Patents

Literature

39results about How to "Conductivity is not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method to Enhance Proppant Conductivity from Hydraulically Fractured Wells

InactiveUS20080196895A1Contributing to overall effectiveness of treatmentConductivity is not affectedFluid removalDrilling compositionSlurryCarrier fluid

A method of mitigating proppant settling in a hydraulic fracture in order to better suspend the proppant as well as ensure a more uniform pack, by mixing a pre-determined volume percent of low density additive, such as glass beads or other suitable material, such as polylactic acid particles, into the fracturing slurry along with the standard high-density proppant, it is anticipated that density gradients can be induced inside the fracture. Upward movement of low density additive due to them having density lower than the carrier fluid will interfere with downward movement of high-density proppant and vice versa. This mutual interference between the two proppants confined in the narrow fracture will significantly hinder the settling / segregation of the high-density proppant. The low density material has a specific gravity of about 0.3, particle size distribution similar to that of standard proppant, and sufficient mechanical strength to survive fracture closure stress.

Owner:CSI TECH LLC A TEXAS LLC

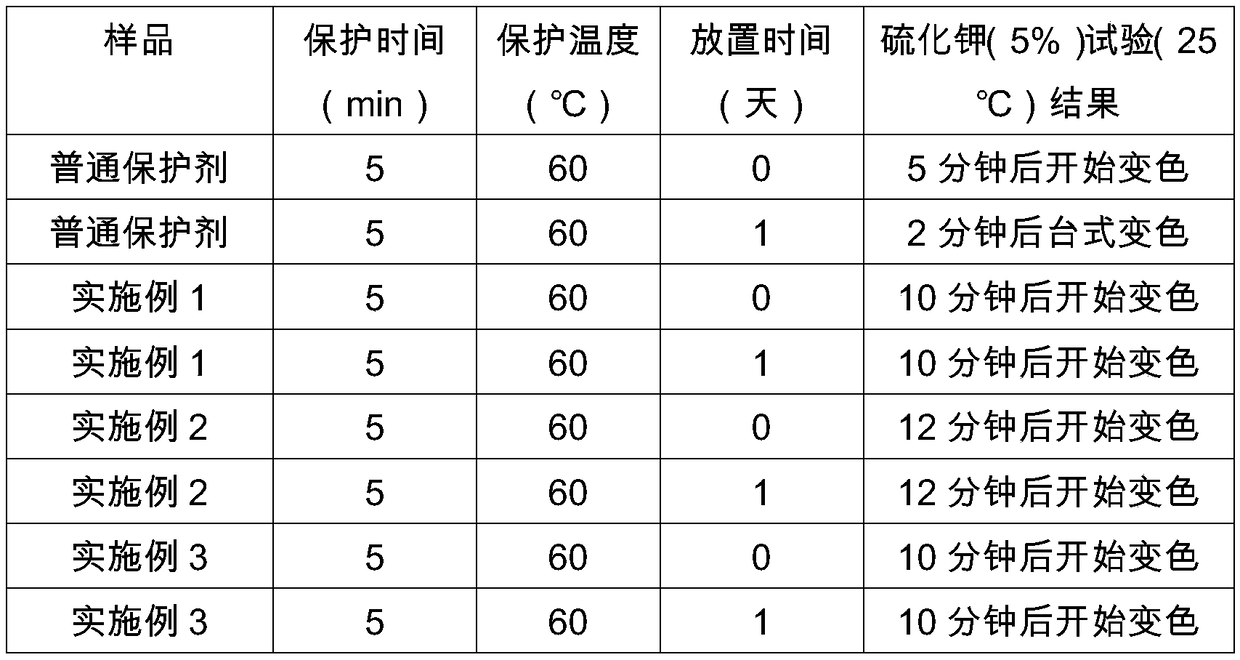

High-stability water-base silver-plating protective agent and preparation method thereof

The invention provides a high-stability water-based silver-plating protective agent. Every liter of the high-stability water-based silver-plating protective agent comprises 40-100 g of octadecanethiol, 4-10 g of trimethyl mercapto phosphate, 100 mg of reduced graphene oxide, 40-100 g of an emulsifier, 10 g of a stabilizer and the balance deionized water. The high-stability water-based silver-plating protective agent adopts the stabilizer and graphene, so that the service life of the protective agent is prolonged, and the corrosion resistance and color change resistance of protected metal are improved; and the surface appearance and performance of the silver-plating layer protected by the protective agent are not affected, a potassium sulfide resistance test of electronic products can be maintained for more than 12 minutes, and the protection time is greatly prolonged.

Owner:SUZHOU HIYIE CHEM CO LTD

Method of producing a titanium-suboxide-based coating material, correspondingly produced coating material and sputter target provided there-with

InactiveUS20060005745A1Improve conductivityConductivity is not affectedPigmenting treatmentMolten spray coatingTitaniumSuboxide

A method of producing a titanium-suboxide-based coating material comprises the following steps: providing a titanium-suboxide base material; and treating the titanium-suboxide base material under oxidizing conditions for in-situ development of a finely dispersed titanium-dioxide component in the ceramic titanium-suboxide base material.

Owner:GFE METALLE & MATERIALIEN GMBH

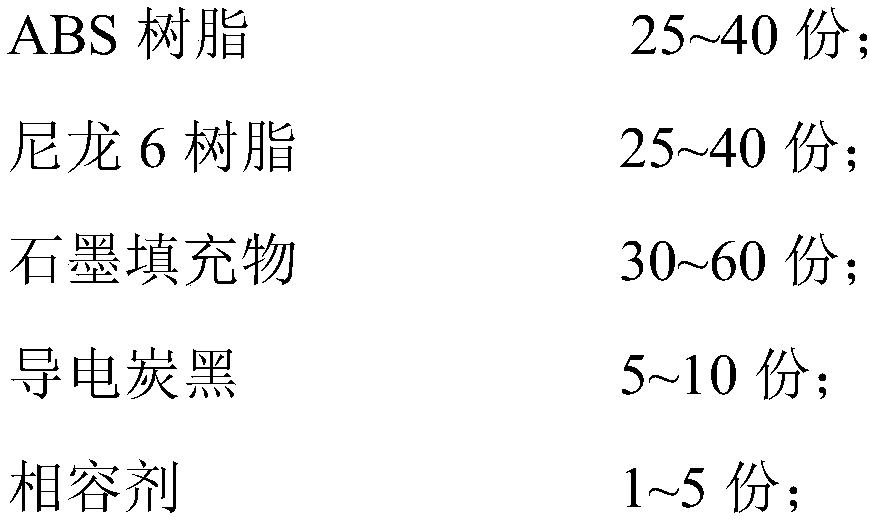

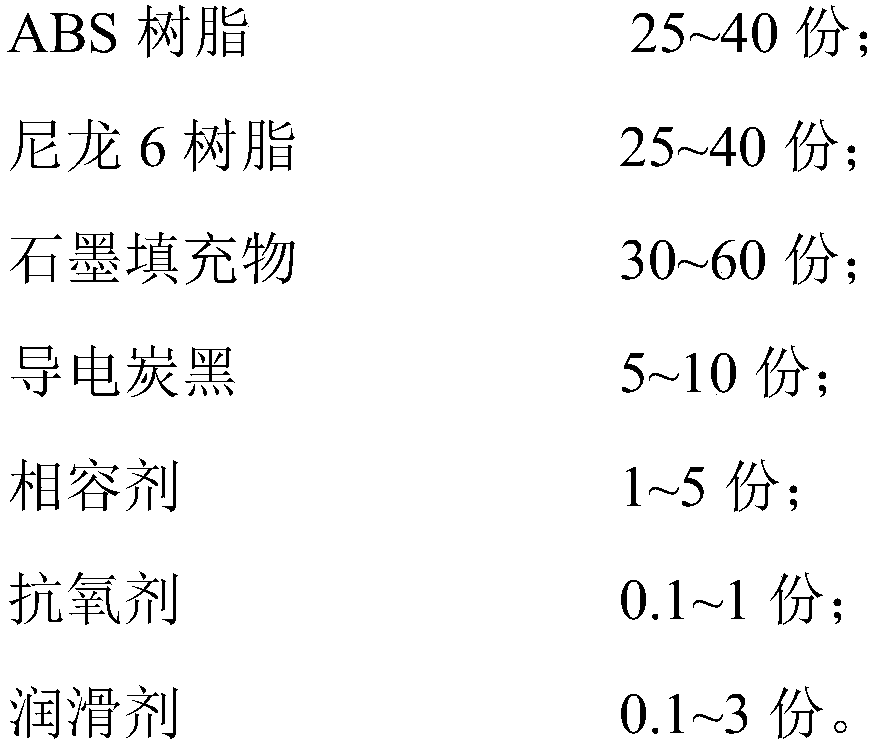

PA/ABS composite material and preparation method thereof

The invention provides a PA / ABS composite material. The PA / ABS composite material comprises the following components in parts by weight: 25-40 parts of ABS resin, 25-40 parts of nylon 6 resin, 30-60 parts of graphite fillers, 5-10 parts of conductive carbon black, 1-5 parts of a compatibilizer, 0.1-1 part of an antioxidant and 0.1-3 parts of a lubricant.

Owner:惠州市沃特新材料有限公司

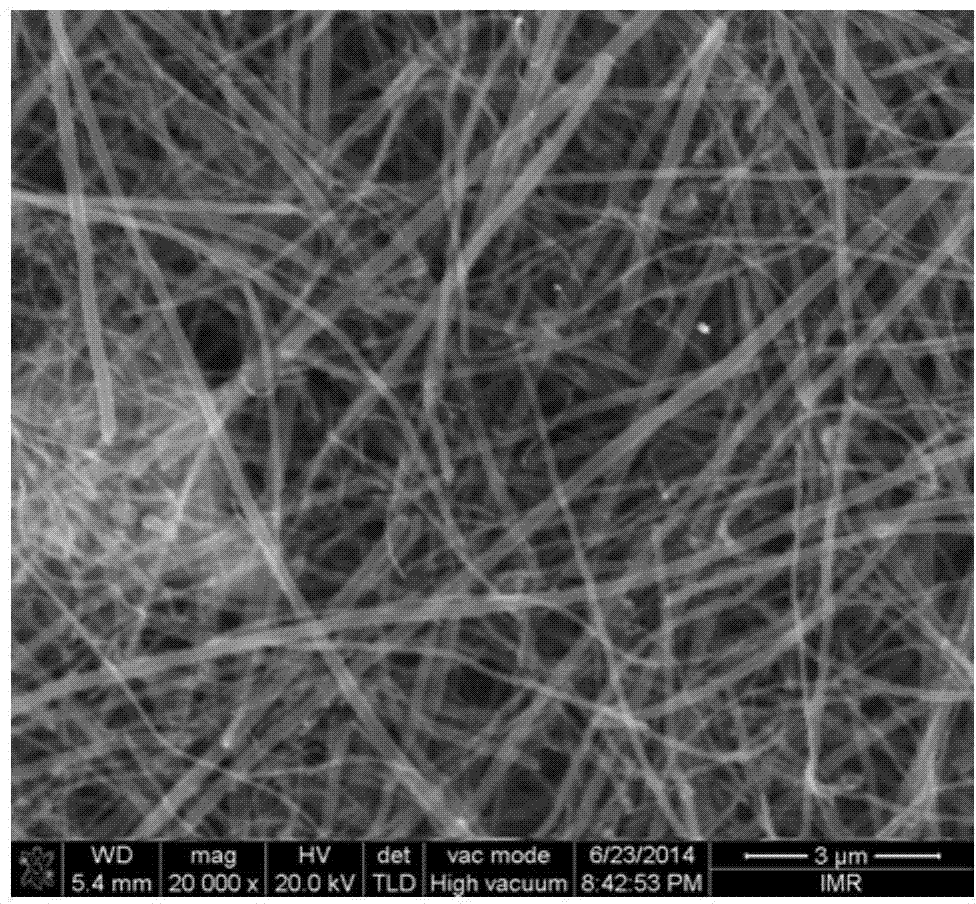

Carbon nano fiber paper and preparation method thereof

InactiveCN104499354AGuaranteed its own characteristicsNo polarizationFibreboardSynthetic cellulose/non-cellulose material pulp/paperActivated carbonSolid carbon

The invention discloses carbon nano fiber paper and a preparation method thereof. The carbon nano fiber paper disclosed by the invention is combined by carbon nano fibers by means of the Van der Waals force and the cross linking of the carbon nano fibers, and the carbon nano fibers comprise one or more of multi-wall carbon nanotubes, single-wall carbon nanotubes, solid carbon nano fibers or activated carbon fibers. The preparation process of the carbon nano fiber paper disclosed by the invention comprises the steps of dispersing, filtering, roasting and rolling. No dispersing agent is needed in the preparation process, and the carbon tubes and the carbon fibers need no functionalized treatment. The carbon nano fiber paper prepared in the invention has the advantages of large specific surface area, good electrical conductivity and high air permeability; the materials are recyclable, so that no waste is generated; and since the process is simple, mass production is liable to achieve.

Owner:武汉艾特米克超能新材料科技有限公司

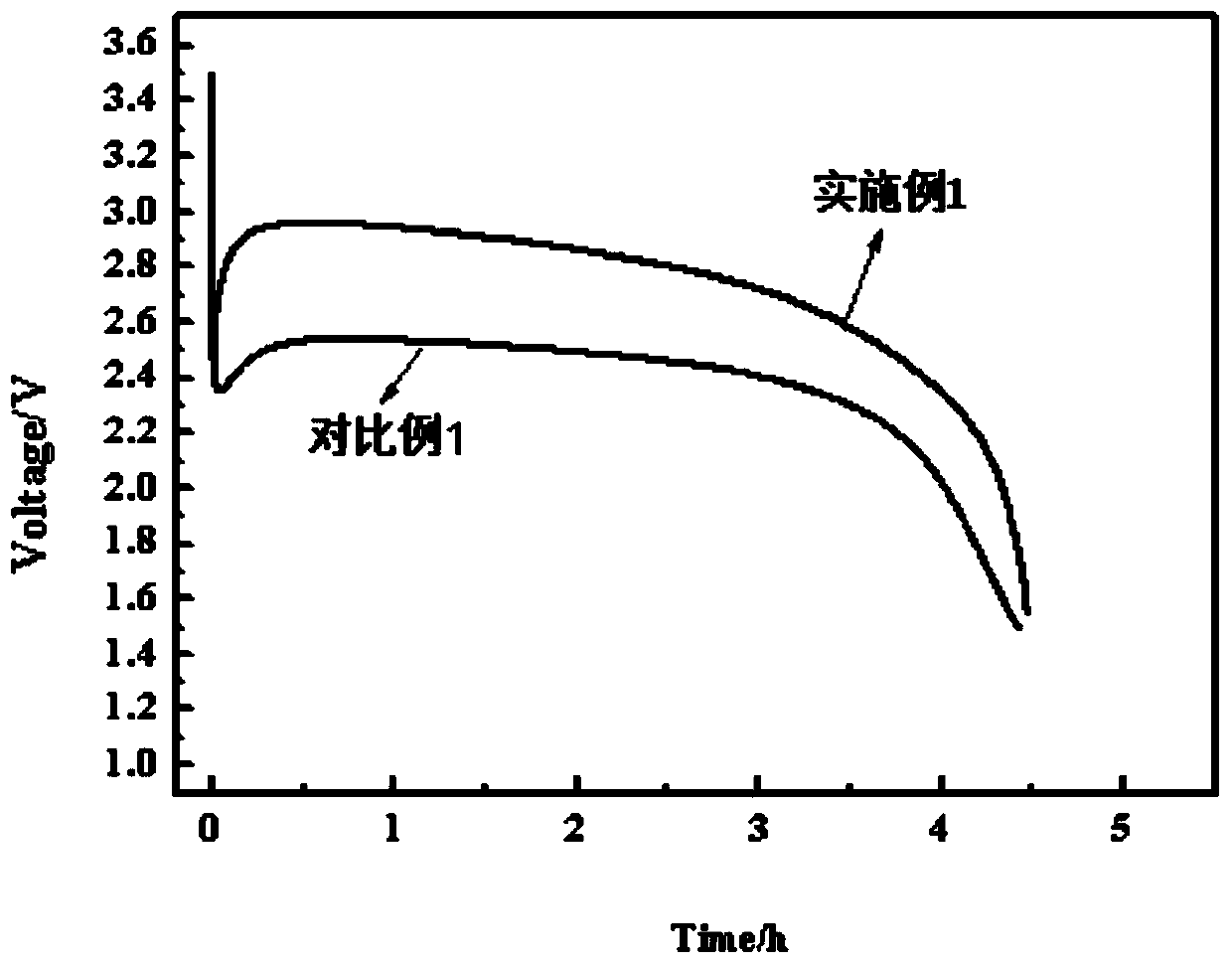

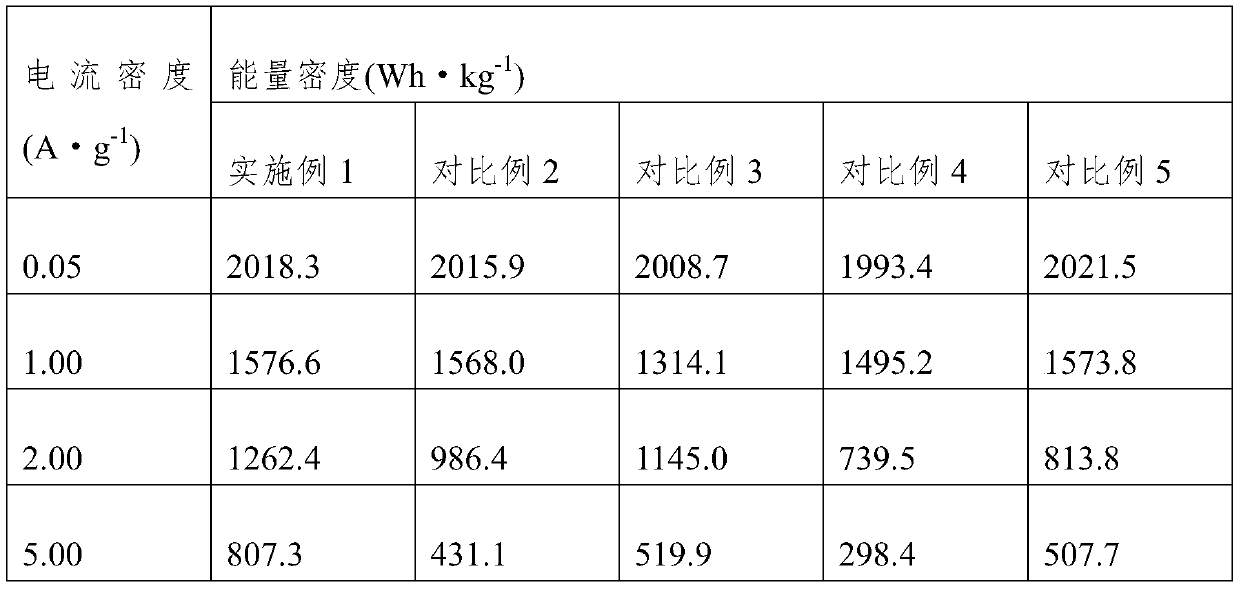

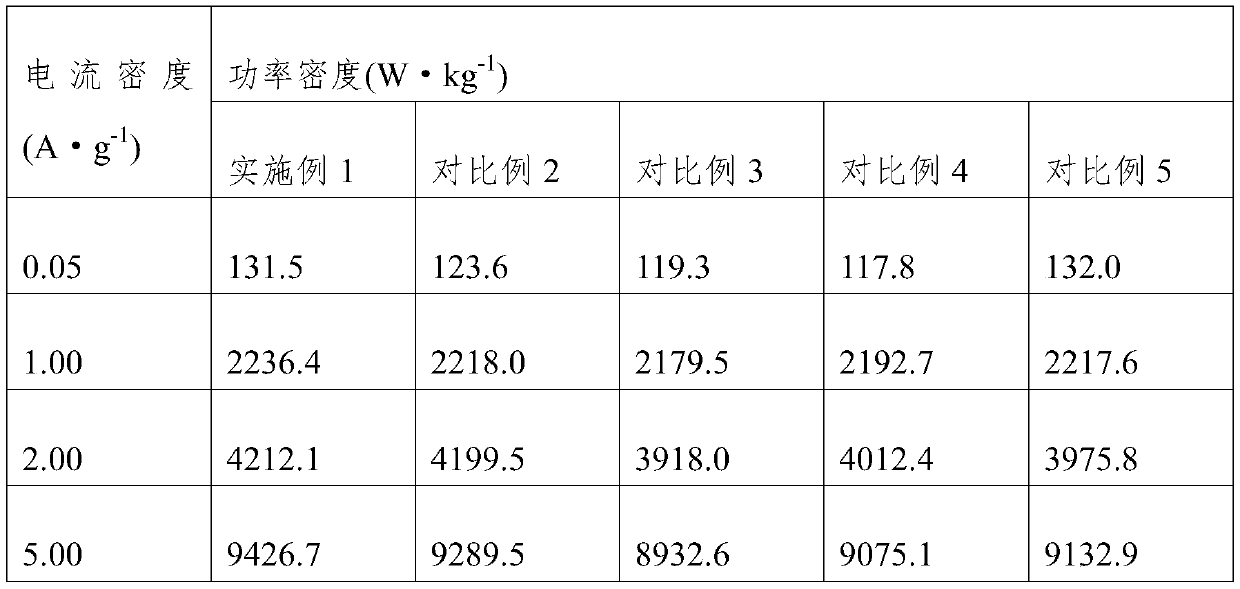

Nano-material modified carbon fluoride electrode material manufacturing method

ActiveCN110783522AImprove conductivityImprove voltage hysteresisMaterial nanotechnologyPrimary cell electrodesCarbon monofluorideModified carbon

The invention discloses a nano-material modified carbon fluoride electrode material manufacturing method. The method comprises the following steps of mixing a medium and carbon fluoride, adding a ferro-nickel alloy and mixing; adding a nano material, reacting, airing, carrying out vacuum drying, grinding, calcining in an argon atmosphere, and cooling to a room temperature; and grinding, and screening with a 100-200-mesh sieve to obtain a nano-material modified carbon fluoride electrode material. A mass ratio of the nano material to the carbon fluoride is (0.5-5):100. In the invention, a carbonfluoride material is modified by adopting the nano material, and the nano material is uniformly distributed on a surface of the carbon fluoride material so that conductivity of the carbon fluoride material is improved, problems of voltage lag and low-temperature performance of the carbon fluoride material are effectively solved, and a rate capability of a lithium carbon fluoride battery is improved.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Preparation method of ultra-fine-crystal high-toughness heat-resistant aluminum alloy lead

ActiveCN111057978AReduced service lifeReduce weightCable/conductor manufactureZirconium alloyInduction furnace

The invention relates to a preparation method of an ultra-fine-crystal high-toughness heat-resistant aluminum alloy lead. The preparation method comprises the following steps: (1) performing proportioning, wherein the aluminum alloy lead consists of the following components in parts by weight: 100 parts of industrial pure aluminum, 0.7 part of aluminum-zirconium alloy, 0.4 part of aluminum-copperalloy, 0.4 part of aluminum-erbium alloy, 0.0015 part of a refiner Al-5Ti-B, 0.06 part of a modifier Sr and 0.5 part of a refining agent hexachloroethane; (2) performing smelting: adding pure aluminuminto a coreless medium-frequency induction furnace, increasing the furnace temperature to 740 DEG C, starting ultrasonic vibration for 20 seconds when the temperature reaches 720 DEG C, adding intermediate alloy, a modifying agent and a refining agent by a bell pressing method after the metal is completely melted, wherein electromagnetic stirring is carried out during the adding process, and thenperforming refining and slagging off; and (3) casting prepared alloy liquid into ingots, then performing multi-directional forging on the alloy ingots, and performing homogenization treatment, rolling, stress removal annealing, low-temperature continuous equal channel angular processing (ECAP), precipitation strengthening, drawing and twisting.

Owner:甘肃西北之光电缆有限公司

Method for collecting semen of primates of macaque by electro stimulation

The invention provides a method for collecting semen of primates of macaque by electro stimulation, belonging to the method of animal reproduction, in particular to the method for collecting sperm of primates of macaque. In the invention, aluminium foil electrodes coated by absorbent cotton infiltrated by saline encircles around the penis of the anesthetized animal and is connected with the impulse power; the voltage begins from 0V, and stimulation is conducted for 10-15s continuously when each 10V is increased, until the voltage reaches 60V; the process is circulated for 6 to 7 times when necessary, with an interval of 20-30s between two stimulations; and the collected semen can be used for fertilization after incubation and separation. The invention can improve the success rate for collecting semen of animals, and has no pollution; the semen collected in the invention has similar index as that of the semen gained through natural mating and can be applied to external fertilization and artificial fertilization.

Owner:昆明亚灵生物科技有限公司

Conductive foam suitable for electromagnetic shielding

ActiveCN108882664AGuaranteed electromagnetic shielding performanceImprove conductivityMagnetic/electric field screeningAlloy thin filmCarbon nanotube

The invention discloses conductive foam suitable for electromagnetic shielding. The conductive foam sequentially comprises an outer protection layer, a foam layer, a first pasting layer, a metal foillayer and a second pasting layer, wherein the layers are combined to form the conductive foam, a nickel-titanium alloy thin film is formed on each of an upper surface and a lower surface of the metalfoil layer, leakage holes are formed in the foam layer and are filled with carbon nanotubes, the carbon nanotubes are porous spongy carbon nanotube block-shaped materials, first surfaces of the nickel-titanium alloy thin films are connected with the foam layer and the carbon nanotubes in the foam layer by the first pasting layer, and second surfaces of the nickel-titanium alloy thin films are connected with the second pasting layer. In the conductive foam provided by the invention, relatively excellent integral shielding performance and conductive performance can be provided for electronic equipment in a closed and narrow space with poor cooling performance.

Owner:XIAMEN BEACONING PRECISION IND CO LTD

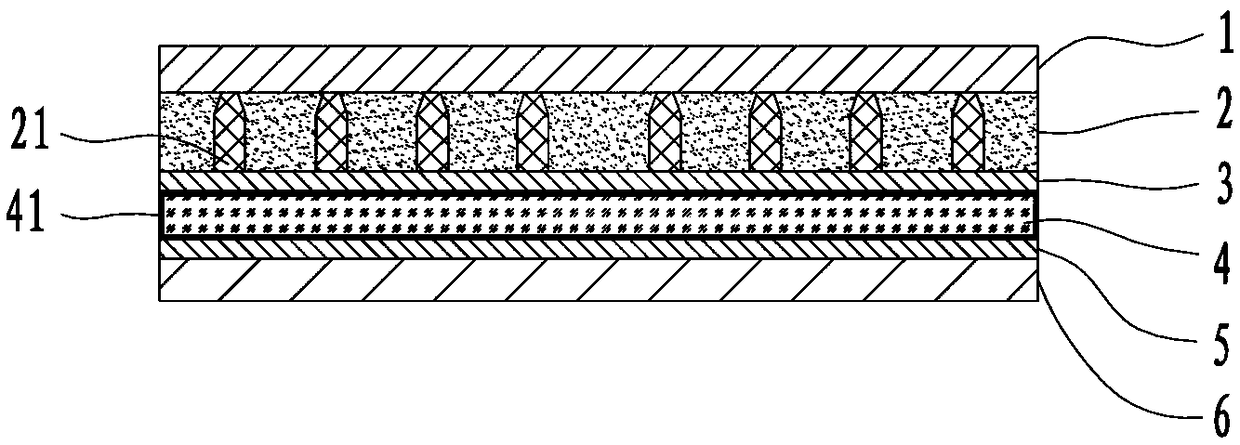

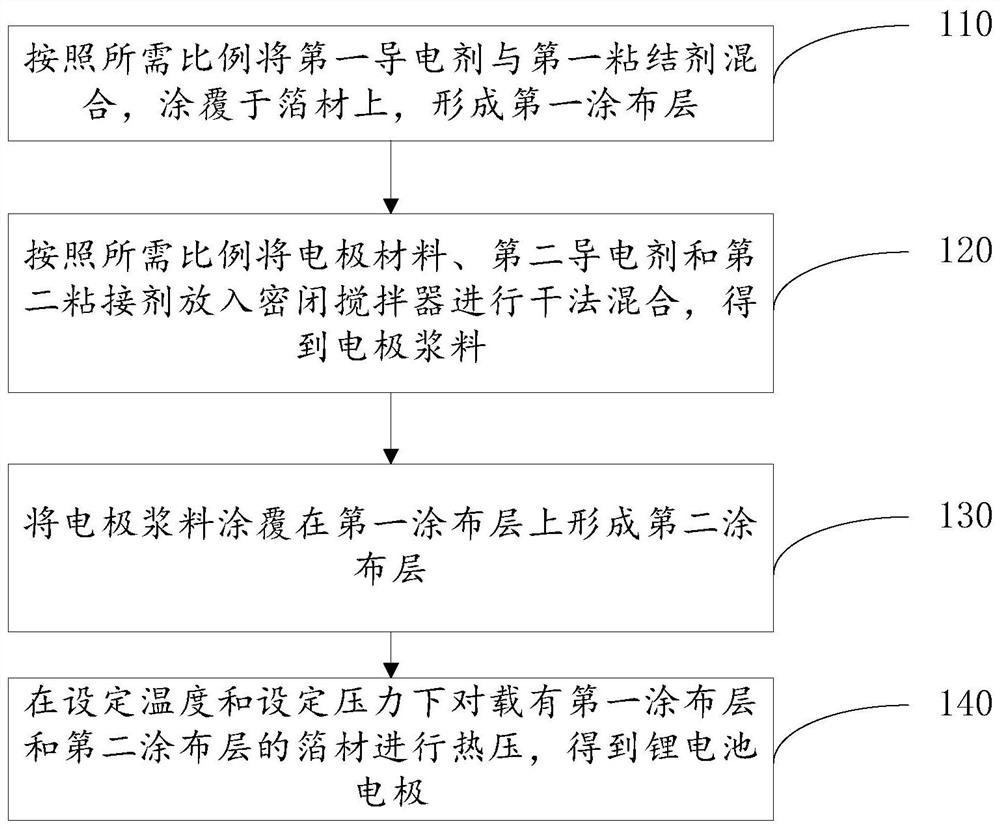

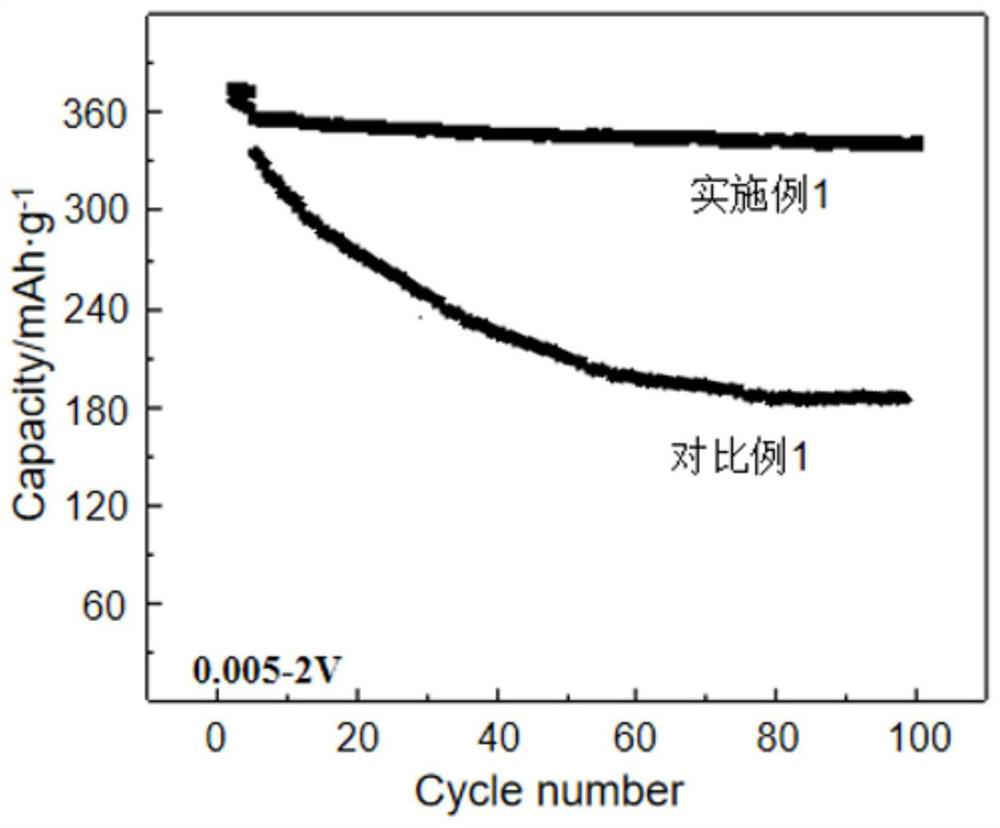

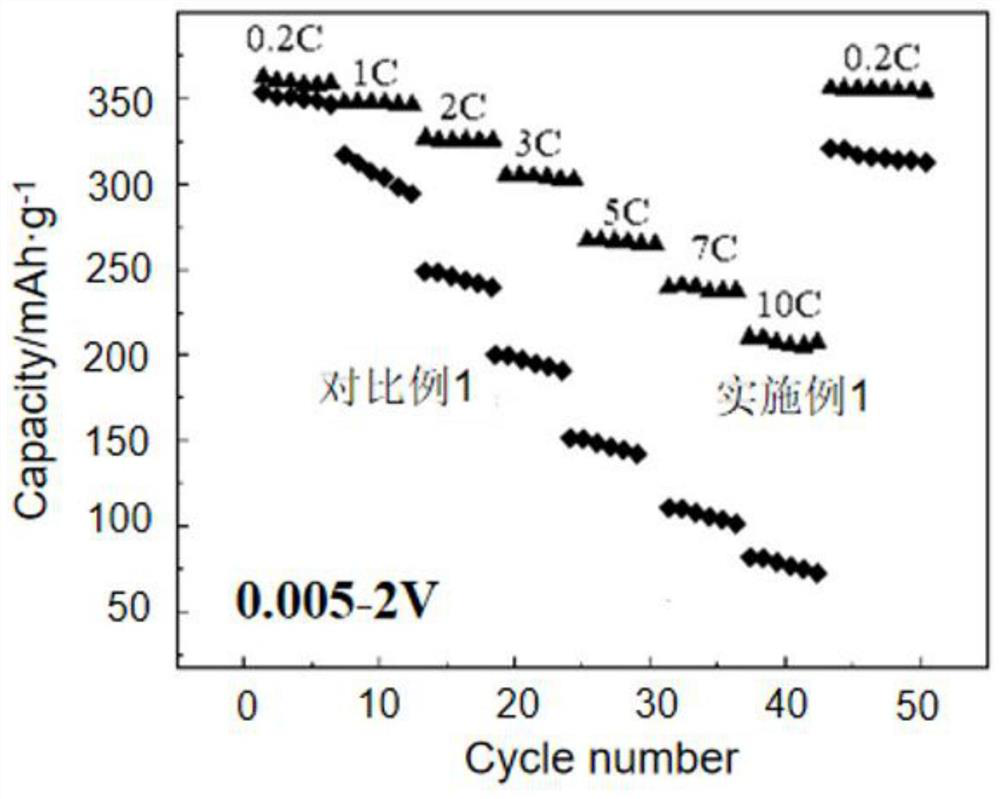

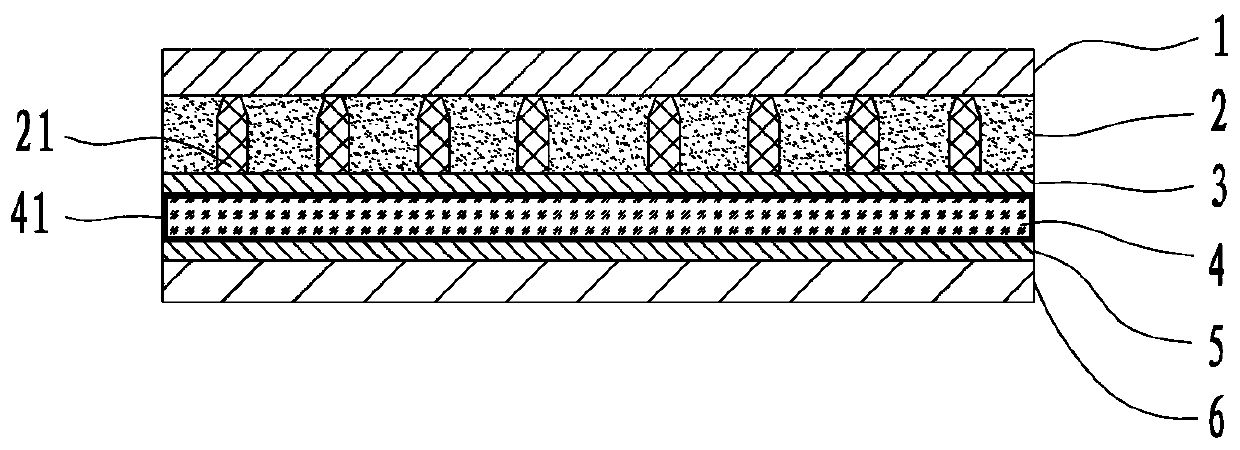

Lithium battery electrode and dry preparation method and application thereof

InactiveCN112635701ALower internal resistanceImprove cycle stabilityElectrode rolling/calenderingElectrode thermal treatmentAdhesiveDry mixing

The invention relates to a lithium battery electrode and a dry preparation method and application thereof. The dry preparation method comprises the following steps of: mixing a first conductive agent with a first binder according to a required ratio, and coating a foil with the mixture to form a first coating layer; putting the electrode material, a second conductive agent and a second adhesive into a closed stirrer according to a required ratio, and performing dry mixing to obtain electrode slurry; coating the first coating layer with the electrode slurry to form a second coating layer; and carrying out hot pressing on the foil loaded with the first coating layer and the second coating layer at a set temperature and a set pressure to obtain the lithium battery electrode.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

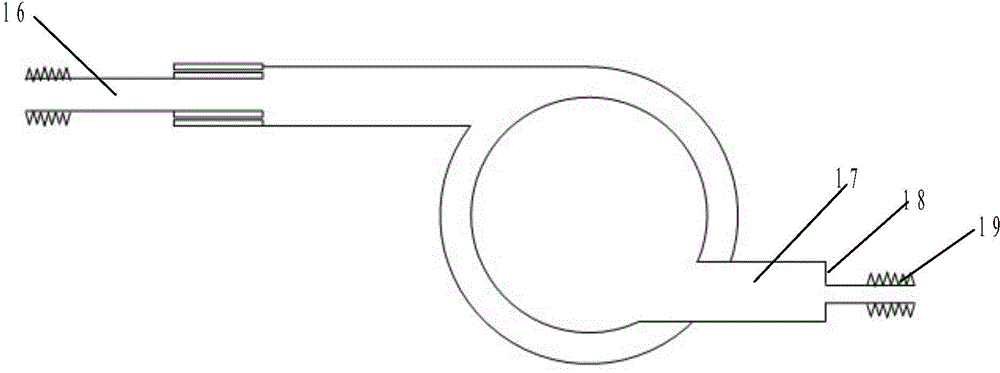

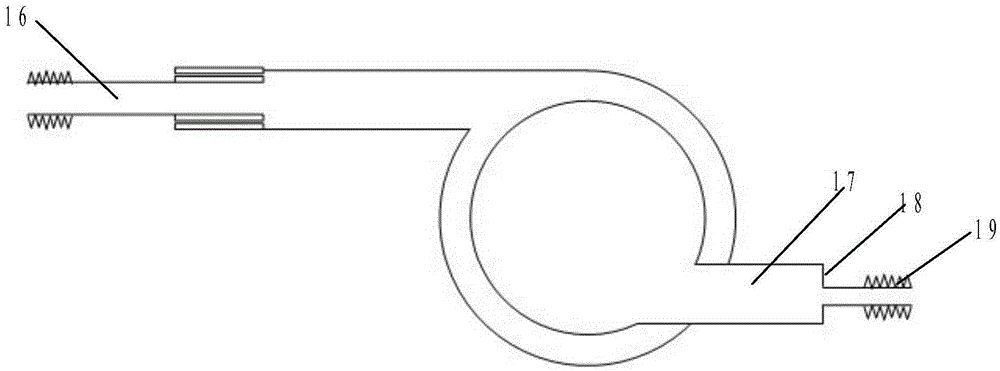

Washing device

ActiveCN104014502AEasy to operateDoes not change the molecular structureCleaning using liquidsUniversal jointHigh pressure

The invention discloses a washing device. The washing device comprises a gun body, a first high-temperature steam pipe, a valve device and an extraction liquid pipe, wherein the gun body comprises a stock and gun barrel segments communicated with the stock, the gun barrel segments include the first gun barrel segment, the second gun barrel segment and the third gun barrel segment, one end of the first gun barrel segment is communicated with one end of the stock, the other end of the first gun barrel segment is communicated with one end of the second gun barrel segment through a universal joint with a hollow cavity, the second gun barrel segment is sleeved with the third gun barrel segment, one end of the third gun barrel segment is connected with the universal joint, an annular space is formed by the end of the third gun barrel segment and the universal joint, and the other end of the third gun barrel segment extends to the front side of the other end of the second gun barrel segment to form a diffusion space; the first high-temperature steam pipe is arranged in the gun body, one end of the first high-temperature steam pipe is communicated with one end of the universal joint, and the other end of the first high-temperature steam pipe extends out of the other end of the stock to be communicated with a high-temperature high-pressure steam generation device; the valve device is arranged between the stock and the first gun barrel segment and used for connecting and disconnecting the first high-temperature steam pipe; the extraction liquid pipe enters the first gun barrel segment and is communicated with the first high-temperature steam pipe and the universal joint.

Owner:ZHEJIANG HELI HYDROGEN ENERGY TECH CO LTD

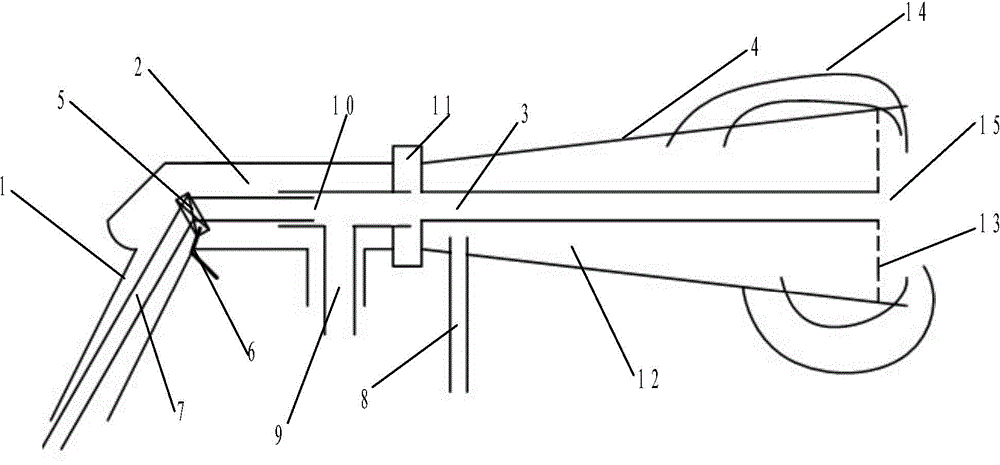

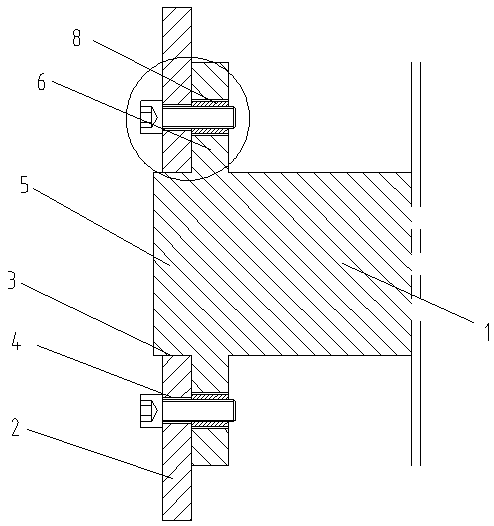

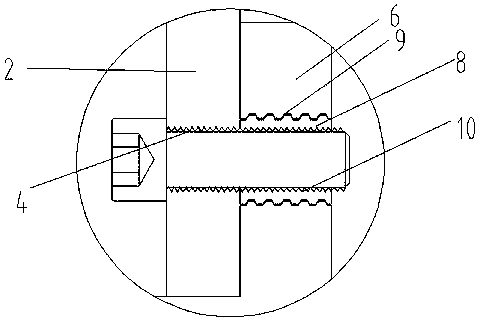

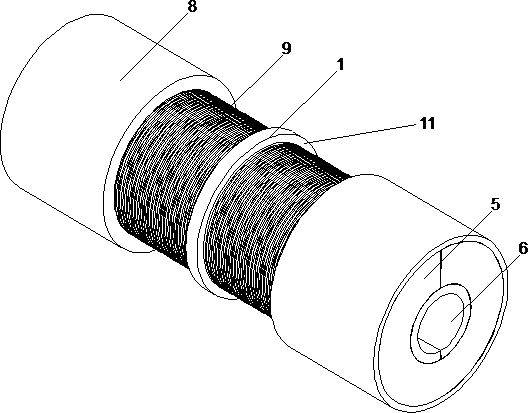

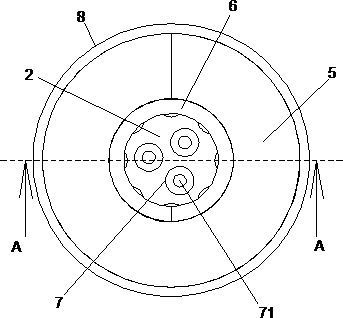

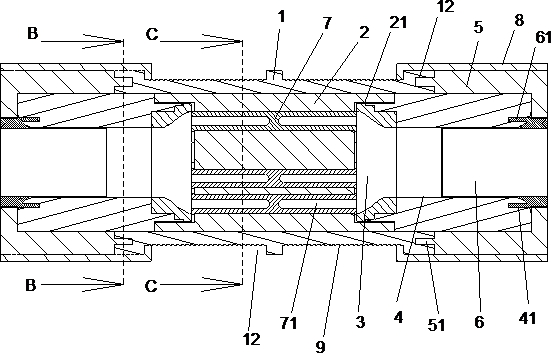

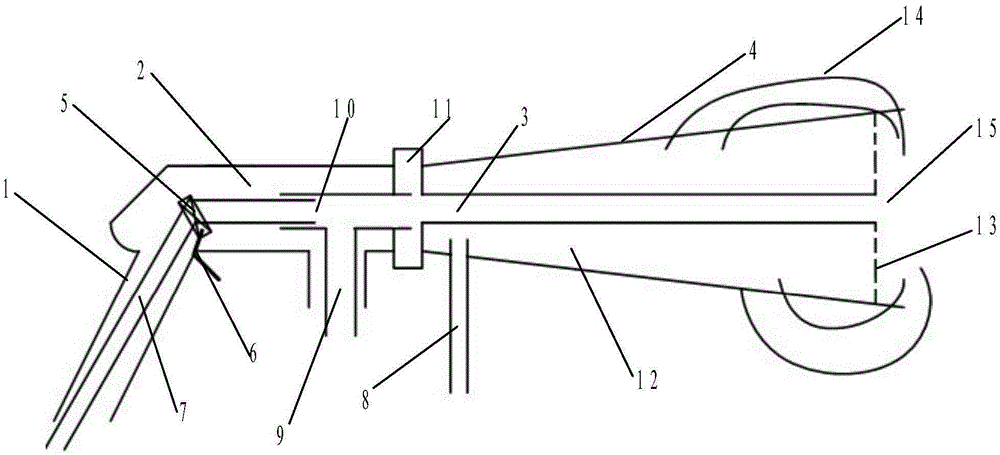

Welding wheel mounting mechanism of narrow lap seam welder

InactiveCN108581157AConductivity is not affectedGuaranteed stabilityWelding with roller electrodesEngineeringFlange

The invention discloses a welding wheel mounting mechanism of a narrow lap seam welder. The mechanism comprises a mandrel and a welding wheel body which is installed on the mandrel; the wheel body isprovided with a central shaft hole, and a plurality of fixed thread holes are distributed in the circumferential direction of the disk surface of the welding wheel body; the mandrel comprises a shafthead and a mounting flange surface, and a plurality of fixing holes are equally distributed in a circumferential direction of the mounting flange surface; an insert is mounted in the fixing hole, andthe inner wall of the fixing hole is provided with trapezoidal threads, the outer wall of the insert is provided with matched trapezoidal threads, and the inner wall of the insert is provided with toothed threads; the welding wheel body is mounted on the shaft head of the mandrel, and is screwed into the insert through the fixing threaded holes by bolts, so as to achieve the bonding and fixing ofthe welding wheel body and the positioned mounting flange surface.

Owner:JIANGSU YONGJIN METAL TECHNOLOGY CO LTD

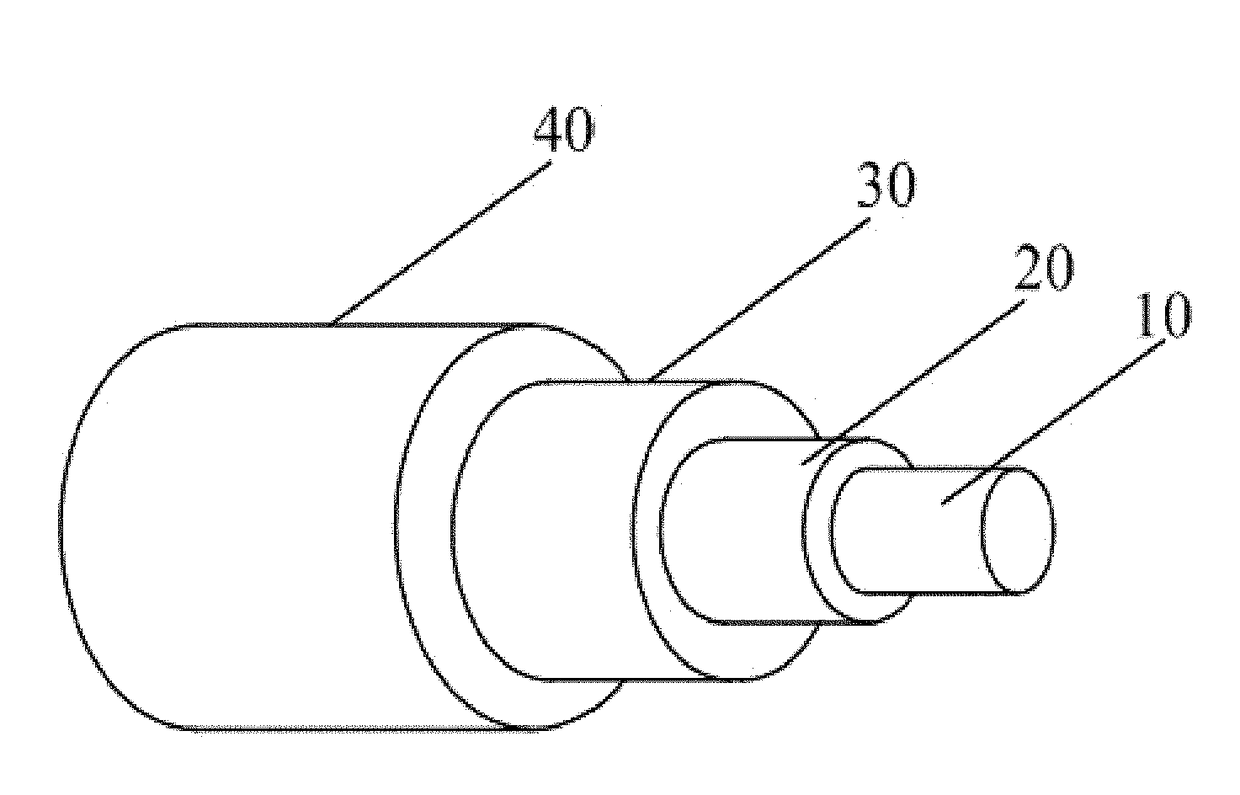

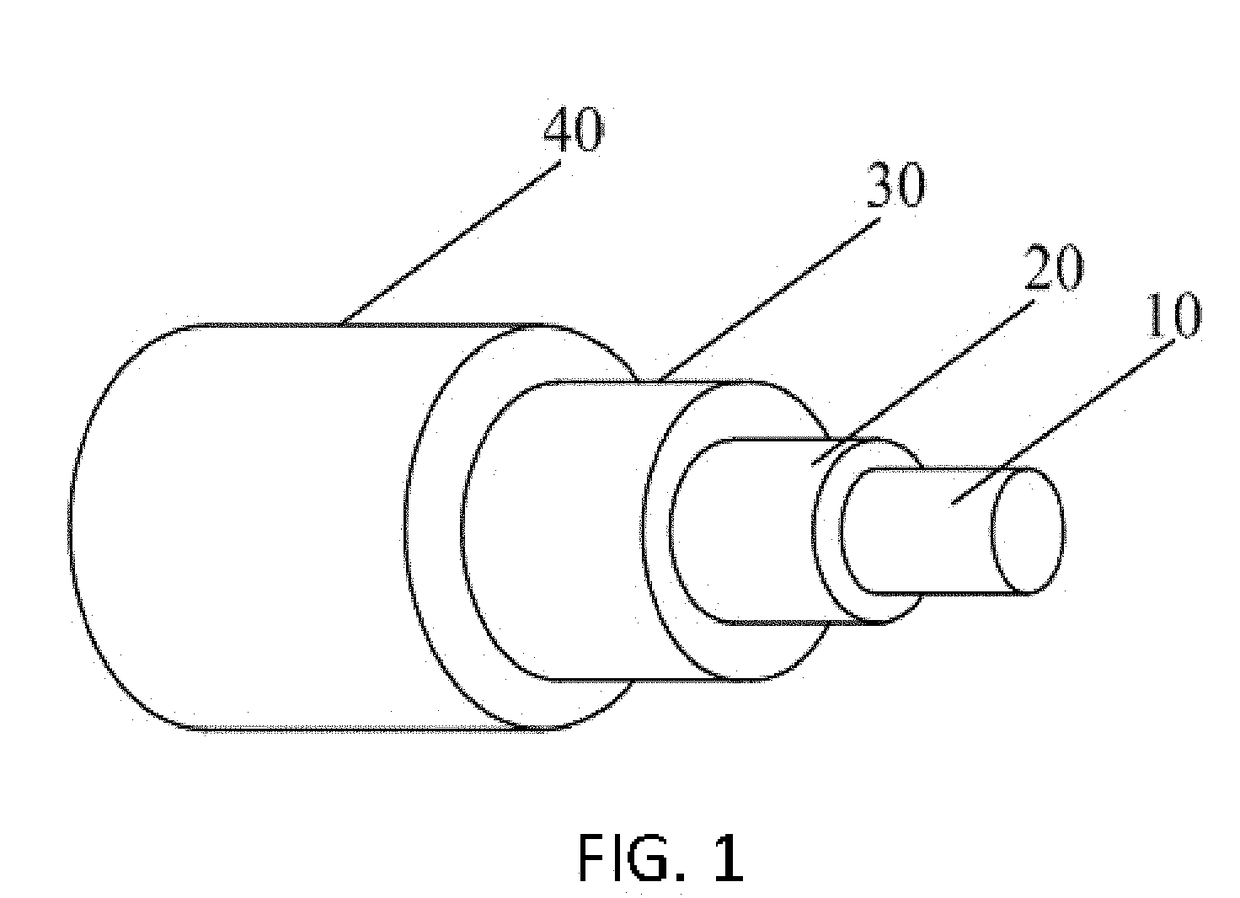

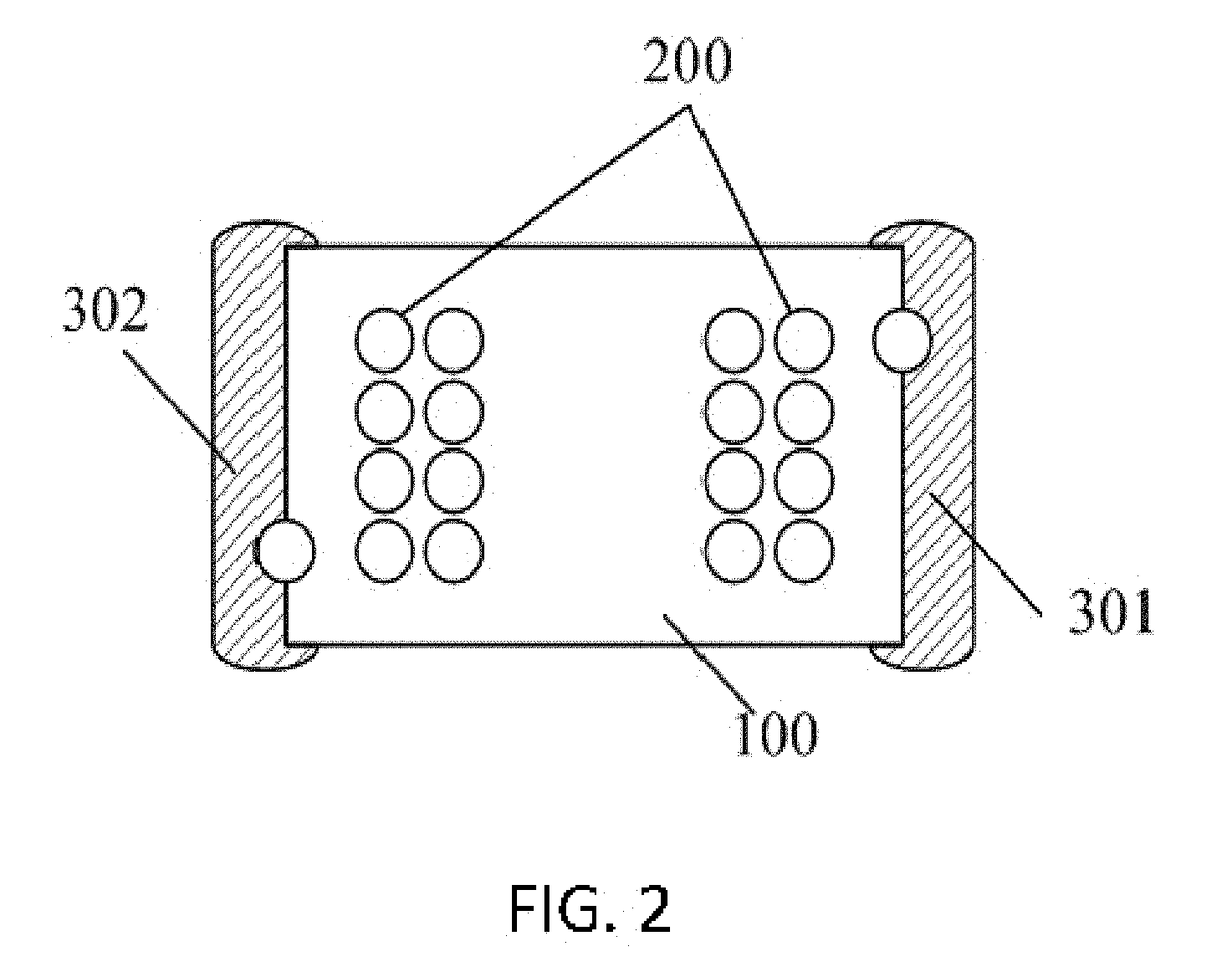

Composite wire, method for preparing same, and method for preparing power inductor

ActiveUS20180137950A1Not easily fall offGood weather resistanceLiquid applicationApparatus for heat treatmentInsulation layerWeather resistance

A composite wire includes a metal inner core, an easily-passivated metal layer wrapping a surface of the metal inner core, and a self-adhesive resin layer wrapping a surface of the easily-passivated metal layer. An insulation layer of the composite wire is a metal passivation layer that is formed by the easily-passivated metal layer obtained after sintering treatment and oxidation. The preparation method is used for manufacturing the composite wire. The method for preparing a power inductor is used for preparing a new type of power inductor including the composite wire. The composite wire is high-temperature resistant and is easily wound. During winding, the easily-passivated metal layer is unlikely to fall off, thereby ensuring that the insulation layer formed by passivation of the easily-passivated metal layer has desirable weather resistance and voltage resistance.

Owner:SHENZHEN SUNLORD ELECTRONICS

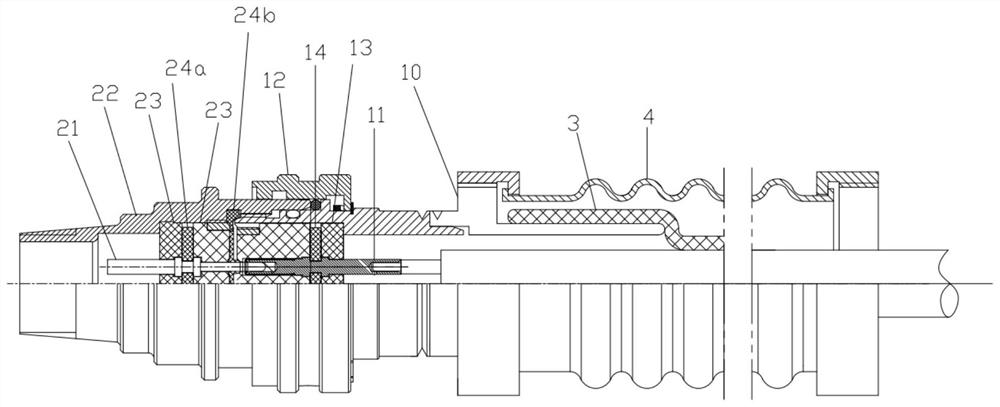

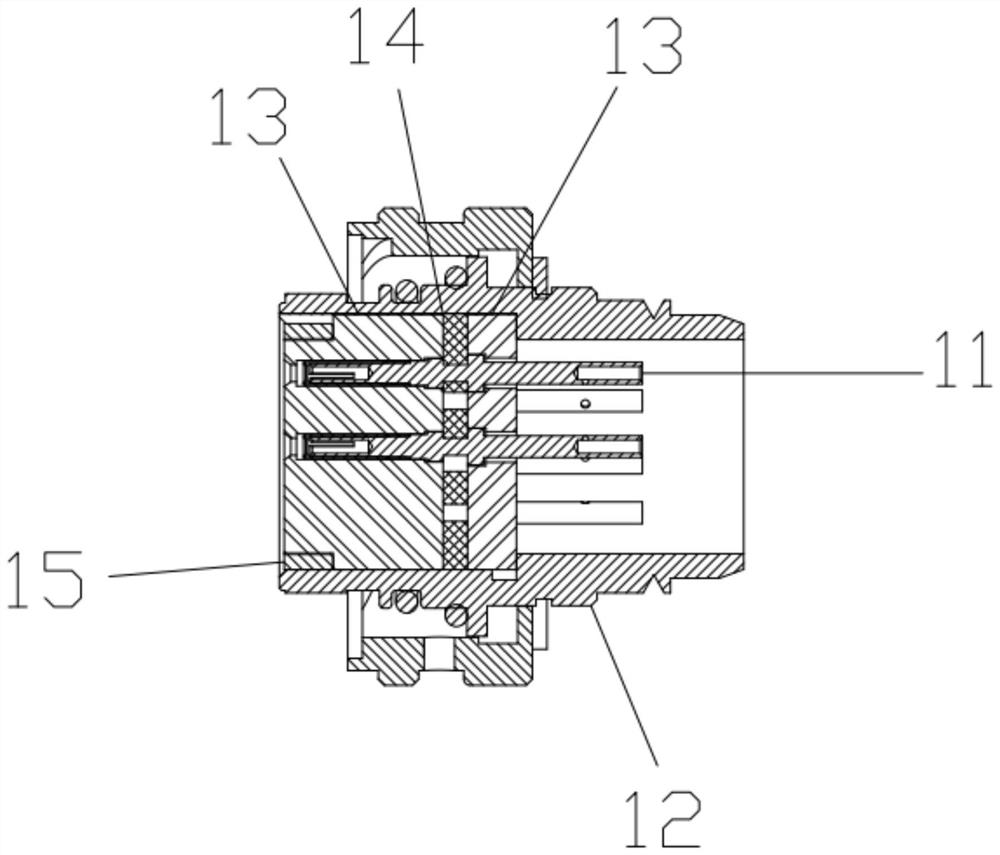

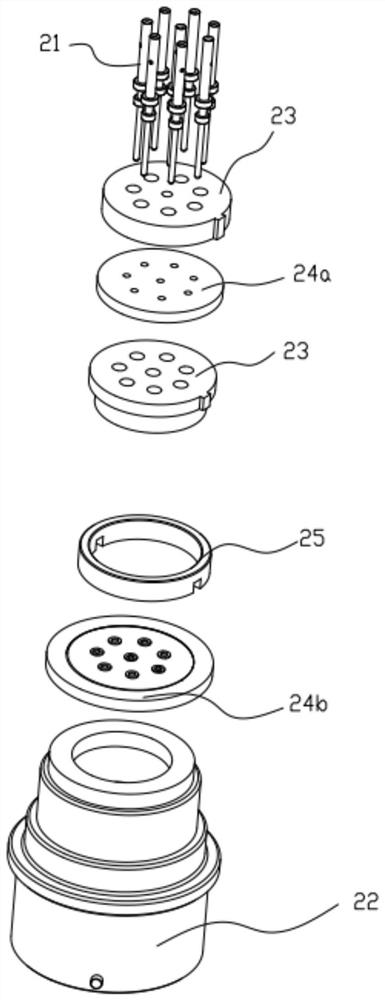

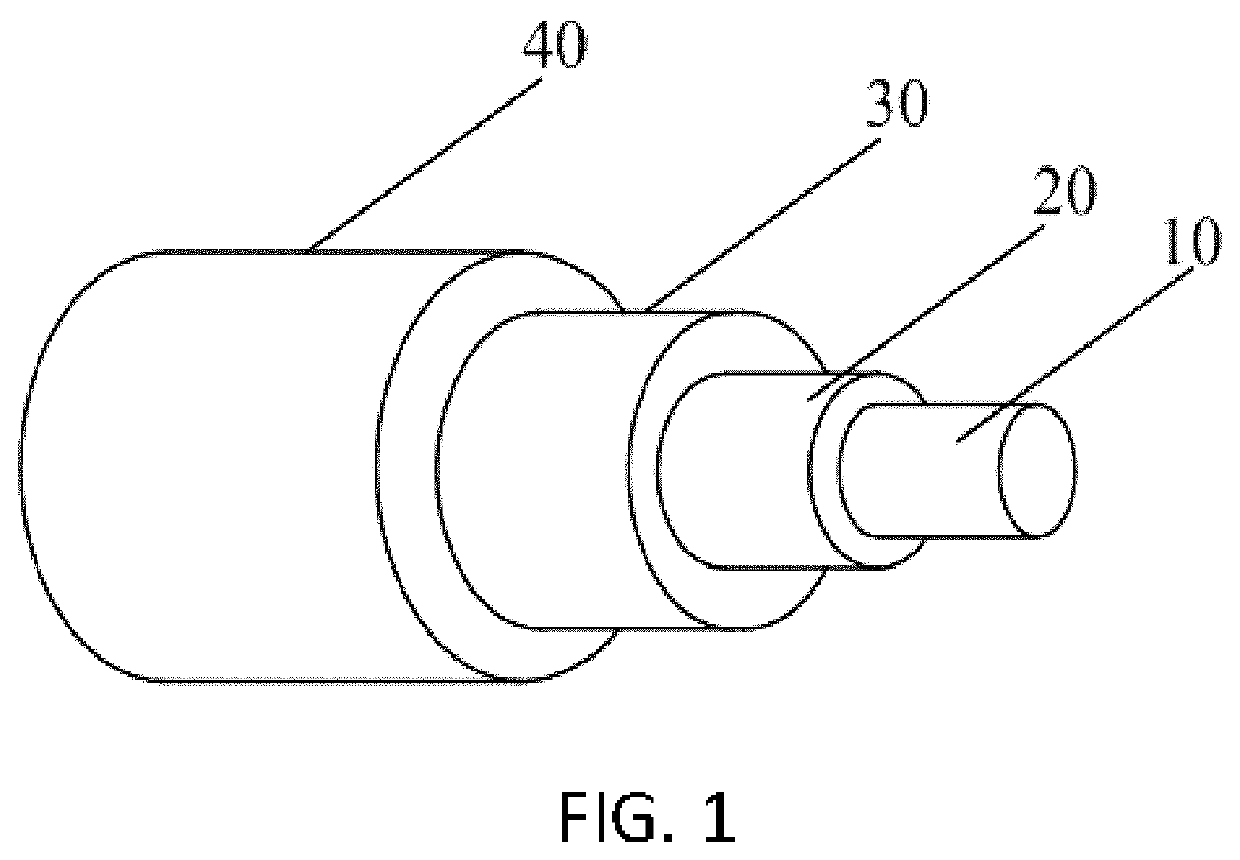

a cable connector

ActiveCN109378652BCompact connectionEasy to switch installationRelieving strain on wire connectionContact member assembly/disassemblyHeat-shrinkable sleeveStructural engineering

The invention provides a cable connector and an assembling method thereof. The cable connector mainly comprises a plug connected to a cable and a socket connected with the plug, wherein the plug and the cable are connected through an adapter; the adapter matches and installs different types of plug and cable so as to achieve a tight plug and cable connection structure, and a user can convenientlyswitch the different types of plug and cable. The manufacturing method of the cable connector provided by the invention mainly comprises cleaning, installation and potting, wherein a gel potting curing method enhances the connection stability and airtightness between the cable and the connector, and while reducing the connection failures between the connector plug and the socket, can firmly connect the cable to the plug and the socket to prevent a unsmooth connection at the joint of the cable and the plug or socket. The cable can be sleeved with a heat shrinkable sleeve and a bellows for further ensuring the airtightness of the cable connector and protecting the cable and the adapter.

Owner:浙江汇核核电技术有限公司

Process for producing green passivation coating of cadmium-plated workpiece

ActiveCN102912337BUniform appearanceStrong resistance to salt spray corrosionMetallic material coating processesHeat stabilitySilicon

The invention discloses a process for producing a green passivation coating of a cadmium-plated workpiece. The process is characterized by comprising steps of performing passivation, color fixing, silicon sealing and solidification for the cadmium-plated workpiece. The process has the advantages that appearance and tone fluctuation during production is reduced, the uniform and consistent appearance of the passivation coating is guaranteed, and the produced green passivation coating is high in the salt spray corrosion resistance and good in heat stability; and after being subjected to silicon sealing, the coating is high in abrasion resistance, the conductivity of the passivation coating is unaffected, and the appearance of the passivation coating is unchanged.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

Absorbing core making technology

InactiveCN106963557AGuaranteed absorptionAvoid breakingAbsorbent padsBaby linensProduction lineEngineering

The invention relates to the field of sanitary product manufacturing, and provides an absorbing core making technology. The technology comprises the steps that lower layer toilet tissue is laid on a conveying belt of a production line, high polymer fixing glue is sprayed to the upper surface of the lower layer toilet tissue through a gluing mechanism, high polymer materials are scattered on the gluing surface of the lower layer toilet tissue through a discharging mechanism to construct a first high polymer material layer, polymer fiber produced online is attached to the first high polymer material layer through an online polymer production mechanism to construct a polymer fiber layer, the high polymer fixing glue is sprayed to the polymer fiber layer through the gluing mechanism, the high polymer materials are scattered to the gluing surface of the polymer fiber layer through the discharging mechanism to construct a second high polymer material layer, and finally upper layer toilet tissue is attached to the second high polymer material layer to make the absorbing core. Accordingly, the problem that an existing absorbing core is too thick or the absorption effect is poor when the absorbing core is produced to be ultrathin is solved.

Owner:QUANZHOU HANWEI MACHINERY MFG

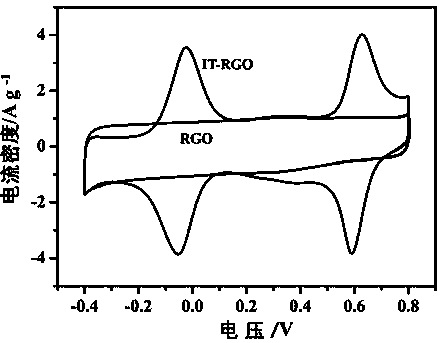

Preparation method and application of indanthrene functionalized graphene three-dimensional network structure composite material

InactiveCN110783113AFully contactedGive full play to pseudocapacitive performanceHybrid capacitor electrodesElectrolytic agentCapacitance

The invention discloses a preparation method of an indanthrene functionalized graphene three-dimensional network structure composite material. The method comprises steps of dispersing graphite oxide into DMF (Dimethyl Formamide), stirring, carrying out ultrasonic treatment, adding mixture into shinthrene solution, stirring again, and carrying out ultrasonic treatment; transferring the mixed solution into a reaction kettle, and carrying out a reaction for 620-720 min at a temperature of 160-180 DEG C; soaking a reaction product with secondary water for multiple times till the solution becomes colorless and transparent; and lastly performing freeze-drying to obtain the product. The method is advantaged in that physical characterization shows that a composite material has a high specific surface area and rich hierarchical porous structures which are communicated with one another, and indanthrene molecules are successfully adsorbed on a surface of graphene. An electrochemical performance test shows that the material has excellent electrochemical capacitance performance and rate capability, more importantly, a potential window of the material can reach 1.2V in sulfuric acid electrolyte / solution, and the material has a good application prospect as an electrode material of a supercapacitor.

Owner:NORTHWEST NORMAL UNIVERSITY

A cable connector structure

ActiveCN113594727BThere will be no loosening, stretching and falling offImprove waterproof performanceRelieving strain on wire connectionCouplings bases/casesStructural engineeringElectric cables

Owner:江苏众联祥博新能源科技有限公司

Application of 3,6-dioxa-1,8-octanediaminetetraacetic acid derivatives and osp treatment solution

ActiveCN107148156BEfficient captureAvoid adsorptionNon-metallic protective coating applicationAcetic acidTinning

The invention relates to an application of a compound with a structure as shown in the formula I in an OSP processing liquid of a printed circuit board. The OSP processing liquid adopts the compound with the structure as shown in the formula I, so that the film thickness on a gold surface can be remarkably reduced, and copper gold selectivity of the OSP is improved; and meanwhile, the high temperature resistance and tinning rate of the OSP film of a PCB test board can be improved, the weldability of the PCB is improved, and the processing capacity of the OSP technology is effectively improved.

Owner:GUANGDONG GUANGHUA SCI TECH +1

Method for preparing a composite wire and a power inductor

ActiveUS10867748B2Good weather resistanceEasily woundLiquid applicationApparatus for heat treatmentWire rodEngineering

Owner:SHENZHEN SUNLORD ELECTRONICS

Nanodiamondene-containing electricity-conducting and heat-conducting electronic paste and preparation method thereof

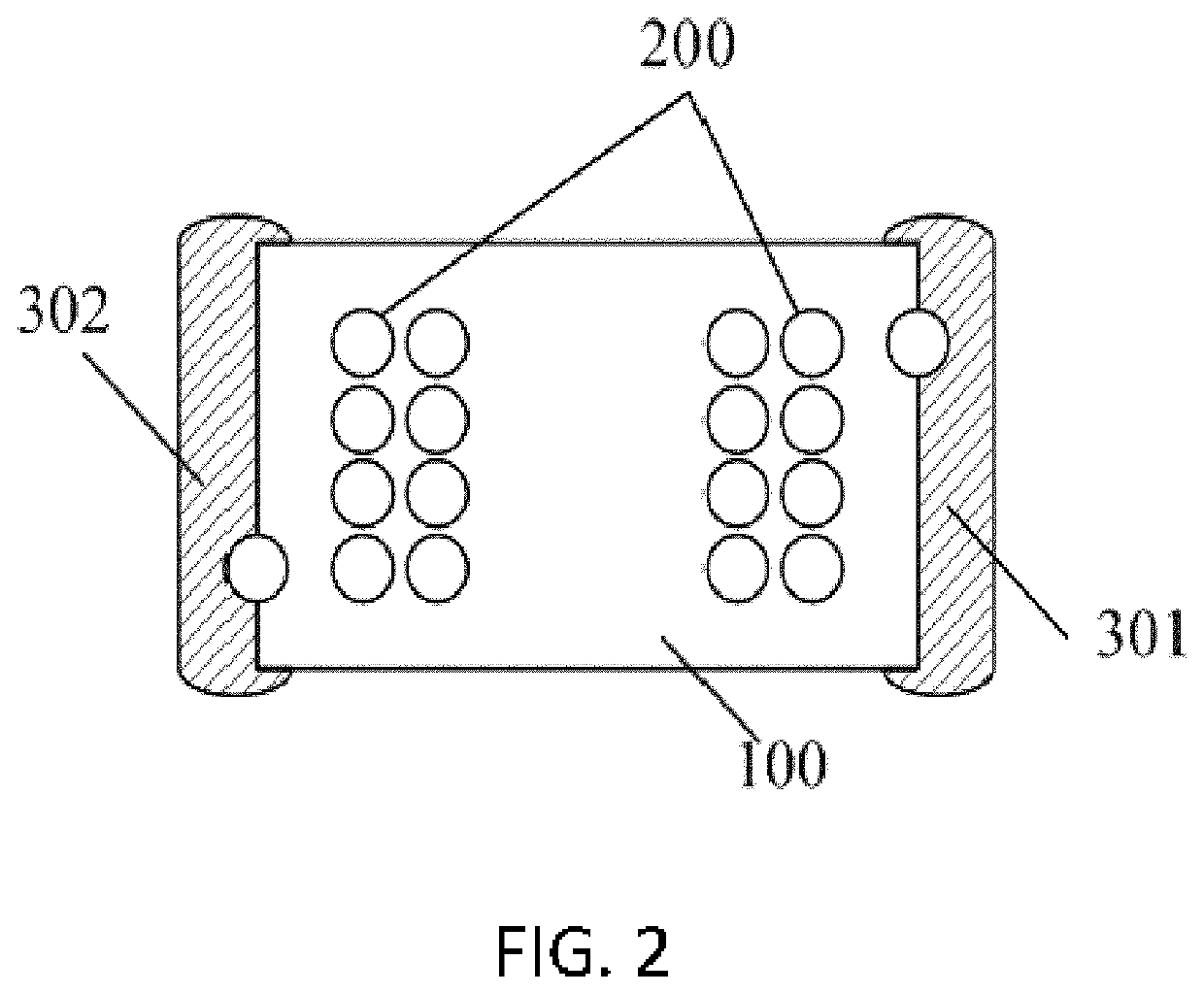

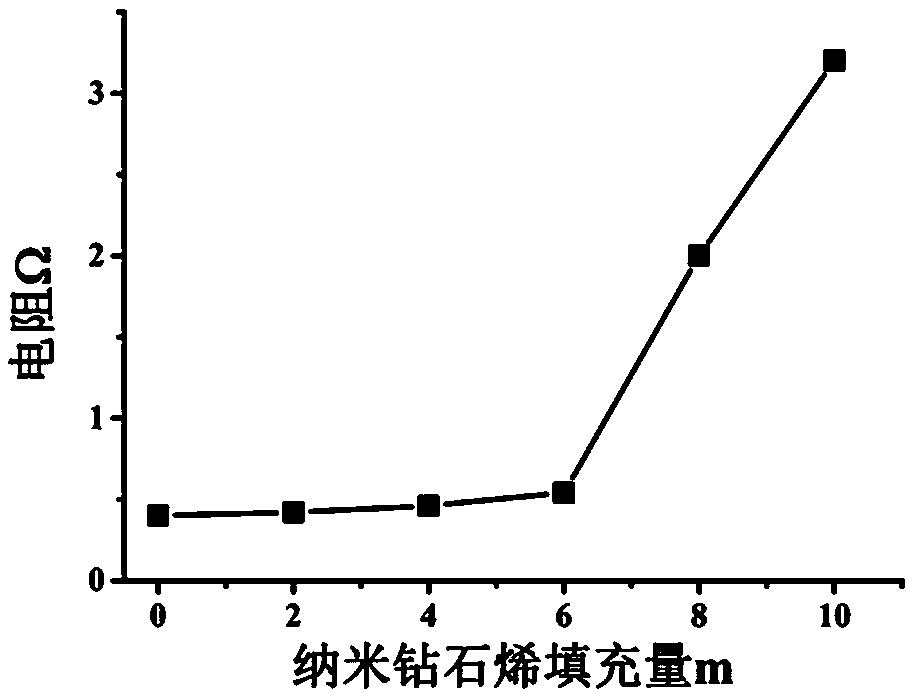

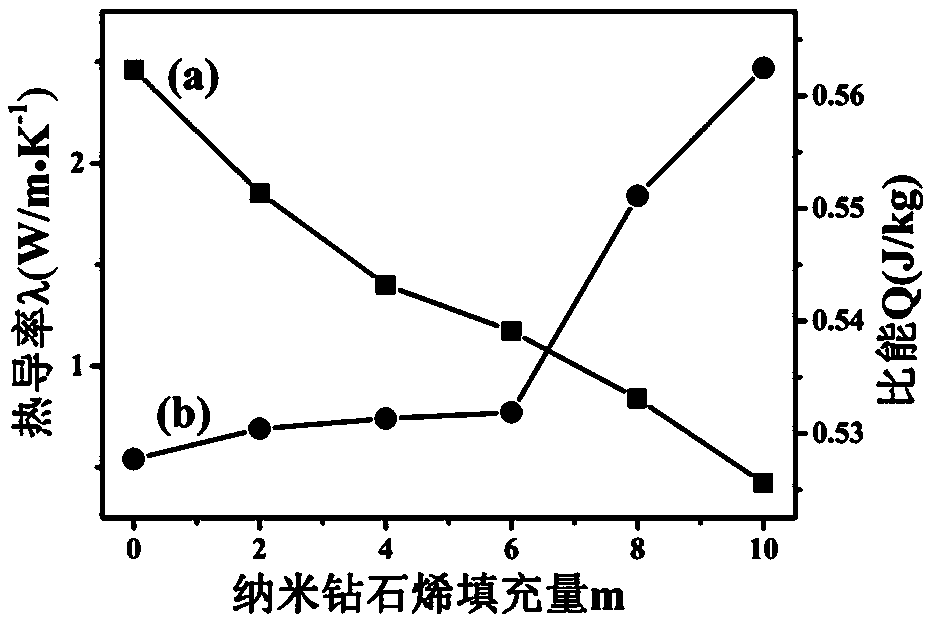

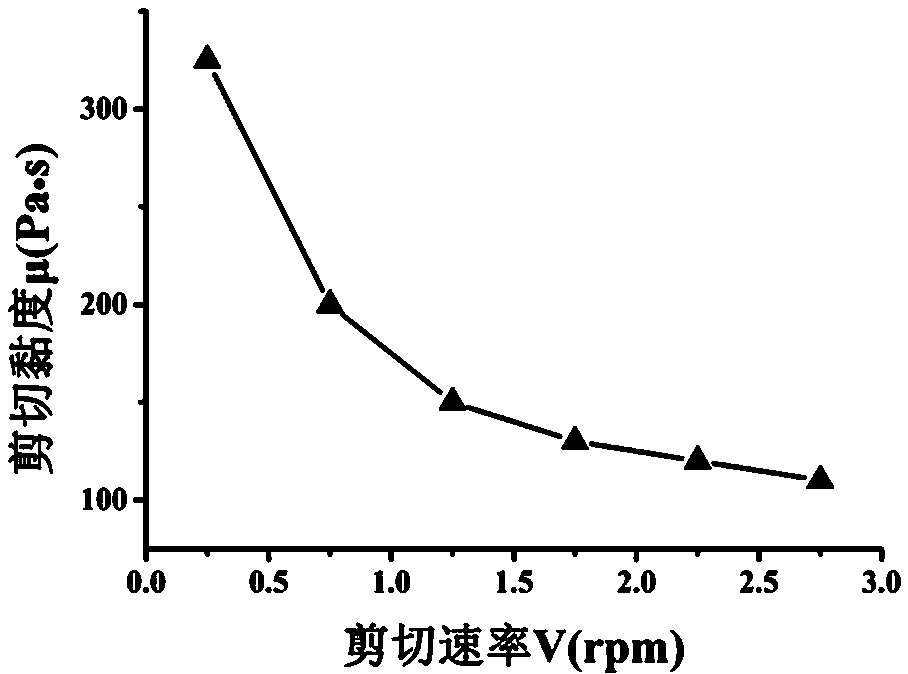

ActiveCN108565042AImprove thermal conductivityConductivity is not affectedNon-conductive material with dispersed conductive materialHeat-exchange elementsElectricityAtmospheric air

The invention discloses a nanodiamondene-containing electricity-conducting and heat-conducting electronic paste. The nanodiamondene-containing electricity-conducting and heat-conducting electronic paste is prepared by adding glass powder into a paste matrix, wherein the paste matrix comprises silvered copper powder and nanodiamondene; when the using amount of the silvered copper powder is 70-80g,the using amount of the nanodiamondene is 1-10g; the addition amount of the glass powder is 5-10% in terms of the weight of the paste matrix. The surface-silvered copper powder and the nanodiamondeneare used as functional phases; the surface-silvered copper powder can prevent the copper powder from directly contacting the atmosphere so as to prevent the copper powder from being oxidized, the electrical conductivity thereof is not affected and the electrical conductivity is good; the used nanodiamondene has high hardness, strong wear resistance and good heat conduction, so that the heat conductivity of the electronic paste can be effectively improved.

Owner:河南省豫星碳材有限公司

a cleaning device

ActiveCN104014502BEasy to operateDoes not change the molecular structureCleaning using liquidsUniversal jointBiochemical engineering

Owner:ZHEJIANG HELI HYDROGEN ENERGY TECH CO LTD

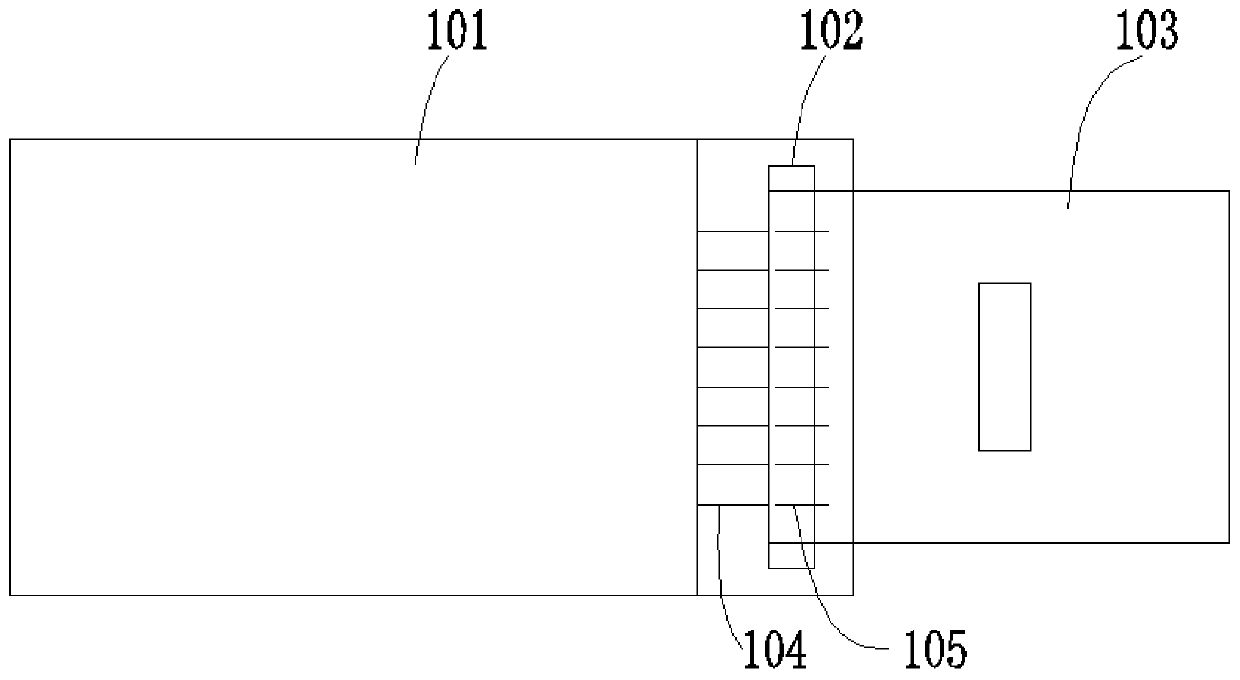

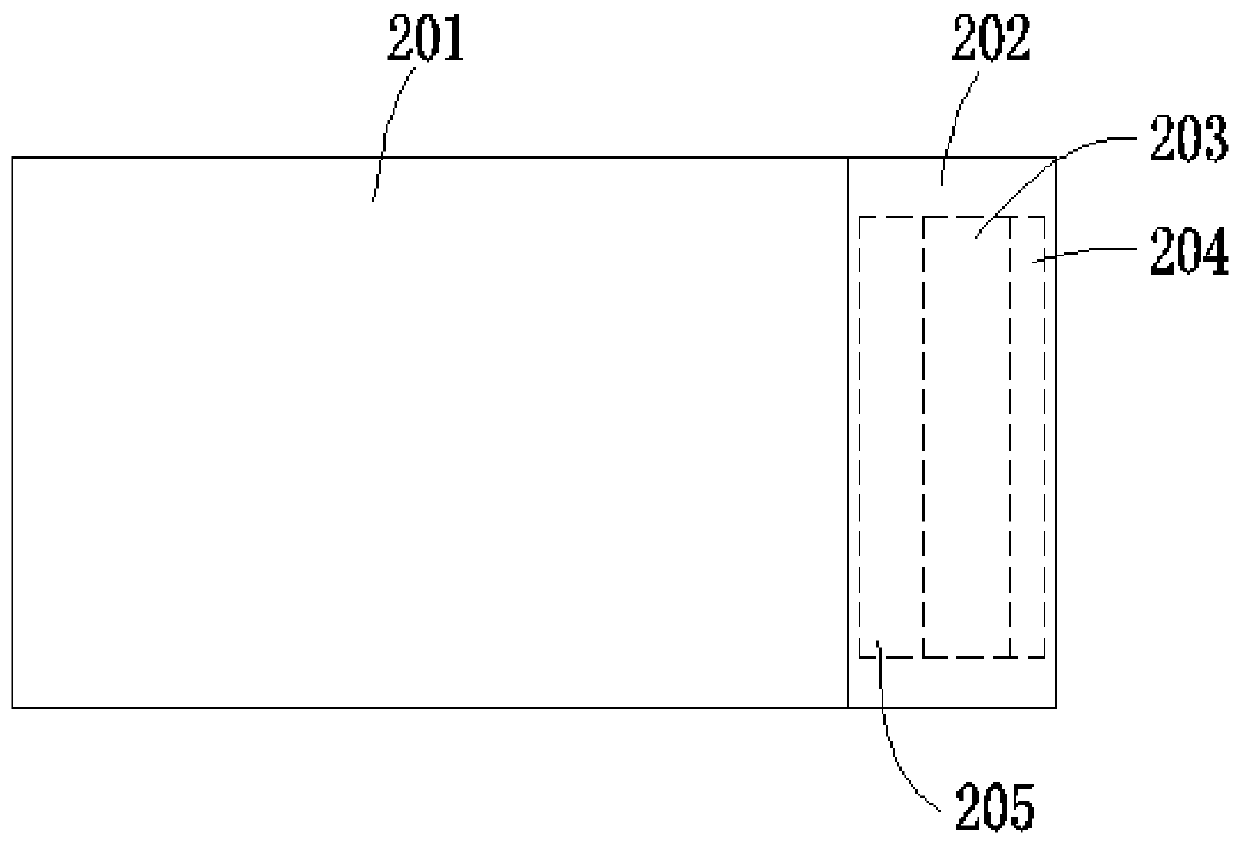

A display panel and binding method

ActiveCN108807717BIncrease widthConductivity is not affectedPrinted circuit aspectsSolid-state devicesEngineeringSignal lines

The present invention provides a display panel and a binding method. The display panel includes a display area and a non-display area located on one side of the display area. At least two signal wires are arranged in the non-display area. A binding area is set in the non-display area; the non-display area and the binding area have an overlapping area and a non-overlapping area, and the non-overlapping area located on one side of the binding area is the first area, which is relatively The non-overlapping area on the other side is the second area; the first area is provided with a waterproof adhesive layer, and the binding area is provided with a conductive adhesive layer; the conductive adhesive layer includes a conductive particle doped area, and a first insulating glue region located on one side of the conductive particle doped region, the first insulating glue region is located between the conductive particle doped region and the second region.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

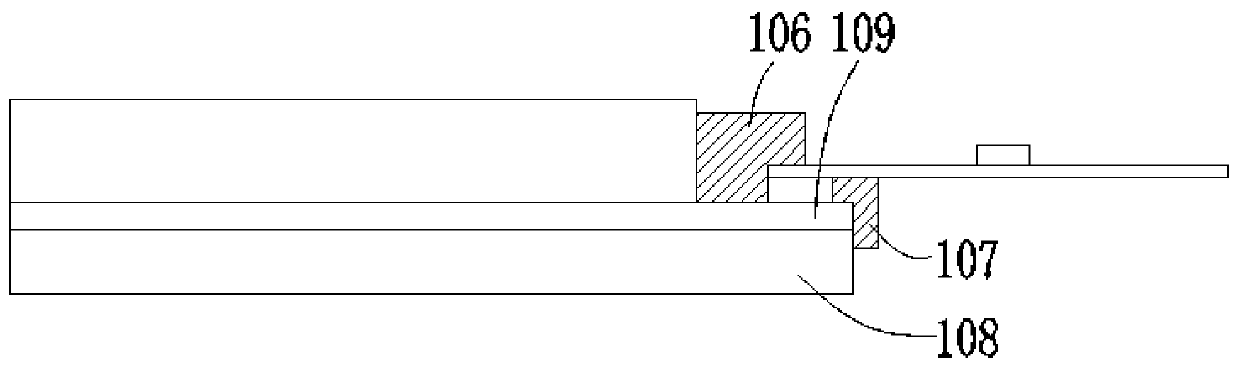

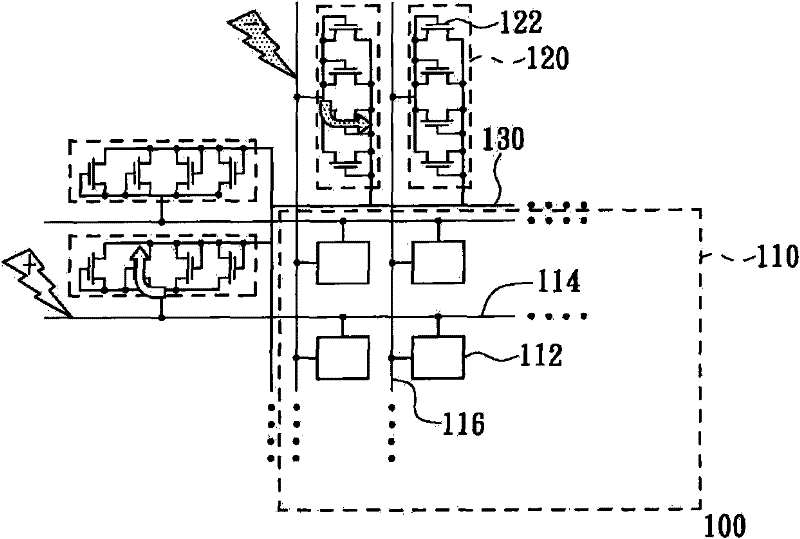

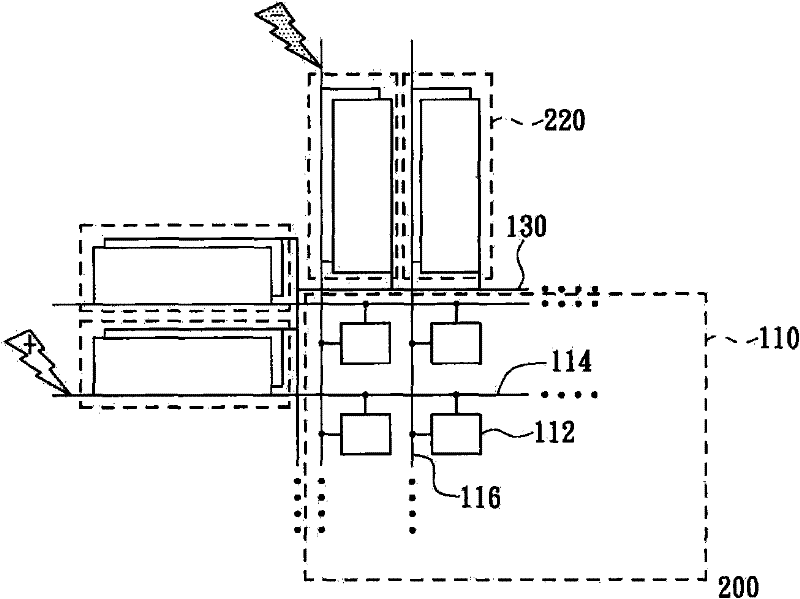

Electrostatic protection circuit and display device adopting same

ActiveCN101859764BConductivity is not affectedNot prone to permanent damageSolid-state devicesNon-linear opticsDividing circuitsPotential difference

The embodiment of the invention provides an electrostatic protection circuit and a display device adopting the same. The electrostatic protection circuit comprises three transistors and two voltage-dividing circuits, wherein one of source / drain of the first transistor is coupled with a first power wire and the other one is coupled with a second power wire; one of source / drain of the second transistor is coupled with the first power wire and the other one is coupled with a grid of the first transistor; one of source / drain of the third transistor is coupled with the grid of the first transistorand the other one is coupled with the second power wire; the first voltage-dividing circuit is used for providing first divided voltage to a grid of the second transistor based on the potential difference of the first power wire and the second power wire, and the second voltage-dividing circuit is used for providing second divided voltage to a grid of the third transistor based on the potential difference of the first power wire and the second power wire. The electrostatic protection circuit of the embodiment of the invention has stable and reliable performance and can not increase the load of the grid drive circuits and the source drive circuits.

Owner:AU OPTRONICS CORP

Preparation method of composite material bipolar plate of proton exchange membrane fuel cell

ActiveCN101667642BImprove bindingImprove corrosion resistanceCell electrodesCollectors/separatorsProton exchange membrane fuel cellPrecipitation

The invention discloses a preparation method of a composite material bipolar plate of a proton exchange membrane fuel cell. The composite material bipolar plate comprises a metal basal plate and an air distribution flow field positioned on the metal basal plate and is characterized in that the air distribution flow field is directly precipitated on the metal basal plate by a precipitation method.The invention can obviously reduce the thickness and the weight of the composite material bipolar plate by preparing the composite material bipolar plate by the method, thereby enhancing the weight ratio power and the volume ratio power of the proton exchange membrane fuel cell; in addition, the composite material bipolar plate has the advantages of low material cost, corrosion resistance, good conductivity and very large scale application potentiality.

Owner:SUNRISE POWER CO LTD

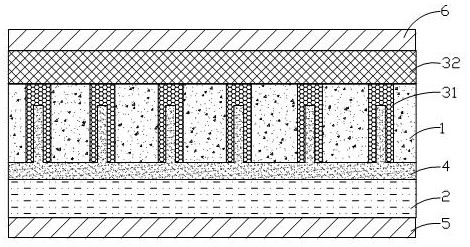

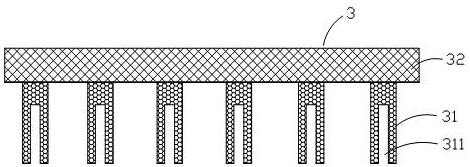

Electromagnetic shielding conductive foam and preparation method thereof

ActiveCN110519980BShape is not affectedStructure is not affectedScreening casingsMetal foilAdhesive glue

The invention provides electromagnetic shielding conductive foam and a preparation method thereof. The electromagnetic shielding conductive foam comprises a conductive foam layer, a metal foil layer arranged below the conductive foam layer, and a rubber column assembly. Multiple positioning holes are uniformly formed in the conductive foam layer. The rubber column assembly comprises multiple rubber columns and a rubber connecting plate connected with one ends of the multiple rubber columns. The multiple rubber columns correspond to the multiple positioning holes in a one-to-one mode, and the rubber columns are arranged in the positioning holes. The rubber connecting plate is bonded to the upper end face of the conductive foam layer through glue. The conductive foam layer and the metal foillayer are bonded through conductive glue. When the electromagnetic shielding conductive foam is bent, the tensile stress generated by the metal foil layer generates a stress corresponding to the bending direction, and the conductive foam layer and the rubber columns in the conductive foam layer have good elastic restoring force and can counteract the generated stress, so that the shape, structure, conductive performance and shielding performance of the metal foil layer will not be influenced.

Owner:深圳市丰正昌精密科技有限公司

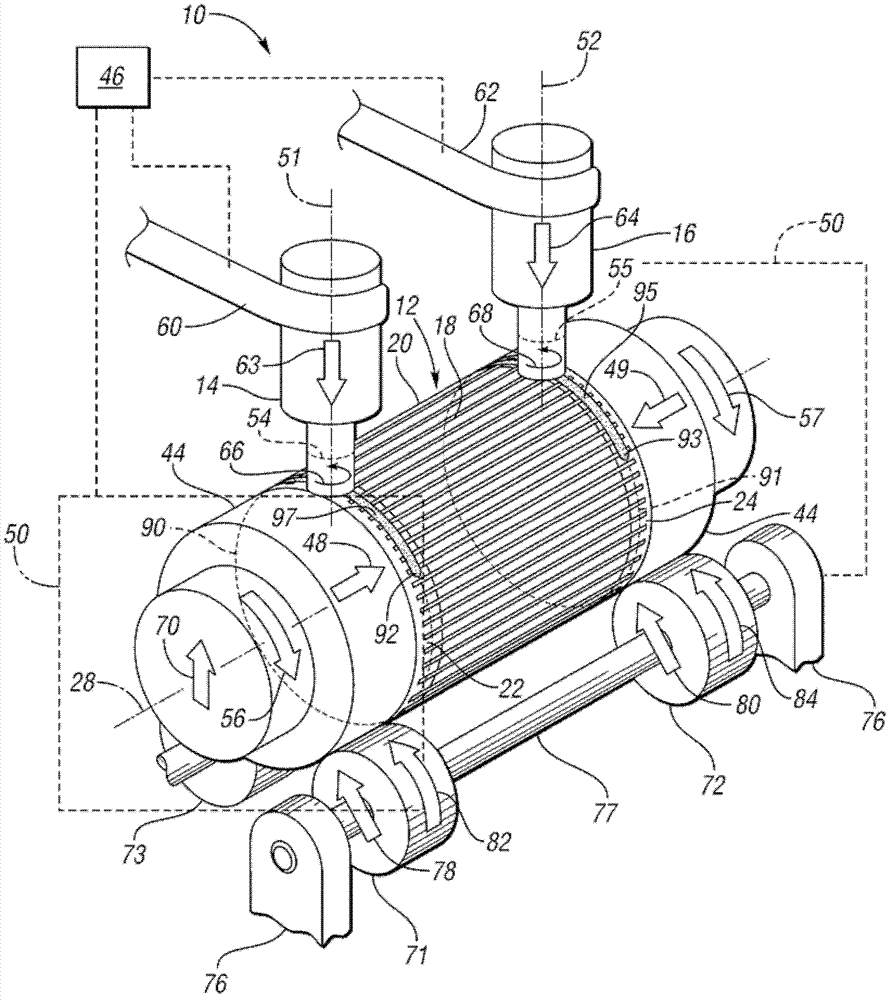

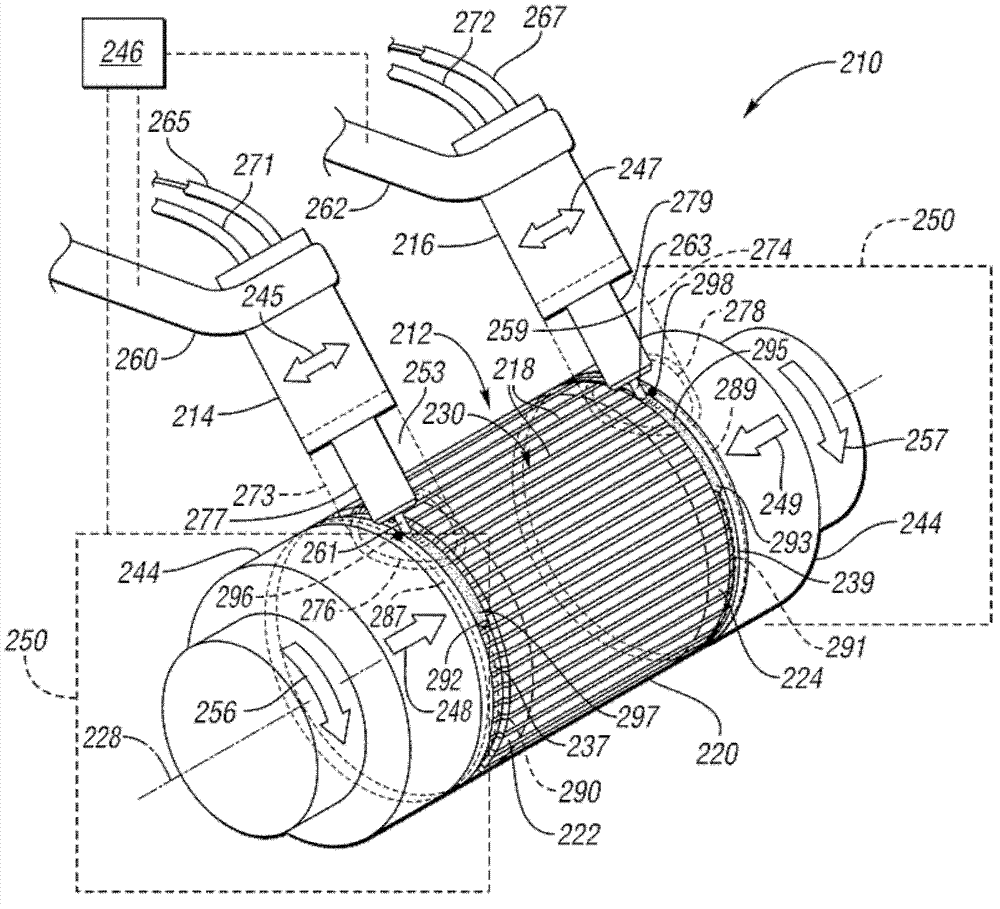

Welding apparatus for induction motor

InactiveCN102672358BReduce duty cycle timeImprove power densityArc welding apparatusManufacturing cage rotorsElectrical conductorInduction motor

Owner:GM GLOBAL TECH OPERATIONS LLC

A conductive foam suitable for electromagnetic shielding

ActiveCN108882664BGuaranteed electromagnetic shielding performanceImprove conductivityMagnetic/electric field screeningMetallic foilCarbon nanotube

The invention discloses conductive foam suitable for electromagnetic shielding. The conductive foam sequentially comprises an outer protection layer, a foam layer, a first pasting layer, a metal foillayer and a second pasting layer, wherein the layers are combined to form the conductive foam, a nickel-titanium alloy thin film is formed on each of an upper surface and a lower surface of the metalfoil layer, leakage holes are formed in the foam layer and are filled with carbon nanotubes, the carbon nanotubes are porous spongy carbon nanotube block-shaped materials, first surfaces of the nickel-titanium alloy thin films are connected with the foam layer and the carbon nanotubes in the foam layer by the first pasting layer, and second surfaces of the nickel-titanium alloy thin films are connected with the second pasting layer. In the conductive foam provided by the invention, relatively excellent integral shielding performance and conductive performance can be provided for electronic equipment in a closed and narrow space with poor cooling performance.

Owner:XIAMEN BEACONING PRECISION IND CO LTD

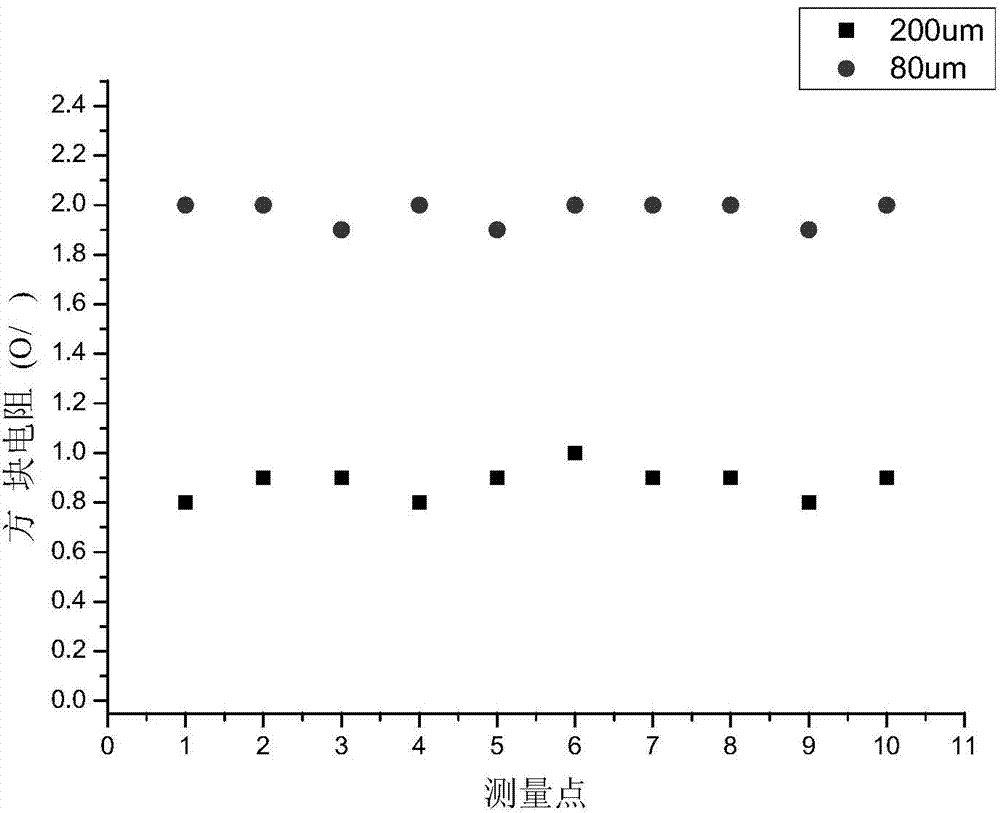

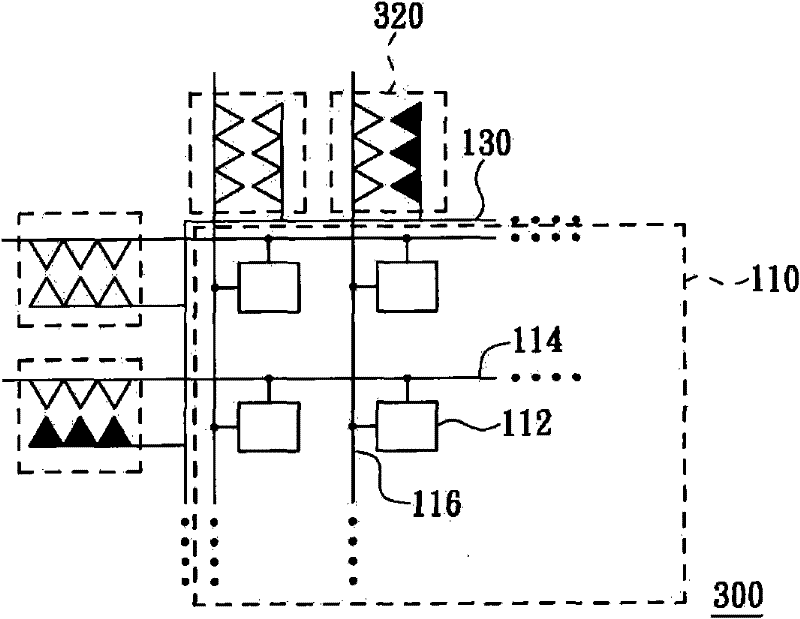

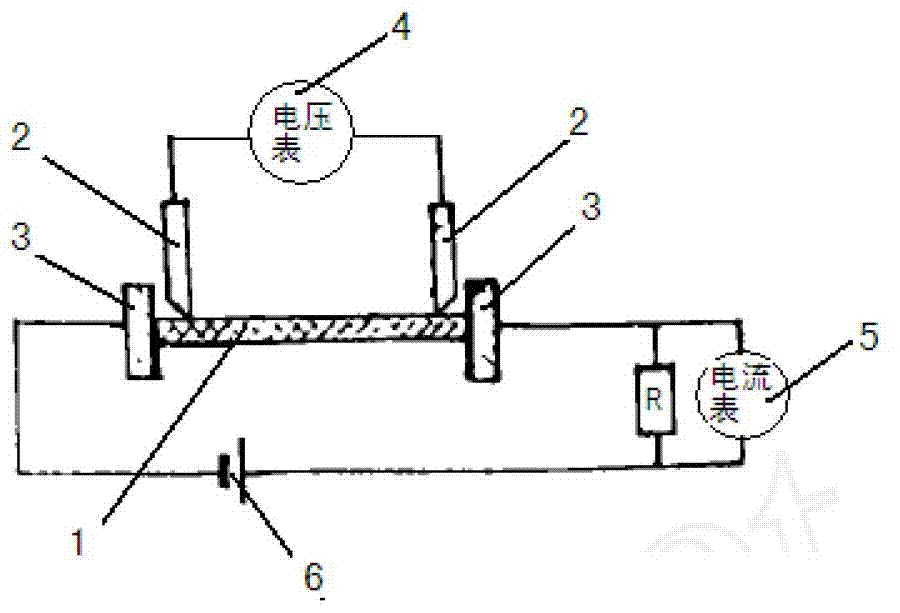

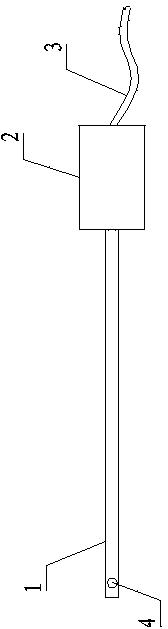

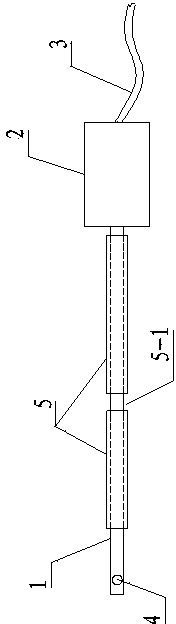

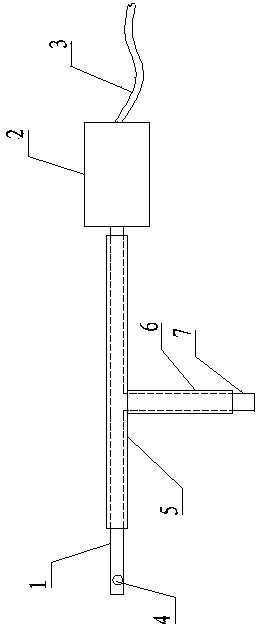

Carbon felt conductivity test method

InactiveCN103424624BReproducible and stableSmall dispersionResistance/reactance/impedenceSolid carbonLiquid state

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Connection structure convenient for charge and discharge and maintenance of accumulator

ActiveCN103682223ASimple structureEase of promotion and implementationSecondary cells testingCell component detailsCharge and dischargeBattery electrode

The invention relates to a connection structure convenient for charge and discharge and maintenance of an accumulator. The connection structure comprises a battery electrode plate I, wherein one end of the battery electrode plate I is provided with a connection hole connected with an accumulator binding post; the other end of the battery electrode plate I is connected with a switch; the switch is connected with a wire connected with an electric appliance. When the connection structure is used, firstly, the switch is disconnected to disconnect the connection with the wire and battery electrode plate I, then a detection connector is connected with the battery electrode plate I; after the detection and the maintenance are finished, the detection connector is taken down and the switch is closed, so that the wire is communicated with the battery electrode plate I, and the problem of a conventional structure that two persons are needed, time and labour are wasted, the operation is inconvenience and a potential safety hazard exits. The connection structure has the advantages that the structure is simple, is convenient to perform and popularize, is convenient and rapid to use, and saves the time and the labour, and only one person can finish the operation.

Owner:JIYUAN POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com