Highly heat-resistant synthetic polymer compound and high withstand voltage semiconductor device

A technology for synthesizing polymers and compounds, which is applied in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc. The effect of high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

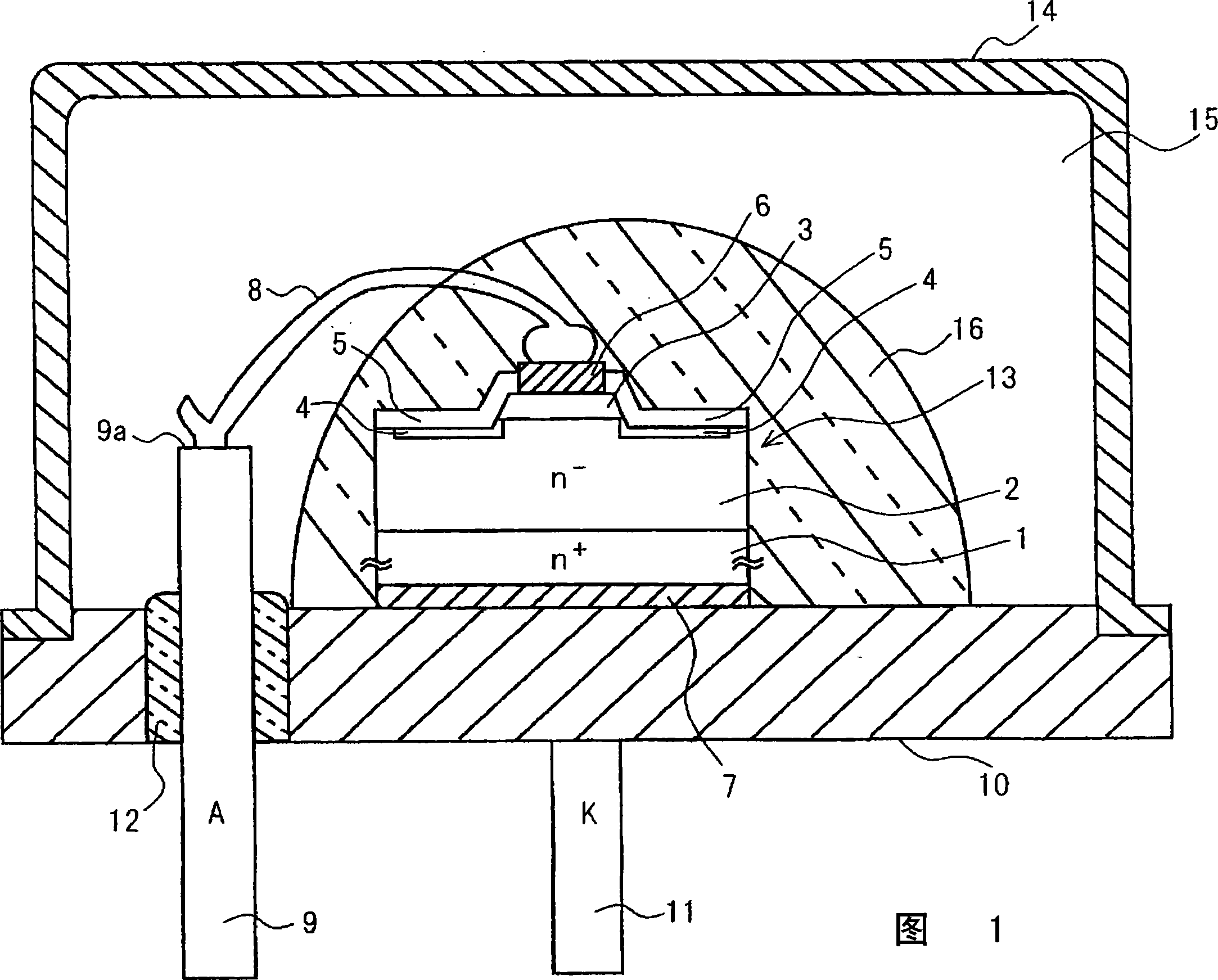

[0072] 1 is a cross-sectional view of a high heat-resistant and high-voltage semiconductor device according to a first embodiment of the present invention. In the semiconductor device of this embodiment, a high withstand voltage SiC (silicon carbide) pn diode element 13 with a withstand voltage of 8 kV is housed in a case 14, and is composed of a synthetic polymer compound of the present invention with high heat resistance and high heat dissipation. Cover 16 covers SiCpn diode element 13 .

[0073] SiCpn diode element 13 has the following structure. An offset layer 2 of n-type SiC having a thickness of about 90 μm and having a low impurity concentration is formed on the cathode region 1 of n-type SiC having a thickness of about 300 μm and having a high impurity concentration. A cathode electrode 7 is formed below the cathode region 1 . An anode region 3 of p-type SiC forming a main junction is formed in the central region of the offset layer 2 . A metal anode electrode 6 is...

no. 2 Embodiment

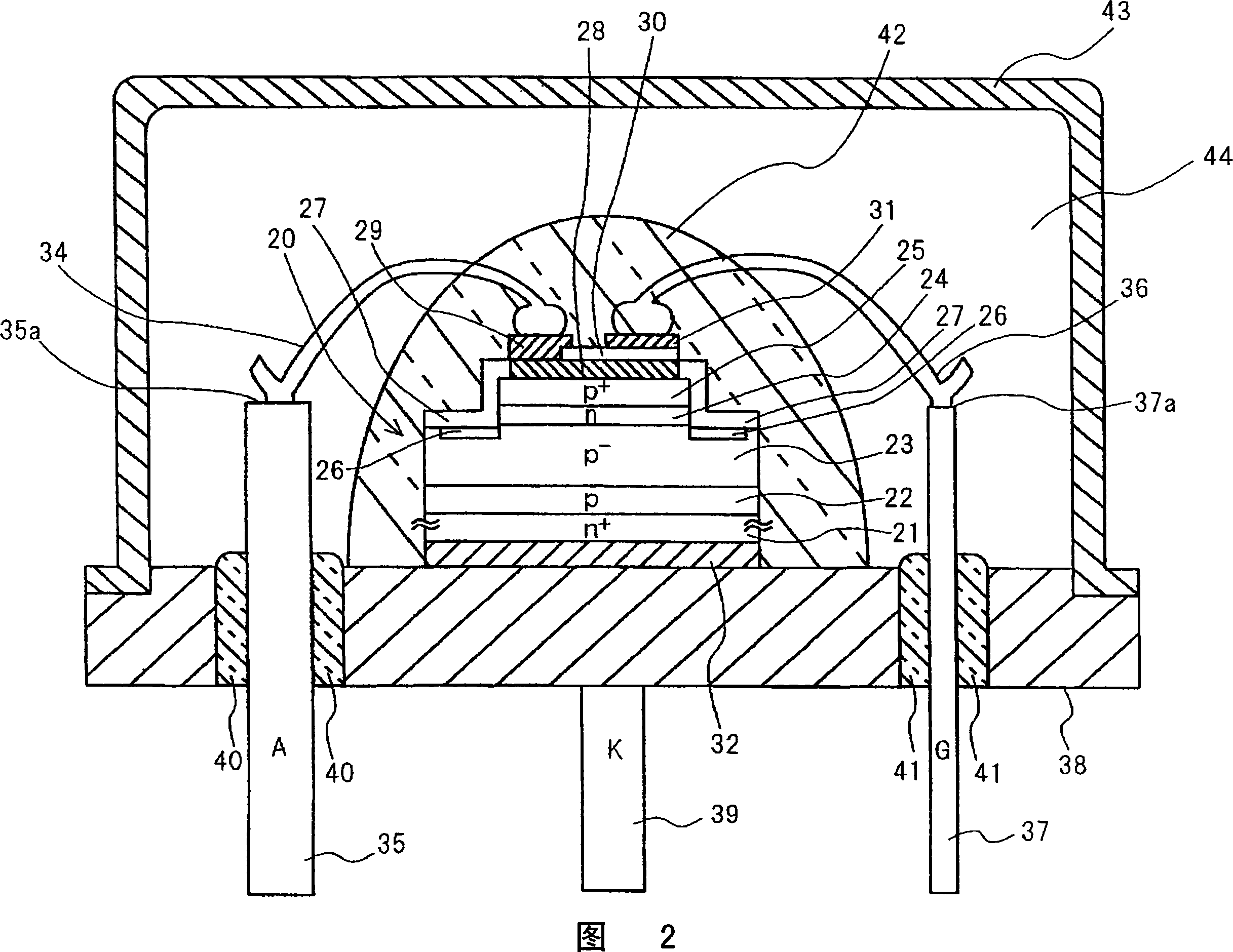

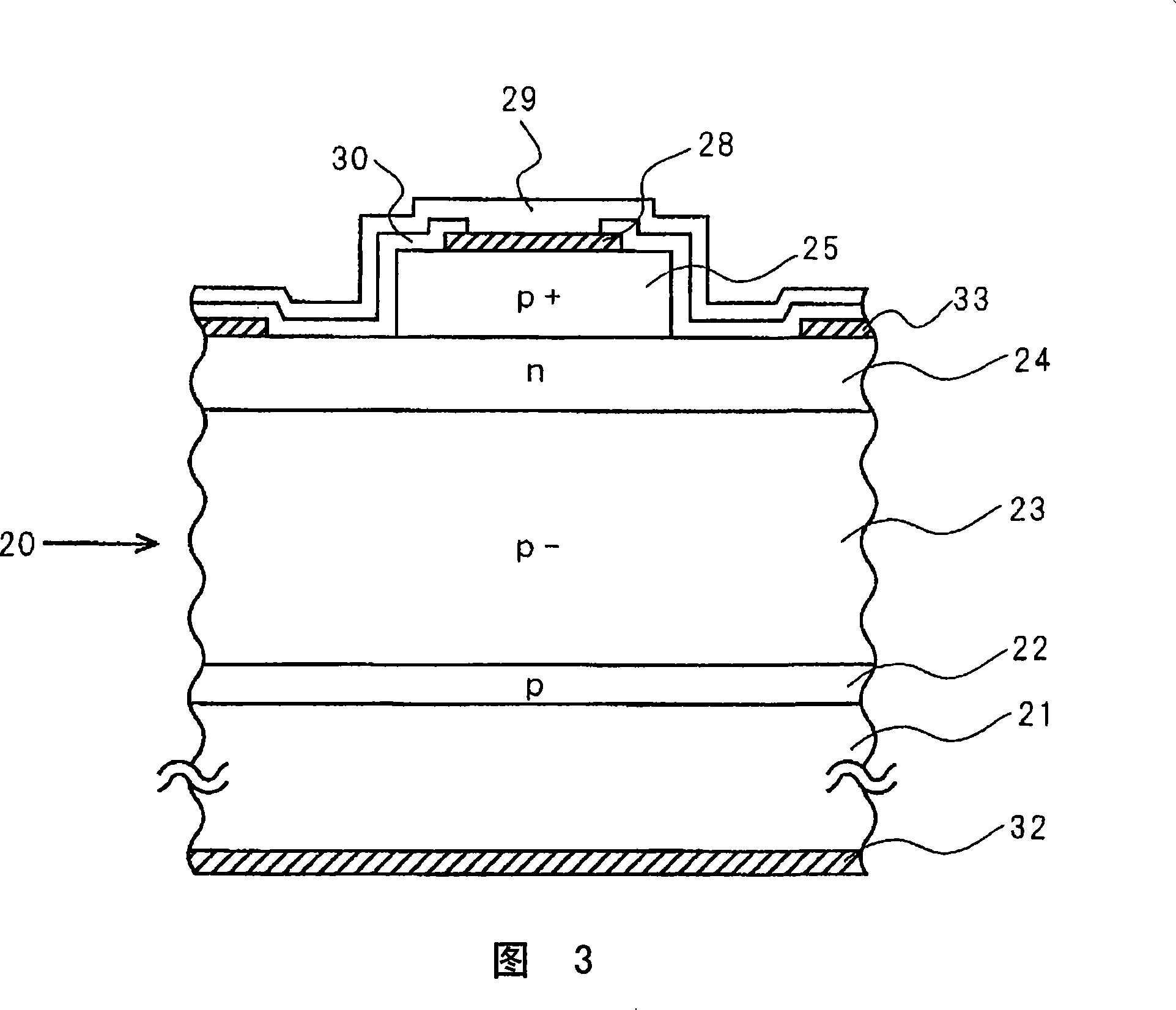

[0085] The semiconductor device according to the second embodiment of the present invention is a SiC-GTO thyristor (Gate Turn off Thyristor) device with a withstand voltage of 5 kV. Fig. 2 is its sectional view. FIG. 3 is a cross-sectional view illustrating a cell formed by cutting the GTO thyristor element 20 in FIG. 2 along a plane perpendicular to the paper. In an actual device, a plurality of units shown in FIG. 3 are connected in the left and right directions of the figure. In FIGS. 2 and 3 , a buffer layer 22 of p-type SiC having a thickness of about 3 μm is provided on the cathode region 21 of n-type SiC having a thickness of about 320 μm and a high impurity concentration. A cathode electrode 32 is arranged below the cathode region 21 . An offset layer 23 of p-type SiC with a low impurity concentration of approximately 60 μm in thickness is provided on buffer layer 22 . An n-type base region 24 and a p-type anode region 25 having a thickness of approximately 2 μm are...

no. 3 Embodiment

[0101] An optically coupled wide-gap power semiconductor device, which is a semiconductor device according to a third embodiment of the present invention, will be described with reference to the cross-sectional view of FIG. 4 . In this embodiment, a GaN (gallium nitride)-npn bipolar (type) transistor 51 with a withstand voltage of 3 kV / current capacity of 200 A is used as a power semiconductor element having a light emitting function. A SiC-photodiode 52 is used as a light receiving element. The SiC photodiode 52 is disposed in the same housing as the GaN-npn bipolar (type) transistor 51 .

[0102]In the GaN-npn bipolar (type) transistor 51 shown in FIG. 4 , a p-type GaN base region 54 with a thickness of about 1.7 μm is formed on an n-type GaN collector region 53 with a thickness of about 300 μm and a high impurity concentration, An n-type emitter region 55 having a thickness of about 3 μm and a high impurity concentration is formed thereon. A collector electrode 66 is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com