Method for preparing anode material of lithium ion battery based on chemically-activated sisal carbon fiber

A lithium-ion battery and sisal fiber technology, applied in chemical instruments and methods, battery electrodes, inorganic chemistry, etc., can solve problems such as short service life, high cost, and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) The raw fibers stripped from sisal leaves are rubbed to remove dandruff, washed with deionized water, and then dried at 80°C for 12 hours.

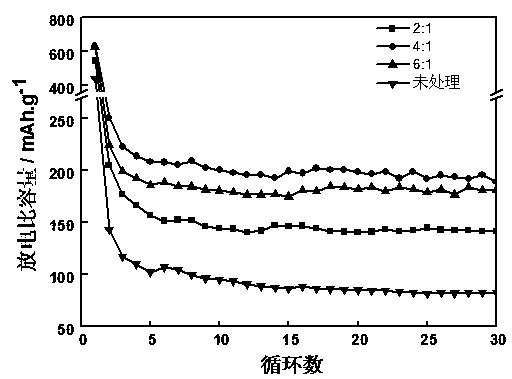

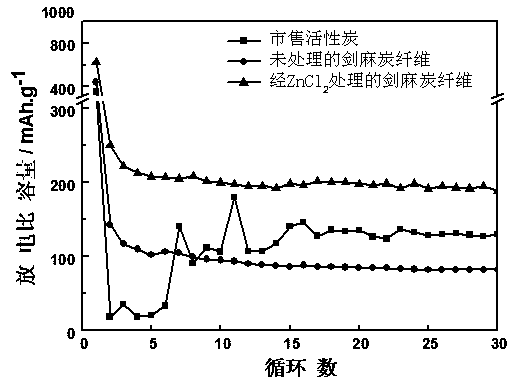

[0017] (2) Take three parts (6g each) of the sisal fibers obtained in step (1) and place them in beakers respectively, and use 25% ZnCl 2 The solution is according to the ZnCl 2 The mass ratio of sisal fiber and sisal fiber is 2:1, 4:1, 6:1 impregnation than soaking for 24 hours, then ZnCl 2 The residual solution was washed with water until neutral, and dried at 80°C for 12 hours.

[0018] (3) Put the sisal fibers obtained in step (2) into 50ml crucibles respectively, then put them into a vacuum tube resistance furnace, and carbonize for 1 hour under a nitrogen atmosphere with a gas flow rate of 40ml / min, and the carbonization temperature is 900°C. The heating rate was 3°C / min, and black fibrous sisal activated carbon fibers were obtained after natural cooling, which were bagged and sealed for storage.

[0019] (4) The sisal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com