Patents

Literature

51results about How to "Increase sputtering rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

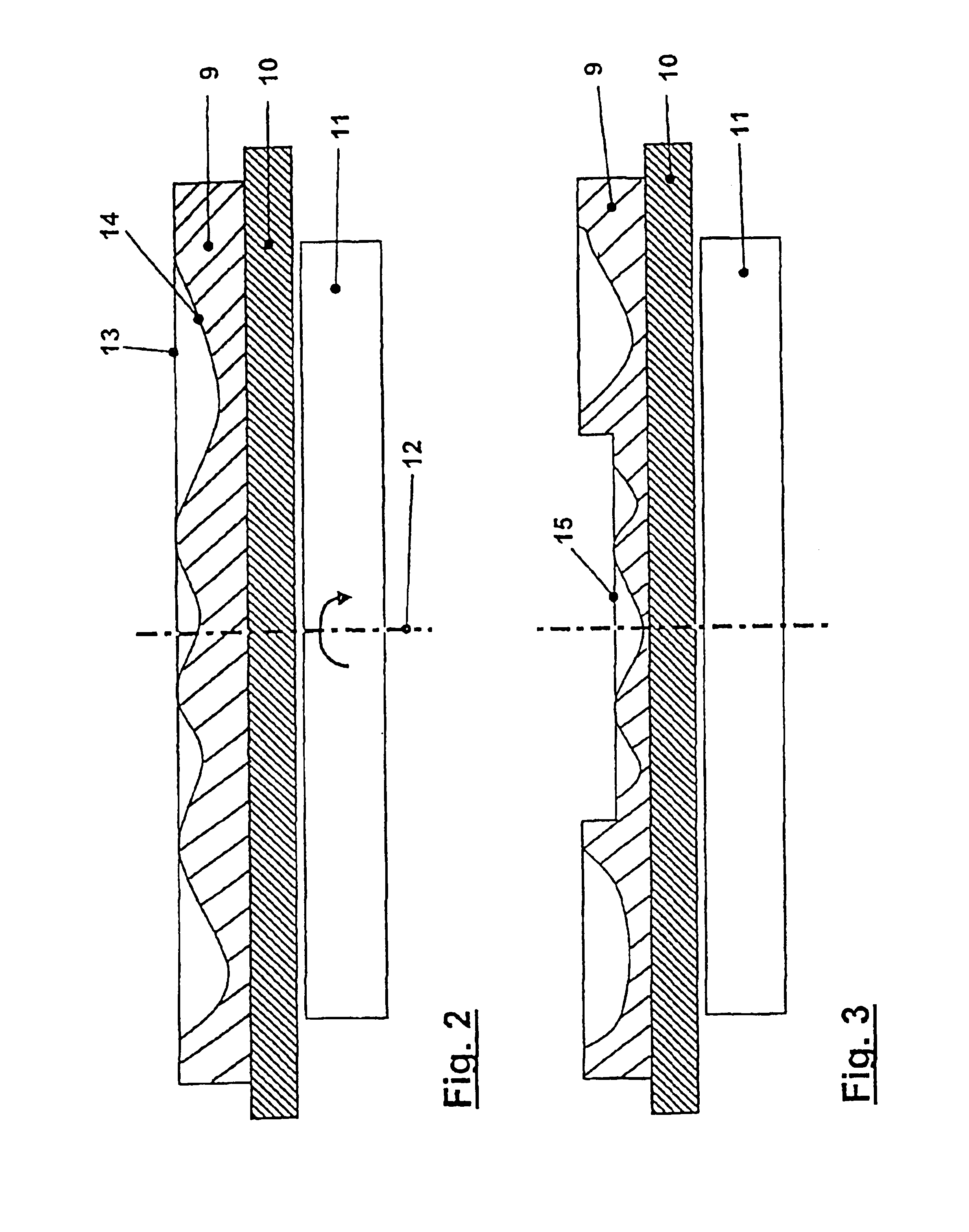

Target comprising thickness profiling for an RF magnetron

InactiveUS6916407B2CapacitanceImprove thermal conductivityCellsElectric discharge tubesOptoelectronicsVacuum chamber

Method for sputtering from a dielectric target (9) in a vacuum chamber (2) with a high frequency gas discharge, the target (9) being mounted on a cooled metallic back plate (10) and this back plate forming an electrode (10) supplied with high frequency, includes a target thickness (Td) profiled (15) differently over the surface such that in the regions of a desired decrease of the sputtering rate the target thickness (Td) is selected to be greater than in the remaining regions.

Owner:ESEC

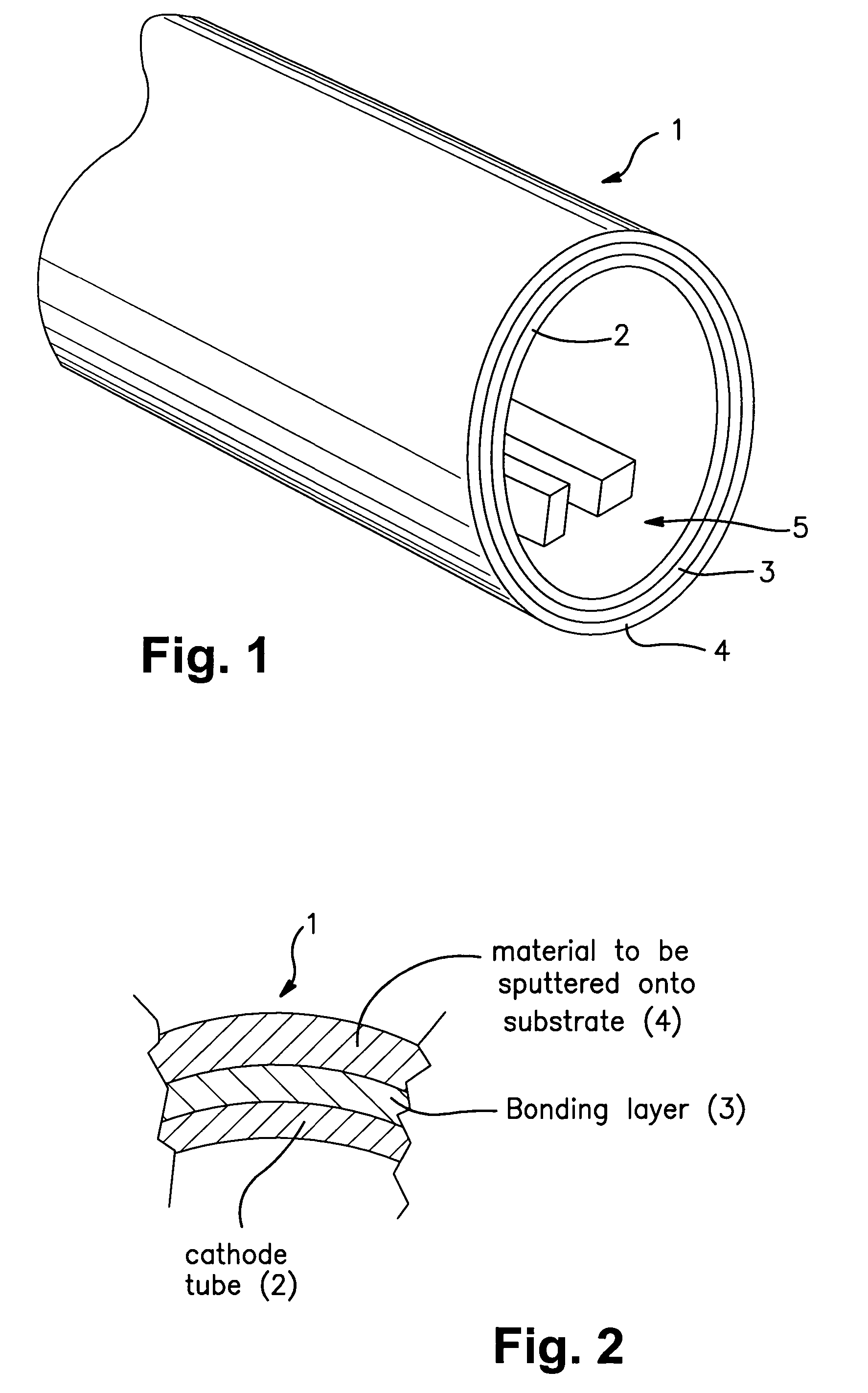

Method of producing a tubular target

InactiveUS20070086909A1Increase sputtering rateReduce discharge lossVacuum evaporation coatingSputtering coatingAlloyVolumetric Mass Density

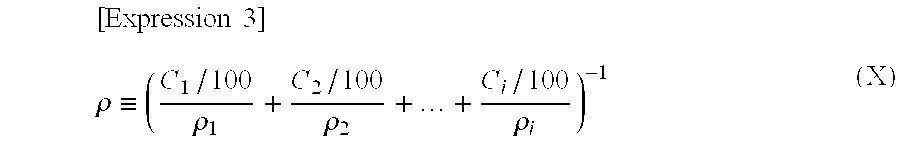

A method for producing a tubular target formed of molybdenum or a molybdenum alloy which has an oxygen content of less than 50 μg / g, a density of greater than 99% of the theoretical density and an average grain size of less than 100 μm and which is connected to a supporting tube. The molybdenum or molybdenum alloy tube is produced by extrusion.

Owner:HEIDELBERGER DRUCKMASCHINEN AG +1

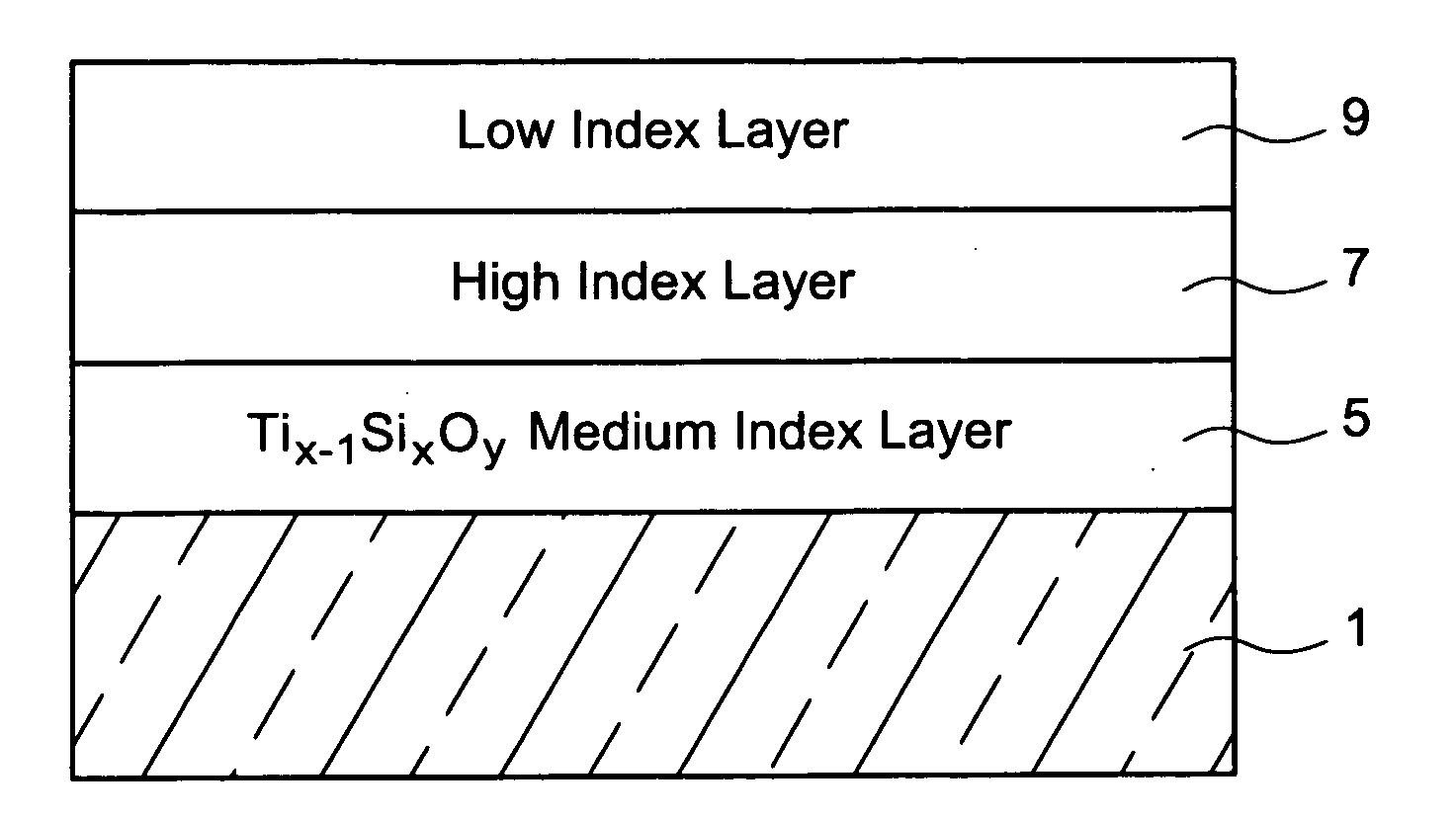

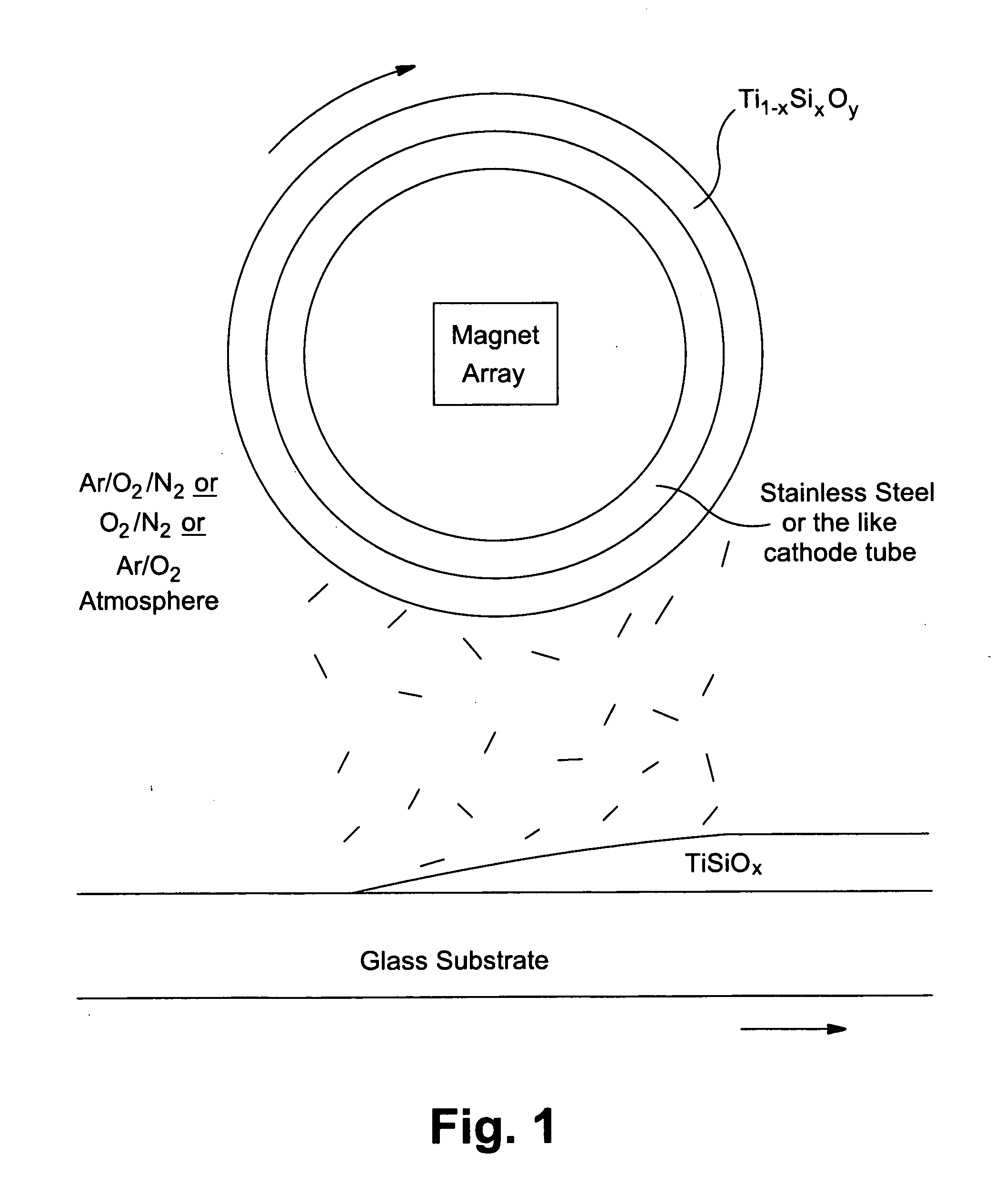

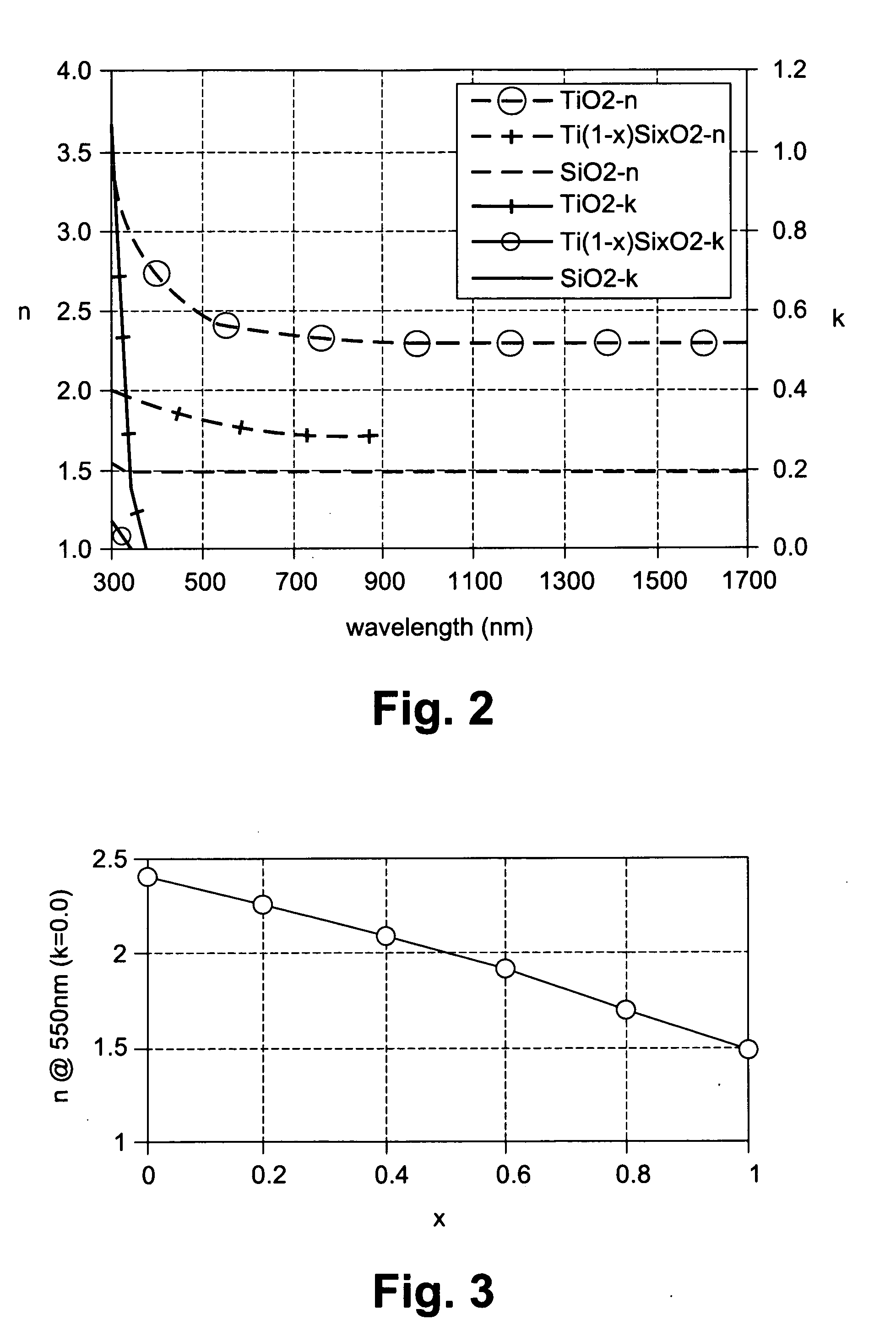

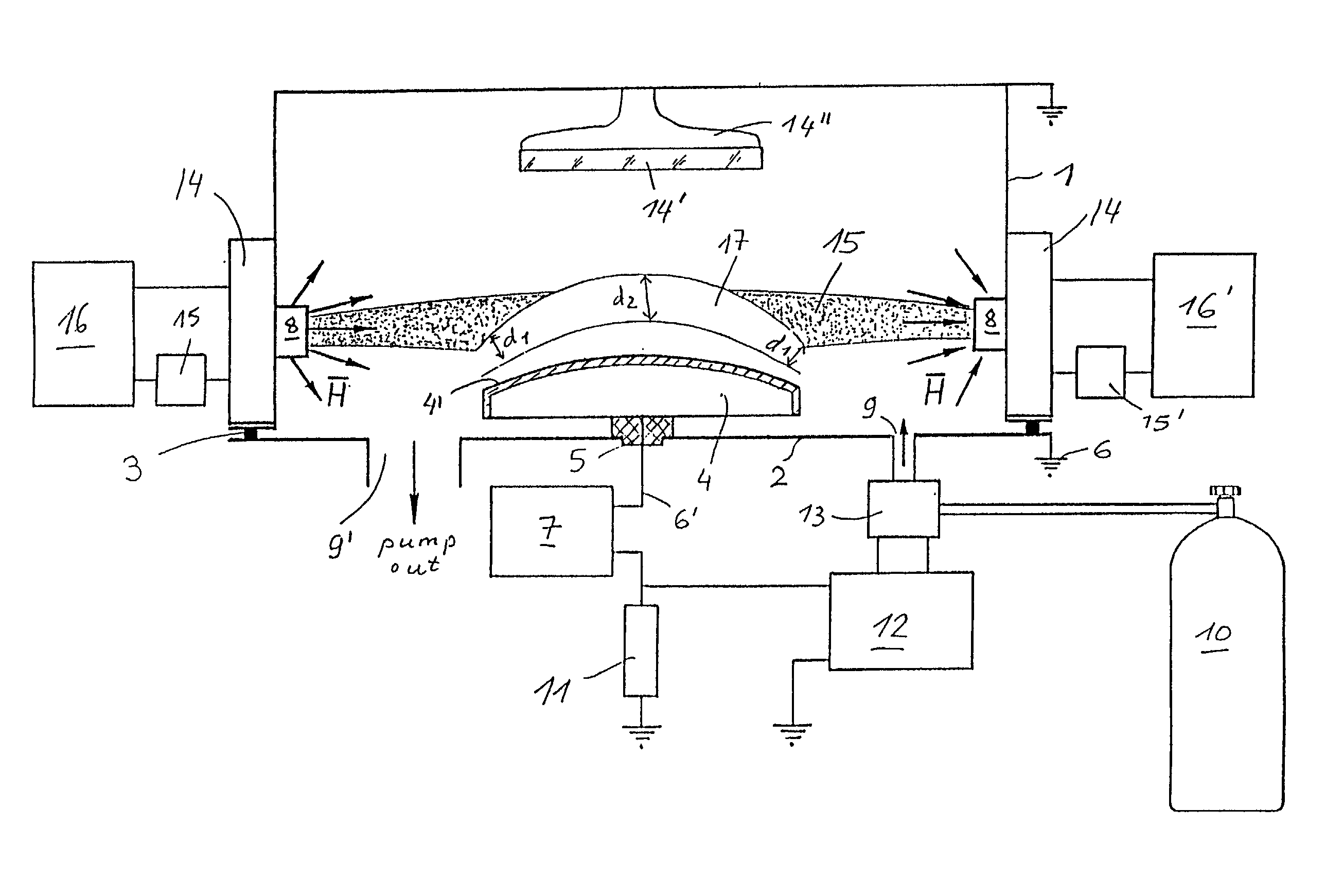

Silicon titanium oxide coating, coated article including silicon titanium oxide coating, and method of making the same

ActiveUS20110081532A1Low refractive indexHigh refractive indexVacuum evaporation coatingSputtering coatingConductive coatingOxygen

Certain example embodiments relate to a layer of or including Ti1-xSixOy and / or a method of making the same. In certain example embodiments, the Ti1-xSixOy-based layer may be substoichiometric with respect to oxygen. In certain example embodiments of this invention, the layer may include Ti1-xSixOy where x is from about 0.05 to 0.95 (more preferably from about 0.1 to 0.9, and even more preferably from about 0.2 to 0.8, and possibly from about 0.5 to 0.8) and y is from about 0.2 to 2 (more preferably from about 1 to 2, and even more preferably from about 1.5 to 2, and possibly from about 1.9 to 2). The layer may have an index of refraction of from about 1.6 to 1.9. The layer may also be used with a transparent conductive oxide in a transparent conductive coating.

Owner:GUARDIAN GLASS LLC

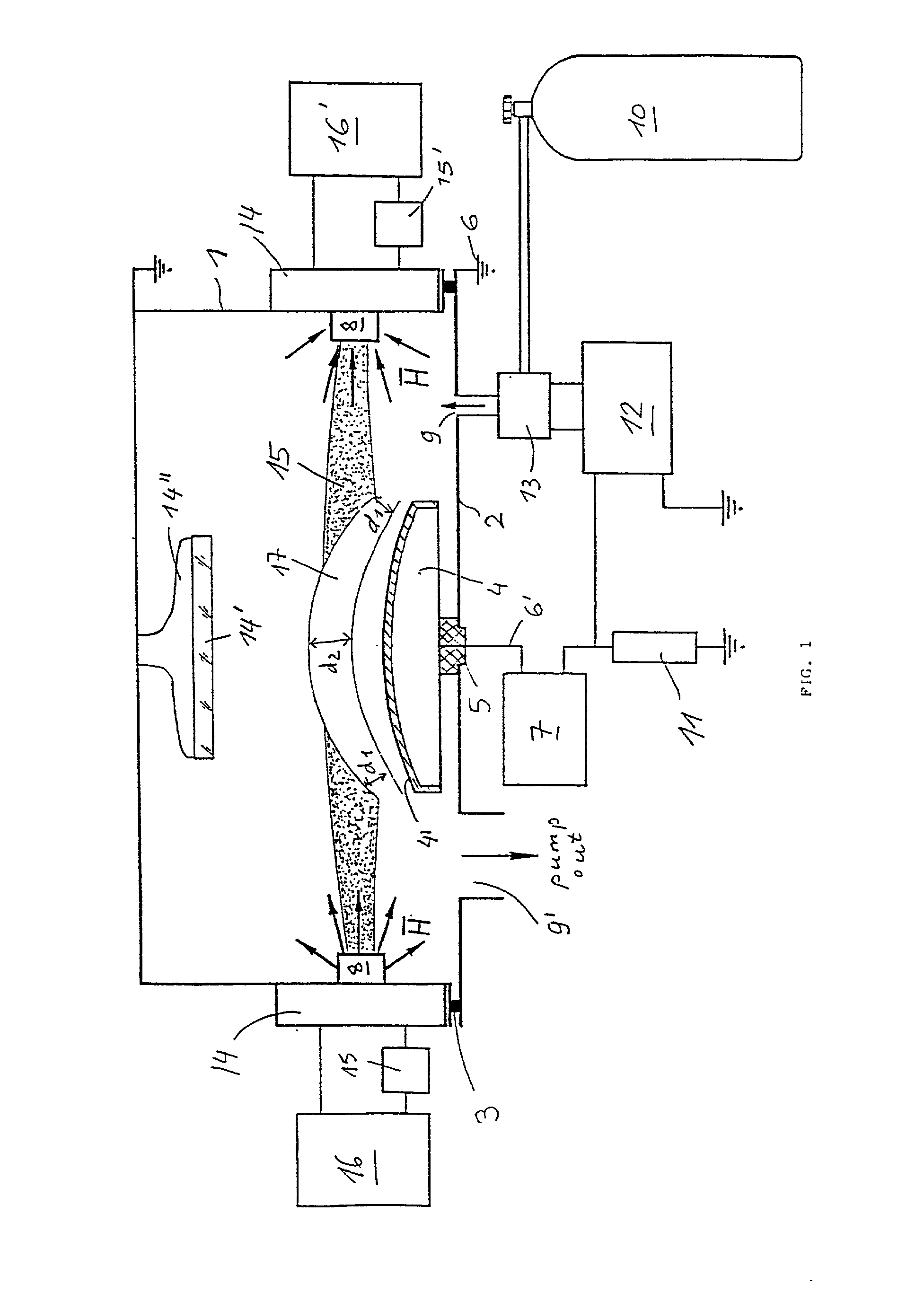

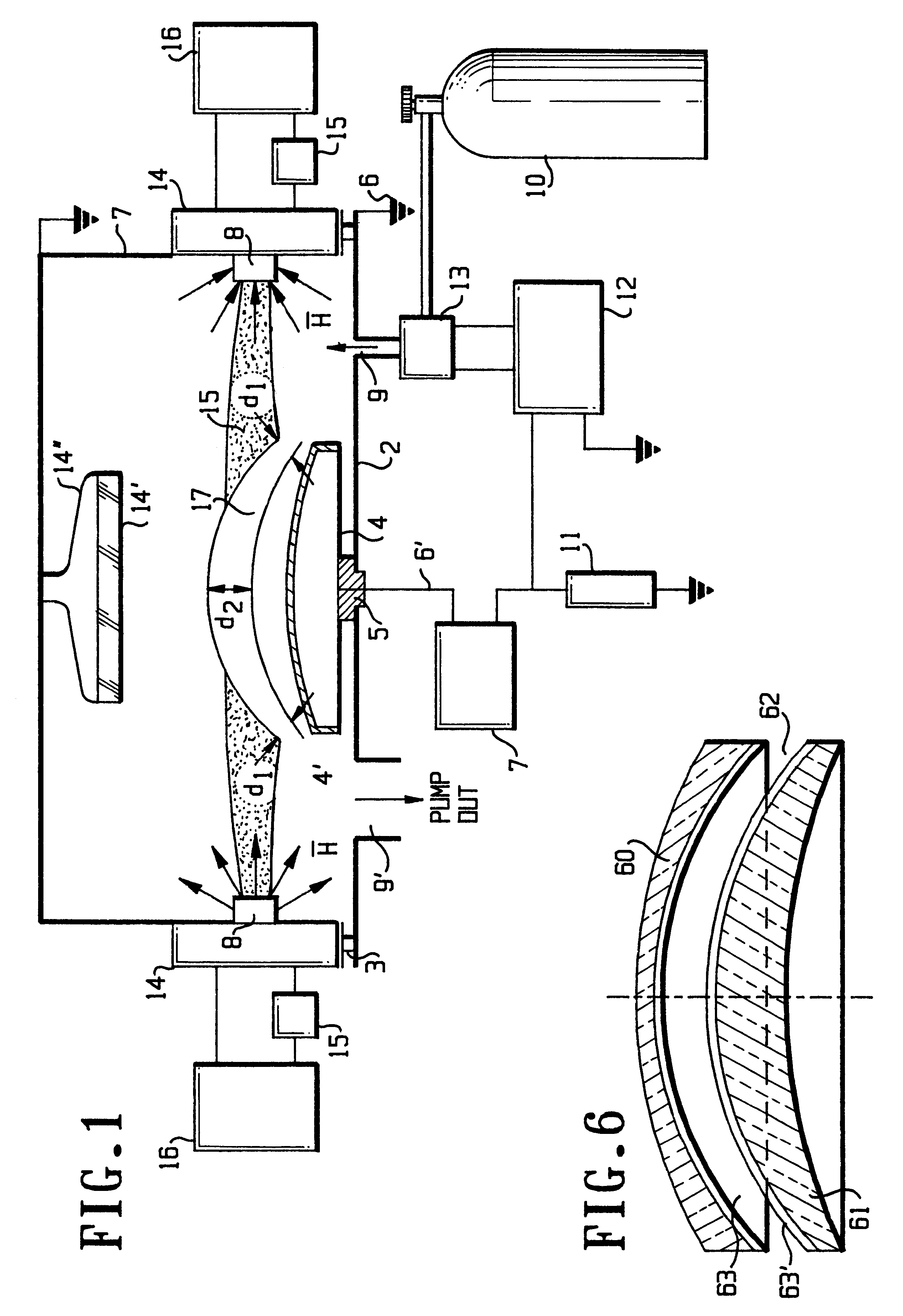

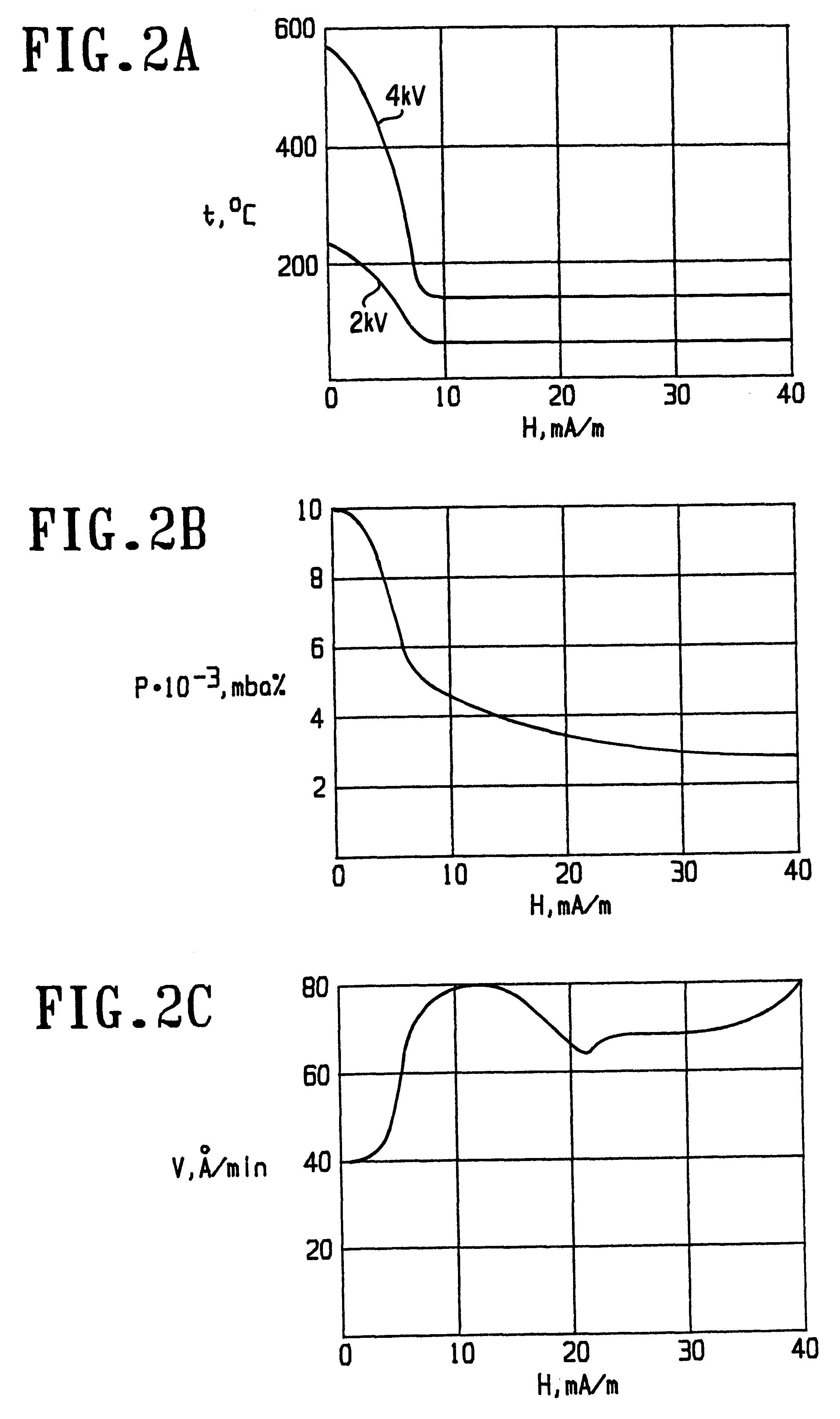

Sputtering method and apparatus for depositing a coating onto substrate

InactiveUS20020148941A1Increase sputtering rateCellsElectric discharge tubesUltimate tensile strengthMaterials science

Sputtering method and apparatus for depositing a coating onto substrate employs variable magnetic field arranged in vicinity of a cathode within a working chamber, filled with ionizable fluid. By controlling a magnetic field topology, i.e. orientation and value of magnetic strength with respect to cathode there is enabled localization and shifting of plasma away from substrate and by thus improvement of adhesion and properties of deposited coatings.

Owner:SOROKOV BORIS +2

Sputtering Target for Magnetic Recording Film and Method for Manufacturing the Same

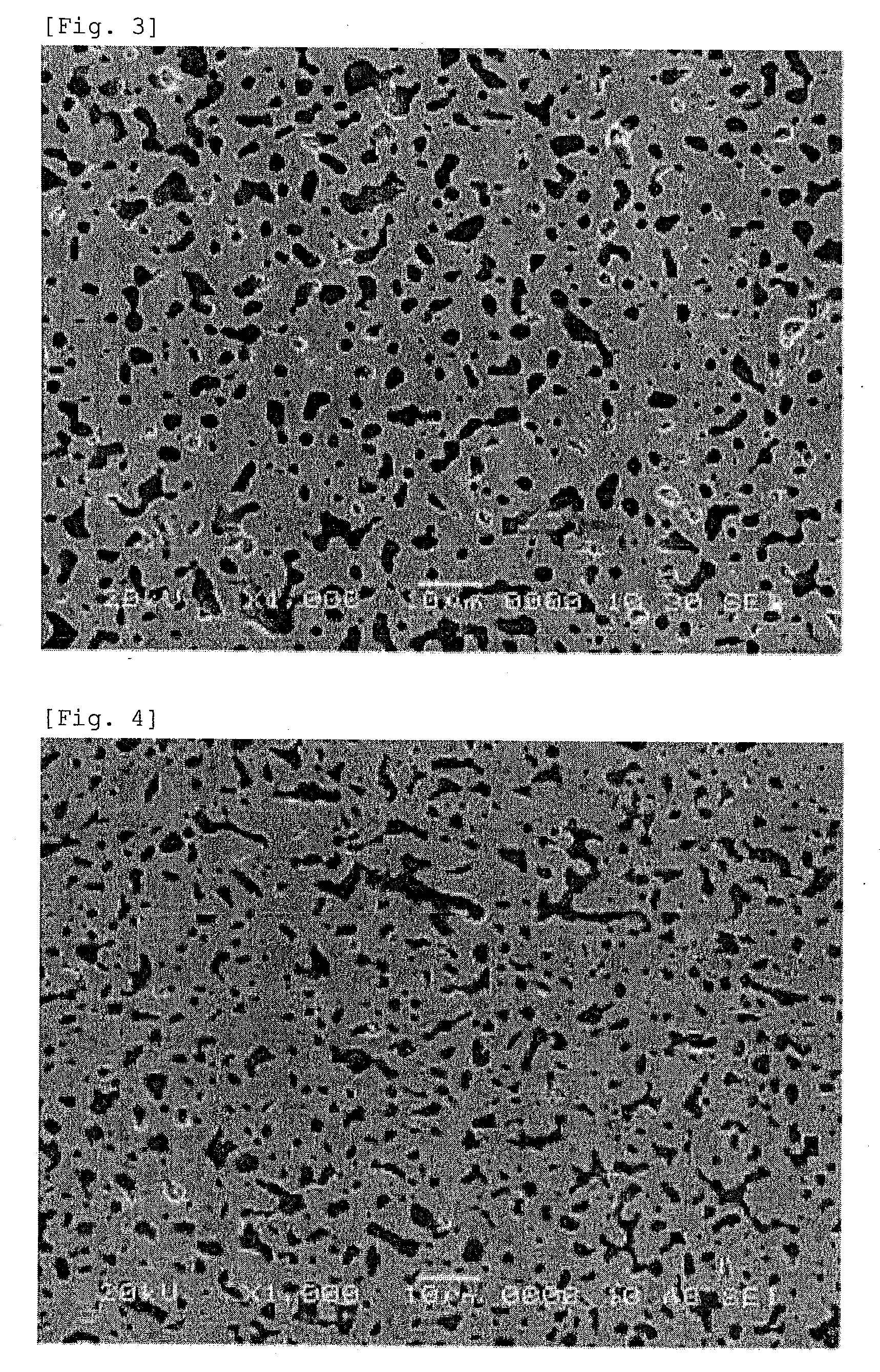

InactiveUS20100243435A1Reduce permeabilityHigh densityCellsVacuum evaporation coatingVolumetric Mass DensityMetal

Provided is a sputtering target for a magnetic recording film, in which film formation efficiency and film characteristics can be improved by suppressing growth of crystal grains, reducing magnetic permeability, and increasing density. A method for manufacturing such a sputtering target is also provided. The sputtering target is composed of a matrix phase which includes Co and Pt and a metal oxide phase for example. The sputtering target has a magnetic permeability in the range of 6 to 15 and a relative density of 90% or more.

Owner:MITSUI MINING & SMELTING CO LTD

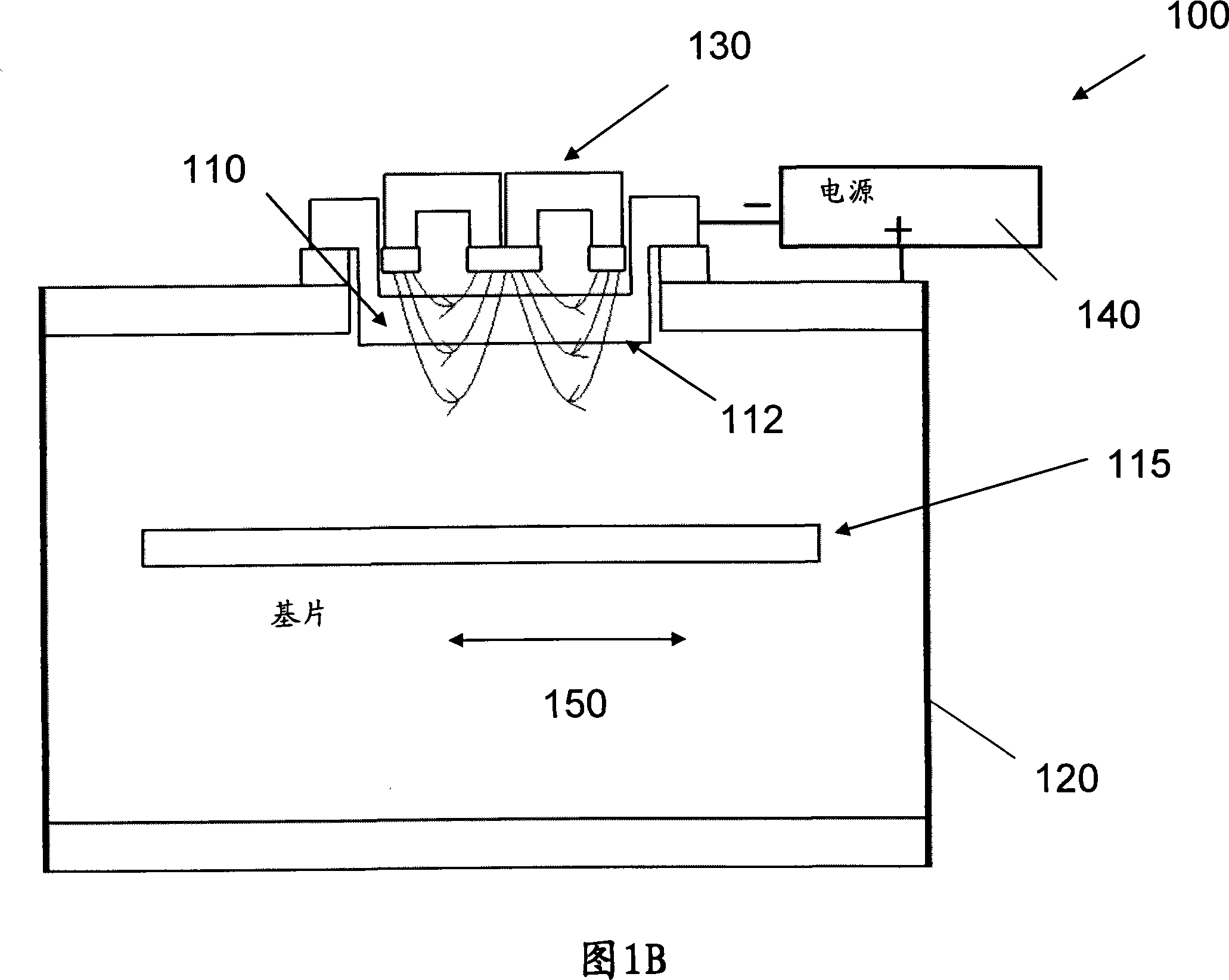

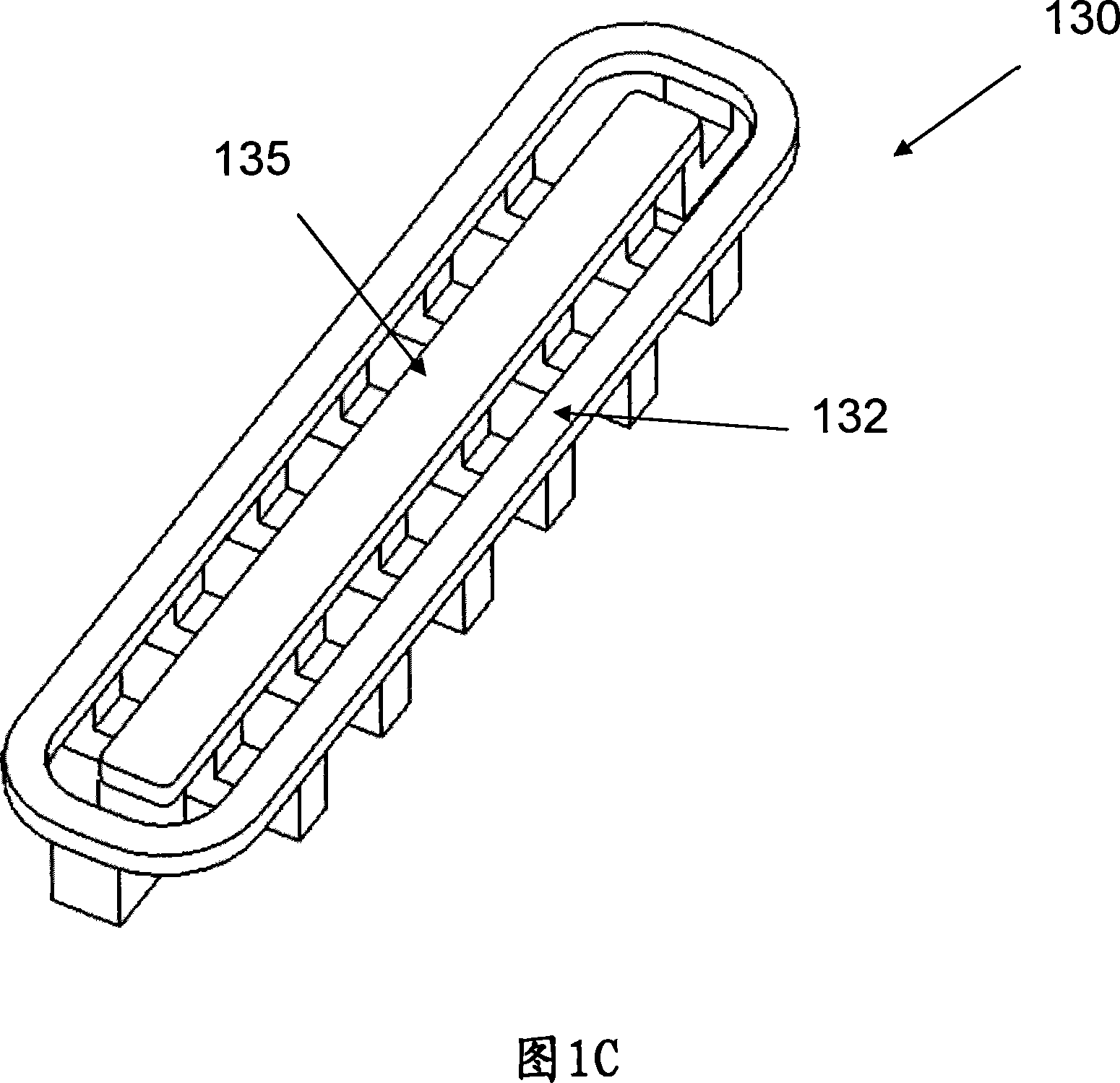

Cathode device for carrying out linear reactive sputtering film coating by utilizing electric-field confinded plasmas

ActiveCN101798675AAvoid enteringIncrease profitVacuum evaporation coatingSputtering coatingElectrical field strengthVolumetric Mass Density

The invention relates to a cathode device for carrying out linear reactive sputtering film coating by utilizing electric-field confinded plasmas, comprising a target stand, a working gas source, a reaction gas source and a first target material and a second target material which are oppositely arranged on the target stand and respectively extend along the longitudinal direction, wherein the two opposite side wall surfaces of the first target material and the second target material respectively concave inwards to form sputtering surfaces, and a target cavity is formed between the two sputtering surfaces; the working gas source and the reaction gas source are respectively arranged at the inlet side and the outlet side of the target cavity; and on the cross section of the cathode device, the minimum distance between the two sputtering surfaces is at the outlet position of the target cavity. In the invention, the distribution of electric fields is changed by changing the shape of the target material, and the direction of the strength of the electric field in the target cavity is along the direction being vertical to the sputtering surfaces, and therefore, the plasmas are intensively confined in the central areas of the pair of target materials, which increases the density of the target materials and further improves the sputtering rate. Meanwhile, the invention also can effectively prevent reaction gas from entering the target cavity, and thereby, target poisoning is avoided.

Owner:苏州力合光电薄膜科技有限公司

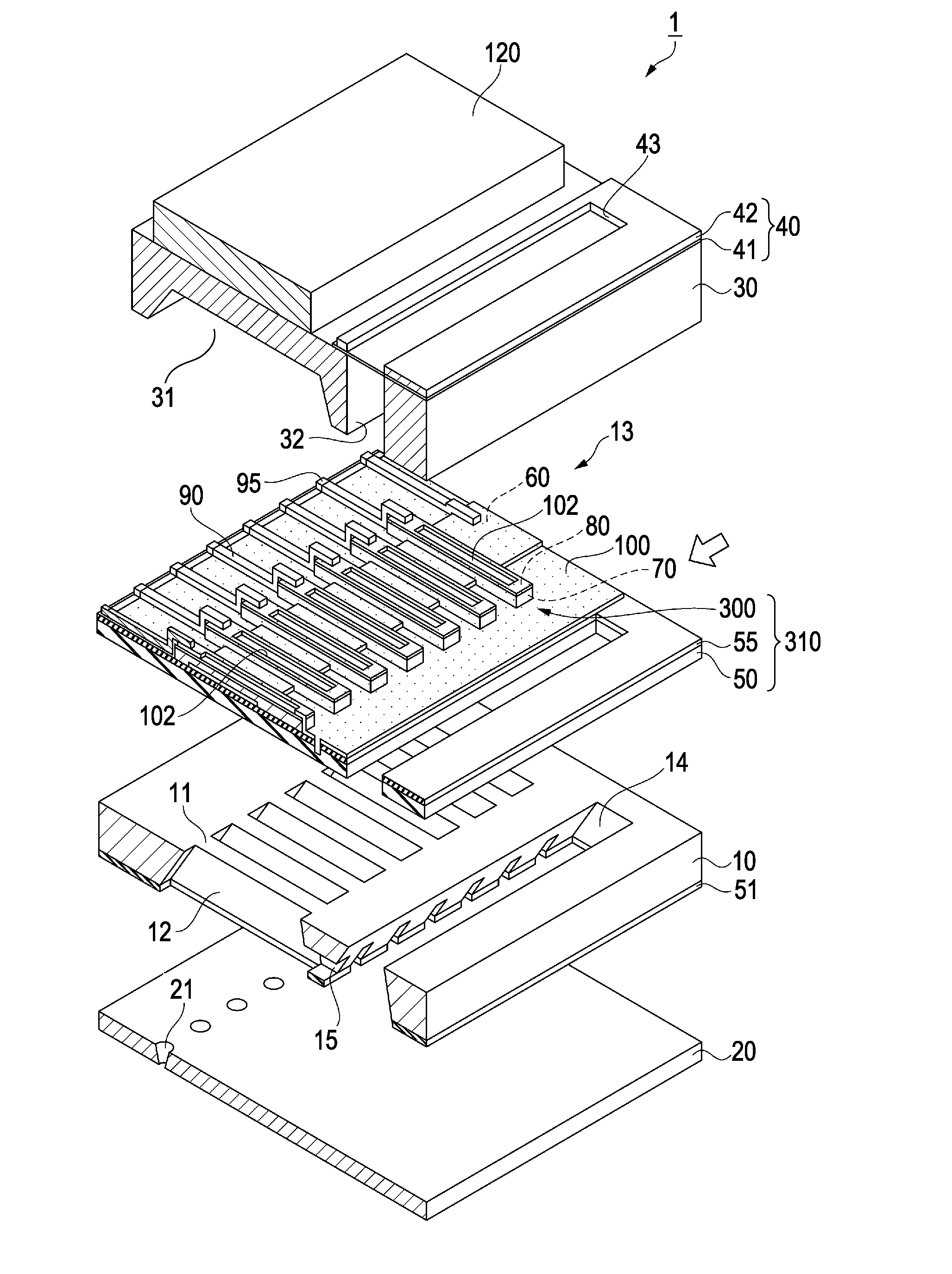

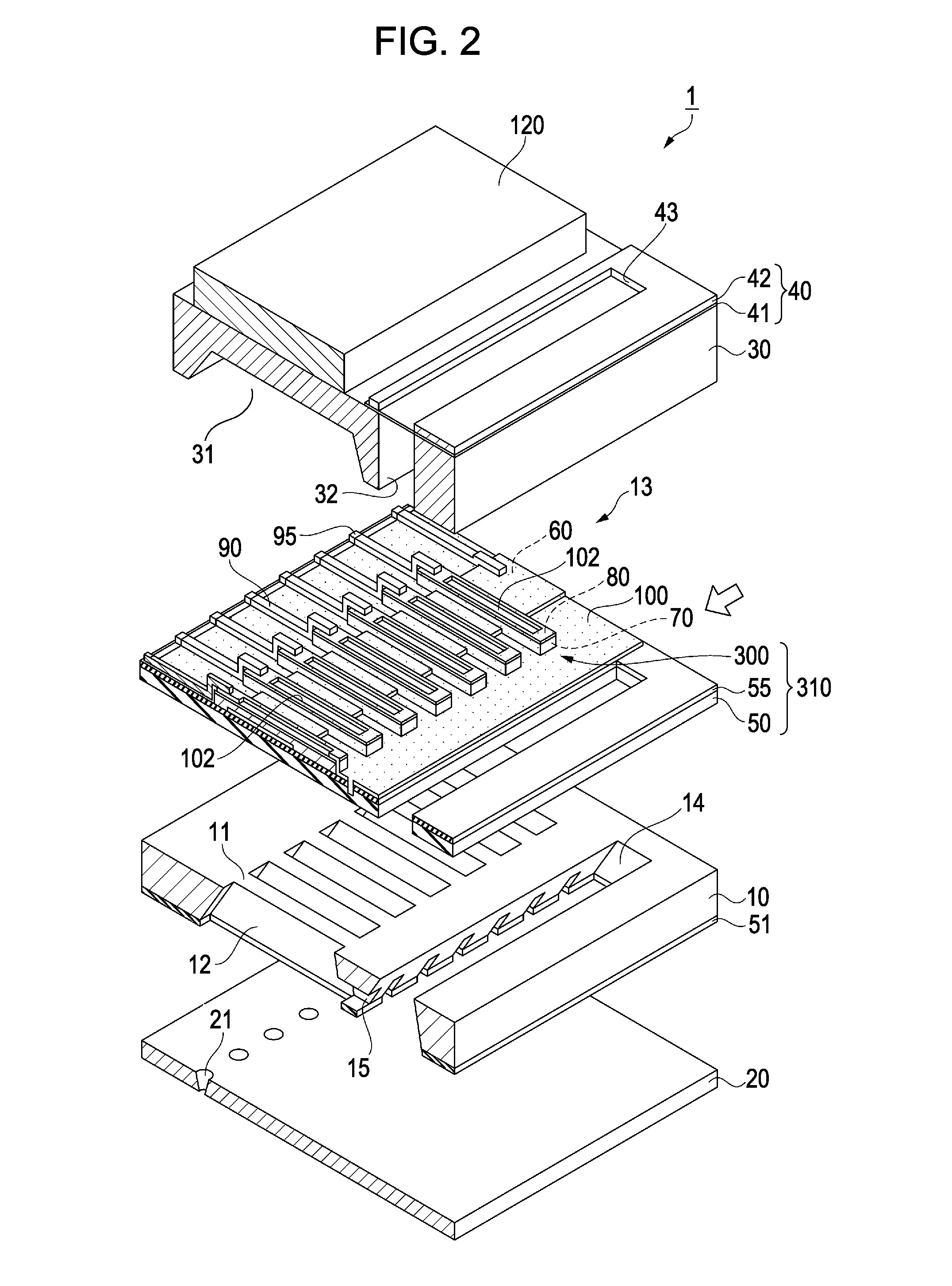

Piezoelectric actuator, method for manufacturing piezoelectric actuator, liquid-ejecting head, and liquid-ejecting apparatus

InactiveUS20110043573A1More resistant to sputteringSmall differencePiezoelectric/electrostrictive device manufacture/assemblyLiquid surface applicatorsTectorial membranePiezoelectric actuators

A piezoelectric actuator includes a substrate; a diaphragm overlying the substrate; a lower electrode overlying the diaphragm; a piezoelectric body overlying the lower electrode; an upper electrode that includes a first upper sub-electrode which overlies the piezoelectric body and which has a first sputtering rate and also includes a second upper sub-electrode which overlies the first upper sub-electrode, which has a second sputtering rate less than the first sputtering rate, and which is the uppermost layer; and a protective film extending over side surfaces of the piezoelectric body and the second upper sub-electrode, a portion of the protective film that overlies the second upper sub-electrode being removed by sputtering.

Owner:SEIKO EPSON CORP

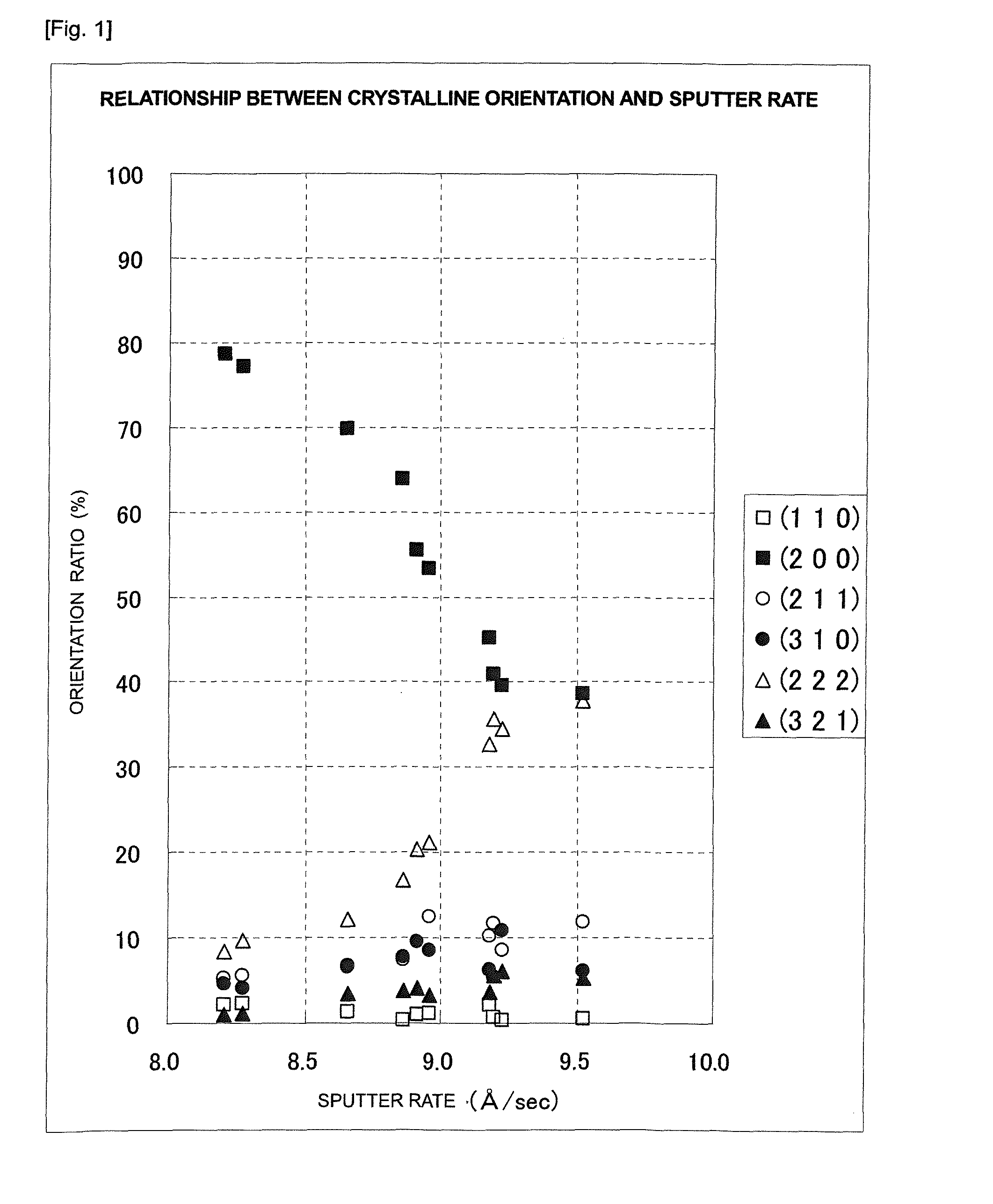

Tantalum Sputtering Target and Method for Manufacturing Same

InactiveUS20140242401A1Increase sputtering rateAvoid pollutionCellsNitrogen-metal/silicon/boron binary compoundsSputteringPlane orientation

Provided is a tantalum sputtering target having a (200)-plane orientation ratio of 70% or less and a (222)-plane orientation ratio of 10% or more at the sputtering surface of the tantalum sputtering target. The sputter rate can be increased by controlling the crystalline orientation of the target, and thereby a film having an intended thickness can be formed in a short time to improve the throughput.

Owner:JX NIPPON MINING & METALS CO LTD

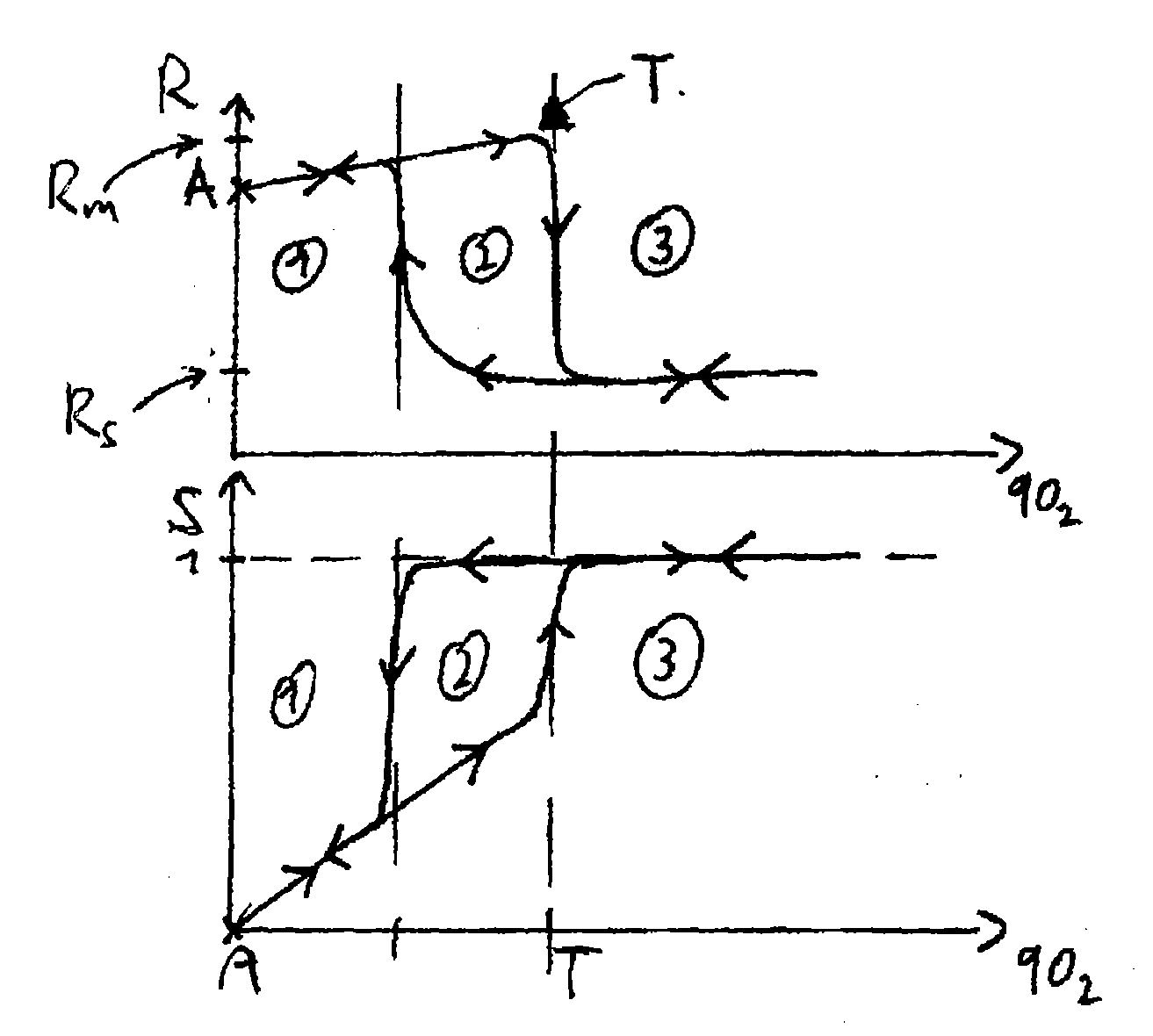

Sputter target, method for manufacturing a layer, particularly a tco (transparent conductive oxide) layer, and method for manufacturing a thin layer solar cell

InactiveUS20090272641A1Increase sputtering rateLow oxygen bombardmentCellsVacuum evaporation coatingThin layerOxygen ions

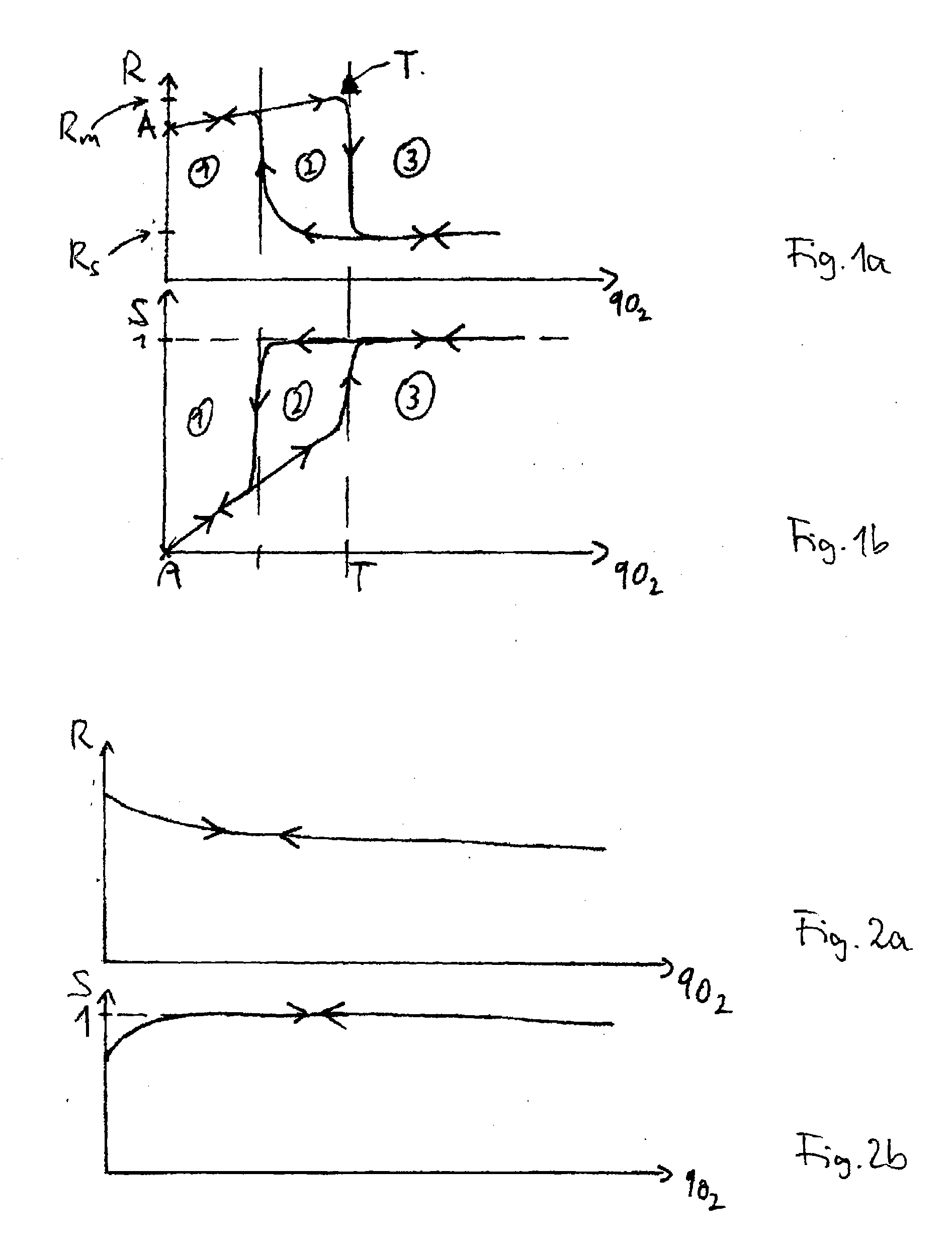

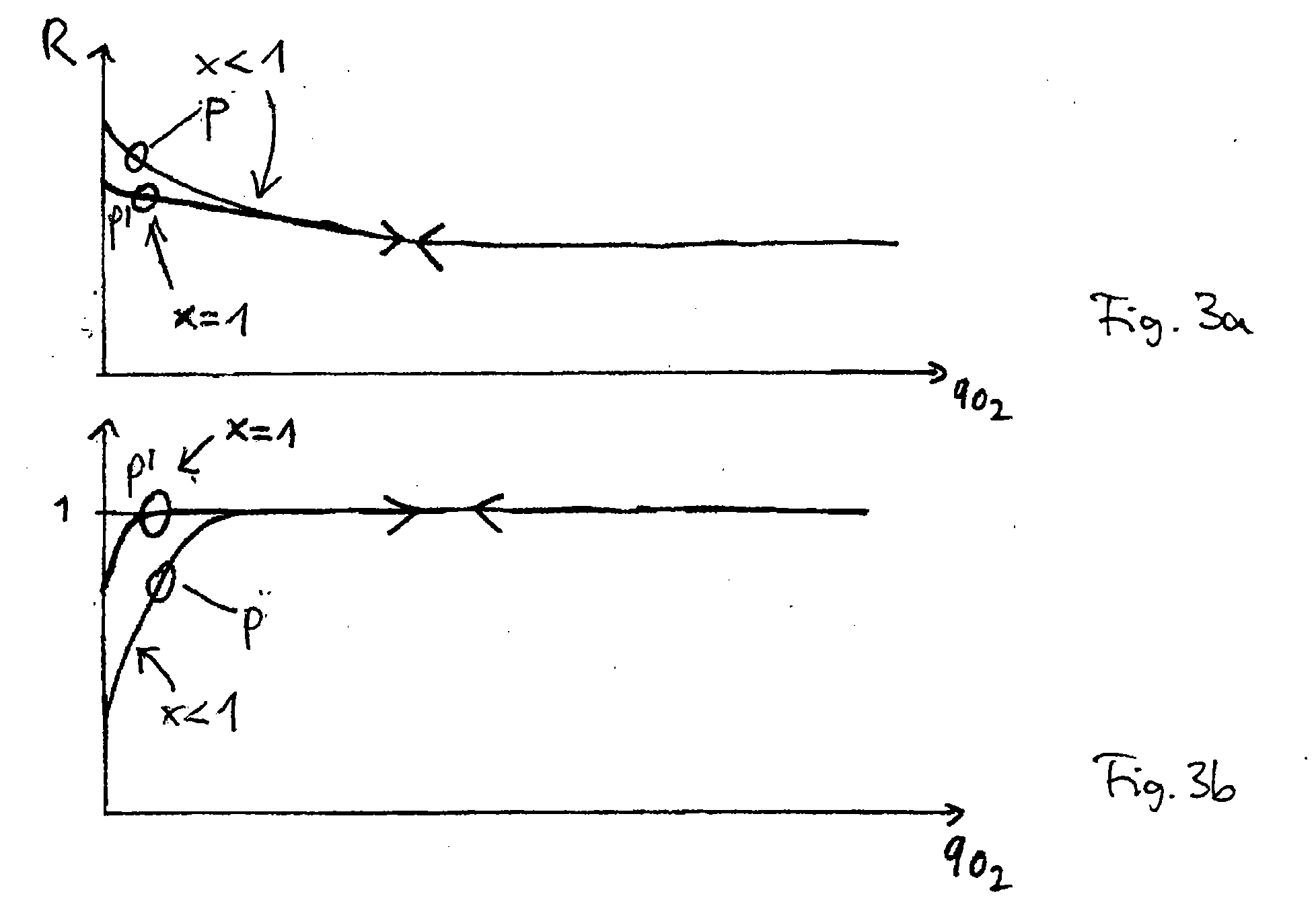

In the present invention a sub-stoichiometric ceramic ZnOx:Al target, with 0.3<x<1, is used for depositing a ZnO:Al layer in a reactive sputtering process. The process is carried out in an Ar / O2 atmosphere. The diagram depicts the deposition rate R depending on the oxygen flow in a sputtering process according to the present invention compared with a conventional sputter process using a stoichiometric ZnO target. The upper line x<1 indicates the deposition rate R when using the inventive target and process. The lower line x=1, for comparison only, indicates the deposition rate R when using a stoichiometric ceramic ZnO target. It can be seen from the diagram that both processes are quite stable as there are no steep slopes when varying the oxygen flow. However, the line x<1 is above the line x=1. Therefore, a working point P may be selected which has a higher deposition rate R than a corresponding working point P of a corresponding ceramic target. A higher deposition rate, however, entails a lower bombardment of the deposited layer with oxygen ions. Therefore, the quality of the ZnO:Al layer is improved as far as the conductivity and the etchability of the layer are concerned.

Owner:APPLIED MATERIALS INC

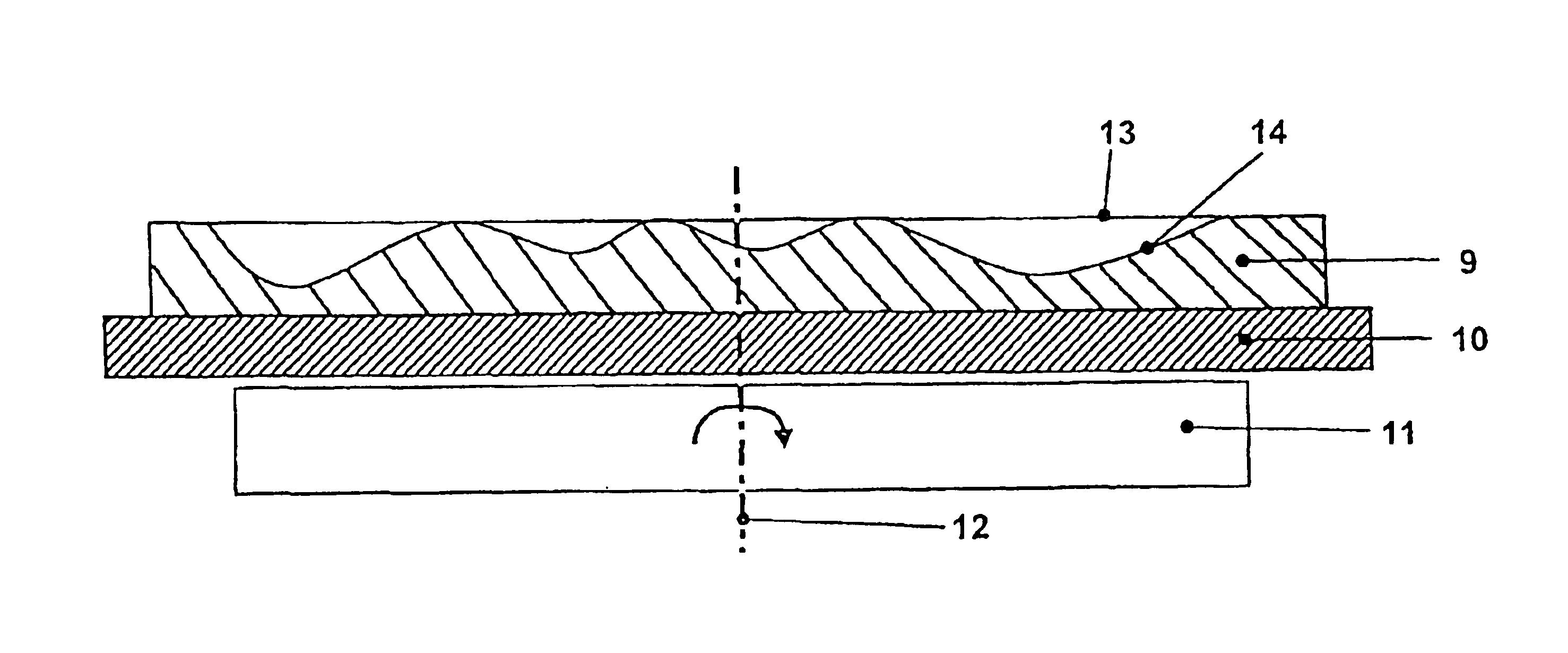

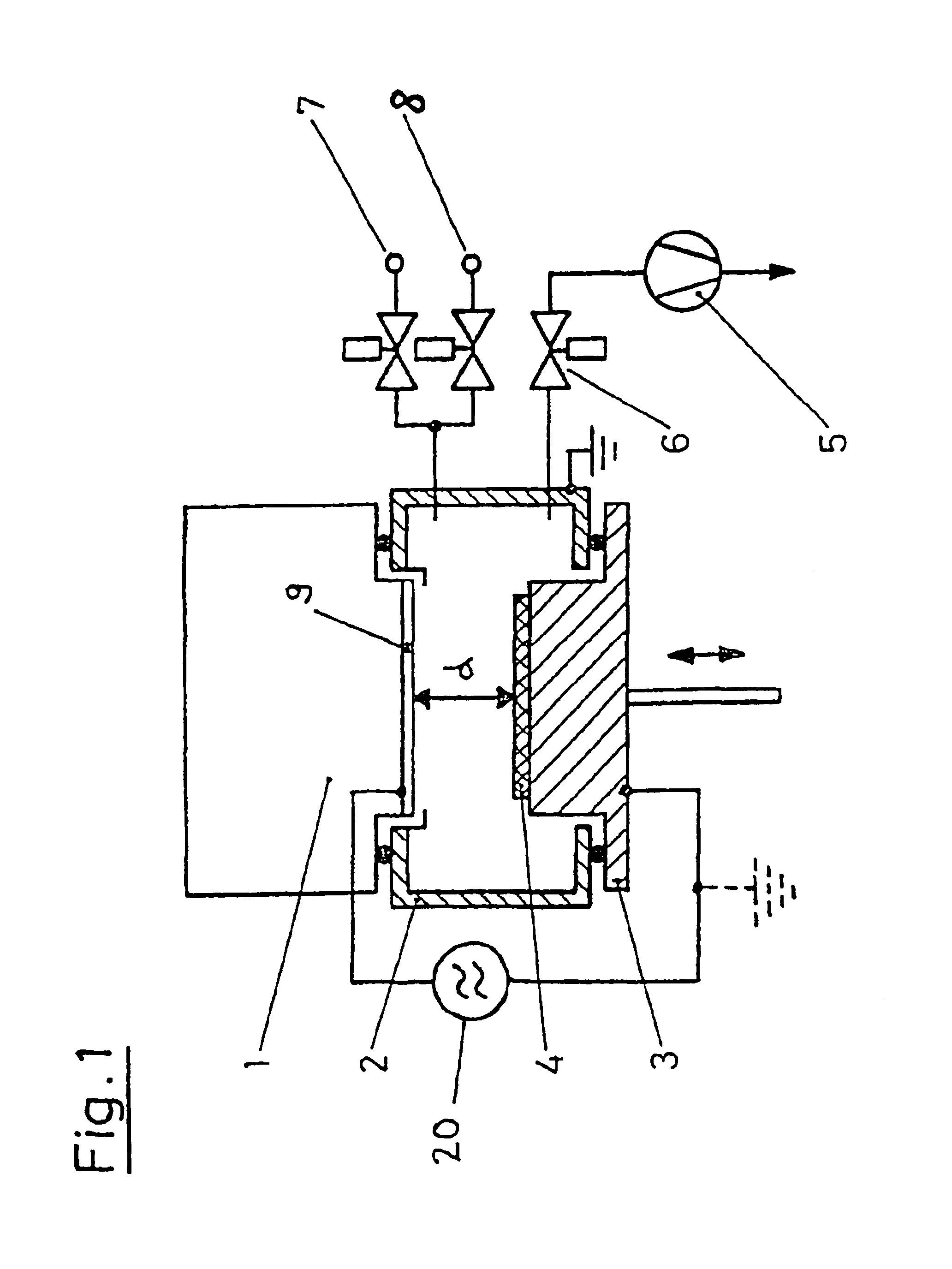

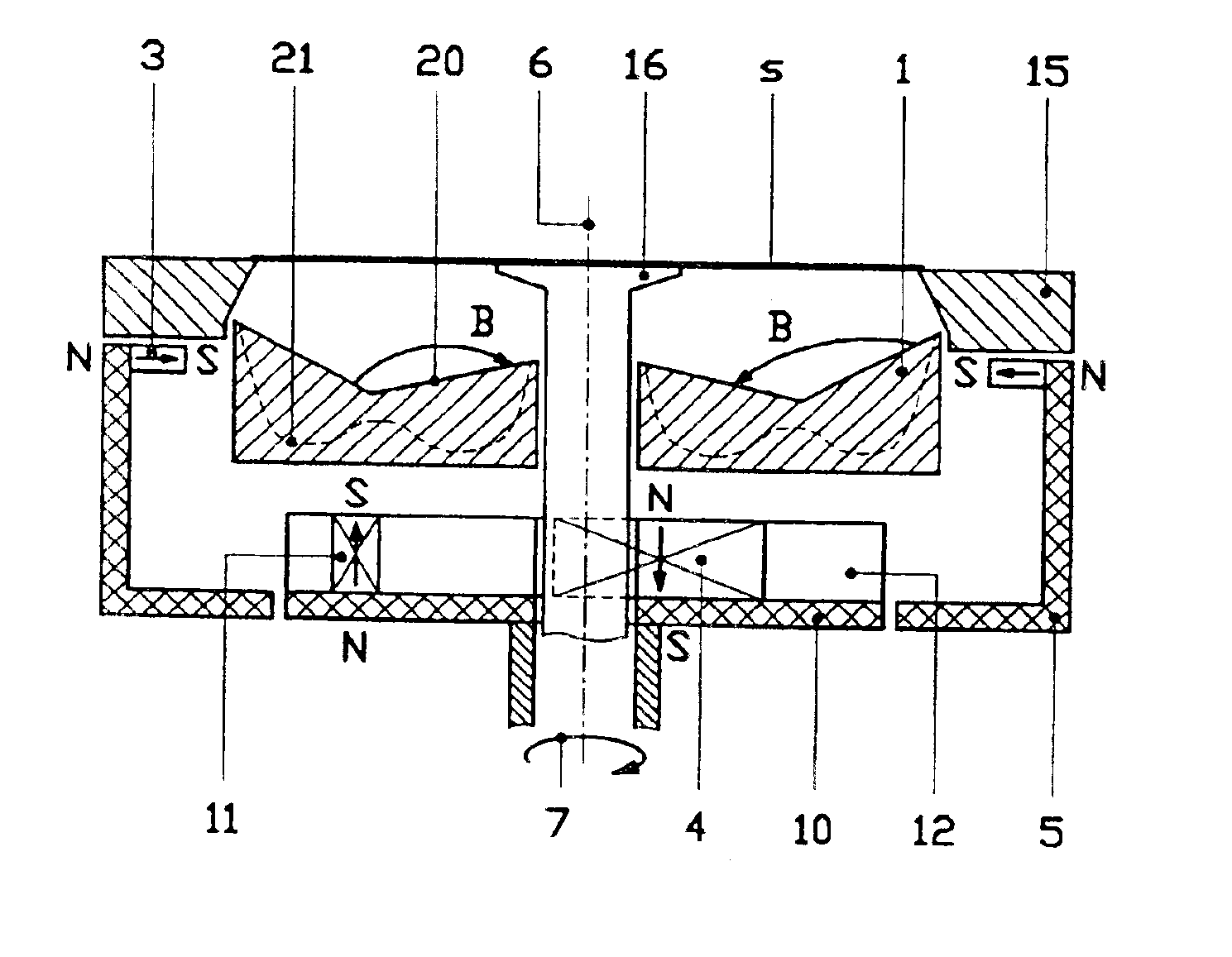

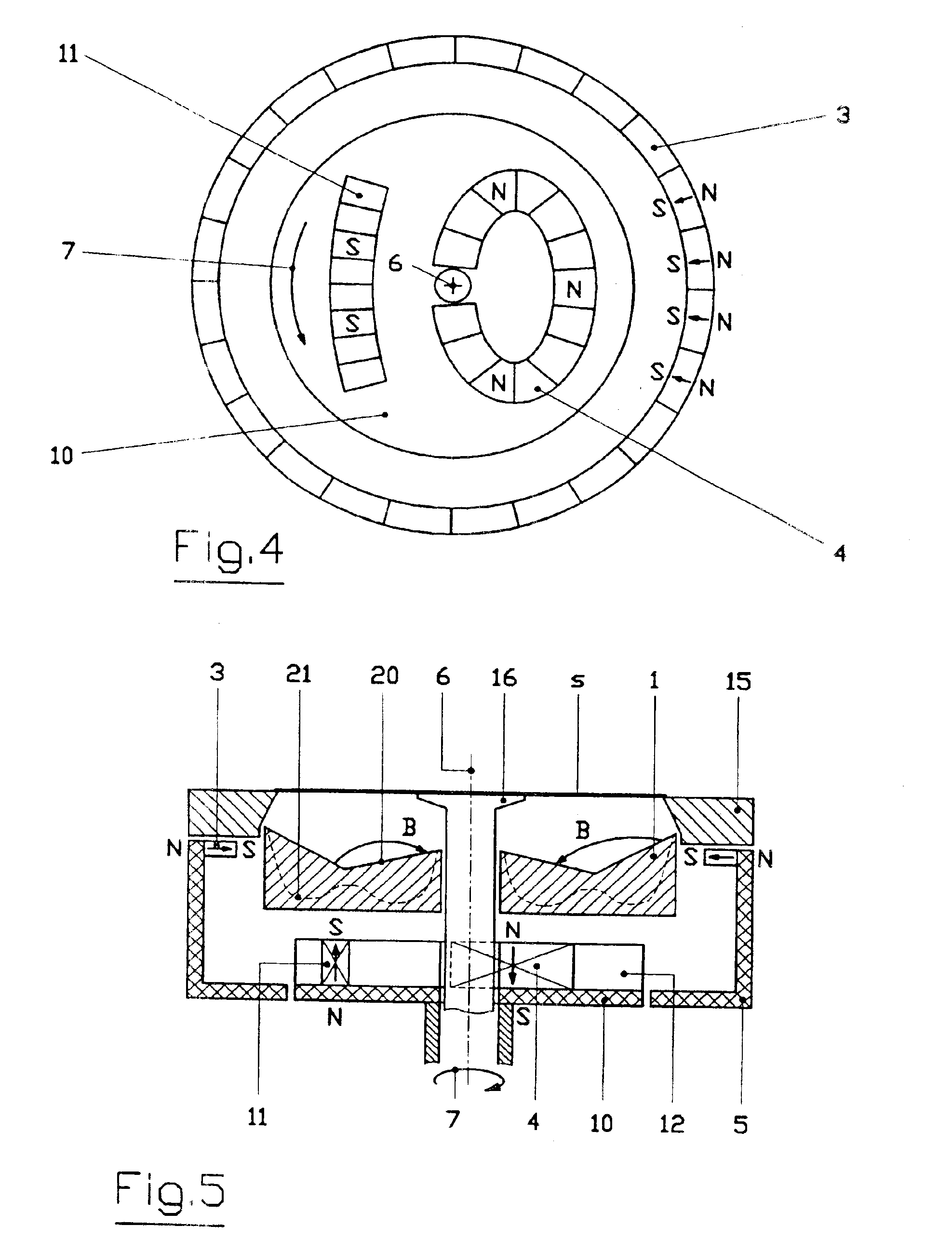

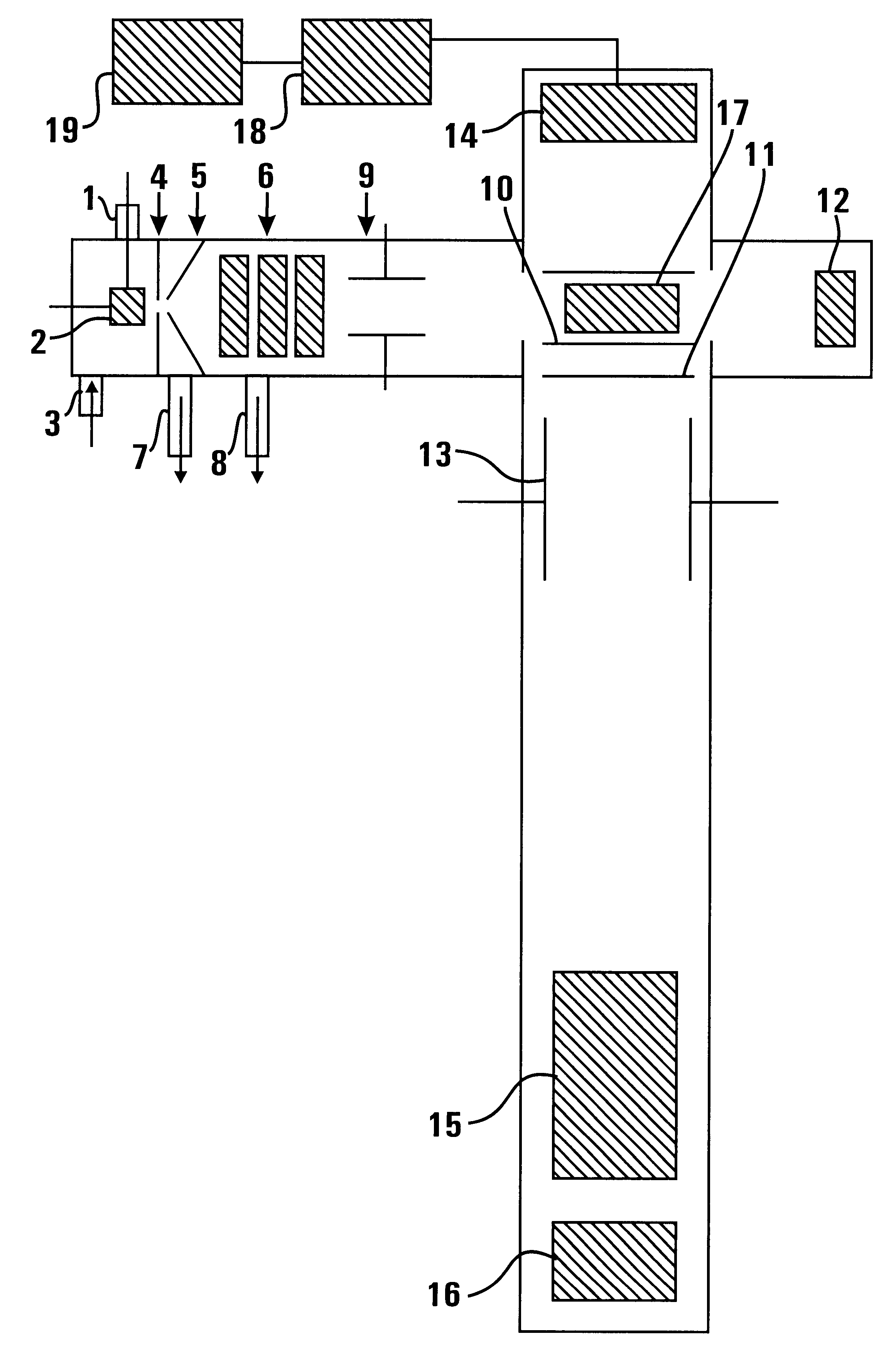

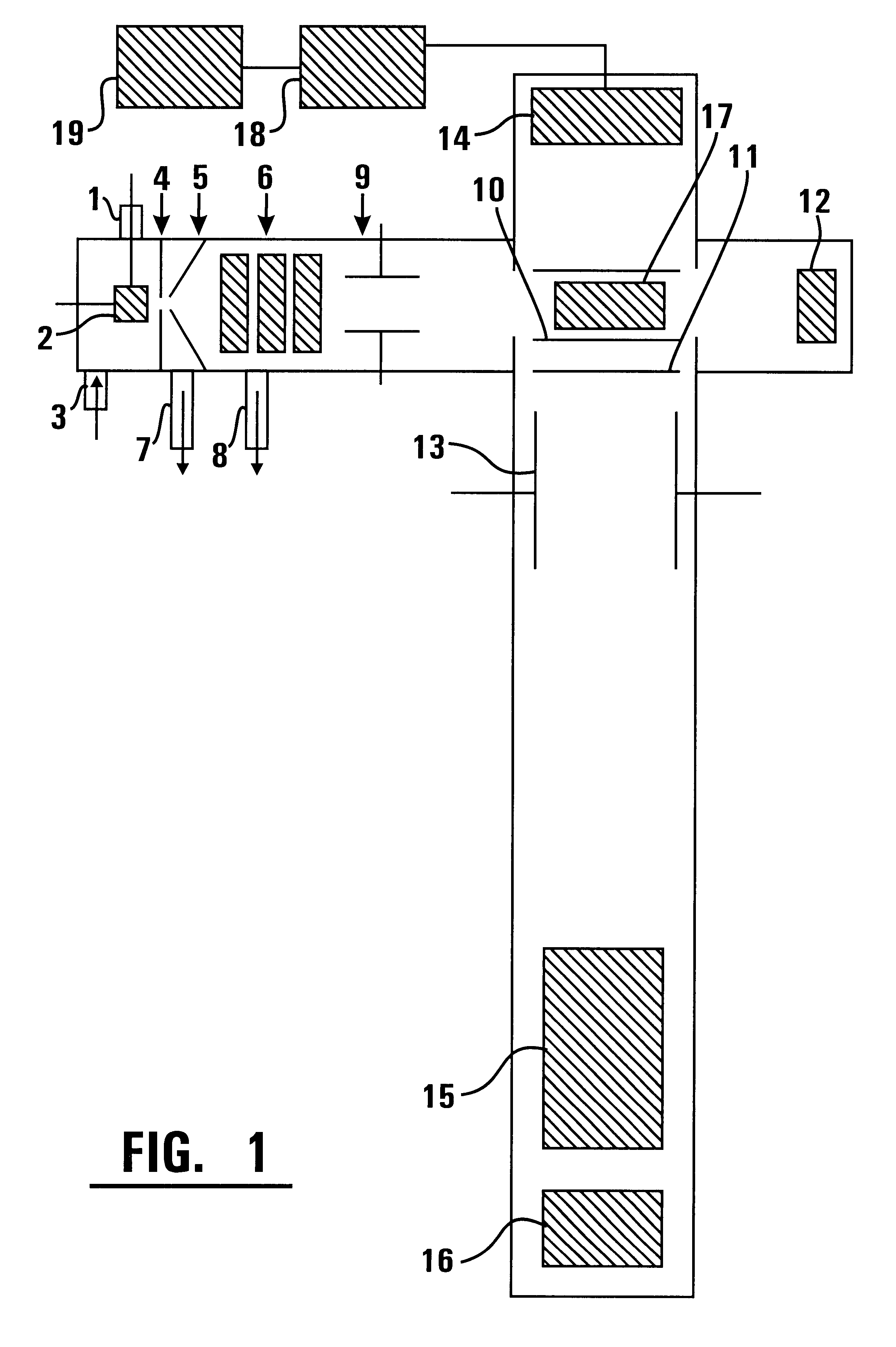

Method for manufacturing a workpiece using a magnetron sputter source

InactiveUS6860977B2Good achievable distribution valueIncrease sputtering rateCellsElectric discharge tubesSmall targetElectron

A workpiece is manufactured using a magnetron source that has an optimized yield of sputtered-off material as well as service life of the target. Good distribution values of the layer on the workpiece are obtained that are stable over the entire target service life, and a concave sputter face in a configuration with small target-to-workpiece distance is combined with a magnet system to form the magnetron electron trap in which the outer pole of the magnetron electron trap is stationary and an eccentrically disposed inner pole with a second outer pole part is rotatable about the central source axis.

Owner:OERLIKON ADVANCED TECH +1

Method of producing a titanium-suboxide-based coating material, correspondingly produced coating material and sputter target provided there-with

InactiveUS20060005745A1Improve conductivityConductivity is not affectedPigmenting treatmentMolten spray coatingTitaniumSuboxide

A method of producing a titanium-suboxide-based coating material comprises the following steps: providing a titanium-suboxide base material; and treating the titanium-suboxide base material under oxidizing conditions for in-situ development of a finely dispersed titanium-dioxide component in the ceramic titanium-suboxide base material.

Owner:GFE METALLE & MATERIALIEN GMBH

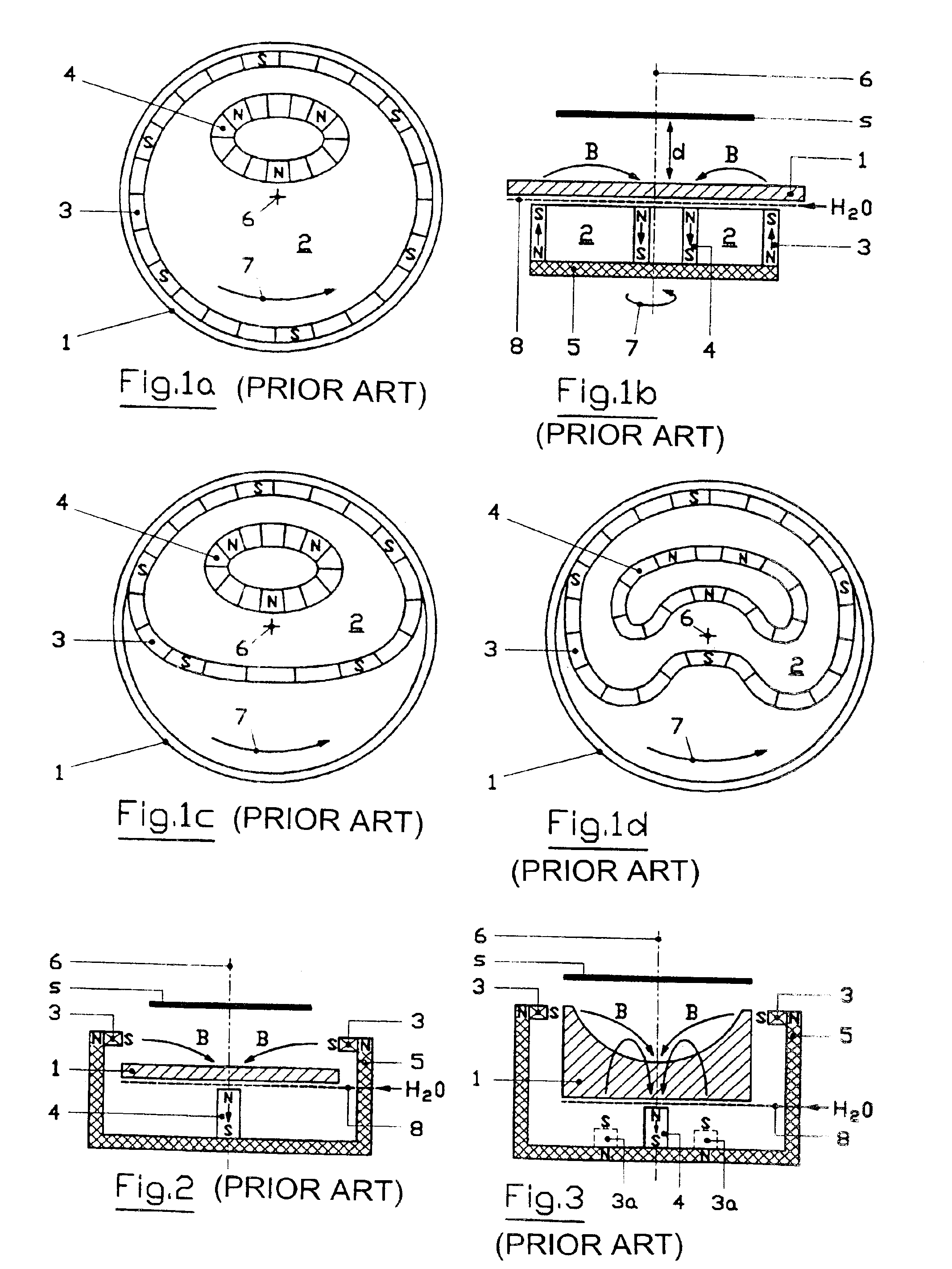

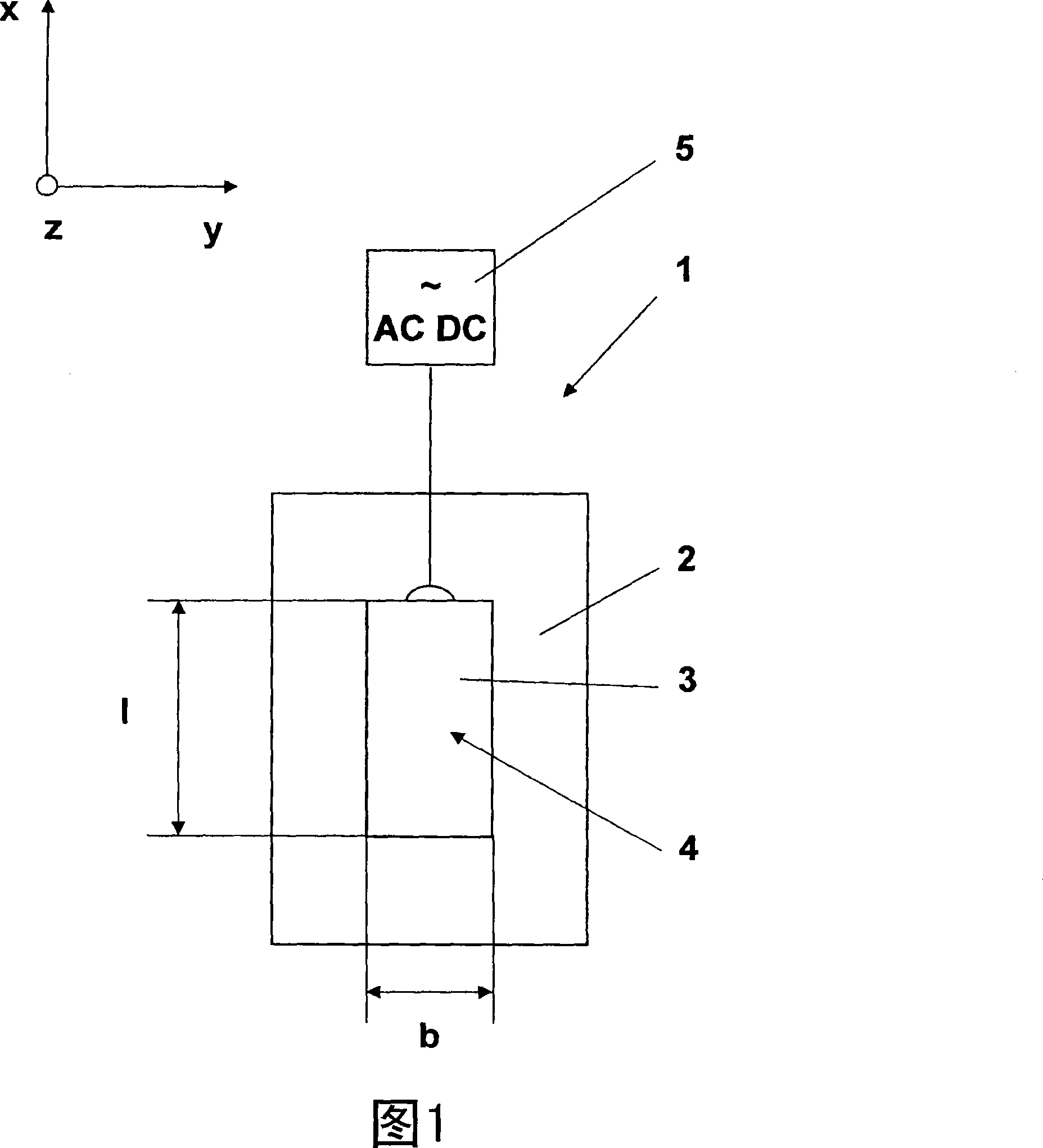

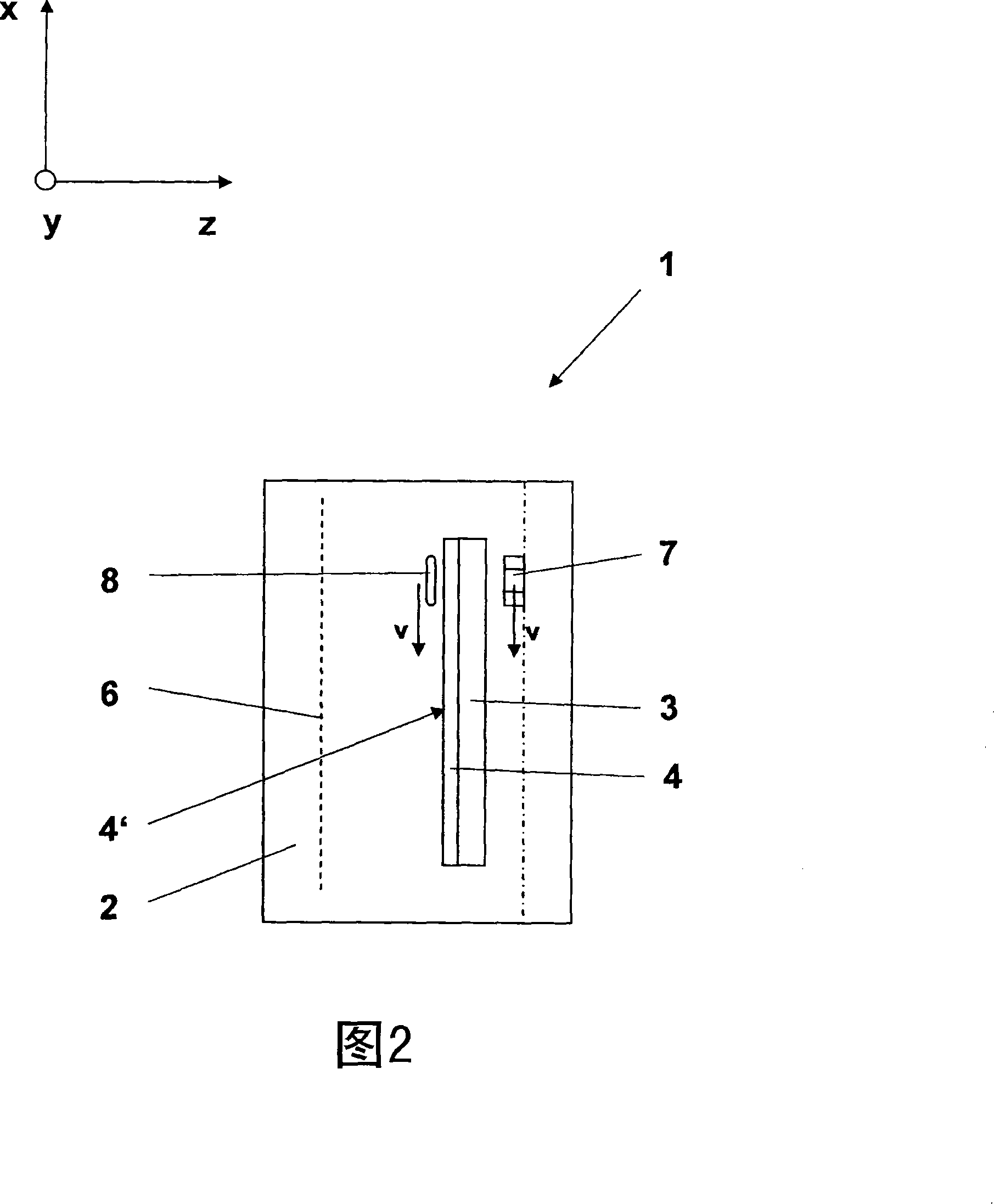

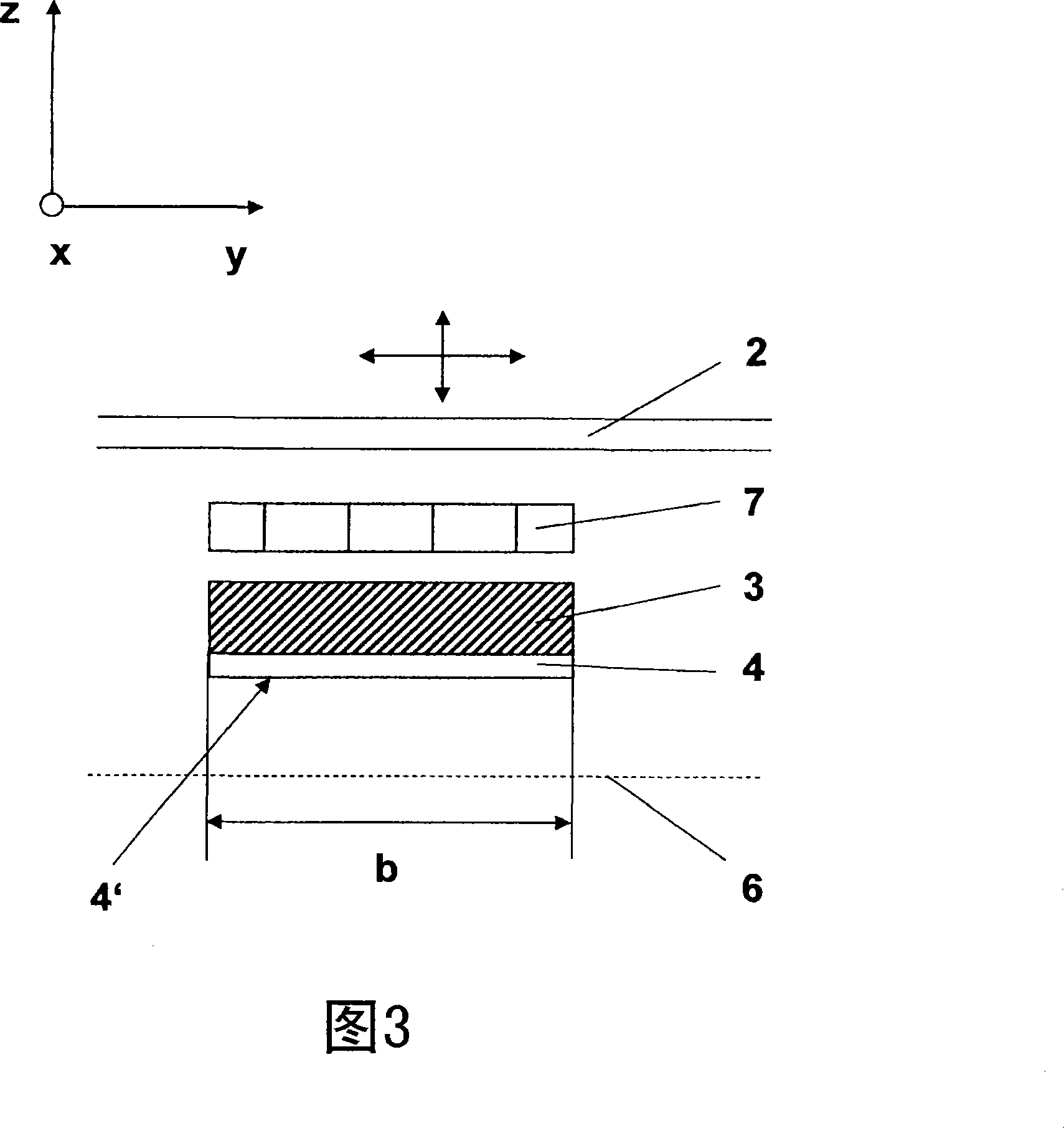

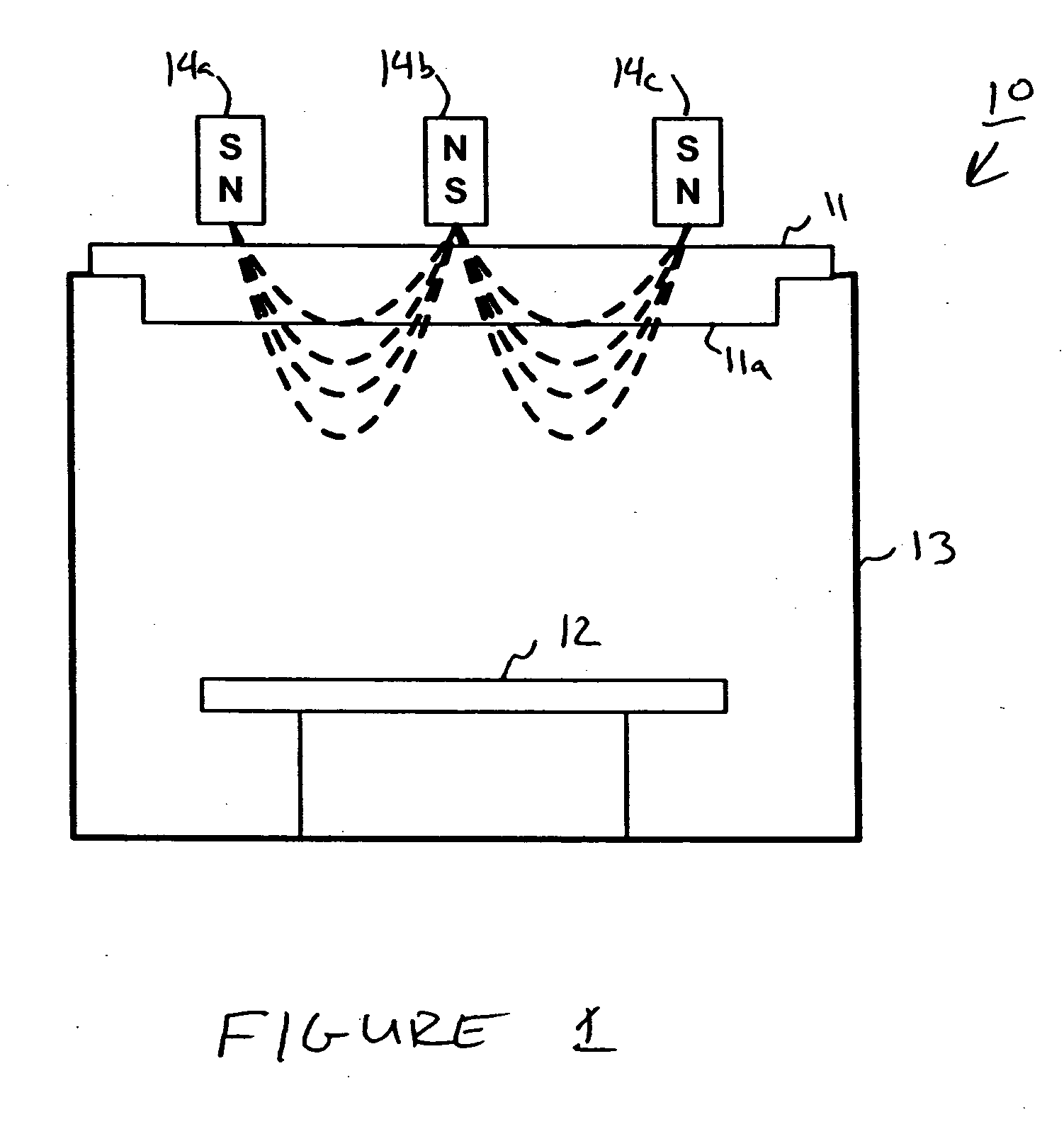

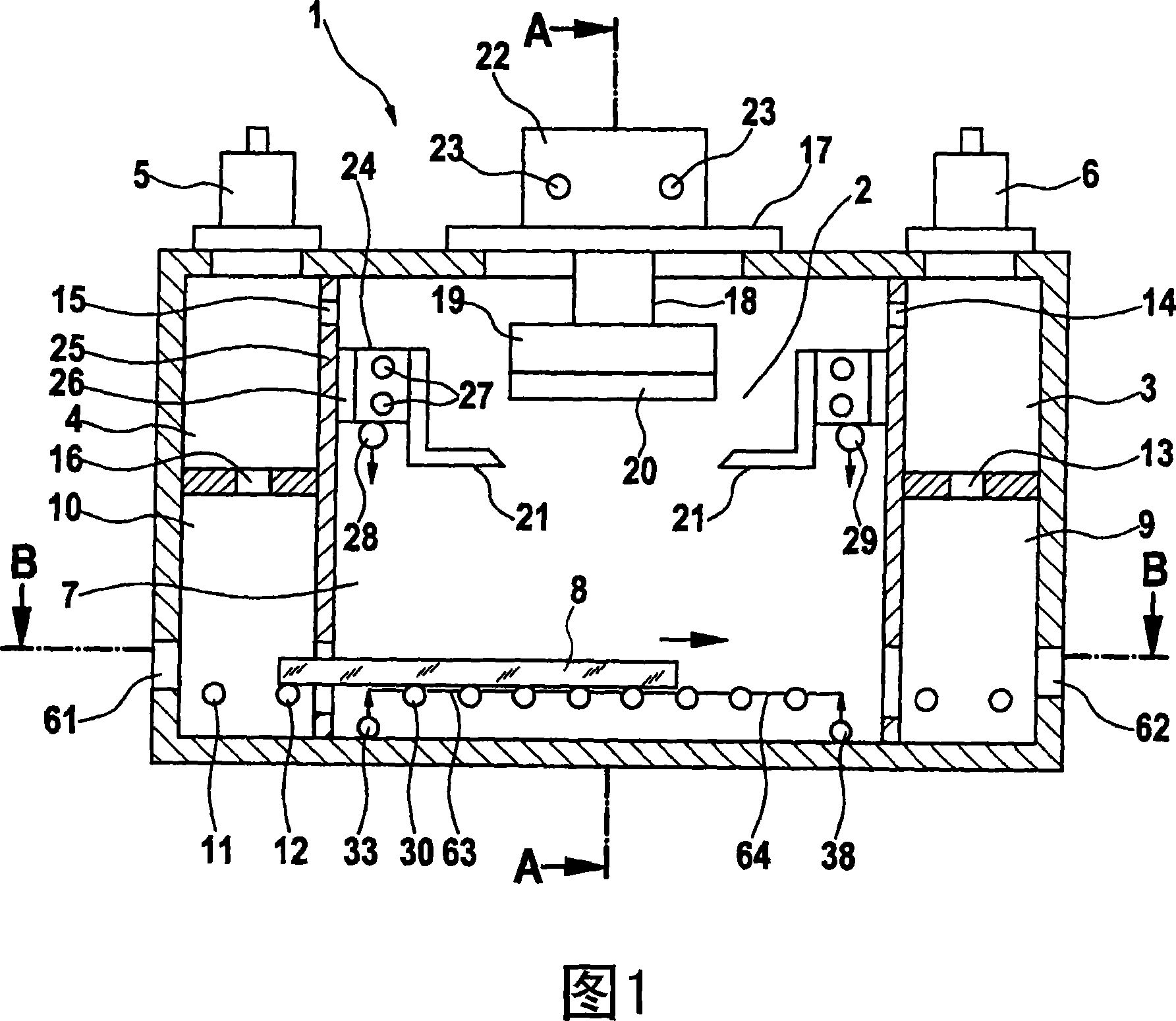

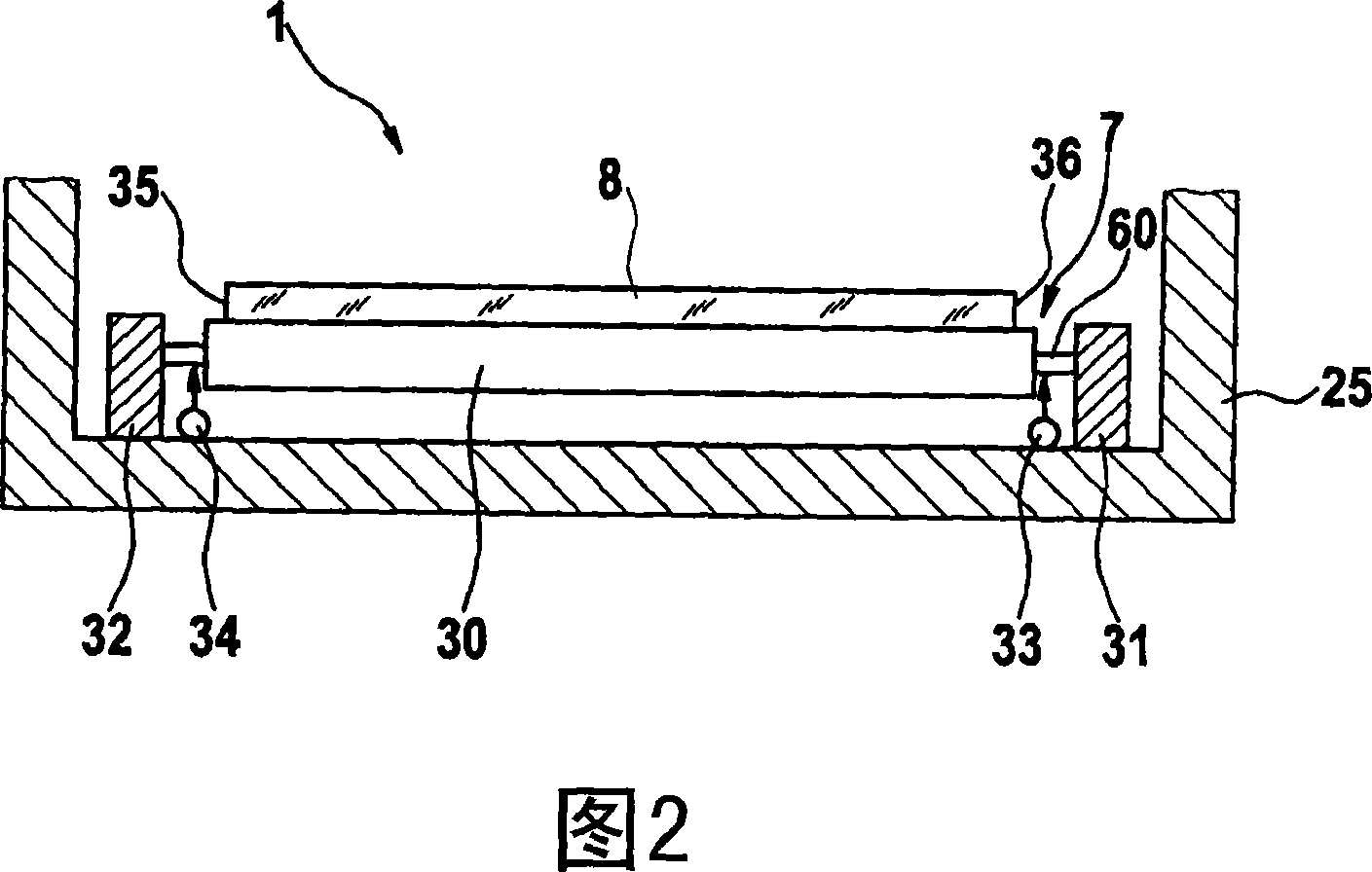

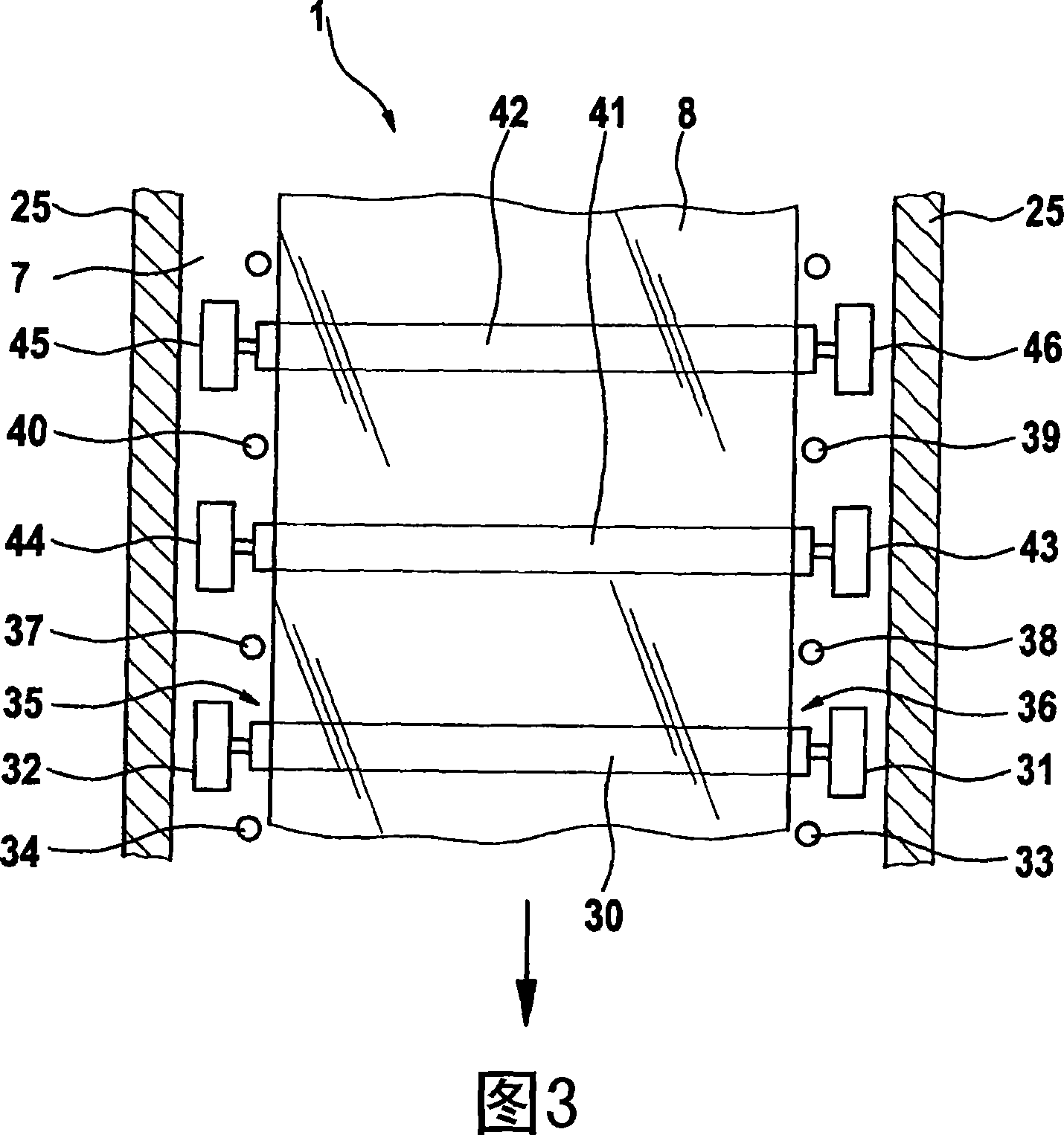

Magnetron sputtering source, sputter coating system and method for coating a substrate

InactiveCN101182631AIncrease sputtering rateLow costElectric discharge tubesVacuum evaporation coatingTarget surfaceCoating system

The magnetron sputtering source for a coating unit (1), comprises a cathode (3), a target (4) assigned to the cathode or integrated into the cathode, means for producing a coating plasma, and a magnet arrangement (7) for producing a magnetic field for the influence of the coating plasma in such a way that a plasma channel (8) is produced over a part of the surface of the target, which provides coating- and / or treatment material. The magnet arrangement and the surface of the target are movably arranged relatively to each other by a drive. which is formed for the reduction of the thermal load of the target surface and an exposure time of the plasma on the surface area.

Owner:APPLIED MATERIALS INC

Method for detecting elements in solutions and device for realizing the same

InactiveUS6518567B1Increase rangeReduce detectionTime-of-flight spectrometersMaterial analysis by electric/magnetic meansMass analyzerTime of flight

The present invention pertains to the construction of analytical instruments and may be used for analysing naturel or industrial waters, biological samples as well as geological samples. The method for detecting elements in solutions comprises pulverising the samples using pulses, ionising the pulverised atoms during Penning's collisions and recording the ions thus formed during a mass spectral analysis while carrying out a separation of the ion time-of-flight. The pulse pulverisation of the sample is carried out from a surface which is heated at a temperature of between 1000 and 1500% C. and on which the sample dried in a flow of ballast gas forms a dry residue. The ballast gas may consist of Kr, Xe or mixtures thereof wich Ar under a pressure of between 1 and 2 torrs. The device for detecting elements in solutions comprises an ionising device which is arranged in a gas-discharge chamber filled with an inert gas. The detection device further includes a time-of-flight mass spectrometer which comprises an ion sampling and focusing system as well as a reflective mass in the shape of a spectral analyser. The ionising device is made in the shape of a thin-wall, metallic, cylindrical and hollow cathode that comprises a dosing opening which is used for introducing the sample to be analysed and which is located on a same axis with a vacuum port.

Owner:GANEEV ALEXANDR AKHATOVICH +1

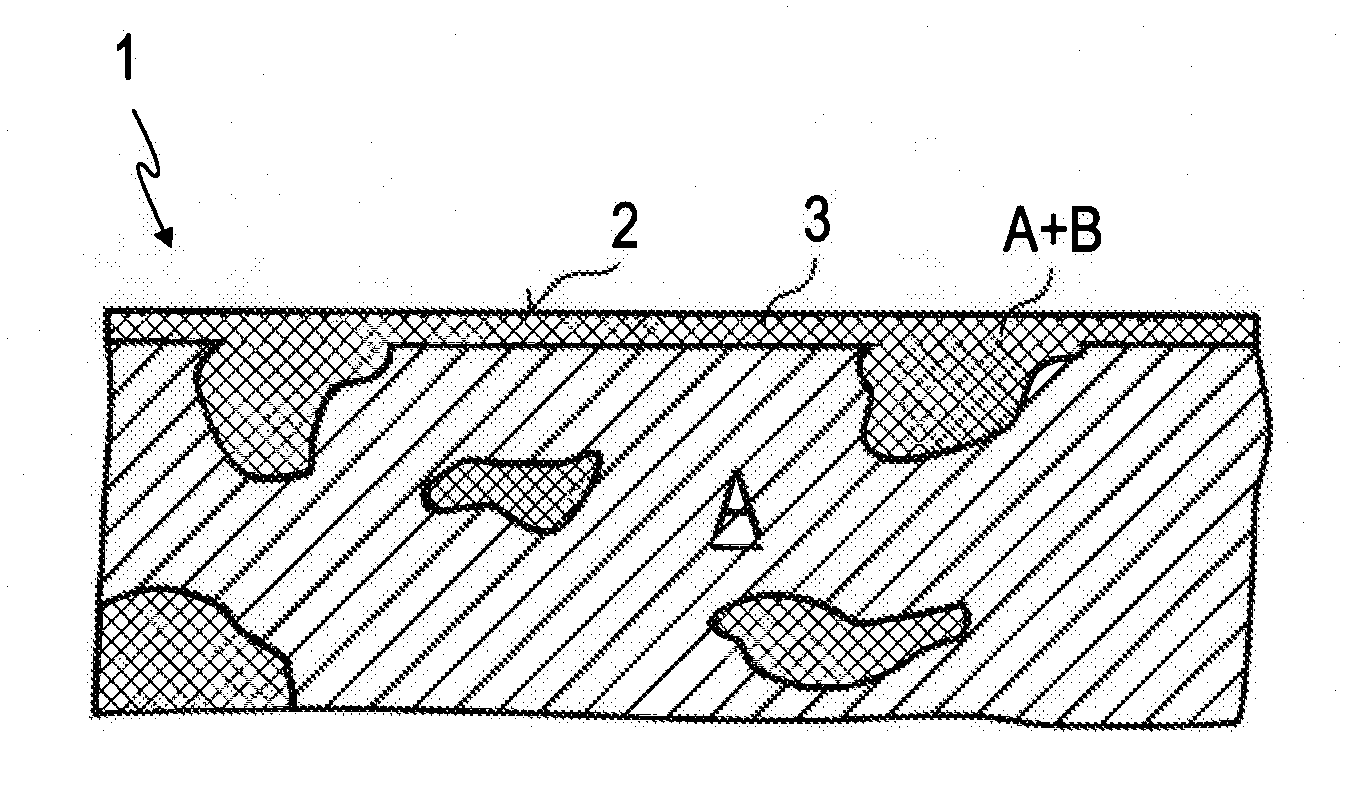

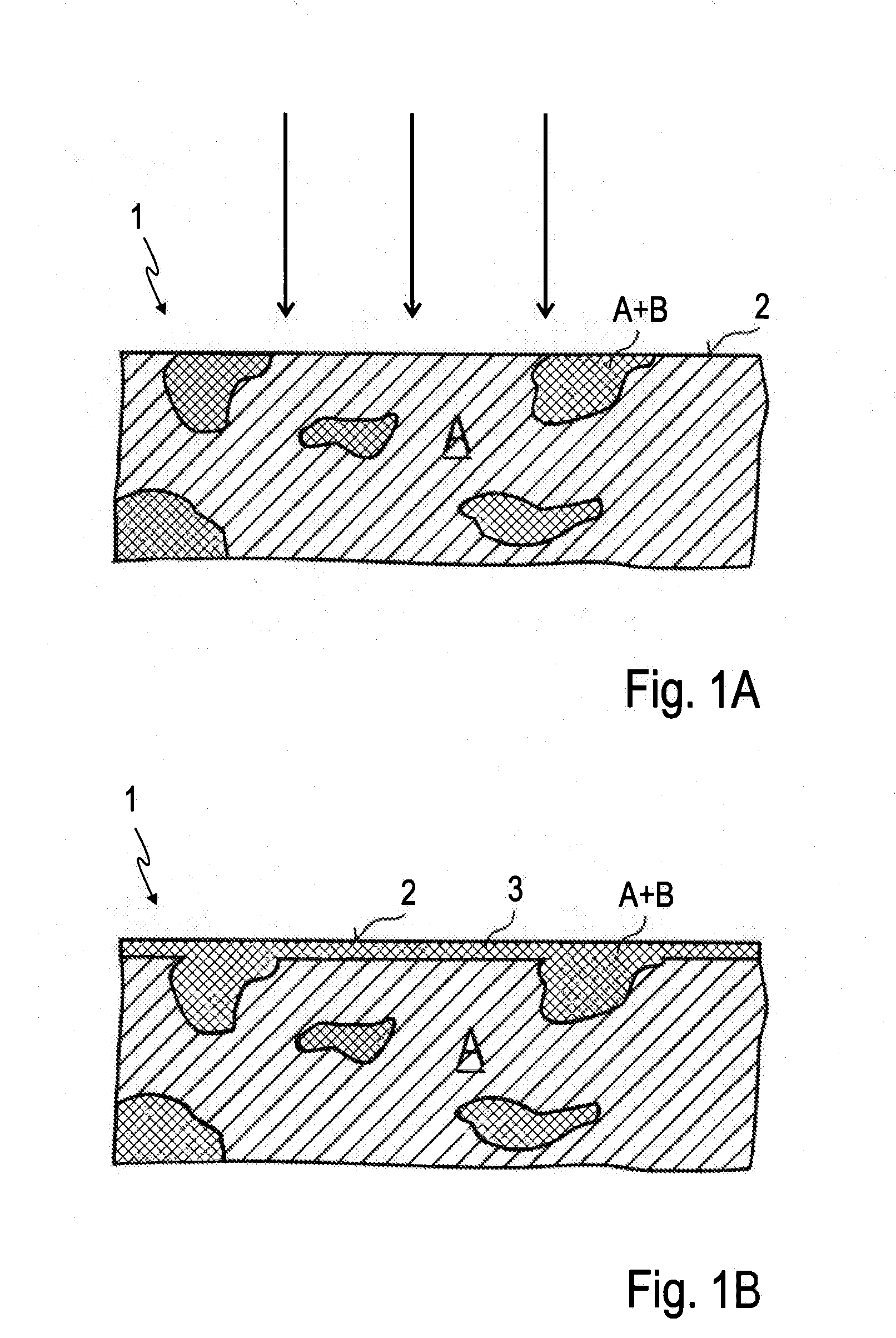

Sputtering process

InactiveUS20130319848A1Increase sputtering rateIncrease stop powerElectric discharge tubesVacuum evaporation coatingHigh-power impulse magnetron sputteringMaterials science

In a process for coating a substrate, the substrate is arranged opposite a removal surface of a target and the coating material is atomized by sputtering under an inert or reactive-gas-containing process gas and deposited on the substrate. The coating takes place from a mixed target with at least one target component A and a target component B. At the beginning of the sputtering process, the distribution of the target components A and B in a superficial target layer of the removal surface is modified by high-power impulse magnetron sputtering.

Owner:VON ARDENNE ANLAGENTECHNIK GMBH

Tantalum sputtering target and method for producing same

ActiveUS20150279637A1Promote generationIncrease plasma stabilityCellsNitrogen compoundsSputteringCrystal orientation

A tantalum sputtering target, wherein, on a sputtering surface of the tantalum sputtering target, an orientation rate of a (200) plane exceeds 70%, an orientation rate of a (222) plane is 30% or less. By controlling the crystal orientation of the target, effects are yielded in that the discharge voltage of the tantalum sputtering target can be reduced so that plasma can be more easily generated, and the voltage drift during deposition can be suppressed.

Owner:JX NIPPON MINING& METALS CORP

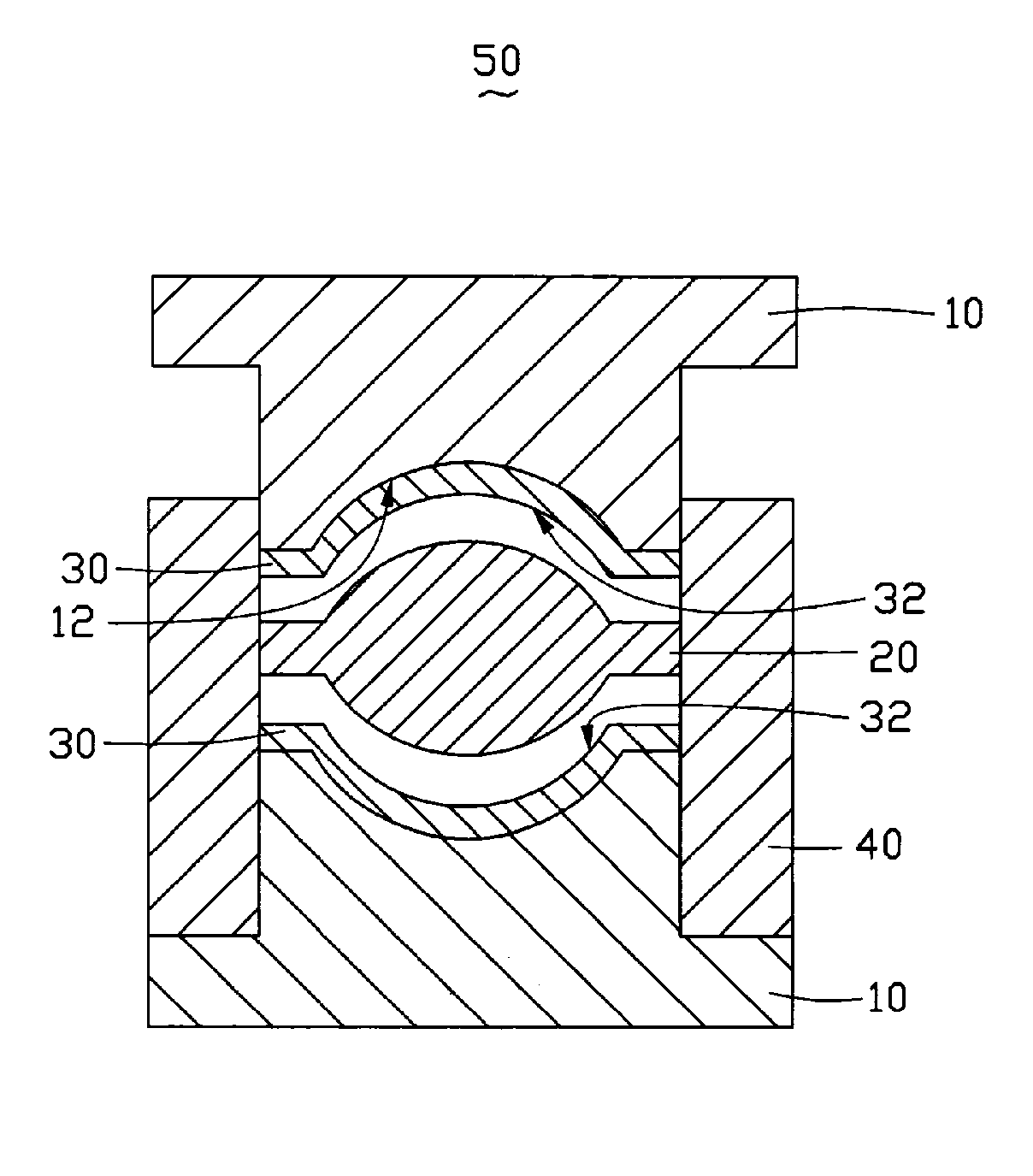

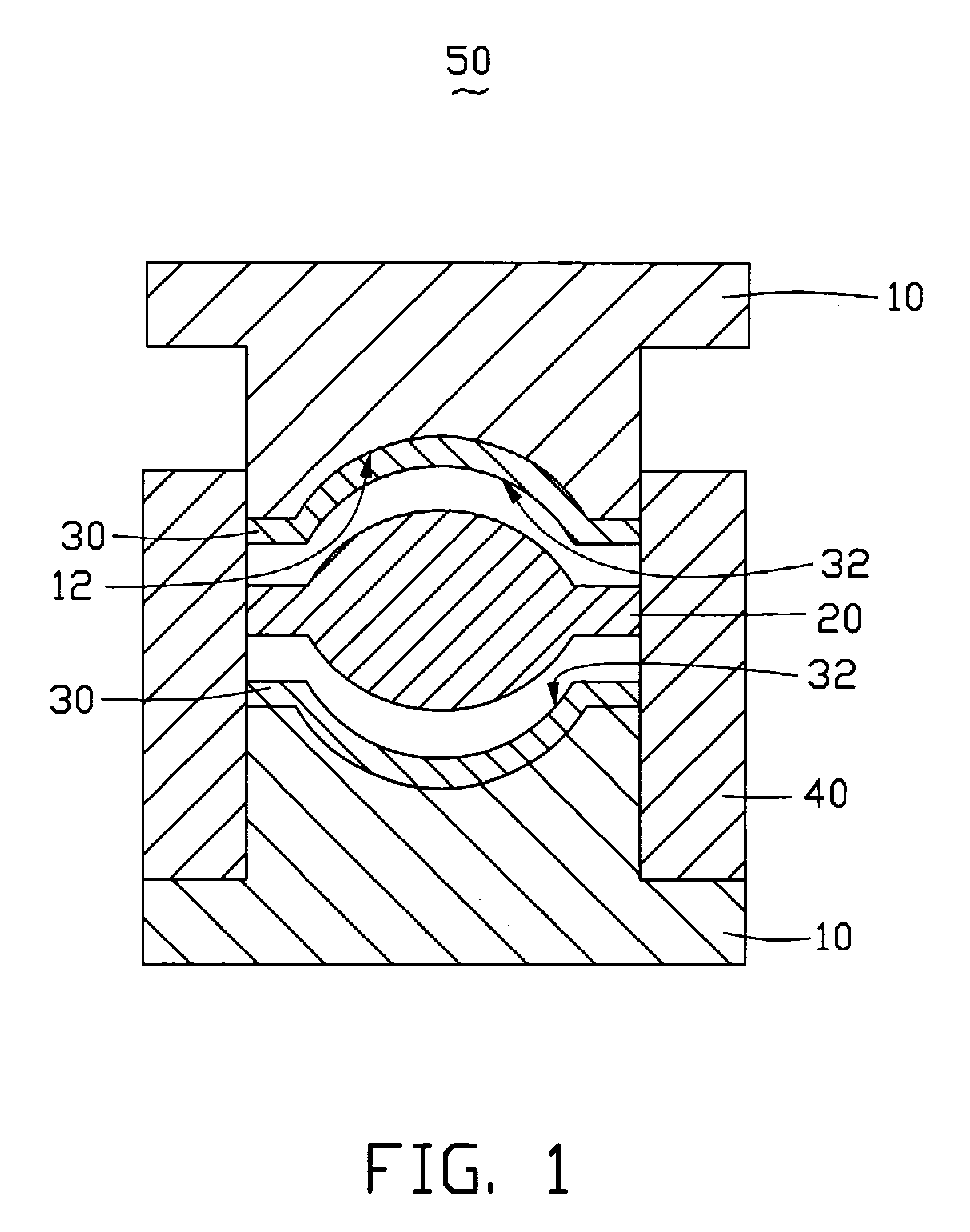

Enhanced magnetron sputtering target

InactiveUS20070007130A1Increase sputtering rateIncrease plasma densityCellsElectric discharge tubesEffective surfaceActive surface

An enhanced sputtering target is provided for use in a magnetron sputtering system. The sputtering target includes an active surface from which target material is sputtered and a back surface opposite the active surface. At least one magnet is embedded in the back surface of the target and is oriented to increase the magnetic field passing through the active surface of the target.

Owner:HERAEUS INC

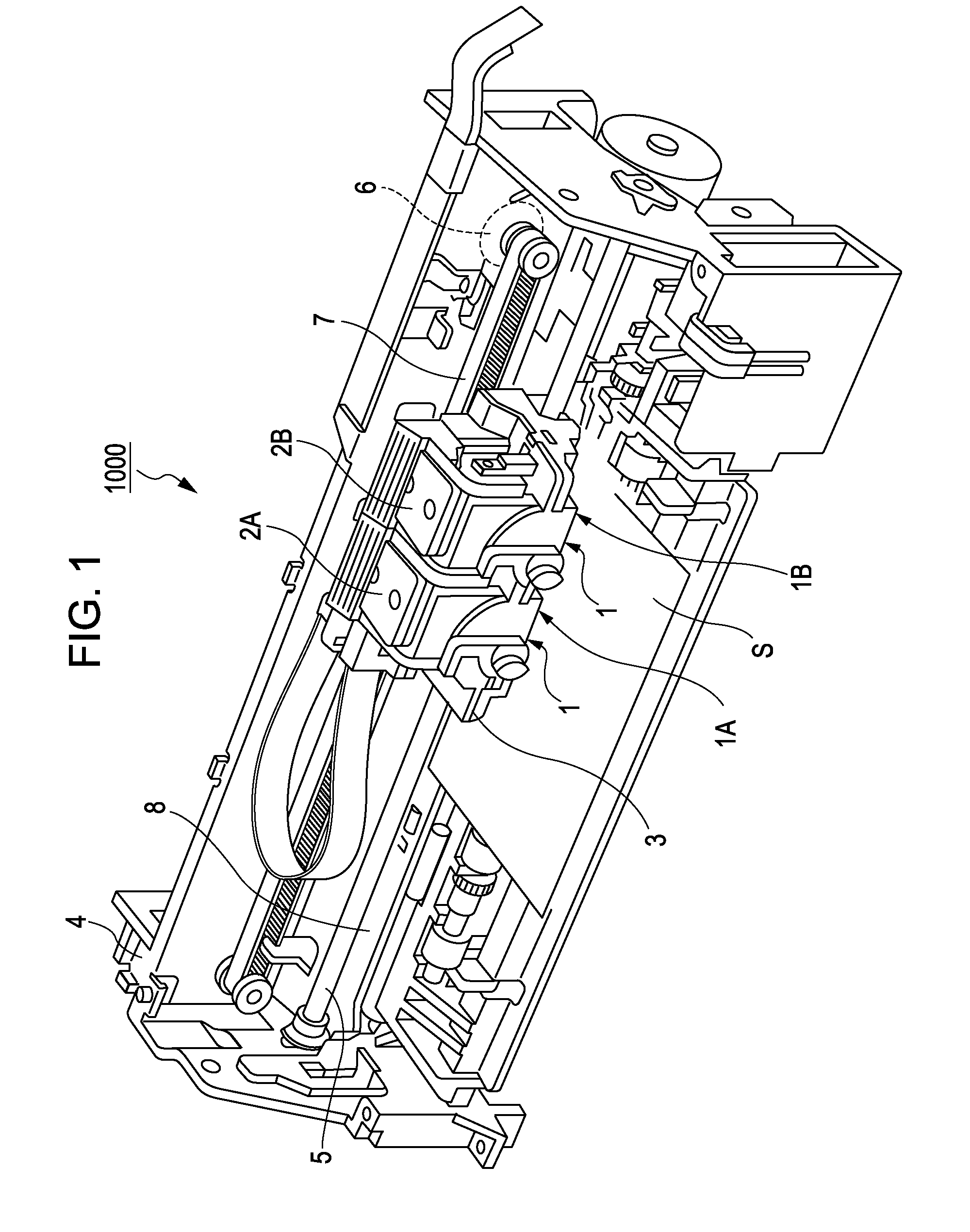

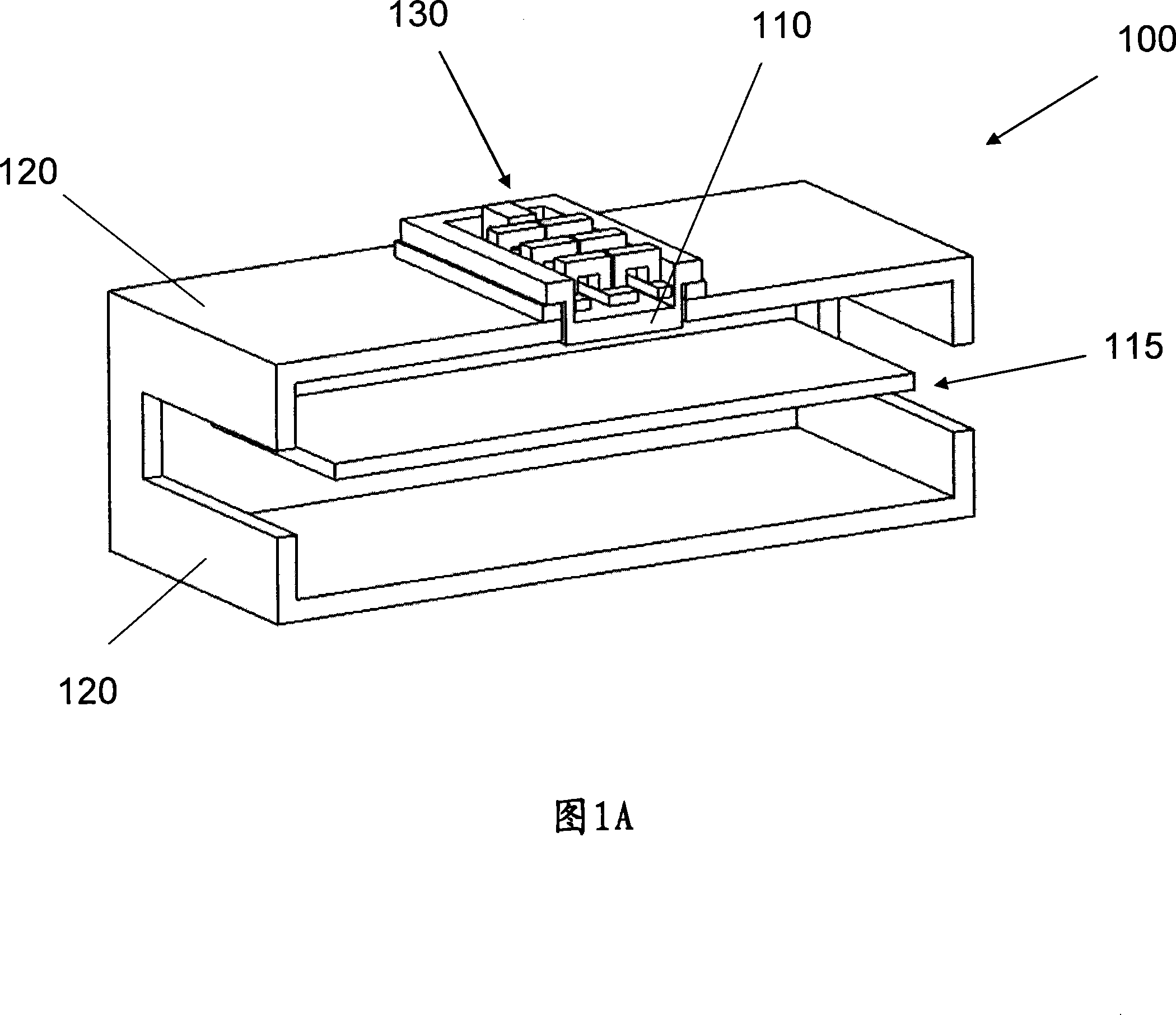

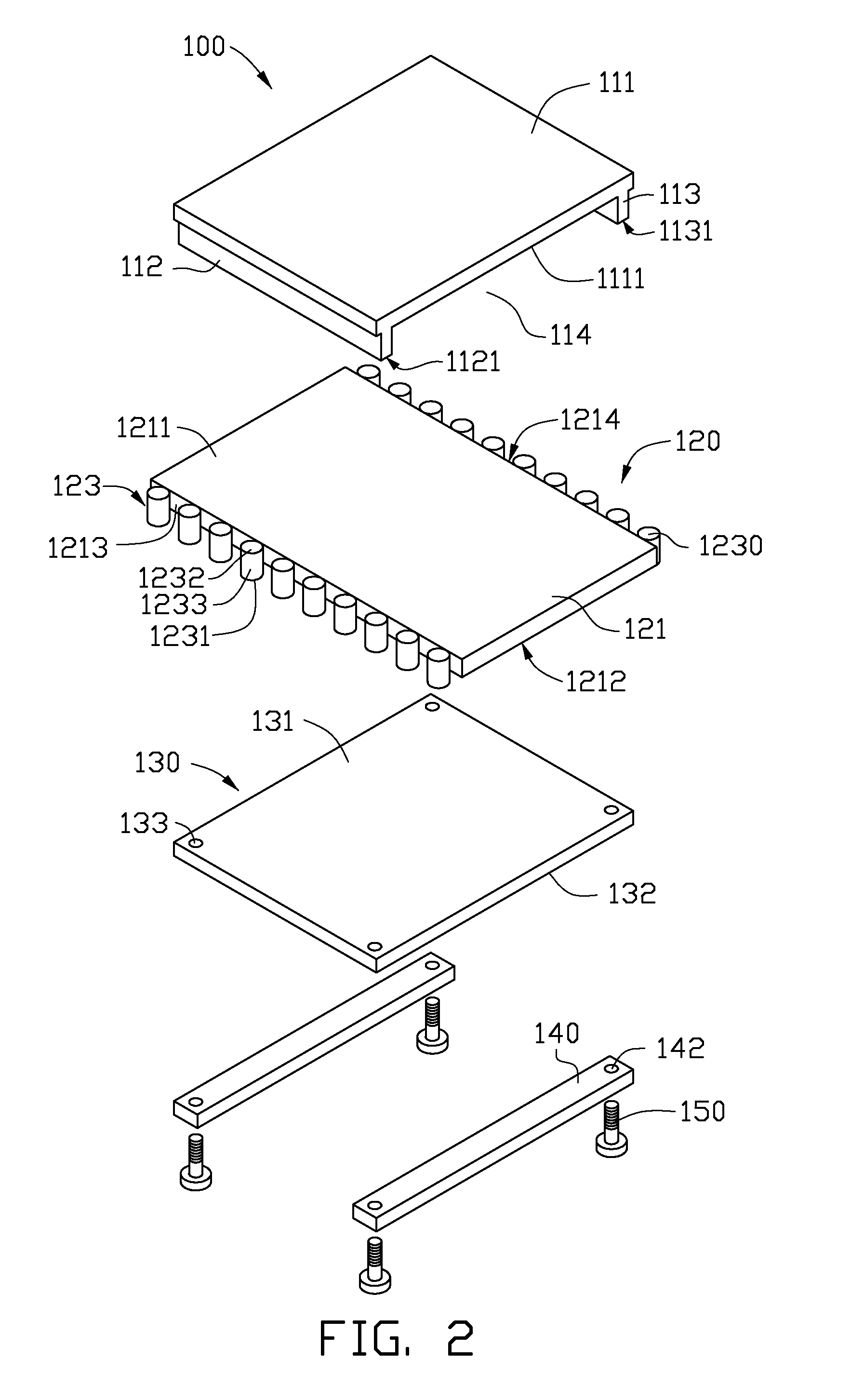

Deposition system and processing system

InactiveCN101187008AReduce system downtimeIncrease profitElectric discharge tubesVacuum evaporation coatingEngineeringMechanical engineering

A deposition system includes a chamber, a plurality of targets in a center region in the chamber and a plurality of substrates in the chamber. The targets are sequentially positioned when viewed in a first direction. At least one of the targets includes a sputtering surface facing outward. The substrates are sequentially positioned when viewed in the first direction. At least one of the substrates includes a deposition surface configured to receive material sputtered off the sputtering surface.

Owner:ASCENTOOL

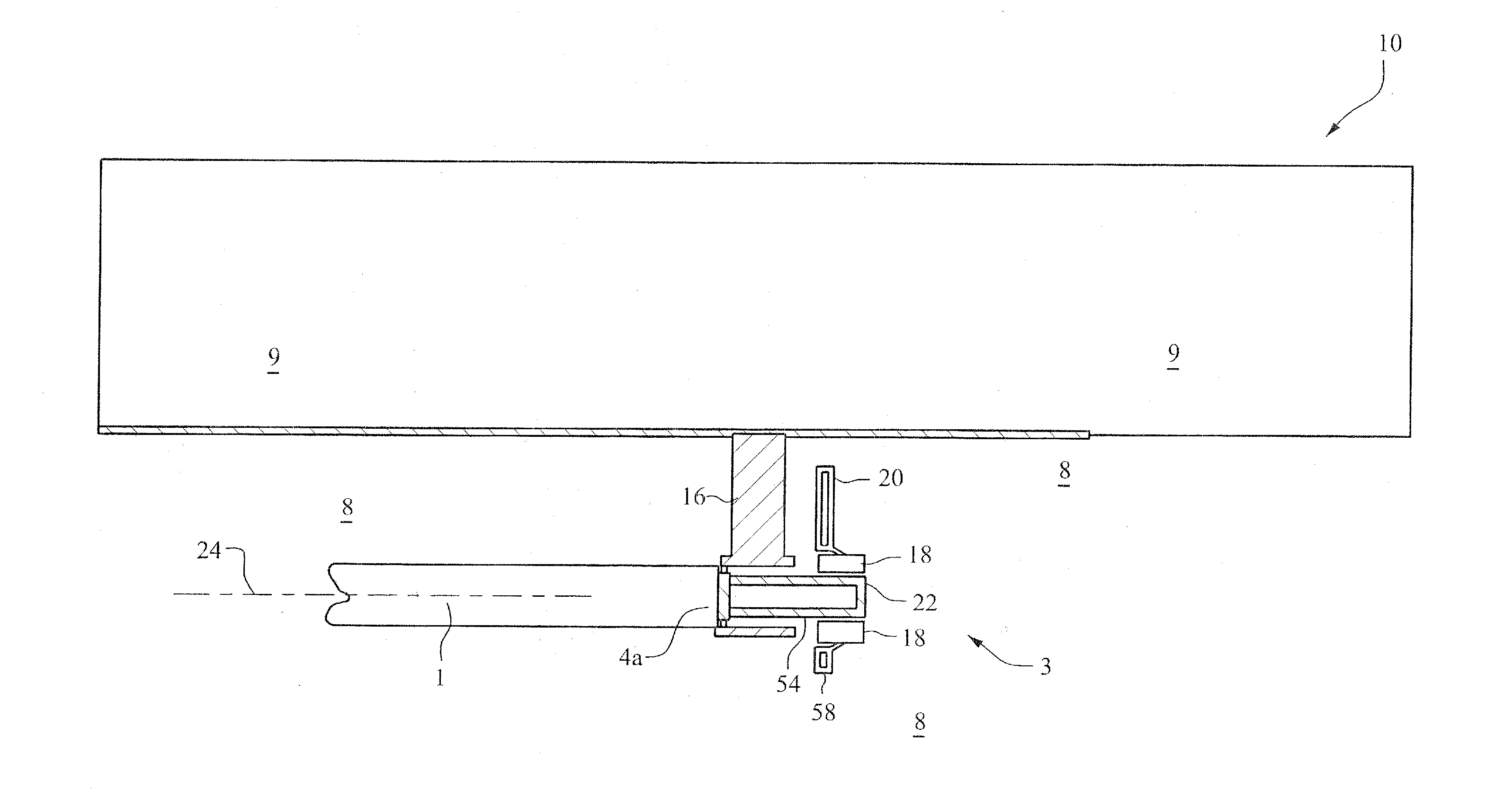

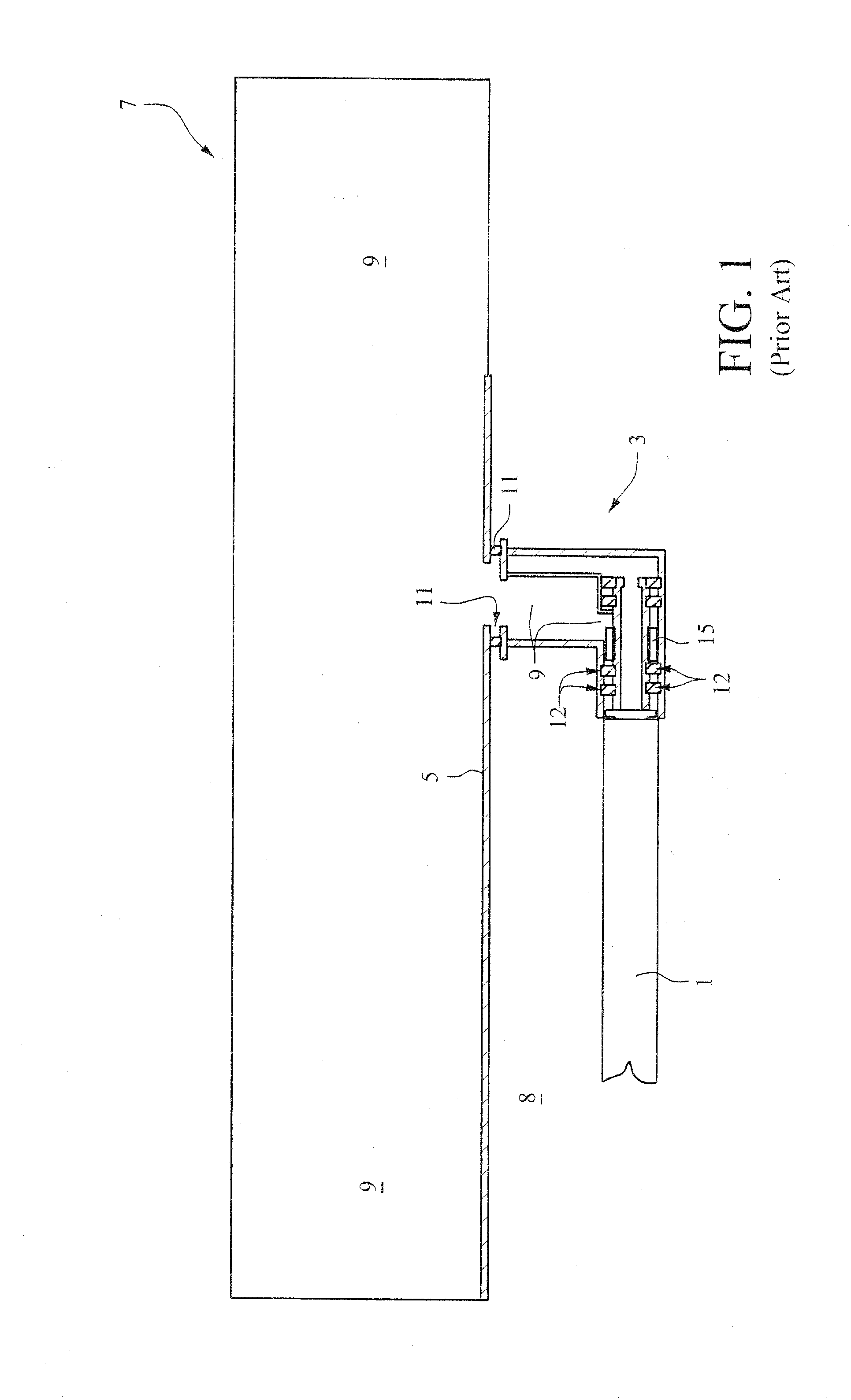

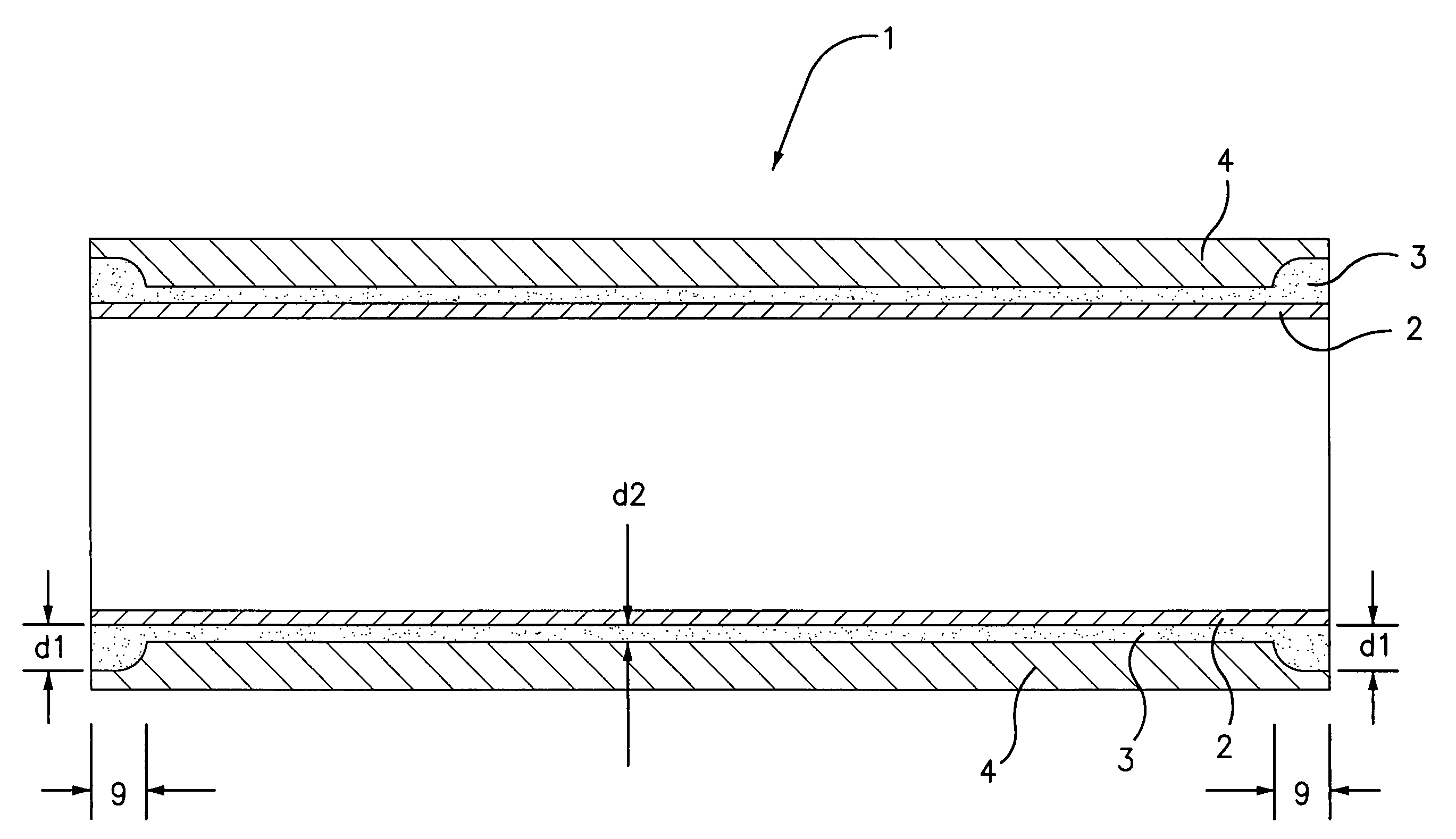

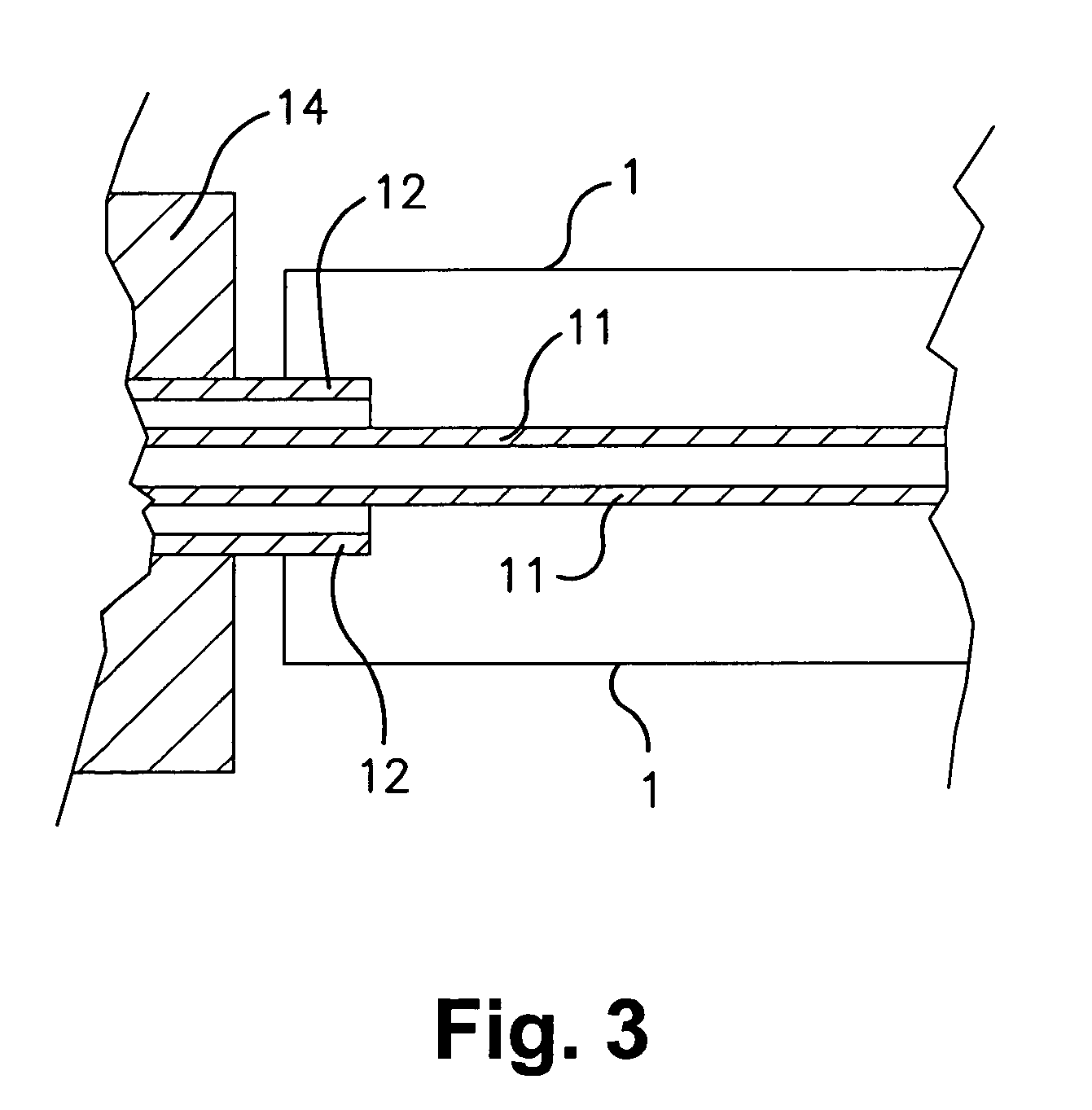

Endblock for rotatable target with electrical connection between collector and rotor at pressure less than atmospheric pressure

ActiveUS20150197847A1Increase sputtering rateImprove cooling effectCellsElectric discharge tubesAtmospheric airElectrical connection

An endblock for a rotatable sputtering target, such as a rotatable magnetron sputtering target, is provided. A sputtering apparatus, including one or more such endblock(s), includes locating the electrical contact(s) (e.g., brush(es)) between the collector and rotor in the endblock(s) in an area under vacuum (as opposed to in an area at atmospheric pressure).

Owner:GUARDIAN GLASS LLC +1

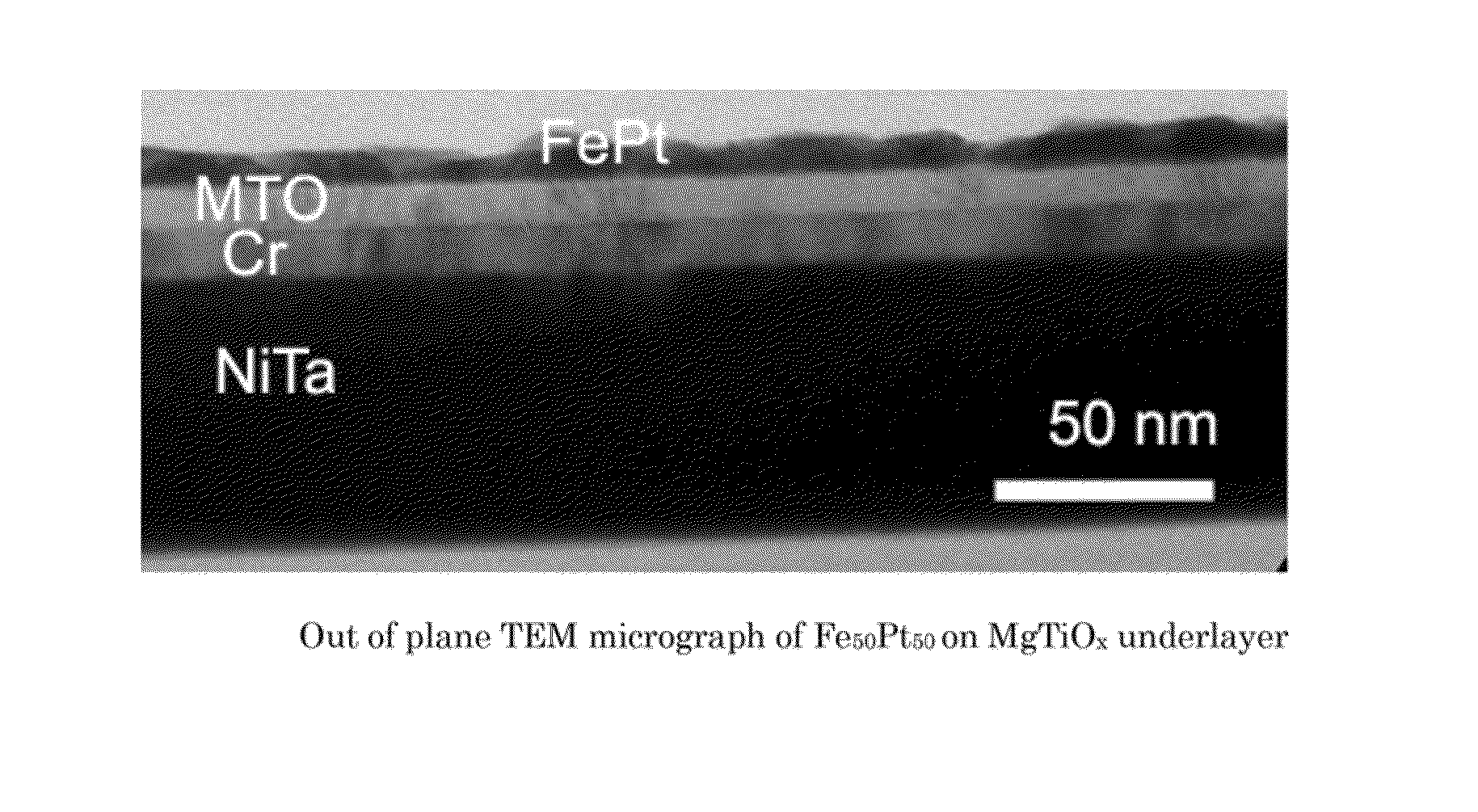

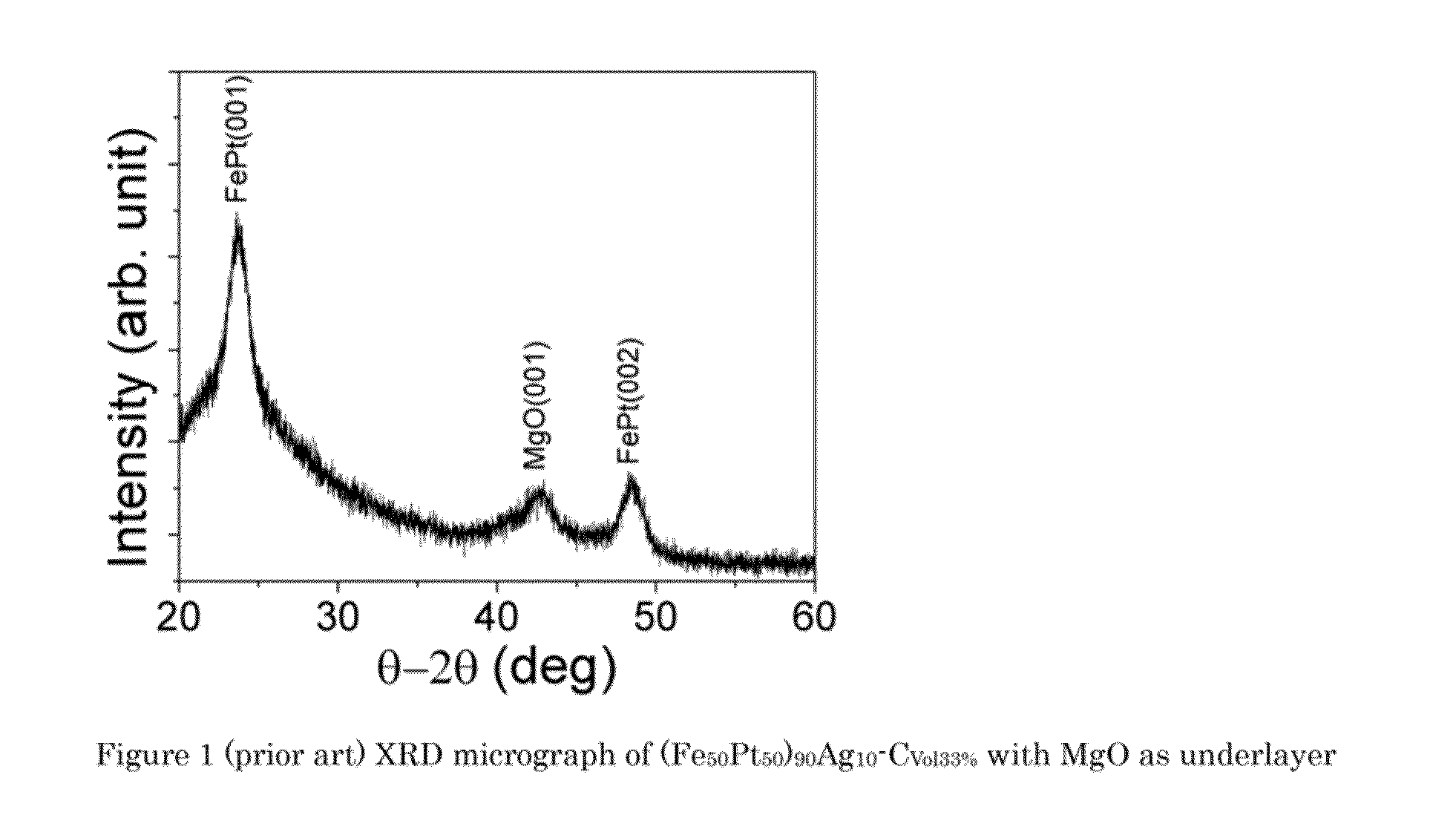

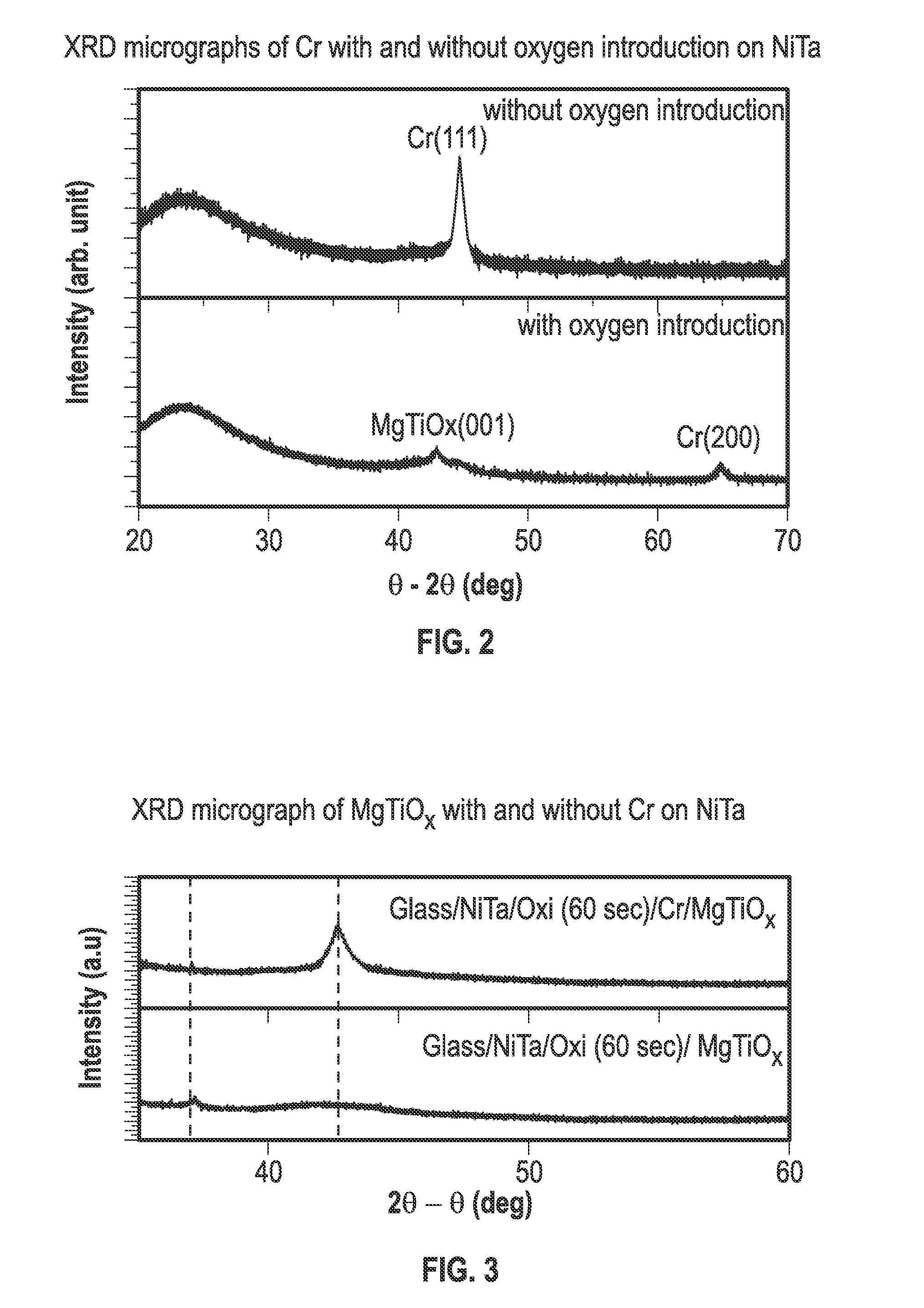

Electrically conductive underlayer to grow FePt granular media with (001) texture on glass substrates

ActiveUS8993134B2High resistivityLow resistivityBase layers for recording layersRecord information storageMagnetic anisotropyGranular media

A perpendicular magnetic recording medium, comprising: a substrate; a buffer layer deposited in a first orientation on top of the substrate; an underlayer deposited in a second orientation on top of the buffer layer, the underlayer comprising an electrically conductive oxide; and a magnetic recording layer deposited on top of the underlayer and having an axis of magnetic anisotropy substantially perpendicular to the surface thereof.

Owner:WESTERN DIGITAL TECH INC +1

Mold for forming optical lens and method for manufacturing such mold

InactiveUS7273204B2Structure moreStrong adhesionAlkali metal silicate coatingsConfectioneryOptoelectronics

Owner:HON HAI PRECISION IND CO LTD

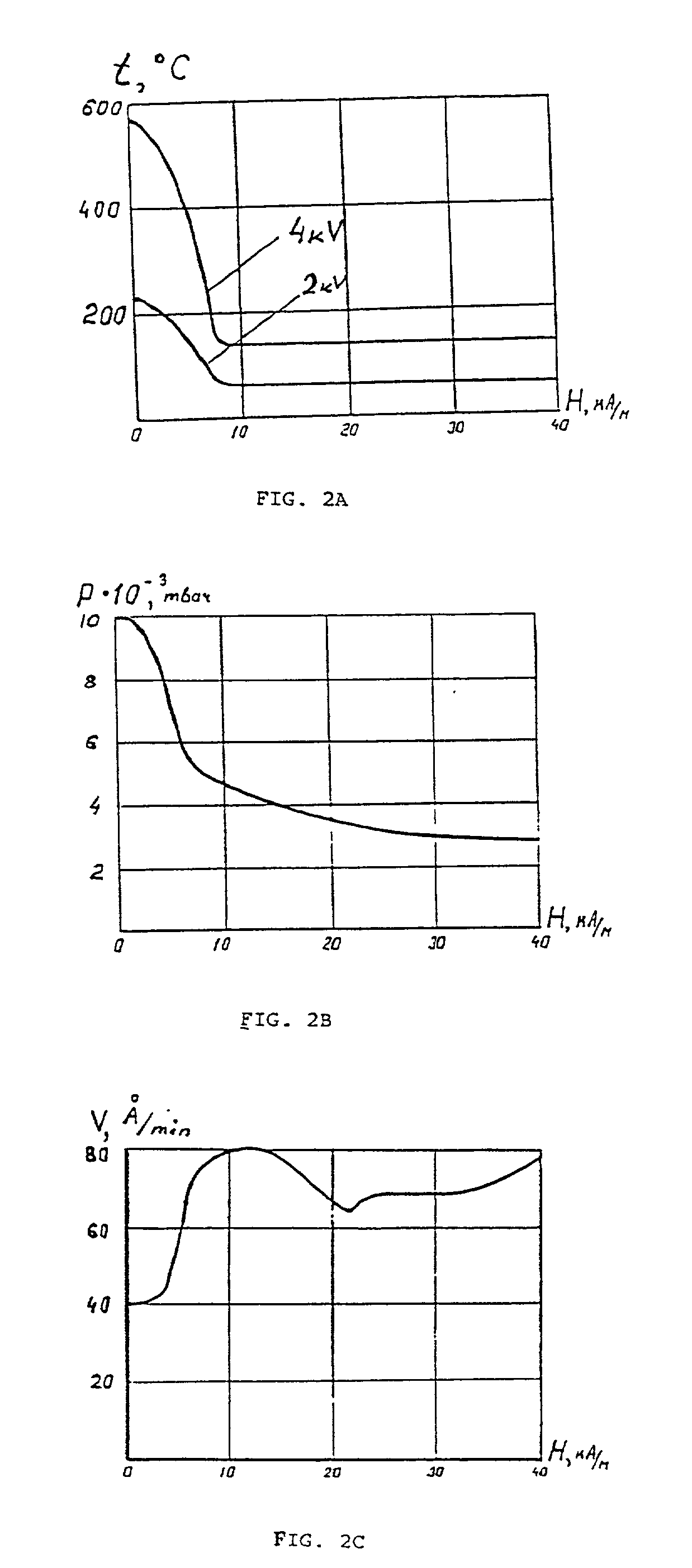

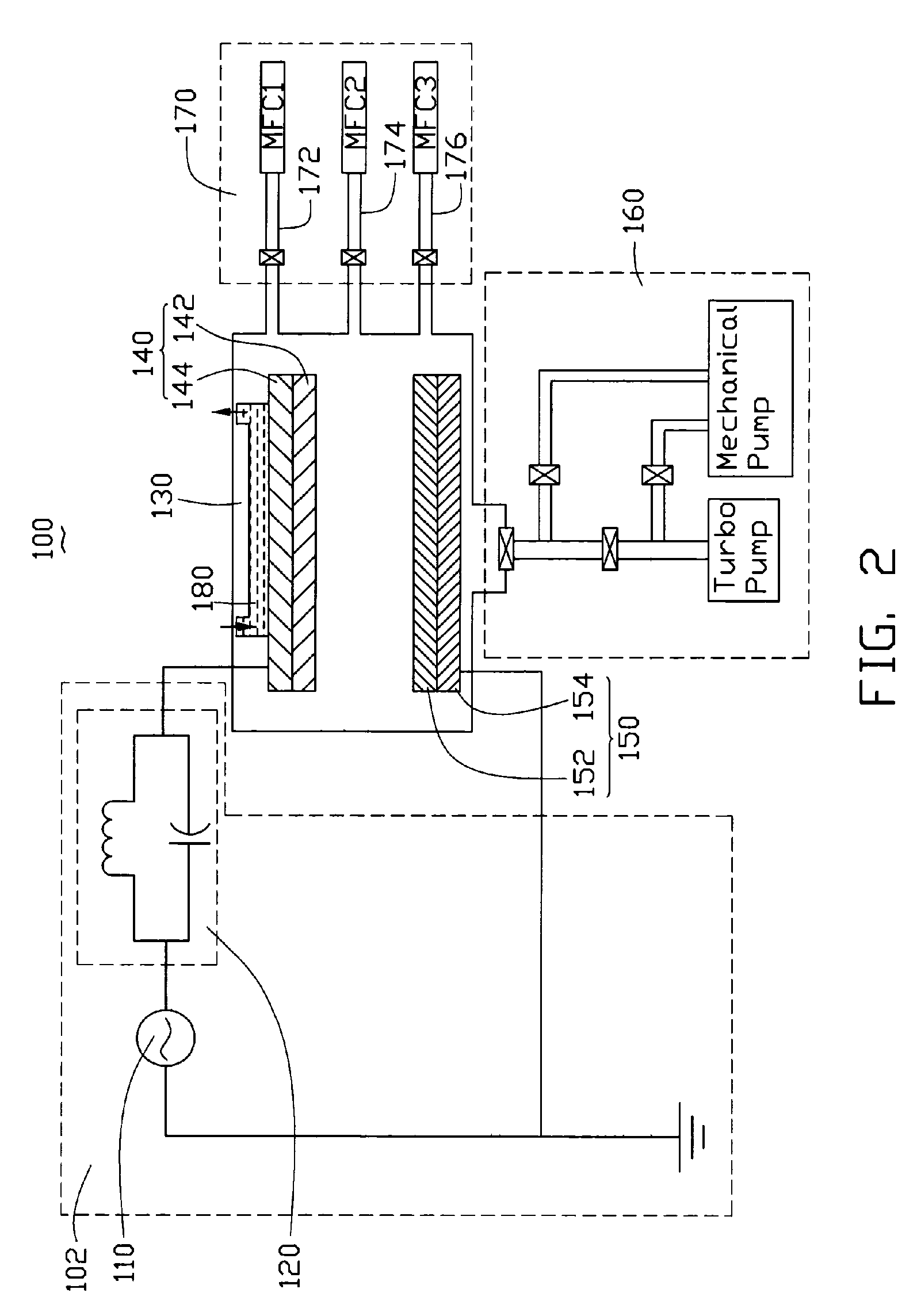

Apparatus and method for enhancing signal intensity of radio frequency glow discharge mass spectrometer by using adjustable magnetic field

InactiveCN108648981AEasy to analyzeAvoid pollutionSamples introduction/extractionElectron/ion optical arrangementsMass spectrometryINTRODUCTION device

The present invention provides an apparatus and method for enhancing the signal intensity of a radio frequency glow discharge mass spectrometer by using an adjustable magnetic field, to better solve the problem of low signal intensity of the existing radio frequency glow discharge mass spectrometer. The apparatus includes a sample introduction device which is provided with a sample introduction rod and on which samples are fixed; and an adjustable magnetic field enhancement portion which is provided with an outer casing and an electromagnet composed of an energizing solenoid and an iron core,the electromagnet is placed in the outer casing, and the adjustable magnetic field enhancement portion is fixed between the sample introduction rod of the sample introduction device and the samples.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

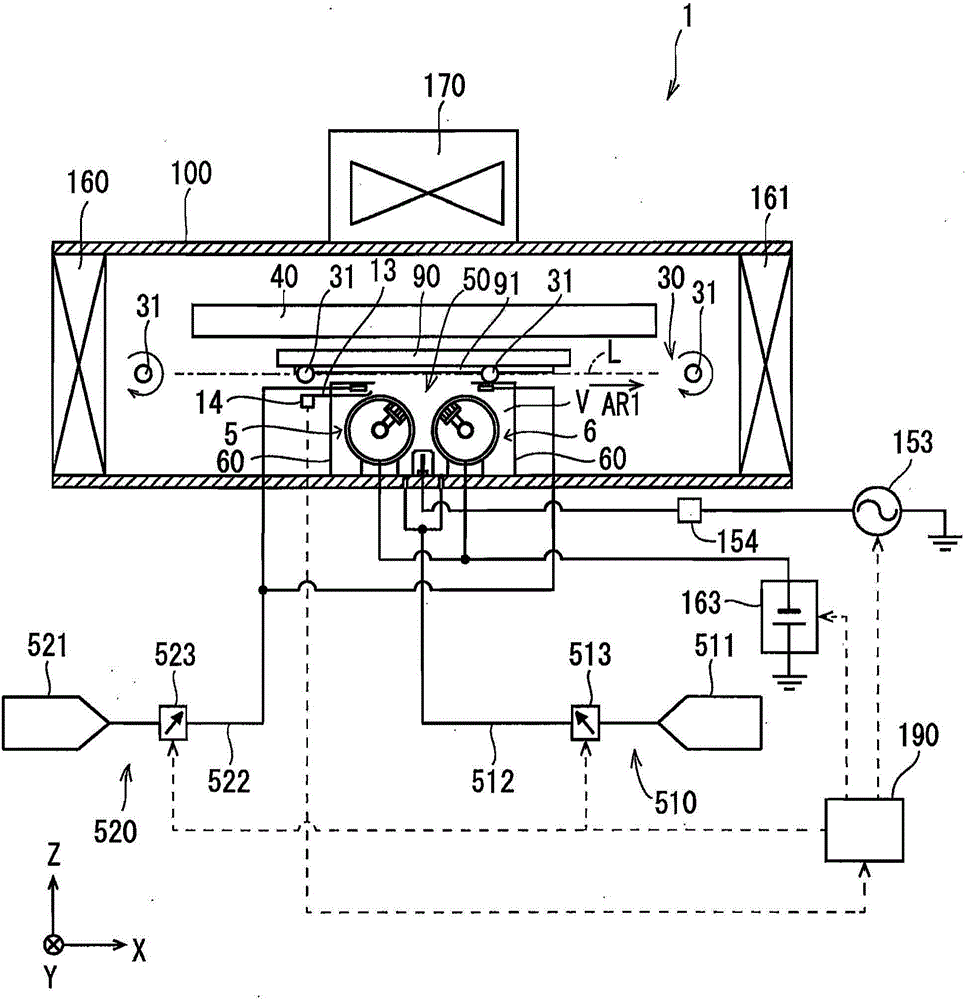

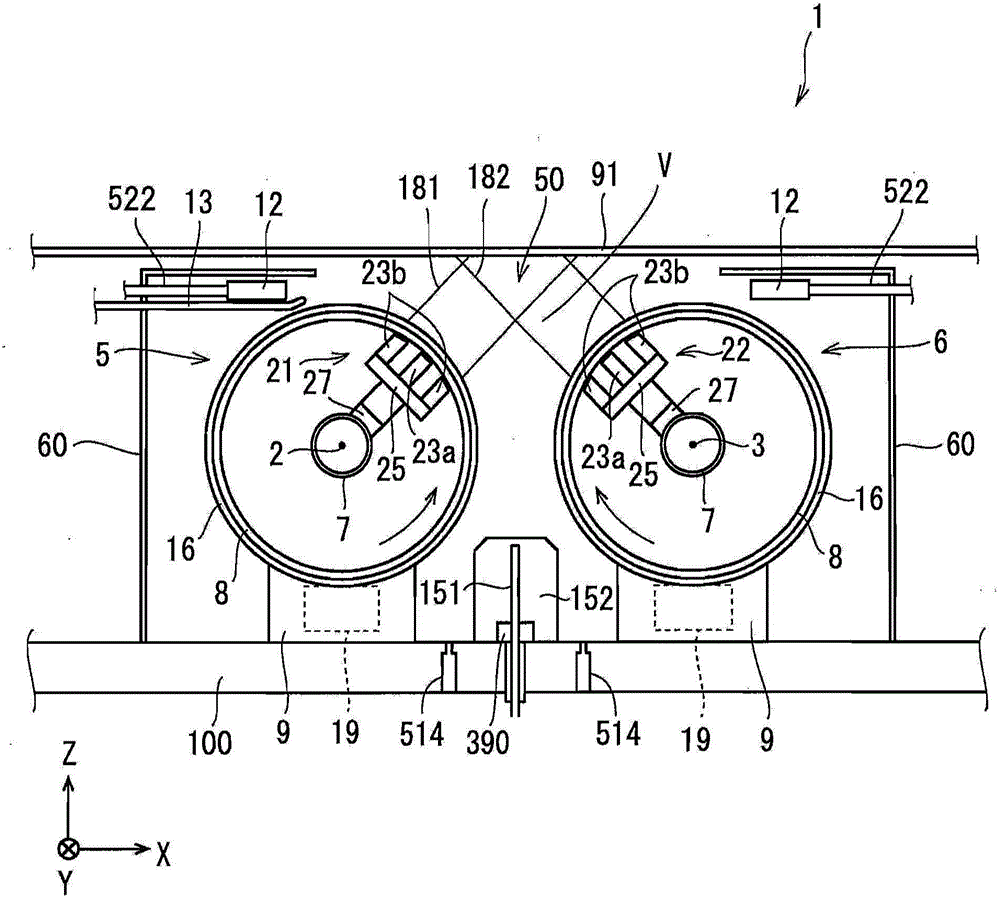

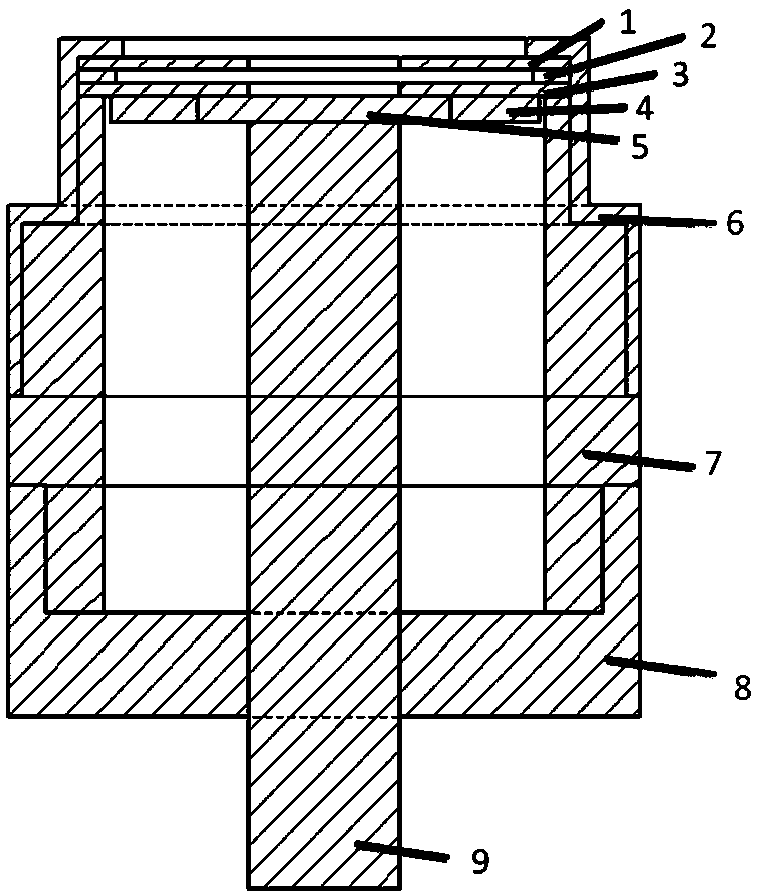

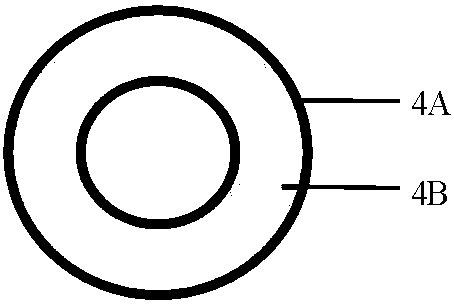

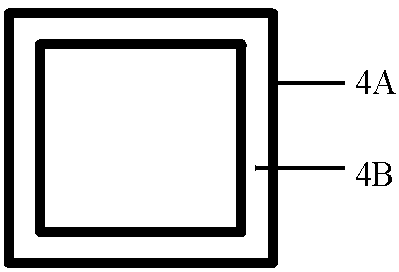

Sputtering device

InactiveCN104947047AIncrease sputtering rateIncrease plasma densityVacuum evaporation coatingSputtering coatingVoltageHigh frequency

The invention provides a sputtering device which restrains target injuries and improves sputtering rate. The sputtering device is provided with a vacuum chamber which is provided with a processing space inside, a sputtering gas supply portion which provides sputtering gas to the processing space, a first mechanism used to make the base material of a film forming object opposite to the processing space, a cylindrical rotating cathode which is arranged in the processing space and can rotate with a central axis as a center, the periphery of the rotating cathode being covered by a target material, a magnetic field forming portion which is arranged in the rotating cathode and forms a magnetic field near the part of the outer peripheral surface of the rotating cathode, the part being opposite to the base material, a rotation drive portion which makes the rotating cathode rotate relative to the magnetic field forming portion with the central axis as a center, a power supply used for sputtering, the power supply applying sputtering voltage on the rotating cathode, a high-density plasma source which generates high-density plasma in the space of the processing space, the space including the part with the magnetic field, and a high-frequency power supply which supplies high frequency electricity for the high-density plasma source.

Owner:SCREEN HLDG CO LTD

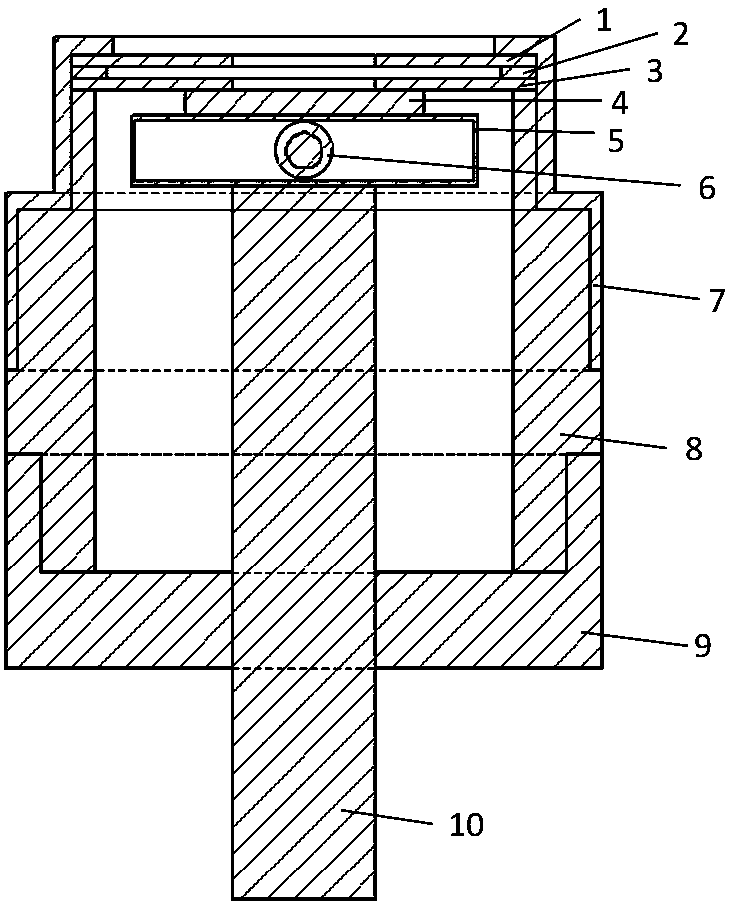

Device and method for enhancing radio frequency glow discharge mass spectrum ion signal intensity through annular magnetic field

InactiveCN108615668AEasy to analyzeSimple structureSamples introduction/extractionElectron/ion optical arrangementsMass spectrometryRadio frequency

The objective of the invention is to provide a device and a method for enhancing radio frequency glow discharge mass spectrum ion signal intensity through an annular magnetic field, and aims at solving the problem of low radio frequency glow discharge mass spectrum signal intensity at present. The device comprises a sample feeding device which is provided with a sample feeding rod and fixed ceramic gaskets; and an annular magnet enhancement part which is provided with a shell and an annular magnet, wherein the annular magnet is put in the shell, and the annular magnet enhancement part is fixedbetween the sample feeding rod and the ceramic gaskets in the sample feeding device.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

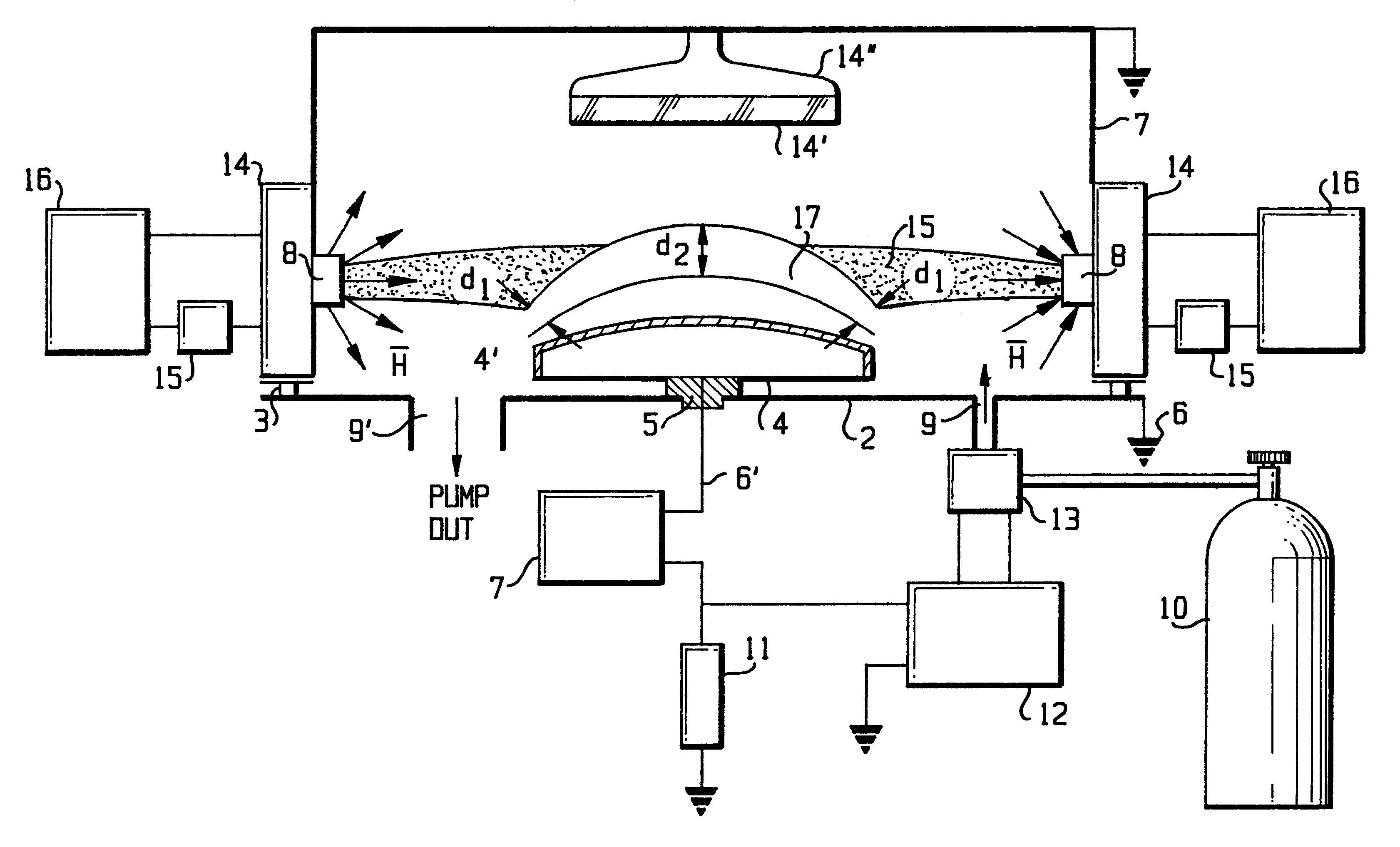

Sputtering method and apparatus for depositing a coating onto substrate

InactiveUS6423191B1Increase sputtering rateReduce formationCellsElectric discharge tubesMaterials scienceMagnetic field

Sputtering method and apparatus for depositing a coating onto substrate employs variable magnetic field arranged in vicinity of a cathode within a working chamber, filled with ionizable fluid. By controlling a magnetic field topology, i.e. orientation and value of magnetic strength with respect to cathode there is enabled localization and shifting of plasma away from substrate and by thus improvement of adhesion and properties of deposited coatings.

Owner:THIN FILMS

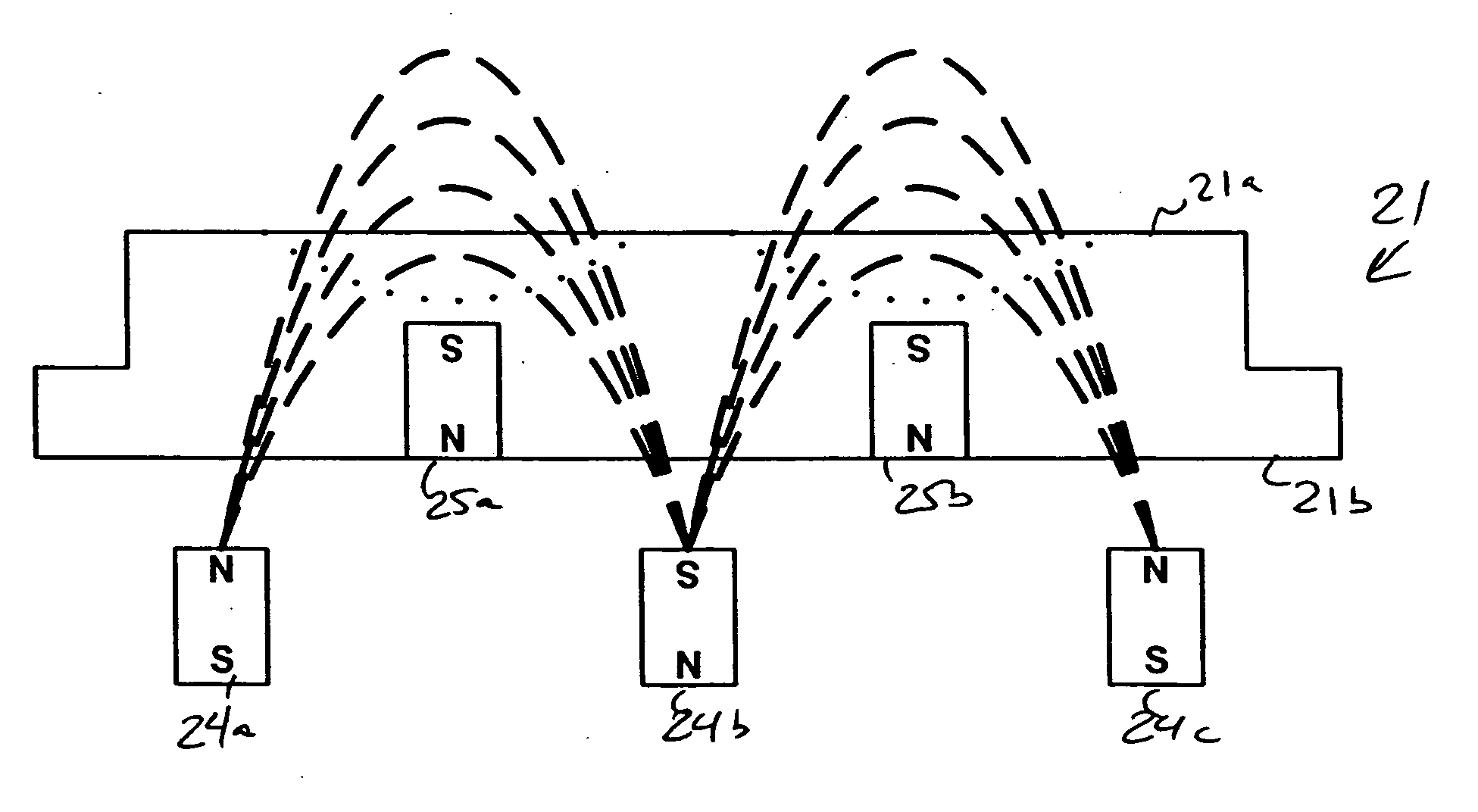

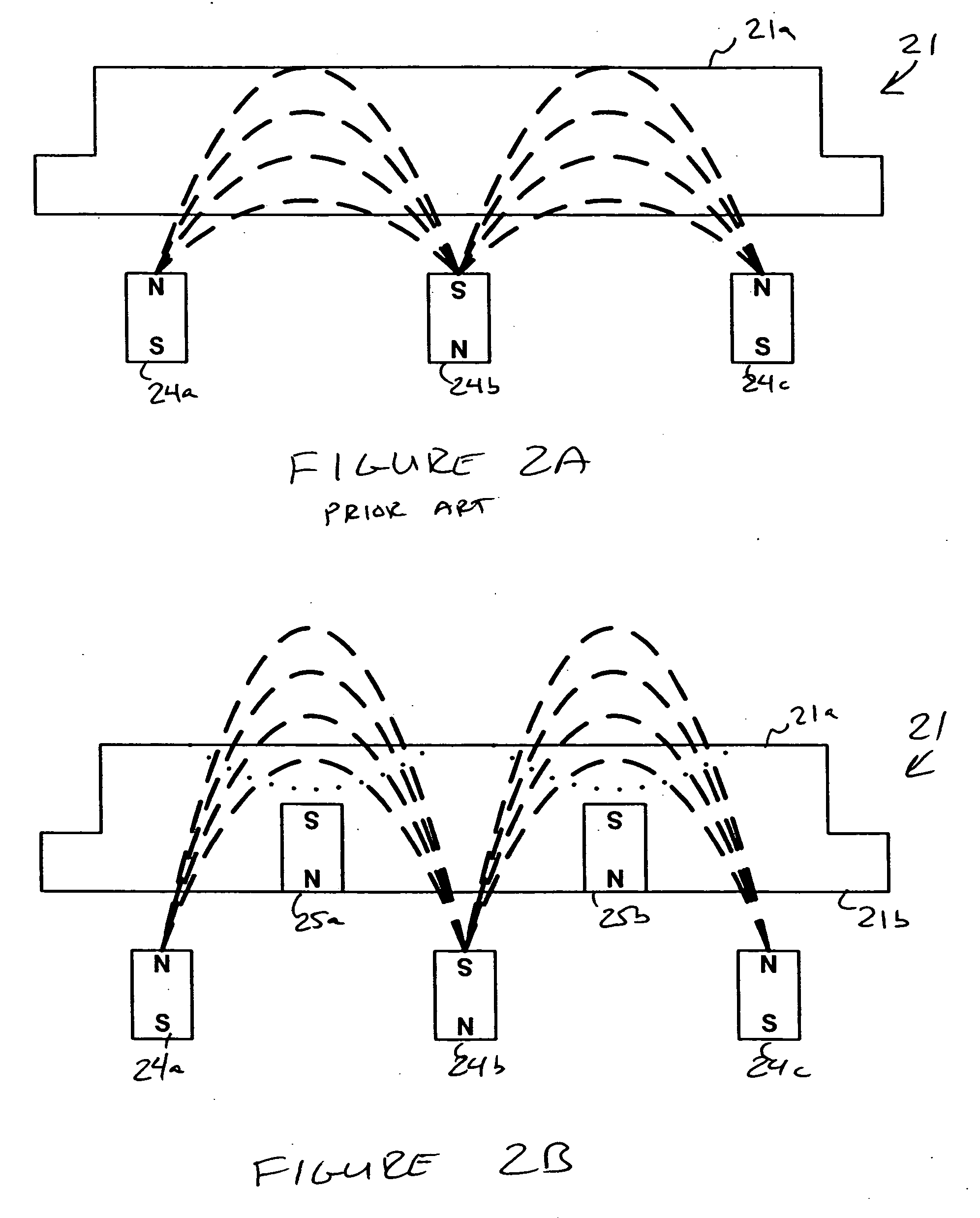

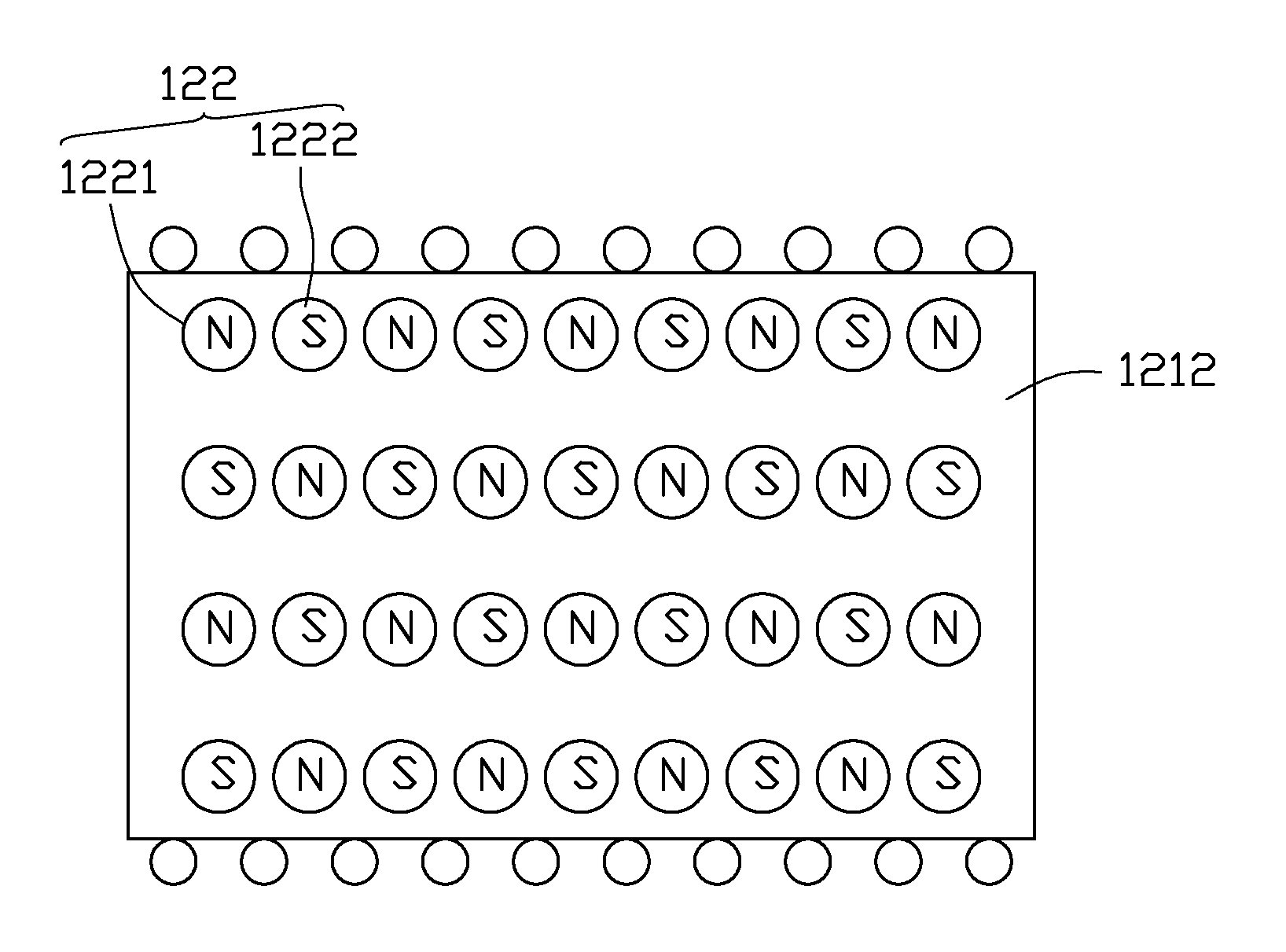

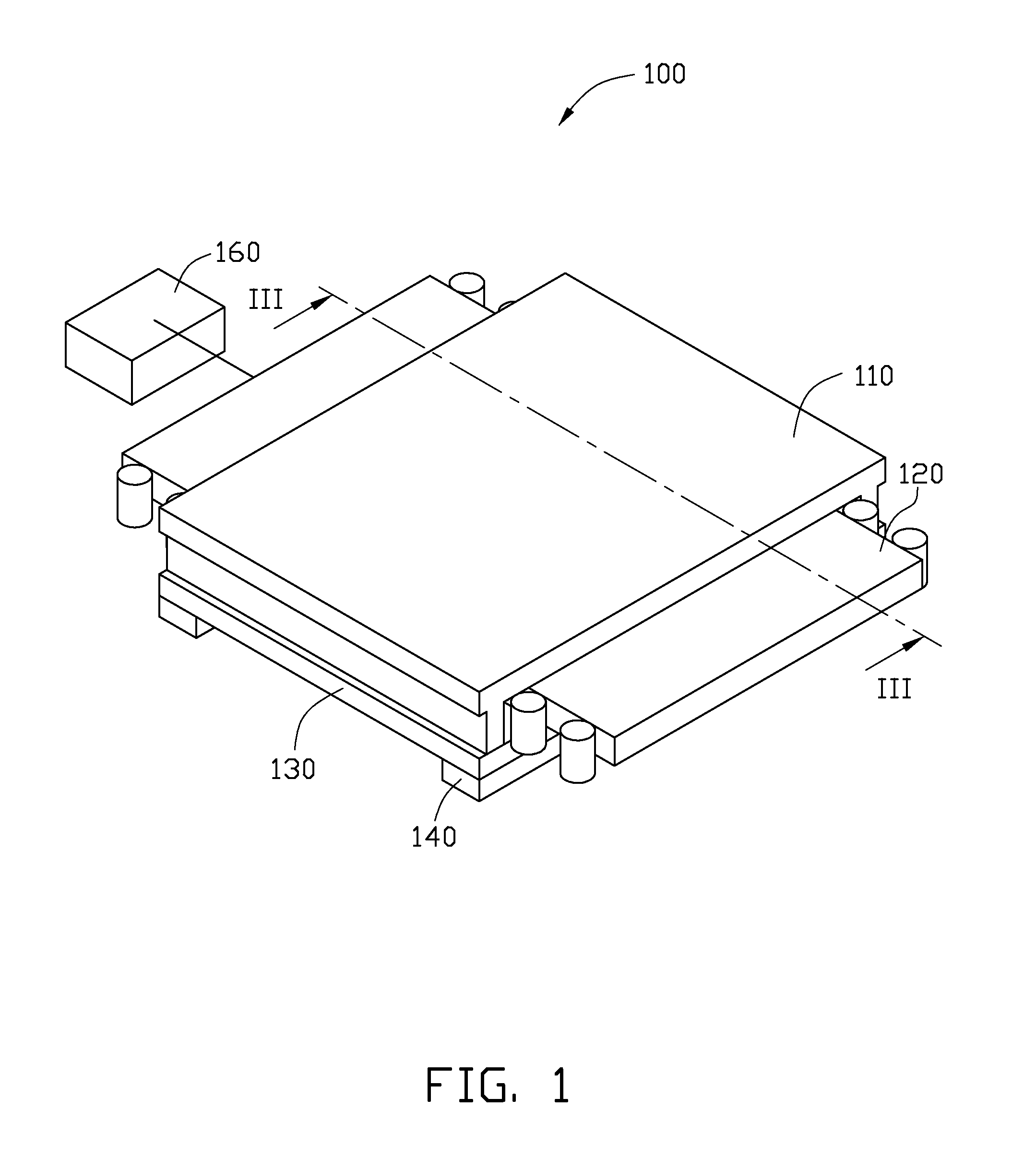

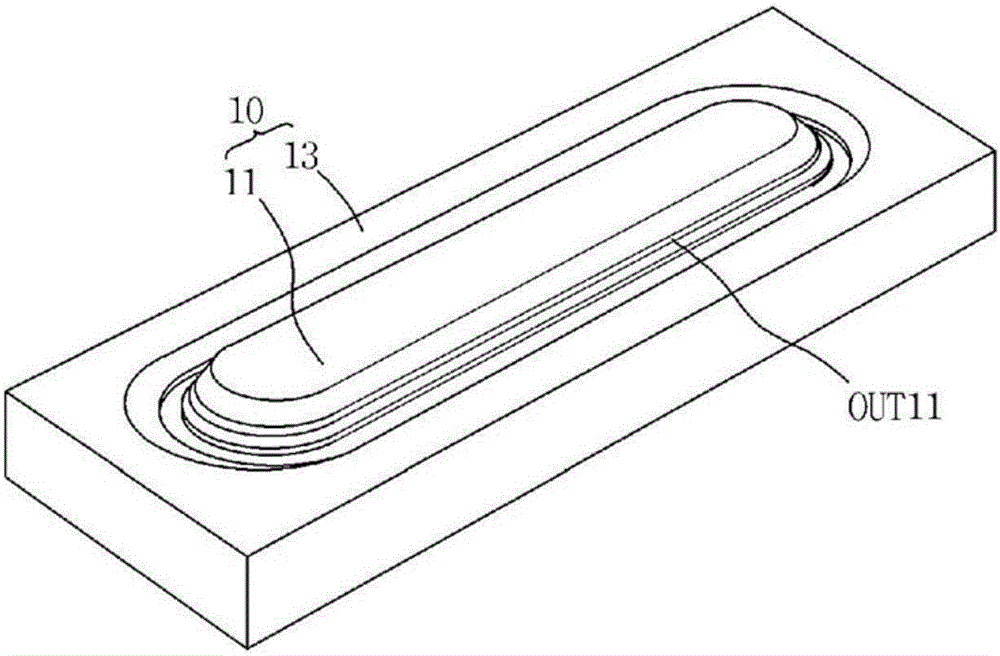

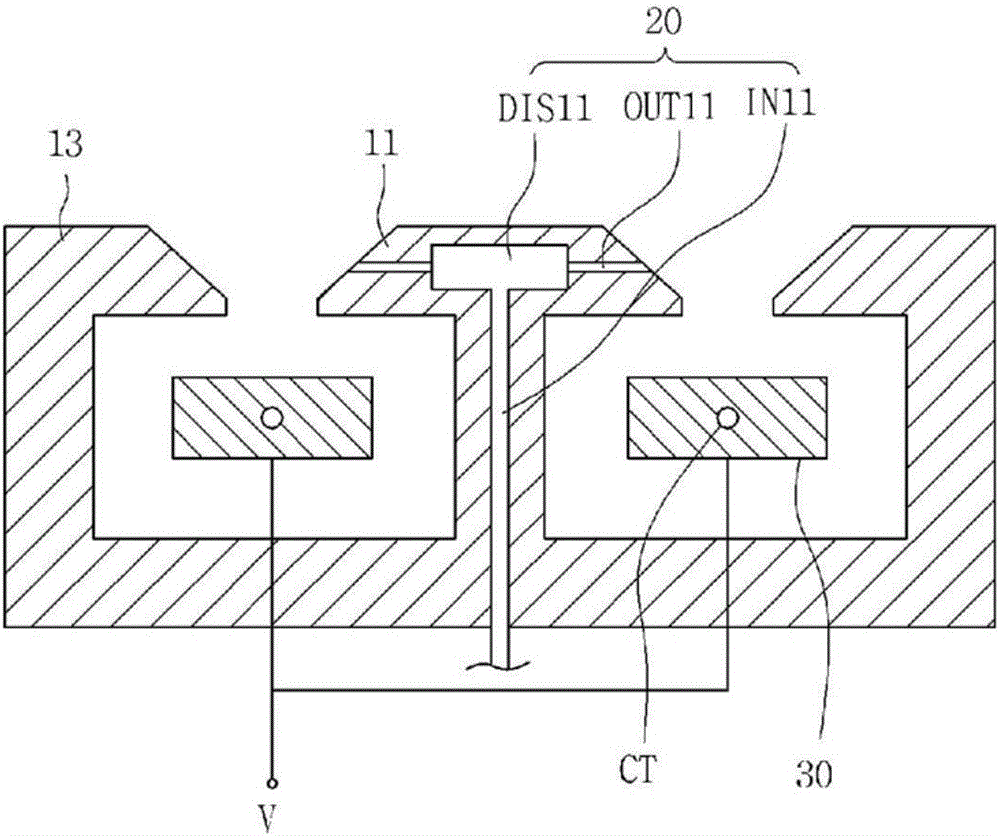

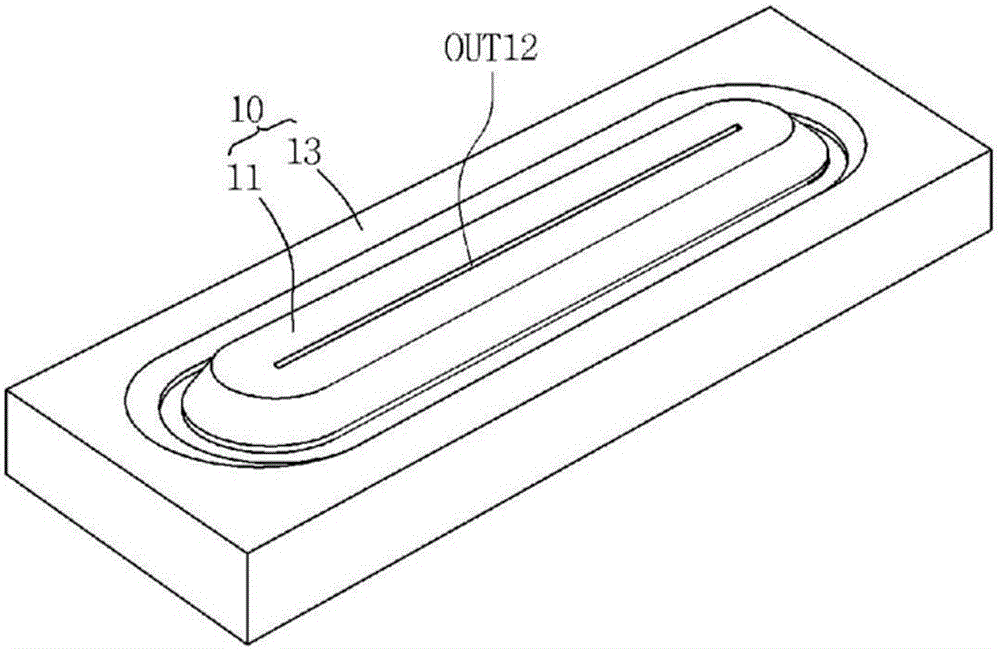

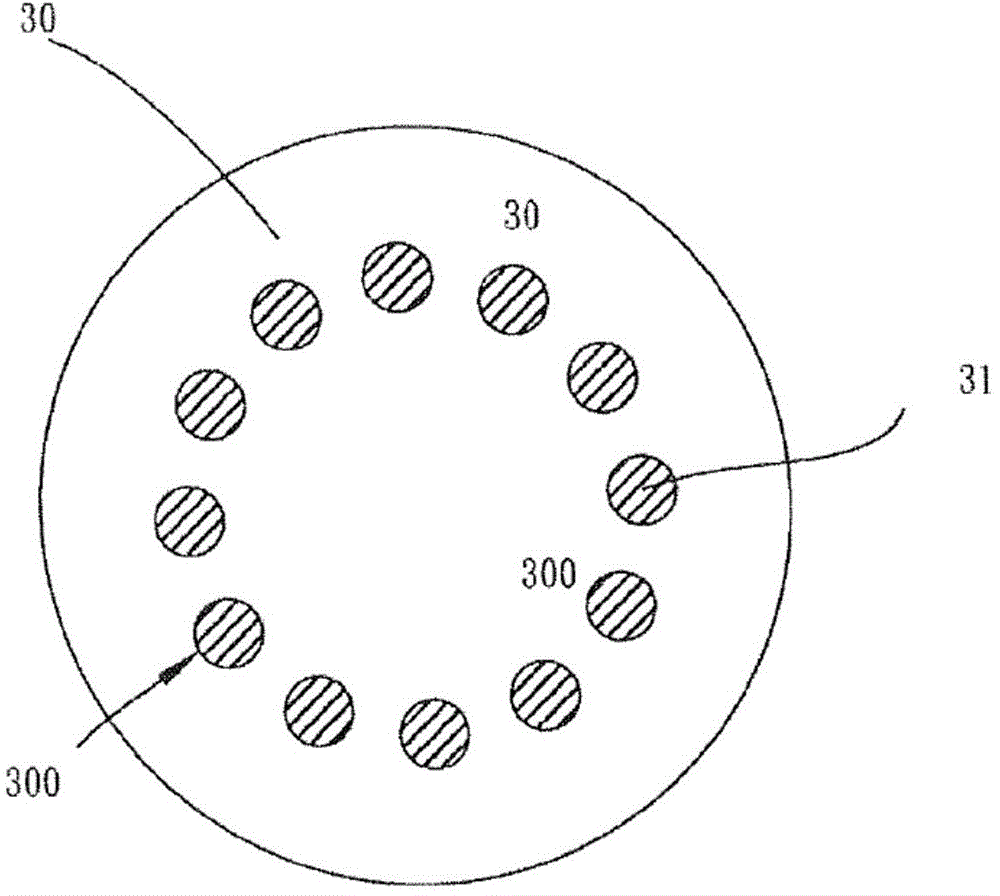

Magnetron sputtering target and magnetron sputtering system

InactiveUS20100252427A1Increase ionization rateIncrease sputtering rateCellsElectric discharge tubesSputteringMaterials science

A magnetron sputtering target comprises a magnetron device and a target positioned in a magnetic field of the magnetron device. The magnetron device comprises a metal plate, a plurality of first magnets and second magnets. A direction of the magnetic lines of the first magnets is opposite to that of the second magnets. The first magnets and the second magnets are embedded in the metal plate and arranged in a number of rows and columns. At least one first magnet is adjacent to a second magnet in one row, and at least one first magnet is adjacent to a second magnet in one column, therefore, there are magnetic lines in row direction and column direction exist in the magnetic field of the magnetron device.

Owner:HON HAI PRECISION IND CO LTD

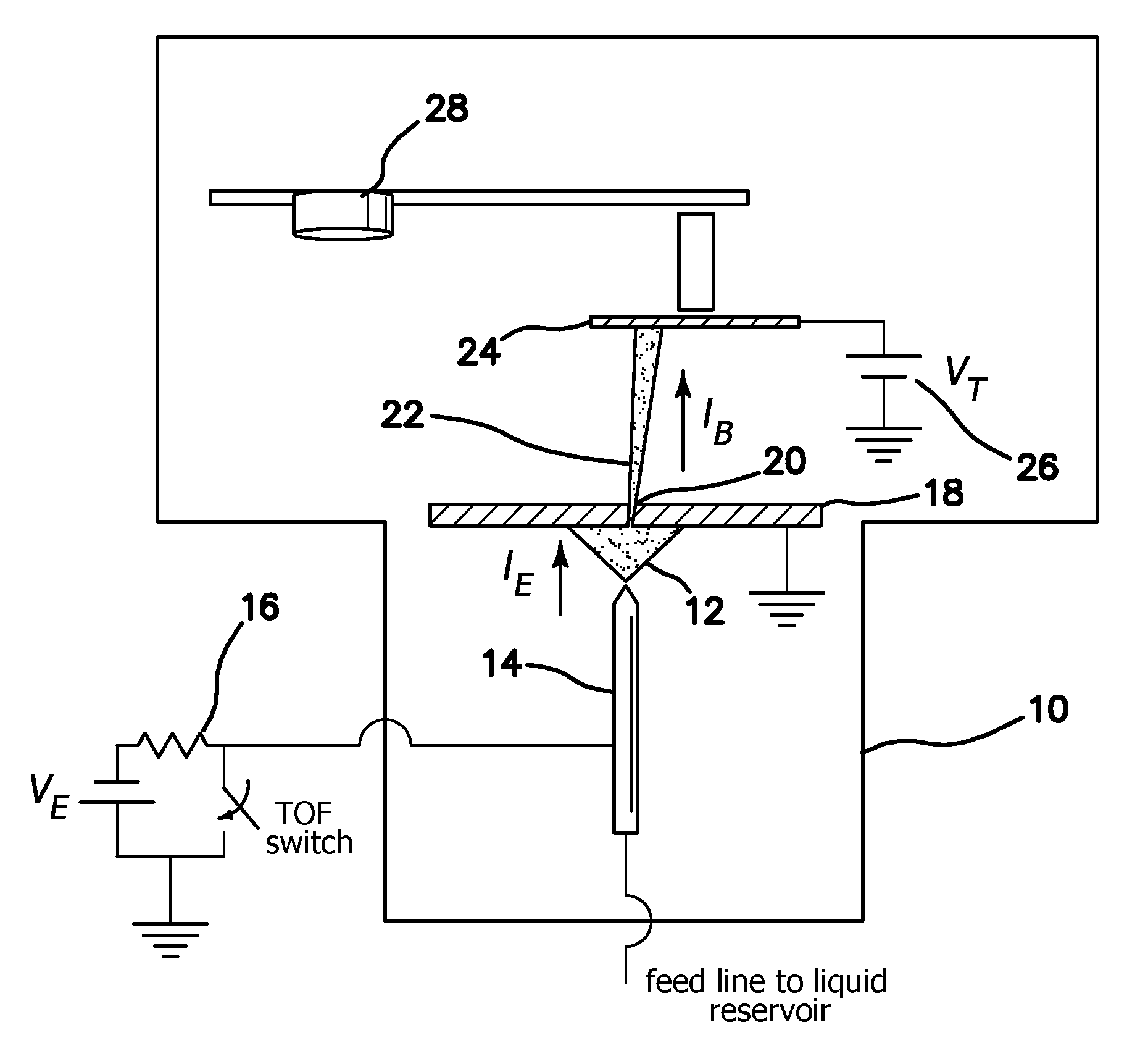

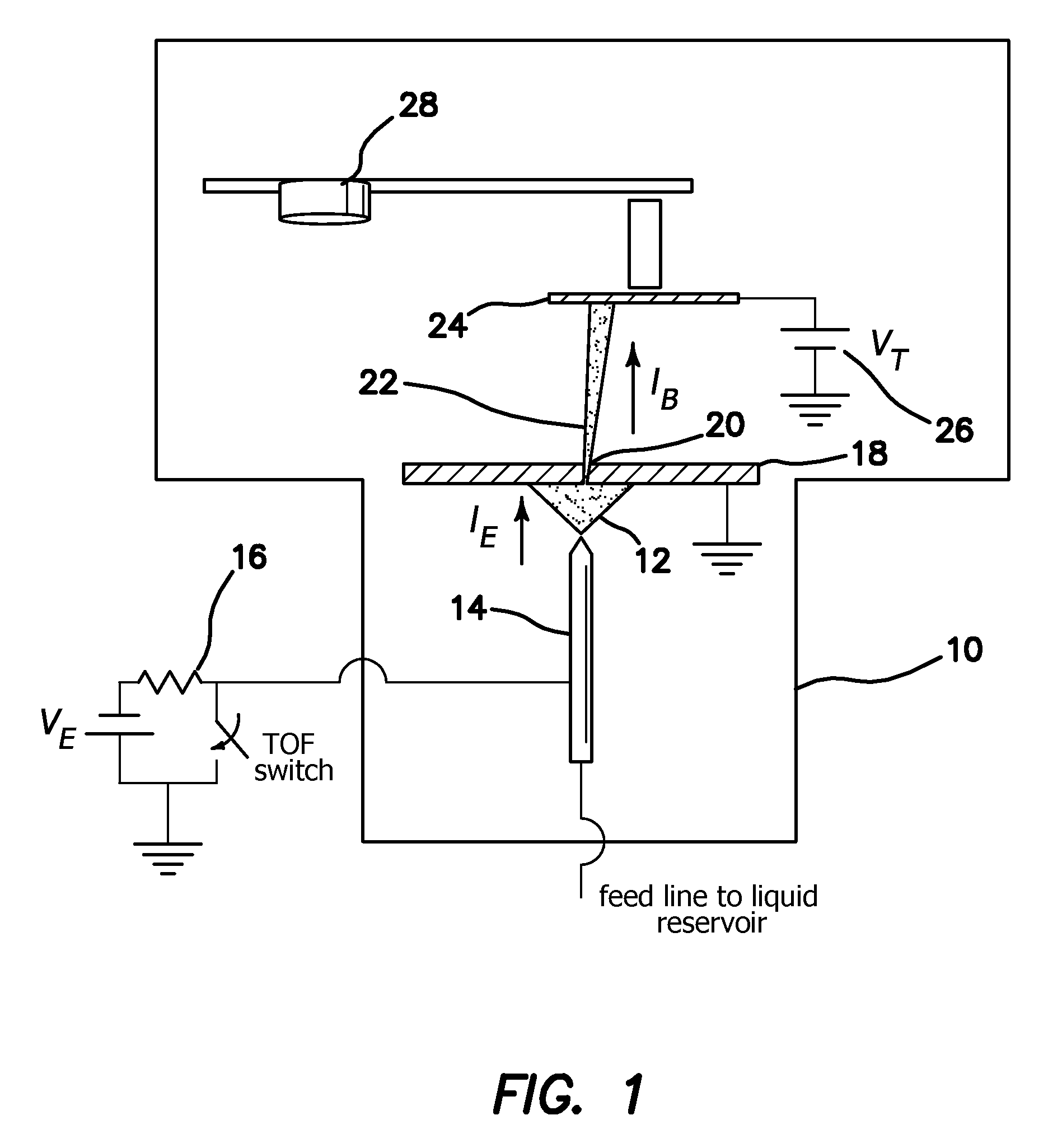

Method and apparatus for providing beams of nanodroplets for high sputtering rate of inert materials

InactiveUS20120286149A1High yieldIncrease sputtering rateStability-of-path spectrometersMaterial analysis using wave/particle radiationSputteringMicromachinings

A method for milling of a workpiece of inert material by nanodroplet beam sputtering includes the steps of providing aliquid; electrohydrodynamically atomizing the liquid to form charged nanodroplets; and directing the atomized charged nanodroplets onto the workpiece to selectively remove material. The method is used for broad-beam milling the workpiece of inert material, for precision micromachining and / or for three dimensionally profiling organic samples via secondary ion mass spectrometry. The liquid is electrosprayed in a cone-jet mode in a vacuum and average nanodroplet diameter, nanodroplet velocity, and molecular energy of the nanodroplets is adjusted by changing liquid flow rate and the acceleration voltage applied to the ionic liquid as it is atomized. Apparatus for performing the method are also included embodiments.

Owner:RGT UNIV OF CALIFORNIA

Ion source

An ion source comprises a magnetic field unit and an electrode. One side of the magnetic field unit, which faces an object to be treated, is open, while the other side thereof is closed. The magnetic field unit has, on one side that is open, an inner magnetic pole and an outer magnetic pole arranged to be spaced from each other, and a magnetic core is connected to the other side of the magnetic field unit, which is closed, thereby forming an acceleration closed loop for plasma electrons on one side thereof, which is open. The inner magnetic pole has a gas injection unit penetrating the interior thereof, thereby supplying a gas towards the acceleration closed loop. The electrode is arranged below the acceleration closed loop inside the magnetic field unit to be spaced from the magnetic field unit.

Owner:发仁首路先株式会社

Target material for anti-electromagnetic wave interference alloy thin film

InactiveCN104451261ASuppress grain coarseningSputtering highVacuum evaporation coatingSputtering coatingAlloy thin filmElectromagnetic interference

The invention provides a target material for an anti-electromagnetic wave interference alloy thin film. The target material for the anti-electromagnetic wave interference alloy thin film smelts alloy main components to a target in the manner of smelting. The main alloy includes 59wt% to 97wt% of zinc, 3wt% to 40wt% of aluminum, and 0.005wt% to 1wt% of a modifier, wherein the modifier is selected from Zn, Al, Ti, C, B, N, Zr, Cr or a group composed of any combination.

Owner:MEGA ENERGY VACUUM

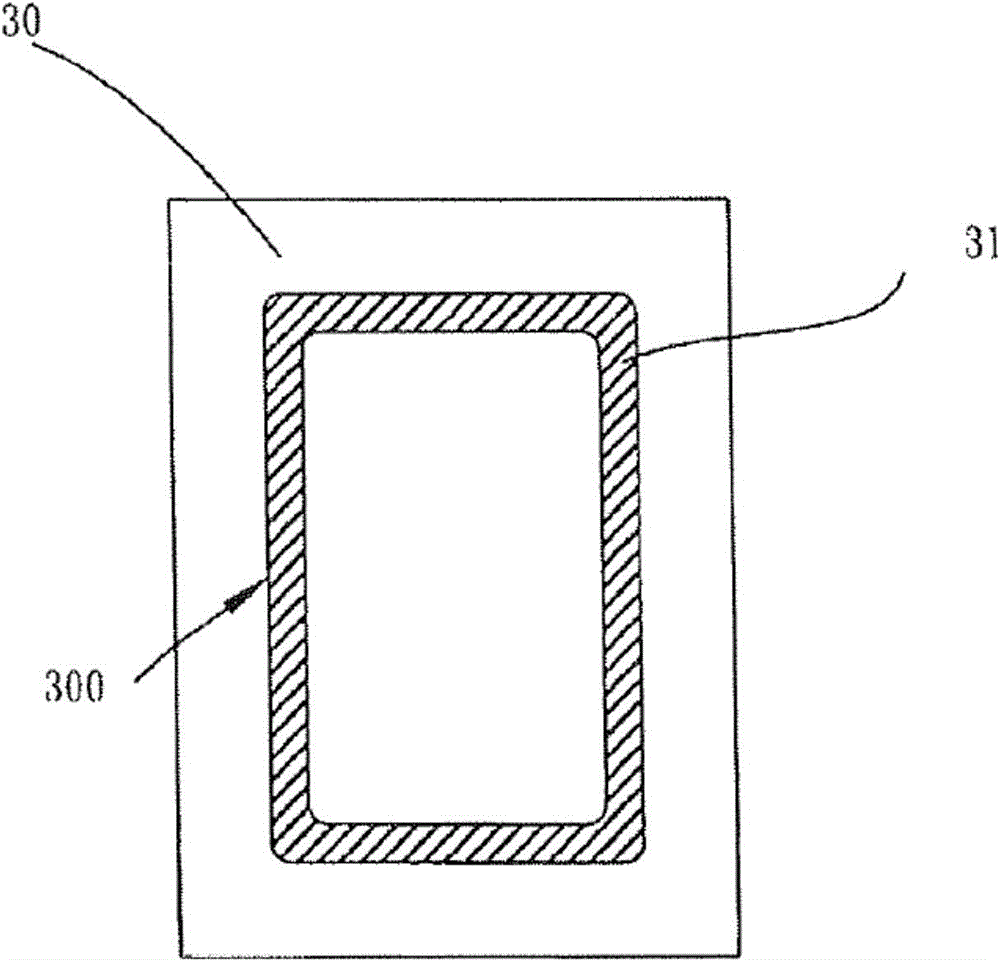

Sputter chamber for coating a substrate

InactiveCN101045987AIncrease sputtering rateMitigate the "picture frame effect"Electric discharge tubesVacuum evaporation coatingProduct gasAirflow

The invention relates to a sputter chamber for coating substrates, in which the so-called ''picture frame effect'' is eliminated or at least largely reduced. The thickness of the coating at the margin of a substrate hereby no longer deviates significantly from the thickness of the coating in the center of the substrate. This is attained thereby that the negative effect of the process gas-or of several process gases-which is introduced into the sputter chamber is equalized by an additional inert or reactive gas. At the margins of the substrates to be coated and on the substrate side facing away from the cathode thus an additional gas stream is generated, which is directed counter to the process gas stream.

Owner:アプライドマテリアルズゲーエムベーハーウントツェーオーカーゲー

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com