Tencel fiber and spun silk fiber blended mercerizing fabric and production process

A technology of spun silk fiber and tencel fiber, which is applied in the field of textile fabrics, can solve the problems of no stiffness, easy deformation, and no elasticity, and achieve the effect of firm texture, good elasticity, and excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

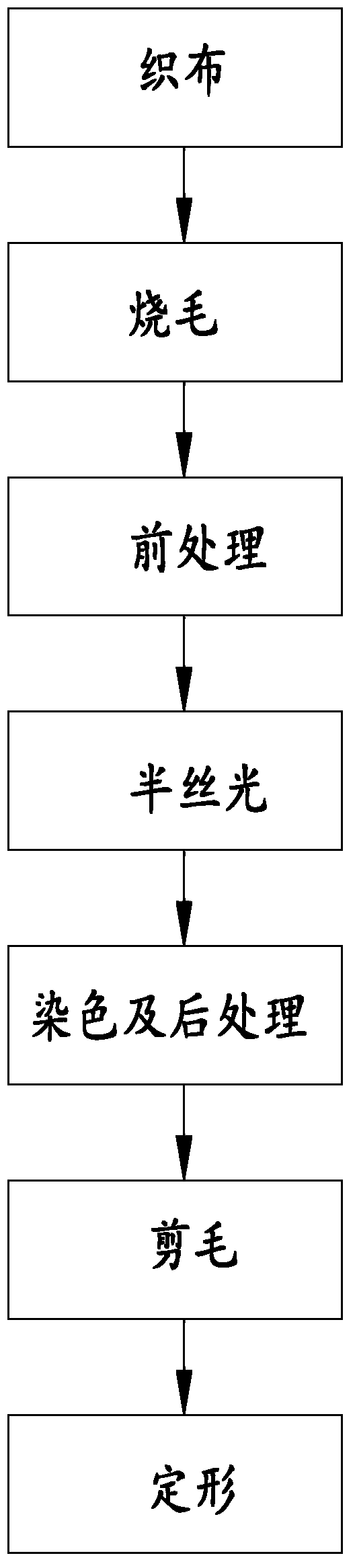

[0157] like figure 1 shown

[0158] Mercerized fabric blended with tencel fiber and spun silk fiber, including the following raw materials:

[0159] Tencel fiber 50wt%,

[0160] Silk fiber 50wt%;

[0161] The blended mercerized fabric is 30S / 1, and the line length of every 100G is 32cm.

[0162] The production process of the blended mercerized fabric of tencel fiber and spun silk fiber comprises the following steps:

[0163] (1) Weaving, according to the ratio of raw materials, weft knitting the tencel fiber and spun silk fiber into a double-sided structure to obtain gray cloth;

[0164] (2) singeing, singeing the fluff layer on the surface of the gray cloth to obtain the singed gray cloth;

[0165] (3) Pretreatment, the singed gray cloth is sequentially scouring, washing, pickling and water washing to obtain the pretreated fabric by removing wax, impurities and oil, and the scouring is carried out in a slightly alkaline scouring solution Carried out in, the pickling is ...

Embodiment 2

[0223] like figure 1 shown

[0224] Mercerized fabric blended with tencel fiber and spun silk fiber, including the following raw materials:

[0225] Tencel fiber 80wt%,

[0226] Silk fiber 20wt%;

[0227] The blended mercerized fabric is 60S / 1, and the line length of every 100G is 39cm.

[0228] The invention also proposes a production process of the fabric, which solves the production problem of the fabric.

[0229] The technical solution is realized in this way, including the following steps:

[0230] (1) Weaving, according to the ratio of raw materials, weft knitting the tencel fiber and spun silk fiber into a double-sided structure to obtain gray cloth;

[0231] (2) singeing, singeing the fluff layer on the surface of the gray cloth to obtain the singed gray cloth;

[0232]Because when weaving, although twisted, there are still many loose fibers exposed on the surface of the yarn. During the weaving process, the yarn guide and the knitting needle rub against the yar...

Embodiment 3

[0295] like figure 1 shown

[0296] Mercerized fabric blended with tencel fiber and spun silk fiber, including the following raw materials:

[0297] Tencel fiber 70wt%,

[0298] Silk fiber 30wt%;

[0299] The blended mercerized fabric is 80S / 1, and the line length of every 100G is 52cm.

[0300] The production process of the blended mercerized fabric of tencel fiber and spun silk fiber comprises the following steps:

[0301] (1) Weaving, according to the ratio of raw materials, weft knitting the tencel fiber and spun silk fiber into a double-sided structure to obtain gray cloth;

[0302] (2) singeing, singeing the fluff layer on the surface of the gray cloth to obtain the singed gray cloth;

[0303] Because when weaving, although twisted, there are still many loose fibers exposed on the surface of the yarn. During the weaving process, the yarn guide and the knitting needle rub against the yarn, resulting in the formation of fluff layers of varying lengths on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line length | aaaaa | aaaaa |

| Line length | aaaaa | aaaaa |

| Line length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com