Patents

Literature

425 results about "Sisal fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hemostatic textile

ActiveUS20070160653A1Quick activationNon-adhesive dressingsPeptide/protein ingredientsLactideSisal fiber

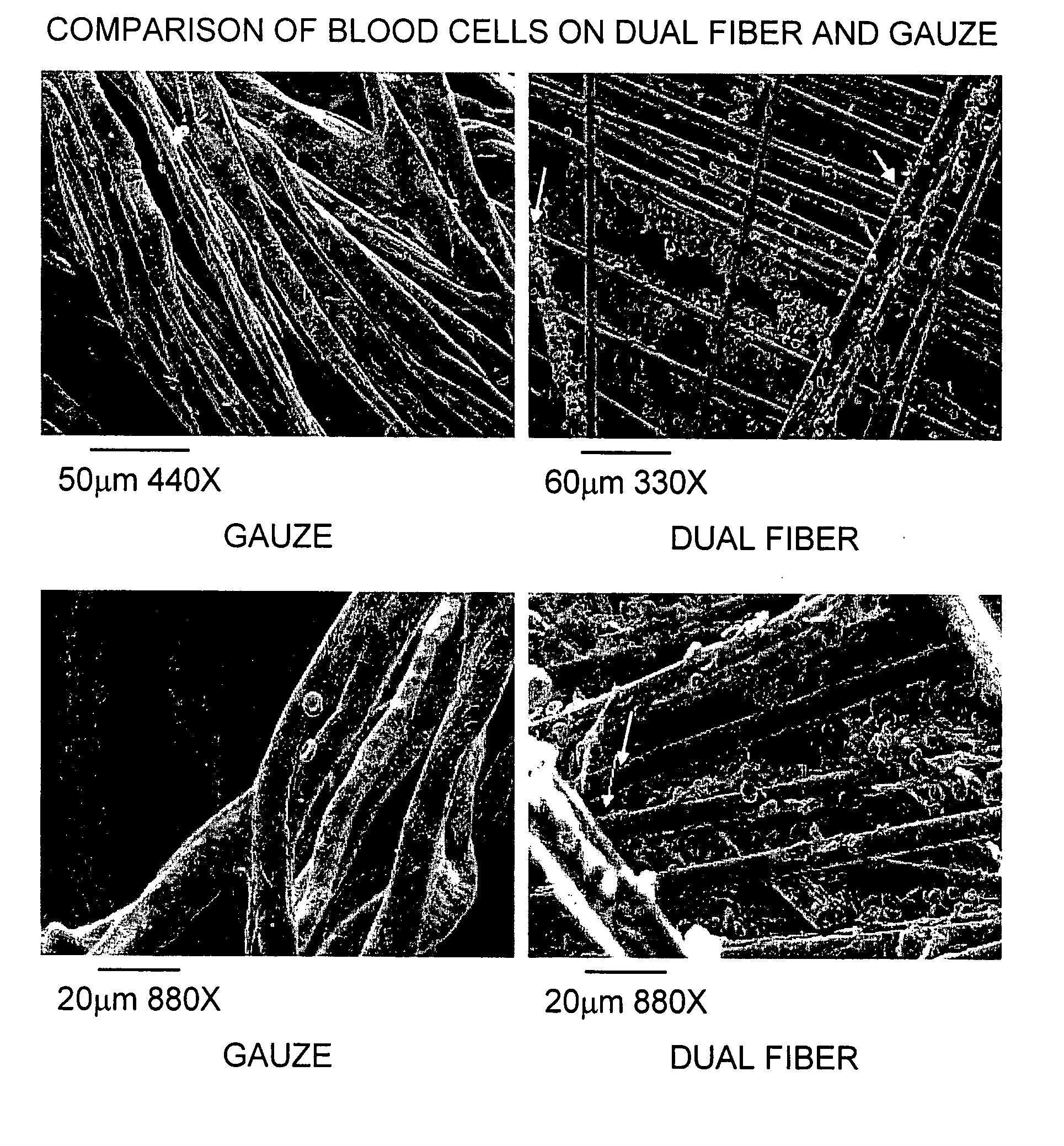

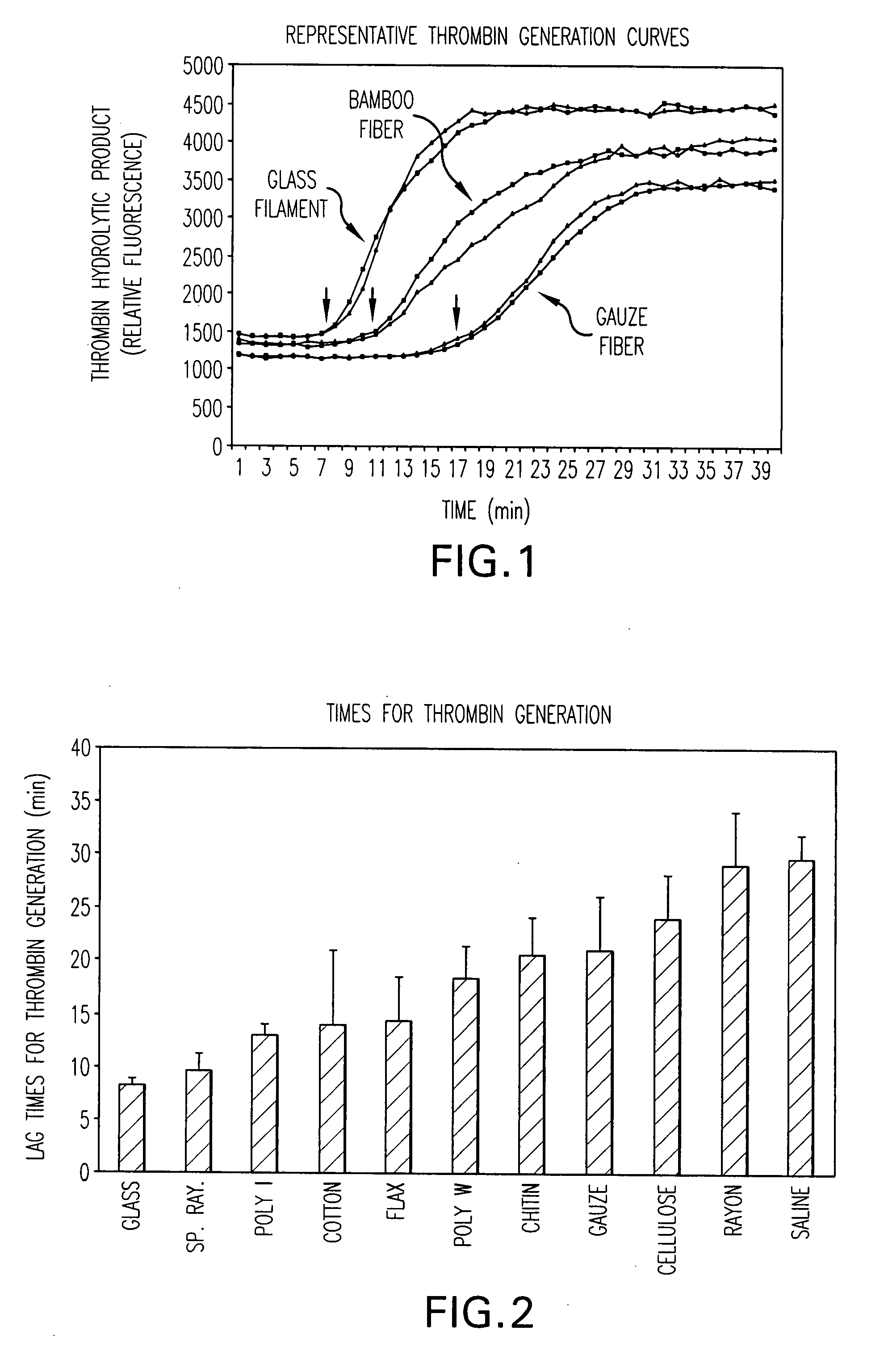

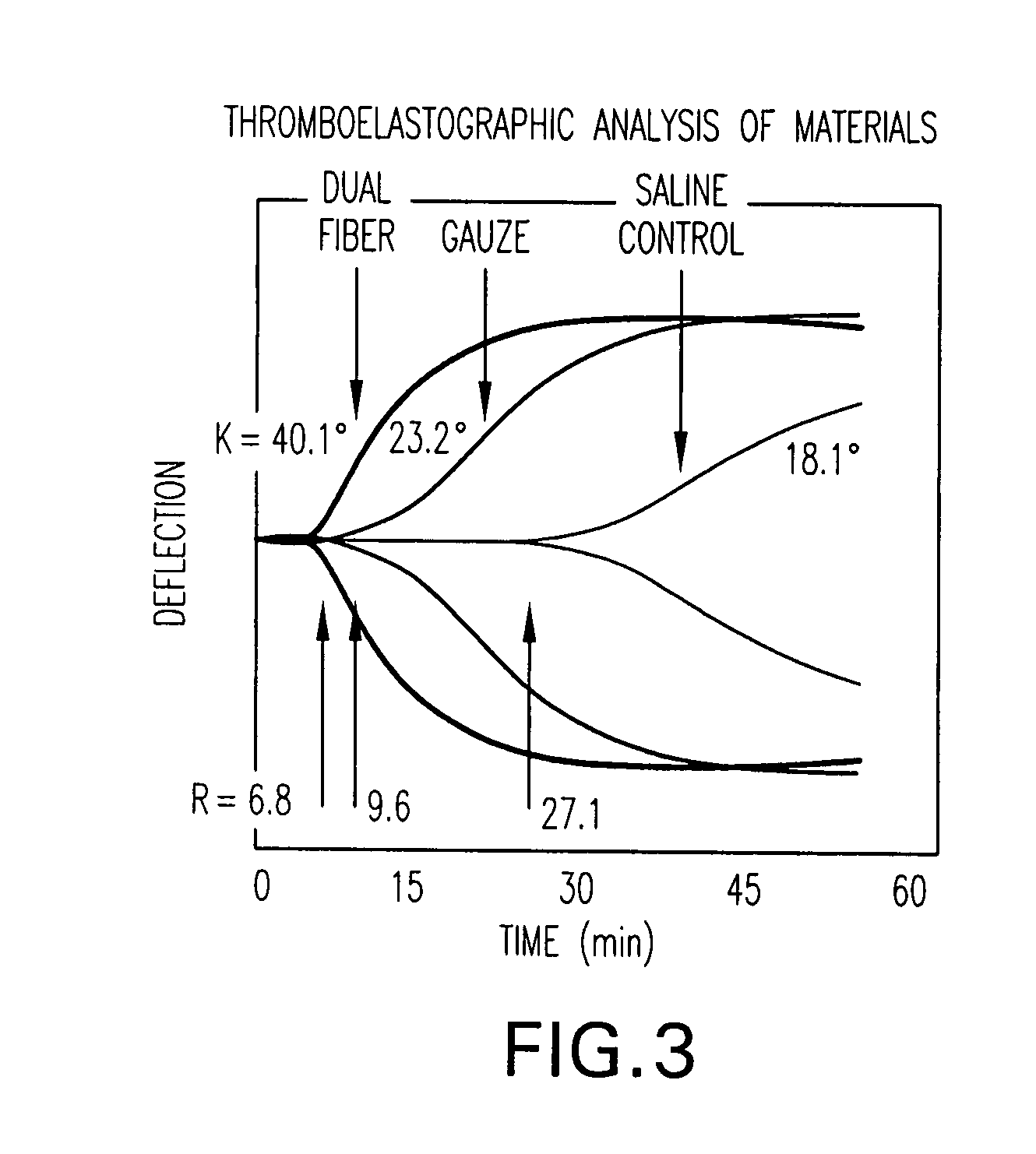

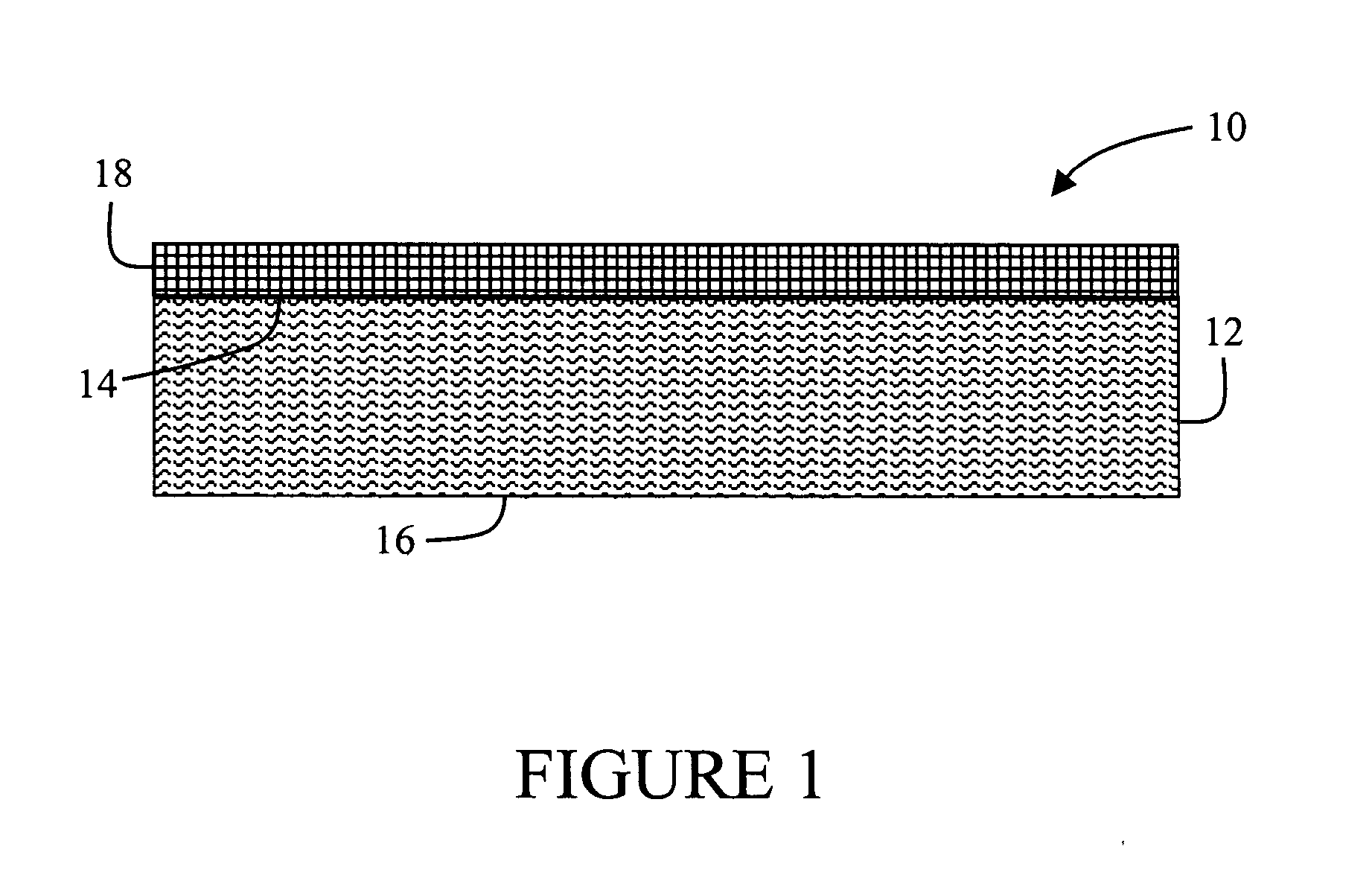

The present invention is directed to a hemostatic textile, comprising: a material comprising a combination of glass fibers and one or more secondary fibers selected from the group consisting of silk fibers; ceramic fibers; raw or regenerated bamboo fibers; cotton fibers; rayon fibers; linen fibers; ramie fibers; jute fibers; sisal fibers; flax fibers; soybean fibers; corn fibers; hemp fibers; lyocel fibers; wool; lactide and / or glycolide polymers; lactide / glycolide copolymers; silicate fibers; polyamide fibers; feldspar fibers; zeolite fibers, zeolite-containing fibers, acetate fibers; and combinations thereof; the hemostatic textile capable of activating hemostatic systems in the body when applied to a wound. Additional cofactors such as thrombin and hemostatic agents such as RL platelets, RL blood cells; fibrin, fibrinogen, and combinations thereof may also be incorporated into the textile. The invention is also directed to methods of producing the textile, and methods of using the textile to stop bleeding.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

Composite thermoplastic sheets including natural fibers

A composite sheet material includes, in an exemplary embodiment a porous core that includes at least one thermoplastic material and from about 20 weight percent to about 80 weight percent of natural fibers based on a total weight of the porous core. The natural fibers include at least one of kenaf fibers, jute fibers, flax fibers, hemp fibers, cellulosic fibers, sisal fibers, and coir fibers.

Owner:HANWA AZDEL INC

Method for polishing wheet from sisal fiber

InactiveCN1562570ARich varietyVarious ventilation structuresFlexible-parts wheelsPlant fibreSisal fiber

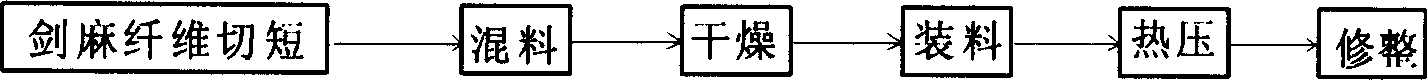

A polishing wheel is made up of short sisal hemp fibres, synthetic resin, plant fibres and inorganic compound through proportionally mixing, drying, hot die pressing and trimming.

Owner:黄焕仪 +1

Natural vegetable fiber reinforced fully-degradable polymer composite material and preparation method thereof

The invention refers to a full-degradable polymer composite material strengthened by the natural plant fiber and the preparing method. It adopts India plant fiber-Hildegardia populifolia, sisal fiber, ramee, wood fibre and so on as the fiber raw material, tand the degradable plastic-the poly-methyl ethyl carbonic acid resin as the basic body, and smelts and commixes the filling and the basic body on the existent / nonexistent condition of the coupling agent to make the composite material. The weight percent content of the fiber is 5-80%, the better fiber 10-40%.

Owner:SUN YAT SEN UNIV

Biodegradable cigarette filter tow and method of manufacture

InactiveUS20150374030A1Promotes quick dispersibilitySimple methodNon-fibrous pulp additionTobacco treatmentPolymer scienceSisal fiber

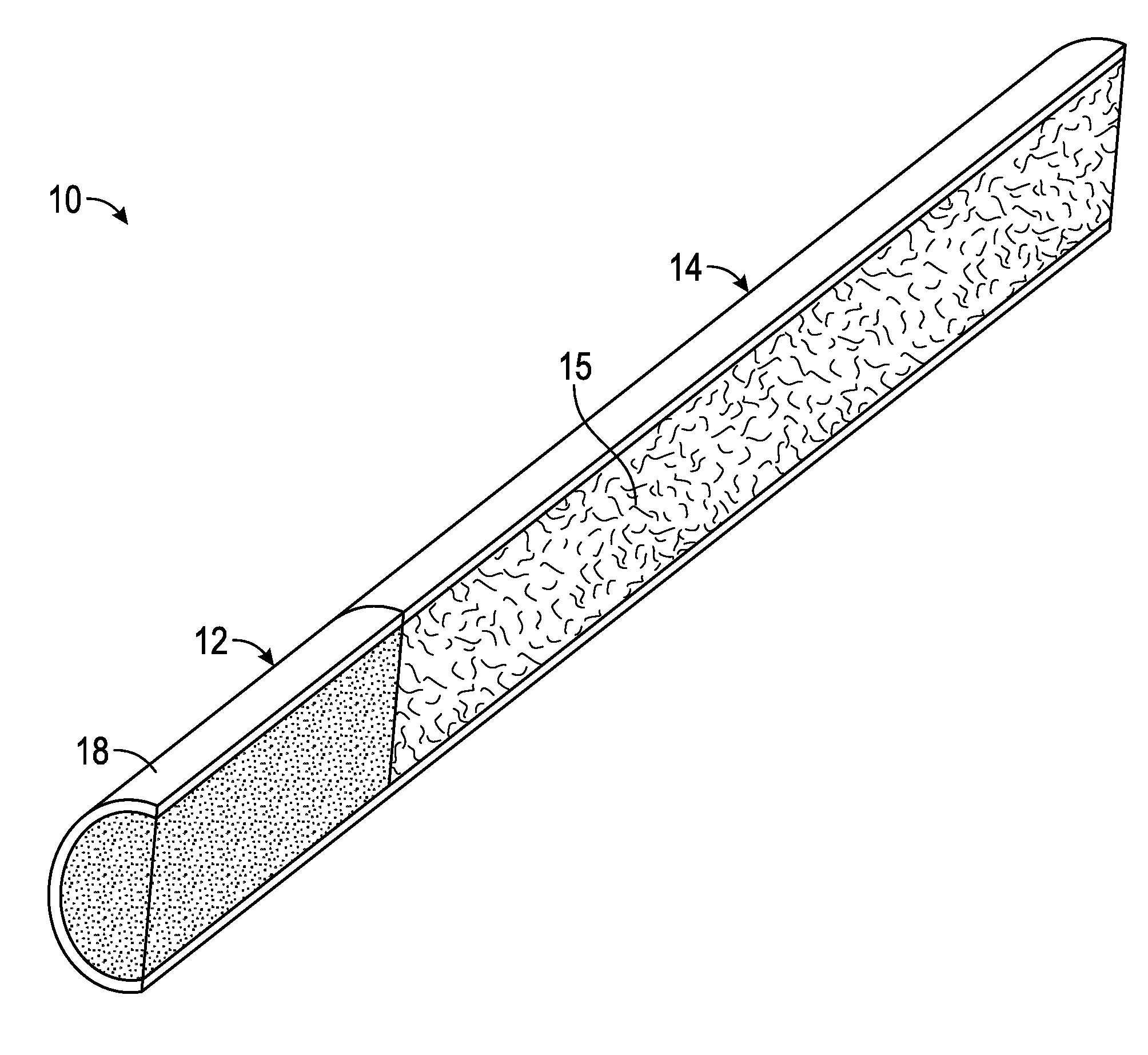

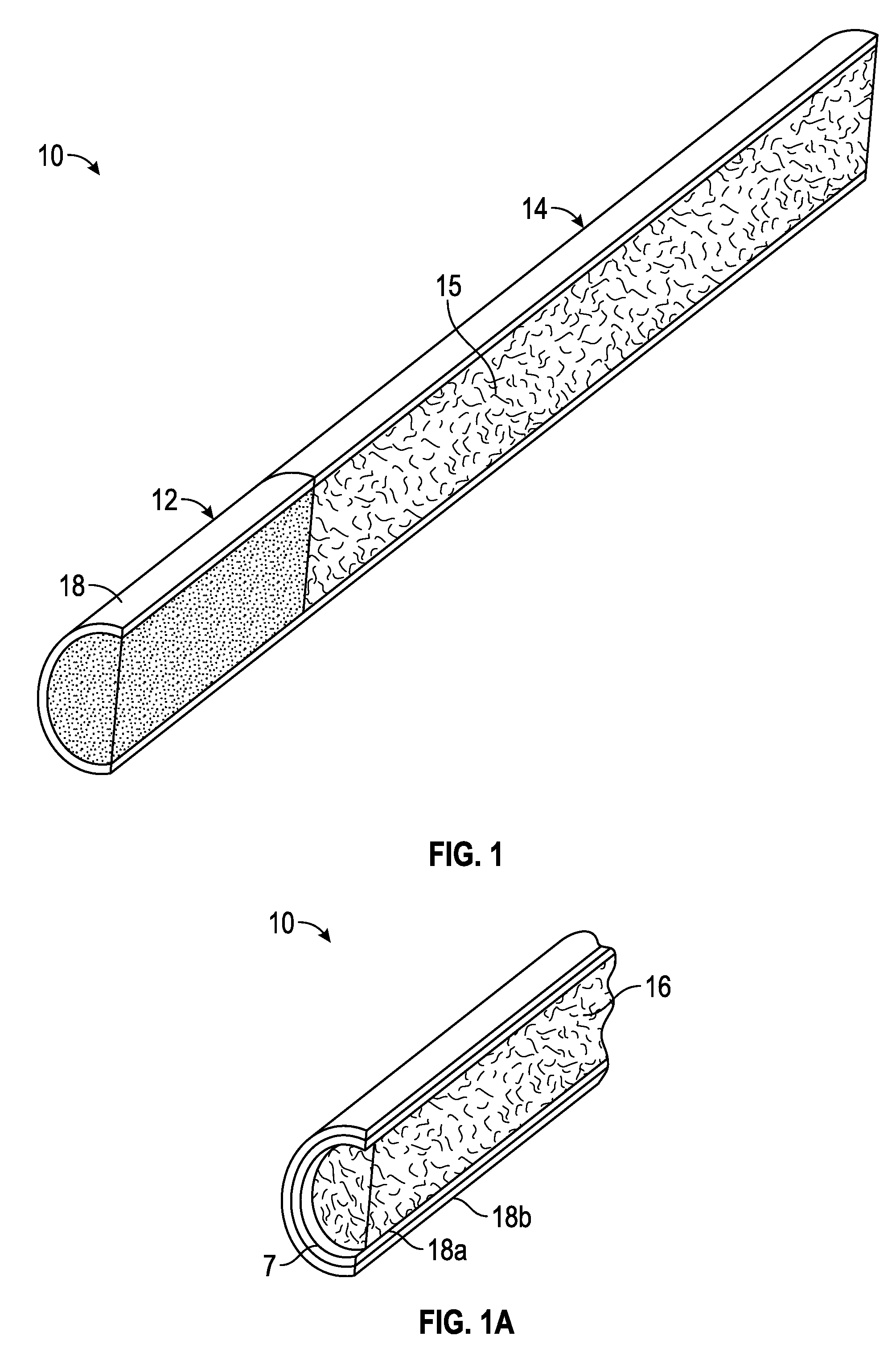

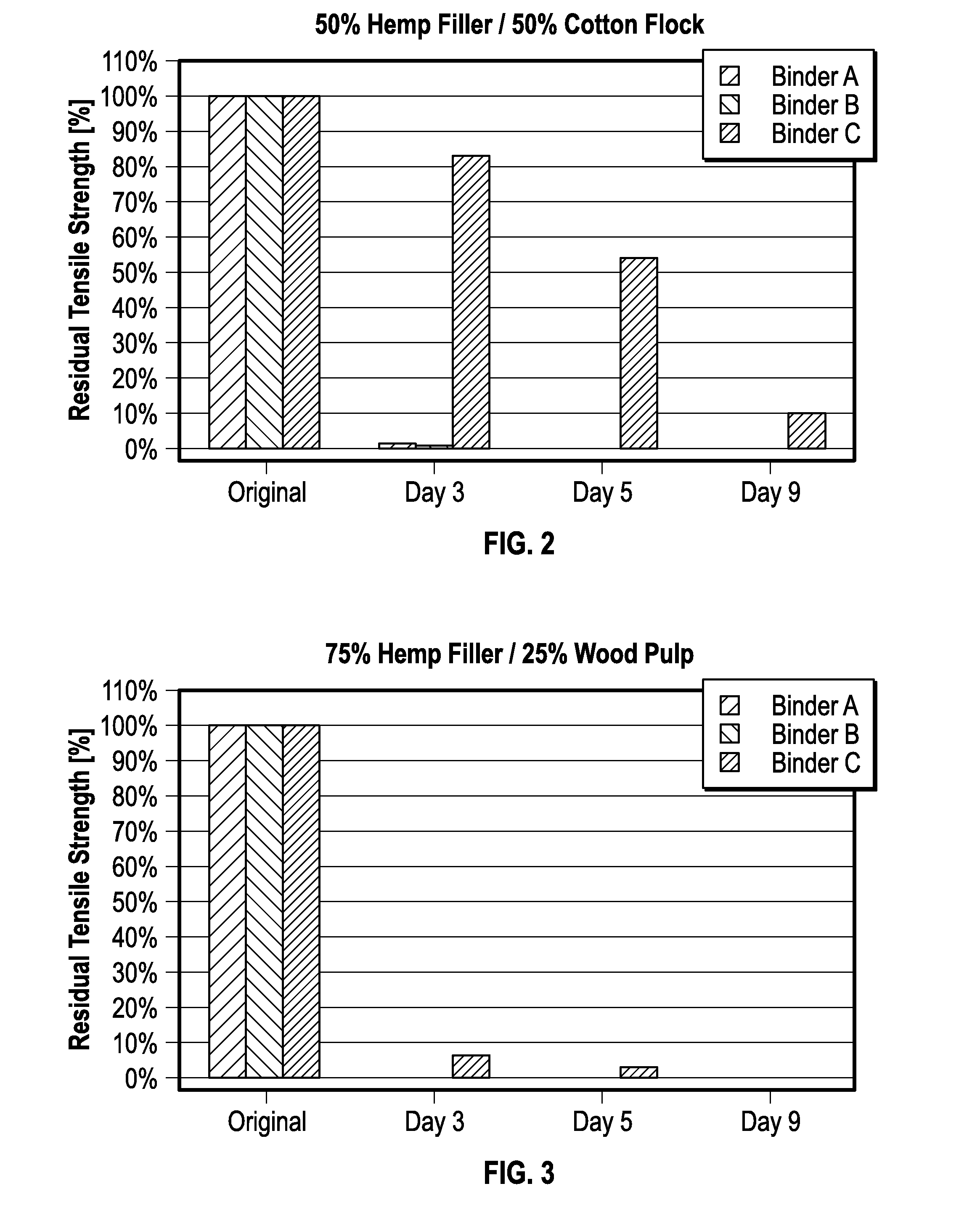

A biodegradable cigarette filter tow includes a mixture of at least two or more natural materials selected from the group consisting of hemp fiber, flax fiber, abaca fiber or pulp, sisal fiber or pulp, wood pulp, and cotton fiber or cotton flock. The mixture may also include regenerated cellulose fibers. The mixture may include a natural binder or may be hydroentangled.

Owner:GREENBUTTS LLC

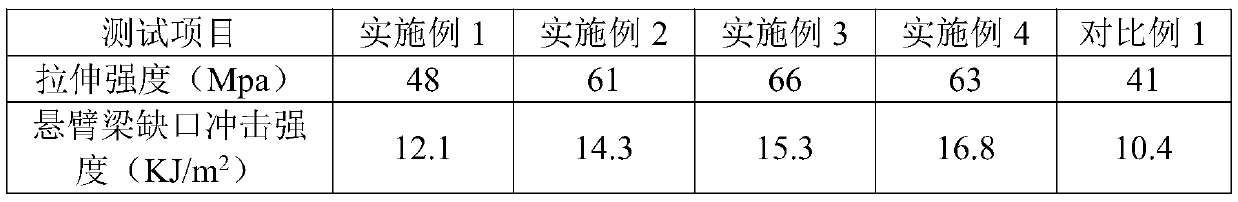

High-toughness full-degradable composite material

The invention provides a high-toughness full-degradable composite material, which is mainly prepared by blending the following components in parts by weight: 100 parts of biodegradable matrix resin; 1-60 parts of modified bio-based fiber; 1-8 parts of a compatilizer; 1-5 parts of a lubricant and 0-5 parts of a coupling agent; wherein the biodegradable matrix resin is one or a composition of more than two of PBAT, PCL, PLA, PBS, PBSA, PPC, PBST, PHB, PHA, PVA and PHBV, wherein the modified bio-based fiber comprises hydrophobic modification of the bio-based fiber or / and coupling modification ofthe bio-based fiber, the bio-based fiber is fibrilia, and the fibrilia is one or more of hemp fiber, flax fiber, sisal fiber and palm fiber. The modified plant fiber disclosed by the invention has a remarkable reinforcing and toughening effect on the bio-based matrix resin, and the interface compatibility and the interface bonding force of the modified plant fiber and the bio-based matrix resin are improved.

Owner:佰信(福建)新材料科技有限公司

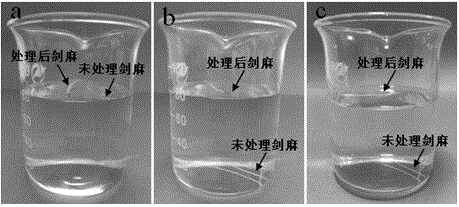

Process for producing sisal fiber

InactiveCN101294309AImprove finenessGood flexibilityMechanical fibre separationFibre treatment to obtain bast fibreColloidHemicellulose

The method for preparing sisal fiber is characterized in that the method comprises the following steps: (1) scraping colloid in sisal leaf pulp by mechanical knocking or rolling, and removing partial lignin, hemicellulose and pectin therein; (2) pre-soaking fiber material in sulfuric solution at 30 to 80 DEG C for 1 to 3 h; (3) cleaning with circulating water to adjust pH value to 6.8 to 7.2; (4) adding the fiber material in a boiler with pressure of 0.1 to 0.2 MPa, and boiling with sodium hydroxide solution for 2 to 6 h; (5) cleaning with circulating water to adjust pH value to 6.8 to 7.2; and (6) post-treating to obtain sisal fiber. The method has the advantages that the fineness and the flexibility of sisal fiber prepared by the method are improved greatly in comparison with unprocessed crude sisal.

Owner:DONGHUA UNIV

Vegetable fiber reinforced flame-retardant thermoplastic starch-based composite material and preparation method thereof

The invention belongs to a vegetable fiber reinforced flame-retardant thermoplastic starch-based composite material and a preparation method thereof. The composite material comprises the following raw materials in part by weight: 100 to 120 parts of starch, 30 to 50 parts of plasticizer, 5 to 30 parts of vegetable fibers and 5 to 40 parts of flame retardant. The banana fiber raw material used by the invention is agricultural waste, namely banana stems, and has low cost; and sisal fibers, jute fibers and the like can be produced industrially and the raw materials are easily obtained. The product can be prepared by simple controllable standard machine-shaping conditions. The finished product has excellent biodegradability, mechanical property and flame retardant property, can be used in the fields of package, automotive trim, household appliances and the like and avoid applying pressure to the environment after being scrapped. Meanwhile, the vegetable fiber reinforced flame-retardant thermoplastic starch-based composite material increases the additional value of the cash crops, increases farmer income and has important significance for reduction of white pollution.

Owner:GUANGXI TEACHERS EDUCATION UNIV

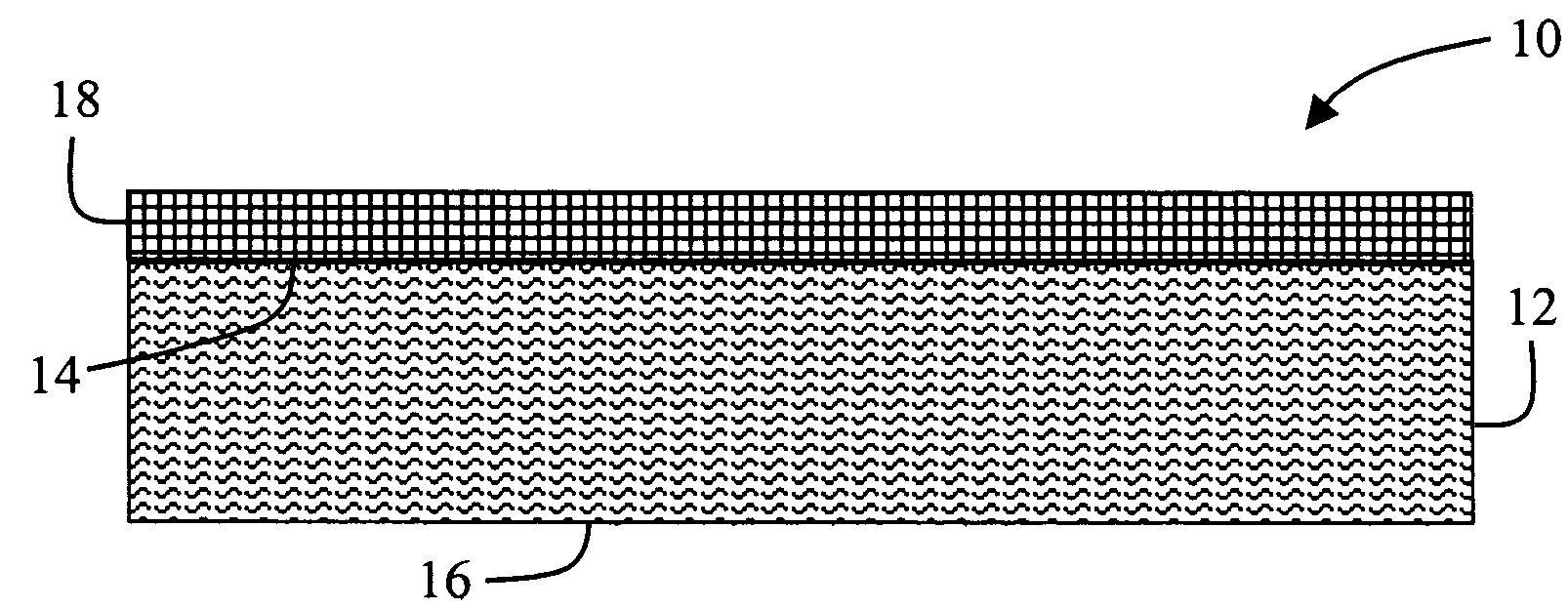

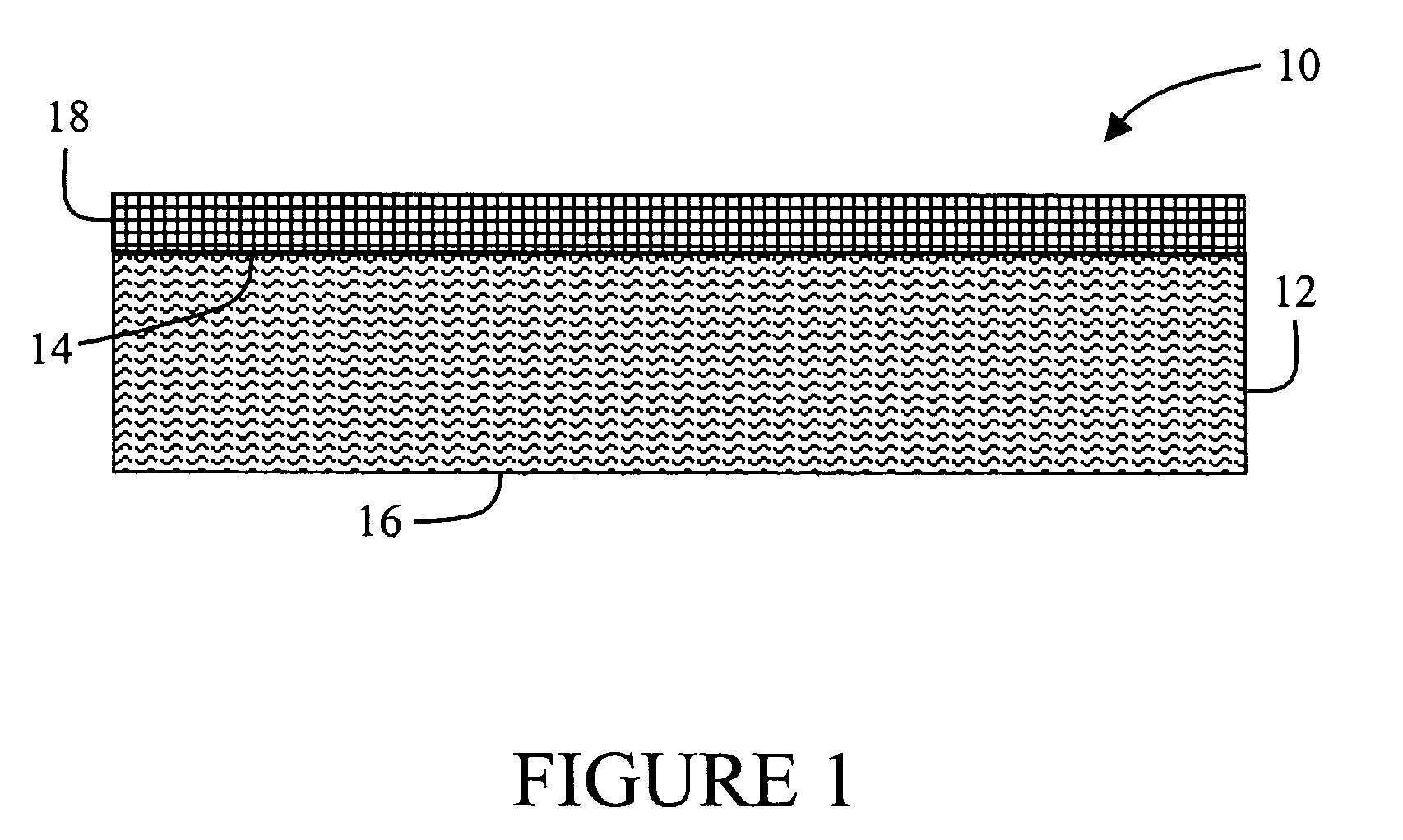

Composite thermoplastic sheets including natural fibers

ActiveUS7431980B2Non-fibrous pulp additionSynthetic resin layered productsSisal fiberCellulose fiber

A composite sheet material includes, in an exemplary embodiment a porous core that includes at least one thermoplastic material and from about 20 weight percent to about 80 weight percent of natural fibers based on a total weight of the porous core. The natural fibers include at least one of kenaf fibers, jute fibers, flax fibers, hemp fibers, cellulosic fibers, sisal fibers, and coir fibers.

Owner:HANWA AZDEL INC

Preparation method of hyperbranched polyester graft modified sisal fiber cellulose microcrystal

The invention discloses a preparation method of a hyperbranched polyester graft modified sisal fiber cellulose microcrystal, which comprises the following steps: dissolving N,N-dicyclohexylcarbodiimide in N,N-dimethylformamide, gradually dropwisely adding into a three-neck flask containing malic acid and tetrahydrofuran under the protection of N2, reacting at 30-40 DEG C for 12 hours while stirring, then filtering to remove grey-white precipitate, and distilling the filtrate to remove solvent, thus obtaining a light yellow oil-like sticky matter, namely carboxyl-terminated hyperbranched polyester; and adding N,N-dimethylformamide, a sisal fiber cellulose microcrystal and the prepared carboxyl-terminated hyperbranched polyester into the three-neck flask, reacting at 30-40 DEG C for 10-30 minutes under the protection of N2 while stirring, then adding N,N-diisopropylcarbodiimide and 4-dimethylaminopyridine, performing thermostatic reaction for 12 hours, filtering, and drying to obtain the hyperbranched polyester graft modified sisal fiber cellulose microcrystal. The method disclosed by the invention is wide in raw material sources, low in raw material price, less in pollution and simple in process; and the obtained product has favorable performance, and can obviously improve the comprehensive performance of a composite material.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Machinable light weight sisal-based concrete structural building material

InactiveUS6881257B2Improve plasticityImprove workabilitySolid waste managementCeramic shaping apparatusSludgeSISAL

A machinable light weight sisal-based concrete structural building material and a method of making the same are disclosed. The material includes short sisal fibers in a range from about 22% (v / v) to about 33% (v / v); a cement in a range from about 12% (v / v) to about 22% (v / v); and perlite in a range from about 51% (v / v) to about 59% (v / v). The method includes the steps of mixing an amount of cement with an amount of perlite to form a solid mixture; adding water and mixing water with the solid mixture to form a sludge; adding an amount of sisal fibers and mixing the sisal fibers into the sludge to form an uniform final composition; and pouring the final composition into a mold and setting the final composition to a solid form structural building material. The produced structural building material can be machined, screwed, cut, and nailed.

Owner:BEAUBOEUF SEYMOUR

Preparation method of sisal hemp cellulose nanowhisker/polylactic acid biological composite material

The invention discloses a preparation method of a sisal hemp cellulose nanowhisker / polylactic acid biological composite material. The preparation method comprises the following steps: grafting a polylactic oligomer on the surface of the sisal hemp cellulose nanowhisker through adopting a grafting treatment method; and forming good interfacial adhesion by means of compatibility between the polylactic oligomer which is grafted on the surface of the sisal hemp cellulose nanowhisker and polylactic acid and preparing the sisal hemp cellulose nanowhisker / polylactic acid biological composite material by adopting an in-situ composite technique. The preparation method disclosed by the invention is simple in preparation process and green and environmental friendly, and the prepared sisal hemp cellulose nanowhisker / polylactic acid biological composite material has excellent mechanical properties and biocompatibility.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

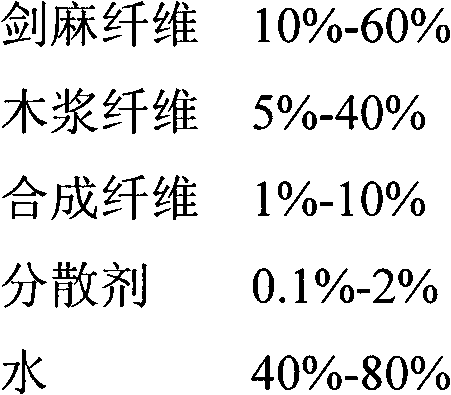

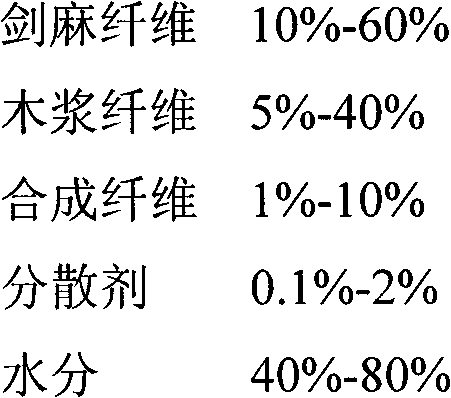

Manufacture method of sisal fiber wet nonwoven fabric

InactiveCN103374852AIncrease elasticityStrong production efficiencyNon-woody plant/crop pulpSynthetic cellulose fibresPapermakingSisal fiber

The invention relates to a manufacture method of a sisal fiber wet nonwoven fabric. According to the manufacture method, the sisal fiber wet nonwoven fabric is mainly prepared from reproducible and naturally degradable sisal fibers and wood in the presence of a small amount of chemical fibers by a wet papermaking process. Mainly aiming at the disadvantages that the chemical fiber nonwoven fabric is difficult to degrade, the invention discloses a sisal fiber nonwoven fabric having the characteristics of simple formula, environmental friendliness and easiness in process operation.

Owner:GUANGDONG PAPER IND RES INST

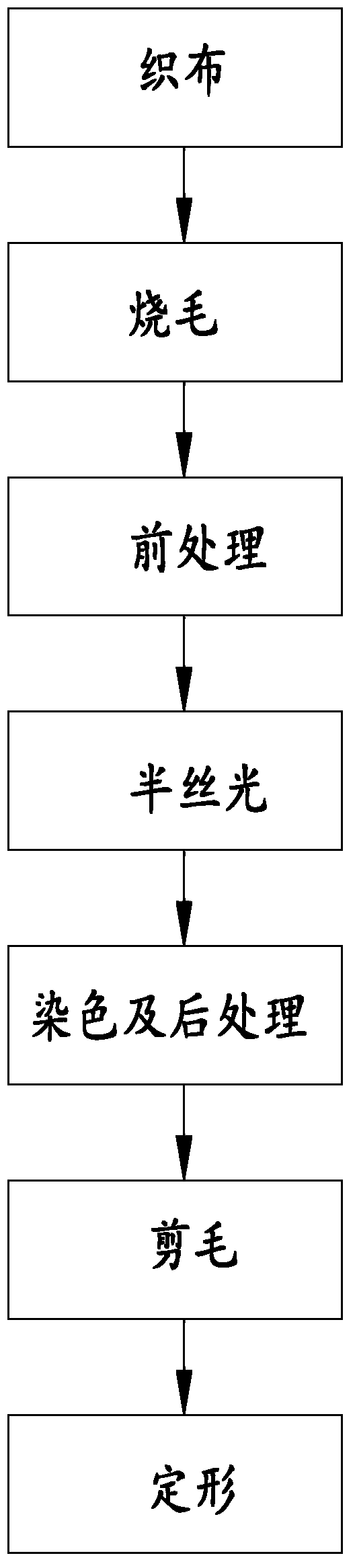

Tencel fiber and spun silk fiber blended mercerizing fabric and production process

ActiveCN103233316AUnique touchGood drapabilitySucessive textile treatmentsWeft knittingSisal fiberSilk fiber

The invention provides tencel fiber and spun silk fiber blended mercerizing fabric which comprises the following raw materials: 50-80wt% of tencel fiber and 20-50wt% of spun silk fiber, wherein the blended mercerizing fabric is 30-80S / l, and the length of each 100G of blended mercerizing fabric is 32-52cm. The invention further provides a production process of the fabric. The production process includes steps of: (1) weaving, (2) singeing, (3) preprocessing, (4) semi-mercerizing, (5) dyeing and post-processing, (6) shearing and (7) setting. By means of the tencel fiber and spun silk fiber blended mercerizing fabric and the production process, the shortcomings that the existing products are apt to deform, have no elasticity and stiff and smooth effect and the like can be overcome.

Owner:山东青枫纺织科技有限公司

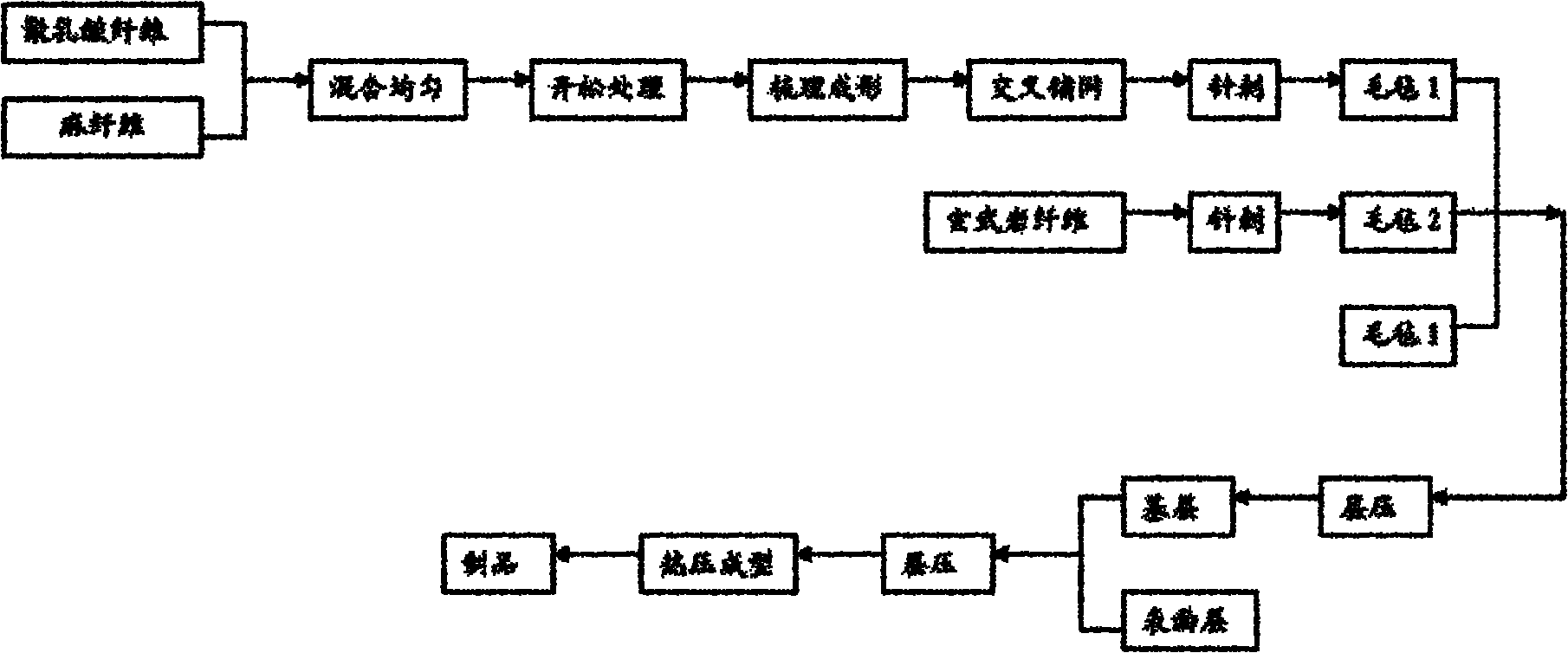

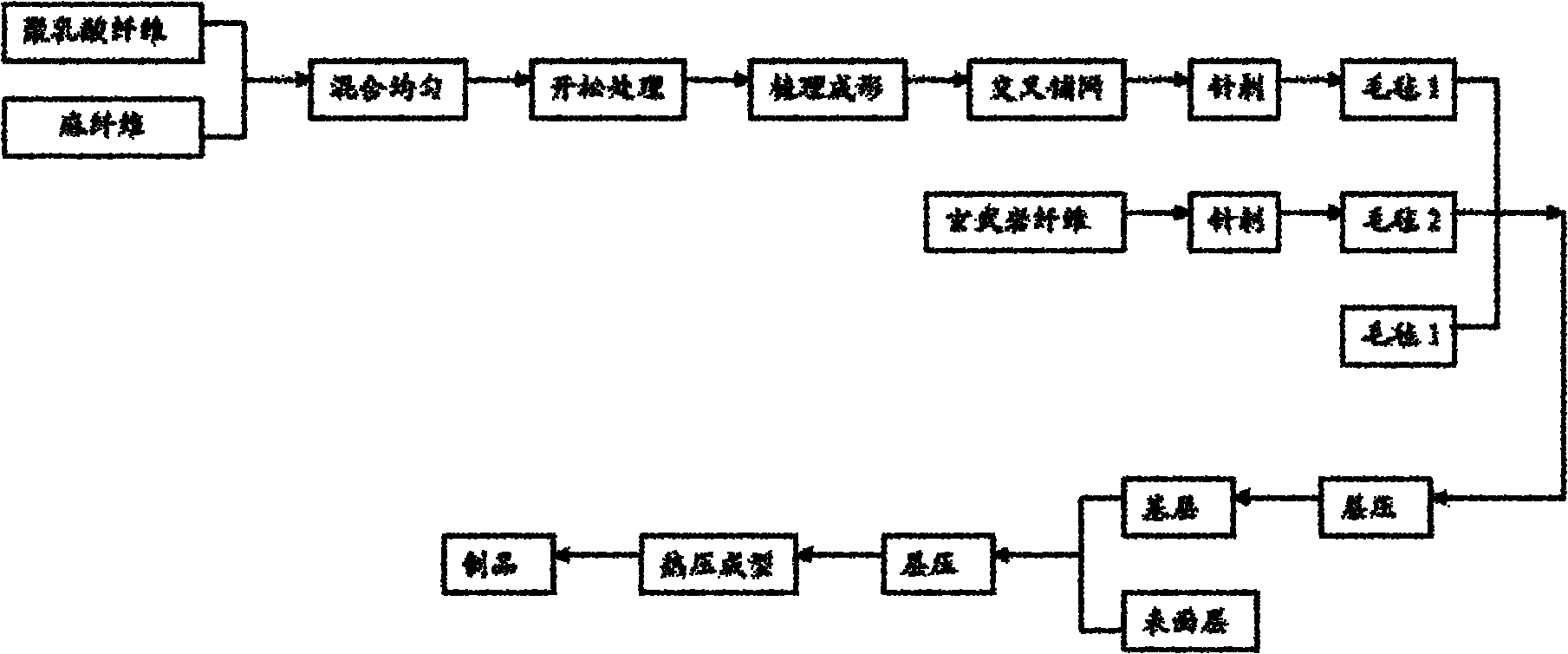

Composite fiber automobile interior board and production method thereof

InactiveCN102166842AImprove tensile propertiesGood filterability at high temperatureLaminationLamination apparatusSurface layerSisal fiber

The invention relates to a composite fiber automobile interior board and a production method thereof. The automobile interior board comprises a base layer and a non-woven or woven surface layer which is laminated on the at least one surface of the base layer, wherein the base layer consists of the following composite fibers: first fibers, namely polylactic acid fibers, second fibers, namely bastose selected from at least one of jute fibers, sisal fibers, ramie fibers, linen fibers, hemp fibers and kenaf fibers, and third fibers, namely basalt fibers in a weight percentage ratio of (20-70):(10-60):(10-60); and the surface layer consists of polylactic acid fibers. The composite fiber automobile interior board can be made into a three-dimensional deep drawing high-strength automobile interior board, and is safe, firm and environment-friendly when used as the base material of an automobile door inner board and a ceiling.

Owner:DALIAN UNIV OF TECH

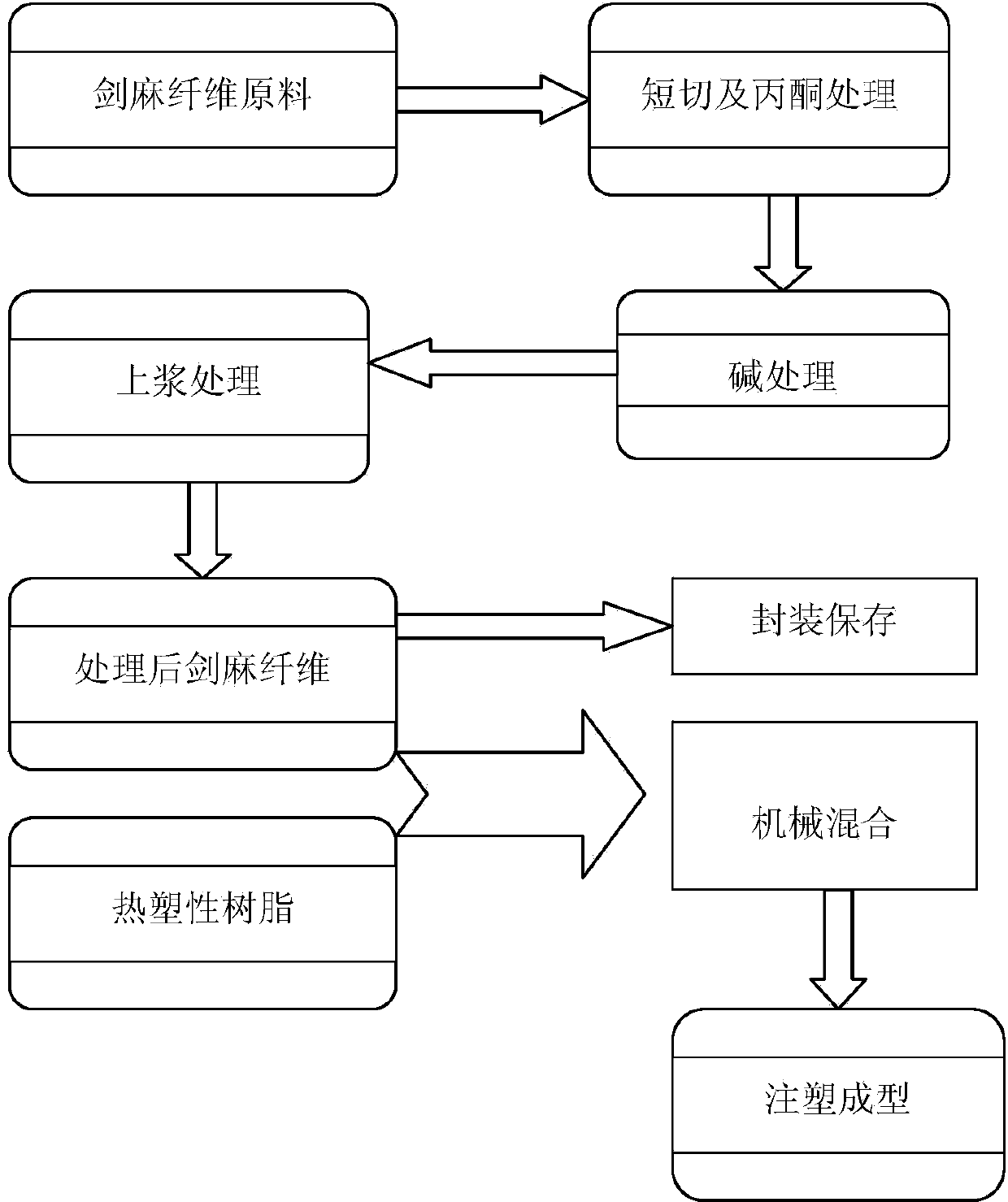

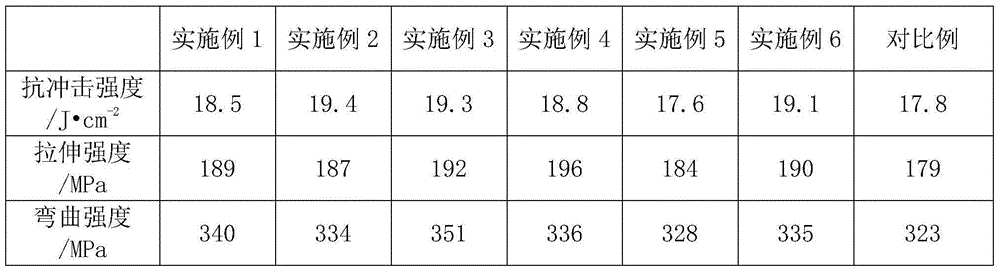

Preparation method of sisal fiber surface sizing agent and sisal fiber composite material

The invention discloses a preparation method of a sisal fiber surface sizing agent and a sisal fiber composite material. The sisal fiber surface sizing agent is water-based emulsion prepared from a modified resin film forming agent (1-60wt%), a coupling agent (0.5-8wt%), a levelling agent (0-1wt%), a wetting agent (0-8wt%), a surface active agent (0.5-8wt%), water and the like according to a phase inversion emulsification method, sisal fibers are treated by the sizing agent and then are mixed with a certain amount of resin, and one-step injection moulding is carried out by adopting an injection moulding machine, so that the sisal fiber composite material is obtained. The sisal fiber surface sizing agent well improves compatibility of the sisal fibers and matrix resin, and tensile strength of the sisal fiber composite material is effectively increased. The preparation method of the sisal fiber composite material is simple, cost is saved, fiber content is easy to control, the problem that compatibility of the sisal fibers and matrix is poor can be well solved, and the preparation method of the sisal fiber composite material can be applied to industrialization production.

Owner:TIANJIN UNIV

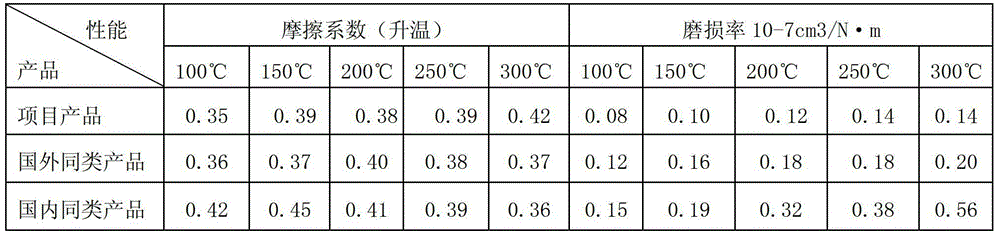

Brake pad made of composite material

InactiveCN106009495AImprove high temperature resistanceImprove heat stabilityFriction liningActuatorsCarbon fibersSisal fiber

The invention discloses a brake pad made of a composite material. The brake pad comprises a steel sheet and a friction block, and the friction block is prepared from boron-modified phenolic resin, organic silicone-modified phenolic resin, barium phenolic resin, phenylacetylene phenolic resin, epoxy-terminated liquid reaction type nitrile rubber, butadiene rubber, molybdenum disulfide, sisal fiber, bamboo carbon fiber, aluminum fiber, molybdenum fiber, poly-p-phenylene benzodioxazole fiber, zinc oxide crystal whiskers, montmorillonite, vermiculite, nanometer aluminum oxide, cerium oxide, zirconium boride, aluminum silicate hollow spheres, graphene oxide, copper powder, carbon nano tubes, nano carbon black, butadiene styrene rubber powder, ammonium molybdate and octaphenyl silsesquioxane. The brake pad made of the composite material is high in high temperature resistance, excellent in heat stability, high in abrasion resistance and long in service life.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts thefollowing steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

Offshore oil drilling platform rig disc brake pad and preparation method thereof

The invention relates to an offshore oil drilling platform rig disc brake pad and a preparation method thereof, and aims to provide a brake pad which has the characteristics of large braking torque and high shearing strength, as well as the preparation method which has the characteristics of simple process, convenience in manufacturing and lower cost. The adopted technical scheme is that the offshore oil drilling platform rig disc brake pad comprises a metal skeleton and a friction material layer, and is characterized in that the friction material layer is prepared from the following raw materials: boric acid-tung oil dual-modified phenolic resin, aramid pulp fiber, carbon fiber, sisal fiber, precipitated barium sulfate, sodium fluoride, antimony sulfide, aluminum hydroxide, diatomaceous earth, polytetrafluoroethylene suspension resin, zinc stearate, cashew nut shell oil friction powder, artificial graphite, foam powdered iron, yellow pyrites powder, hydrogenated nitrile-butadiene rubber and butyronitrile emulsion. The preparation method of the offshore oil drilling platform rig disc brake pad comprises the following steps: 1), weighing the raw materials; 2), mixing and taking out a mixture; 3), mould pressing for molding; 4), thermal curing; 5), processing to obtain the disc brake pad.

Owner:杭州克尔菲利科技有限公司

Novel steel wire rope core and production method thereof

ActiveCN110055780AReduce lossReduce glitchesFibre typesFilament/thread formingSisal fiberEngineering

The invention discloses a novel steel wire rope core and a production method thereof. The production method comprises the following steps: picking up hemp, carding the hemp (adding oily water), drawing, spinning, twisting into strands (soaking with oil), twisting into a rope and warehousing. According to a spinning machine disclosed by the invention, a sisal spinning machine modified by a technology is adopted, a drafting part adopts a drafting system of the TGS0950 type sisal spinning machine, and the twisting part is modified into a twisting roller type self-twist spinning twisting and winding device; one of feeding raw materials adopts sisal fibers while the other one of the feeding raw materials adopts chemical fiber filaments, self-twist spinning of the chemical fiber filaments and the sisal fibers is implemented, and then thread twisting, oiling and rope making are carried out. High-strength high-modulus low-elongation polyester filament yarns and ultra-high molecular weight polyethylene filament yarns are respectively added in a spinning process, wherein the ultra-high molecular weight polyethylene filament yarns are pretreated, and the polyester filament yarns and the ultra-high molecular weight polyethylene filament yarns are trilobal structural sections. The invention provides a novel method for producing the steel wire rope core, the process flow is shortened, and surface burrs of yarns are reduced.

Owner:NANTONG CITY TONGZHOU DISTRICT DADA HEMP TEXTILE +1

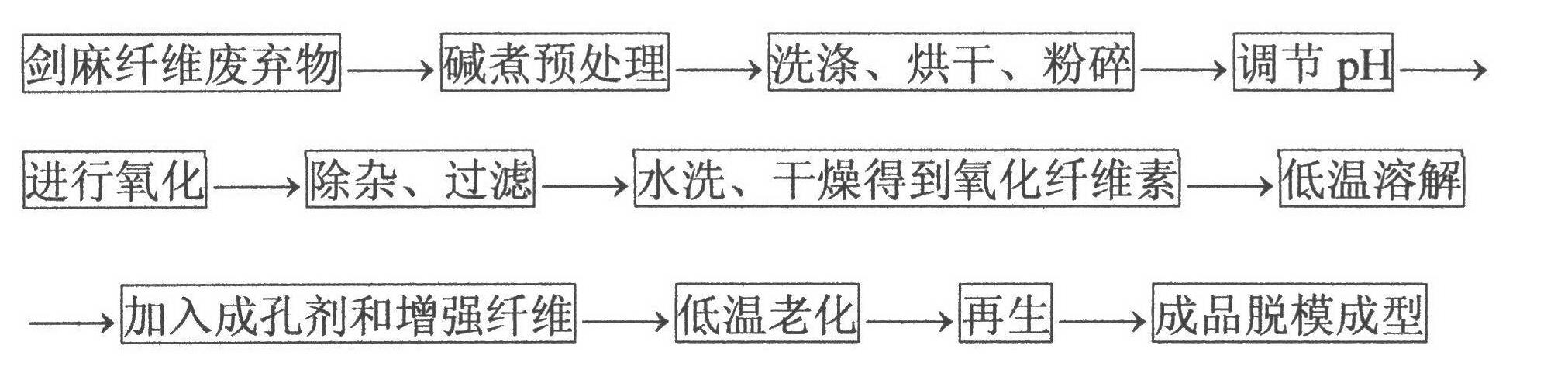

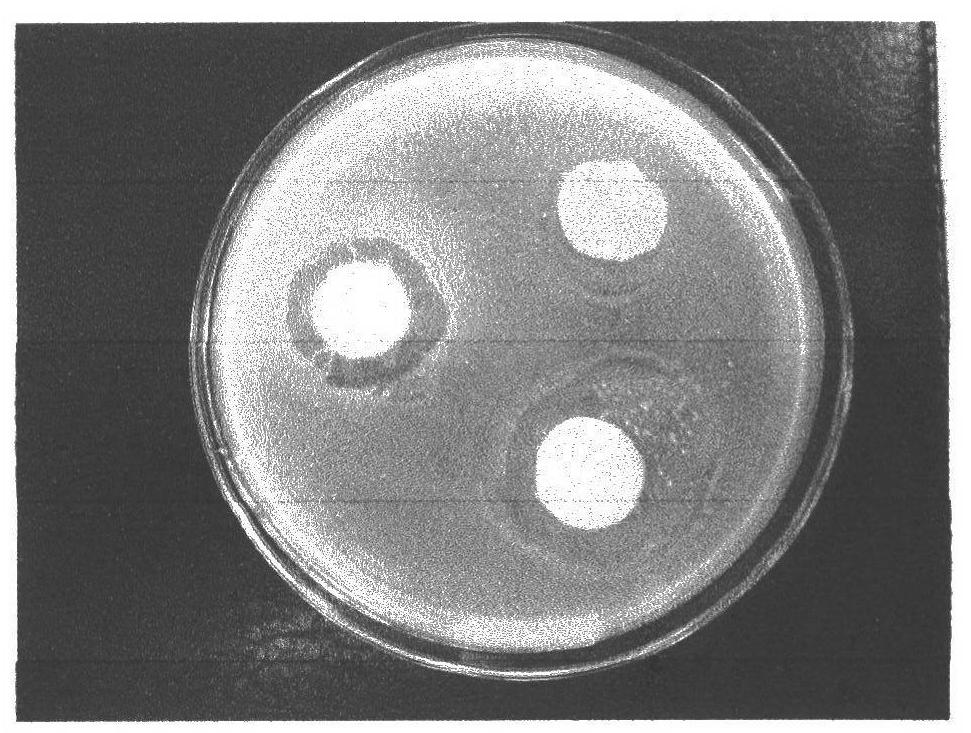

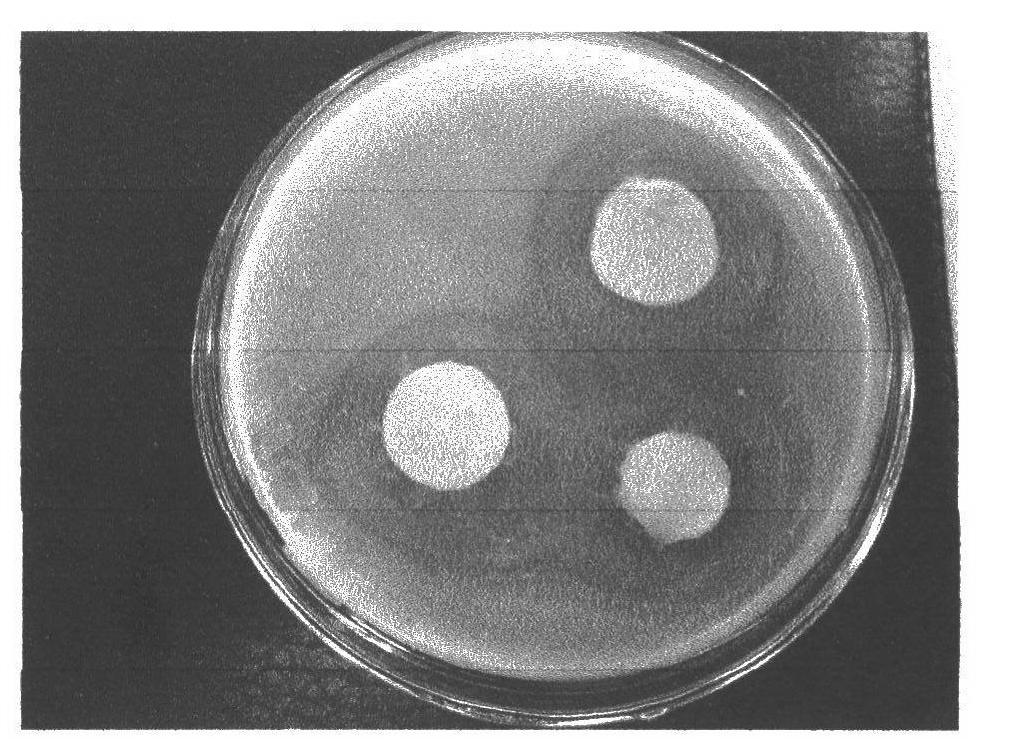

Method for preparing hemostatic sponge by use of sisal cellulose oxide

ActiveCN102634069ATo achieve the purpose of comprehensive utilization of sisal wasteAbsorbent padsBandagesCelluloseThiourea

The invention discloses a method for preparing hemostatic sponge by use of sisal cellulose oxide. The method comprises the following steps of: performing basic boiling of the sisal fiber waste by use of sodium hydroxide solution, washing to neutrality, and drying and crushing to obtain powder; adding the powder of the sisal fiber waste to the sodium periodate solution with adjusted pH, and stirring for reaction at constant temperature; after the reaction is over, adding ethylene glycol solution and continuing stirring; filtering, washing the filter cake with distilled water to neutrality, anddrying to obtain the sisal cellulose oxide; preparing the mixed solution of sodium hydroxide and thiourea; adding the prepared sisal cellulose oxide to the mixed solution for low-temperature dissolution; adding the pore-forming agent sodium sulfate, stirring uniformly and adding absorbent cotton; after low-temperature ageing, performing regeneration reaction in the coagulating bath formed by concentrated sulfuric acid and sodium sulfate; and washing clean with water to obtain the hemostatic sponge. According to the invention, the sisal cellulose oxide sponge is prepared by use of sisal fiber waste, and the obtained sisal cellulose oxide sponge has good antibacterial activity and can be used as hemostatic sponge.

Owner:桂林华诺威基因药业股份有限公司

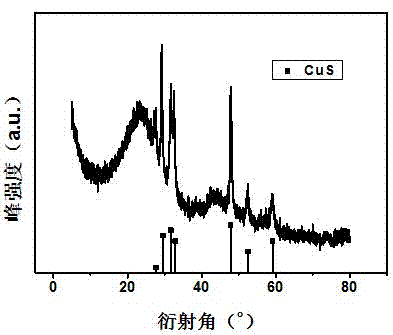

Submicron copper sulfide/sisal fiber carbon anode material for lithium ion battery and preparation method thereof

ActiveCN104852016AImprove conductivityIncrease irreversible capacityCell electrodesSecondary cellsThioureaSisal fiber

The invention discloses a submicron copper sulfide / sisal fiber carbon anode material for a lithium ion battery and a preparation method thereof. The preparation method comprises the following steps of carbonizing, grinding and sieving the sisal fibers into a tubular atmosphere oven, uniformly mixing with copper nitrate and thiourea in the solution, transferring into a reaction kettle to carry out hydrothermal reaction, and filtering, cleaning and drying an obtained sample to obtain the submicron copper sulfide / sisal fiber carbon anode material for the lithium ion battery. Copper sulfide particles with irregular shapes and the particle sizes of 200-500 nm are uniformly dispersed in the surface and holes of sisal fiber carbon with a multilevel pore structure in the anode material, and a mass ratio of the copper sulfide to a compound is 1 to 5. The submicron copper sulfide / sisal fiber carbon anode material for the lithium ion battery, which is prepared by the invention, has better cycle performance and rate performance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Antistatic bamboo fiber fabric and preparation method thereof

ActiveCN103966689AImprove antistatic performanceFeel goodElectroconductive/antistatic filament manufactureMonocomponent cellulose artificial filamentFiberCutaneous microcirculation

An antistatic bamboo fiber fabric is prepared from the following components in parts by weight: 3-4 parts of nano chitin, 40-50 parts of 1-ethyl-3-methylimidazole acetate, 3-5 parts of potassium acetate, 40-50 parts of 1-ethyl-3-methylimidazolium chloride, 14-17 parts of plastic starch, 2-3 parts of aloe gelatin, 14-20 parts of binata fiber, 7-10 parts of water, 60-70 parts of bamboo fiber, 5-8 parts of sisal fiber, 1-2 parts of graphite powder, 1-2 parts of hops, 1-2 parts of ginkgo biloba, 0.4-0.8 part of a spinning auxiliary. According to the invention, nano aloe gelatin and graphite powder are added into the fabric, so that the fabric is good in antistatic performance; the strength of the fiber is enhanced and the hand feeling and waterproof property are improved by the addition of the nano chitin and the plastic starch; skin microcirculation can be enhanced by the addition of the hops and the ginkgo biloba.

Owner:JIXI YUANDAO AGRI IND TECH

Brake gasket and its preparng metod

The preparation process of brake gasket includes the following steps: preparing sisal fiber via cutting sisal into 10-20 mm long segment, soaking in anhydrous alcohol plus benzene solution, washing with anhydrous alcohol and deionized water, boiling in NaOH solution, cooling to room temperature, washing with deionized water to neutrality and stoving in stove; mixing sisal fiber, phonetic resin, copper powder, graphite powder, MoS2, pre-polymer, metal oxide, butadiene-acrylonitrile rubber, non-metal compound and barium sulfate in a high speed mixer to form mixture material; making blank with the mixture material; hot pressing the blank to form; and heat treatment at 190-200 deg.c. The present invention makes asbestos-free brake gasket with sisal fiber as reinforcing material, and the brake gasket has stable friction coefficient, less heat degradation, low wear, no couple wear, smooth braking, low noise and no environmental pollution.

Owner:XI AN JIAOTONG UNIV +1

Vehicle brake pad with composite material

InactiveCN106438791AImprove high temperature resistanceImprove heat stabilityOther chemical processesFriction liningCarbon fibersSisal fiber

The invention discloses a vehicle brake pad with a composite material. The vehicle brake pad comprises a steel sheet and a friction block; and the friction block includes raw materials of: boron modified phenolic resins, organic silicon modified phenolic resins, barium phenolic resins, phenylacetylene phenolic resins, terminal epoxy liquid reaction nitrile rubber, butadiene rubber, molybdenum disulfide, sisal fibers, carbon fibers, aluminum fibers, molybdenum fibers, polyphenylene benzodioxazole fibers, zinc oxide whiskers, montmorillonoid, vermiculite, nanometer aluminum oxide, cerium oxide, zirconium boride, aluminum silicate hollow spheres, oxidized graphene, copper powder, carbon nanotubes, nanometer carbon black, powder butadiene styrene rubber, ammonium molybdate, and octaphenyl silsesquioxane. The vehicle brake pad with the composite material is excellent in high-temperature resistance and heat resisting stability, high in wear resistance and long in service life.

Owner:CHONGQING SHUAIBANG MACHINERY CO LTD

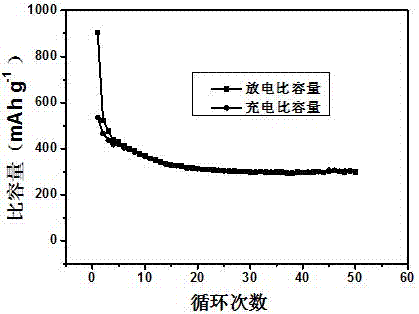

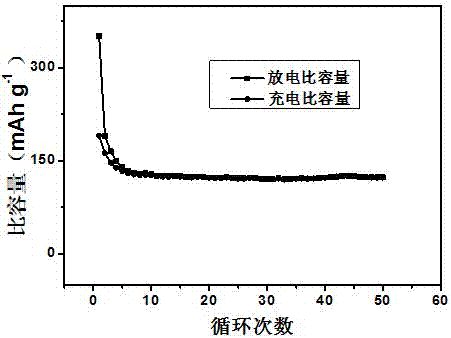

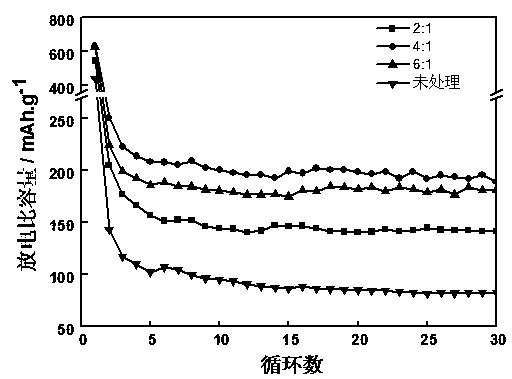

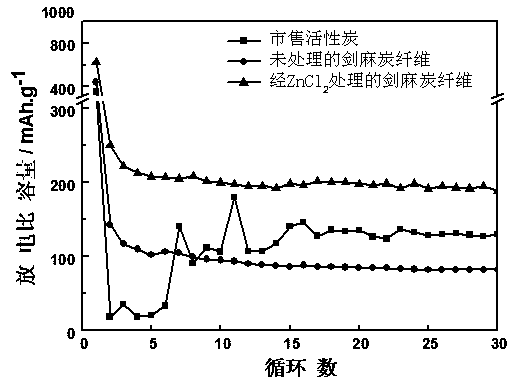

Method for preparing anode material of lithium ion battery based on chemically-activated sisal carbon fiber

ActiveCN103441242AImprove electrochemical performanceCarbon compoundsCell electrodesActivated carbonSisal fiber

The invention discloses a method for preparing an anode material of a lithium ion battery based on chemically-activated sisal carbon fiber. The method comprises the following steps: rubbing, washing and drying sisal fiber; soaking the sisal fiber for 24h by using a ZnCl2 solution with the mass percentage of 15-25% according to the ZnCl2 to sisal fiber impregnation ratio of (2-6):1, flushing the sisal fiber by using deionized water, and drying the sisal fiber at the temperature of 80-100 DEG C for 12-24h; and placing the sisal fiber into a vacuum tubular resistance furnace, carbonizing the sisal fiber at the atmosphere of nitrogen gas and the gas flow of 40ml / min for 0.5-1h, and naturally cooling the sisal fiber to obtain the black fiber-shaped sisal activated carbon fiber, wherein the carbonizing temperature ranges from 700 DEG C to 1000 DEG C, and the temperature rise speed is 1-10 DEG C / min. The lithium ion battery is assembled by taking a lithium tablet as a cathode material and the ground sisal activated carbon fiber as the anode material, a constant-current charging / discharging test is carried out, and the result shows that the sisal carbon fiber subjected to chemical modification treatment has better electrochemical property as comparison with untreated sisal carbon fiber and commercially available activated carbon.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Foam brick produced from biogas residues and preparation method thereof

The invention discloses a foam brick produced from biogas residues. The foam brick is characterized by being prepared from the following raw materials in parts by weight: 60-70 parts of waste glass, 15-10 parts of biogas residues, 5-10 parts of attapulgite, 5-10 parts of plant ash, 3-5 parts of bamboo charcoal powder, 3-5 parts of sisal fiber, 2-4 parts of sodium tripolyphosphate, 2-4 parts of tartaric acid, 1-2 parts of carboxymethyl chitosan, 1-2 parts of lauryl sodium sulfate, 0.5-1 part of polyvinyl alcohol, 2-4 parts of a modifying additive and 50-60 parts of water. The waste residues generated by a biogas digester are recycled to produce the foam brick, the effects of saving resources, protecting environment and reducing cost are achieved, the product performance reaches the standard, and the foam brick is safe, harmless and high in environmental and economic benefits.

Owner:HEFEI KANGLING HEALTH TECH

Method for preparing waterproof material by modifying surfaces of sisal fibers with water-based organosilicone

InactiveCN106400507AChange hydrophilicityImprove interfacial adhesionLiquid repellent fibresVegetal fibresWater basedPolymer science

The invention discloses a method for preparing a waterproof material by modifying surfaces of sisal fibers with water-based organosilicone. The method utilizes sisal fibers as raw materials, and through the simple immersion curing process, surfaces of the sisal fibers form organosilicone hydrophobic layers. The method which produces sisal fibers with high hydrophobicity through hydrophilicity change is a simple and effective sisal fiber surface modification method. The method has the advantages of use of cheap and easy raw materials with wide raw material sources and simple and fast preparation process. The method realizes the synergistic effects of organosilicone and sisal fibers and overcomes the defects of use of the single material. The organosilicone hydrophobic layer coats the sisal fiber surface so that the sisal fibers have hydrophobicity, fiber interface adhesion is improved and sisal fiber application development is broadened.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation method for polyimide composite material for automobile

The invention provides a preparation method for a polyimide composite material for an automobile. The method comprises the following steps that 1, impurities in sisal fiber are removed, the sisal fiber is dried and added into a sodium hydroxide solution to be soaked, the sisal fiber is taken out to be washed to obtain alkalified sisal fiber, a silane coupling agent is dissolved into an acetic acid solution, the PH value is adjusted to be 7 through ammonium hydroxide, conditioning fluid is obtained after standing, and the alkalified sisal fiber is added into the conditioning fluid for ultrasonic dispersion and taken out for drying, taking, dispersion and smashing to obtain modified sisal fiber; 2, talcum powder is added into a mixing machine to be stirred, then a titanate coupling agent is added, and modified talcum powder is obtained after taking out and drying are performed; 3, polyimide, the modified sisal fiber and the modified talcum powder are added into a stirring machine for stirring and mixing and then taken out to be put into a mold for compression molding forming, and mold stripping is performed to obtain the polyimide composite material for the automobile. According to the preparation method, raw materials are cheap and easy to obtain, the production cost is saved, and the obtained composite material has the good mechanical performance, has the certain degradability and is environmentally friendly.

Owner:SUZHOU ZHENZHAN TECHCAL MATERIAL CO LTD

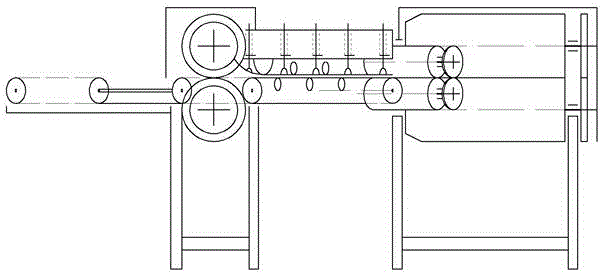

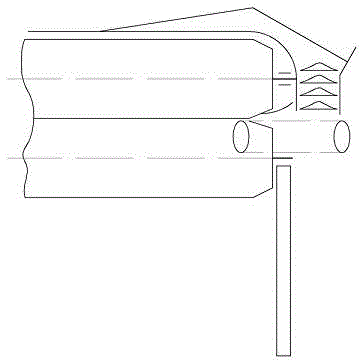

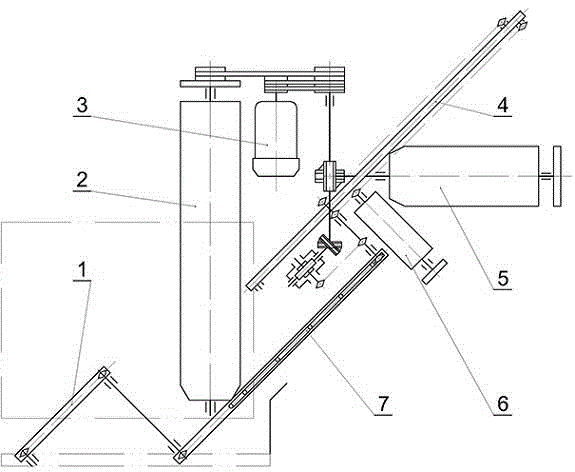

Novel sisal fiber extraction method and device

The invention provides a novel sisal fiber extraction method and device. The method comprises the steps that sisal leaves are crosswise fed into one hemp peeling mechanism from the middle of the sisal leaves, and fibers are obtained through direct reverse drawing. The device comprises a feeding mechanism, a sisal leaf clamping and delivery mechanism, a fiber clamping and delivery mechanism, a left hemp peeling mechanism and a right hemp peeling mechanism, sisal leaf base crushing mechanism, and a power and transmission device, wherein the sisal leaves and the fiber clamping and delivery mechanism are arranged in an inclined mode toward the hemp peeling mechanisms and perpendicular to the crushing mechanism, a chain and a belt are arranged in parallel and the delivery speeds are the same, and the linear speed of a crushing roller is 1.4 times those of the chain and the belt. Double-vane rolling cylinders with two vanes rotating in opposite directions serve as the hemp peeling mechanisms. The sisal leaves are crosswise fed into the left hemp peeling mechanism by the feeding mechanism, fibers are drawn out by the sisal leaf clamping chain and enter the fiber clamping belt, tip fibers are further drawn out, bases enter the right hemp peeling mechanism after winding around the shaft end of the crushing roller, and base fibers are reversely drawn out. By the adoption of the method and device in sisal fiber extraction, the per capita productivity of an existing device is improved by 2 to 3 times, and the productivity per kilowatt hour is improved by 1 to 2 times.

Owner:XIANNING AGRI ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com