High-stability water-base silver-plating protective agent and preparation method thereof

A technology of high stability and protective agent, applied in the direction of coating, etc., can solve the problems of poor stability of protective layer, poor stability of protective agent, and improved silver surface protection effect, so as to improve service life, improve stability, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

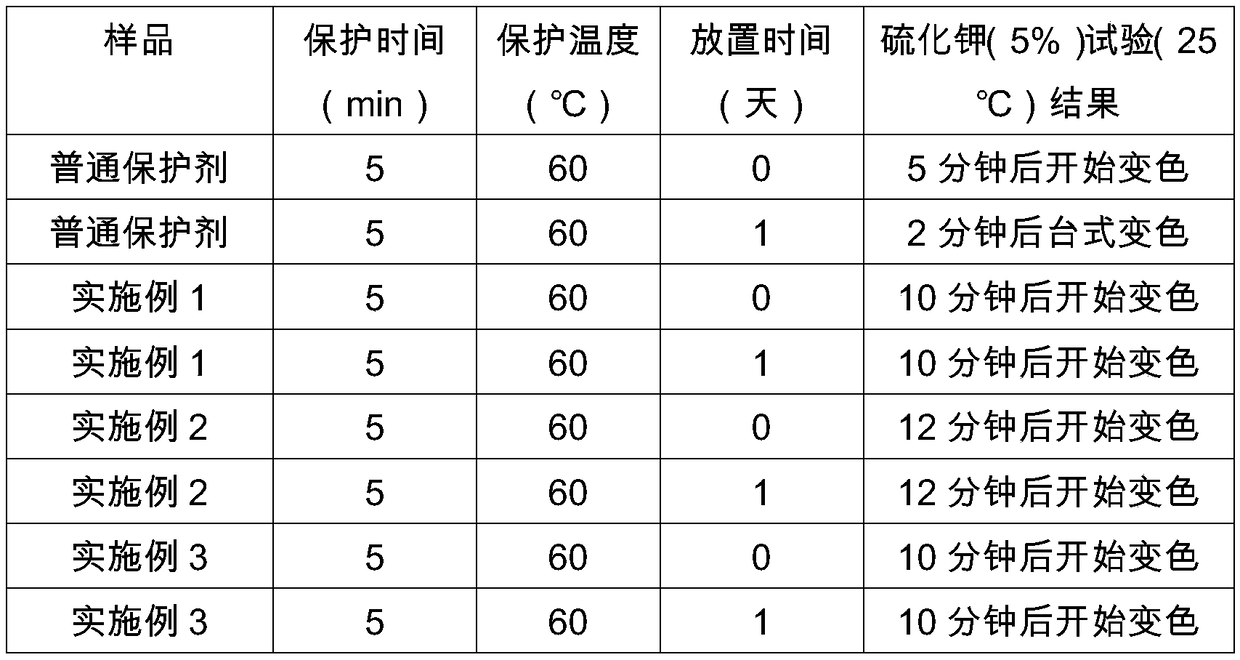

Examples

Embodiment 1

[0038] Take 60g of stearyl mercaptan and 6g of trimethyl mercapto phosphate at 60°C and mix thoroughly to form Agent A, take 30g of Pingpingjia O, 30g of oleyl alcohol polyoxyethylene ether, and 10g of mercaptosuccinic acid to dissolve In 860mL of deionized water, mix thoroughly at 60°C to form agent B, at 60°C, stir agent A and agent B with a stirrer at 400 rpm for 3 hours to fully emulsify, add 100mg of graphite to the mixture Then make up the mixture to 1000ml, and use an ultrasonic disperser to ultrasonically disperse it under 30Khz ultrasonic waves for 6 hours to obtain a high-stability water-based silver plating protection agent.

Embodiment 2

[0040] Take 80g of octadecyl mercaptan and 8g of trimethyl mercapto phosphate and mix it well at 60°C to form Agent A. Take 60g of Pingpingjia O and 10g of mercaptosuccinic acid and dissolve it in 840mL of deionized water. Mix well at 60°C to form Agent B. Stir Agent A and Agent B with a stirrer at a speed of 400 rpm for 3 hours to fully emulsify at 60°C. Add 100 mg of graphene to the mixture, and make up the mixture to 1000ml, use an ultrasonic disperser to ultrasonically disperse under 30Khz ultrasonic waves for 6 hours to obtain a high-stability water-based silver plating protection agent.

Embodiment 3

[0042] Take 80g of octadecyl mercaptan and 8g of trimethyl mercapto phosphate at 60°C and mix thoroughly to form Agent A. Take 60g of alkylphenol polyoxyethylene ether and 10g of 6-mercaptocaproic acid and dissolve them in 840mL In deionized water, mix thoroughly at 60°C to form agent B, and at 60°C, stir agent A and agent B with a stirrer at a speed of 400 rpm for 3 hours to fully emulsify, add 100 mg of graphene to the mixture, Then make up the mixed solution to 1000ml, and use an ultrasonic disperser to ultrasonically disperse it under 30Khz ultrasonic waves for 6 hours to obtain a high-stability water-based silver plating protection agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com