Curable resin composition, dry film, cured product, electronic component, and printed-wiring board

A curable resin, printed circuit board technology, used in the fields of curable resin compositions, dry films, cured products and electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

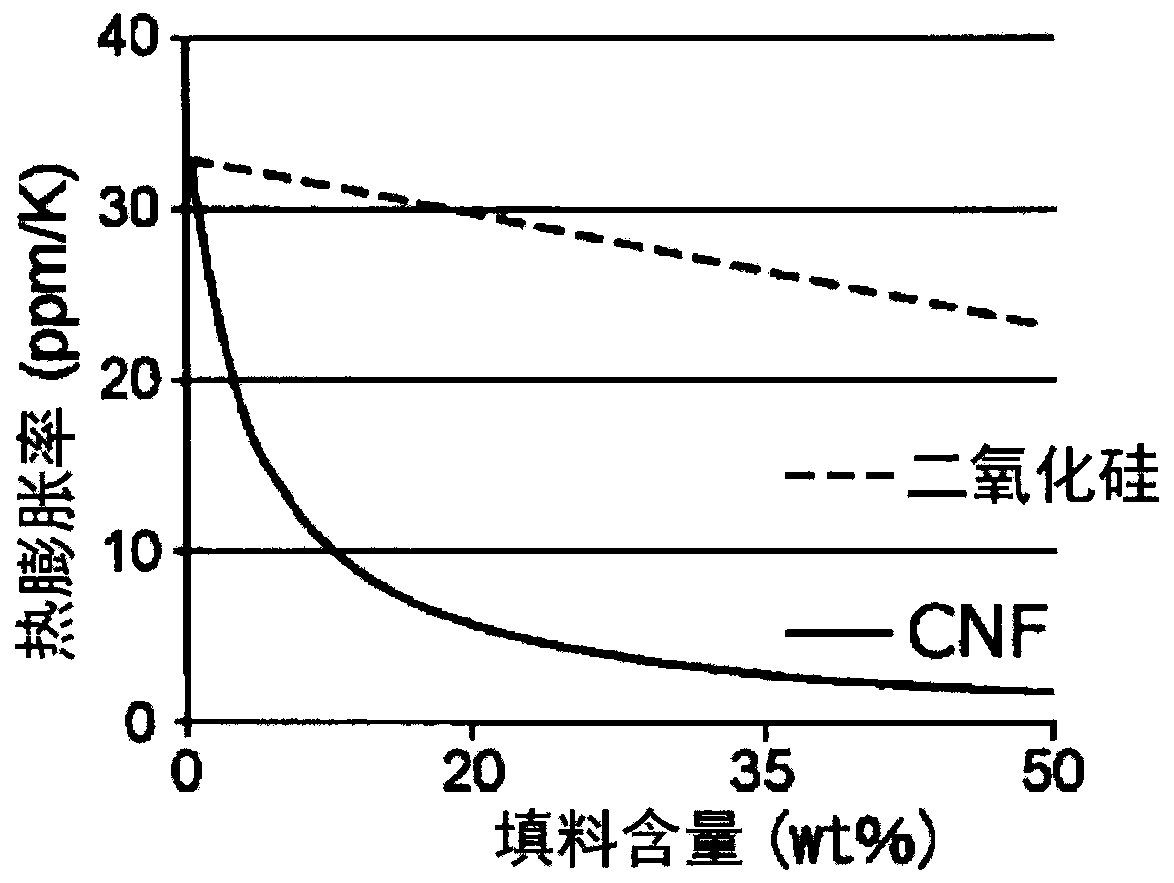

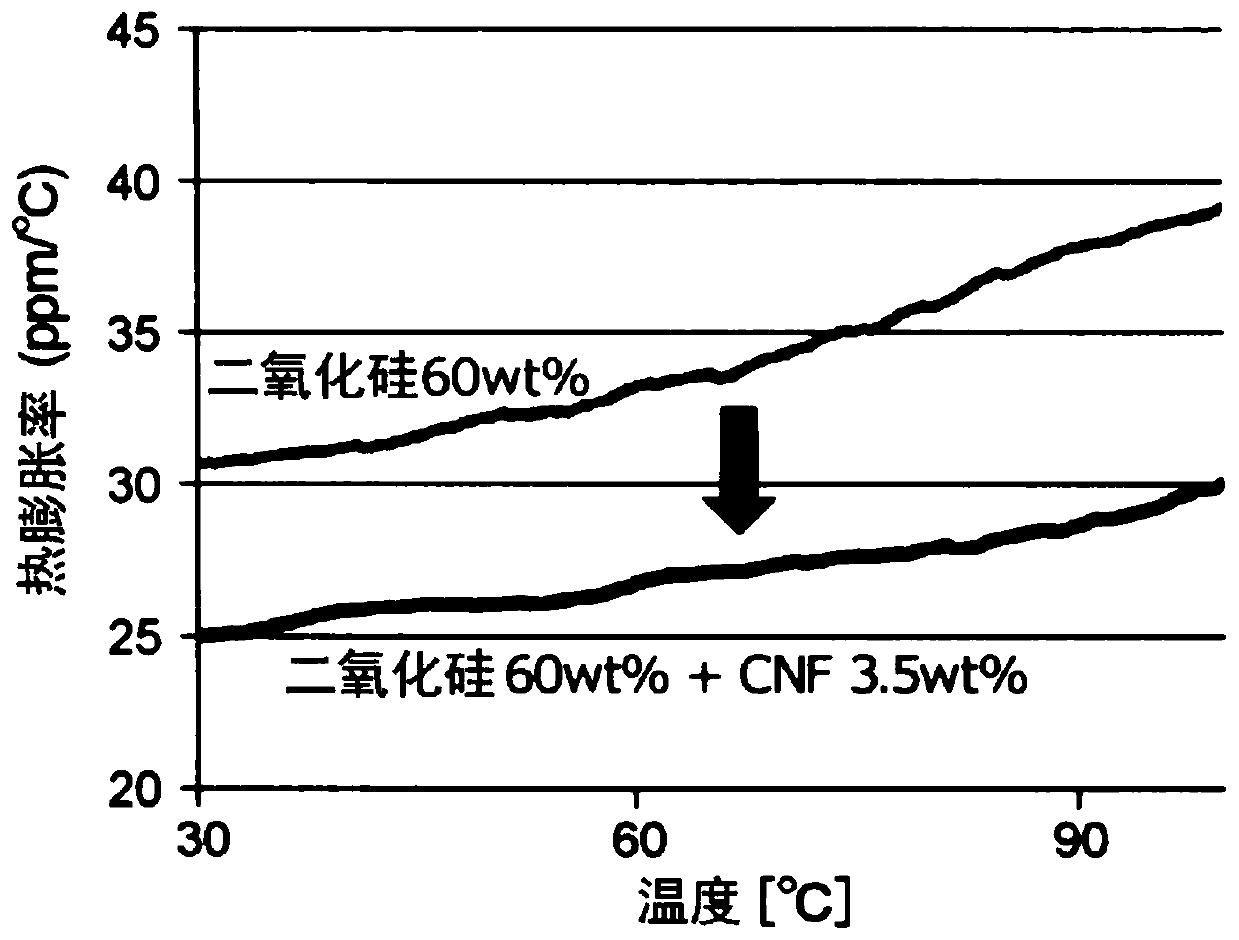

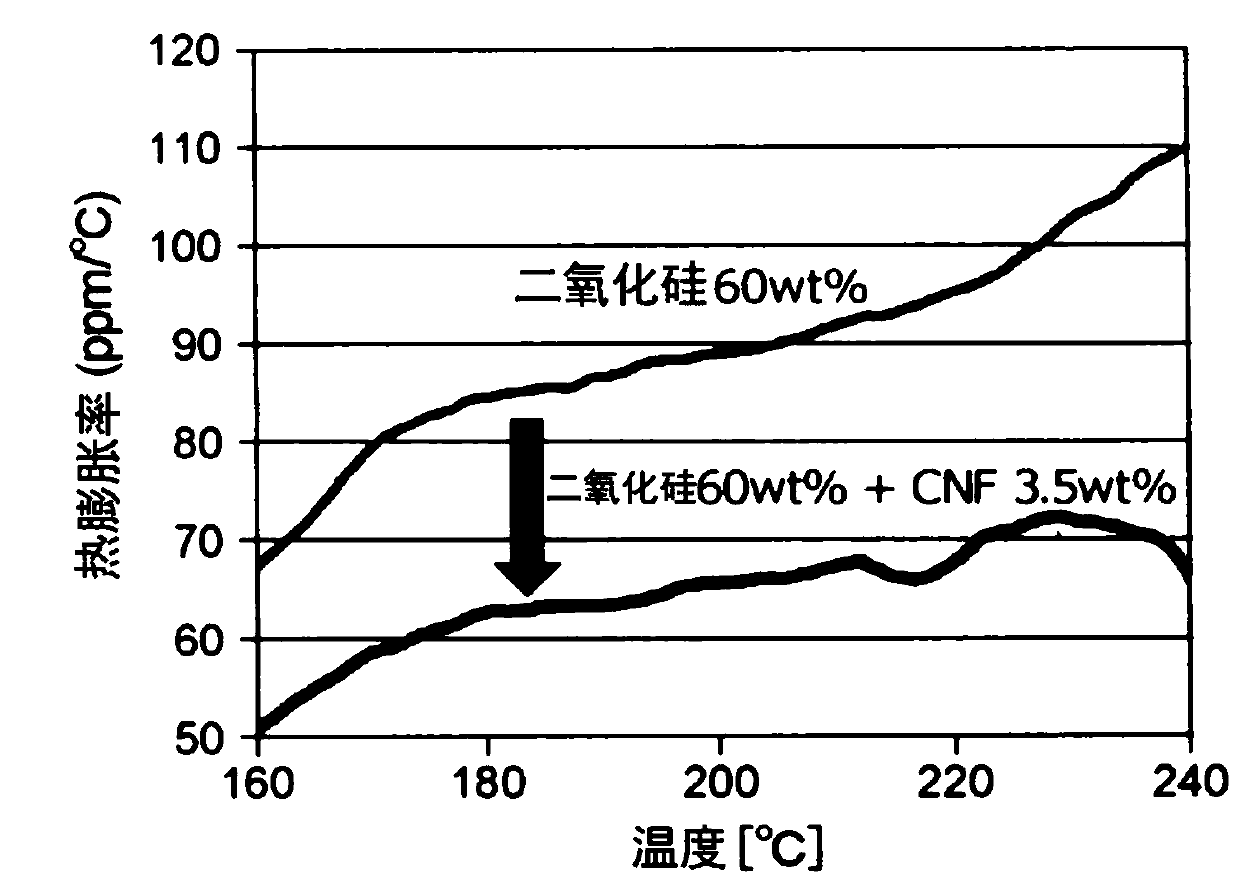

[0115] The curable resin composition according to the first embodiment of the present invention is most characterized in that fine powder and a filler other than fine powder are used in combination as fillers.

[0116] With such a configuration, regarding the first object, it is possible to provide a cured product that maintains a low coefficient of thermal expansion even in a temperature range exceeding 200° C. during component mounting and is excellent in various properties such as toughness.

[0117] [fine powder]

[0118] The fine powder used in the present invention refers to a powder with at least one dimension less than 100nm, and as mentioned above, includes not only fine nearly spherical powder, but also fibrous powder with a cross-sectional diameter of less than 100nm and a thickness of less than 100nm. flake (scale-like) powder, etc. Such a fine powder has a much larger surface area per unit mass and a larger ratio of atoms exposed on the surface than a case where ...

no. 2 approach

[0348] The curable resin composition according to the second aspect of the present invention is characterized by comprising: (A) a fine powder having at least one dimension of less than 100 nm; and (B) a thermosetting component.

[0349] According to the characteristic configuration of the second embodiment of the present invention, it is possible to exhibit the characteristic effect of the present invention that, in the printed circuit board having at least one of the concave portion and the through hole, even during high-temperature heating during component mounting Resin filler-filled via holes, recesses such as via holes, conductor pads on via holes, and wiring such as via holes do not swell.

[0350] The detailed mechanism of the expansion of the wiring during this high-temperature heating is not clear, but it is considered that the cause is a large difference in thermal expansion coefficient between the via hole formed of copper and the via hole and the resin filler at hi...

Embodiment

[0407] Hereinafter, the present invention will be described in more detail using examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com