Chromium iron slag processing method and ceramic tiles

A technology for ferrochromium slag and ceramic bricks, which is applied in the production, application, household appliances and other directions of ceramic materials, can solve the problems of residents' life safety threats, the need for further development of ferrochromium slag, and environmental impact, and achieve significant economic and environmental benefits. , the effect of broadening resource utilization and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

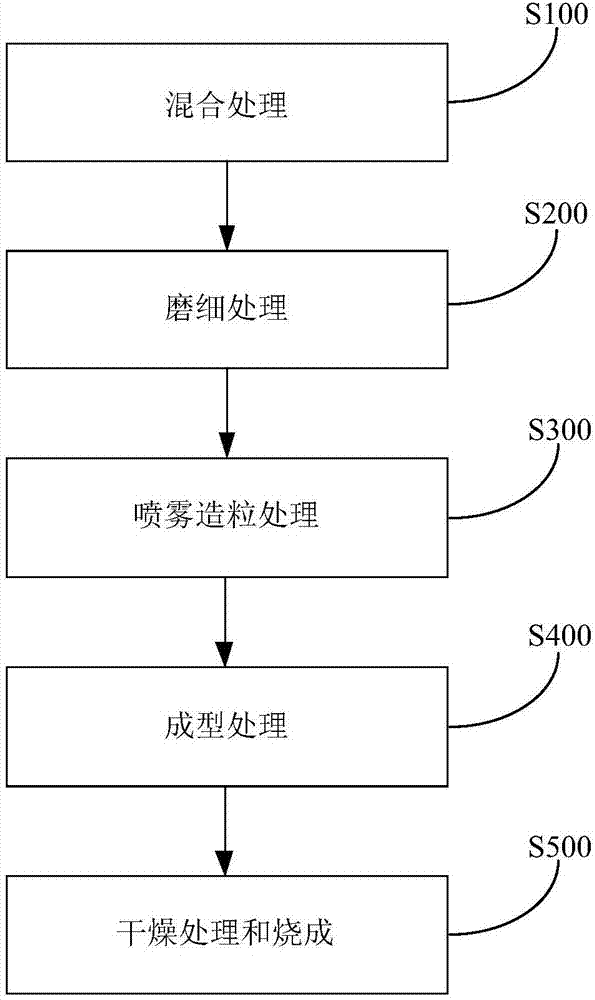

[0050] Follow the steps below to prepare ceramic tiles from ferrochrome slag:

[0051] (1) Mix ferrochrome slag, clay and sandstone according to the mass ratio of 50:30:20.

[0052] The main components in ferrochrome slag are CaO 3%, SiO 2 30%, MgO 25%, Al 2 o 3 20%, Cr 2 o 3 8%, TiO 2 0.3%, TFe 3%, (K 2 O+Na 2 O) 0.4%,

[0053] The mass percentage of the main component in the clay is SiO 2 70%, Al 2 o 3 10%.

[0054] The mass percentage of the main component in sandstone is SiO 2 90%.

[0055] (2) Crushing and mixing the above-mentioned materials, transporting them into a ball mill for grinding treatment, so as to obtain powdery materials, and the mass percentage of powders with a particle size of not higher than 45 μm in the powdery materials is 90%.

[0056] (3) The finely ground powdery material is subjected to spray granulation, and the particle size of the obtained granular material is about 1mm.

[0057] (4) The granular material is pressed and for...

Embodiment 2

[0063] Follow the steps below to prepare ceramic tiles from ferrochrome slag:

[0064] (1) Mix ferrochrome slag and clay according to the mass ratio of 80:20.

[0065] The main components in ferrochrome slag are CaO 2%, SiO 2 25%, MgO 30%, Al 2 o 3 15%, Cr 2 o 3 10%, TiO 2 0.5%, TFe 4%, (K 2 O+Na 2 O) 0.2%,

[0066] The mass percentage of the main component in the clay is SiO 2 60%, Al 2 o 3 20%.

[0067] (2) The above materials are crushed and mixed, and transported into a ball mill for grinding treatment, so as to obtain powdery materials, in which the mass percentage of powder with a particle size not higher than 45 μm is 96%.

[0068] (3) The finely ground powdery material is subjected to spray granulation, and the particle size of the obtained granular material is about 0.5 mm.

[0069] (4) The granular material is pressed and formed to form a raw material board of a certain size, and the forming pressure is 15 MPa.

[0070] (5) Place the raw board in ...

Embodiment 3

[0075] Follow the steps below to prepare ceramic tiles from ferrochrome slag:

[0076] (1) Mix ferrochrome slag, clay and sandstone in a mass ratio of 65:25:10.

[0077] The main components in ferrochrome slag are CaO 2.5%, SiO 2 28%, MgO 27%, Al 2 o 3 18%, Cr 2 o 3 9%, TiO 2 0.4%, TFe 3.5%, (K 2 O+Na 2O) 0.3%,

[0078] The mass percentage of the main component in the clay is SiO 2 65%, Al 2 o 3 15%.

[0079] The mass percentage of the main component in sandstone is SiO 2 88%.

[0080] (2) crushing and mixing the above-mentioned materials, transporting them into a ball mill for grinding treatment, so as to obtain powdery materials, the mass percentage of powders with a particle size not higher than 45 μm in the powdery materials is 94%.

[0081] (3) Spray and granulate the pulverized material, and the particle size of the obtained granular material is about 0.7 mm.

[0082] (4) The granular material is pressed and formed to form a raw material board of a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com