Diselenide/layered double hydroxide composite water electrolysis catalytic material as well as preparation method and application thereof

A layered bimetallic, diselenide technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrolysis processes, etc., can solve the problems of increasing the voltage of the electrolytic water tank, the cost of hydrogen production, and the overpotential of the oxygen evolution reaction. Achieve excellent water electrolysis catalytic performance, low hydrogen evolution overpotential, and the effect of solving boundary effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

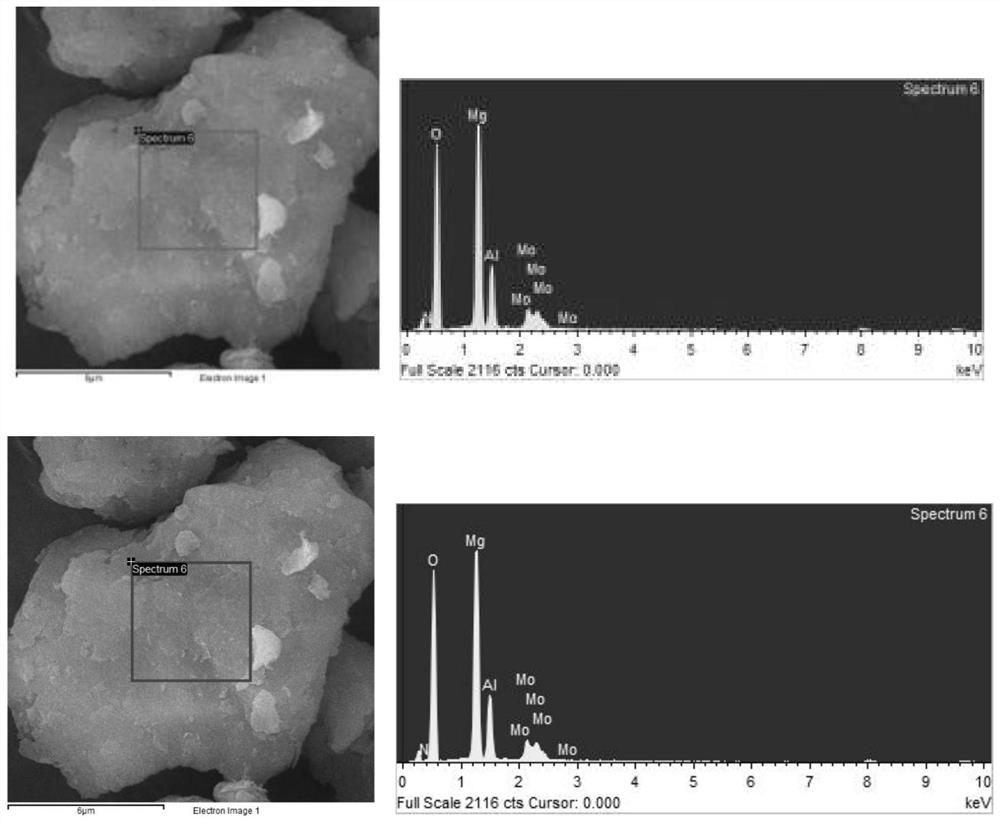

[0080] A kind of preparation of molybdenum diselenide / MgAl hydrotalcite composite catalytic material of the present invention, it specifically comprises the following steps:

[0081] (1) Add 0.03mol magnesium nitrate, 0.015mol aluminum nitrate, 0.01mol sodium molybdate and 0.1mol sodium hydroxide to 100mL water, stir and react at 45°C for 1h; then raise the temperature to 85°C for 6h; crystallize After the end, centrifuge and wash, filter after 30 minutes of ultrasonic field action, disperse the filter cake in 50mL water to make hydrotalcite prepolymer suspension;

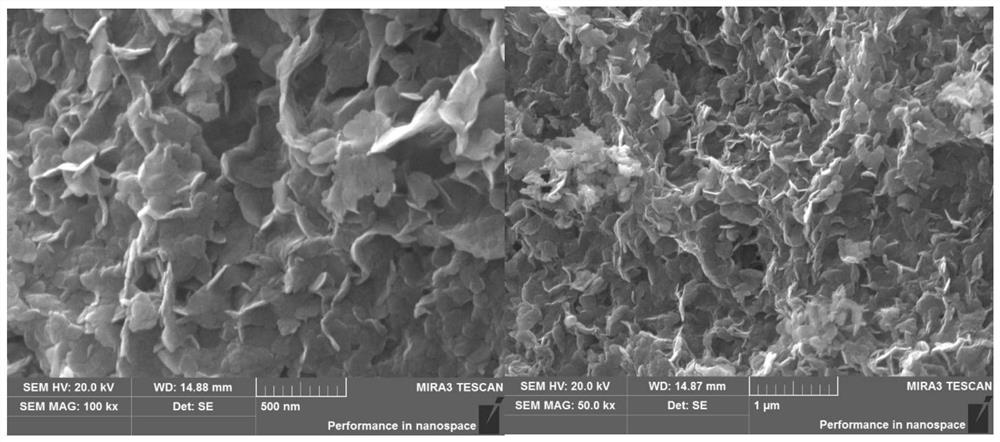

[0082] (2) After stirring 0.632g of selenium powder and 10mL of hydrazine hydrate in a three-necked flask for 30min, add 40mL of the above-mentioned hydrotalcite prepolymer suspension and ultrasonically disperse it, place it in a high-pressure reactor, and heat up at a rate of 5 ° C / Raise the temperature to 200°C under the condition of 1 min, keep the temperature for 720 minutes (when 360 minutes, take out the ul...

Embodiment 2

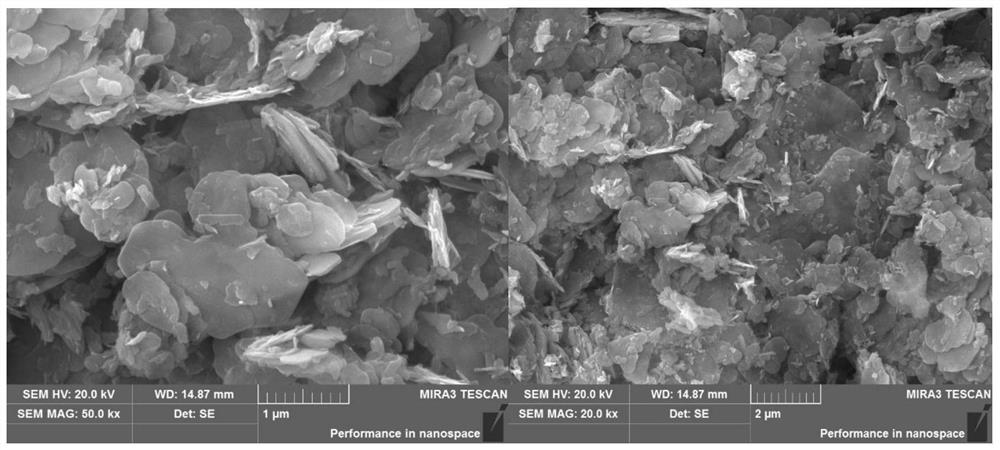

[0117] The preparation method is similar to Example 1, the only difference is that the hydrothermal reduction reaction temperature in step 2 is increased from 200°C to 230°C, and the others are the same, and the selenium disulfide / MgAl hydrotalcite composite catalytic material L is prepared.

[0118] Using the same test method as in Example 1, the performance of the total hydrolysis of the composite catalytic material L was tested. It was found that the current density reached 10mV / cm 2 , the hydrogen evolution overpotential of the composite catalytic material M is 243mV, and the oxygen evolution potential is 1.49V.

[0119] The study found that an appropriate increase in the hydrothermal reduction temperature is conducive to the improvement of the electrocatalytic performance of the composite material.

Embodiment 3

[0121] The preparation method is similar to that of Example 1, except that the hydrothermal reduction reaction temperature in step 2 is increased from 200°C to 250°C, and the others are the same, and the selenium disulfide / MgAl hydrotalcite composite catalytic material M is prepared.

[0122] Using the same test method as in Example 1, the performance of the total hydrolysis of the composite catalytic material M was tested. It was found that the current density reached 10mV / cm 2 , the hydrogen evolution overpotential of the composite catalytic material M is 326mV, and the oxygen evolution potential is 1.58V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com