Patents

Literature

106results about How to "No exudation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing tungsten-copper composite material with fine grain

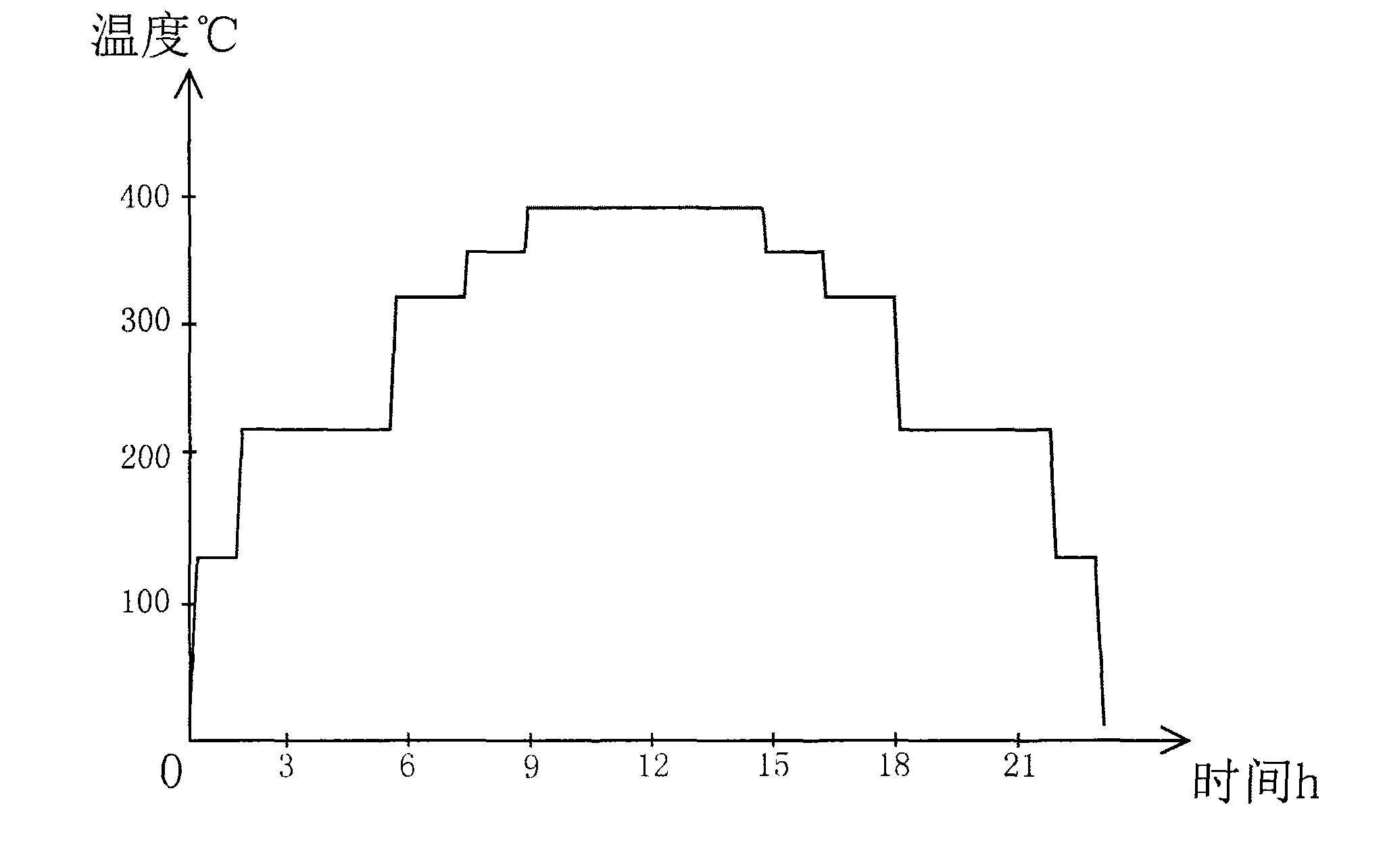

The invention relates to the field of powder metallurgy technology characterized in that, forming the powder with 200 MPa-500 MPa and feeding into sintering furnace, elevating the temperature to 400-700 deg. C. at the speed of 5-20 deg. C per minutes, heat preserving for 15-120 mins, elevating the temperature to sintering temperature of 1150-1350 deg. C. at the speed of 20-60 deg. C per minutes, heat preserving for 30-120 mins.

Owner:CENT SOUTH UNIV

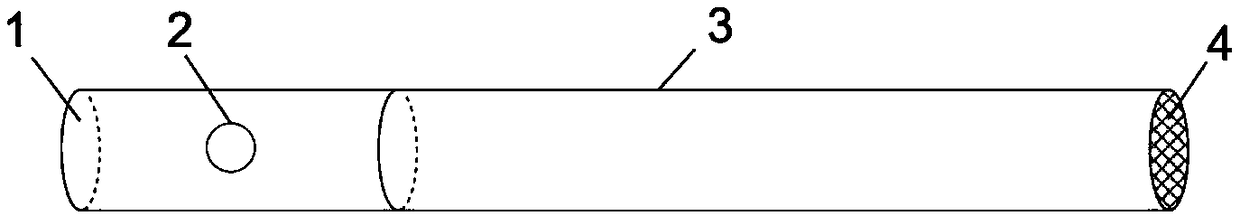

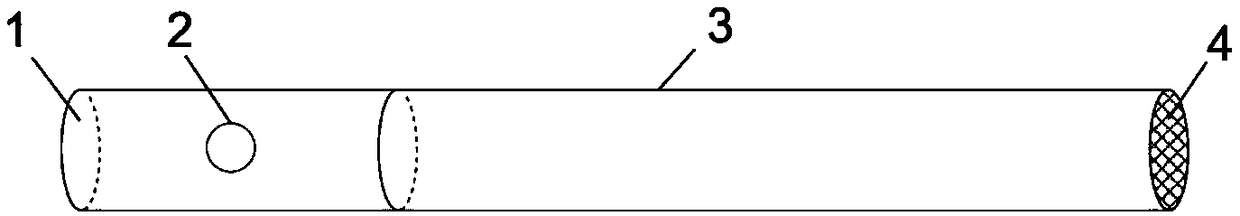

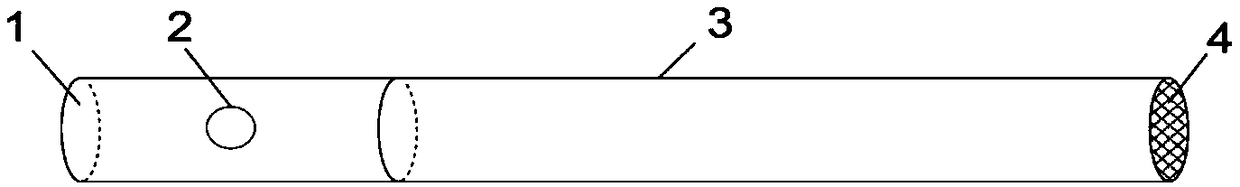

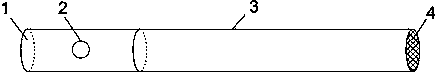

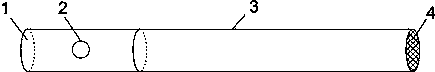

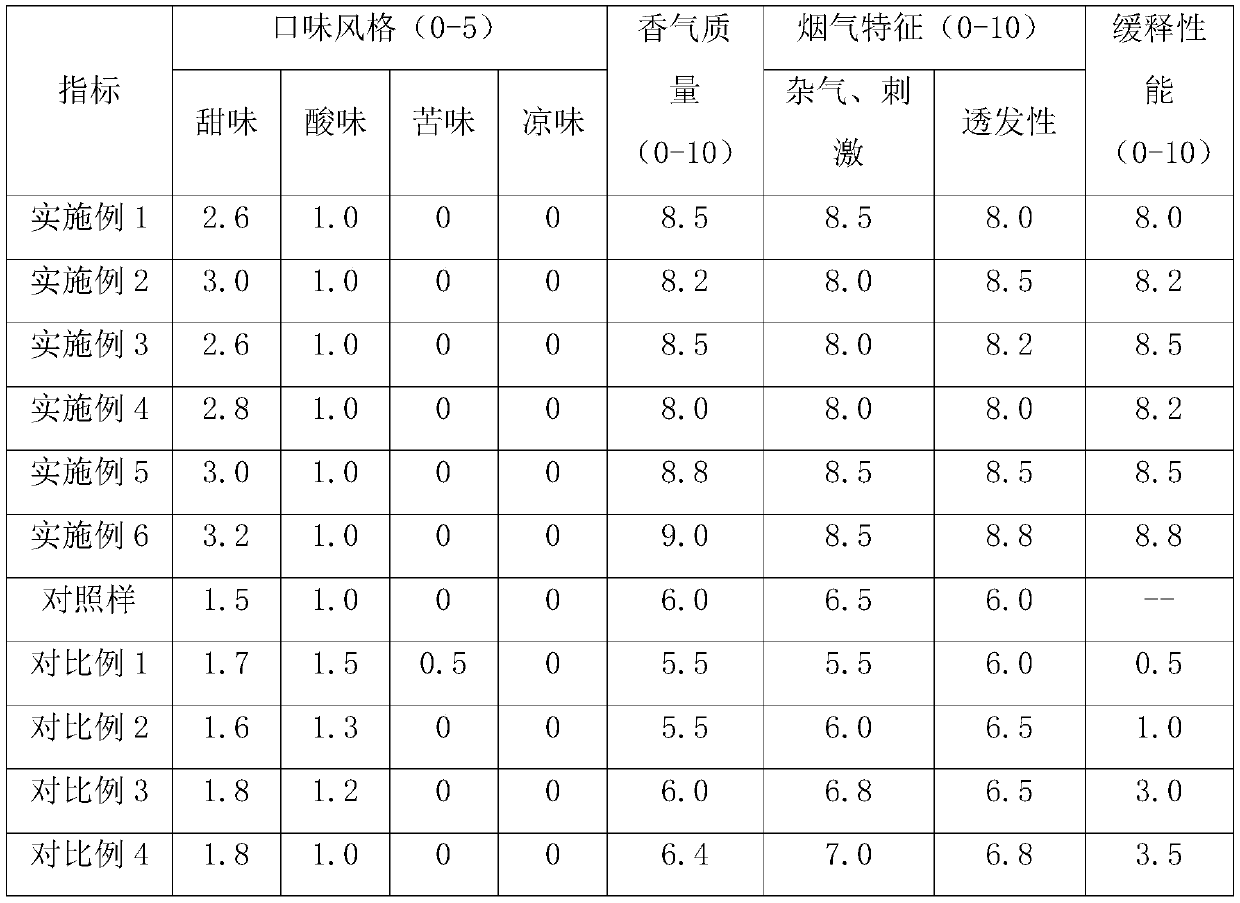

Thin cigarette filter rod containing single solid aromatic bead particle and preparation method of thin cigarette filter rod

ActiveCN108851214AFragrance rate is stableWill not be affected by the aroma of cigarettesTobacco smoke filtersGel preparationCombustion

The invention discloses a thin cigarette filter rod containing a single solid aromatic bead particle and a preparation method of the thin cigarette filter rod, and relates to the field of cigarette flavor spices. The solid aromatic bead particle is loaded in the middle of a cigarette filter rod tow and mainly prepared from activated montmorillonite by processes such as gel preparation, crystallization, ball making and flavor attachment, and an approach is provided for adding cigarette flavor with weak aroma keeping effects. In the smoking process, the flavor in the filter rod is not involved in combustion and slowly and uniformly released along with smoke, and the problem of aroma deterioration caused by combustion is solved. The thin cigarette filter rod has the advantages that the singlesolid aromatic bead particle is applied to the cigarette filter rod, the cigarette filter rod is simple in structure, poisonless and tasteless, a consumer does not need to worry about safety of tinyadditives such as zeolite powder, the aromatic bead is simple in preparation process and stable to form, the total control rate of the concentration of the aromatic bead is more stable, the qualification rate and the production stability of the aromatic bead are better than those of an 'explosion bead', additional solvents are omitted in flavor attachment, and aroma is elegant and volatile.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

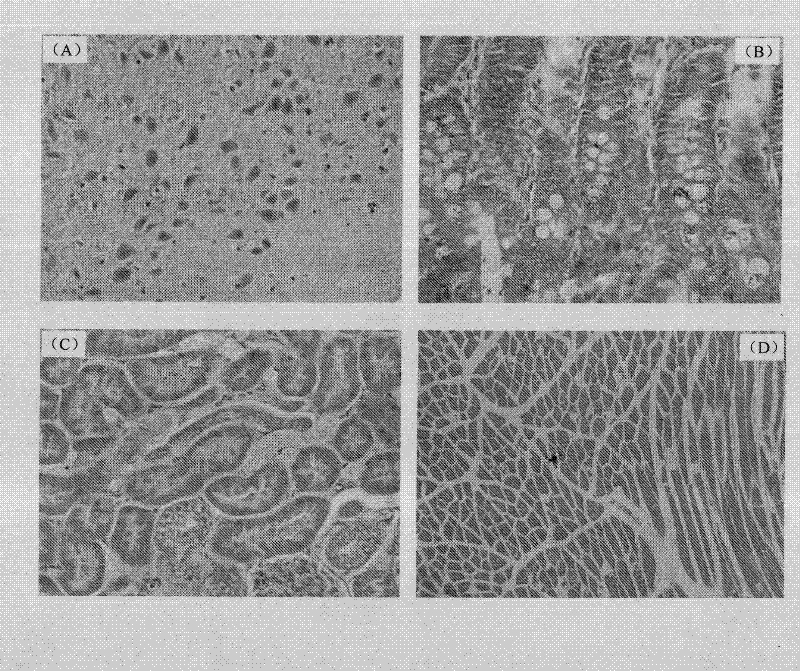

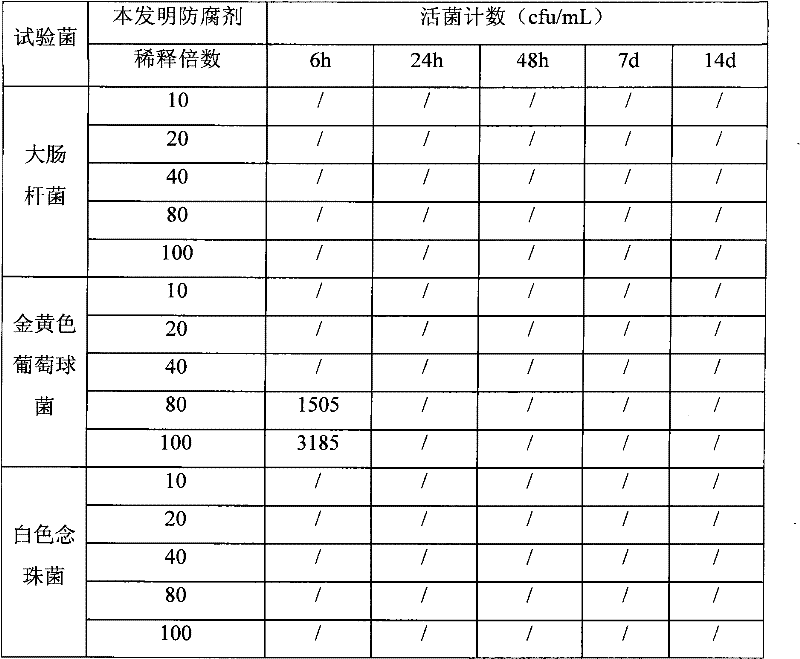

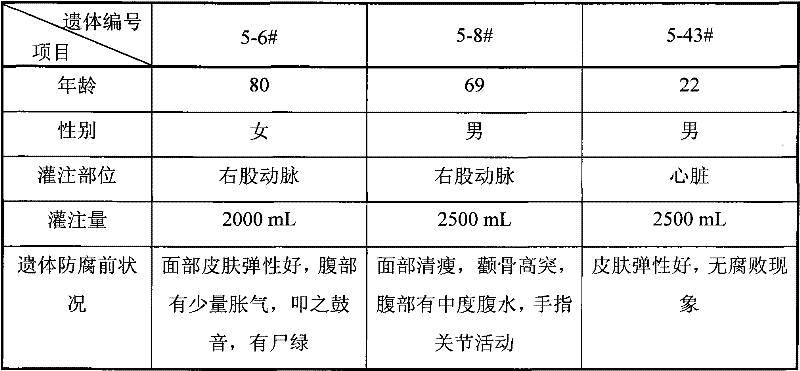

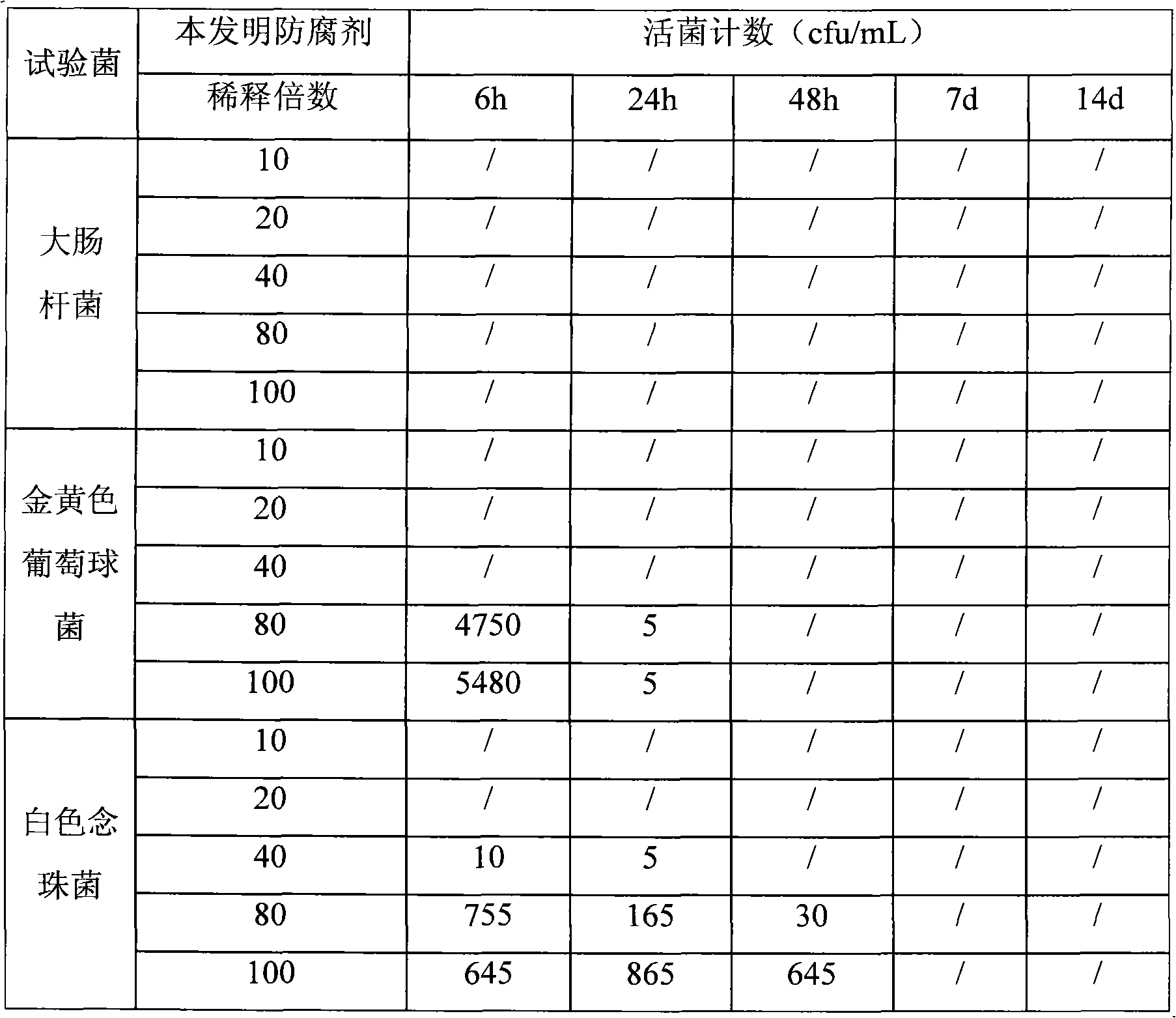

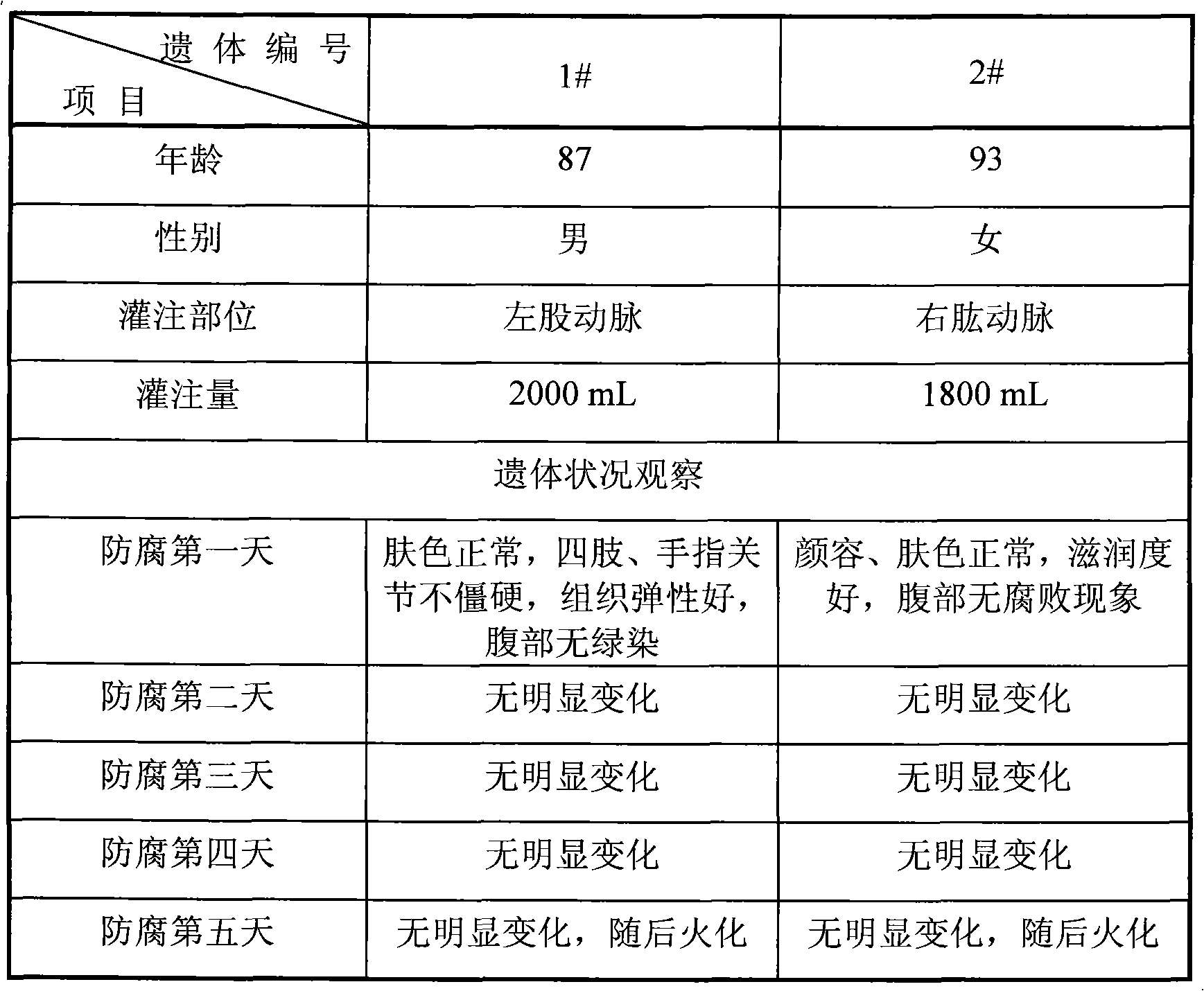

Efficient and environment-friendly remains preservative and application thereof

The invention relates to an efficient and environment-friendly remains preservative free of formaldehyde and application thereof. The remains preservative mainly comprises, by volume, 0.5-10% of phenoxyethanol, 0.2-1.5% of isothiazolinone, 3-15% of organic acid, 5-20% of propylene glycol, 5-30% of glycerol, 20-75% of ethanol and 5-35% of distilled water, and, by weight, 1-10% of hexamethylenetetramine and 0-2% of ethylenediamine tetraacetic acid disodium salt. The preservative can be poured through an aorta and an aortic arch and injected through the abdominal cavity, the thoracic cavity, the pharyngeal cavity and the cranial cavity so as to carry out antiseptic preservation, disinfection and smell removal to remains. Quantification sterilization experiments, animal experiments and funeral home field experiments prove that the remains preservative is efficient in antibacterial property, quick in action speed, low in toxicity and suitable for short-term or long-term remains antisepsis or specimen preservation of funeral homes and medical colleges at home and abroad.

Owner:民政部一零一研究所

Cigarette filter rod containing large-particle solid aromatic bead and preparation method of cigarette filter rod

ActiveCN108851213AWill not be affected by the aroma of cigarettesImprove adsorption capacityTobacco smoke filtersFlavorCombustion

The invention discloses a cigarette filter rod containing a large-particle solid aromatic bead and a preparation method of the cigarette filter rod, and belongs to the field of cigarette flavor spices. The large-particle solid aromatic bead is loaded in the middle of a filter rod tow and mainly prepared from porous powder quartz by processes such as pulping, calcination pore-forming and flavor attachment, and slight aromatic and volatile cigarette flavor is added. In the smoking process, the flavor is slowly and uniformly released along with smoke, and the problem of aroma deterioration causedby combustion is solved. The single solid aromatic bead is loaded into the cigarette filter rod, the cigarette filter rod is simple in structure, poisonless, harmless and better in qualification rateand production stability, a smoker does not need to worry about safety of tiny additives, the preparation processes of the aromatic bead are simple, the total control rate of the concentration of thearomatic bead is more stable, additional solvents are omitted in flavor attachment, and aroma is elegant and volatile.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Low-toxicity, environment-friendly short-term remains preservative and usage thereof

ActiveCN102461496AReasonable formulaAppropriate proportionDead animal preservationChemistryOrganic acid

The invention relates to a low-toxicity, environment-friendly short-term remains preservative based on alcohols and usage thereof. The remains preservative mainly comprises 60 to 75 percent of ethanol, 5 to 20 percent of propylene glycol, 3 to 15 percent of organic acid, 0 to 0.3 percent of essence and 10 to 40 percent of distilled water according to volumetric proportion as well as 0.2 to 10 percent of nipagin ester, 0.3 to 3 percent of thymol, 0.5 to 3 percent of mannitol (or sorbierite) and 0.05 to 0.5 percent of low-toxicity metal salt according to weight ratio. The invention can adopt the immersion method or the infusion method to preserve and fix remains (tissues), and the preservative can be infused via the aorta (arch) and injected via the thoracic cavity and the abdominal cavity, and has the fast and effective effects of disinfection, embalmment and preservation. The preservative is highly antibacterial, can effectively prevent bacteria from corroding the remains and the autolysis of the tissues, can be used as histocyte fixative, and is applicable to short-term remains embalmment or specimen preservation in domestic and foreign funeral homes and medical academies.

Owner:民政部一零一研究所

A medium-size cigarette mouth stick containing large granular solid fragrant beads and a preparation method thereof

ActiveCN109198721AFragrance rate is stableImprove adsorption capacityTobacco smoke filtersEssential-oils/perfumesFlavorCombustion

A medium-size cigarette mouth stick containing large granular solid fragrant beads and a preparation method thereof are provided, belonging to the field of cigarette flavor and perfume. The circumference of that middle cigarette nozzle bar is 19.8 + / - 0.2 mm, and the middle part of the tow is loaded with a large solid perfume bead with the diameter of 3.25 + / - 0. 15 mm. The solid perfume bead is made from clay by pulping, calcining, pore-forming, perfume adding and the like, and provides a more ideal way for the addition of the heat-sensitive tobacco flavor. In the process of smoking, the essence in the mouth stick does not take part in the combustion, with the smoke slowly and evenly released, the problem of aroma deterioration caused by combustion is solved. The mouth stick has the advantages of simple structure, non-toxicity and harmlessness, and avoids the safety worries of consumers on fine additives such as biocharcoal powder and zeolite powder. The preparation process of fragrant beads is simple, the overall control rate of fragrant bead concentration is more stable, the qualified rate, the production stability is better than the ''exploded beads'', and the fragrance is morepure without additional solvent added when the fragrance is added.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

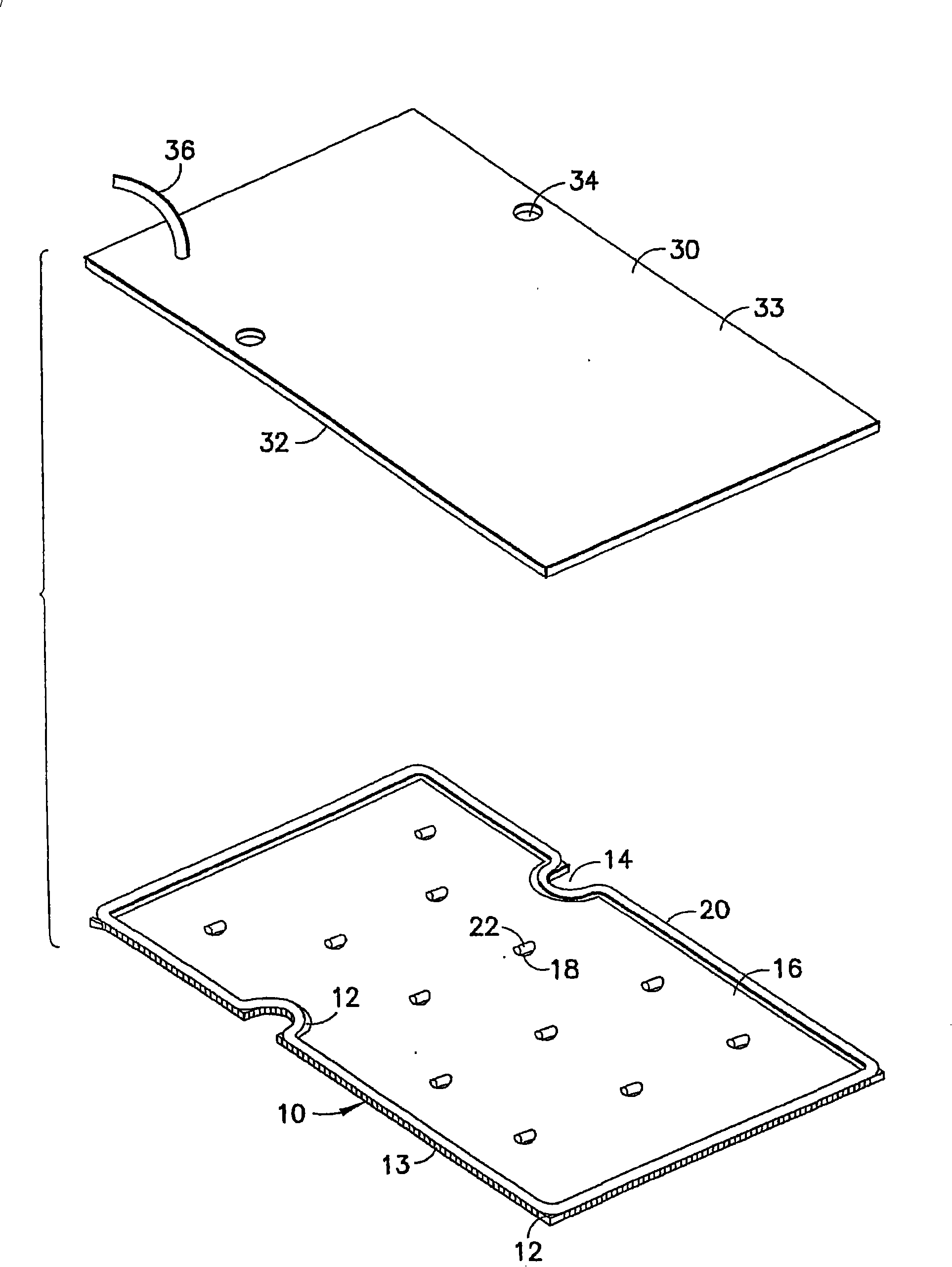

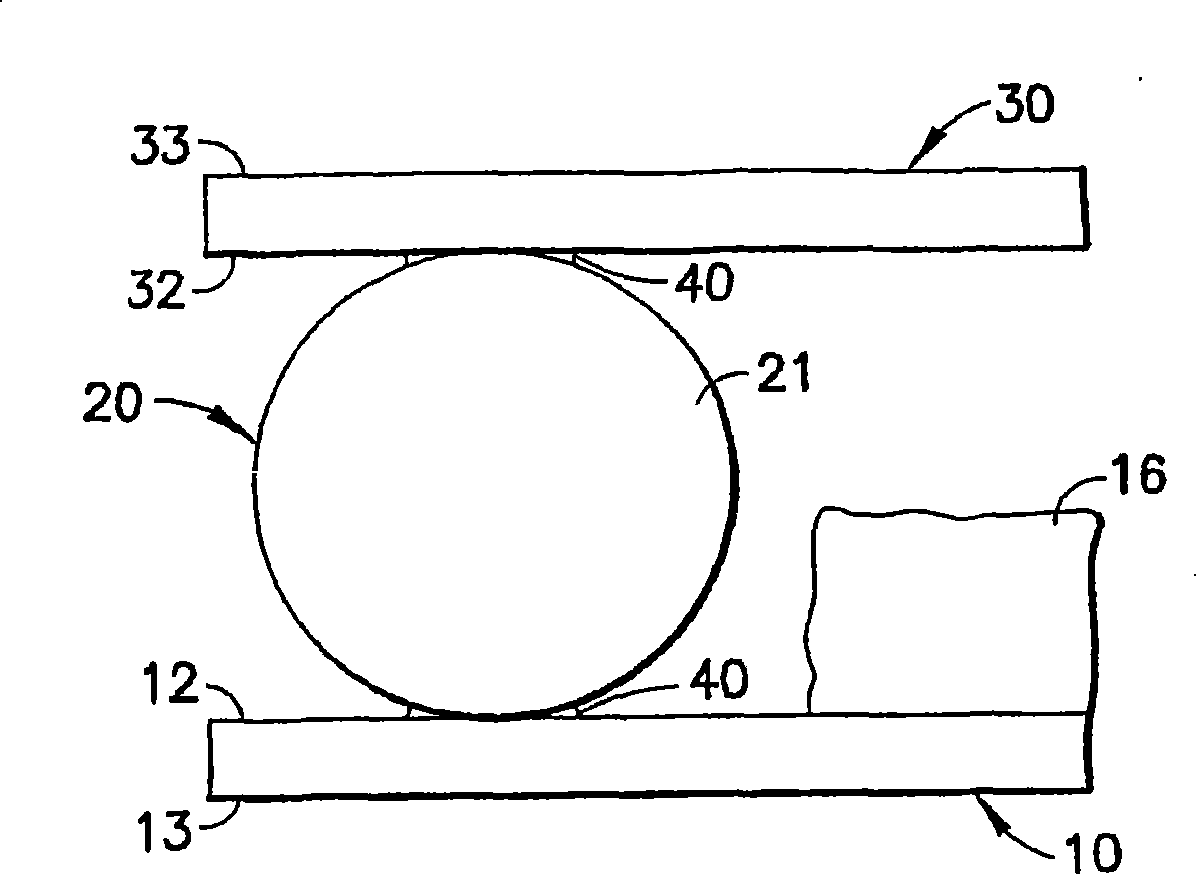

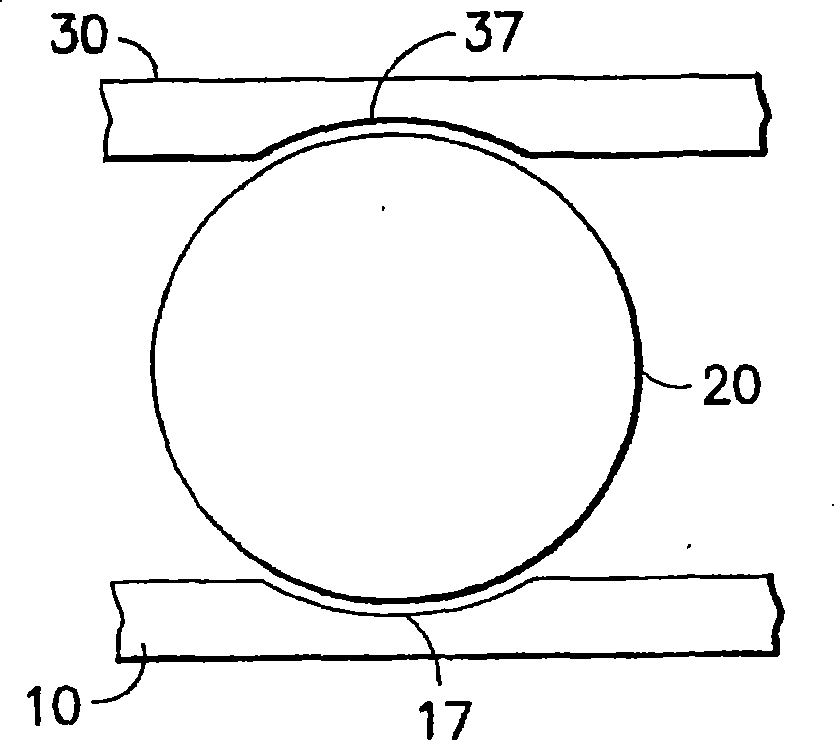

Fluid-containing cooling plate for an electronic component

InactiveCN101208576AReduce exudationNo exudationSolid-state devicesStationary conduit assembliesEngineeringAlloy

A fluid-containing cooling plate includes a bottom plate, a top plate, and metal wire or tubing formed into a circuit and sandwiched between the plates to form a chamber. The wire is plated or otherwise coated with a brazeable or solderable alloy which bonds it to the plates when the assembly is heated, thereby sealing the chamber. To make a two-phase cooling plate, slugs of plated metal are placed in the chamber and are bonded to the plates to provide support against collapse. The chamber is provided with a wicking structure, and is partially filled with an evaporable fluid via an inlet. A partial vacuum is then drawn, and the inlet is closed off. To make a single-phase cooling plate, wire partitions serving as baffles are provided in lieu of the slugs. These partitions can be arranged to provide a serpentine flow path between the inlet and an outlet, and are likewise plated with an alloy which melts to bond them to the plates.

Owner:AAVID THERMALLOY LLV

Preservative liquid for corpses, tissue and dissections, and application method thereof

ActiveCN104094923ALess irritatingLow environmental and human health hazardsDead animal preservationOrganic acidChemistry

The invention provides a preservative liquid for corpses, tissue and dissections and an application method thereof. The preservative liquid mainly comprises 0.5 to 2% by mass of glutaraldehyde, 0.3 to 3% by mass of thymol, 0.5 to 3% by mass of sodium benzoate, 0.1 to 1% by mass of sodium citrate (or citric acid), 0.5 to 3% by mass of mannitol (or D-sorbitol), 40 to 65% by volume of ethanol, 5 to 15% by volume of glycerol, 1 to 5% by volume of organic acid, 0 to 1% by volume of essence and 14 to 54% by volume of water. The preservative liquid can realize preservation and fixation of corpses, tissue and dissections via a soaking or perfusion method and exerts anticorrosive, preservative, disinfecting and stink-removing effects. According to results of animal experiments of the preservative liquid in a laboratory, on-site experiments in a mortuary house, etc., the preservative liquid has high efficiency bacteriostatic performance, safety and low toxicity and is applicable to preservation of corpses, tissue and dissections in medical teaching and scientific research and funeral services.

Owner:民政部一零一研究所

Thermoplastic elastomer composition and molded article thereof

A thermoplastic elastomer composition which comprises a mixture of an ethylene / alpha-olefin copolymer (A1) or an oil-extended rubber (X) consisting of an ethylene / alpha-olefin copolymer (A2) and a mineral oil softener (E2) with a thermoplastic alpha-olefin resin (B) comprising a crystalline thermoplastic alpha-olefin resin (B1) and / or a noncrystalline thermoplastic alpha-olefin resin (B2) and, incorporated in the mixture, an unmodified organopolysiloxane (C), a vinylated organopolysiloxane (D), and a mineral oil softener (E1); and a molded article obtained by molding the composition. The thermoplastic elastomer composition imparts initial sliding properties due to the organopolysiloxane, which has a low viscosity. Since the thermoplastic elastomer composition contains the vinylated organopolysiloxane, which has been crosslinked, it has long-lasting antiwear properties (long-term sliding properties). It gives a molding having an excellent appearance.

Owner:JSR CORPORATIOON

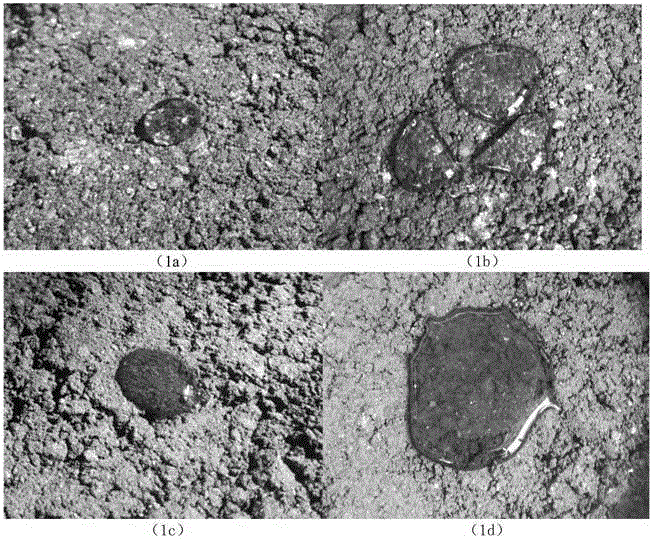

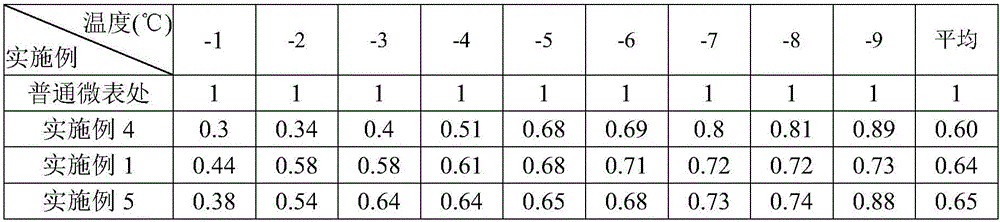

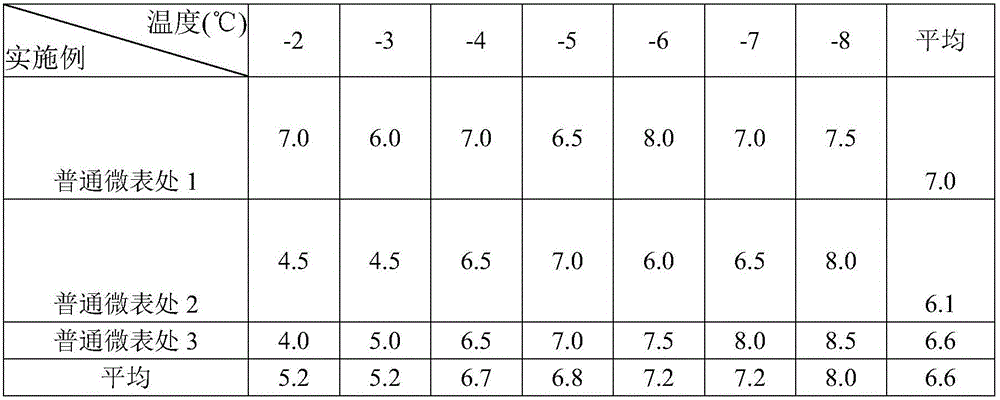

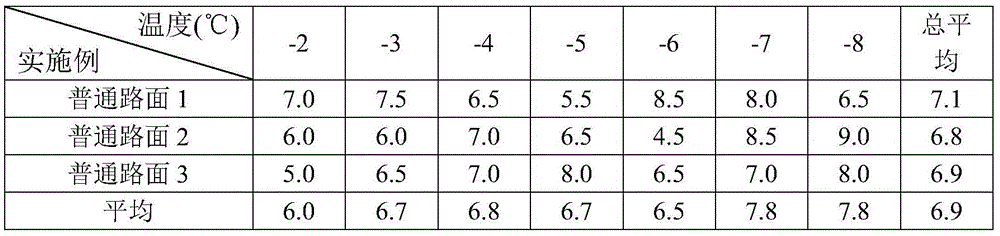

Preparation method for pavement micro-surfacing with hydrophobicity and anti-icing performance

The invention discloses a preparation method for pavement micro-surfacing with hydrophobicity and anti-icing performance. According to the invention, by combining a hydrophobic surface with a pavement micro-surfacing maintenance technology, a hydrophobic agent highly dispersed in emulsified asphalt is uniformly distributed in a pavement layer after being subjected to demulsification, while the hydrophobic agent dispersed in the pavement layer forms a hydrophobic surface on the pavement surface through hydrophobic long chains of the hydrophobic agent; thus, surface energy of the pavement is reduced; adhesion properties of an ice layer to the asphalt pavement is significantly weakened, so the ice layer on the asphalt pavement in winter is liable to be removed; and the hydrophobic agent is dispersed in the whole micro-surfacing structure layer, so hydrophobicity of a maintenance layer does not rapidly decline with the wearing action of vehicle wheels.

Owner:SHANXI ROAD & BRIDGE CONSTR GROUP +1

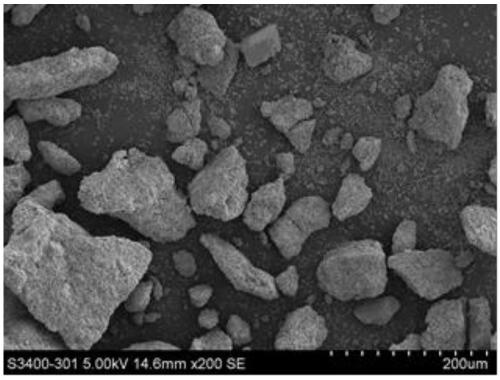

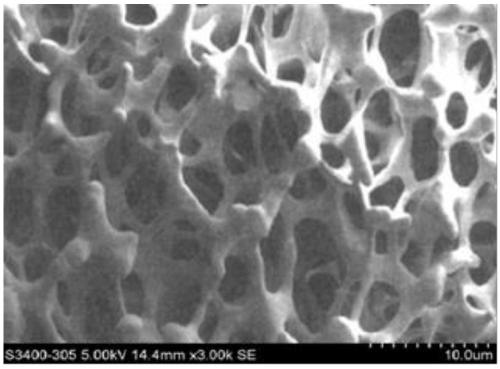

Novel preparation method of soilless culture medium

The invention relates to a novel preparation method of a soilless culture medium, which is characterized by comprising the following steps: mixing 10-30 wt% of 0.5-300 mu m glass powder, 1-15 wt% of cosolvent, 80-25 wt% of ceramic powder and 9-30 wt% of pore increasing agent, and grinding into a uniform powder mixture; and firing the powder mixture at 600-1100 DEG C for 1-4 hours, crushing and screening to obtain the soilless culture medium. The pore increasing agent is one or mixture of coal powder, crop straw fine powder and herbal plant fine powder; the ceramic powder is one or mixture of coal gangue, red mud, polished brick waste and waste ceramic tile powder of which the particle size is 0.5-5 mu m; and the cosolvent is sodium fluosilicate or sodium silicate, or mixture of sodium fluosilicate or sodium silicate in any proportion. The pore size of the soilless culture medium can be controlled at 0.1-0.5mm; the pores are uniformly distributed inside and outside and form interlocking pores; and thus, the soilless culture medium has favorable water retention property.

Owner:SHANDONG UNIV OF TECH

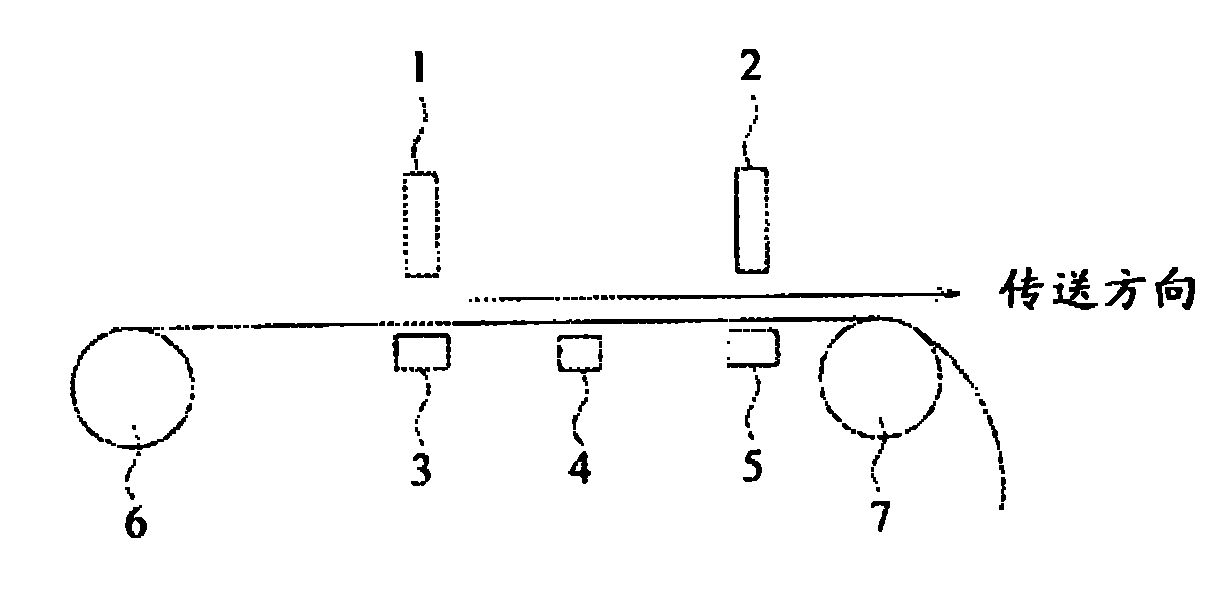

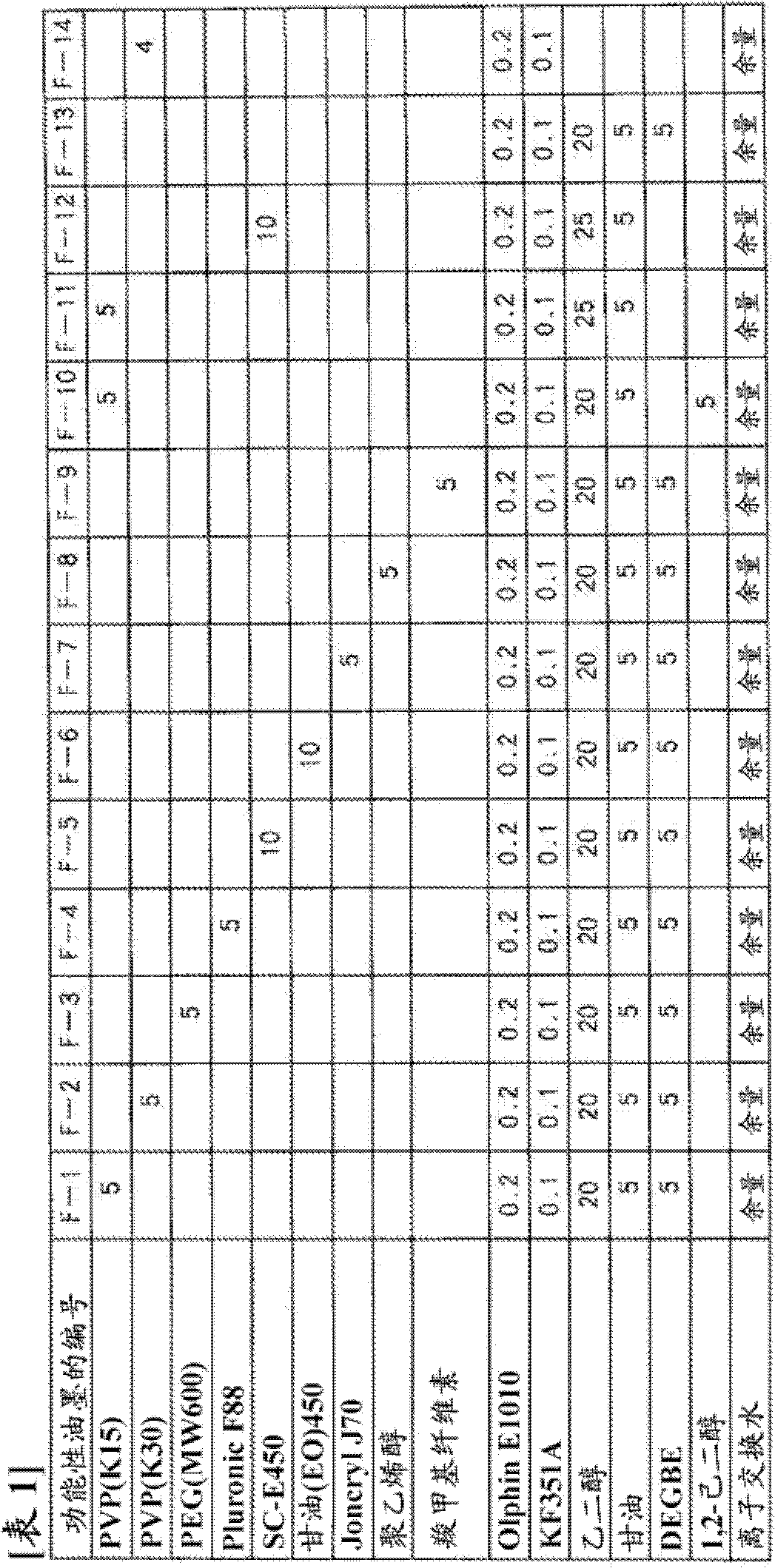

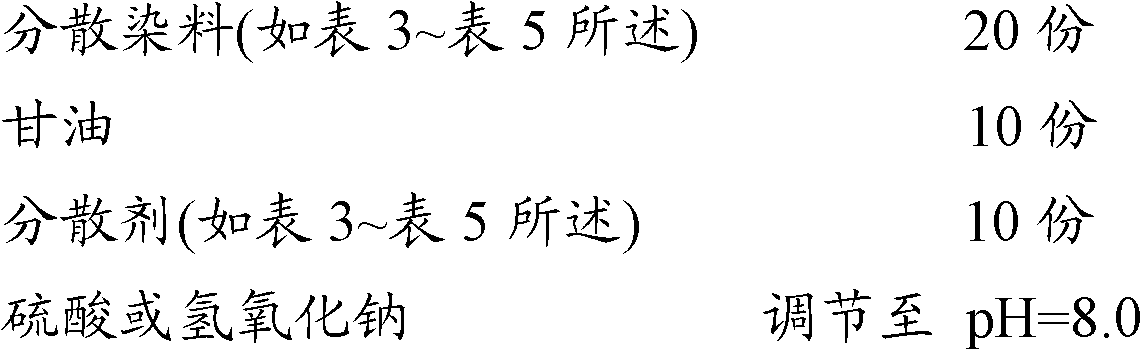

Ink-Jet Textile Printing/Recording Process

ActiveCN102341543ANo adverse conditions such as prime land pollutionImprove printing qualityDuplicating/marking methodsDyeing processTextile printerDisperse dye

Provided is an ink-jet textile printing / recording process, by which it is possible to form high-quality prints which do not suffer from bleeding, lowering in the density of developed color, contamination of non-printed white areas, or other faults. Thus, the ink-jet textile printing / recording process enables the expression of colorful designs. The ink-jet textile printing / recording process comprises applying a functional ink by an ink-jet system to at least portions of a textile where printed areas with the maximum density are to be formed, and then applying a recording ink to the resulting textile by an ink-jet system, wherein the functional ink contains both a water-soluble polymer and a water-soluble organic solvent, and the recording ink contains a disperse dye, a binder resin, and a water-soluble organic solvent.

Owner:KONICA MINOLTA IJ TECHNOLOGIES INC

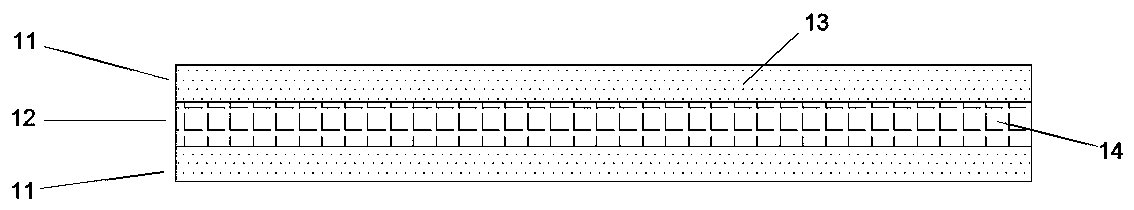

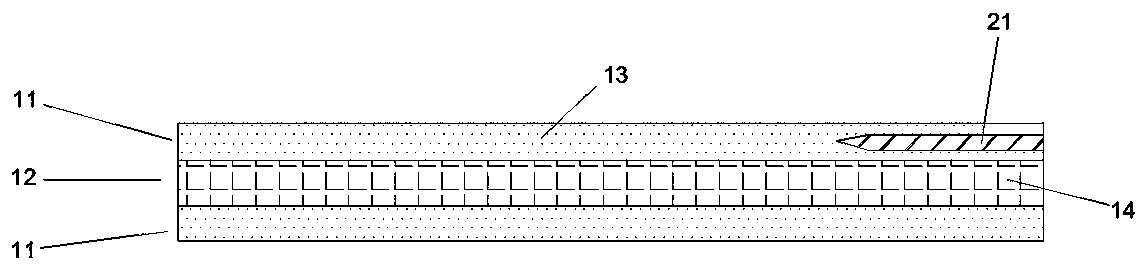

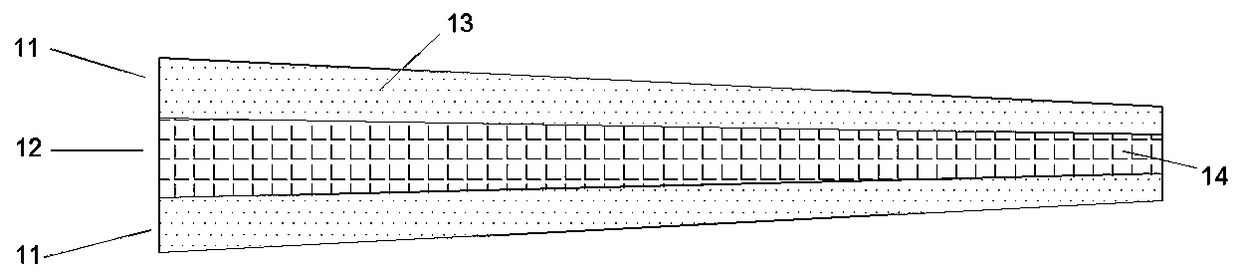

Modified polyvinyl butyral (PVB) resin with high plasticizer absorption rate, and sound reduction PVB film containing modified PVB resin

InactiveCN108384163ANo exudationReduce noiseSynthetic resin layered productsAbsorption rateChemistry

The invention discloses modified polyvinyl butyral (PVB) resin with high plasticizer absorption rate, and a sound reduction PVB film containing the modified PVB resin. Every 100 parts by weight of themodified PVB resin can absorb 40-120 parts by weight of plasticizer, and the plasticizer absorption rate of the modified PVB resin is 1.03-3.08 times the highest plasticizer absorption rate of the ordinary PVB resin; the sound reduction PVB film prepared from the modified PVB resin is free from plasticizer seepage for a long time, and can reduce noise by 1-10 decibels (dB) compared with the ordinary PVB of the same thickness. In addition, the sound reduction PVB film can also be transformed into a wedge-shaped structure from a rectangular structure by means of a hot pressing process, thus being conveniently used for head-up display type laminated glass.

Owner:ZHANGJIAGANG ALIEN NEW MATERIAL TECH CO LTD

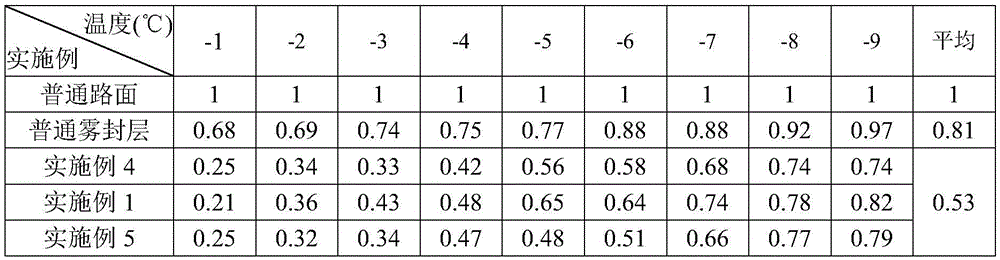

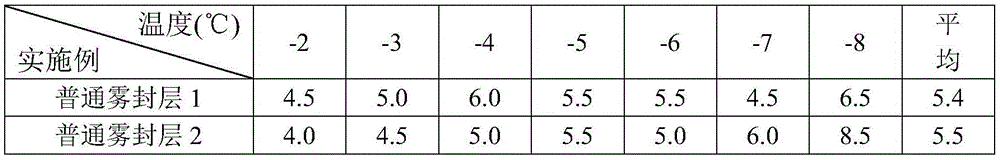

Production method of hydrophobic anti-icing pavement fog seal layer

InactiveCN105647211AHas hydrophobic anti-icing propertiesImproved hydrophobic anti-icing propertiesBuilding insulationsCross-linkEpoxy

The invention discloses a production method of a hydrophobic anti-icing pavement fog seal layer. Fog seal layer emulsified asphalt that is demulsified to be hydrophobic and anti-icing is produced by combining low-surface-energy organic silicon rubber and emulsified asphalt through a specific shearing process, and the fog seal layer emulsified asphalt is spread to a pavement before a snowy season to form a hydrophobic anti-icing fog seal layer with a contact angle of greater than 130 degrees on the pavement; by adding waterborne epoxy resin adhesive, a mesh cross-linked structure is formed in the asphalt without excessive increase in the viscosity, improving the ability of the fog seal layer to resistant external force destruction, improving bonding performance of the fog seal layer with the pavement and thus enhancing wear resistance of the fog seal layer. It is possible to effectively reduce the strength of bonding of an ice layer with the pavement and reduce maintenance and deicing difficulty in the case of a thick ice layer. The hydrophobic emulsified asphalt demulsified hydrophobing agent used herein has certain self-assembly function, molecular long chains of the hydrophobing agent will self-assemble on the surface of an asphalt film, thus further enhancing and maintaining hydrophobicity of the fog seal layer.

Owner:CHANGAN UNIV

Boiling-resistant aqueous composite ink and preparation method thereof

InactiveCN102532997AGood resolubilityExcellent retort resistanceInksPolymer sciencePigment dispersion

The invention discloses boiling-resistant aqueous composite ink and a preparation method thereof. The boiling-resistant aqueous composite ink mainly comprises raw materials including aqueous polyurethane resin, a pigment and water, and a surface wetting agent, a wetting dispersing agent and a defoaming agent are additionally added. The preparation method of the boiling-resistant aqueous composite ink comprises the following steps of: firstly, adding partial aqueous polyurethane resin into a stirring reaction kettle; secondly, slowly adding the surface wetting agent, the wetting dispersing agent and partial defoaming agent, and adding the pigment after stirring and dispersing; thirdly, stirring and dispersing at high speed, and grinding after dispersing; fourthly, adding the residual aqueous polyurethane resin and defoaming agent and stirring and dispersing, and adding the water until the required viscosity is obtained through regulation; and at last, stirring, dispersing, filtering and packaging. The boiling-resistant aqueous composite ink, provided by the invention, is prepared by taking the high-performance aqueous polyurethane resin as a connecting material, and has the advantages of good pigment dispersibility, wide use range, lower film forming temperature, better mechanical property of formed film, more uniform particle size distribution and the like, and can be used for soft retort packages.

Owner:ZHENGZHOU LETONG NEW MATERIAL TECH

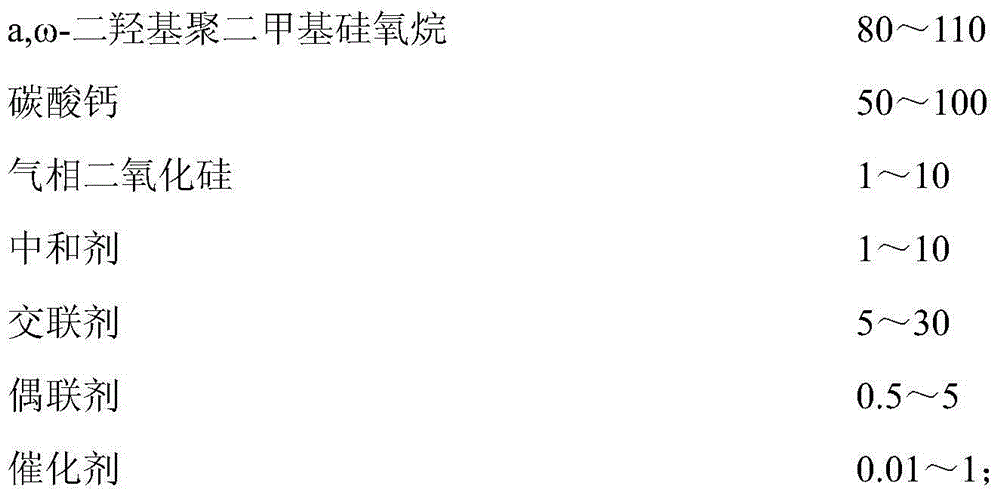

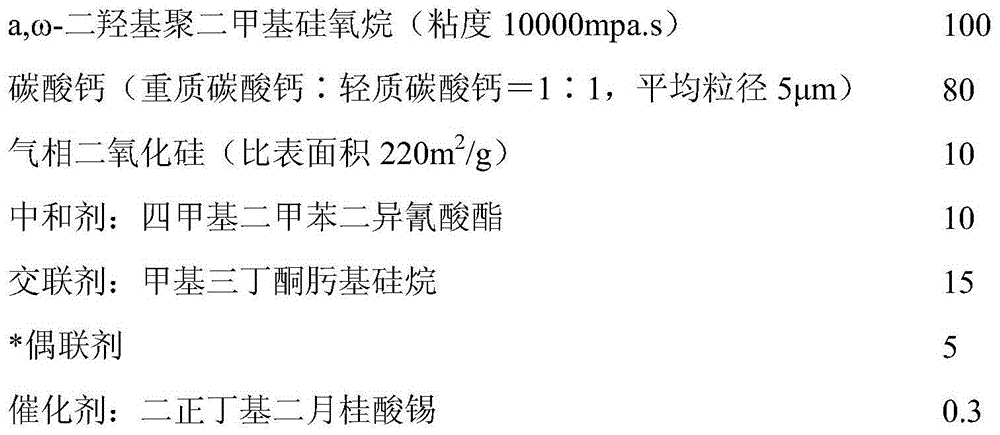

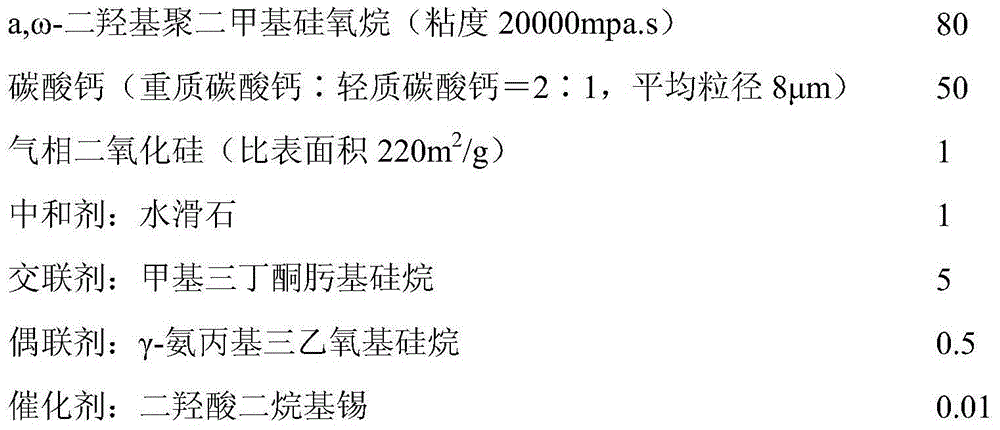

Low-volatility single-component de-ketoxime type silicone rubber for lamps and preparation method of silicone rubber

InactiveCN104371640AReduce or neutralize volatile matterEliminate the effects ofNon-macromolecular adhesive additivesPolymer scienceGas phase

The invention discloses low-volatility single-component de-ketoxime type silicone rubber for lamps. The silicone rubber comprises, by weight, 80-110 parts of a, omega-dyhydroxy polydimethyl siloxane, 50-100 parts of calcium carbonate, 1-10 parts of fumed silica, 1-10 parts of neutralizer, 5-30 parts of cross-linking agent, 0.5-5 parts of coupling agent and 0.01-1 part of catalyst, wherein the neutralizer is one or combination of hydrotalcite, aluminum silicate, magnesium silicate, zeolite, bamboo charcoal powder and organic isocyanate. The silicone rubber has the advantages the influence of ketoxime substances on PC materials is eliminated by lowering volatile content, and the rubber does not generate unpleasant smells during actual application, does not corrode and destroy the PC materials and good in cohesiveness.

Owner:GUANGZHOU HUINA NEW MATERIAL TECH

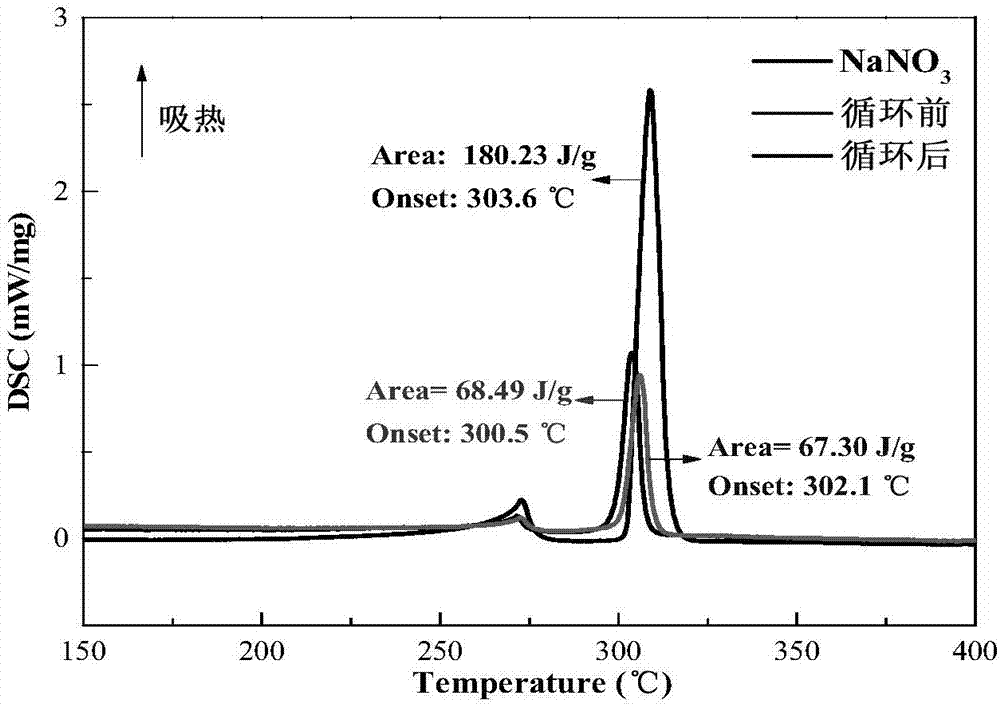

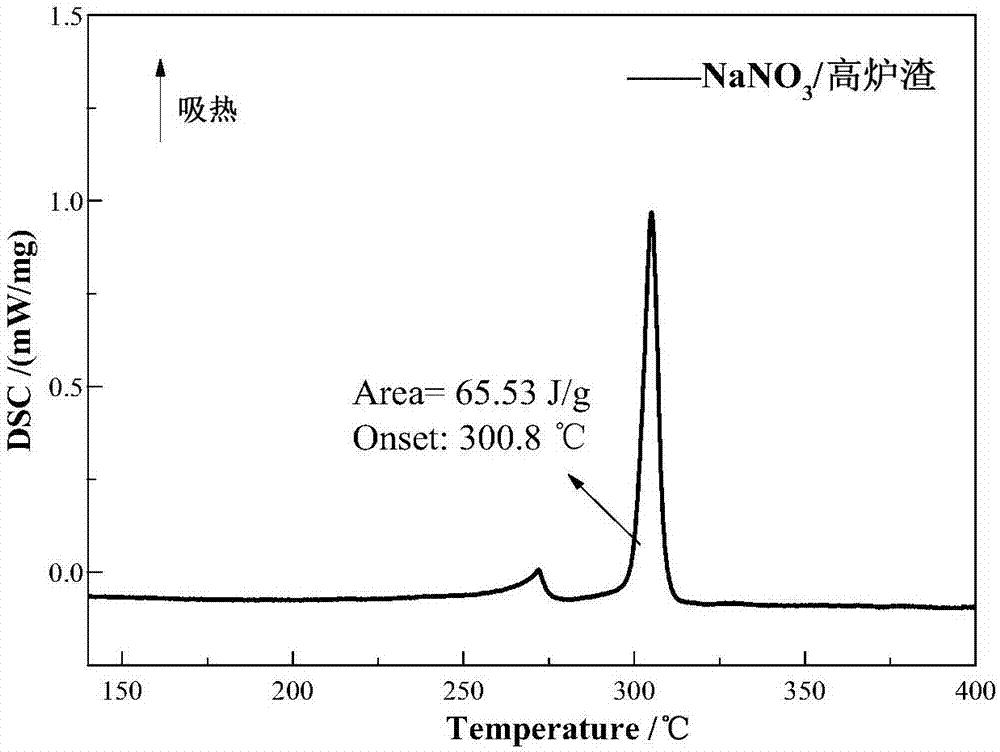

Preparation method of blast furnace slag-based composite phase-change heat storage material

ActiveCN107099275ARealize value-added utilizationReduce manufacturing costHeat-exchange elementsAir atmosphereSlag

The invention discloses a preparation method of a blast furnace slag-based composite phase-change heat storage material. The preparation method comprises the following steps: performing ball-milling pretreatment to a blast furnace slag raw material, uniformly mixing with an inorganic salt phase-change material and an adhesive, and pressing into a blank; sintering the blank in an air atmosphere to obtain the blast furnace slag-based composite phase-change heat storage material. The blast furnace slag has an excellent porous characteristic and can sufficiently adsorb the phase-change material, so that the formed composite phase-change heat storage material is uniform in appearance and stable in shape, does not seep out the phase-change material in the phase change process and can maintain the original outer shape; after multiple thermal cycles, the composite phase-change heat storage material still has good thermal stability, phase change latent heat and phase change temperature stability; the working temperature range of the composite phase-change heat storage material can be extended to a temperature of 300-850 DEG C according to different types of phase-change materials.

Owner:CENT SOUTH UNIV

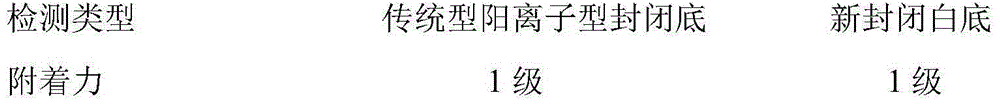

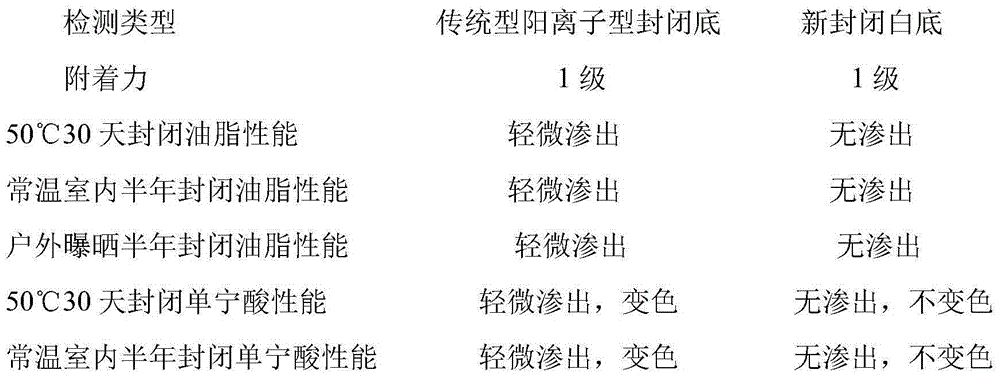

Aqueous white primer for sealing wood oil and tannic acid

The invention discloses aqueous white primer for sealing wood oil and tannic acid. The aqueous white primer comprises the following components in percentage by weight: 5-10% of water, 1-2% of a dispersant, 0.5-1% of a thickener, 0.1-0.2% of a pH adjustor, 1-2% of a defoamer, 15-20% of a titanium dioxide white pigment, 3-5% of a tannic acid inhibitor, 2-3% of a film forming solution, 8-10% of talcum powder and 47.8-64.4% of an acrylic emulsion. The invention relates to aqueous white primer which can be dried at normal temperature and coated to wooden furniture or artware, so that an extremely strong adhesive force and an excellent oil and tannic acid sealing property are achieved, and the purpose of excellent decoration and protection is realized.

Owner:上海展辰涂料有限公司 +4

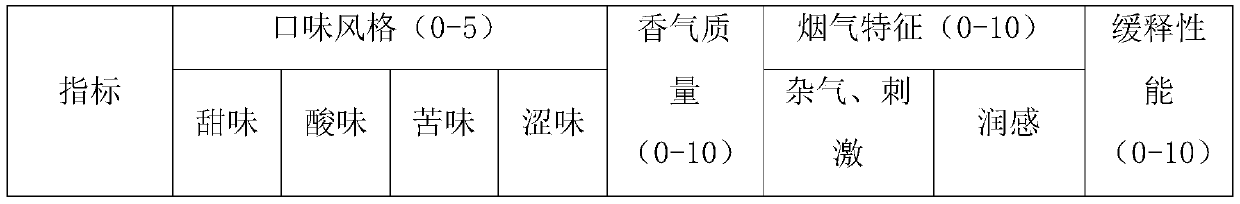

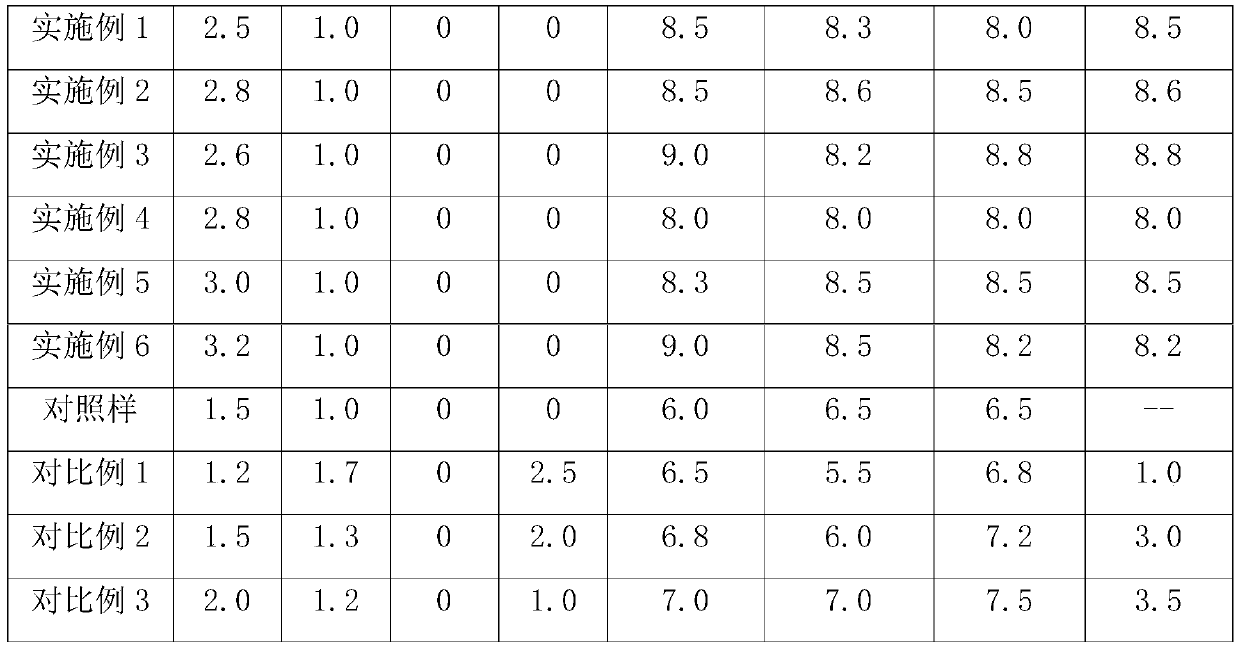

Cigarette dry bead filter rod capable of improving sweet feeling of cigarettes

ActiveCN110226774ANo astringencyRich and sweet aromaCigar manufactureTobacco smoke filtersMolecular sieveHippophae rhamnoides fruit

The invention discloses a cigarette dry bead filter rod capable of improving the sweetness of cigarettes. The circumference of the bottom surface of a nozzle rod is 24mm. A dry bead with the diameterthereof to be 3.25 + / -0.15 mm is loaded on the middle section of a tow. The dry bead takes a zeolite molecular sieve as a main raw material. The hippophae rhamnoides fruit composite extract for improving the sweetness of cigarettes is adsorbed on the dry bead. Due to the porous structure of the dry bead, in the cigarette smoking process, the essence is slowly and uniformly released along with smoke and is not combusted. Therefore, the diversity of smoking taste is improved. Meanwhile, the sweetening and moistening effect can be achieved.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Hydrophobic and anti-icing emulsified asphalt and preparation method thereof

InactiveCN107474564AImprove adhesionGood adsorption and permeabilityBuilding insulationsFluorinated ethylene propylenePolymer chemistry

The invention discloses hydrophobic and anti-icing emulsified asphalt and a preparation method thereof. The hydrophobic and anti-icing emulsified asphalt is composed of matrix asphalt, a soap liquid, a hydrophobing agent, an interface agent, waterborne epoxy resin and a curing agent, wherein the hydrophobing agent is a polyfluoroalkoxy or a fluorinated ethylene propylene copolymer with the fineness of 625-1250mu. The hydrophobic and anti-icing emulsified asphalt disclosed by the invention is relatively good in adhesion to various aggregates and capable of adapting to relatively disadvantage interface conditions and still keeping good hydrophobicity after being permeated into a gap of an asphalt pavement and the insides of the surfaces of the aggregates and being acted by a vehicle load for a relatively long term. The hydrophobic and anti-icing emulsified asphalt id directly spread or is mixed and spread with the aggregates to form a hydrophobic and anti-icing layer by which the adhesive force of an ice layer and the asphalt pavement can be remarkably reduced, so that the ice layer of the asphalt pavement in winter is easily eliminated. A construction technology of the hydrophobic and anti-icing emulsified asphalt is simple, rapid, wide in application range, high in economic and social benefits, high in practicability, good in use effect and convenient to popularize.

Owner:CHANGAN UNIV

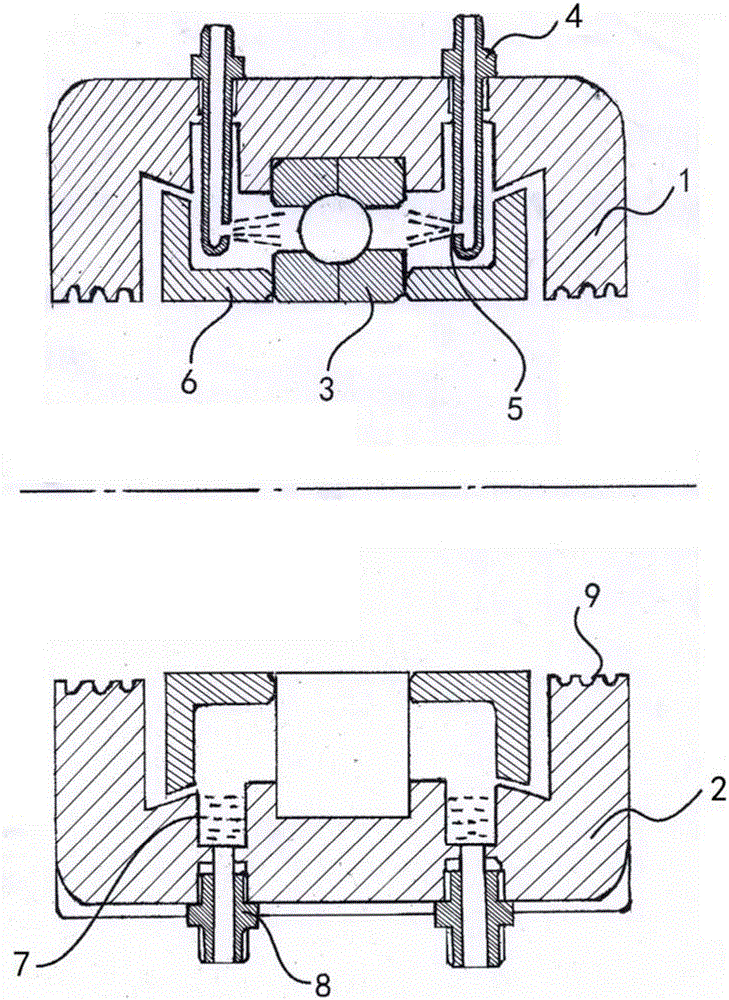

Splitting-type thin oil lubricating bearing seat

ActiveCN105003548AReduce the temperatureIncrease limit speedEngine lubricationBearing unit rigid supportOil canNozzle

The invention provides a splitting-type thin oil lubricating bearing seat. The splitting-type thin oil lubricating bearing seat comprises an upper cover and a base. After the upper cover is fixed to the base in a jointing mode, an annular groove used for installing of a bearing is formed. The outer ring of the bearing is arranged in the annular groove in an embedded mode. The portions, arranged on the two sides of the annular groove, on the top of the upper cover are axially provided with radial through holes respectively. An oil nozzle is arranged in each radial through hole. The portions, close to the lower ends, on the sides of the oil nozzles are provided with nozzle holes which face the bearing. According to the splitting-type thin oil lubricating bearing seat, oil can be supplied continuously through a hydraulic station by lubricating oil, it is not needed that oil supplying is carried out by manpower in a timing mode, the lubricating oil is returned back to an oil tank of the hydraulic station for being recycled, oil retainers are utilized, it is guaranteed that the lubricating oil cannot be leaked, and the leakage phenomenon does not exist. Meanwhile, a part of ball friction heat is taken away by the lubricating oil, the temperature of the bearing seat is far lower than the temperature of a lubricating grease lubricating bearing seat, the limit speed of the bearing can be improved by 20%, the temperature of the bearing is lowered, the service life of the bearing is prolonged, and maintaining of the bearing is lowered.

Owner:JIANGSU HENGLIANG CENTRIFUGE MFG

Cigarette dry bead filter tip rod with function of improving smoke permeability

ActiveCN110403236ASmall and dense pore sizeImprove adsorption capacityCigar manufactureTobacco smoke filtersMolecular sieveEngineering

The invention discloses a cigarette dry bead filter tip rod with a function of improving smoke permeability; the circumference of the bottom surface of the filter tip rod is 19.8mm, and the middle section of the strand is loaded with a dry bead with the diameter of 2.75 + / -0.15 mm; the dry bead is prepared by taking a zeolite molecular sieve as the main raw material through steps of pelletizing, agilawood attaching and forming processes; an agilawood composite extract capable of improving the smoke permeation function is adsorbed on the dry bead; due to the porous structure of the dry bead, inthe smoking process of the cigarettes, the essence is slowly and uniformly released along with the smoke gas without burning, so that the diversity of the smoking taste is increased; and meanwhile, the effect of improving the smoke permeability function can be achieved.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

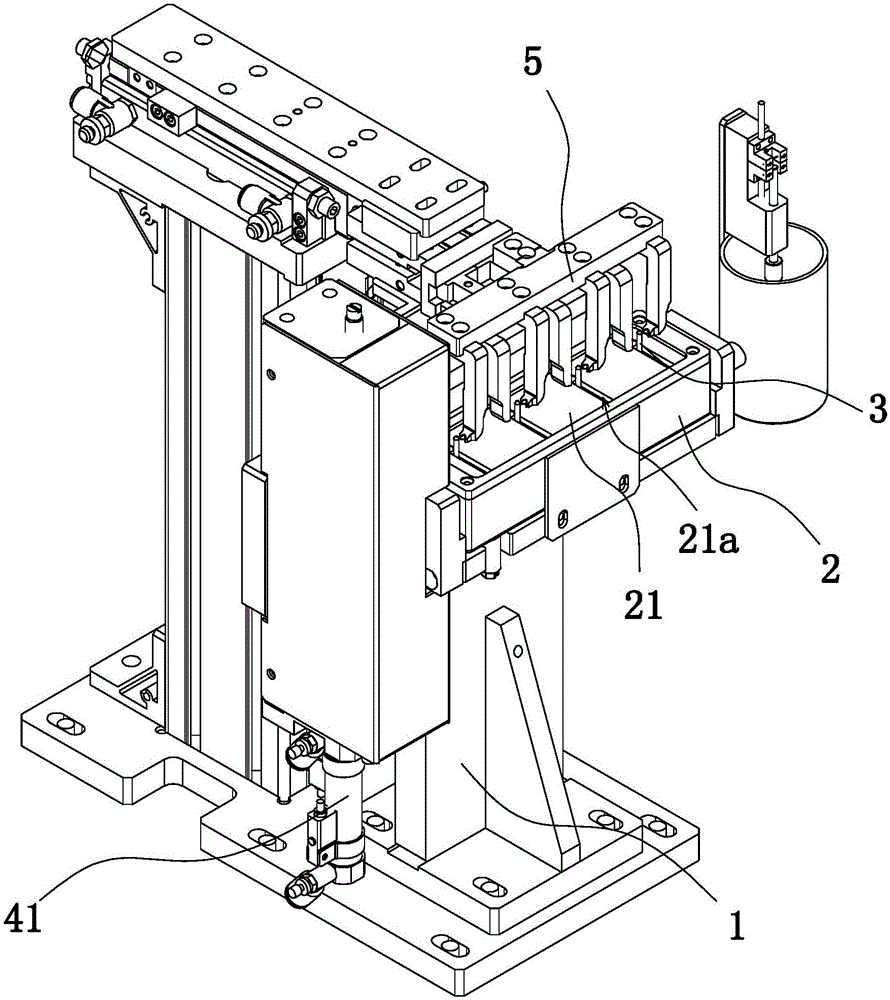

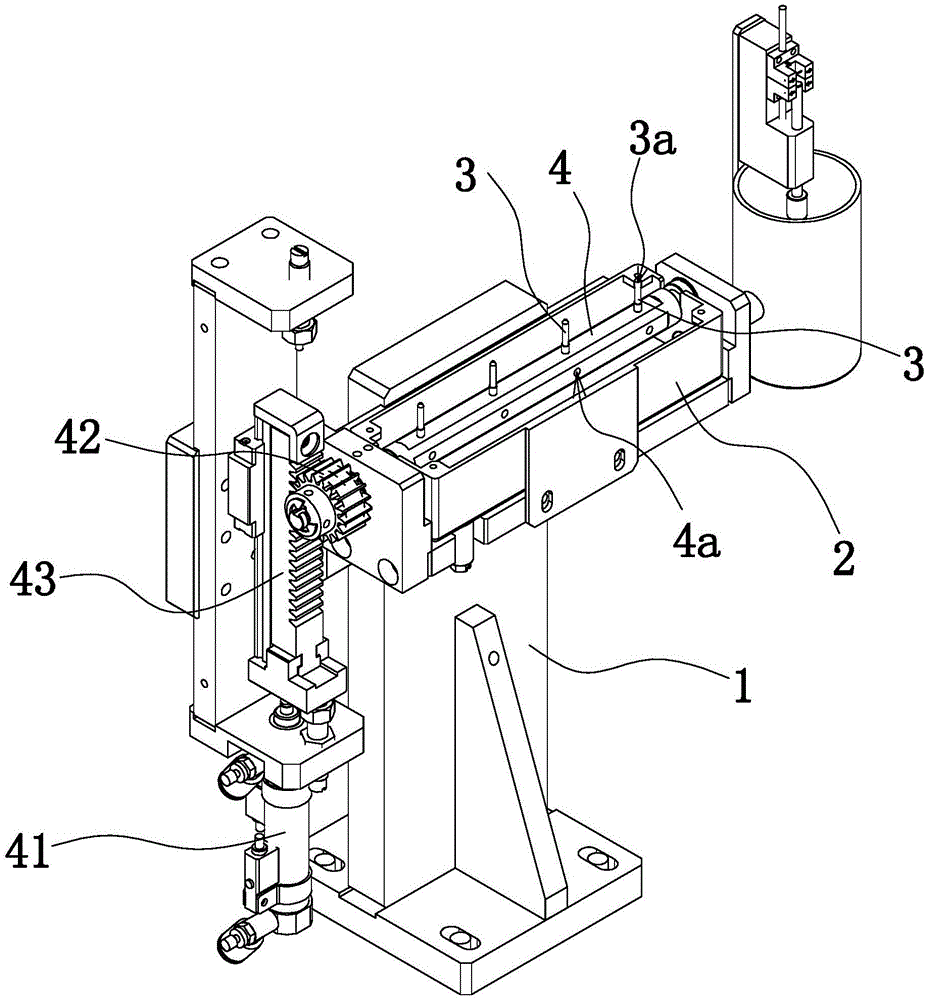

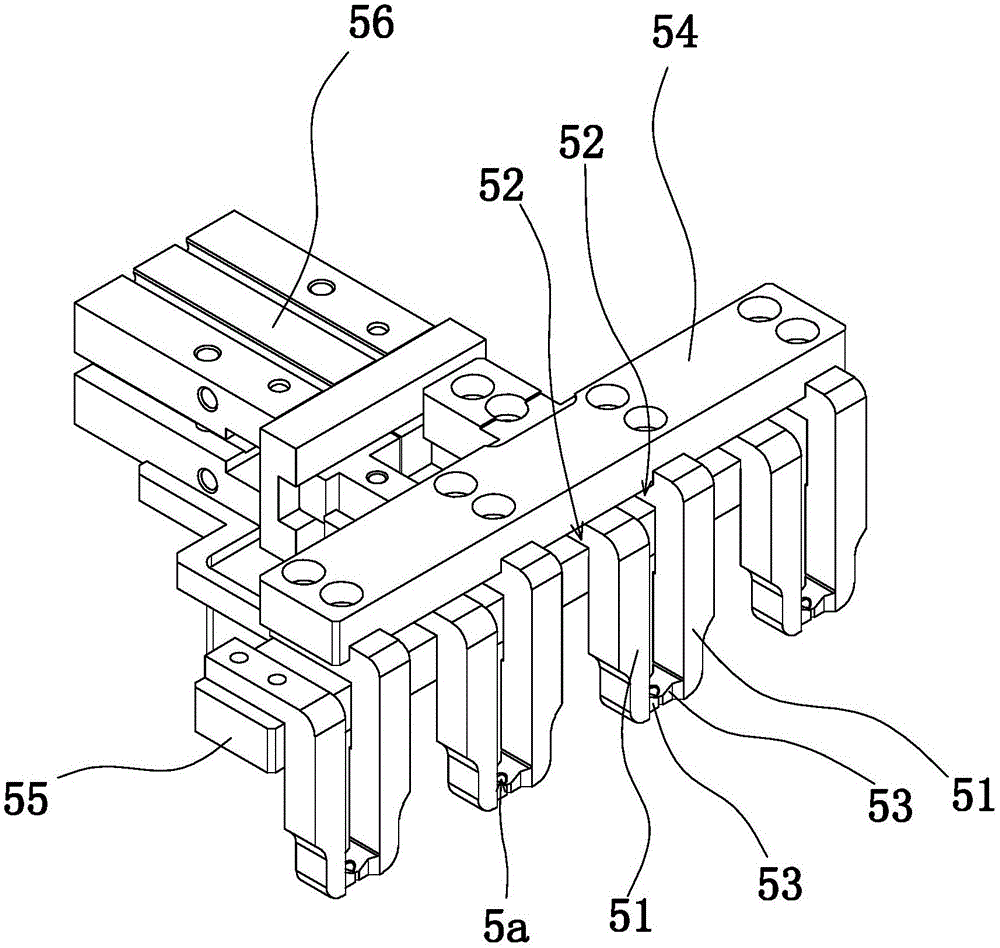

Adhesive applying device for medical accessory assembly machine

ActiveCN105107679AAvoid overdoseNo exudationLiquid surface applicatorsCoatingsAdhesiveBiomedical engineering

The invention provides an adhesive applying device for a medical accessory assembly machine, belonging to the technical field of manufacturing equipment of medical apparatuses and solving the technical problems that excessive adhesive applying and other circumstances are easily present in an existing adhesive applying device. The adhesive applying device for the medical accessory assembly machine comprises an adhesive applying claw, wherein a cover plate is fixed at an opening of an adhesive box; the cover plate is provided with at least one adhesive taking hole; the adhesive applying claw is arranged above the cover plate; an adhesive applying hole is formed when the adhesive applying claw is closed; an adhesive taking rod corresponding to the adhesive taking hole in position is arranged in the adhesive box; a driving location structure capable of driving the adhesive taking rod to rotate is arranged on the adhesive box; the driving location structure can allow an adhesive dipping end of the adhesive taking rod to extend into the adhesive box to dip an adhesive; the driving location structure can also allow the adhesive dipping end of the adhesive taking rod to penetrate through the corresponding adhesive taking hole to be located; in addition, the adhesive dipping end is positioned in the adhesive applying hole when the adhesive applying claw is closed and is in contact with the hole wall of the adhesive applying hole. The adhesive applying device has the advantages that the adhesive amount on the hole wall of the adhesive applying hole is kept at a moderate level through twice adhesive dipping.

Owner:MAIDER MEDICAL IND EQUIP

Polytetrafluoroethylene (PTFE) outer lining butterfly plate making method

The invention provides a polytetrafluoroethylene (PTFE) outer lining butterfly plate making method which is characterized by comprising the following steps: A. placing PTFE suspension powder and a metal board core inside a die with the metal board core in a die centre shaft; B. placing the die in a press, pressurizing to 19-21Mpa with the pressure holding time of 60-100 minutes, then demolding to obtain a butterfly plate semi-finished product; and C. putting the butterfly plate semi-finished product into a sintering furnace for multi-segment sintering for moulding to obtain a butterfly plate product. After the multi segment sintering for moulding, the butterfly plate mould pressing sintering moulding rate can reach more than 85%. After the metal board core is coated with the PTFE suspension powder, no arc phenomenon is produced in PTFE surface and the metal board core which is internally coated in the PTFE surface by 20000 volt electric shock test, so that the PTFE surface is qualified in density. If the PTFE surface is not qualified in density, arc phenomena may be produced. The valve plate surface water drop seepage phenomenon can be tested by use of 1.1Mpa of water pressure, the pressure is held for 3 minutes, and no water drop is seeped, so that a valve plate is qualified by a water pressure seal test.

Owner:TIANJIN BINHAI JINHANG CERAMIC VALVE

Traditional Chinese medicine oral liquid for treating poultry virus hepatitis and hepatic injury

InactiveCN101396427AThe curative effect is sureImprove lesionOrganic active ingredientsDigestive systemDiseaseVitamin C

The invention relates to traditional Chinese medicine oral liquid for treating viral hepatitis and liver injury of poultry, and the traditional Chinese medicine oral liquid comprises four medicines of false Chinese swertia herb, virgate wormwood herb, baicalein and vitamin C. The drug is applicable to treating the viral hepatitis, the liver injury, and the like, of poultry, such as viral hepatitis and other diseases of ducks. The drug overcomes the shortcoming that the use of antibiotics is easy to generate the drug resistance, the formulation is combined with the special physiological structure that the reproductive tract of the poultry is short and can not digest wood fibers, the drug is prepared into the oral liquid which can be rapidly dispersed in drinking water for feeding, and the drug delivery of the sick livestock and the poultry is carried out by the drinking water, thereby facilitating and being conductive to the absorption and being able to achieve the purpose of realizing the function fast.

Owner:TIANJIN RINGPU BIO TECH

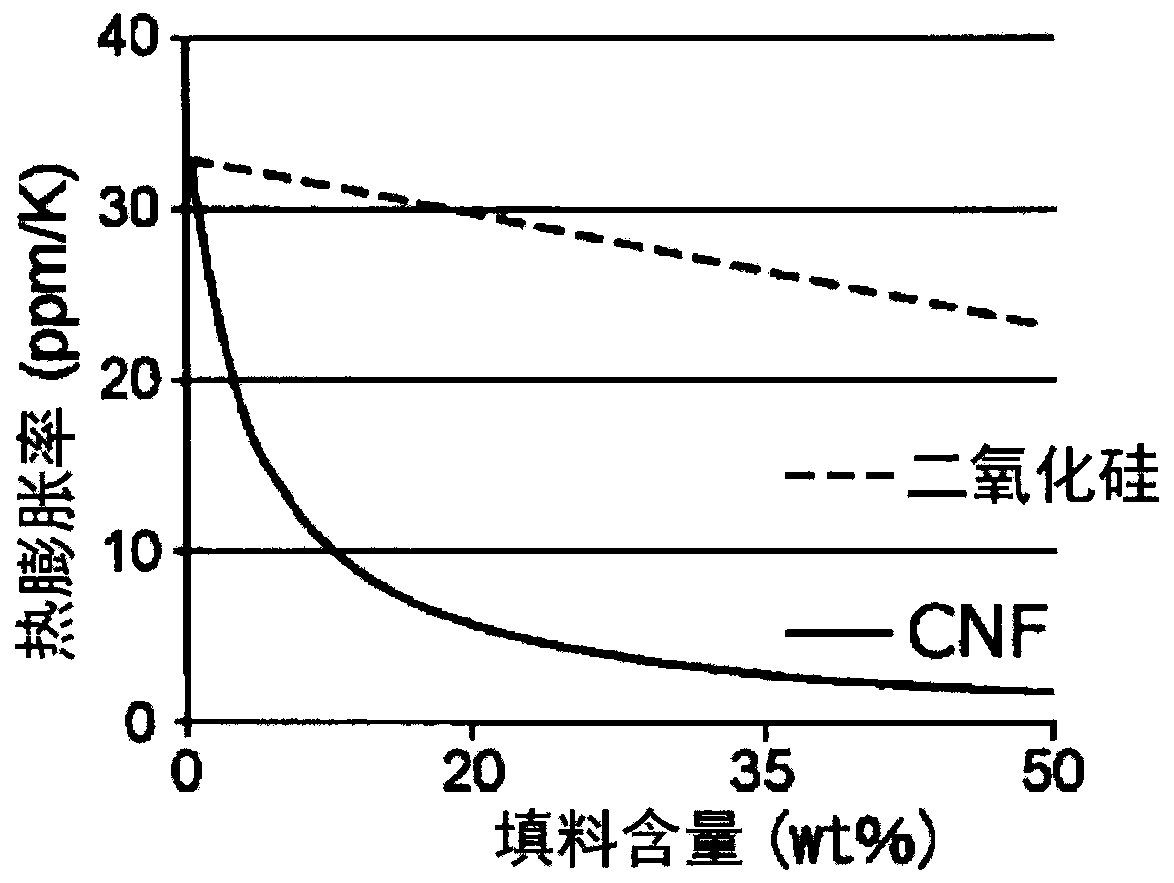

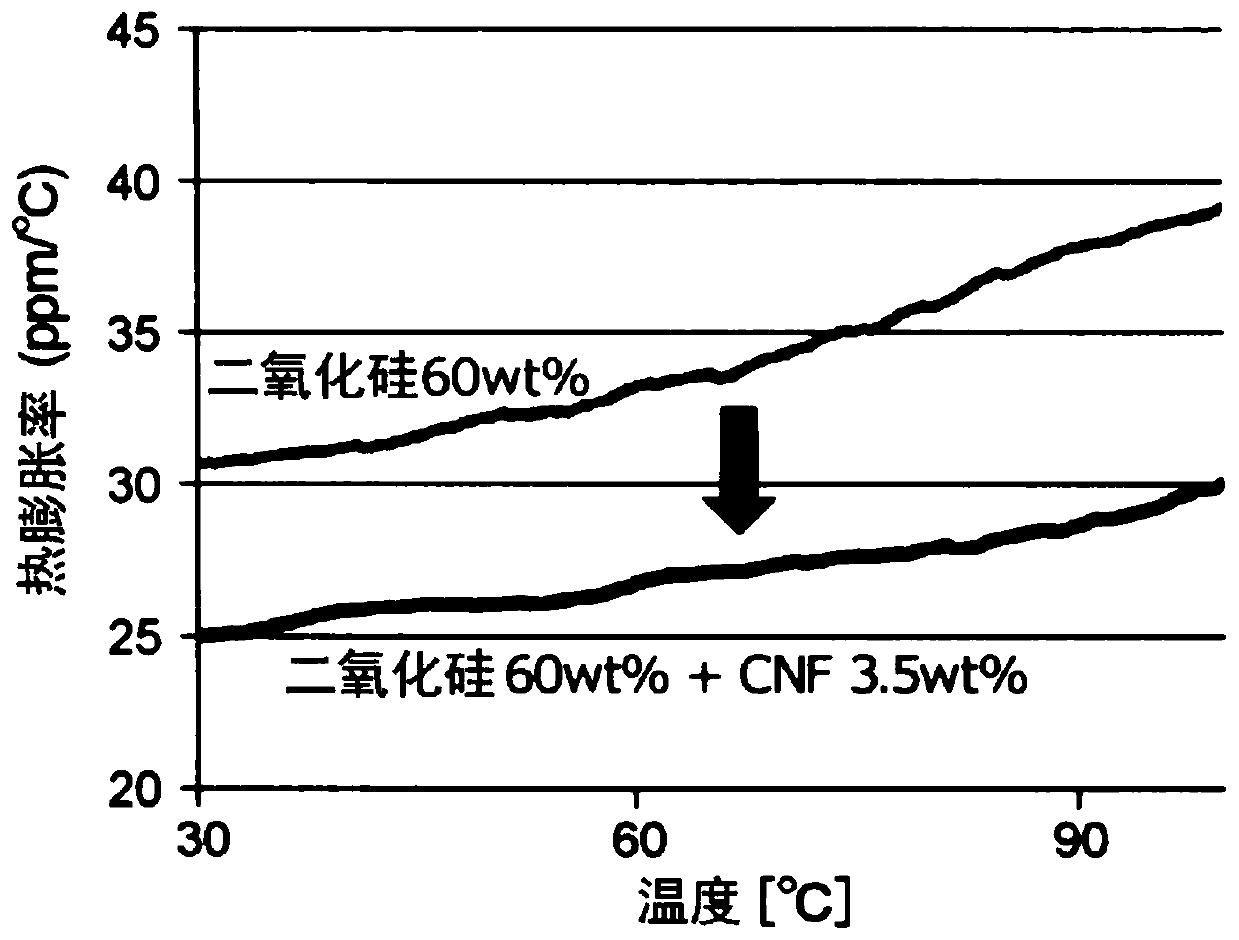

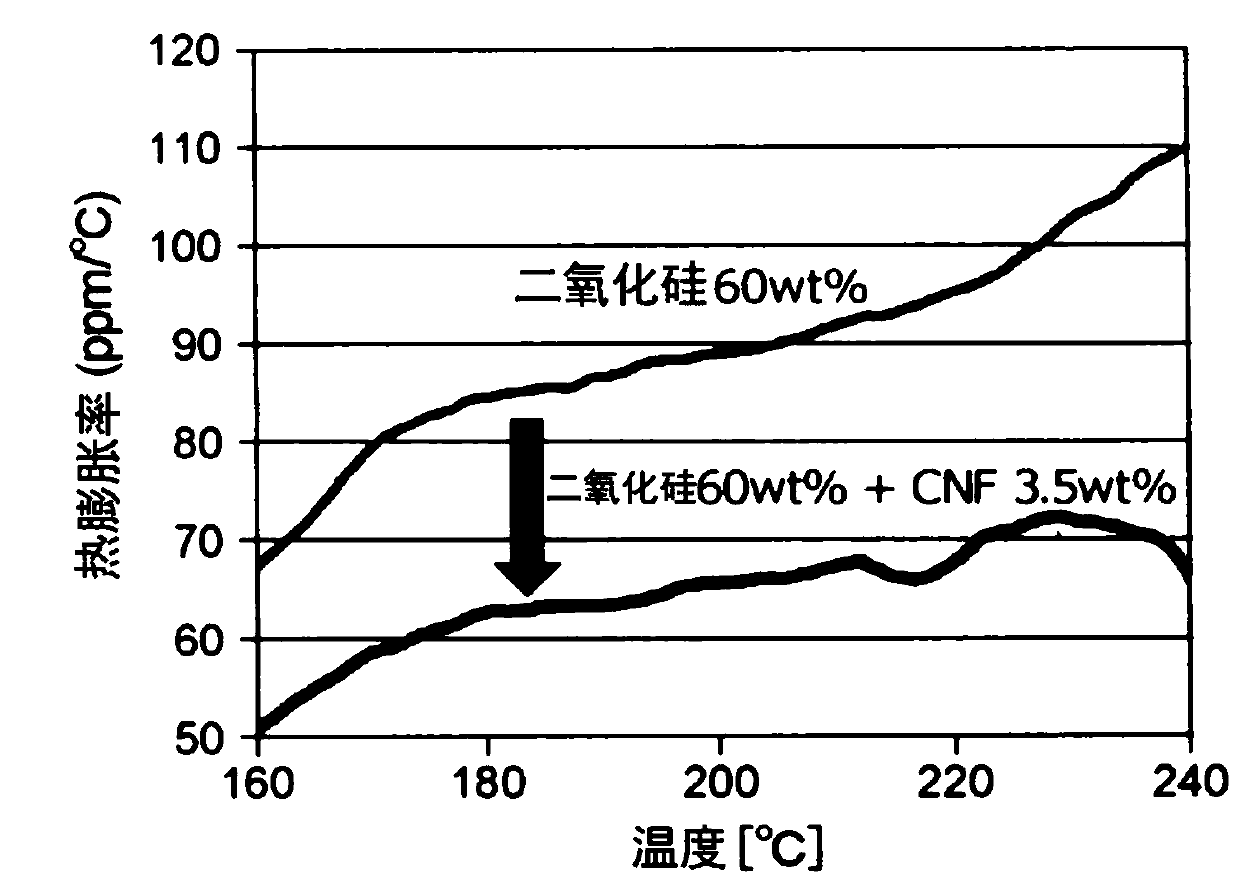

Curable resin composition, dry film, cured product, electronic component, and printed-wiring board

ActiveCN110520475ALow thermal expansionImprove toughnessCoatingsNon-metallic protective coating applicationPolymer scienceElectronic component

The present invention provides a curable resin composition with which it is possible to obtain a cured product that is capable of retaining a low thermal expansion rate even in a high-temperature range during component mounting and that exhibits various excellent properties such as toughness; and a dry film, a cured product, and an electronic component using the curable resin composition. The curable resin composition comprises a curable resin, a fine powder in which at least one of the dimensions is smaller than 100 nm, and a filler other than the fine powder. The dry film, the cured productand the electronic component are obtained by using said curable resin composition.

Owner:TAIYO INK MFG

Medicine for removing vegetation from human body and its preparing process and application

InactiveCN1365664AGood effectPromote recoveryDermatological disorderAnhydride/acid/halide active ingredientsAqueous solutionTrichloroacetic acid

A medicine for removing the vegetation from human body is an aqueous solution of trichloroacetic acid, which is prepared from water and dehydrated trichloroacetic acid in Wt. ratio of 1:(18-24). Its advantages include high effect, no residual scar, no untoward effect, and low poison.

Owner:王怀琛

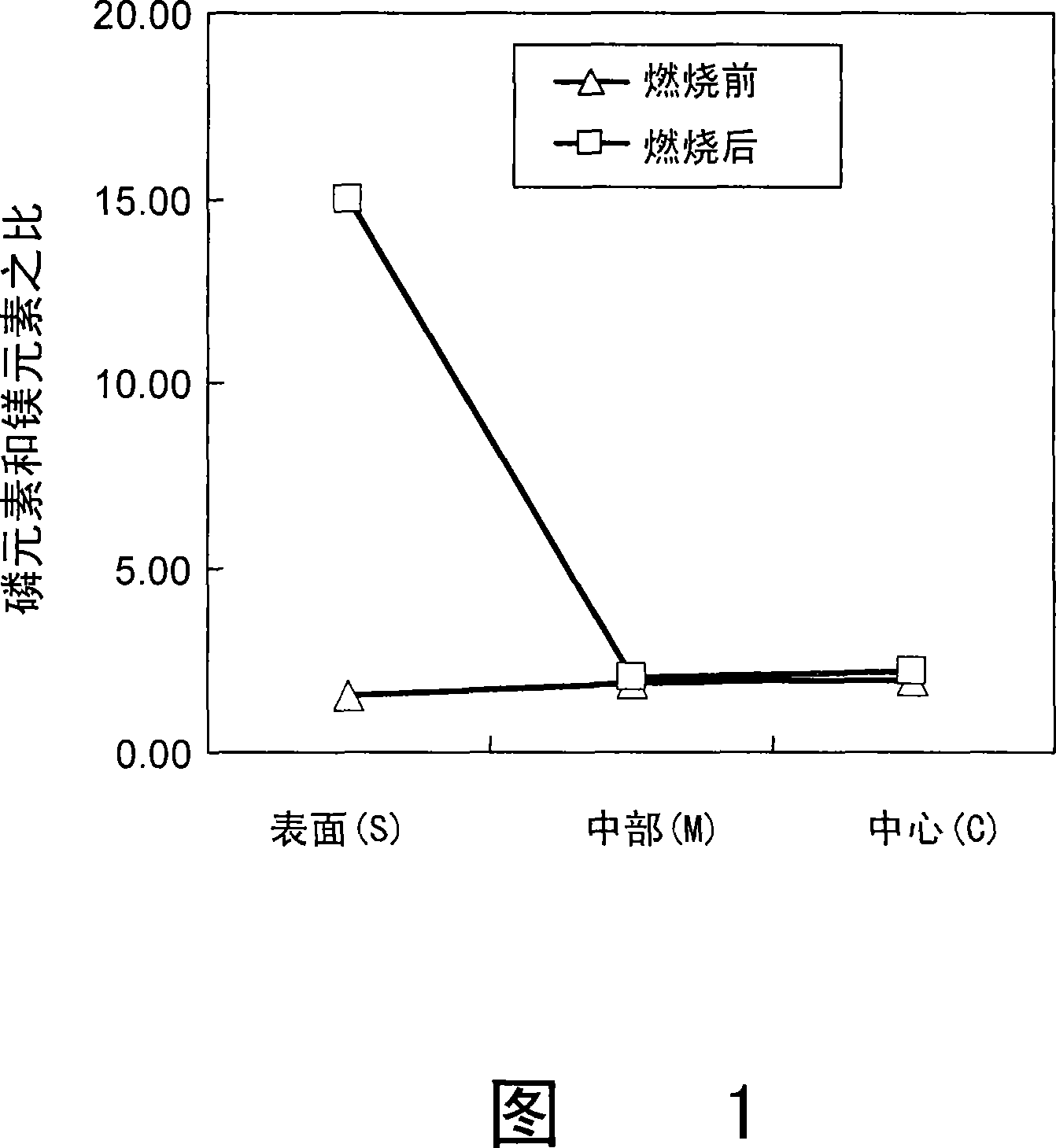

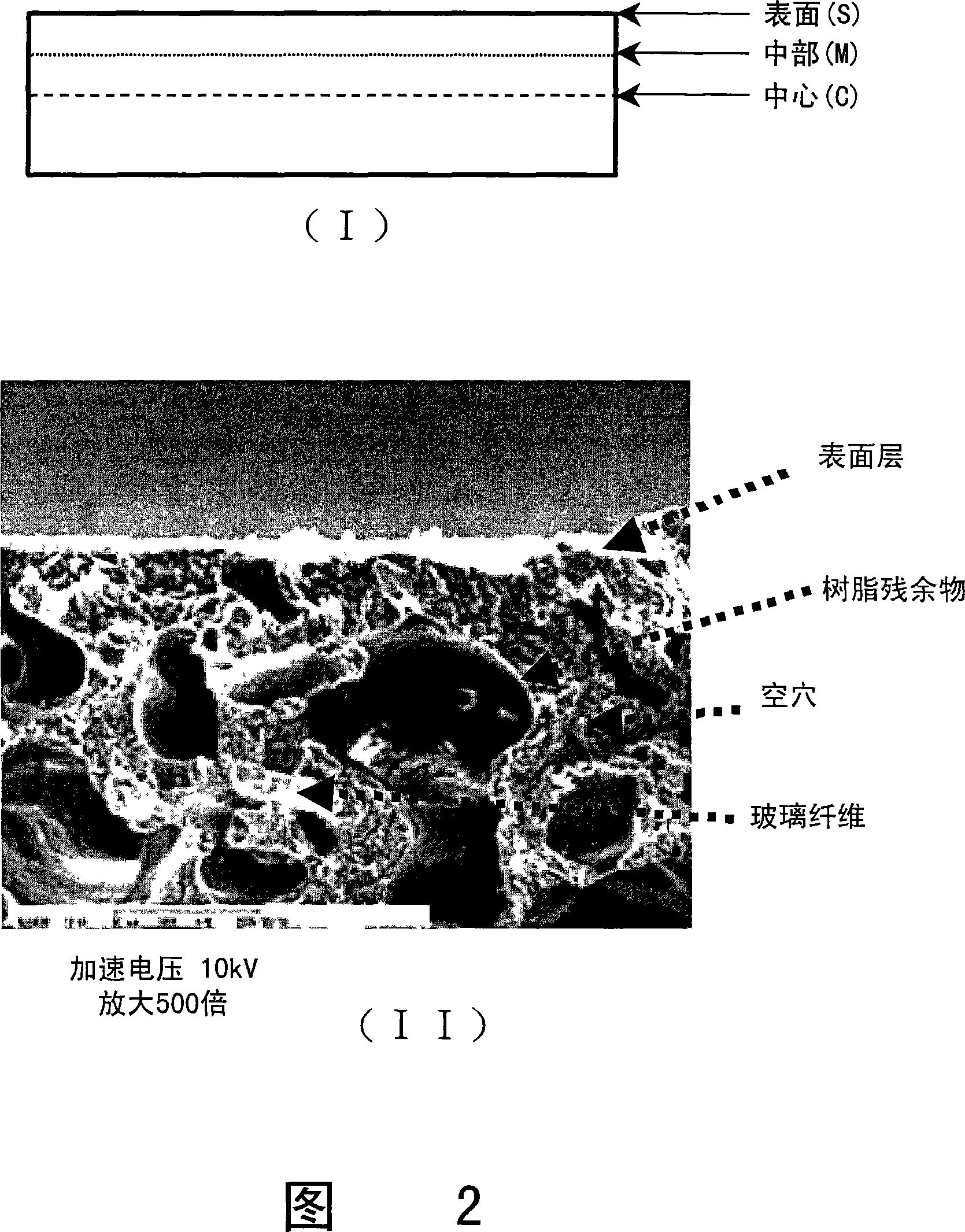

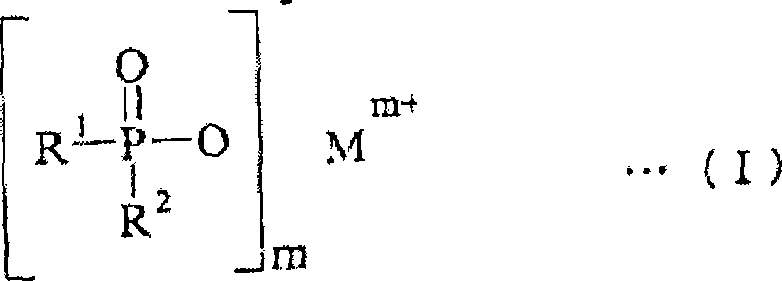

Flame retardant resin treated article

Owner:FUJI ELECTRIC CO LTD +1

Natural silk sericin-free silk fibroin core and application thereof

InactiveCN102327644AHigh mechanical strengthDoes not cause discomfortSurgeryProsthesisHuman bodySILK SERICIN

The invention discloses novel application of a natural silk sericin-free silk fibroin core to preparation of a medical surgical instrument for human bodies. The natural silk sericin-free silk fibroin core has high mechanical property, high flexibility and an appropriate degradation speed. As proved by an in-vivo experiment on an animal, the natural silk sericin-free silk fibroin core is immune to exclusive reactions and toxic reaction, and is a good material for preparing various in-vivo medical instruments.

Owner:邱轶伟

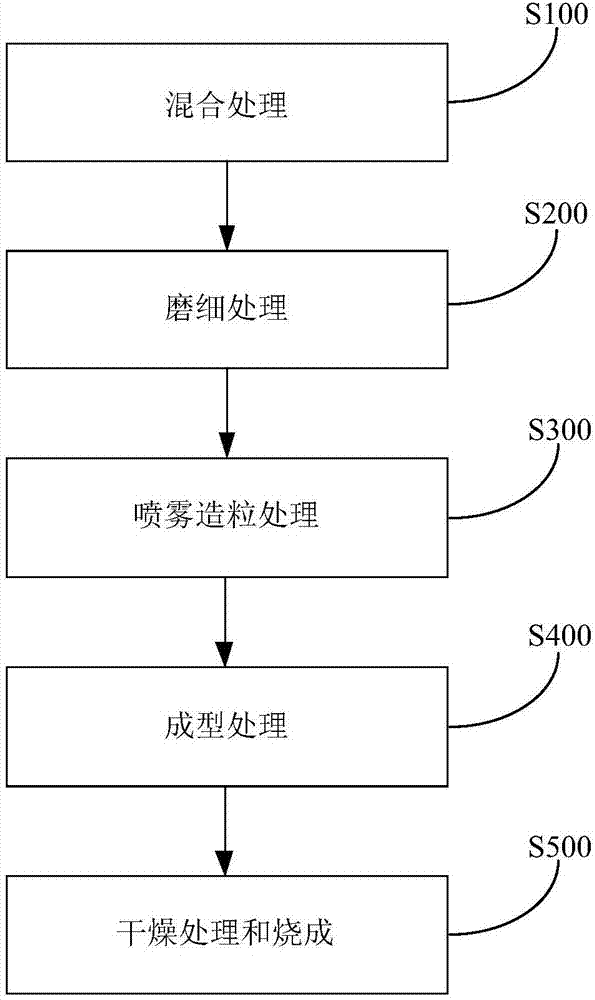

Chromium iron slag processing method and ceramic tiles

PendingCN107973586AEnhanced destructive strengthBroaden the way of resource utilizationCeramic materials productionClaywaresSpray GranulationBrick

The invention discloses a chromium iron slag processing method and ceramic tiles. The method comprises the following steps: (1) performing mixing on the chromium iron slag, clay and sandstone to obtain a mixture; (2) performing fine grinding treatment on the mixture to obtain a powdery material; (3) performing spraying granulation treatment on the powdery material to obtain a particle material; (4) performing molding treatment on the particle material to obtain raw material boards; and (5) performing drying treatment and firing on the raw material boards to obtain the ceramic tiles. Accordingto the method, high-quality ceramic tiles can be prepared by effectively using metallurgical scrap chromium iron slag, so that a new way for resource utilization of the chromium iron slag is opened up, therefore, the method has significant economic and environmental benefits.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com