Patents

Literature

92results about How to "Reduce hydrogen evolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

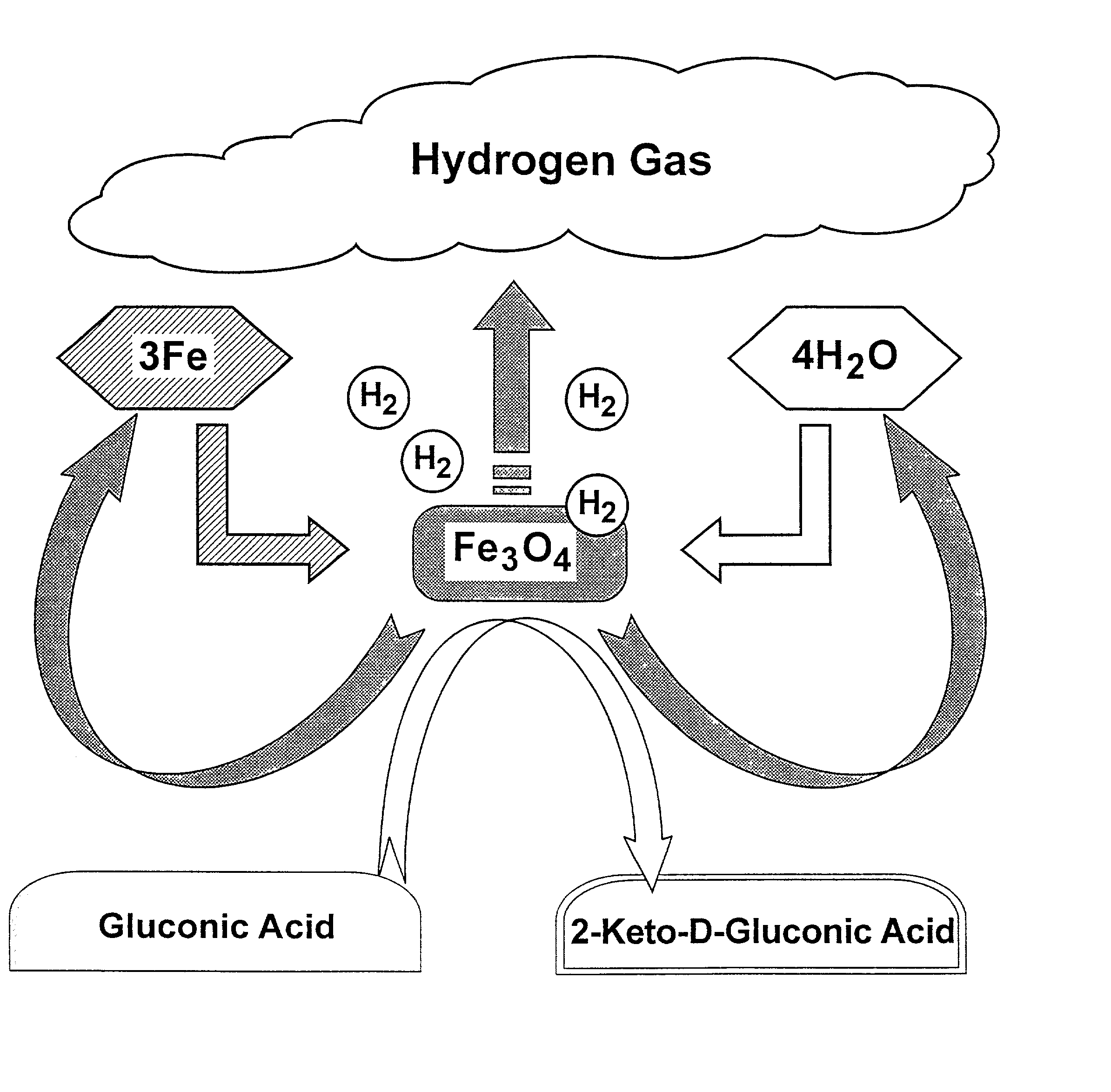

Method for the continuous production of hydrogen

InactiveUS6395252B1Low costEasy and relatively inexpensive to regenerateHydrogen productionChemical recyclingOrganic acidPresent method

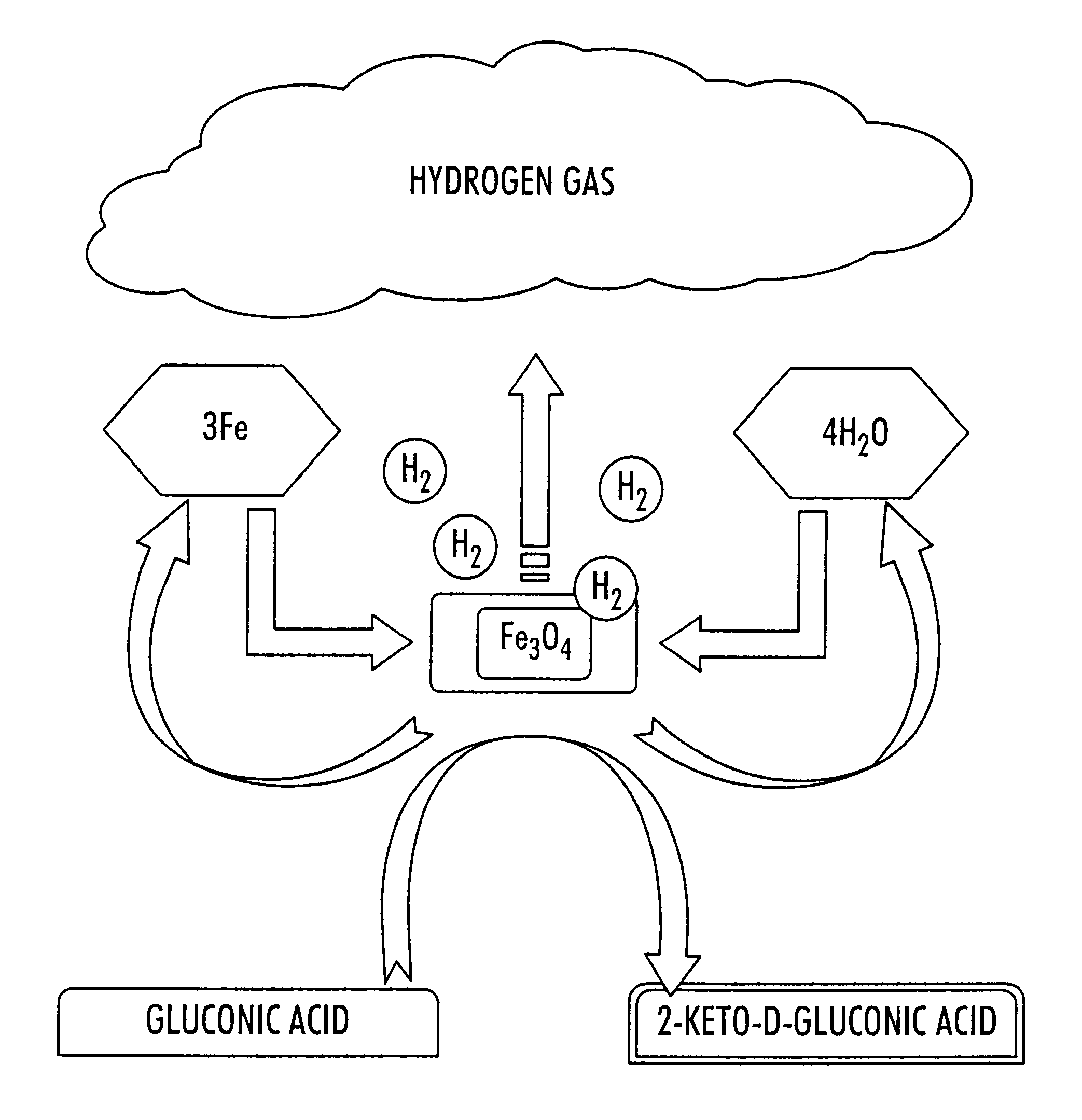

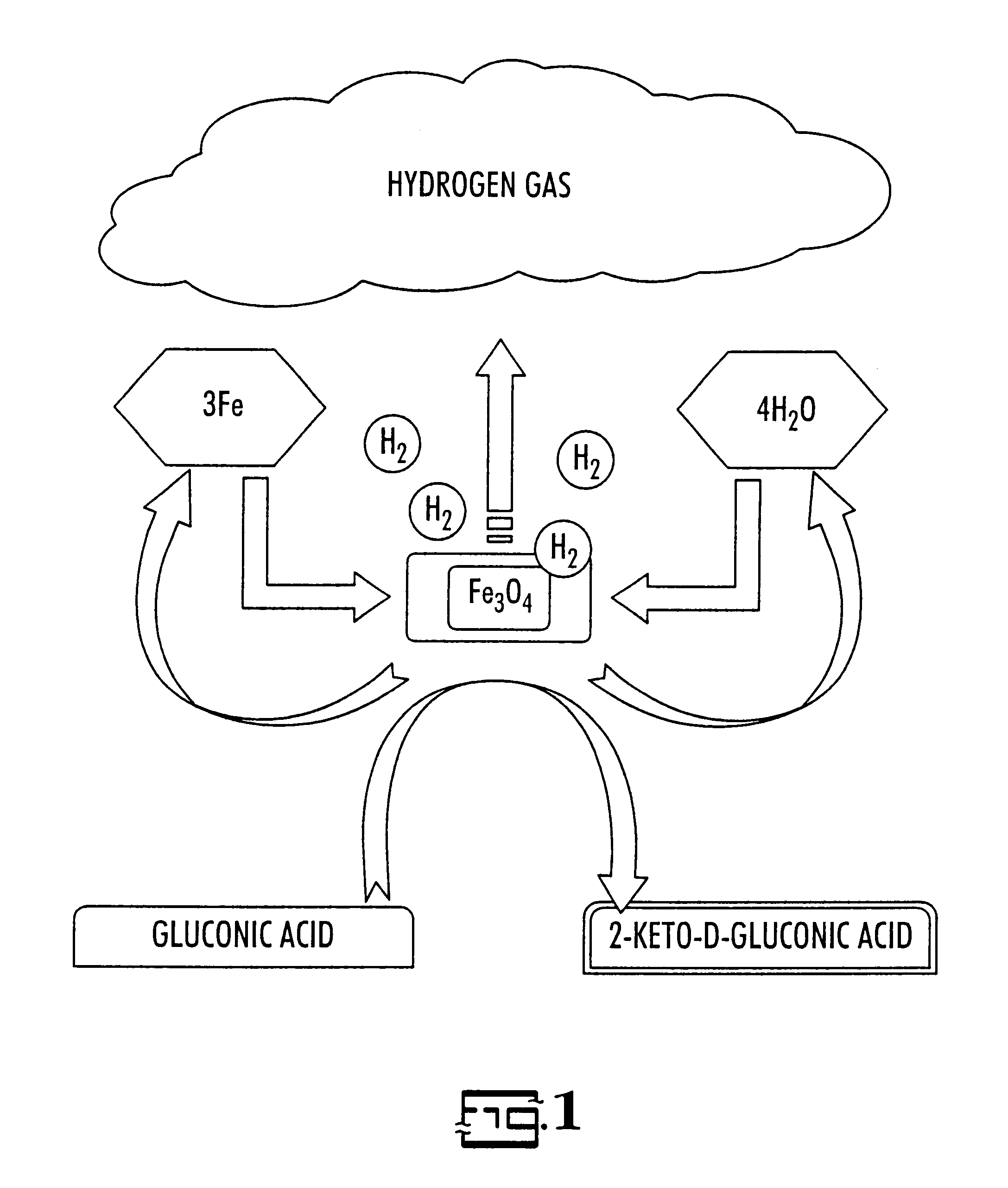

The present invention is a method for the continuous production of hydrogen. The present method comprises reacting a metal catalyst with a degassed aqueous organic acid solution within a reaction vessel under anaerobic conditions at a constant temperature of <=80° C. and at a pH ranging from about 4 to about 9. The reaction forms a metal oxide when the metal catalyst reacts with the water component of the organic acid solution while generating hydrogen, then the organic acid solution reduces the metal oxide thereby regenerating the metal catalyst and producing water, thus permitting the oxidation and reduction to reoccur in a continual reaction cycle. The present method also allows the continuous production of hydrogen to be sustained by feeding the reaction with a continuous supply of degassed aqueous organic acid solution.

Owner:UT BATTELLE LLC

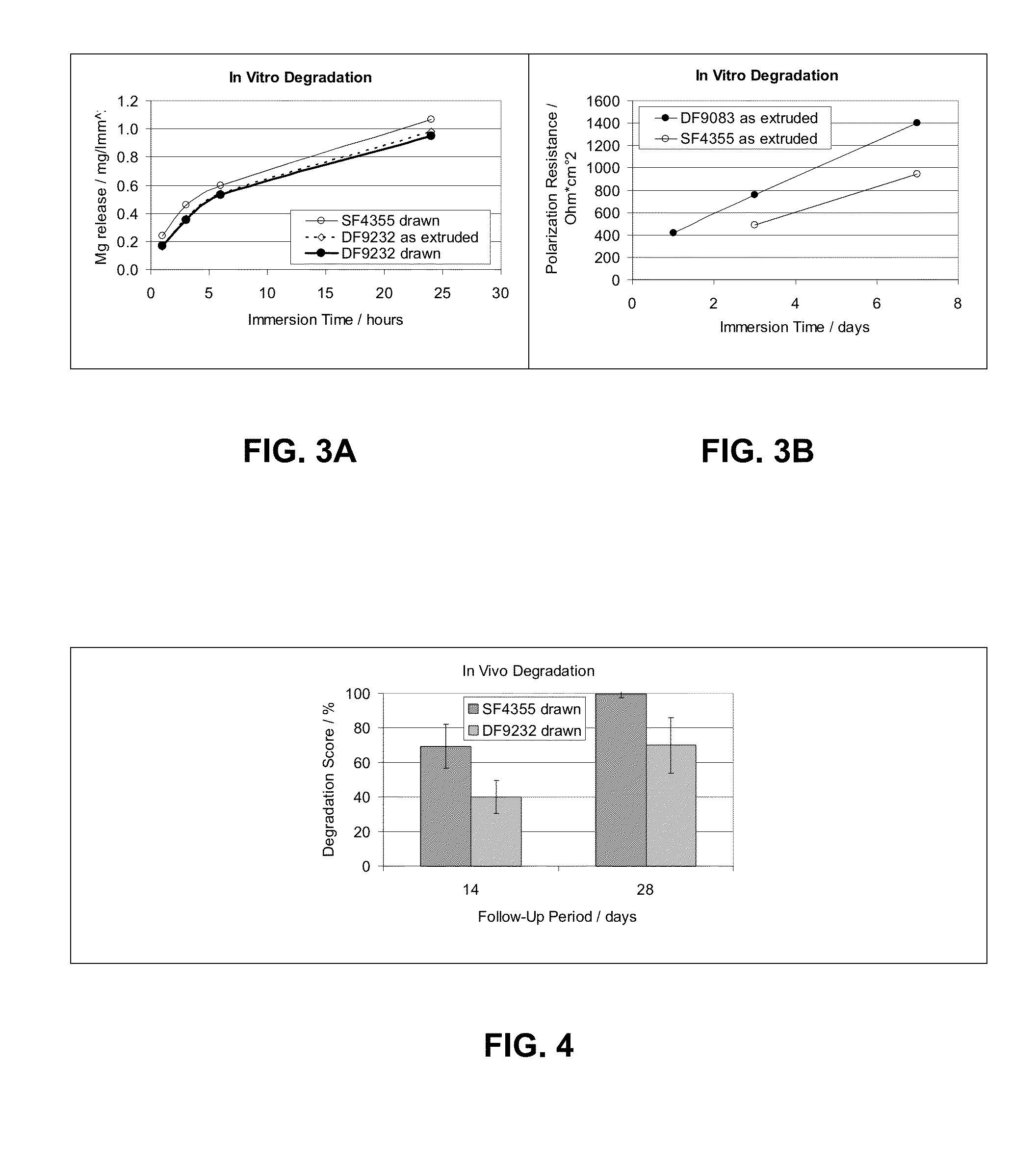

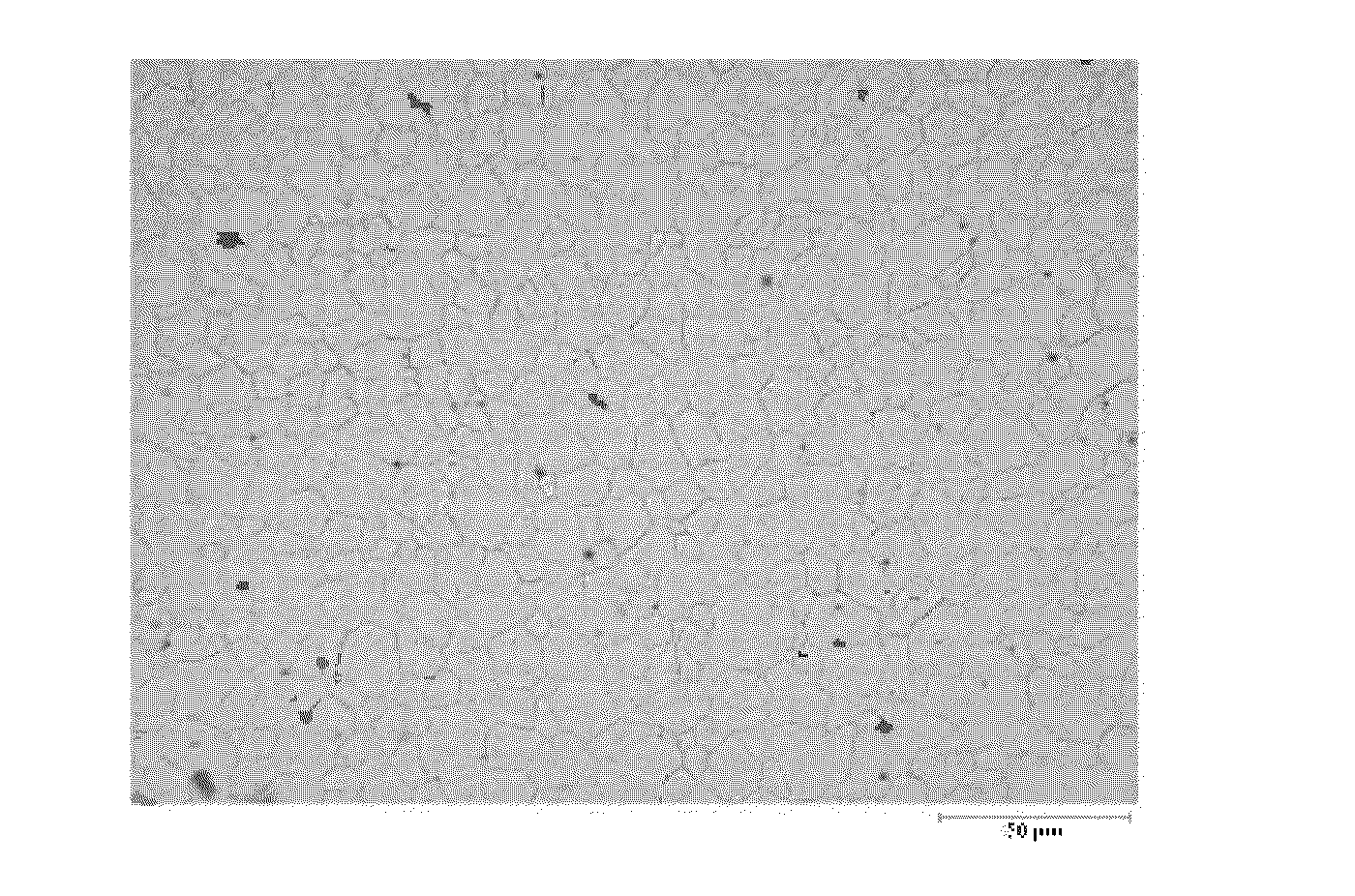

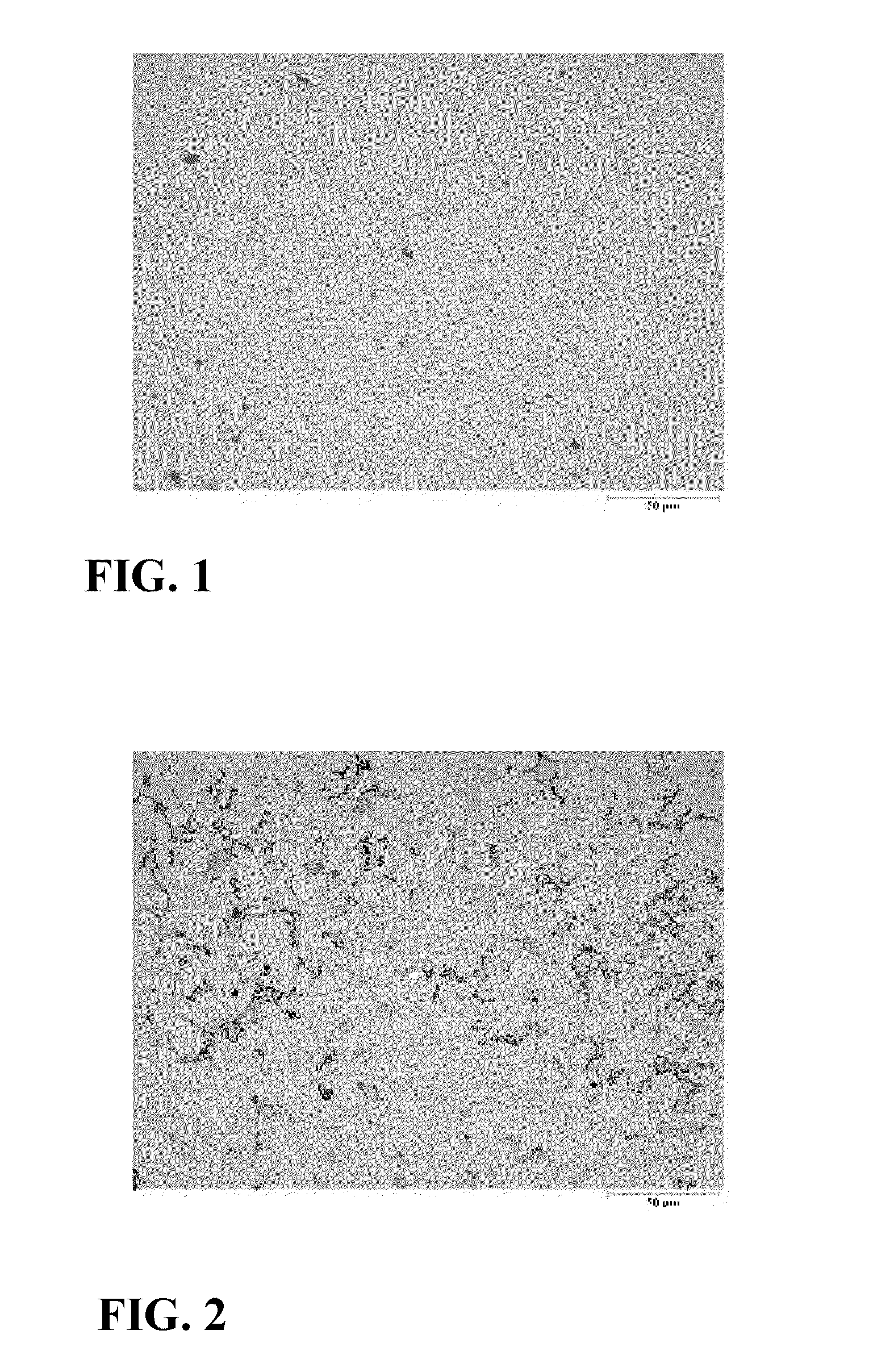

Implant Made of a Biodegradable Magnesium Alloy

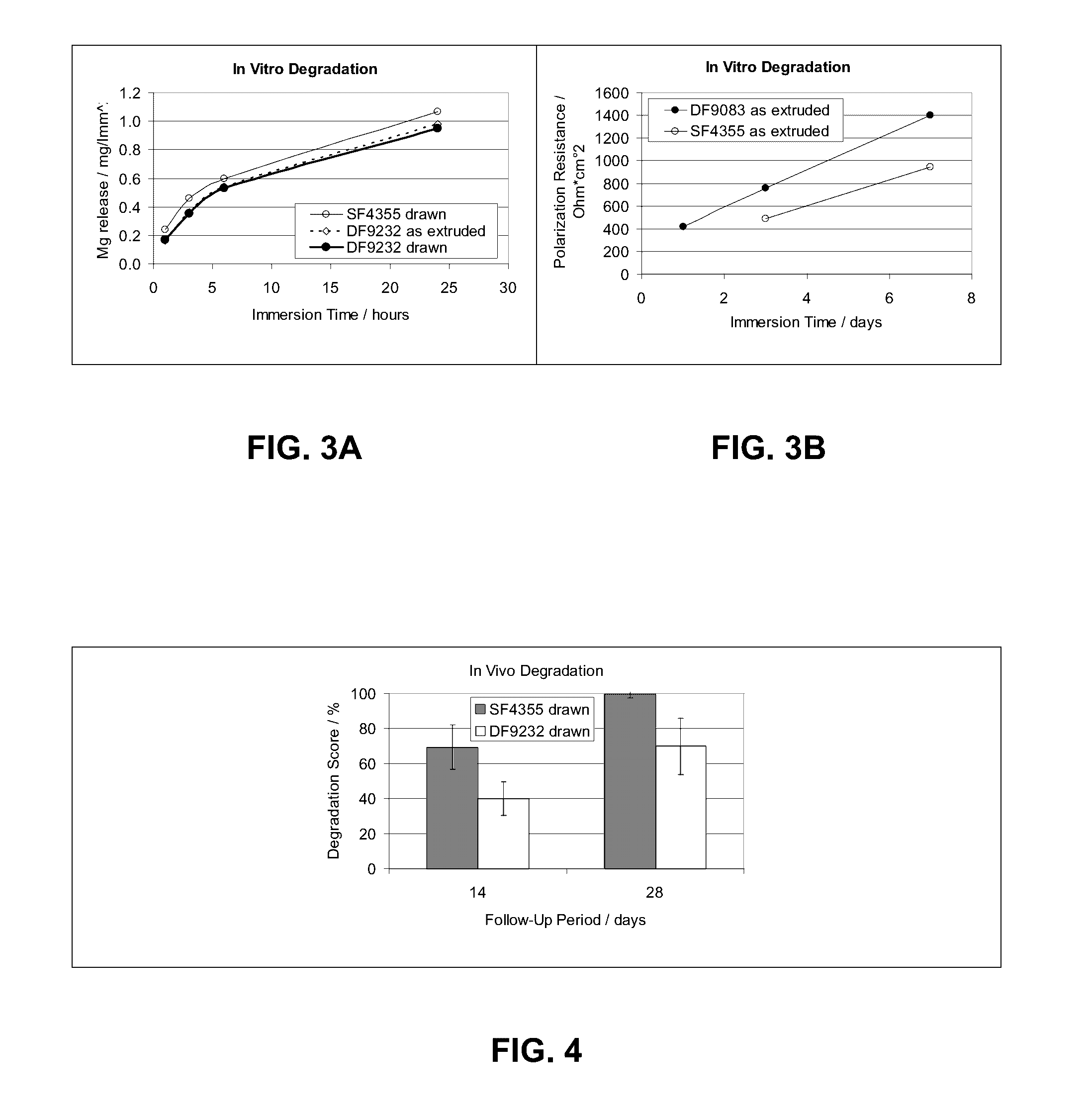

ActiveUS20100082092A1Easy to processImprove material performanceStentsSurgeryBiodegradable magnesium

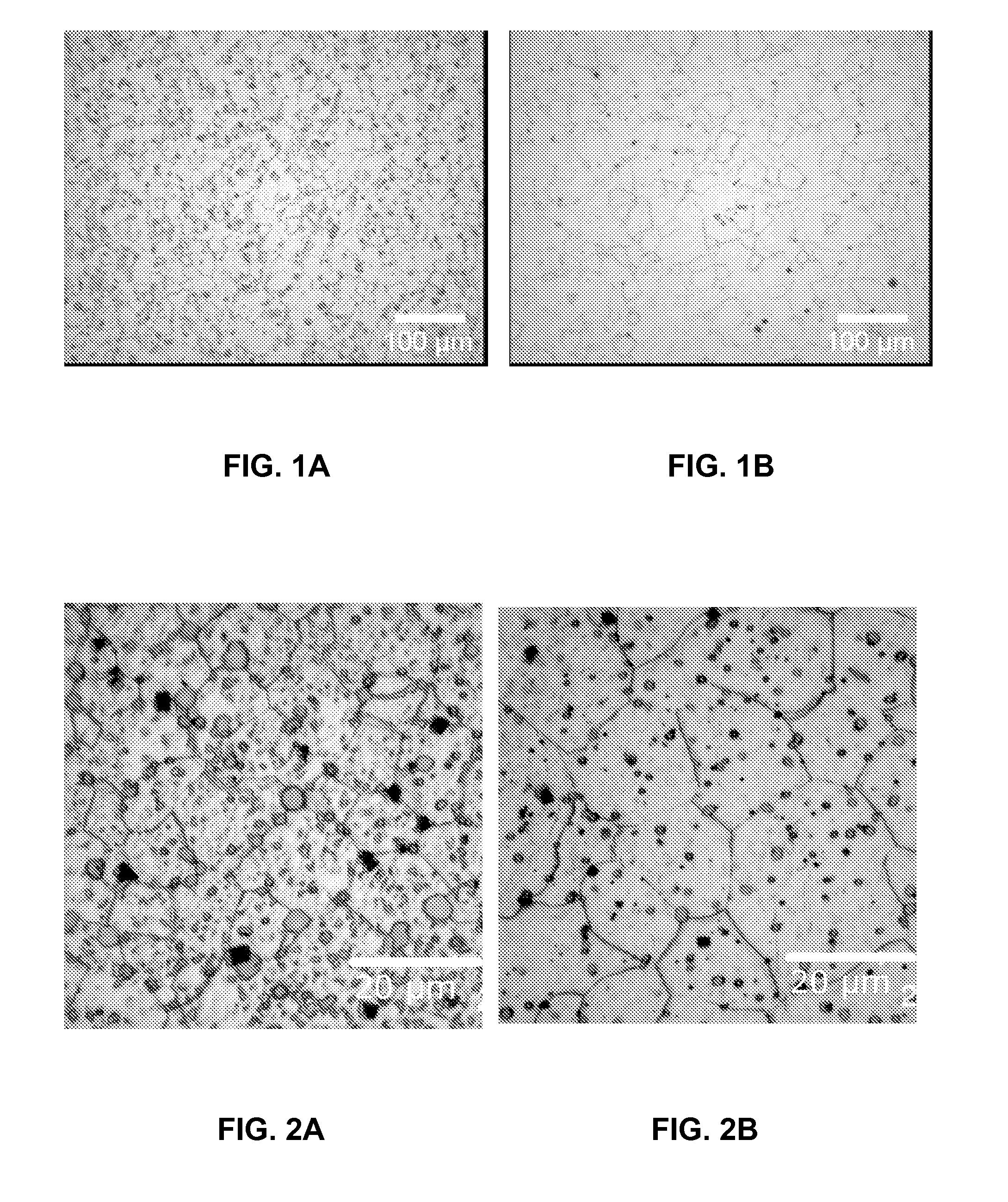

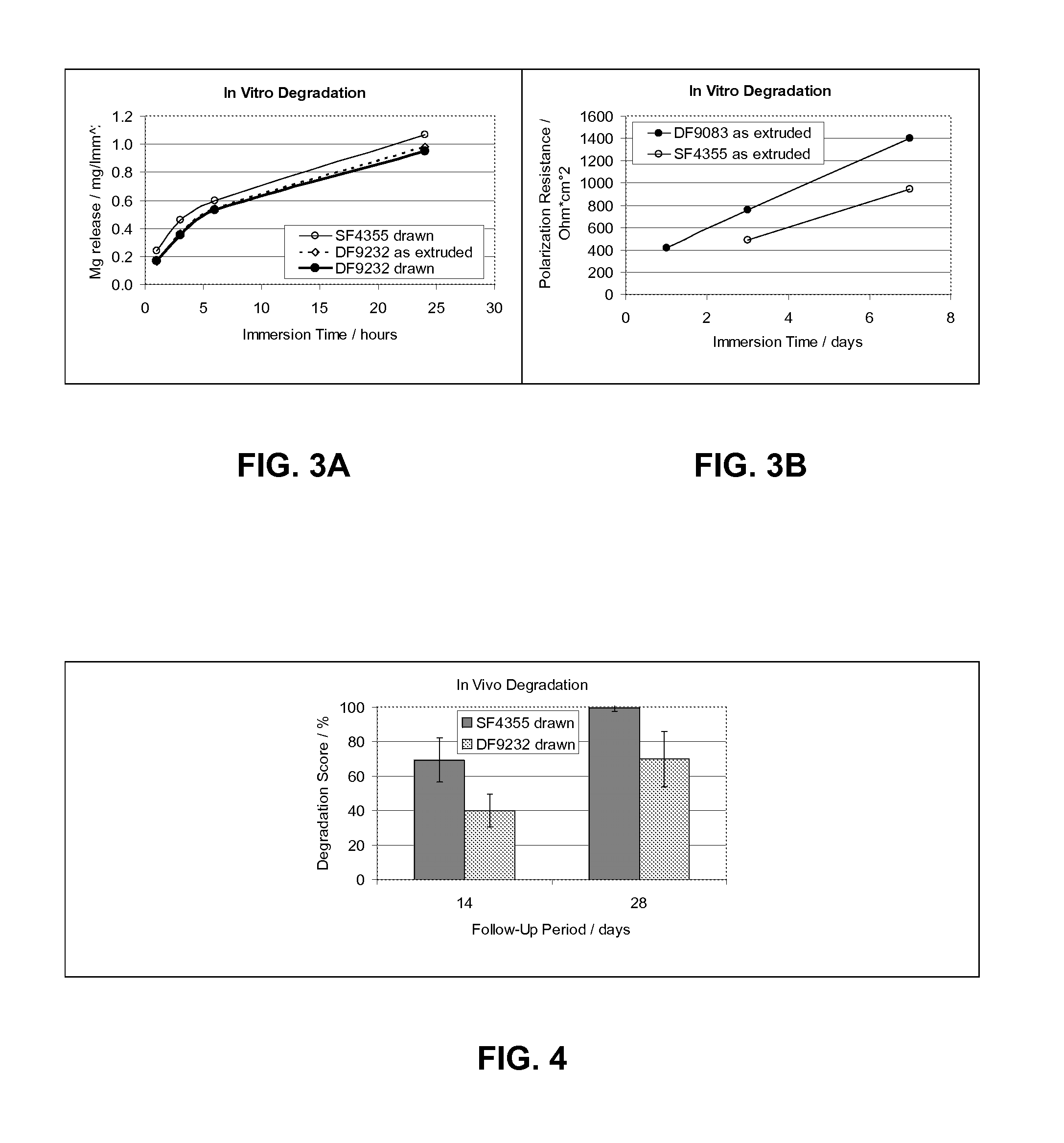

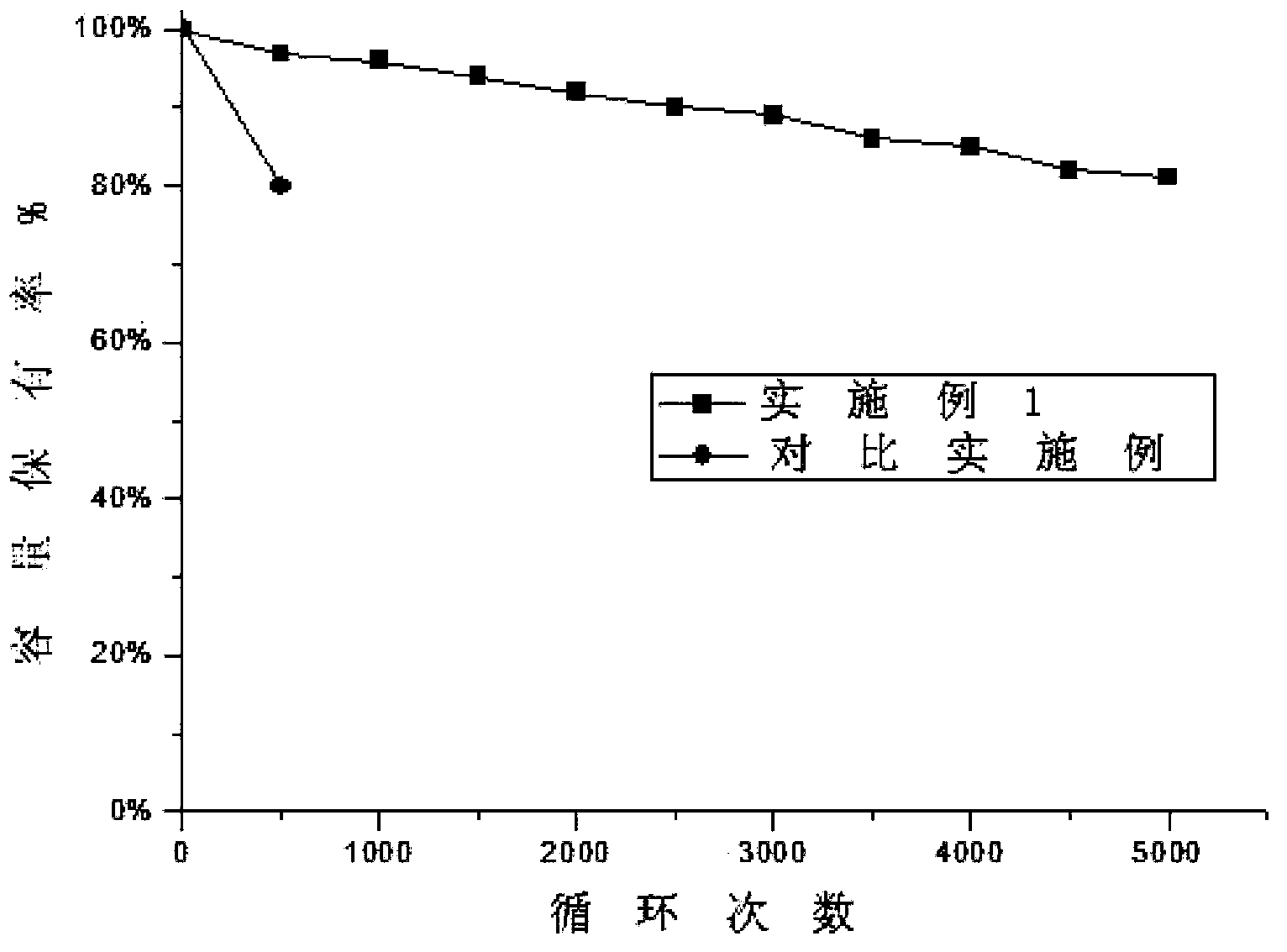

An implant made in total or in parts of a biodegradable magnesium alloy consisting of Y: 2.0-6.0% by weight, Nd: 1.5-4.5% by weight, Gd: 0-4.0% by weight, Dy: 0-4.0% by weight. Er: 0-4.0% by weight, Zr: 0.1-1.0% by weight, Li:0-0.2% by weight, Al: 0-0.3% by weight, under the condition that a) a total content of Er, Gd and Dy is in the range of 0.5-4.0% by weight and b) a total content of Nd, Er, Gd and Dy is in the range of 2.0-5.5% by weight, the balance being magnesium and incidental impurities up to a total of 0.3% by weight.

Owner:BIOTRONIK AG

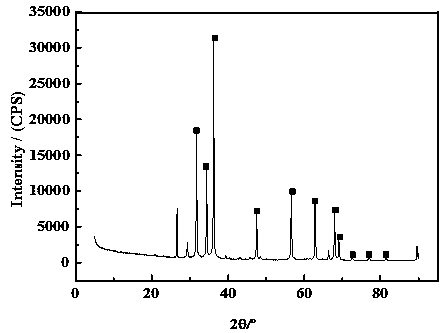

Graphene-bismuth oxide composite material as well as preparation method thereof, lead carbon battery cathode diachylon as well as preparation method thereof and lead carbon battery cathode plate

InactiveCN103811763AInhibitionGuaranteed lifeLead-acid accumulator electrodesHydrogenOxide composite

The invention discloses a graphene-bismuth oxide composite material. The graphene-bismuth oxide composite material comprises graphene as well as bismuth oxide loaded on a graphene sheet layer, wherein the mass ratio of bismuth oxide to graphene is (0.005-0.25):1. The invention also discloses a preparation method of the composite material as well as lead carbon battery cathode diachylon comprising the composite material as well as a preparation method of the lead carbon battery cathode diachylon and a lead carbon battery cathode plate. According to the invention, the generation of hydrogen on the surface of graphene is inhibited by loading bismuth oxide on the sheet layer of graphene, so that the hydrogen evolution phenomenon of the lead carbon battery cathode plate is inhibited; the reduction of lead carbon battery current efficiency and the battery water loss phenomenon are prevented effectively; the service life of the lead carbon battery is ensured.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Filling oil-containing semi-solid composition for fibre-otpical composite overhead earth wire

A filling grease for composite fibre-optical overhead earth wire is prepared by mixing 36®|hydrogenated white oil and PAO-8 synthesized oil with PriCO-3002 polybasic alcohol ester and viscosity exponential improver Lc-212, adding into additive OB fluorescent brightening agent, grease-separating inhibitor BP2400 and G1702, raising temperature, stirring, adding into organic thickening agent gas-phase carbon white H20, raising temperature, thickening, adding into antioxidant AT-215 and inorganic thickening agent SEP1650, raising temperature, thickening, shearing, circulation feeding back, cooling to normal temperature, homogenizing, degassing, filtering and obtaining the grease. It achieves good hydrogen absorption and stable fibre-optical transmitting performance.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

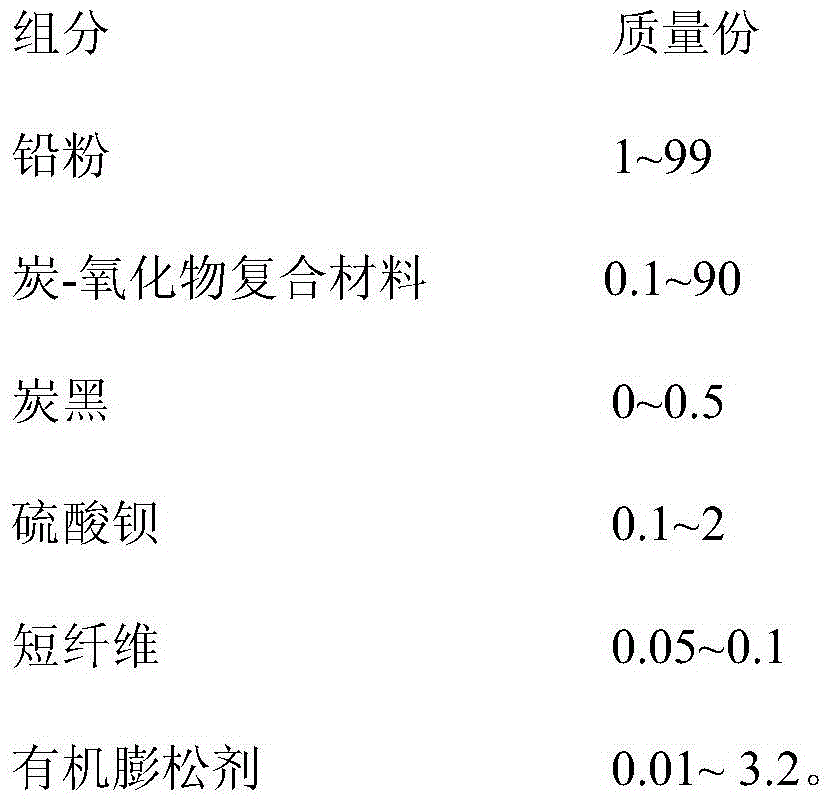

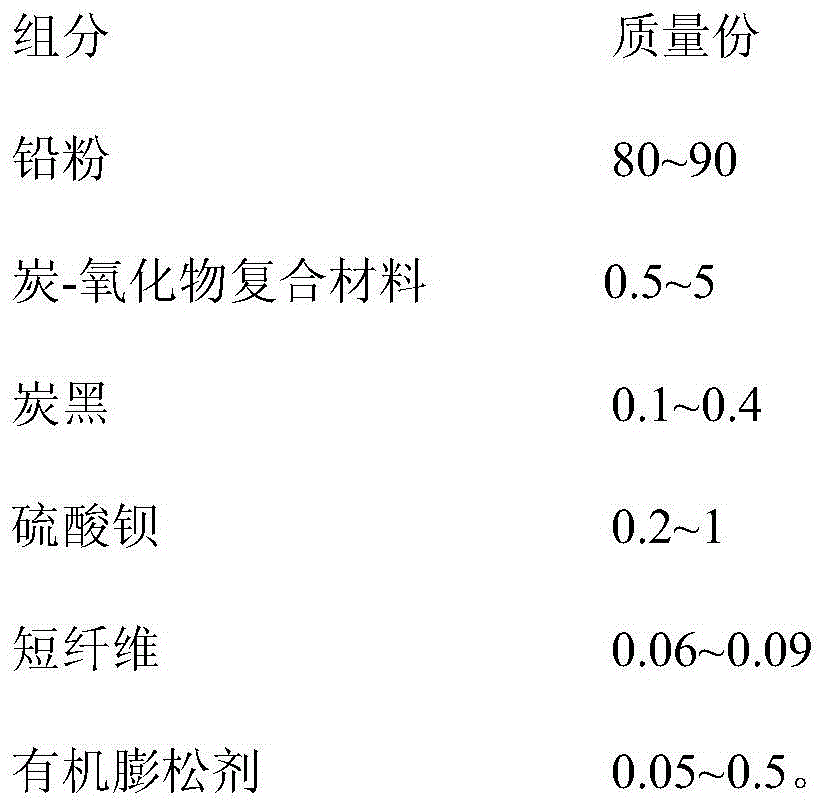

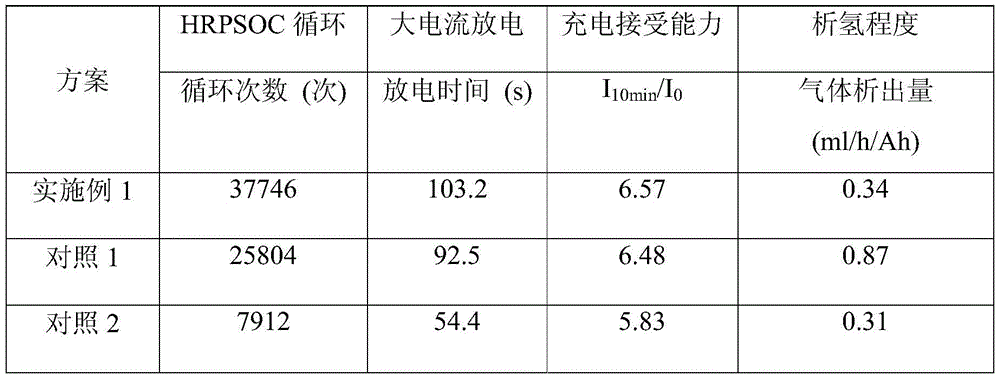

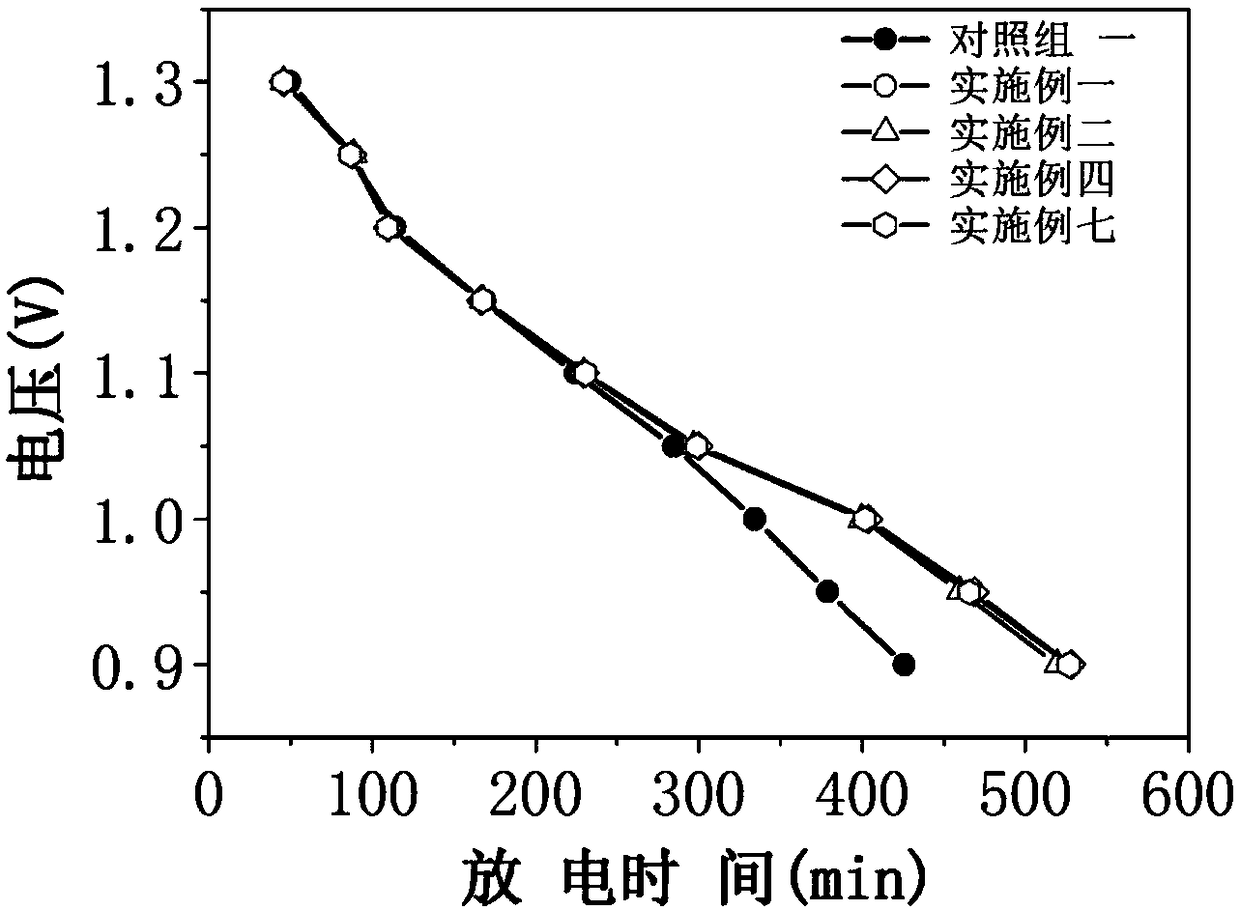

Negative lead paste for lead-carbon battery

ActiveCN105489887ALarge specific surface areaDelayed softening and sheddingFinal product manufactureCell electrodesFiberCapacitance

The invention provides a negative lead paste for a lead-carbon battery. The negative lead paste is prepared from the following components in parts by weight: 1-99 parts of lead powder, 0.1-90 parts of a carbon-oxide composite material, 0-0.5 part of carbon black, 0.1-2 parts of barium sulfate, 0.05-0.1 part of a short fiber and 0.01-3.2 parts of an organic swelling agent. Oxides on the surface and in holes of the carbon material of the lead paste are tightly adsorbed to the periphery of the carbon material in an ionic form, and are recombined on the surface and in the holes of the carbon material in curing and drying processes; and a tiny oxide film is evenly attached to the active surface and the holes of the carbon material by 'dissolving and recombination', so that the bonding degree of the carbon material and the oxides is greatly improved; the conduction characteristics and the capacitance characteristics of the carbon material are put into a fully play; and hydrogen evolution on the surface of the carbon material is limited.

Owner:CHINA ELECTRIC POWER RES INST +3

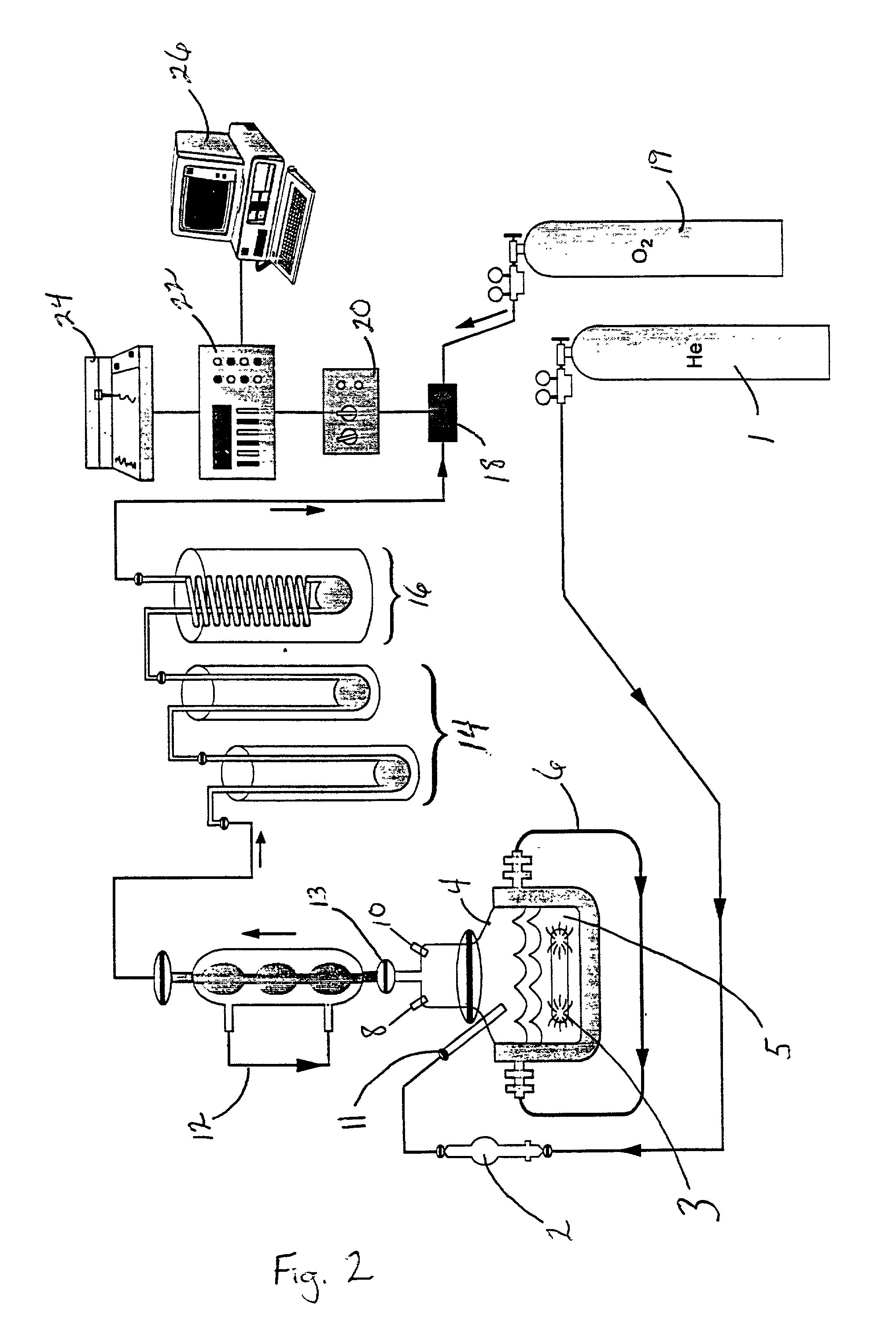

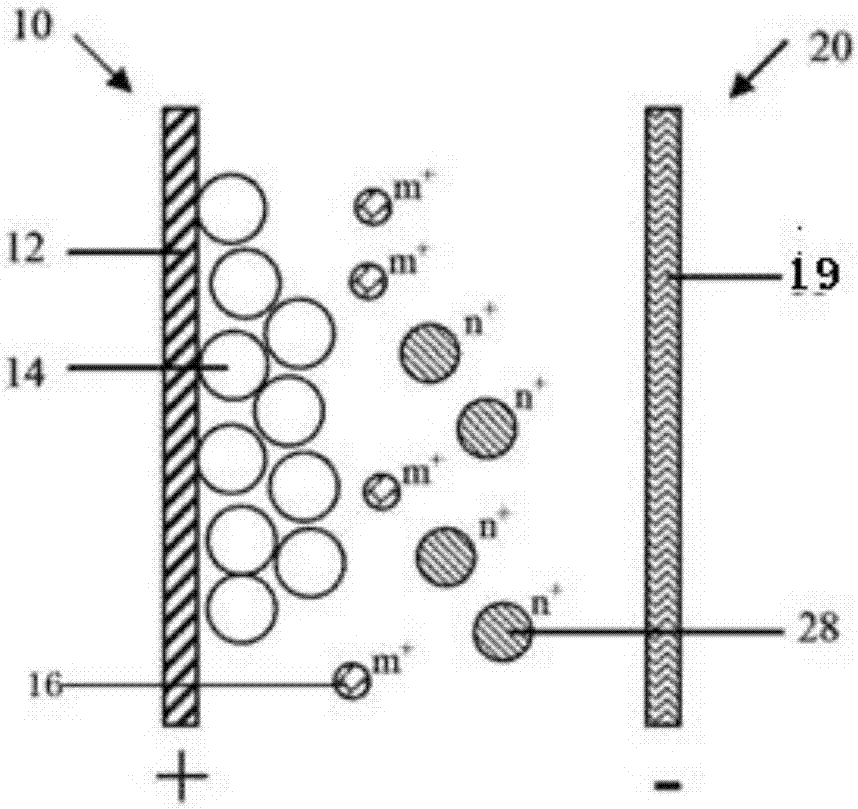

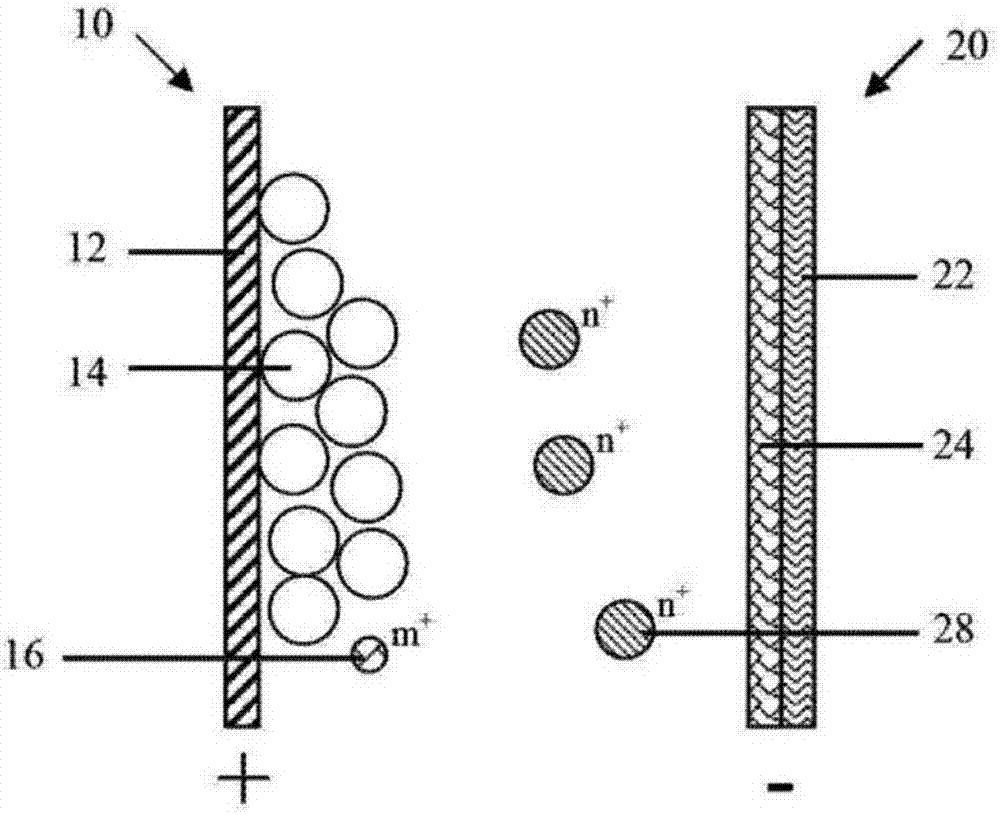

Hydrogen-powered energy-producing device and system for continous production of hydrogen

InactiveUS20020090539A1Easy and relatively inexpensive to regenerateReduce hydrogen evolutionFuel cell auxillariesHydrogen productionFuel cellsHydrogen

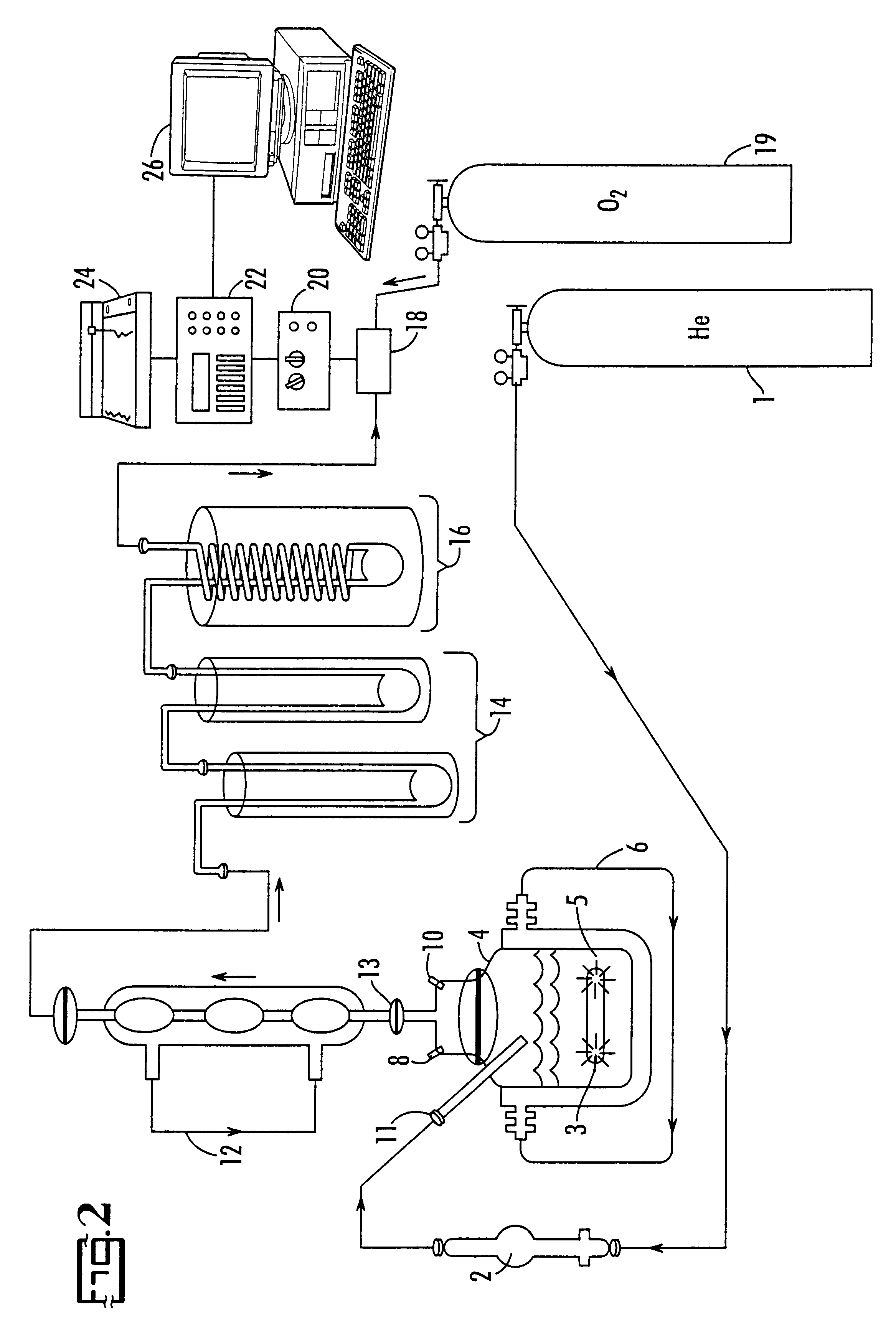

The present invention is an energy-producing device powered by a system for the continuous production of hydrogen comprising a reaction chamber containing reactant components under anaerobic conditions whereby hydrogen is continually produced when the reactant components react with one another. The device further comprises a fuel cell adjacent the reaction chamber wherein the hydrogen produced is to be used as fuel and is diffused into the fuel cell; the fuel cell has positive and negative electrodes to convert the hydrogen into energy. The present invention also includes a hydrogen-generating system for the continuous and sustained production of hydrogen.

Owner:UT BATTELLE LLC

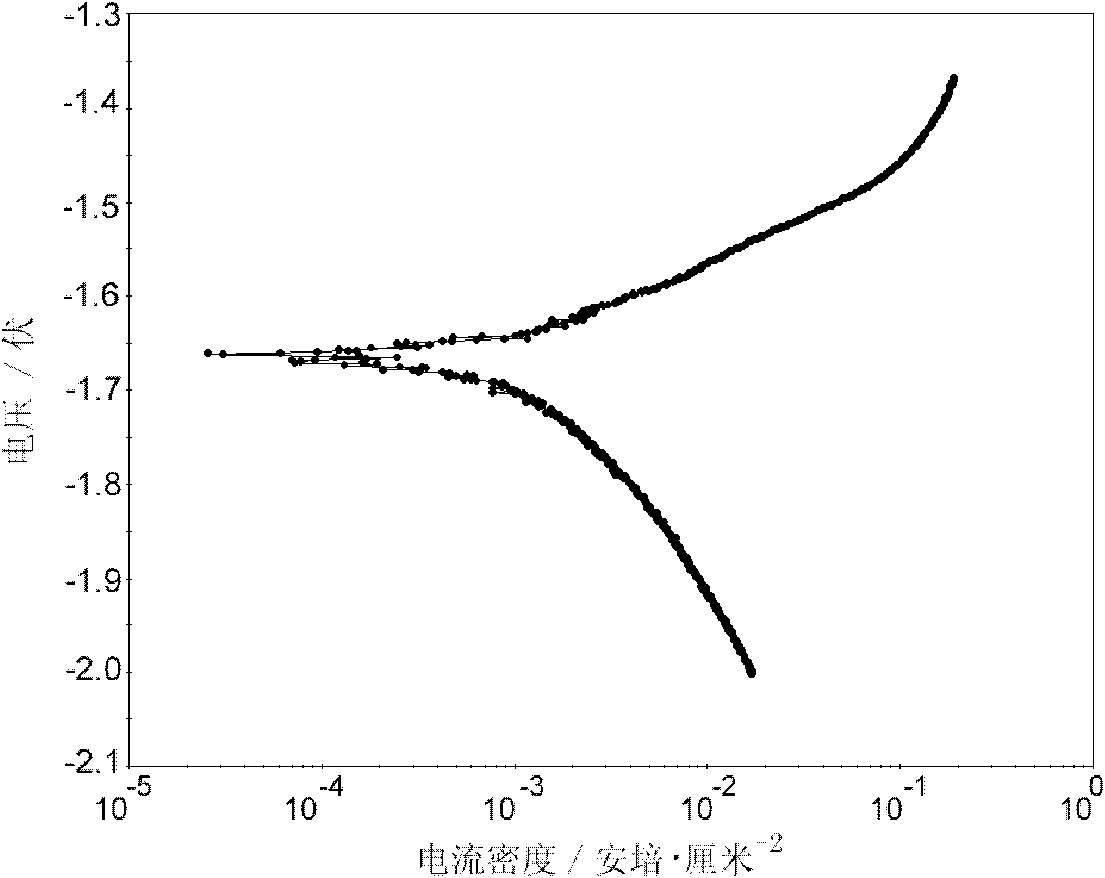

Water system secondary battery

InactiveCN107403968AImprove operational safetyReduce manufacturing costCell electrodesSecondary cellsCharge dischargeSolvent

The invention relates to a water system secondary battery, in particular an alkaline water system secondary lithium ion battery and a preparation method and an application thereof. The invention also relates to electrolyte liquid for the water system secondary battery. The battery comprises an anode, a cathode and the electrolyte liquid. The active substance of the anode is ions, through which a NMC type active substance can be reversibly deviated or embedded; the electrolyte liquid comprises at least one solvent capable of dissolving electrolyte and ionizing electrolyte; the electrolyte comprises ions, through which the active substance of the anode can be reversibly deviated or embedded; the pH of the electrolyte liquid is greater than 8, and the charge-discharge voltage range is 1.40-2.10V. The oxidation corrosion of carbon in an anode conductive agent can be inhibited, and the hydrogen evolution phenomenon of cathode can be alleviated.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

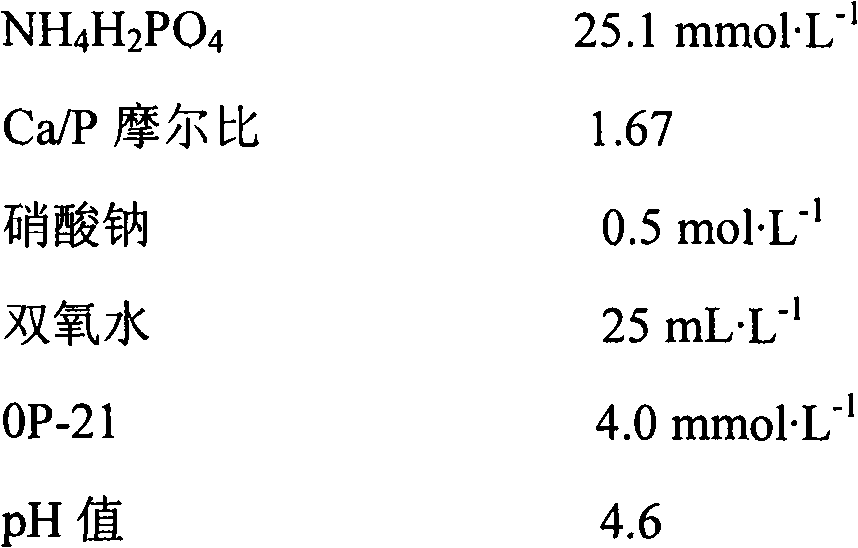

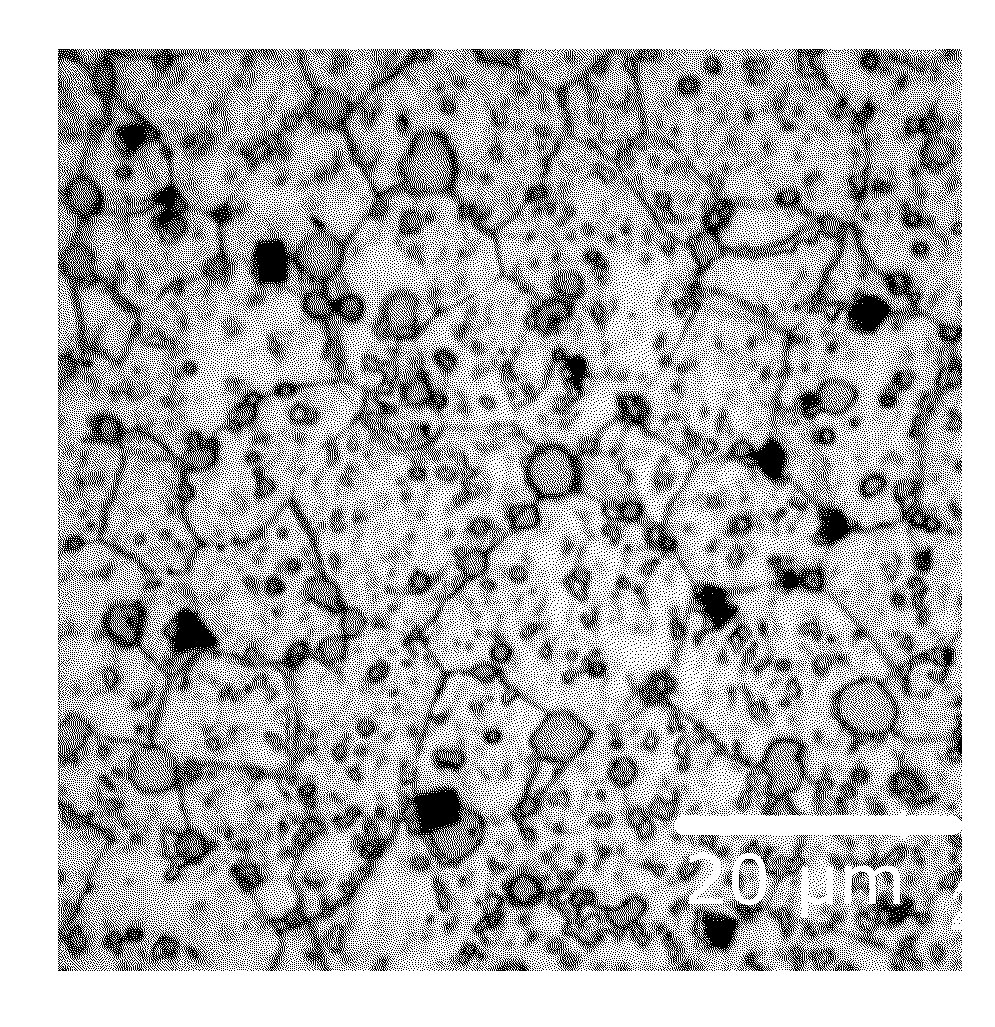

Electrodeposition preparation method for biomedical titanium base hydroxyapatite composite material

InactiveCN103014801ASimple operation processEasy to controlElectrolytic inorganic material coatingSupporting electrolyteApatite

The present invention discloses a preparation method for electrodeposition of a hydroxyapatite coating on the surface of titanium or a titanium alloy. The method comprises: adopting a pretreated titanium substrate or a pretreated titanium alloy substrate as a cathode, adopting a platinum-plated titanium mesh as an anode, heating an electroplating solution to a constant temperature of 40-80 DEG C, and adopting a constant current manner or a constant potential manner under a magnetic stirring condition to carry out electrodeposition, wherein a current density is 1.0-50.0 mA.cm<-2>, a deposition potential is 1.0-10.0 V, the electroplating solution comprises 20.2-80.0 mmol.L<-1> of Ca<2+> and 10.0-50.0 mmol.L<-1> of H2PO4<->, a Ca / P molar ratio is 1.6-2.0, a supporting electrolyte concentration is 0.1-1.0 mol.L<-1>, and the pH value is 4.2-5.0. According to the present invention, the hydroxyapatite coating prepared through electrodeposition by using the constant current manner or the constant potential manner has characteristics of fine crystal, smooth surface, strong bonding force with the substrate, good biological activity and mechanical property. The preparation method for the titanium base hydroxyapatite composite material has characteristics of mild reaction condition, avoidance of influence on material biological activity by a high temperature treatment, simple process, and low equipment investment, wherein a series of problems caused by expensive equipment and complex operation of the existing method are overcome with the preparation method.

Owner:TIANJIN XUANZHEN BIOMEDICAL TECH DEV

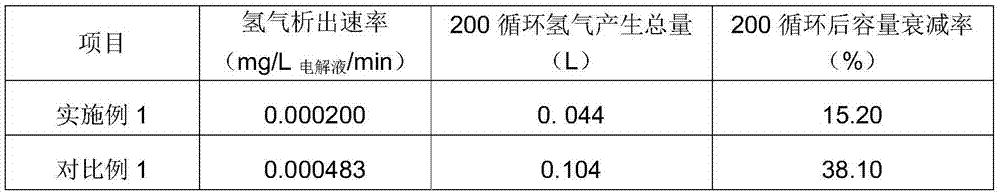

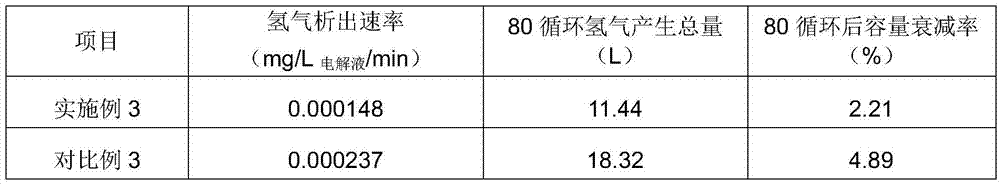

Method for eliminating impurity influence of all-vanadium redox flow battery electrolyte

InactiveCN106997958ASave or reduce cleaning stepsSimple operation processElectrolyte stream managementRegenerative fuel cellsPhosphoric acidOrganic phosphates

The invention discloses a method for eliminating impurity influence of an all-vanadium redox flow battery electrolyte. The method comprises the steps of adding a complexing agent into the electrolyte, and fully stirring the electrolyte, wherein the complexing agent is phosphoric acid, inorganic phosphate, hydramine, amino carboxylate, hydroxy carboxylate or organic phosphate. By the method, the steps of impurity elimination during the preparation process of the electrolyte is omitted or reduced, the operation process is simple, the product is rich in raw material, complicated impurity elimination equipment is not needed to be matched, the impurity elimination cost is low, and the method is suitable for application on a large scale; by a mode of adding the complexing agent, impurity metal ions form a complexity body, a reaction electrical pair shifts out of a reaction potential section of an active substance of the all-vanadium redox flow battery electrolyte, the hydrogen evolution promotion effect of the metal ions is eliminated, the hydrogen evolution quantity of the redox flow battery is reduced, the capacity attenuation is reduced, and the lifetime of the redox flow battery is prolonged; and impurity ions introduced during the construction, running and maintenance process of the redox flow battery can be rapidly eliminated, and the method is simple and convenient and is suitable for promotion and application.

Owner:DALIAN RONGKE POWER

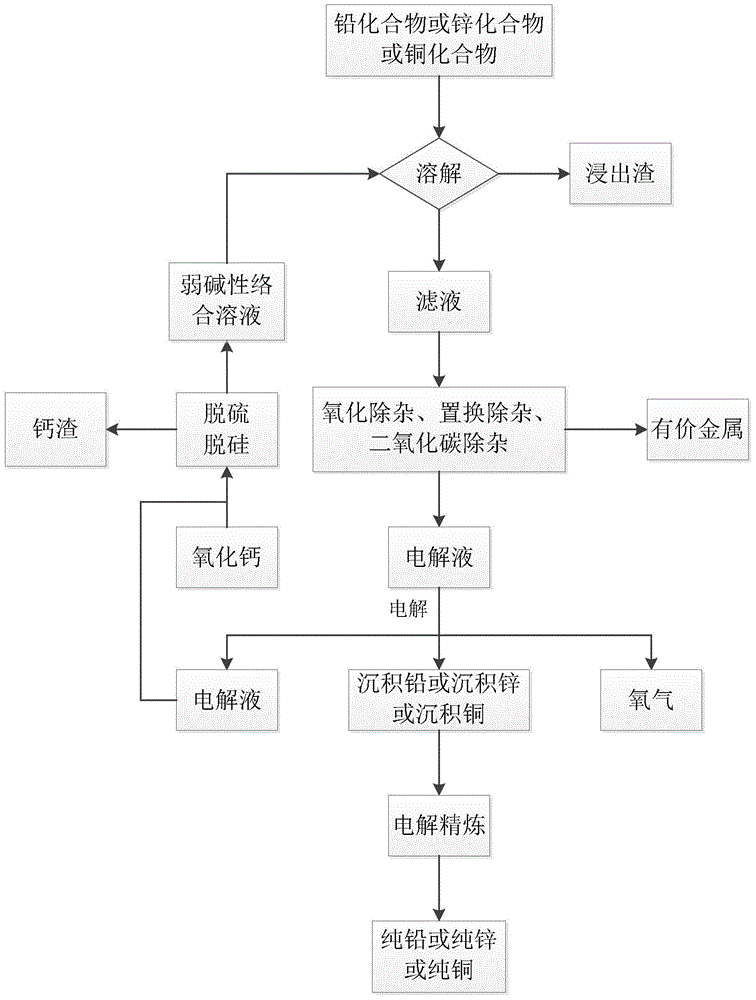

Method for electrolyzing metals through wet method

InactiveCN105274565AImprove leaching rateIncrease profitPhotography auxillary processesProcess efficiency improvementElectrolysisOxygen

The invention provides a process for electrolyzing and refining lead, zinc and copper through a wet method. The process includes the specific steps that an alkalescent complexing solution with high complexing capacity is selected as a leaching solution and all valuable metals are leached out; impurities of the leaching solution are removed through a metal replacement mode; deposited lead or deposited zinc or deposited copper and oxygen are obtained through an electrolytic method; then the solution is subjected to desulfuration and desilicication through calcium oxide or calcium hydroxide; and finally, the lead or the zinc or the copper is obtained after being refined. The alkalescent complexing solution is adopted for leaching and electrolyzing, so that the problems that the leaching rate is low and metal silicates and ferrates are hard to dissolve in terms of current metal smelting with the wet method are solved. Compounds of calcium or barium are adopted for desulfuration of metal sulfates, so that the problem of high desulfuration cost caused by current desulfuration through sodium carbonate or sodium hydroxide is solved. The potential of hydrogen (pH) value of the alkalescent complexing solution is controlled to be 7.5-13.5, the electrolytic voltage is substantially lowered, and the energy consumption is effectively reduced.

Owner:北京中金瑞丰环保科技有限公司

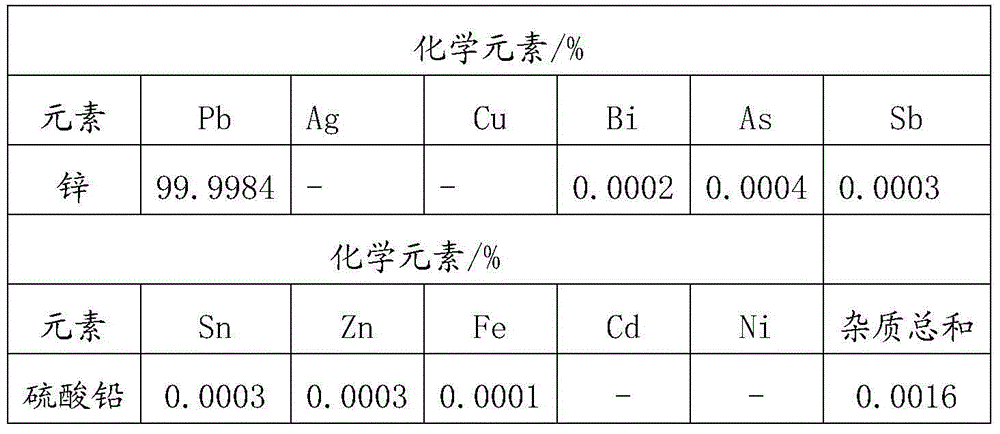

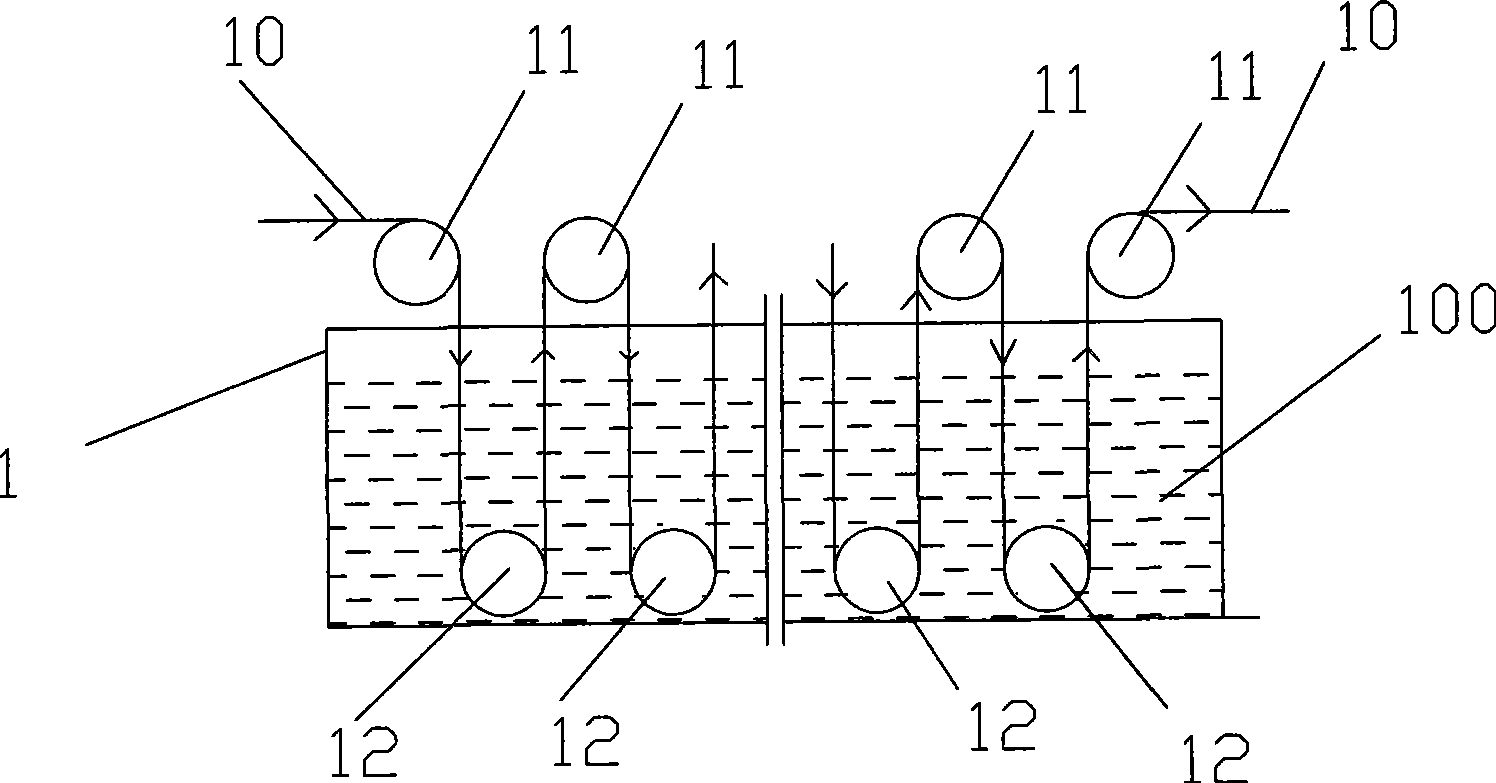

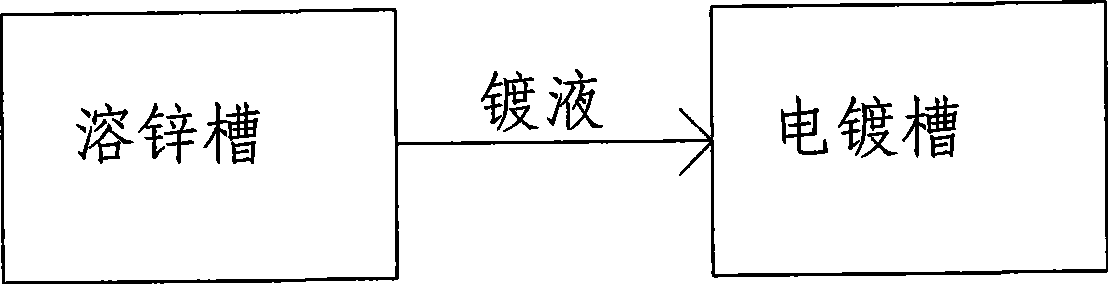

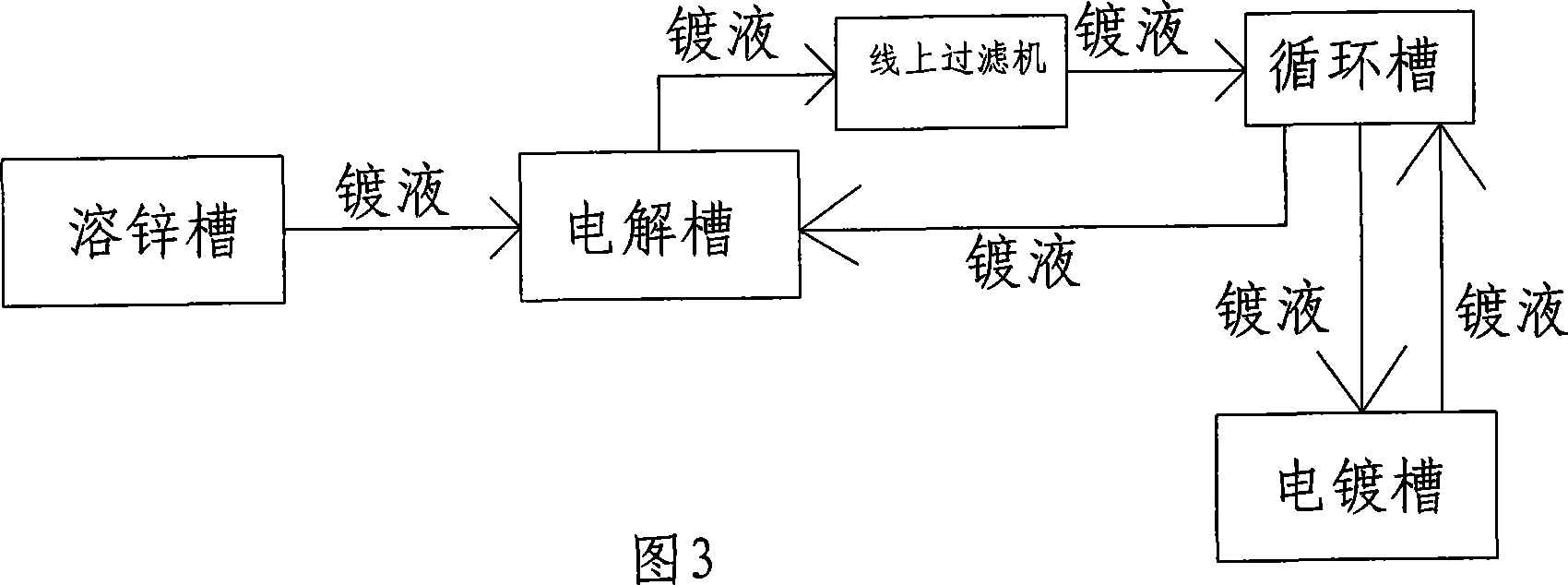

Apparatus and technology for controlling and improving plating solution PH value on fingerprint resistant production chain

The invention provides a technical method for controlling and raising the PH value of galvanizing solution on a fingerprint resistant continuous and automatic production line of the electro-galvanizing and roller coating of a rolled plate; the galvanizing solution rich in zinc ions enters a galvanizing bath from a dezincification bath; the technique is characterized in that: after entering the galvanizing bath from the dezincification bath, the galvanizing solution enters a circulating tank after going through an on-line filtering machine and then enters the galvanizing bath from the circulating tank; the galvanizing solution in the galvanizing bath returns to the galvanizing bath through the circulating tank; and the galvanizing solution is electrolyzed by the current density of 0.1A / dm<2> to 0.3A / dm<2> in an electrobath. The electrobath is internally provided with three anodes and two cathodes at intervals. The technical proposal has the advantages of not only removing hazardous metal impurities, but also increasing dezincification speed, particularly properly raising the PH value, increasing the overpotential of hydrogen, reducing hydrogen evolution, fining electro-galvanizing layers and reducing electric energy consumption, thereby greatly improving product quality.

Owner:长江润发(江苏)薄板镀层有限公司

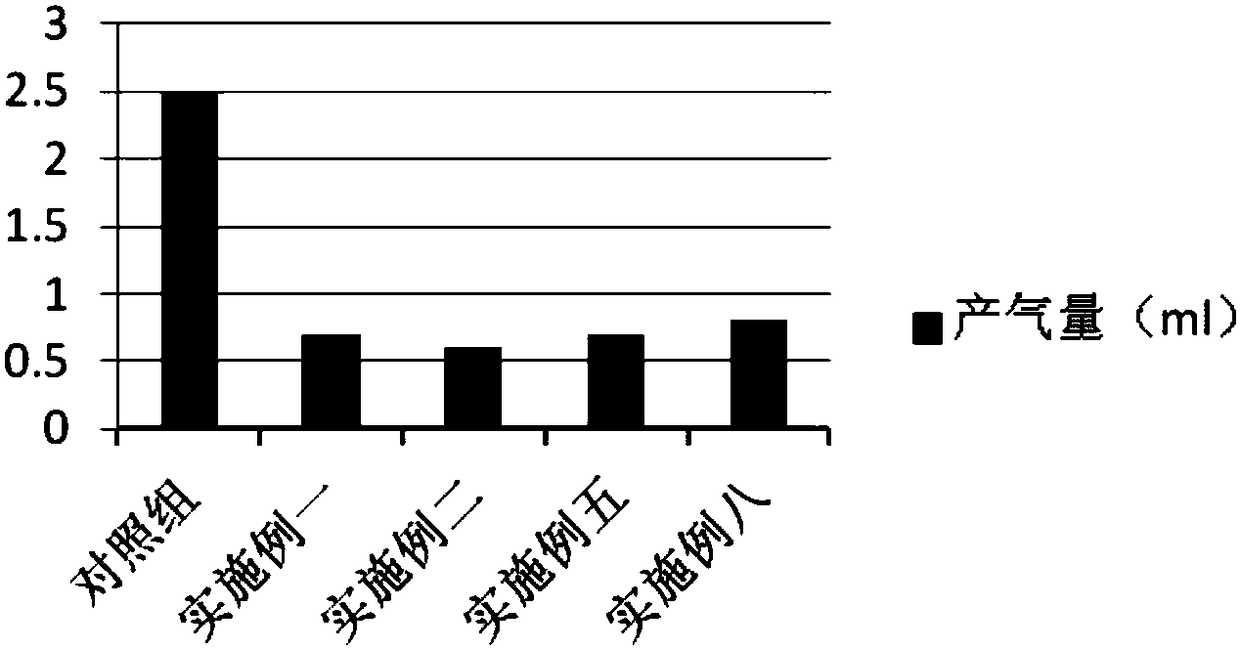

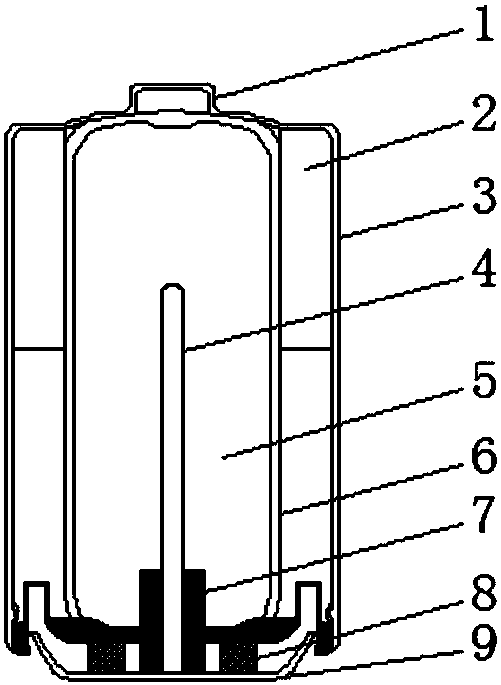

Alkaline zinc-manganese dioxide cell

InactiveCN108598516AImprove discharge performanceReduce hydrogen evolutionDry cellsElectrolysisPolyethylene glycol

The invention relates to the field of alkaline zinc-manganese dioxide cells, and specifically relates to an alkaline zinc-manganese dioxide cell. The alkaline zinc-manganese dioxide cell comprises a positive electrode cap (1), a positive electrode ring (2), a steel shell (3), a current collector copper nail (4), a negative electrode zinc gel (5), diaphragm paper (6), a sealing ring (7), a supportring (8) and a negative electrode bottom (9); the positive electrode ring (2) is composed of electrolytic manganese dioxide, conductive agent graphite and electrolyte; and the negative electrode zincgel (5) comprises zinc powder, a binding agent, an expanding agent, an electrolyte potassium hydroxide solution and polyethylene glycol 2000. According to the alkaline zinc-manganese dioxide cell provided by the invention, the discharge performance of the alkaline zinc-manganese dioxide cell is not influenced or even slightly improved, and the problem of expansion of the zinc gel is effectively solved; and meanwhile, the hydrogen content of the cell is remarkably reduced, and the liquid leakage risk of the cell is greatly reduced, therefore, the discharge performance of the cell is effectivelyimproved, the storage life of the cell is prolonged, and the safety performance of the cell is remarkably improved.

Owner:GUANGDONG LIWANG NEW ENERGY

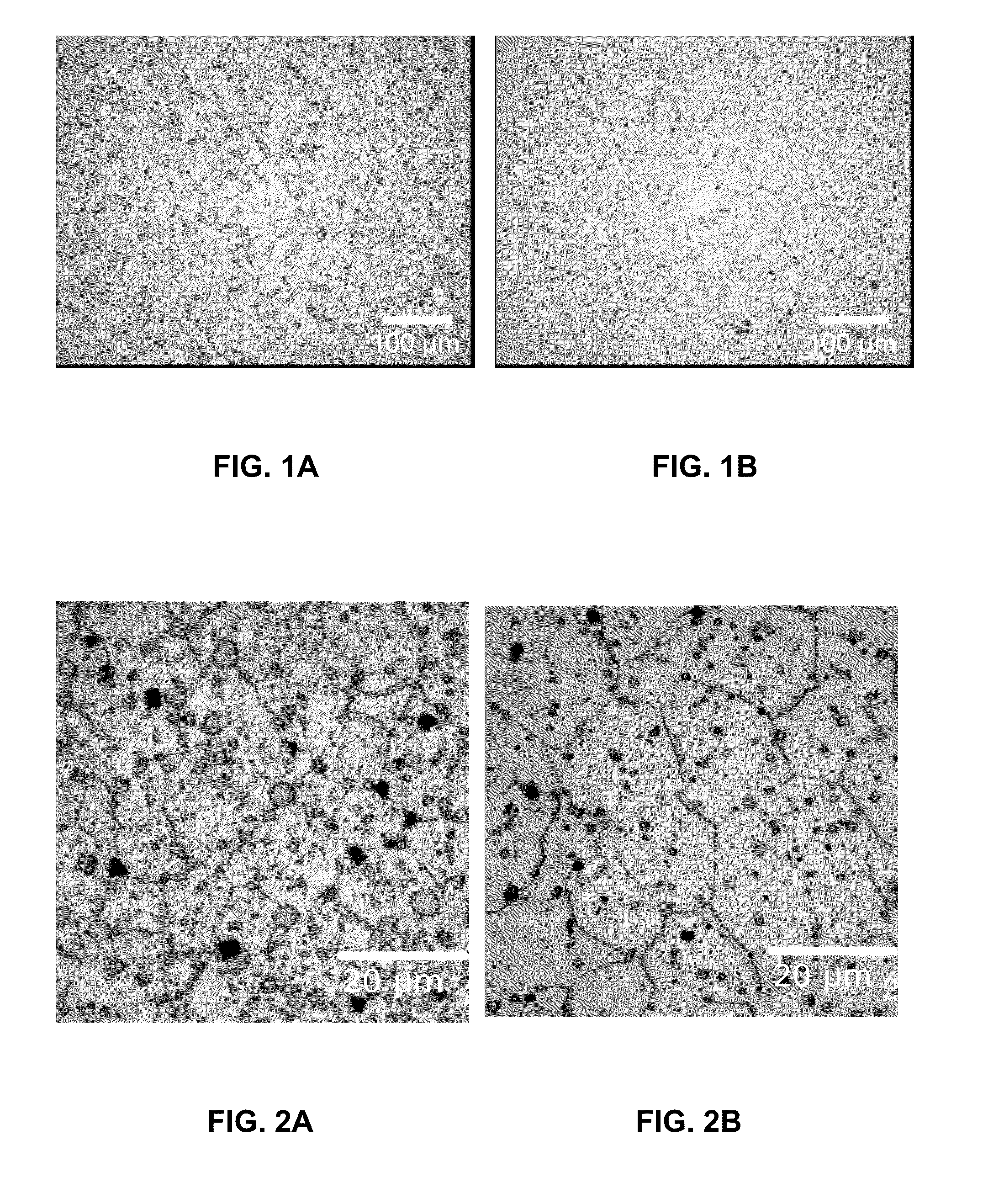

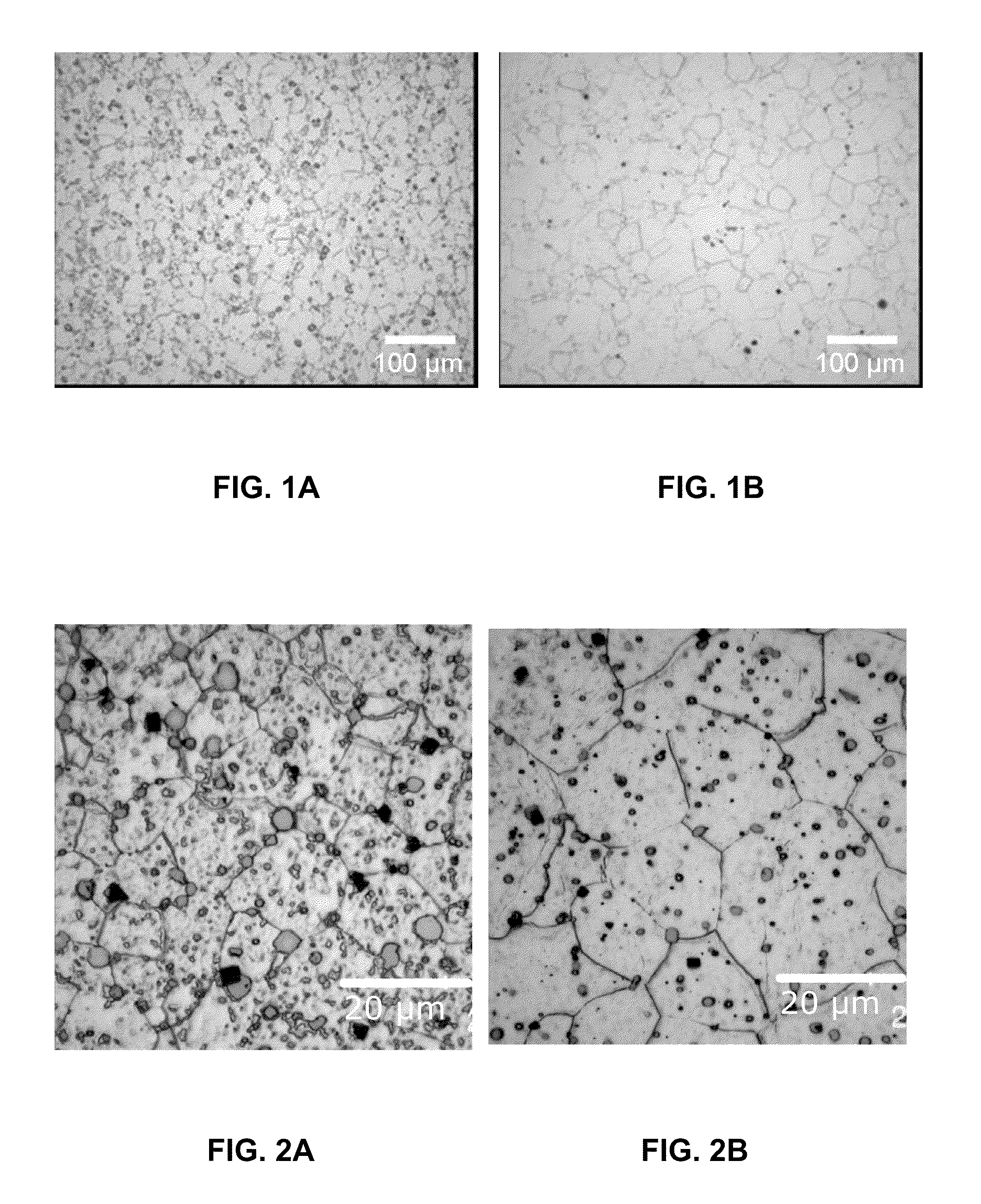

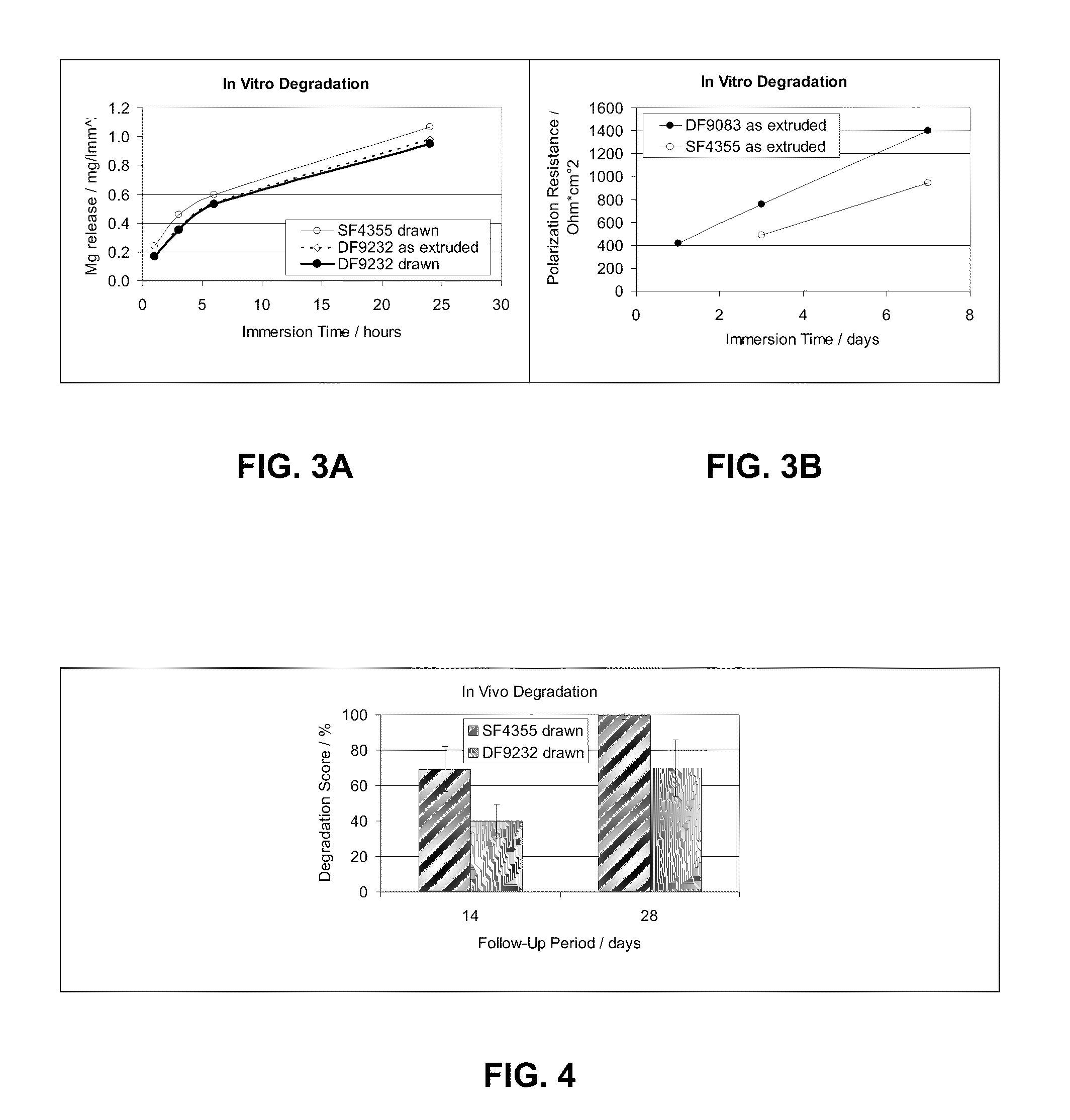

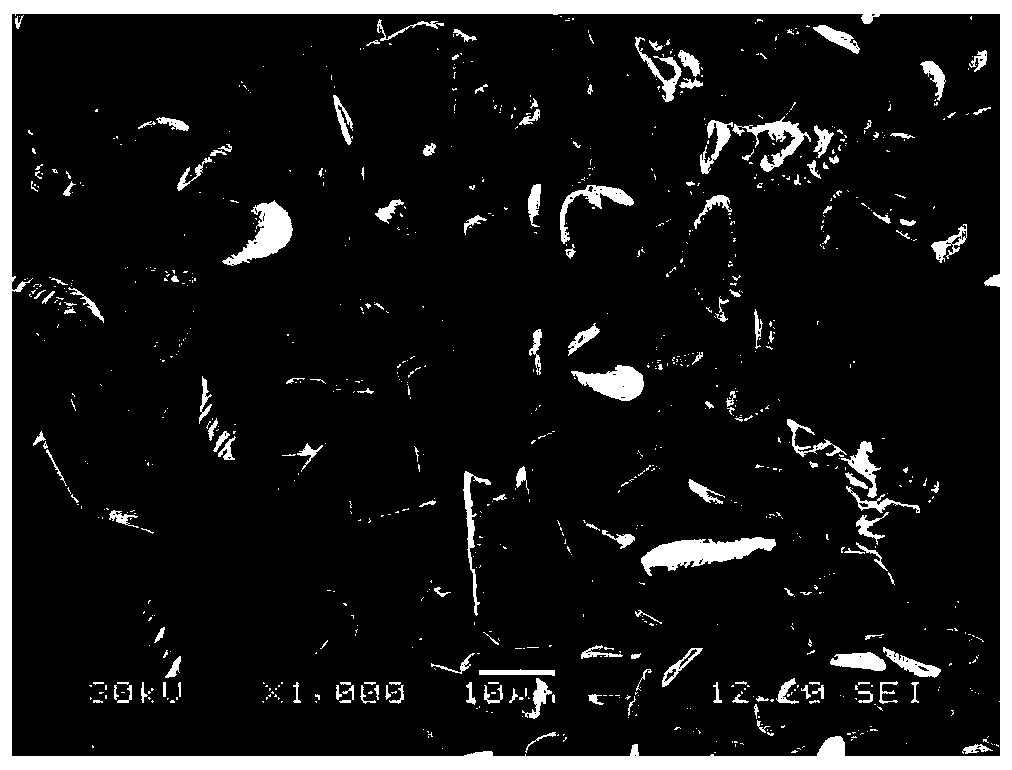

Implant made of a biodegradable magnesium alloy

ActiveUS20130060326A1Easy to processImprove material performanceStentsSurgeryMaterials scienceBiodegradable magnesium

An implant made in total or in parts of a biodegradable magnesium alloy consisting of Y: 2.0-6.0% by weight, Nd: 1.5-4.5% by weight, Gd: 0-4.0% by weight, Dy: 0-4.0% by weight, Er: 0-4.0% by weight, Zr: 0.1-1.0% by weight, Li:0-0.2% by weight, Al: 0-0.3% by weight, under the condition that a) a total content of Er, Gd and Dy is in the range of 0.5-4.0% by weight and b) a total content of Nd, Er, Gd and Dy is in the range of 2.0-5.5% by weight, the balance being magnesium and incidental impurities up to a total of 0.3% by weight.

Owner:BIOTRONIK AG

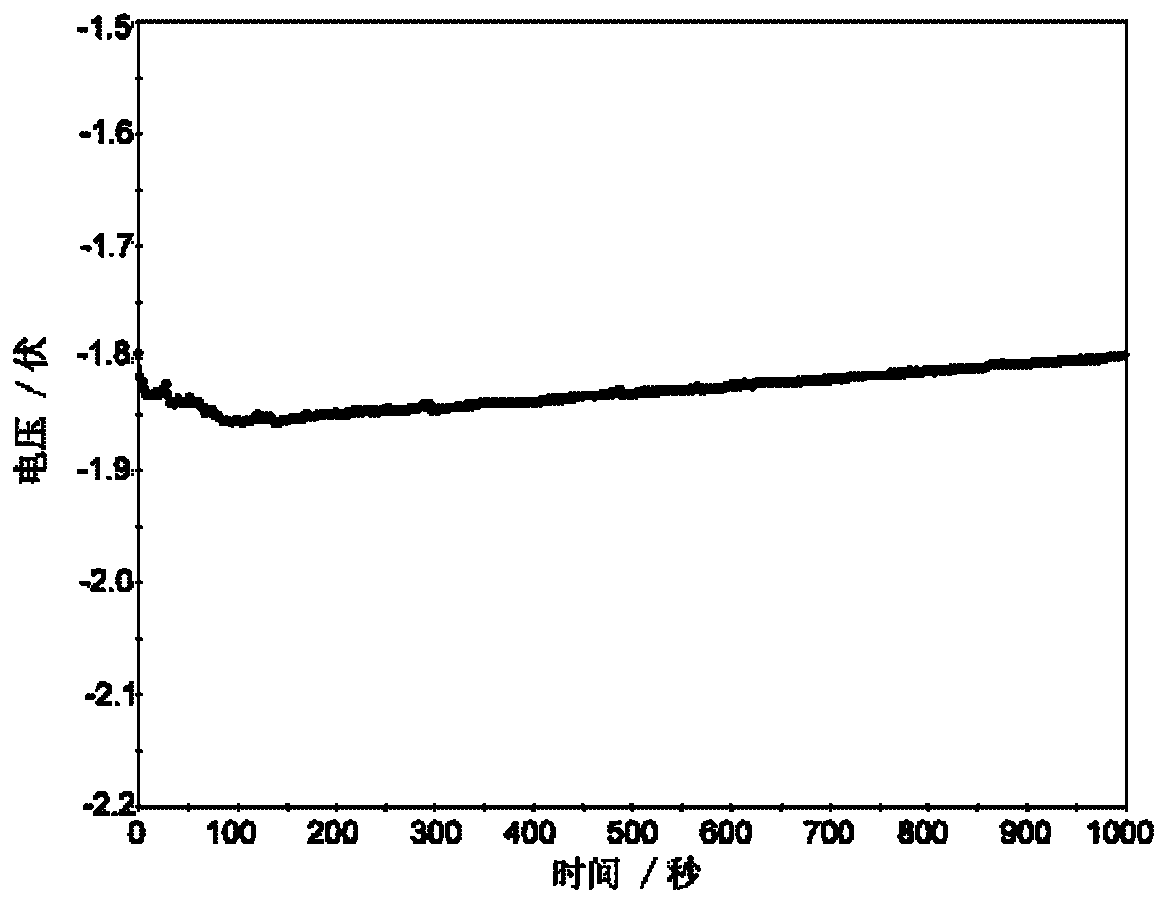

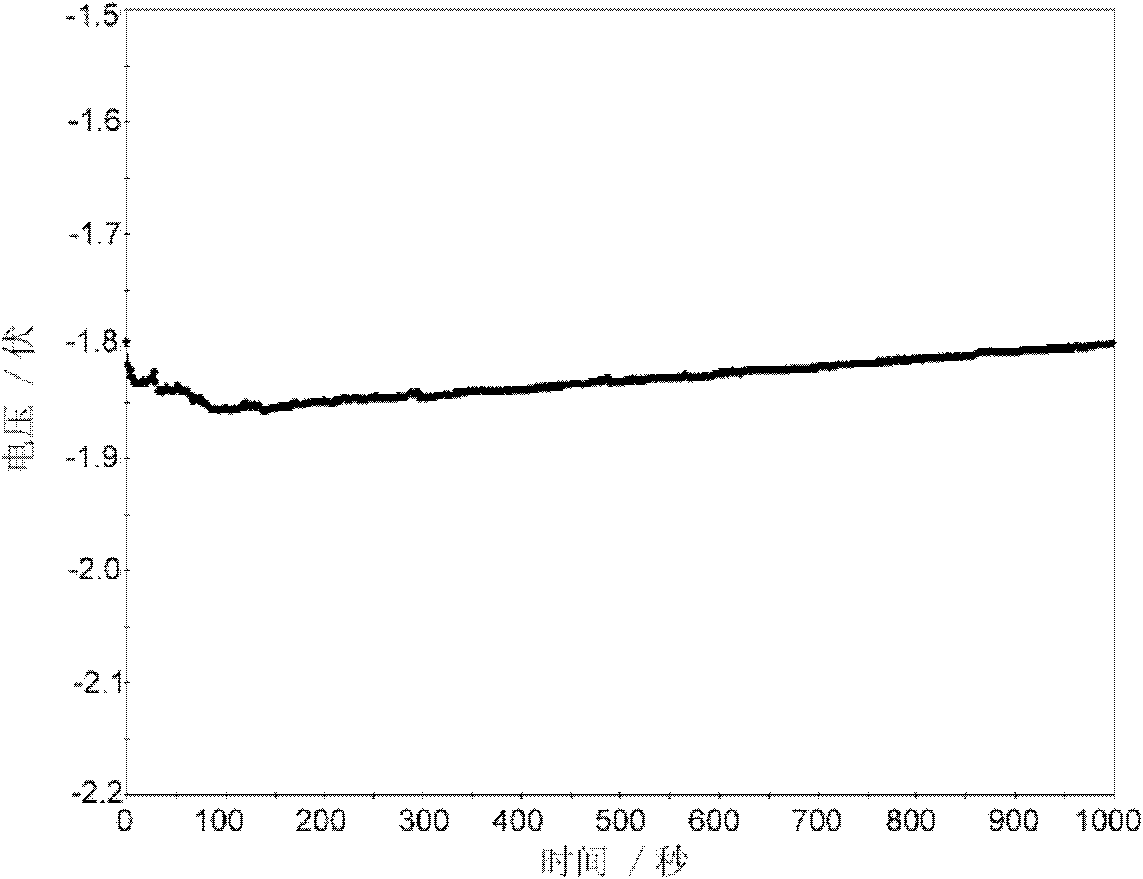

Aluminum anode material for seawater power battery

InactiveCN101814595AImprove electrochemical activityLittle electrochemical activityPrimary cell electrodesSeawaterTin

The invention discloses an aluminum anode material for a seawater power battery, which adopts aluminum as a base body, and comprises the following components in percentage by weight: 0.01 to 1.0 percent of activating element mercury, 0.05 to 2.0 percent of gallium, 0.05 to 2.0 percent of magnesium, 0.01 to 1.0 percent of tin and 0.01 to 1.0 percent of zinc. By designing the alloy composition and researching the electrochemical performance and the element activating mechanism, the alloy elements and compositions which can reduce the passivation and polarization of the aluminum anode and can improve the electrochemical activity and corrosion resistance of the aluminum anode material are selected, and the aluminum anode material for the large-power seawater-activating power battery with the advantages of short activating time, high current efficiency, stable discharging, less hydrogen evolution quantity, long service life and the like is prepared.

Owner:CENT SOUTH UNIV

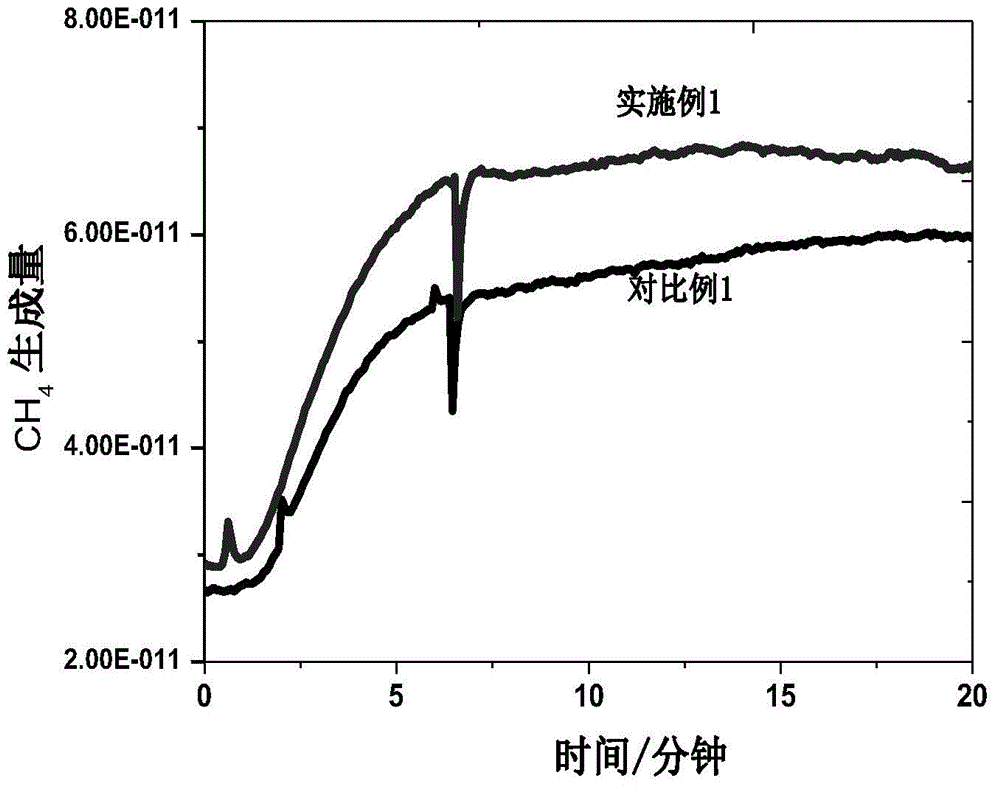

Preparation method of electrode used for CO2 electrochemical reduction reaction

The invention relates to a preparation method of an electrode used for CO2 electrochemical reduction reaction. The electrode is prepared with foam copper, a copper wire mesh, a copper foil, a copper plate, a titanium wire mesh or a titanium plate as a substrate. The preparation method includes the steps of uniformly mixing a copper precursor solution being 0.01-2.0 M in concentrate and a template agent being 0.01-1.5 M in concentrate according to the molar ratio of 5:1-1:20 and magnetically stirring the solution for more than 30 min; moving the solution into a reaction kettle, immersing the substrate into the solution and performing a sealing reaction for 4-12 h; moving the substrate out from the reaction kettle, washing and drying the substrate, and performing thermal treatment to the substrate at 300-800 DEG C for 1-5 h under protection of an inert gas or an oxidizing atmosphere to obtain the substrate to which metal oxides are attached; and performing electrochemical reduction to the substrate to which metal oxides are attached in an acidic electrolyte to obtain the electrode. The preparation method is simple in preparation method and is suitable for large-scale production. The electrode is large in specific surface area and is high in CO2 oxygen reduction catalytic performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Implant made of a biodegradable magnesium alloy

InactiveUS20130041455A1Easy to processImprove material performanceStentsSurgeryBiodegradable magnesium

The present invention relates to implants made of a biodegradable magnesium alloy. The inventive implant is made in total or in parts of a biodegradable magnesium alloy comprising:Y: 0-10.0% by weightNd: 0-4.5% by weightGd: 0-9.0% by weightDy: 0-8.0% by weightHo: 0-19.0% by weightEr: 0-23.0% by weightLu: 0-25.0% by weightTm: 0-21.0% by weightTb: 0-21.0% by weightZr: 0.1-1.5% by weightCa: 0-2.0% by weightZn: 0-1.5% by weightIn: 0-12.0% by weightSc: 0-15.0% by weightincidental impurities up to a total of 0.3% by weightthe balance being magnesium and under the condition thata) a total content of Ho, Er, Lu, Tb and Tm is more than 5.5% by weight;b) a total content of Y, Nd and Gd is more than 2% by weight; andc) a total content of all alloy compounds except magnesium is more than 8.5% by weight.

Owner:BIOTRONIK AG

Peo coating on mg screws

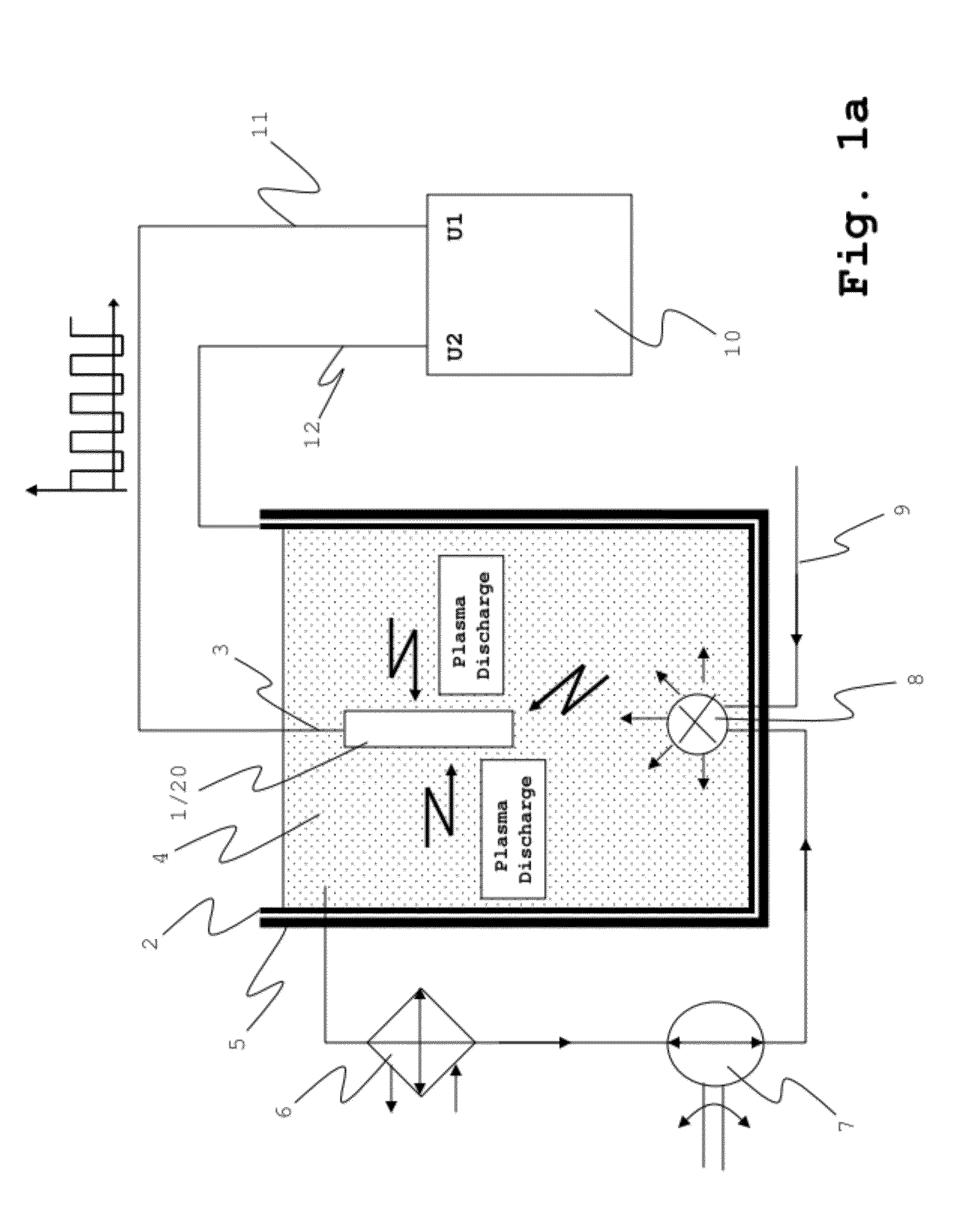

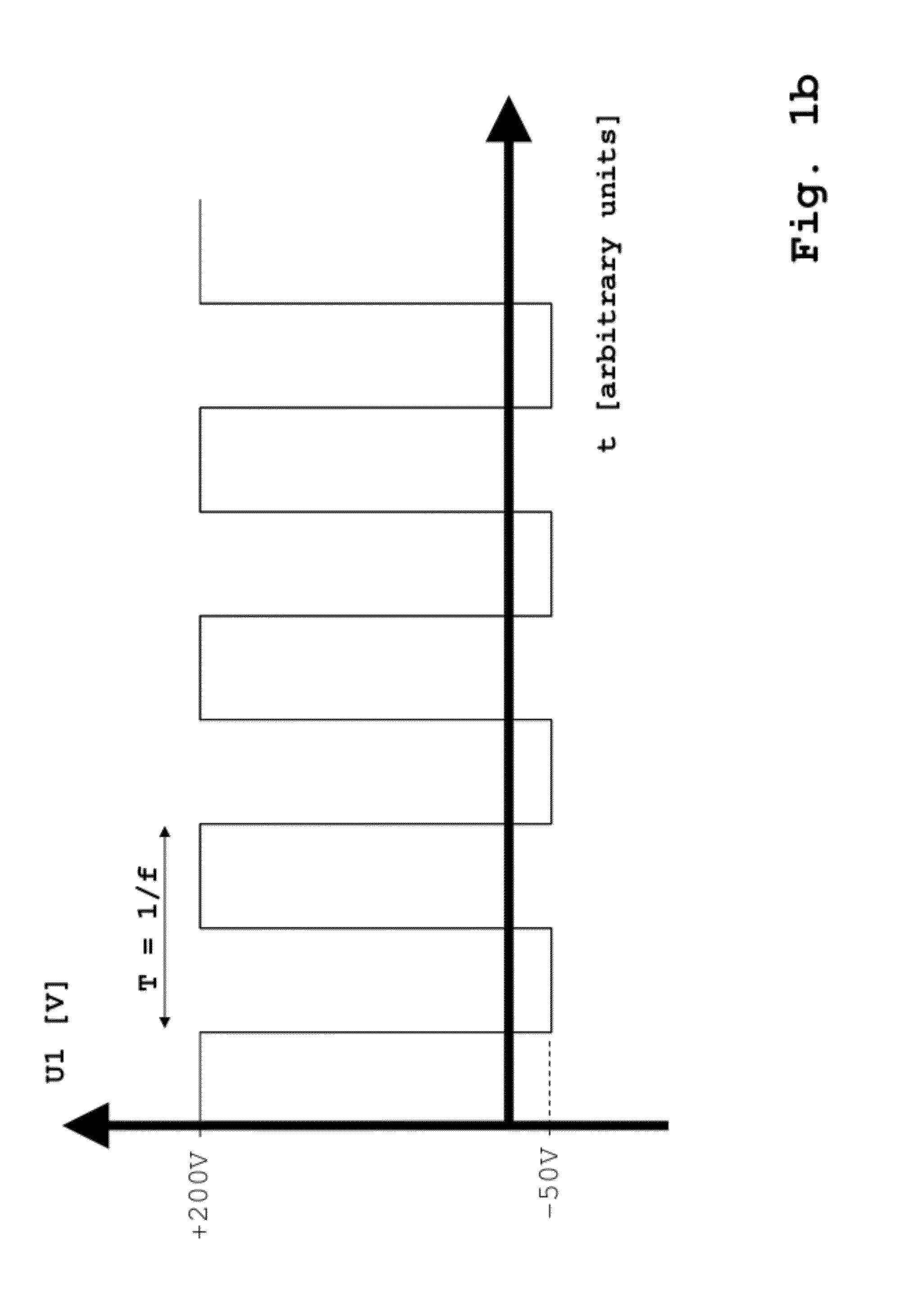

ActiveUS20120150295A1Avoid pollutionGood biocompatibilityAnodisationSurgeryPlasma electrolytic oxidationOsseointegration

The present invention relates generally to a bio-degradable implant based on magnesium having a reduced corrosion rate and to a method for the production of such an implant. It is a a method for treating a surface of a bio-degradable metallic implant comprising the following steps: providing a dispersed system comprising a colloid-dispersed apatite and adding an apatite powder to the dispersed system, subjecting an implant to the dispersed system such that a surface of the implant which is to be treated is immersed in the dispersed system wherein the implant comprises a magnesium based alloy, applying an AC voltage difference between the implant as a first electrode and a second electrode positioned in the dispersed system for generating a plasma electrolytic oxidation on the immersed surface of the implant so that the immersed surface is converted to an oxide film which is at least partially covered by apatites formed by the colloid-dispersed apatite and the apatite powder. The evolution of corrosion induced hydrogen gas evolution is decreased and osseointegration is improved.

Owner:AAP IMPLANTATE AG

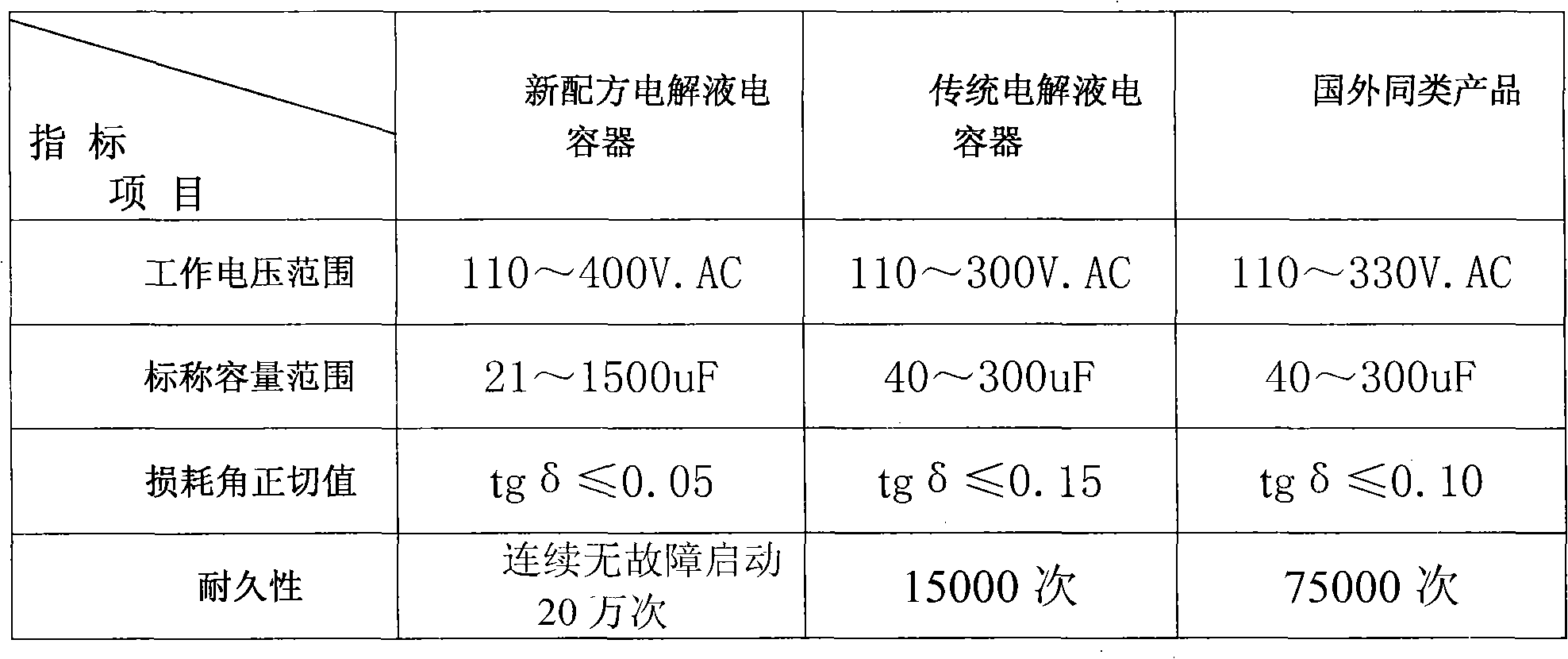

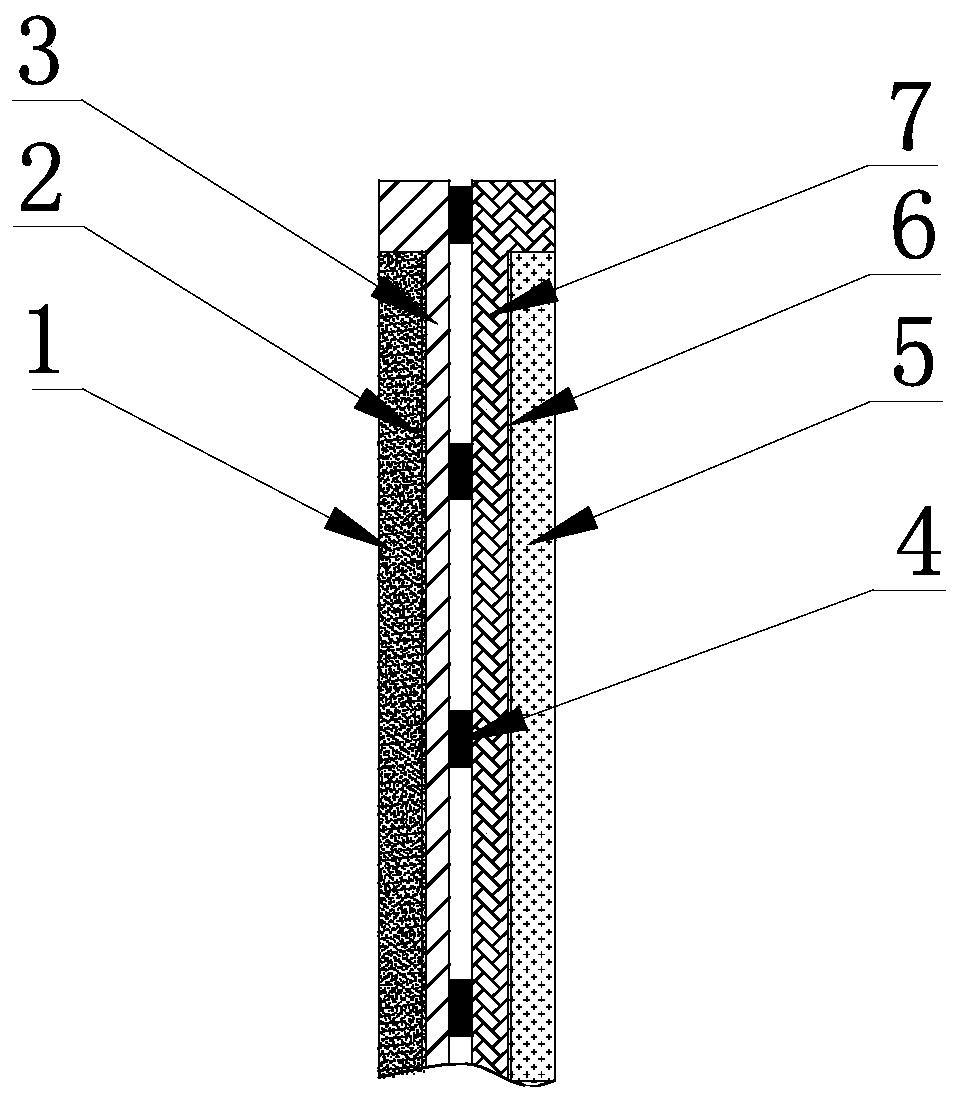

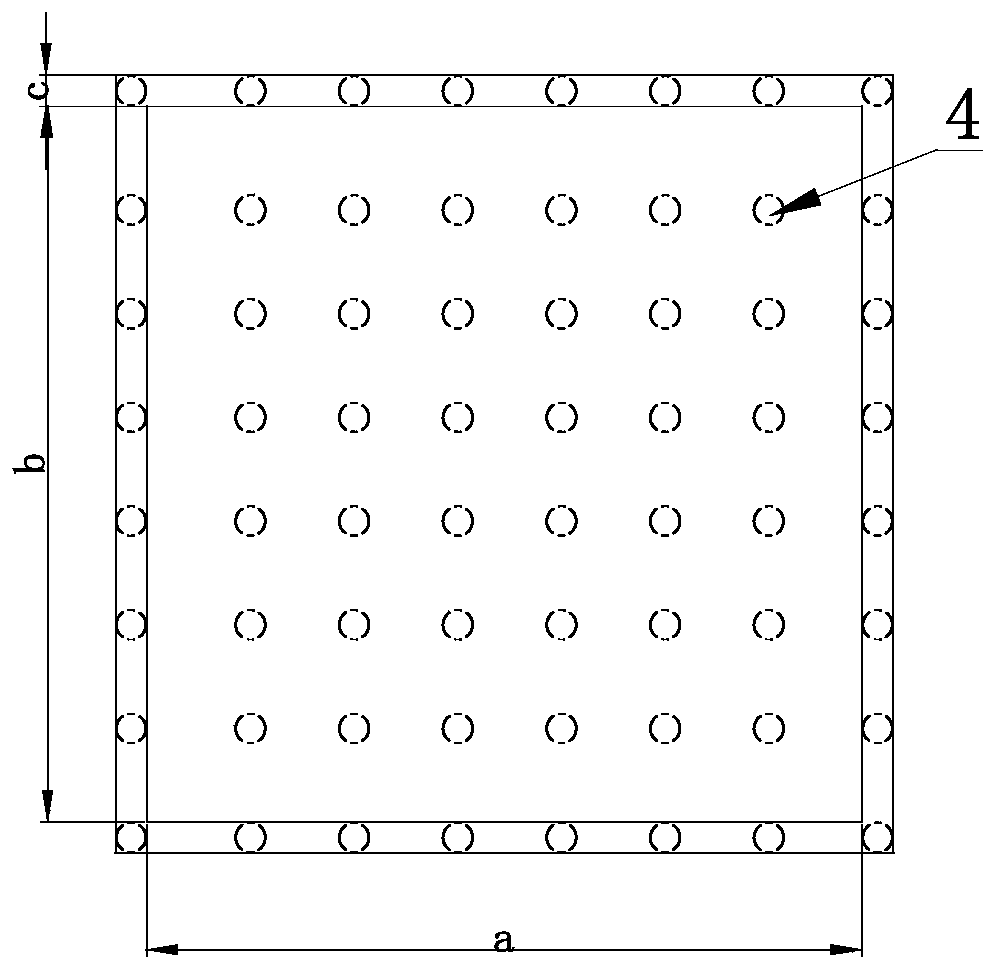

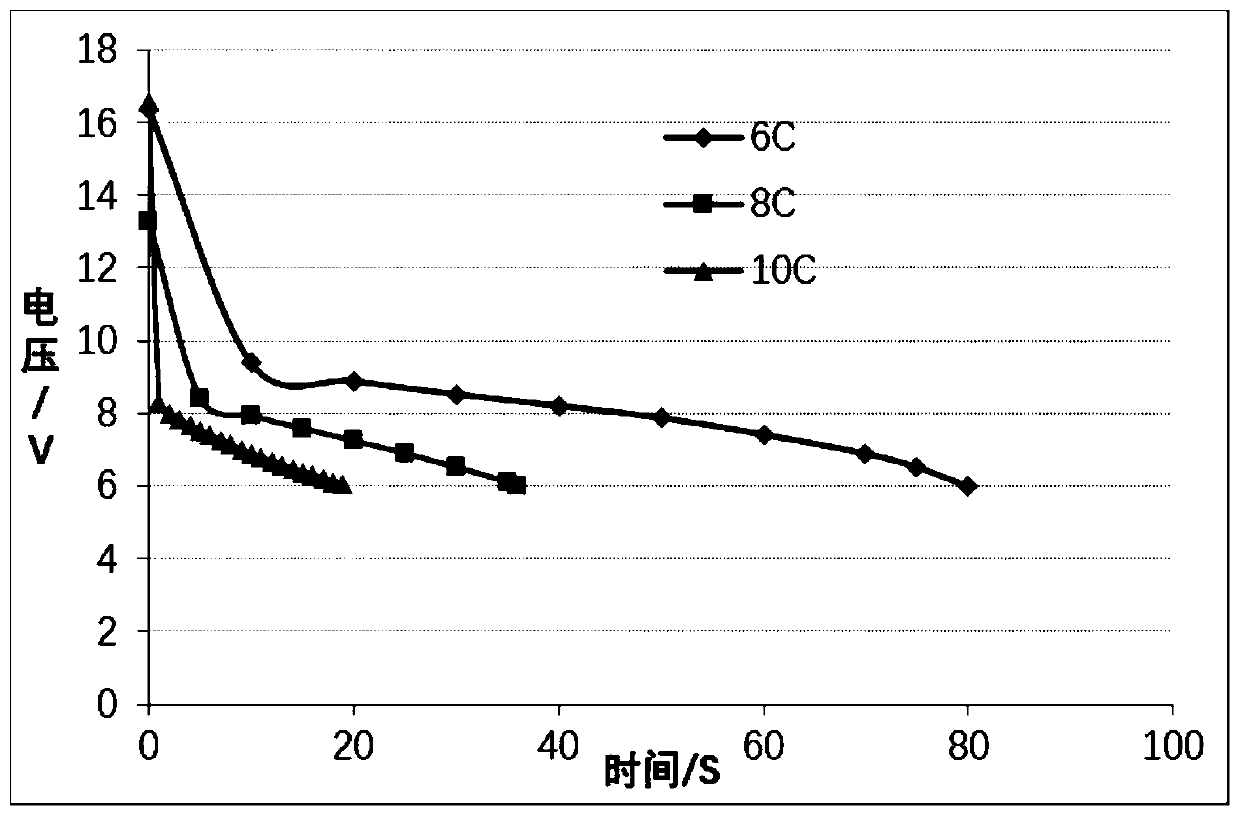

Aluminum electrolytic capacitor electrolyte and preparation method thereof

ActiveCN101894673AReduce water productionReduce hydrogen evolutionElectrolytic capacitorsAmmonium pentaborateAmmonium adipate

The invention relates to an aluminum electrolytic capacitor electrolyte and a preparation method thereof, wherein the electrolyte is prepared from the following raw materials in percentage by weight: 70% of glycol, 1.5% of ammonium dihydrogen phosphate, 8% of ammonium pentaborate, 14% of ammonium adipate, 4.5% of breakdown voltage enhancing agent, 1% of phosphorous acid and 1% of deionized water. The preparation method comprises the following steps: taking and adding 70kg of glycol and 1kg of deionized water into a container, uniformly stirring, and heating to 110 DEG C; weighing 4.5kg of breakdown voltage increasing agent, 1.5kg of ammonium dihydrogen phosphate, 1kg of phosphorous acid, 8kg of ammonium pentaborate and 14kg of ammonium adipate by using a scale, and then, sequentially adding the materials into the container and stirring; and keeping the mixture at the constant temperature of 110 DEG C for 30 minutes, naturally cooling the mixture to the room temperature, and then discharging. The invention has the advantages of enhancing the breakdown voltage of the electrolyte, improving the capacity of repairing aluminum foil oxidation films by oxygen ions of the electrolyte, reducing generation of water and precipitation of hydrogen gas in the working process, and obviously improving the service performance of the aluminum electrolytic capacitor.

Owner:黄山振州电子科技股份有限公司

Bipolar battery pole plate and preparation method thereof

ActiveCN110336038AImprove corrosion resistanceLight in massFinal product manufactureElectrode carriers/collectorsEngineeringCopper

The invention belongs to the technical field of a lead-acid storage battery and specifically relates to a bipolar battery pole plate and a preparation method thereof. The bipolar battery pole plate comprises a bipolar plate grid, a positive electrode active material and a negative electrode active material. The bipolar plate grid is composed of a titanium foil and a copper plate. The bipolar battery pole plate prepared by electroplating a lead layer on positive and negative poles of the bipolar plate grid simultaneously, and then, coating the positive electrode active material and the negativeelectrode active material is high in power, high in mass specific energy and small in gas evolution amount, and has better mechanical strength and corrosion resistance, and pole plate current and potential are evenly distributed. The preparation method can reduce production cost, reduce environmental protection pressure and improve battery performance.

Owner:ZIBO TORCH ENERGY

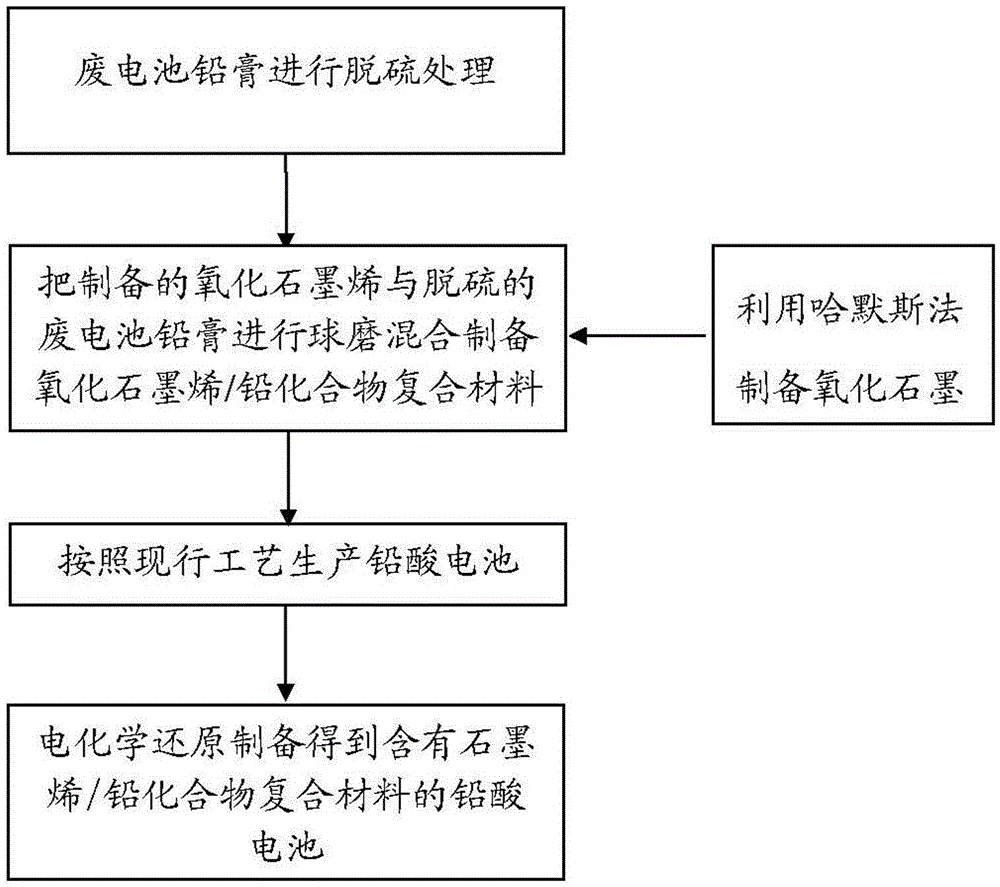

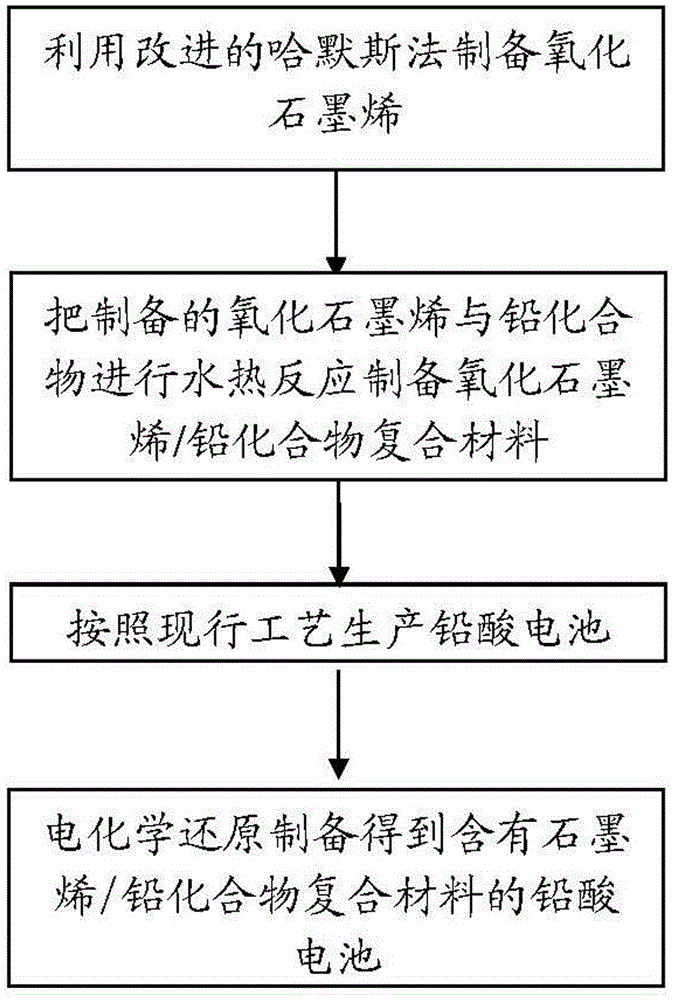

Preparation method for graphene/lead compound composite material and lead-acid battery

ActiveCN105428613AGood dispersionIncrease the effective contact areaLead-acid accumulatorsCell electrodesGrapheneElectrode material

The invention provides a preparation method for a graphene / lead compound composite material. A production method for a lead-acid battery comprises: firstly, performing hydrothermal reaction mixing or ball-milling mixing on a lead compound and graphene oxide to obtain a graphene oxide / lead compound composite material; secondly, assembling the lead-acid battery by taking the graphene oxide / lead compound composite material as an electrode material additive; and thirdly, performing electrochemical reduction on the lead-acid battery to obtain the lead-acid battery containing the graphene / lead compound composite material. The lead-acid battery produced with the method contains the graphene / lead compound composite material, so that the agglomeration of the graphene is avoided, uniform dispersion of the graphene and the lead compound is realized, and the graphene and the lead compound can be uniformly mixed; and moreover, a graphene / lead compound superbattery is easily obtained through the electrochemical reduction, so that the charge acceptance capability of the battery is remarkably improved and the cyclic life of the battery is remarkably prolonged.

Owner:湖北雄韬电源科技有限公司

Graphene lithium ion battery electrolyte

InactiveCN105098239AImprove withstand voltage performanceReduce hydrogen evolutionSecondary cellsOrganic electrolytesLithium electrodePrecipitation

The invention relates to graphene lithium ion battery electrolyte, which comprises a lithium salt, a non-aqueous organic solvent and an additive, wherein the additive is prepared from the following components: 5%-6.5% of hexamethyl disilazane, 0.5%-3.5% of octamethylcyclotetrasiloxane, 4.5%-8.5% of graphene and 0.3%-5.3% of vitamin E on the basis of total weight of the electrolyte. The graphene is added to the lithium ion battery electrolyte, so that the voltage resistance of the electrolyte can be greatly improved; the electrolyte is not easy to decompose at high pressure; corrosive substances in an electrolyte system and the corrosive substances dissociating on the surface of a positive electrode can be effectively removed by the octamethylcyclotetrasiloxane; a lead electrode surface is adsorbed in the charging and discharging process due to the addition of the hexamethyl disilazane; equivalently, the deposition potential of hydrogen is improved; precipitation of hydrogen can be reduced; the lithium ion battery is stored in a high-temperature state; the capacity retention ratio and the capacity recovery rate are high; and the cycle performance is excellent.

Owner:NINGBO POLYTECHNIC

Silicon steel pickling promoter and preparation method thereof

The invention specifically relates to a silicon steel pickling promoter and a preparation method thereof. According to a technical scheme in the invention, the silicon steel pickling promoter is prepared from 0.1 to 5.0 wt% of a corrosion inhibitor, 10.0 to 50.0 wt% of an inorganic salt reducing agent, 0.1 to 5.0 wt% of an emulsifier, 5.0 to 20.0 wt% of an organic metal ion chelating agent, 0.1 to 5.0 wt% of a defoaming agent, 0.1 to 5.0 wt% of a synergist and 20.0 to 80.0 wt% of water through uniform mixing at normal temperature with stirring. The silicon steel pickling promoter provided by the invention has the characteristics of convenience in usage, high pickling efficiency, low cost, environment friendliness, a good corrosion inhibition effect, etc.

Owner:WUHAN UNIV OF SCI & TECH

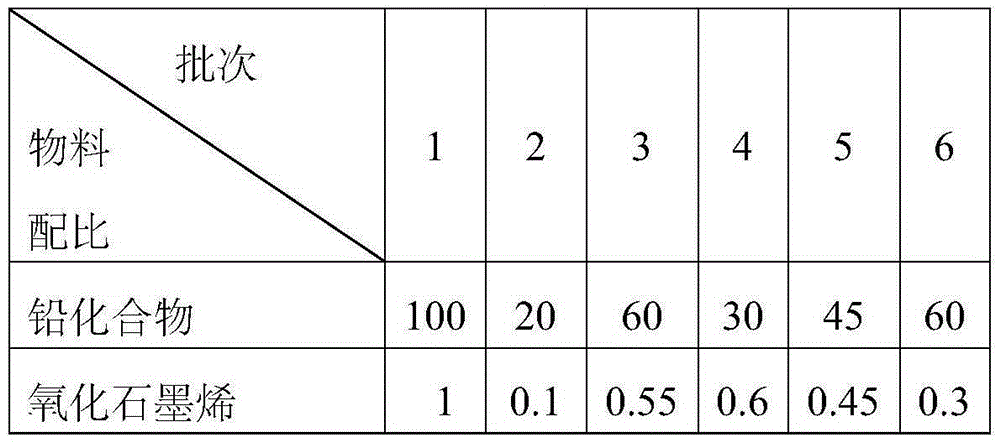

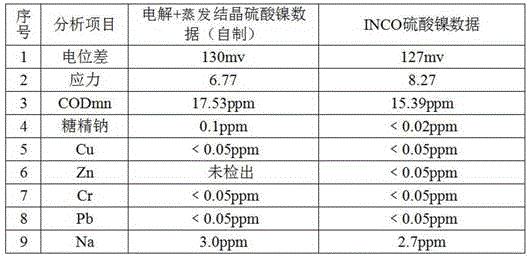

Method for preparing high-purity nickel salt by recycling industrial nickel-containing wastewater

The invention discloses a method for preparing high-purity nickel salt by recycling industrial nickel-containing wastewater. Nickel salt in the industrial nickel-containing wastewater is purified, crystallized, recycled and reused, the three-level purifying process including the steps of nickel resin adsorption primary concentration and purification, pulse electrolysis impurity removing and the third-level purification of evaporation crystallization impurity removing is adopted, nickel metal salt is recycled, obtained nickel salt is high in purity with the impurity and metal ions lower than the international standards, and the outsourcing quantity of nickel metal salt materials is greatly reduced; in addition, the method is easy to implement, low in cost, high in safety and significant in economic and social value.

Owner:XIAMEN RUNNER IND CORP

High-performance lead-carbon negative electrode lead paste and preparation method thereof

InactiveCN111710861ASimple and scientific designImprove conductivityLead-acid accumulatorsNegative electrodesConductive polymerPhysical chemistry

The invention relates to high-performance lead-carbon negative electrode lead paste and a preparation method thereof, and belongs to the technical field of lead-carbon batteries. The high-performancelead-carbon negative electrode lead plaster is obtained by compounding a carbon material, a conductive polymer and other assistants by using a method of dissolving sodium lignosulphonate and then separating out sodium lignosulphonate. According to the high-performance lead-carbon negative electrode lead paste, the formula design is simple and scientific, and the prepared product is good in conductivity, high in power characteristic and small in hydrogen evolution amount. The invention also provides a simple and feasible preparation method which is beneficial to industrial production.

Owner:ZIBO TORCH ENERGY

Implant made of a biodegradable magnesium alloy

ActiveUS8915953B2Easy to processImprove material performanceSurgeryBlood vesselsBiodegradable magnesium

An implant made in total or in parts of a biodegradable magnesium alloy consisting of Y: 2.0-6.0% by weight, Nd: 1.5-4.5% by weight, Gd: 0-4.0% by weight, Dy: 0-4.0% by weight, Er: 0-4.0% by weight, Zr: 0.1-1.0% by weight, Li: 0-0.2% by weight, Al: 0-0.3% by weight, under the condition that a) a total content of Er, Gd and Dy is in the range of 0.5-4.0% by weight and b) a total content of Nd, Er, Gd and Dy is in the range of 2.0-5.5% by weight, the balance being magnesium and incidental impurities up to a total of 0.3% by weight.

Owner:BIOTRONIK AG

High-dispersibility alkaline non-cyanide zinc-plating brightener and preparation method and application thereof

The invention discloses a high-dispersibility alkaline non-cyanide zinc-plating brightener and a preparation method and application thereof and belongs to the field of surface treatment electrogalvanizing. The preparation method comprises the following steps that 5-amino-8-quinolinol and salicylic aldehyde are dissolved in an organic solvent which is mutually soluble with water at the mole ratio of 1-3:1-3, a small amount of paraformaldehyde is added as a catalyst, the temperature is raised to 80-90 DEG C, and a reflux reaction is performed for 4-5 h; after the reaction is completed, a sodiumhydroxide solution is added, the temperature is raised to 40-50 DEG C, propane sultone is dropwise added, after adding, the temperature is raised to 90-105 GEG C, after a sufficient reaction, the alkaline non-cyanide zinc-plating brightener is obtained. The mole ratio between the propane sultone and the 5-amino-8-quinolinol is 1.0-1.3:1. The current density range of a plating solution prepared from the prepared alkaline non-cyanide zinc-plating brightener is 0.5-11 A / dm<2>, when the through current is 2A, the current efficiency is higher than or equal to 80%, and the dispersive capacity reaches about 88%. The high-dispersibility alkaline non-cyanide zinc-plating brightener has good application prospect.

Owner:武汉奥邦表面技术有限公司

Implant made of a biodegradable magnesium alloy

ActiveUS9468704B2Easy to processImprove material performanceSurgeryBlood vesselsMaterials scienceBiodegradable magnesium

An implant made in total or in parts of a biodegradable magnesium alloy consisting of Y: 2.0-6.0% by weight, Nd: 1.5-4.5% by weight, Gd: 0-4.0% by weight, Dy: 0-4.0% by weight, Er: 0-4.0% by weight, Zr: 0.1-1.0% by weight, Li: 0-0.2% by weight, Al: 0-0.3% by weight, under the condition that a) a total content of Er, Gd and Dy is in the range of 0.5-4.0% by weight and b) a total content of Nd, Er, Gd and Dy is in the range of 2.0-5.5% by weight, the balance being magnesium and incidental impurities up to a total of 0.3% by weight.

Owner:BIOTRONIK AG

Preparation method of electrolyte of iron-chromium flow battery and obtained electrolyte

ActiveCN114551956AEasy to makeLow costTitanium carbideRegenerative fuel cellsElectrolytic agentRedox

The invention discloses a preparation method of an electrolyte of an iron-chromium flow battery and the obtained electrolyte. The electrolyte is prepared by adding one or more additives into a basic electrolyte of ferric chloride, ferrous chloride, chromium chloride and hydrochloric acid. The invention particularly introduces an additive of the electrolyte, wherein the additive comprises one or more of ammonium chloride, propylene diamine tetraacetic acid, indium chloride, carbon quantum dots and Mxene quantum dots; and the concentration of the additive in the electrolyte is 0.1-30 mol / L. Compared with the prior art, the additive introduced in the invention can be directly added in the process of preparing the electrolyte without introducing a subsequent additional adding process, so that the preparation process is simple, the property of the electrolyte cannot be changed, and the electrolyte is non-toxic, harmless, low in price, safe and environment-friendly. The activity of positive and negative electrode redox reaction can be effectively improved, the battery performance is improved, and the side reaction of cathode hydrogen evolution is inhibited.

Owner:中海储能科技(北京)有限公司 +1

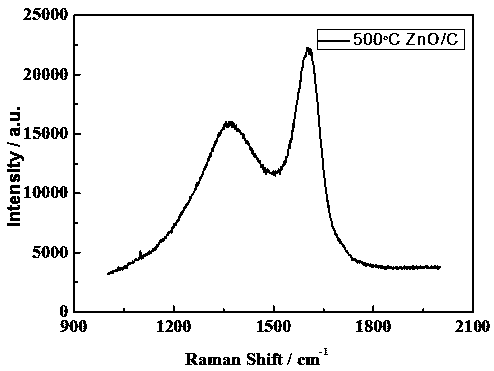

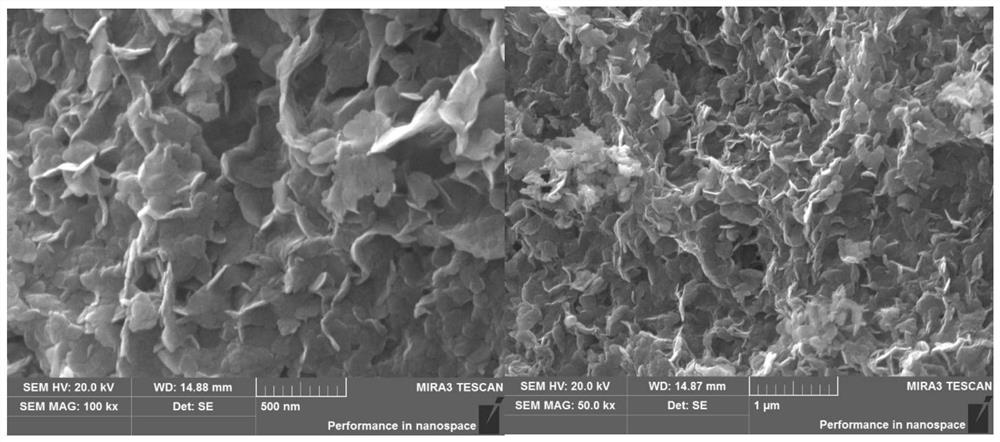

Preparation method of ZnO/sisal fiber-based carbon composite material and application thereof

InactiveCN109449380AThe production process is simpleReduce hydrogen evolutionFinal product manufactureCell electrodesPre treatmentCarbon composites

The invention discloses a preparation method of a ZnO / sisal fiber-based carbon composite material and an application thereof. The preparation method comprises the steps of first, pretreating a sisal fiber, mainly treating surface impurities and low polymer molecules of the sisal fiber through an acid-alkali two-step treatment method; and then preparing the ZnO / sisal fiber-based carbon composite material by taking the pretreated sisal fiber and zinc hydroxide as raw materials and adopting an in-situ carbon-thermal synthesis method. The prepared ZnO / sisal fiber-based carbon composite material isapplied to preparation of a negative electrode material; and the abovementioned material has good hydrogen evolution inhibition and electrochemical performance through detection and analysis of an electrochemical workstation.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

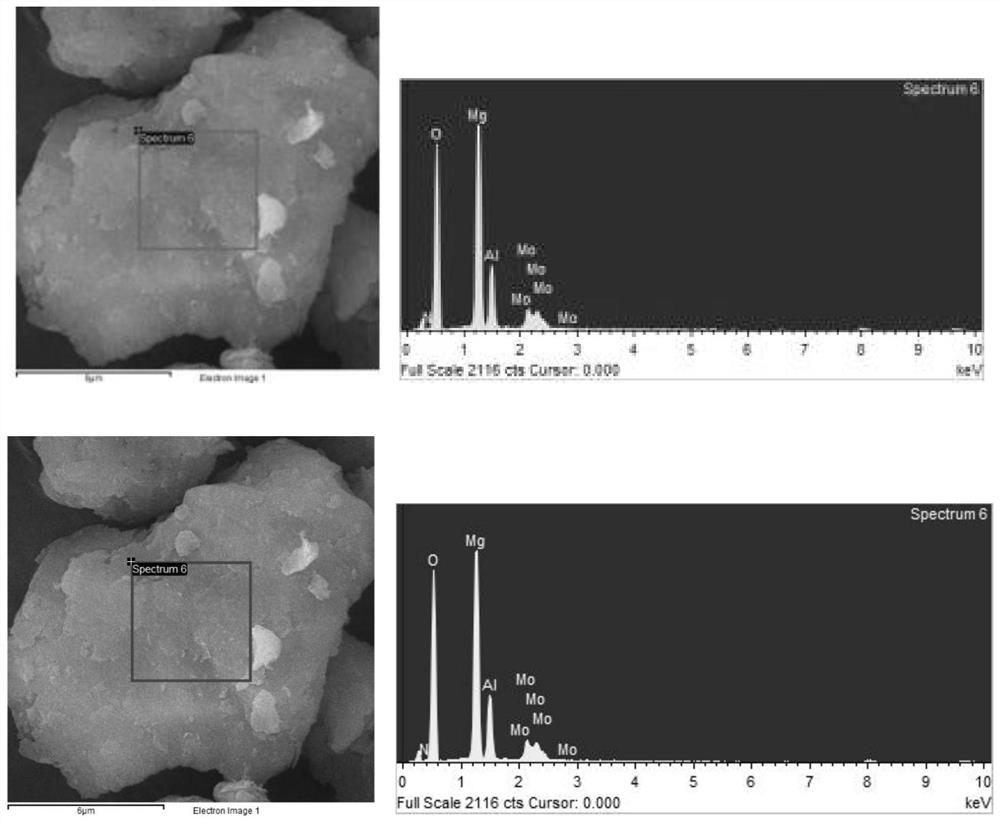

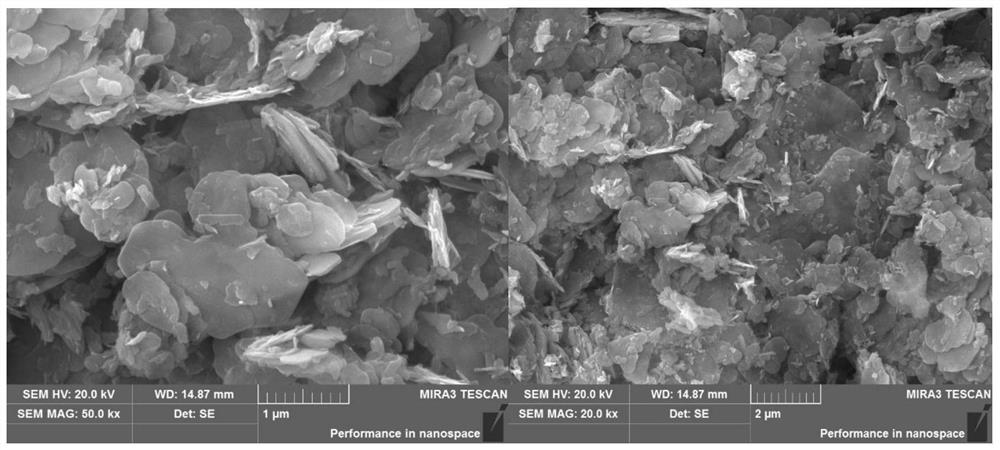

Diselenide/layered double hydroxide composite water electrolysis catalytic material as well as preparation method and application thereof

ActiveCN112076765AExcellent water electrolysis catalytic performanceReduce hydrogen evolutionPhysical/chemical process catalystsCell electrodesMolybdenum diselenideOxygen evolution

The invention discloses a diselenide / layered double hydroxide composite water electrolysis catalytic material which is a material with diselenide growing on the surface of layered double hydroxide in-situ. Diselenide is molybdenum diselenide and / or tungsten diselenide. The invention also provides an in-situ anion intercalation and in-situ self-assembly preparation method of the diselenide / layereddouble hydroxide composite water electrolysis catalytic material under ultrasonic enhancement. The invention also discloses an application of the diselenide / layered double hydroxide composite water electrolysis catalytic material as an HER and / or OER material. The prepared diselenide / layered double hydroxide composite water electrolysis catalytic material not only has a low hydrogen evolution over-potential, but also has oxygen evolution reaction (OER) over-potential basically equivalent to that of noble metal, and is very excellent in performance. Therefore, the catalytic material is of greatsignificance to the improvement of the water electrolysis hydrogen production level.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com