Aqueous white primer for sealing wood oil and tannic acid

A technology of tannin and white primer, applied in the direction of coating, etc., can solve the problems of easy migration of tannin, increase of customer cost, scrapping of coating equipment for coating pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

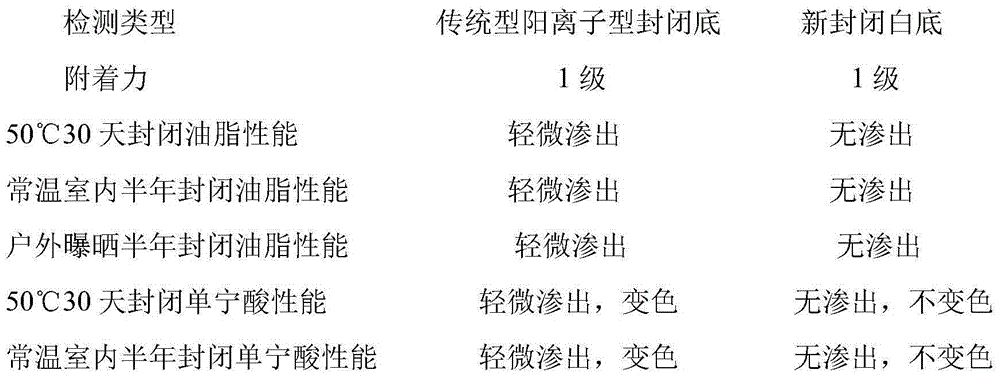

Examples

Embodiment 1

[0031] 10 kg of water,

[0032] Dispersant 1 kg,

[0033] Thickener 0.5 kg,

[0034] PH regulator 0.1 kg,

[0035] Defoamer 1 kg,

[0036] Titanium dioxide white pigment 15 kg,

[0037] Tannin inhibitor 5 kg,

[0038] 2 kg of film-forming solvent,

[0040] Acrylic emulsion 55.4 kg,

[0041] Described water is common tap water or distilled water

[0042] The dispersant is an acrylic block copolymer solution containing pigment affinity groups, and BYK 190 from BYK Company of Germany can be used.

[0043] Described thickener is polyurethane thickener, can adopt the ACRYSOLRM-12 of U.S. Dow.

[0044] The pH regulator is 2-amino-1-methyl-propanol, and AMP-95 from American Dow Chemical can be used.

[0045] The defoamer is polysiloxane, BYK028 from BYK Company of Germany can be used.

[0046] The titanium dioxide white pigment is rutile titanium dioxide, which can be R-706 from DuPont Company of the United States.

[0047] The tannic acid inhi...

Embodiment 2

[0055]

[0056] Described water is common tap water or distilled water

[0057] The dispersant is an acrylic block copolymer solution containing pigment affinity groups, and BYK 190 from BYK Company of Germany can be used.

[0058] Described thickener is polyurethane thickener, can adopt the ACRYSOLRM-12 of U.S. Dow.

[0059] The pH regulator is 2-amino-1-methyl-propanol, and AMP-95 from American Dow Chemical can be used.

[0060] The defoamer is polysiloxane, BYK028 from BYK Company of Germany can be used.

[0061] The titanium dioxide white pigment is rutile titanium dioxide, which can be R-706 from DuPont Company of the United States.

[0062] The tannic acid inhibitor is amino zirconium salt, and L-44 from HALOX Company of the United States can be used.

[0063] The film-forming solvent is dipropylene glycol monomethyl ether, and DPM from Yangzhou Hualun can be used.

[0064] Described talcum powder is 1250 mesh talcum powder, can adopt the KB-2 of Guangxi Guiguang ...

Embodiment 3

[0070]

[0071] Described water is common tap water or distilled water

[0072]The dispersant is an acrylic block copolymer solution containing pigment affinity groups, and BYK 190 from BYK Company of Germany can be used.

[0073] Described thickener is polyurethane thickener, can adopt the ACRYSOLRM-12 of U.S. Dow.

[0074] The pH regulator is 2-amino-1-methyl-propanol, and AMP-95 from American Dow Chemical can be used.

[0075] The defoamer is polysiloxane, BYK028 from BYK Company of Germany can be used.

[0076] The titanium dioxide white pigment is rutile titanium dioxide, which can be R-706 from DuPont Company of the United States.

[0077] The tannic acid inhibitor is amino zirconium salt, and L-44 from HALOX Company of the United States can be used.

[0078] The film-forming solvent is dipropylene glycol monomethyl ether, and DPM from Yangzhou Hualun can be used.

[0079] Described talcum powder is 1250 mesh talcum powder, can adopt the KB-2 of Guangxi Guiguang C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com