Ion source

A technology of ion source and plasma, applied in the field of ion source with gas injection part on the magnetic pole, which can solve the problems of high production cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

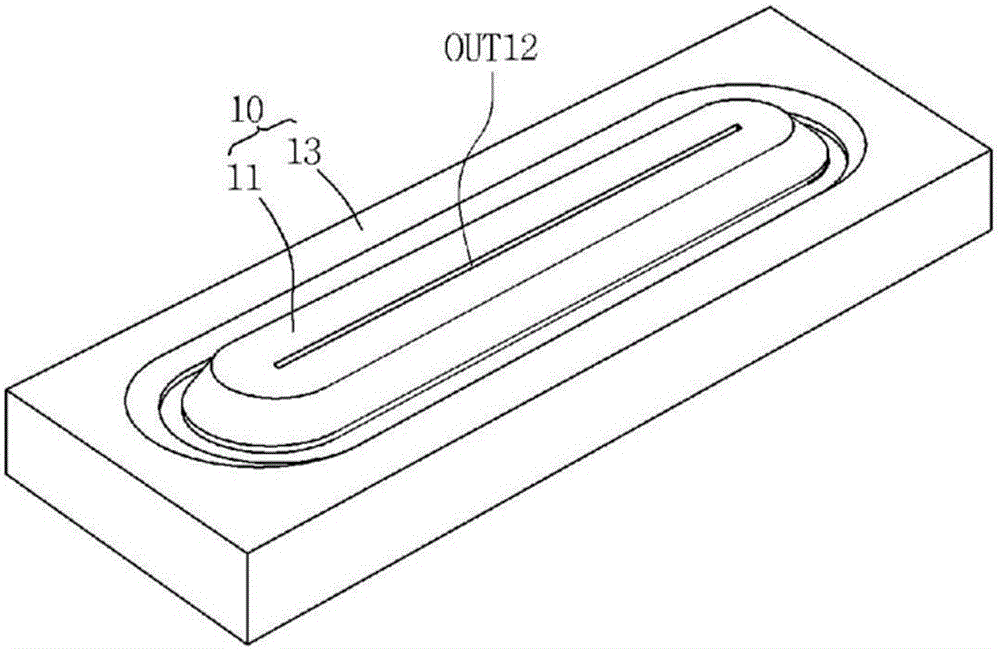

[0082] Figure 2a , 2b are perspective and sectional views showing a second embodiment of the ion source of the present invention.

[0083] Such as Figure 2a , 2b As shown, in the second embodiment, an inner front gas ejection portion OUT12 that opens toward the direction of the substrate is formed in the inner gas injection portion 21, and the inner side gas ejection portion OUT12 that opens toward the accelerated closed-loop direction of the first embodiment may not be included. OUT11.

[0084] The inner front gas ejection portion OUT12 may be formed along the longitudinal direction of the inner magnetic pole 11 . One side of the inner front gas ejection portion OUT12 communicates with the inner gas dispersion portion DIS11, and the other side communicates with the substrate direction. The inner front gas ejection portion OUT12 has a smaller cross section than the inner gas dispersion portion DIS11, and therefore ejects the gas in the inner gas dispersion portion DIS11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com