Deposition system and processing system

A processing system and deposition technology, applied in the fields of deposition systems and processing systems, can solve problems such as waste of sputtering materials, and achieve the effects of reducing chemical raw materials, improving utilization, and reducing target costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

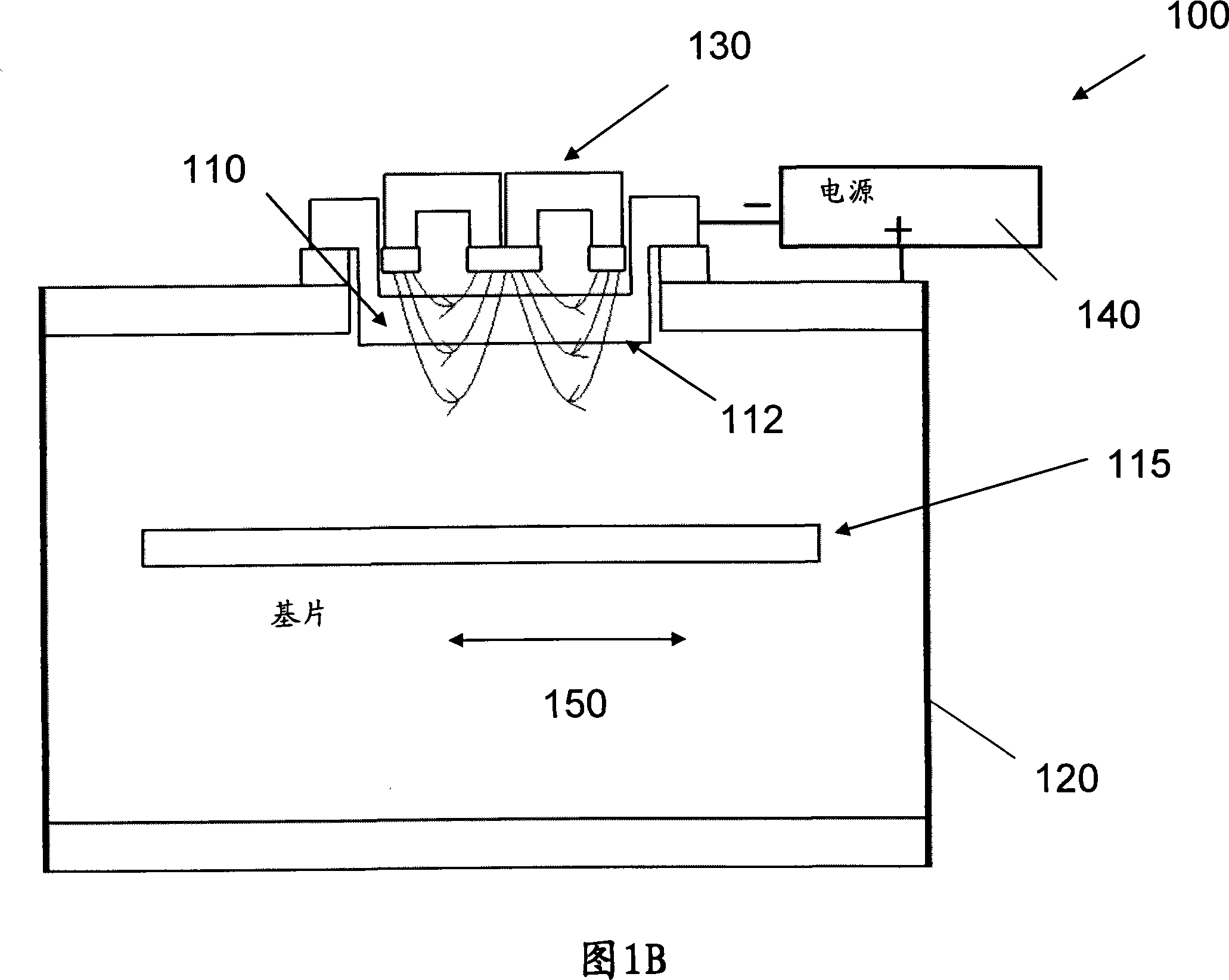

[0051] Referring to FIGS. 3A-3E , a processing system 300 includes a chamber 320 that may be sealed to form a vacuum environment in a space 350 . Processing system 300 may include a sputter deposition system or other types of processing stations as described below. Cavity 320 may include one or more inner cavity walls 321 a - 321 c , one or more outer cavity walls 325 a - 325 c , and end cavity walls 323 and 324 . The inner cavity walls 321a-321c and the outer cavity walls 325a-325c may form one or more pairs of opposing cavity walls.

[0052] A plurality of substrates 315a-315c may be disposed on outer cavity walls 325a-325c, respectively. A plurality of targets 310a-310c may be held on inner cavity walls 321a-321c, respectively. Each target 310 a , 310 b or 310 c includes a sputtering surface 312 facing the space 350 . Each substrate 315a, 315b or 315c includes a deposition surface 317 facing the space 350 and opposite the sputtering surface 312 on the corresponding targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com