Cigarette dry bead filter tip rod with function of improving smoke permeability

A technology for dry beads and cigarettes, which is used in tobacco, e-liquid filter, and cigar manufacturing. , strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

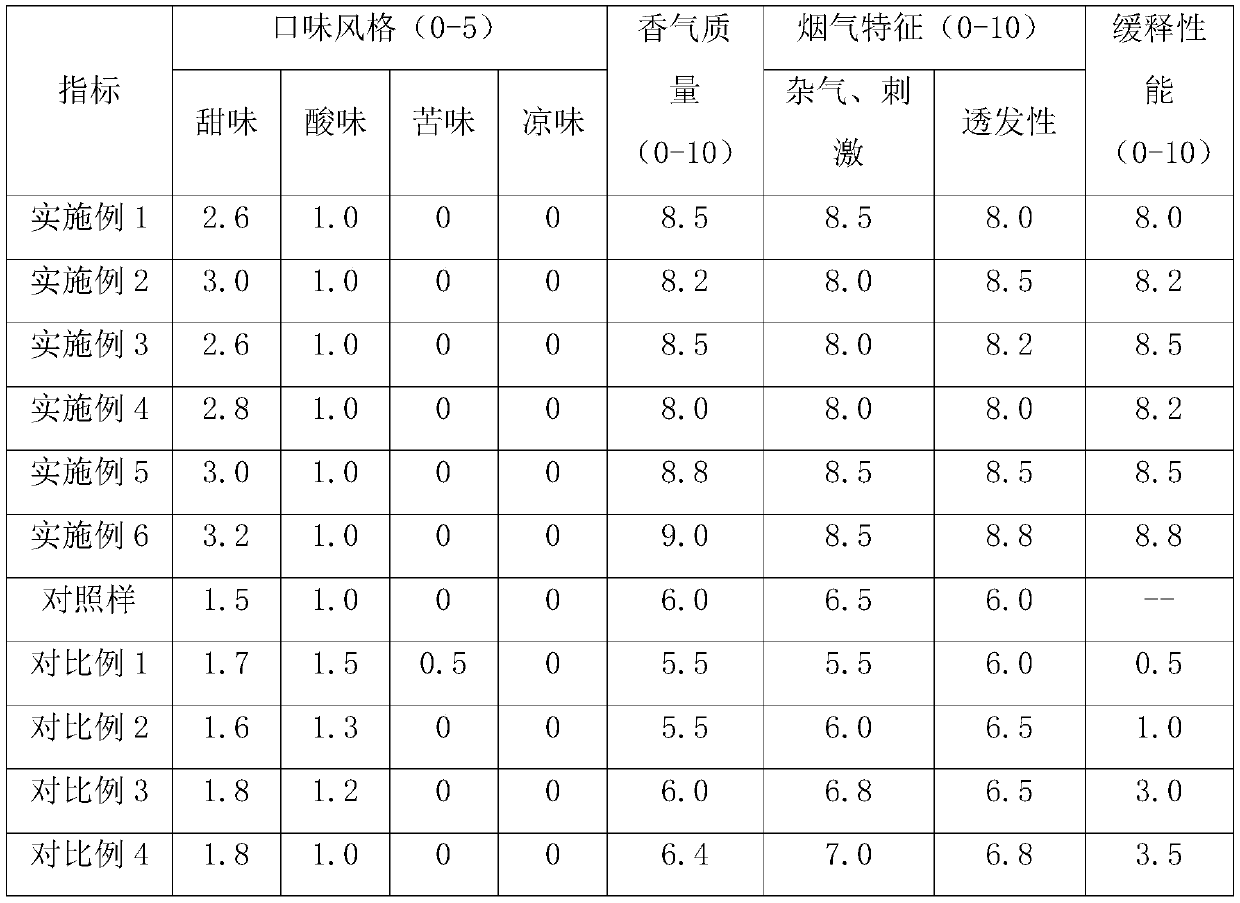

Examples

Embodiment 1

[0032] Prepare cigarette dry bead mouth stick according to the following method:

[0033] 1) Pelletizing: take a certain amount of 5A zeolite molecular sieve, after grinding, mix the two evenly according to the mass ratio of zeolite molecular sieve:silica sol (solid content 25%)=2:1, and place them in the pelletizing machine for ball rolling Forming, screening qualified samples with a diameter of 2.75±0.15mm, calcining the bead-shaped green body at 1300°C for 6 hours, washing with water, and drying to obtain dry beads with a porous structure;

[0034] 2) Fuxiang: mix the dry beads and agarwood composite extract evenly according to the mass ratio of 1:1, seal it, place it on a shaker at 150 rpm for 6 hours, and then let it stand for 12 hours to make the essence evenly adsorbed on the dry beads Air-dried at 40-50°C for 2 hours in a porous channel to obtain dried beads with fragrance;

[0035] 3) Mouth stick forming: add a dry bead with fragrance to the middle section of the tip...

Embodiment 2

[0041] Prepare cigarette dry bead mouth stick according to the following method:

[0042]1) Pelletizing: take a certain amount of Y-type zeolite molecular sieve, after grinding, mix the two evenly according to the mass ratio of zeolite molecular sieve:silica sol (solid content 50%)=2:3, place in the pelletizing machine and roll Ball molding, screening qualified samples with a diameter of 2.75±0.15mm, calcining the bead-shaped body at 1300°C for 2 hours, washing with water, and drying to obtain dry beads with a porous structure;

[0043] 2) Fuxiang: mix the dry beads and agarwood composite extract evenly according to the mass ratio of 1:1, seal it, place it on a shaker at 150 rpm for 6 hours, and then let it stand for 12 hours to make the essence evenly adsorbed on the dry beads Air-dried at 40-50°C for 2 hours in a porous channel to obtain dried beads with fragrance;

[0044] 3) Mouth stick forming: add a dry bead with fragrance to the middle section of the tip tow of the cig...

Embodiment 3

[0050] Prepare cigarette dry bead mouth stick according to the following method:

[0051] 1) Pelletizing: Take a certain amount of 4A zeolite molecular sieve, after grinding, mix the two evenly according to the mass ratio of zeolite molecular sieve:silica sol (solid content 30%)=2:3, and place them in the pelletizing machine for ball rolling Forming, screening qualified samples with a diameter of 2.75±0.15mm, calcining the bead-shaped green body at 1000°C for 4 hours, washing with water, and drying to obtain dry beads with a porous structure;

[0052] 2) Fragrance: Mix the dry beads and the compound extract of agarwood in a mass ratio of 2:3, seal it, place it on a shaker at 150 rpm, and attach the incense for 12 hours, then let it stand for 12 hours to make the essence evenly adsorbed on the dry beads Air-dried at 40-50°C for 2 hours in a porous channel to obtain dried beads with fragrance;

[0053] 3) Mouth stick forming: add a dry bead with fragrance to the middle section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com