Ink-Jet Textile Printing/Recording Process

A recording method, inkjet printing and dyeing technology, applied in the directions of reproduction/marking method, dyeing method, printing, etc., can solve problems such as inability to suppress exudation, increase in total liquid amount, and difficulty in alignment of positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

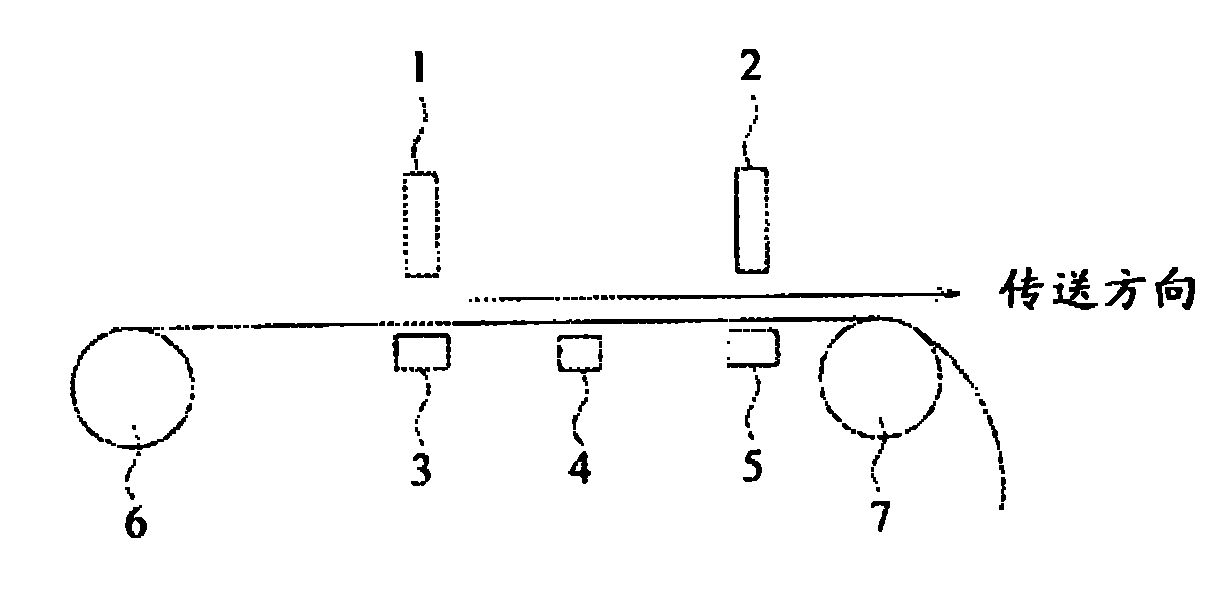

Image

Examples

Embodiment 1

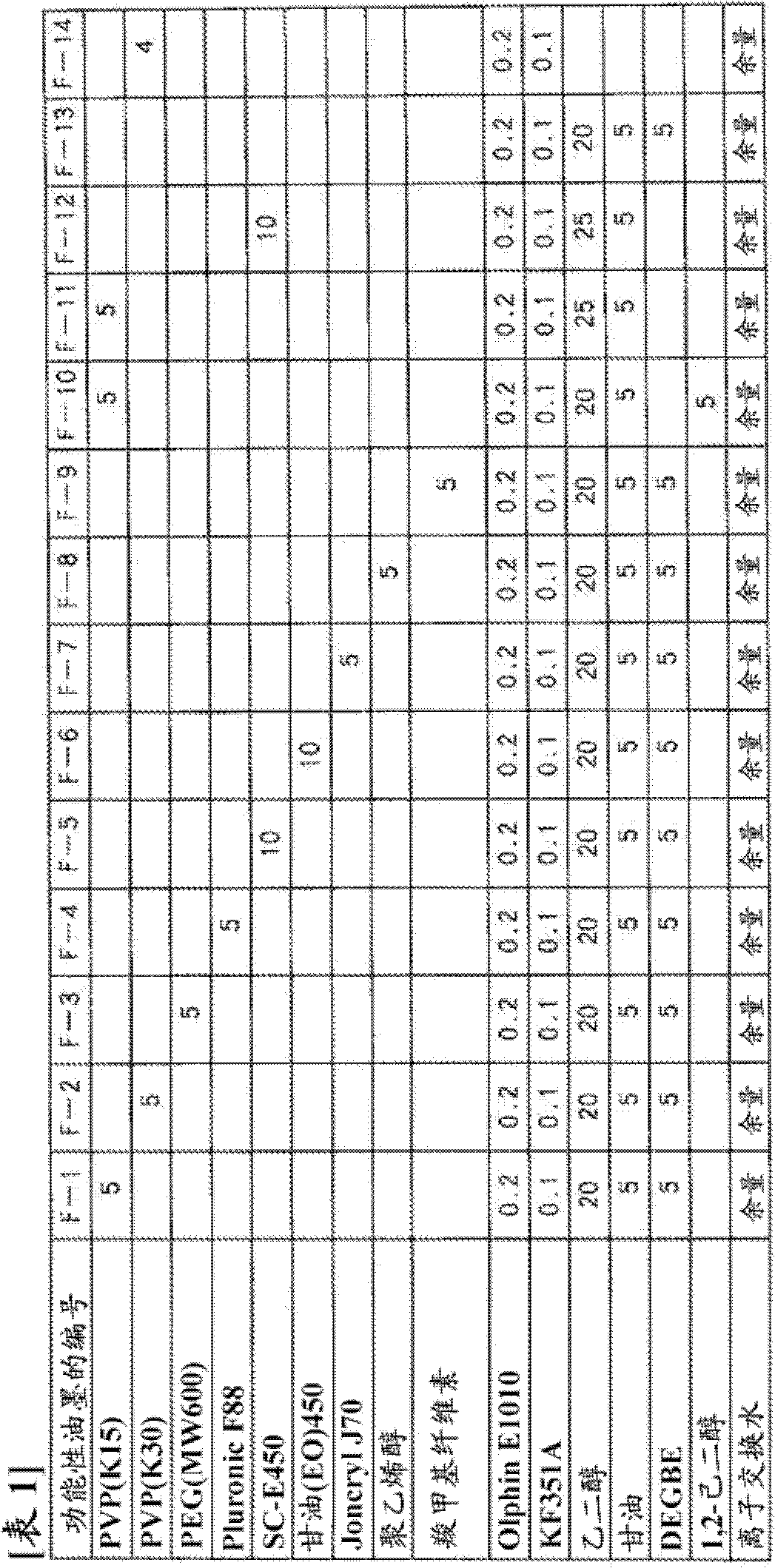

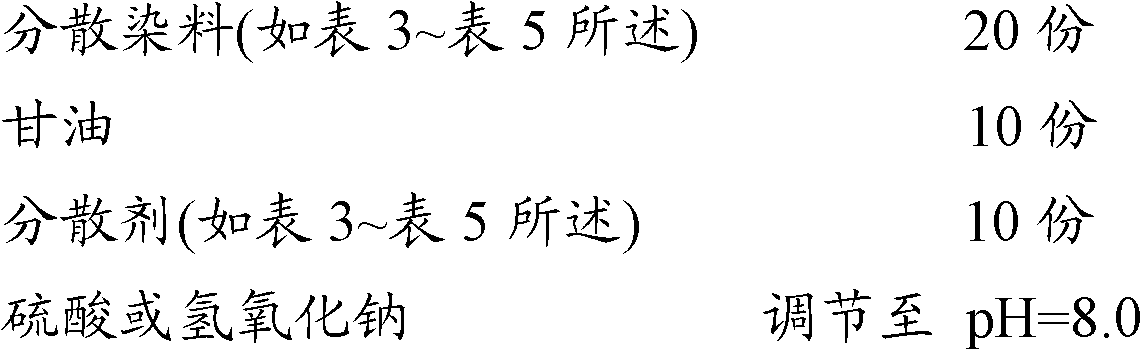

[0154] 〔Preparation of functional ink〕

[0155] The functional inks were prepared according to the formula shown in Table 1. Next, filtration was performed with a 3 μm membrane filter, and a degassing treatment was performed. In the degassing treatment, the prepared functional inks flow into the gas-permeable hollow fiber membranes, and the outer surface of the hollow fiber membranes is decompressed by a water flow aspirator, thereby removing the dissolved gas in the functional inks. In addition, after degassing, it is filled into a vacuum package to prevent the incorporation of air. The compounds used are shown below.

[0156] PVP(K15), PVP(K30): polyvinylpyrrolidone (Tokyo Chemical Industry)

[0157] PEG (Mw600): Polyethylene glycol (Kanto Chemical)

[0158] Pluronic F88: Ethylene oxide propylene oxide copolymer (ADEKA Corporation)

[0159] SC-E450: Polyethylene oxide adduct of glycerin (Sakamoto Pharmaceutical Co., Ltd.)

Embodiment 2

[0241] Change the functional ink F-1 of embodiment 1 and recording ink Y-1, M-1, the addition of the water-soluble polymer of the functional ink of embodiment 1 in the preparation of C-1 and recording ink Y, M, The addition amount of each resin binder in C is such that the total amount of the two nozzles from the first nozzle bracket is 18ml / m on the maximum concentration part of the monochrome 2 11ml / m of the functional ink from the nozzle on the second nozzle bracket 2 The amount of water-soluble macromolecules and resin binders given when the Y, M, and C recording inks are printed as a monochrome solid image of 10 cm × 10 cm is the amount shown in Table 7, and the same process as in Example 1 is carried out. evaluate. The results are shown in Table 7.

[0242] [Table 7]

[0243]

[0244] As shown in Table 7, it can be seen that the total amount of the water-soluble polymer applied to the fabric by the functional ink and the amount of the resin binder applied to the fa...

Embodiment 3

[0246] In Example 1, the temperature of the heater H3 was controlled to change the surface temperature of the cloth portion to which the recording ink was applied, and the bleeding suppression effect was remarkable in the temperature range of 35°C to 70°C. Furthermore, the heating for drying makes the bleed-out suppressing effect more prominent than the case where the heater H2 is not used between the step of applying the functional ink and the step of applying the recording ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com