Target material for anti-electromagnetic wave interference alloy thin film

An alloy film, anti-electromagnetic wave technology, applied in the field of sputtering targets, can solve the problems of complex manufacturing process, increase the complexity of control equipment, etc., and achieve the effect of simplifying sputtering control control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

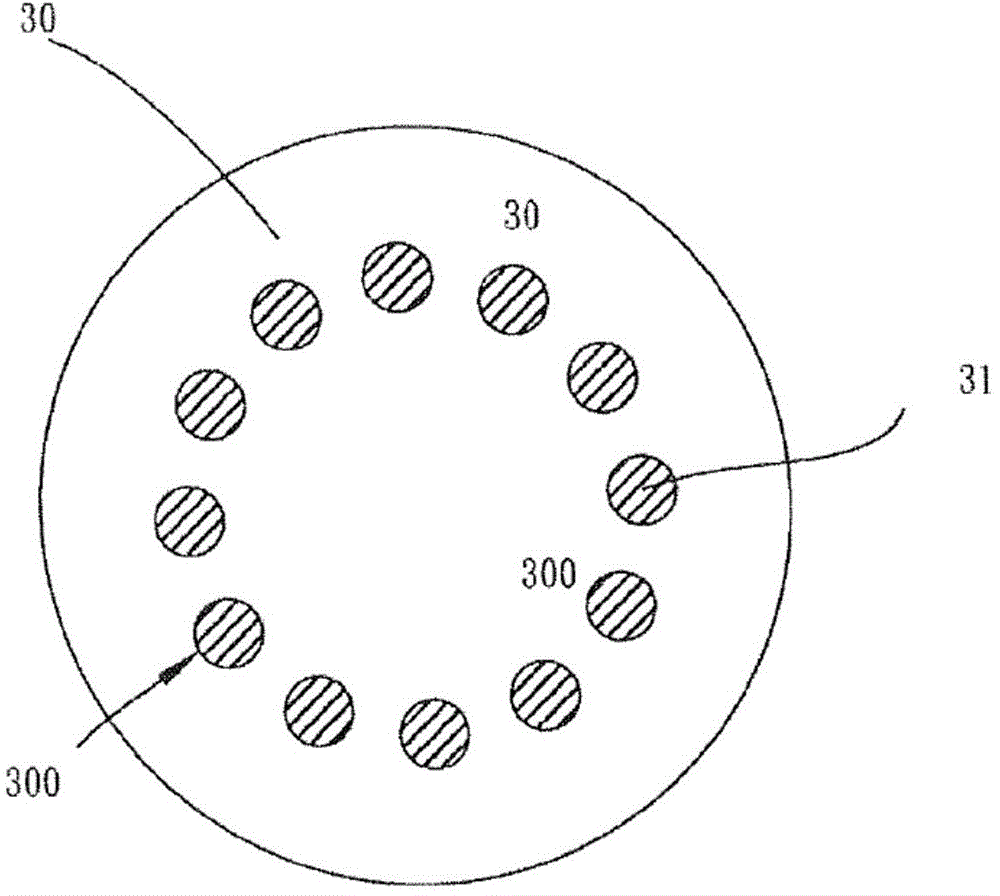

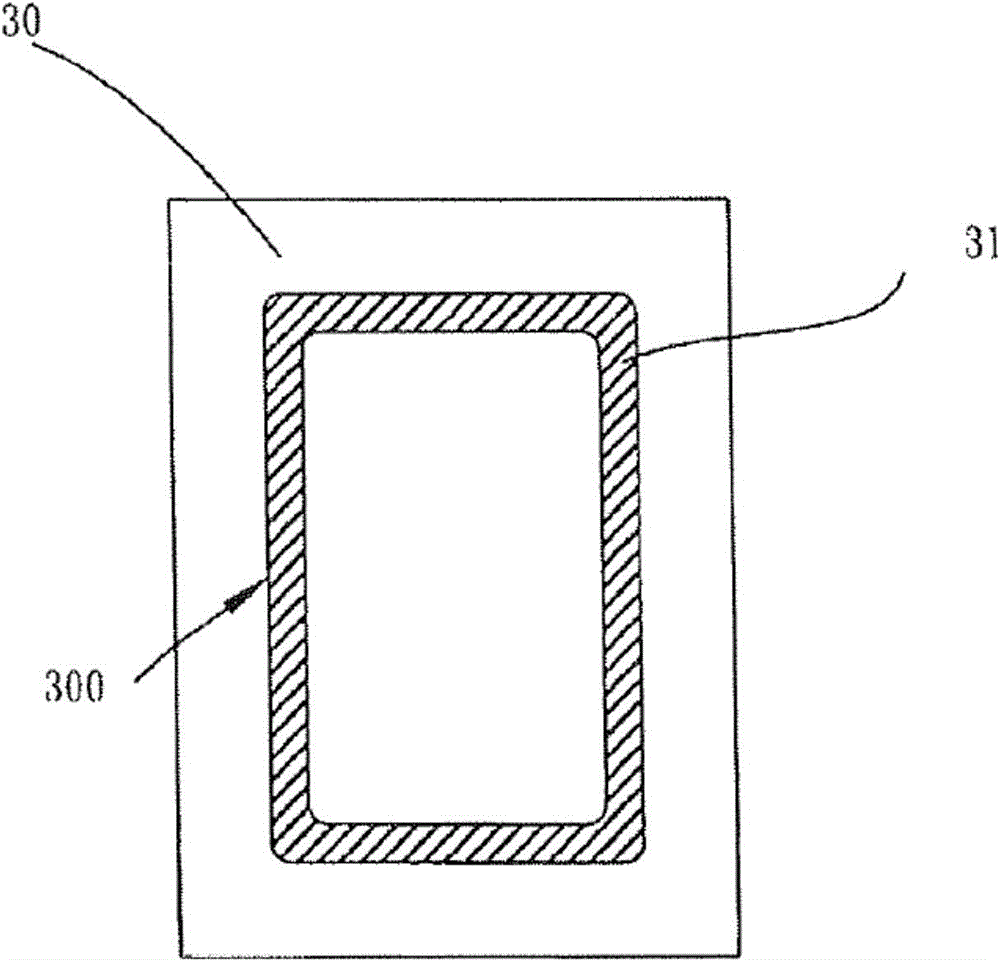

[0031] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, a preferred embodiment of the magnetron target material designed according to the present invention, together with the accompanying drawings, is described in detail as follows.

[0032] The main component of the target material of the present invention is zinc-aluminum alloy, and 0.005-1wt% of modifier is added during the process of smelting zinc-aluminum alloy. The modifier is selected from Zn, Al, Ti, C, B, N, Zr, Cr And any one of the groups formed by any combination thereof to achieve the purpose of improvement.

[0033] The preferred combination in the modifier is any of the following (i)-(viii)

[0034] (i) Al-Ti-C, weight percentage: Ti is 0.8-25wt%, C is 0.01-3wt%, and the rest is Al.

[0035] (ii) Al-Ti-B-C, weight percentage: Ti is 1-20wt%, boron carbide B 4 C is 0.1-7wt%, and the rest is Al.

[0036] (iii) Al-Ti-B-N, weight percentage: Ti is 1-20wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com