Production process for corona resistant polyimide film to produce winding wire

A polyimide film and production method technology, applied in windings, electric components, cable/conductor manufacturing, etc., can solve the problems of uneven discharge energy and small area, and achieve lower temperature rise, lower thermal resistance, better performance The effect of electrical insulation properties

Inactive Publication Date: 2010-11-10

JIANGSU ICE CITY INSULATION MATERIALS STOCK

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Recently, corona discharge treatment is available for the surface of non-corona-resistant polyimide film, but for corona-resistant polyimide film, because of its strong corona resistance, corona discharge treatment is used. At the same time, the corona discharge is a filamentary discharge, the discharge energy is uneven, and the area on the film to be treated is relatively small, only 60-70% of the area

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

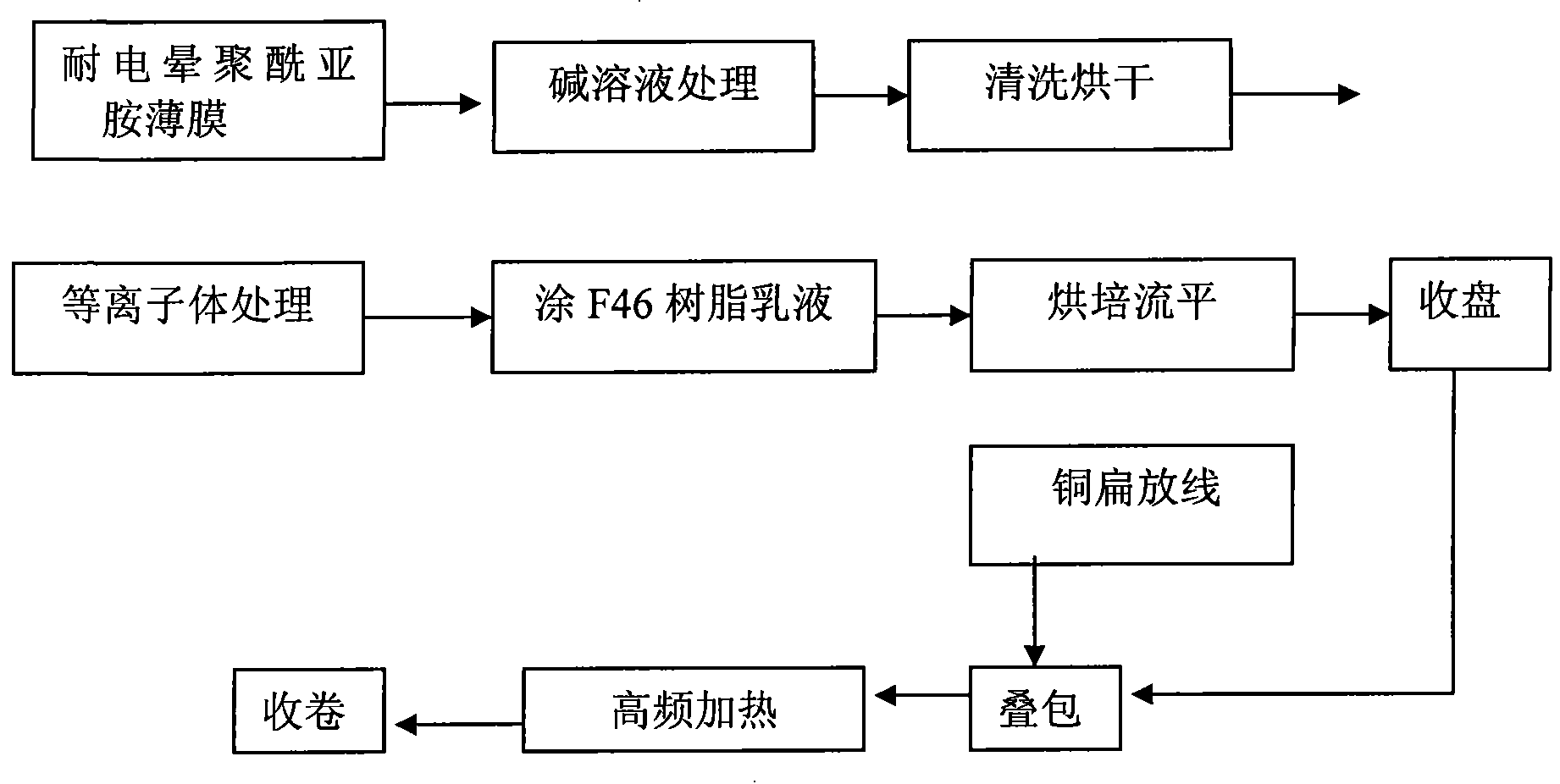

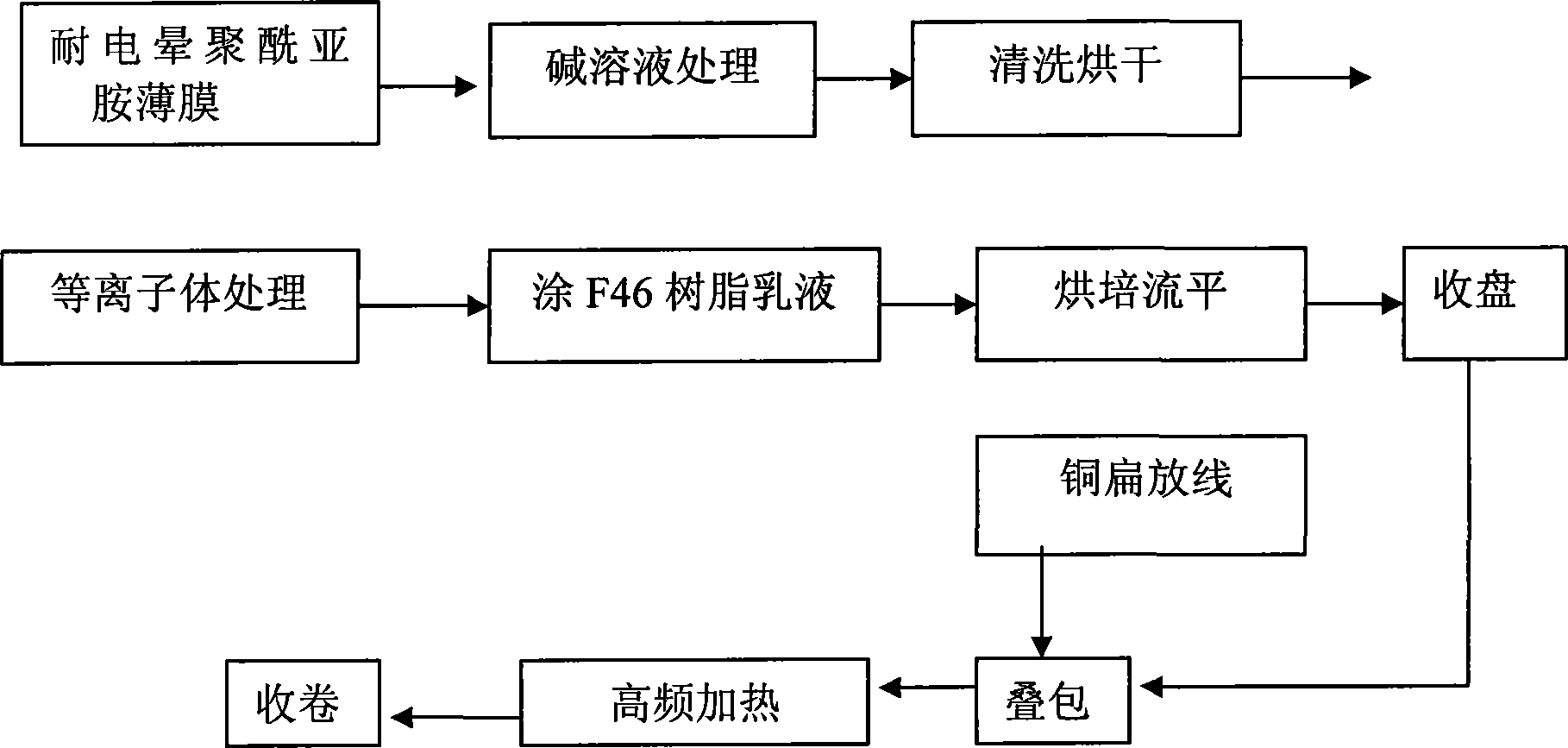

The present invention discloses a method for manufacturing winding wires by corona resistant polyimide films, comprising the following steps: 1) alkaline solution processing; 2) cleaning and drying; 3) plasma processing at normal temperature; 4) coating resin latex; 5) baking and flowing and leveling; 6) withdrawing trays; 7) releasing copper flat wires; 8) folding packages; 9) high-frequency heating; 10) roll-up. With the present invention, after a surface chemical treatment and a normal temperature plasma treatment, the adhesion between the film and the copper conducting wires and between the films is firm, the mechanical strength is high. After being bent or stretched, the winding wire still has good adhesion performance and electric insulation performance, sealing and moisture resistant performance, heat resistant performance, and heat conduction performance. The thickness of the film is controlled between 0.03 and 0.038 mm. In the condition that the volume of a motor is not changed, the cross section of the conductor of the motor can be enlarged. The thermal resistance encountered during the period, when the heat generated during the running process of the motor is dissipatedoutward, is reduced. The insulation thermal aging speed is slowed and the service life of the motor is greatly prolonged.

Description

Production method of winding wire made of corona-resistant polyimide film technical field The invention relates to a production method of a corona-resistant polyimide film insulated winding wire. Background technique A large number of motors are used in all walks of life. The average operating efficiency of ordinary motors is 10-20 percentage points lower. The annual loss of the motor itself will waste about 1500-1800 kWh of electric energy. In order to solve the problem of high energy consumption of this motor, frequency conversion is used. A variable speed motor is the most effective measure. However, in order to develop large-scale high-end variable frequency speed regulation motors, a large number of corona-resistant polyimide film winding wires are needed to solve the problem of short insulation life of frequency conversion speed regulation motors. The core of the motor, the applicant once applied for a Chinese invention patent application number 200710024321.5 on Ju...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B13/00H01B7/08H02K3/00

Inventor 朱艾成

Owner JIANGSU ICE CITY INSULATION MATERIALS STOCK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com