Preparation method of ZnO/sisal fiber-based carbon composite material and application thereof

A carbon composite material, sisal fiber technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc. Simple and effective in reducing hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The present invention is further illustrated below in conjunction with specific examples, but the examples do not limit the protection scope of the present invention.

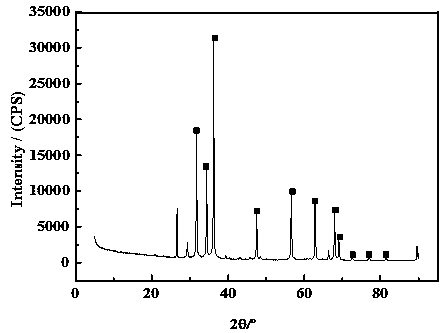

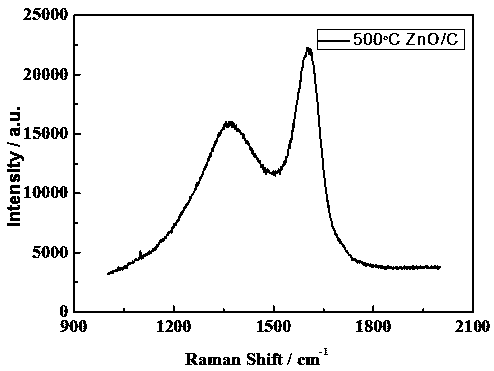

[0026] The concrete steps of preparing ZnO / sisal fiber-based carbon composite material are:

[0027] After cleaning the sisal fiber with distilled water, it is placed in an oven for drying, and the temperature of the oven is set at 90°C. The dried sisal fiber is cut into 1 centimeter with scissors again, and the sodium hydroxide solution that the mass percent concentration is 5% is poured in the sisal fiber and soaked 24 hours. Then soak in 5% phosphoric acid solution for 24 hours with mass percent concentration. After soaking, the sisal fibers were fished out and dried in a vacuum drying oven for 8 h at a set temperature of 90 °C.

[0028] Put the dried sisal fiber into a closed grinder for grinding, and grind it into 300-400 mesh sisal fiber powder. Weigh 2.0 g sisal fiber powder and 0.37 g Zn(OH) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com