car air filter

An air filtration and automotive technology, applied in automotive air filtration. It can solve the problems of increased vehicle maintenance costs, increased vehicle maintenance frequency, and large filtering burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

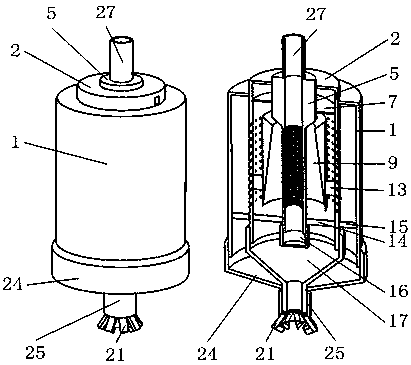

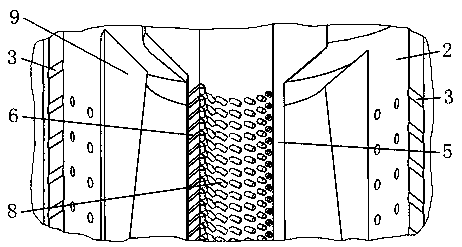

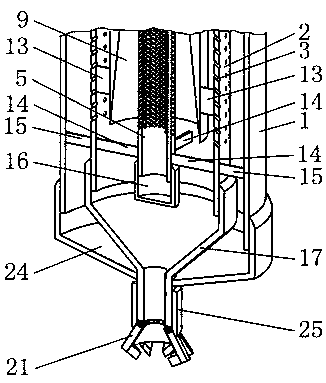

[0035] Such as figure 1 , 2 , 3, it includes cylinder A1, cylinder B2, cylinder C5, spiral sheet 7, swirl tube 8, cylinder D9, collection sleeve A16, collection sleeve B17, pendulum block 21, fan-shaped block 22, elastic soft film 23, collection Set C24, threaded sleeve 25, such as figure 1 , 2 , 5, the outer cylindrical surface of the tube C5 is a stepped cylindrical surface, and the outer cylindrical surface of the large-diameter part of the upper section of the tube C5 and the outer cylindrical surface of the small-diameter part of the lower section of the tube C5 are transitionally connected through the outer tapered surface 12; as figure 1 As shown, the cylinder B2 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com