve the problems of slow curing speed, moisture resistance and voltage resistance of the use requirements, etc. , to achieve excellent water resistance, good mechanical and thermal properties, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

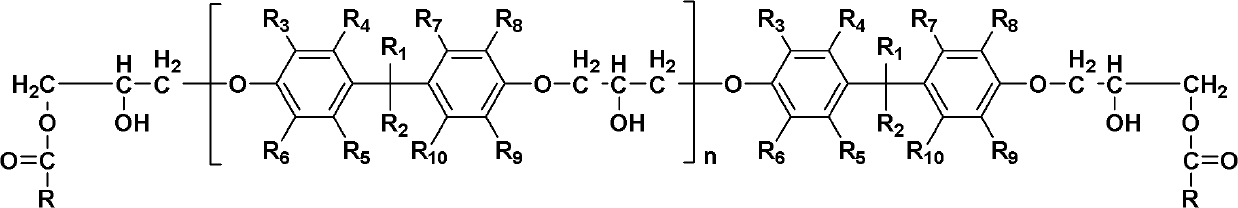

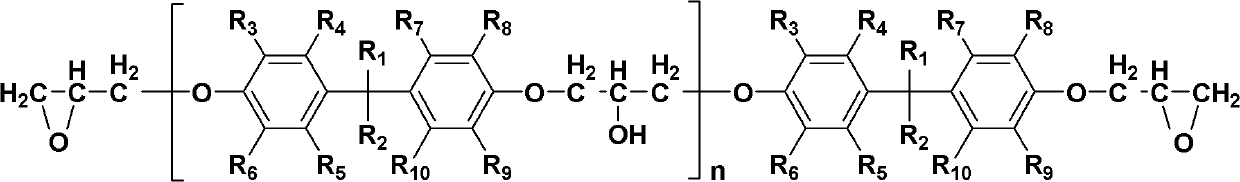

[0040] The present invention also provides a method for preparing the above-mentioned fluorine-containing resin, the method comprising performing condensation reaction and / or ring-opening addition reaction on a resin precursor containing fluorine atoms and an unsaturated fatty acid under the action of a catalyst, wherein the unsaturated The fatty acid molecular structure contains multiple carbon-carbon double bonds, and at least two of the multiple carbon-carbon double bonds are separated by a methylene group.

[0041] In the present invention, the resin precursor containing fluorine atoms and the unsaturated fatty acid undergo condensation reaction and / or ring-opening addition reaction under the action of a catalyst, so that a chemical bond is formed between the resin precursor containing fluorine atoms and the unsaturated fatty acid, thereby obtaining The fluorine-containing resin of the present invention. Therefore, the molecular structure of the resin precursor containing ...

Embodiment 1

[0084] This example is used to illustrate the fluorine-containing resin and its preparation method according to the present invention.

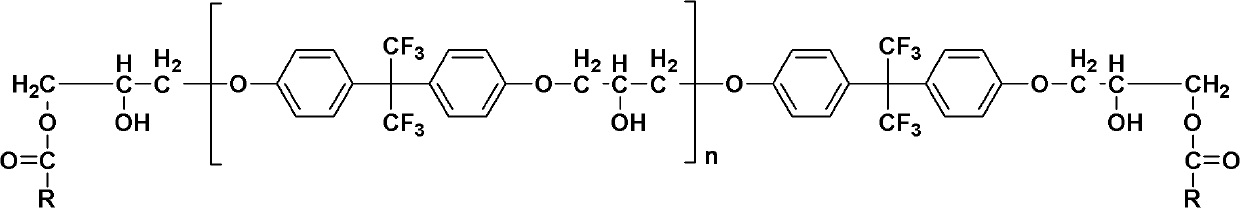

[0085] Add 36.6g of hexafluorobisphenol A, 75.0g of epichlorohydrin and 150ml of N-methylpyrrolidone into a 500ml three-necked flask as a reaction solvent. After the above two reactants are completely dissolved, add 2.75g of tetrabutylammonium chloride, React at 55° C. for 3 hours; then, add 4 g of sodium hydroxide to the reaction system, and react at 70° C. for 4 hours. After the reaction is completed, the method of distillation under reduced pressure is used for purification to obtain the epoxy resin precursor containing fluorine atoms of the present invention. The epoxy equivalent of the epoxy resin precursor containing fluorine atoms is 410, the number average molecular weight is 840, and the molecular weight distribution is 1.05, corresponding to the epoxy resin precursor containing fluorine atoms in structural formula 6 where n=1.

[008...

Embodiment 2

[0088] This example is used to illustrate the fluorine-containing resin and its preparation method according to the present invention.

[0089] In a 500ml three-necked flask, add 36.6g hexafluorobisphenol A, 19.3g epichlorohydrin and 100ml N-methylpyrrolidone as a reaction solvent, and after the above two reactants are completely dissolved, add 2.75g of tetrabutylammonium chloride, React at 60° C. for 4 hours; then, add 4 g of sodium hydroxide to the reaction system, and react at 70° C. for 5 hours. After the reaction is completed, the method of distillation under reduced pressure is used for purification to obtain the epoxy resin precursor containing fluorine atoms of the present invention. The epoxy equivalent of the epoxy resin precursor containing fluorine atoms is 1215, the number average molecular weight is 2400, and the molecular weight distribution is 1.09 respectively, corresponding to the epoxy resin precursor containing fluorine atoms in structural formula 6 where n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com