In-situ replacement type auxiliary embedded parts

An embedded, in-situ technology, applied in building components, instruments, analytical materials, etc., can solve problems such as inability to replace in-situ, inability to accurately calculate force analysis, and large buried depth of embedded parts, and achieve sealing and moisture-proof effects. Good, improve the connection strength and anchoring strength, reduce the effect of secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the embodiments, technical solutions and advantages of the present invention more obvious, the technical solutions of the present invention will be described clearly and completely below with reference to the accompanying drawings. Obviously, the described embodiments are some of the embodiments of the present invention, not all of them. Example. It should be understood by those skilled in the art that these embodiments are only used to explain the technical principle of the present invention, and are not intended to limit the protection scope of the present invention.

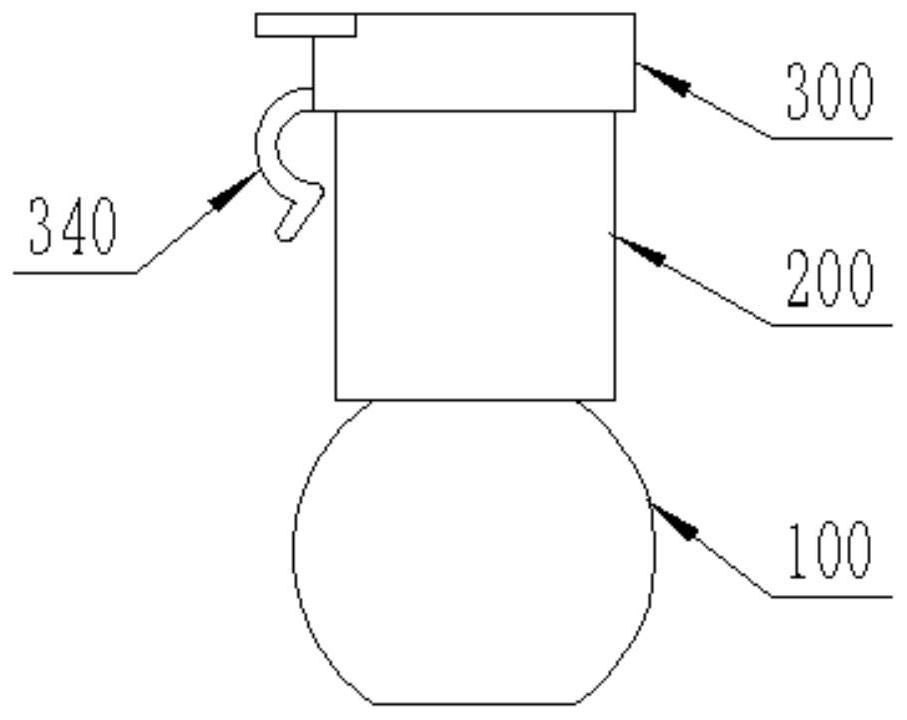

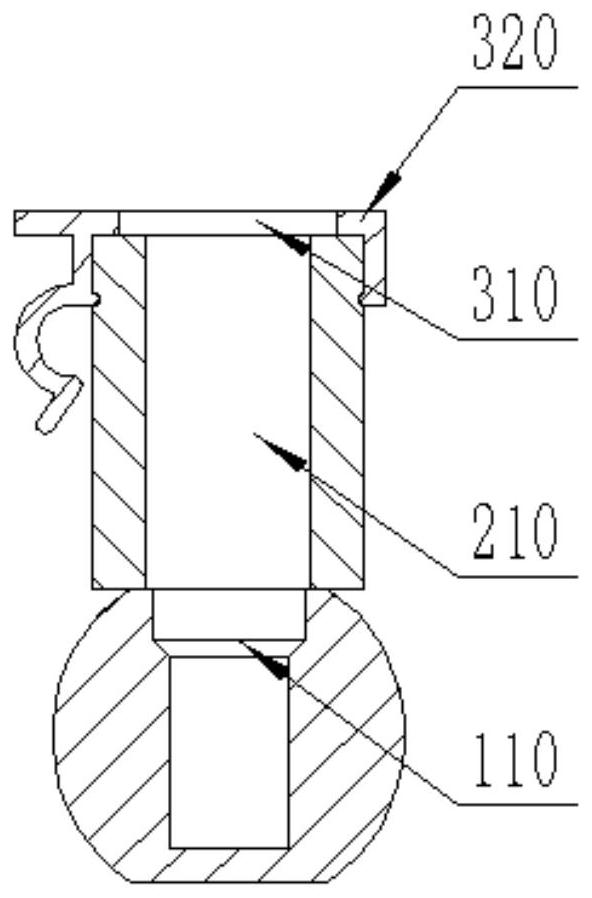

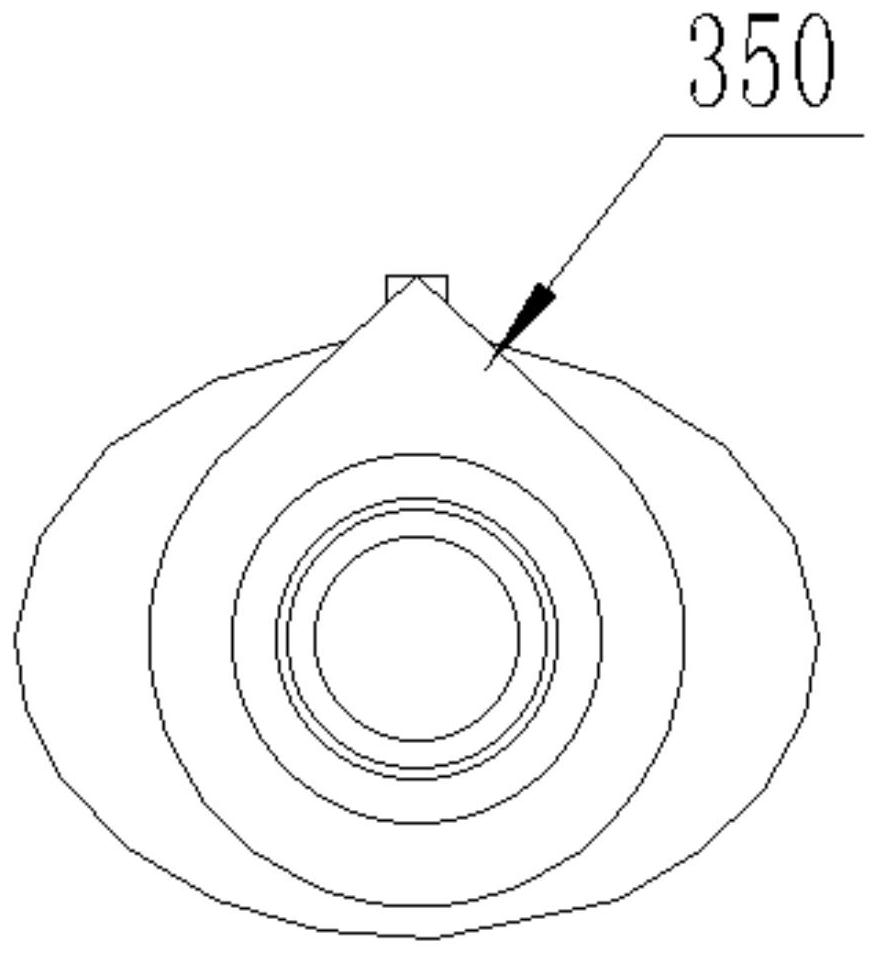

[0032] An in-situ replacement auxiliary embedded part of the present invention, the in-situ replacement auxiliary embedded part comprises a first part, a second part and a third part connected in sequence, wherein:

[0033] The first component is an anti-extraction structure that is enlarged compared to the second component, the second component is a tubular structure, and the third com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com