Submerged arc sintering flux for ferrite-austenite duplex stainless steel and preparation method thereof

A duplex stainless steel and sintered flux technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of poor intergranular corrosion resistance, reduced mechanical properties of welded joints, and deterioration of corrosion resistance, etc. and construction cost, good sealing and moisture-proof performance, and high anti-destructive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

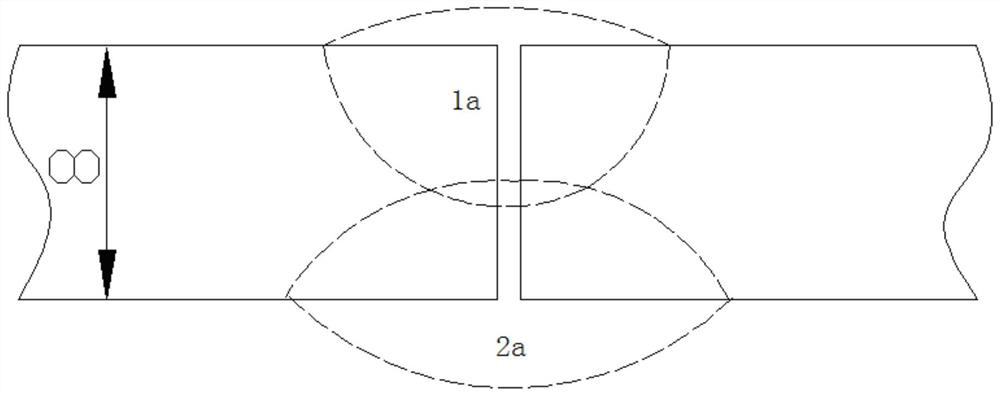

Image

Examples

Embodiment Construction

[0031] The flux of each embodiment is prepared from 20% potassium-sodium water glass (potassium-sodium ratio is 1:1, modulus 2.8, Baume degree 40~45) of solder and solder weight, wherein said solder is composed of the following mass percentages: The raw materials are mixed, and the specific preparation method is as follows:

[0032] Weigh the raw materials in the solder according to the proportion, sieve the actual required particles, and then carry out the batching according to the weight ratio. After fully mixing, add potassium sodium water glass for wet stirring, and then use a granulator to granulate. The final wet granular flux is dried at 200-300°C in a low-temperature furnace, and the dried flux is sieved to 12-48 meshes, and then sintered at a high temperature of 750-780°C in a high-temperature furnace, and finally sieved and cooled. , packed into an iron drum with good sealing and moisture-proof performance and high anti-destructive strength during storage and transpo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com