Flame retardant resin treated article

一种阻燃性、制品的技术,应用在防火涂料等方向,能够解决降低模塑性、产生有害气体、分散不充分等问题,达到极佳阻燃性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

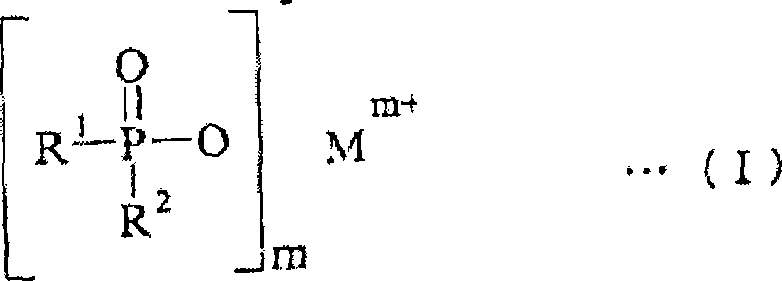

[0141]In a side-flow type twin-screw extruder (manufactured by The Japan Steel Works, LTD.), the following components were mixed and kneaded at 280° C. to obtain resin pellets: 55.5 parts by mass as thermoplastic resin Nylon-66 (produced by Ube Industries, Ltd.: 2020B), glass fibers of 25 parts by mass as reinforcing fibers, which were each surface-treated with a silane coupling agent, and each fiber length was about 3 mm (ASAHIFIBER GLASS Co. , Ltd. production: 03.JAFT2Ak25), 0.2 mass parts of carbon black as a colorant, 0.3 mass parts of an antioxidant (Chiba Specialty Chemicals Co., Ltd. production: Irganox 1010), 5 mass parts of an inorganic filler Particle diameter is the talc of 2 microns, the compound of formula (I-2) as 10 mass parts of metal phosphinate, and the compound of formula (II-3) of 4 mass parts as active organic phosphorus flame retardant compound. The pellets were dried at 115°C for 4 hours, and then molded using an injection molding machine (manufactured ...

Embodiment 2

[0143] The resin-treated article of Example 2 was prepared in the same manner as in Example 1, except that, in Example 1, Nylon-66 (produced by Ube Industries, Ltd.: 2020B) was used as the thermoplastic resin The addition amount of the compound was changed to 51.5 parts by mass, and 4 parts by mass of nanoparticle-sized clay (manufactured by Volclay Japan, Co.: Nanomer I30T) was newly added.

Embodiment 3

[0145] The resin-treated product of Example 3 was prepared in the same manner as in Example 1, except that, in Example 1, Nylon-66 (produced by Ube Industries, Ltd.: 2020B) as a thermoplastic resin Add-on becomes 51.5 mass parts, replaces the compound of formula (I-2) with the compound of formula (I-5) of 10 mass parts and adds as metal phosphinate, with the compound of formula (II-1) of 4 mass parts Instead of the compound of formula (II-3) added as an active organic phosphorus flame retardant, 4 parts by mass of an organic phosphorus-based flame retardant represented by the following structural formula (A) was newly added.

[0146] [chemical formula 14]

[0147]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com