Simple steel-frame structure

A steel frame and simple technology, applied to building components, building structures, roofs, etc., can solve the problems of inability to move as a whole, low reuse rate, poor wind resistance and earthquake resistance, etc., to achieve convenient and fast splicing and combination, and reduce waste , the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

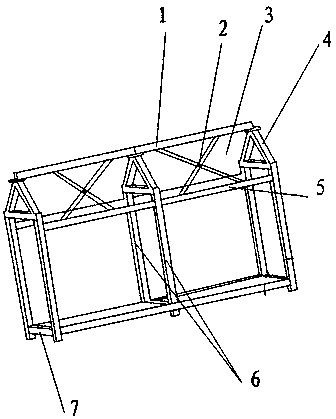

[0012] like figure 1 Shown, a kind of simple and easy steel frame structure, it comprises top beam 1, roof support bar 2, insulation board 3, roof tripod 4, support beam 5, column 6 and support stringer 7, roof tripod 4, column 6 and The supporting longitudinal beams 7 are connected by end connectors to form a supporting member of a simple house, and three or more supporting members are fixedly connected through the roof beam 1 and the supporting beam 5 to form an overall steel frame structure of the house, and the roof beam 1 is locked in place by bolts. The top of each roof tripod 4, the support beam 5 is fixedly installed on the top and bottom of the column 6, the roof support bar 2 is cross-connected between the top beam 1 and the upper support beam 5, and the roof support bar 2 inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com