Method for increasing height of electronic packaging cavity

An electronic packaging and cavity technology, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of high cost and long shell cycle, and achieve the effect of increasing the height of the cavity and increasing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

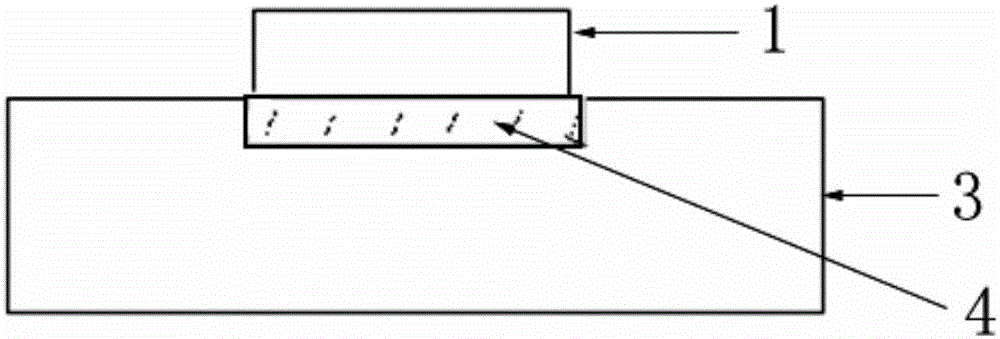

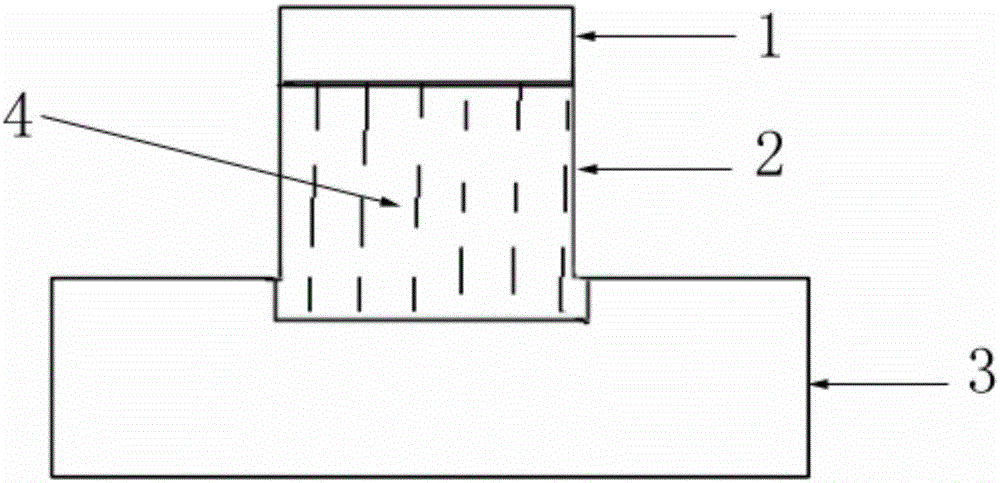

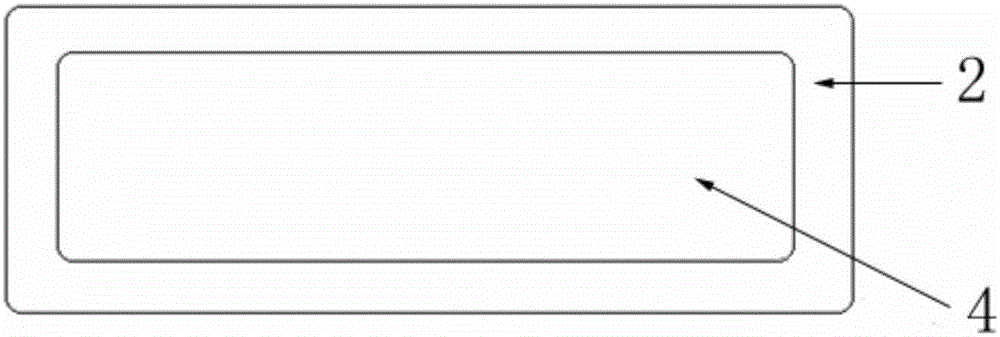

[0027] The process of the method for increasing the height of the electronic packaging cavity in this embodiment is as follows:

[0028] (1) First, a 1.0 μm gold-plated layer is provided on the surface to be welded of the cover plate and the tube seat, and a ring-shaped alloy is preset on the surface to be welded between the metal seal ring and the cover plate and between the metal seal ring and the tube seat. Solder, wherein: the pre-set solder between the cover plate and the metal sealing ring is annular AuSn alloy solder, the mass fraction of Au in the AuSn alloy solder is 80%, and the mass fraction of Sn is 20%; The solder used is ring-shaped AuGe alloy solder, in which the mass fraction of Au is 88%, and the mass fraction of Ge is 12%. Then assemble to form a package body; select the height of the metal sealing ring according to the required height of the package cavity.

[0029] (2) Use fixtures to fix and pre-tighten the tube-shell assembly, and the applied pre-tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com