Patents

Literature

53results about How to "Decomposition will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

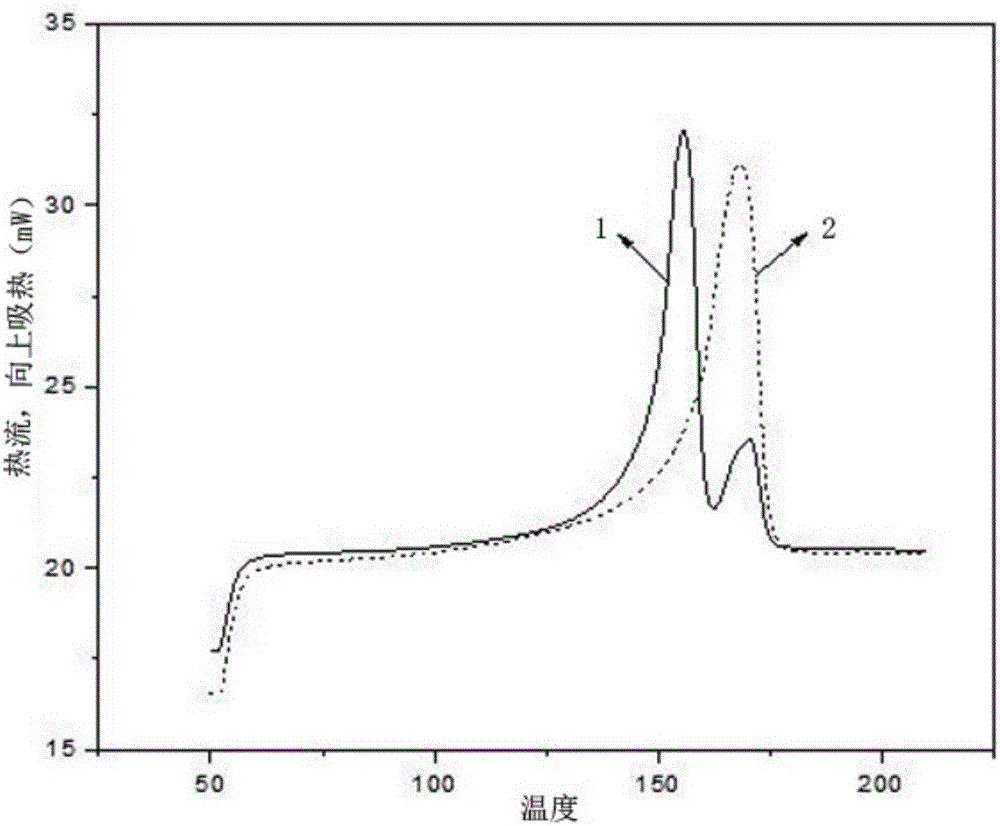

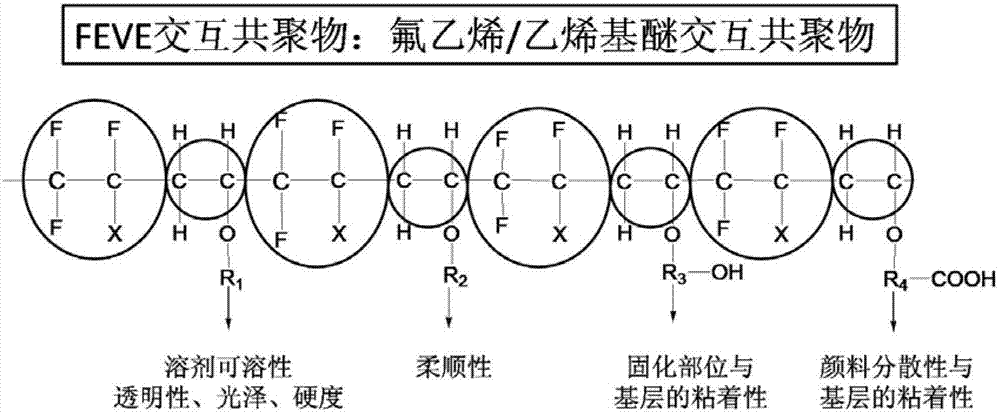

Self-cleaning super-weather-proof powder paint and preparation method thereof

ActiveCN103194140AImprove stabilityProtect against agingPowdery paintsPolyester coatingsPolyesterAging resistance

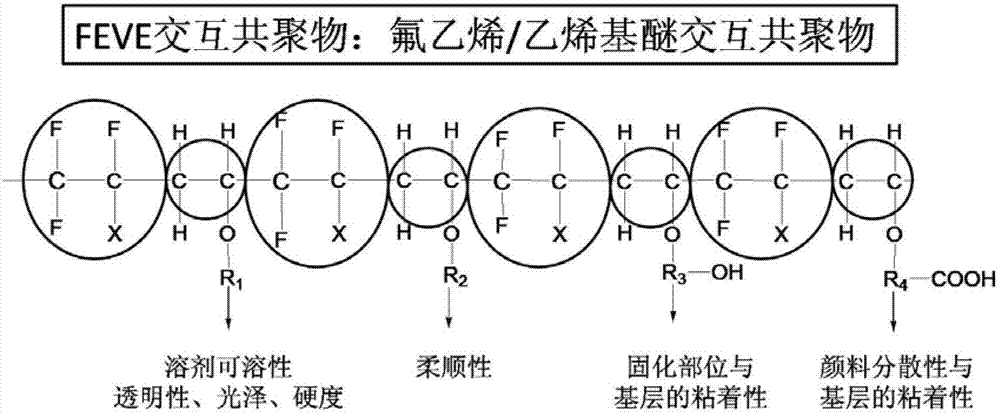

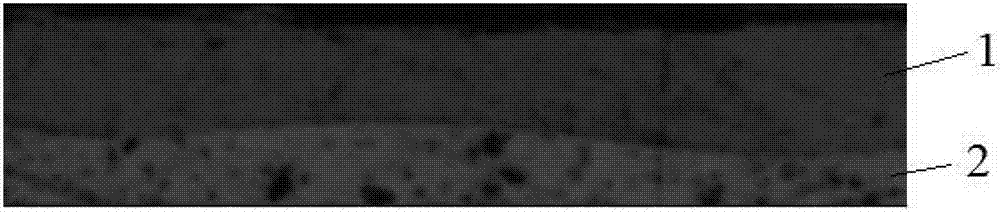

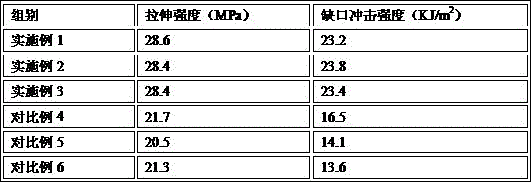

The invention belongs to the field of powder paints and particularly relates to a self-cleaning super-weather-proof powder paint. The self-cleaning super-weather-proof powder paint comprises a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system in a weight part ratio of 4:1-1:4, wherein the fluorocarbon resin particle system contains TiO2 nano-particles. As carboxyl-terminated polyester is introduced into a pure fluorocarbon paint, the phase separation occurs in a solidification process, and the fluorocarbon resin floats up to the surface of a coating to serve as coating protection and ageing resistance; the carboxyl-terminated polyester and the like and a substrate can be well wetted, so that the coating and the substrate can be well adhered and can hardly crack and spall; as the TiO2 nano-particles only exist in a fluorocarbon phase, the resin on a bottom layer cannot be broken, and the excellent stability of the system is guaranteed; and the TiO2 nano-particles are scattered in a dry blending manner, and the complex preprocessing is avoided, so that the preprocessing process can be greatly shortened, the cost is lowered, and the efficiency is improved.

Owner:NINGBO SOUTH SEA CHEM

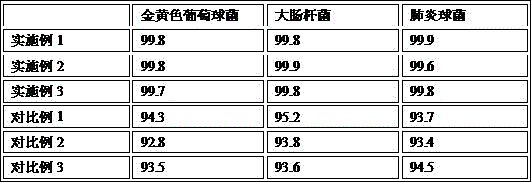

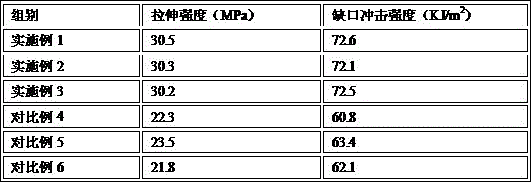

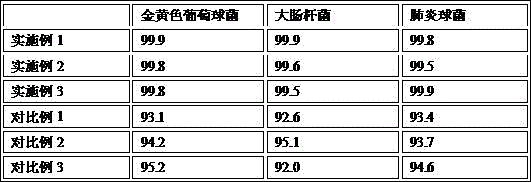

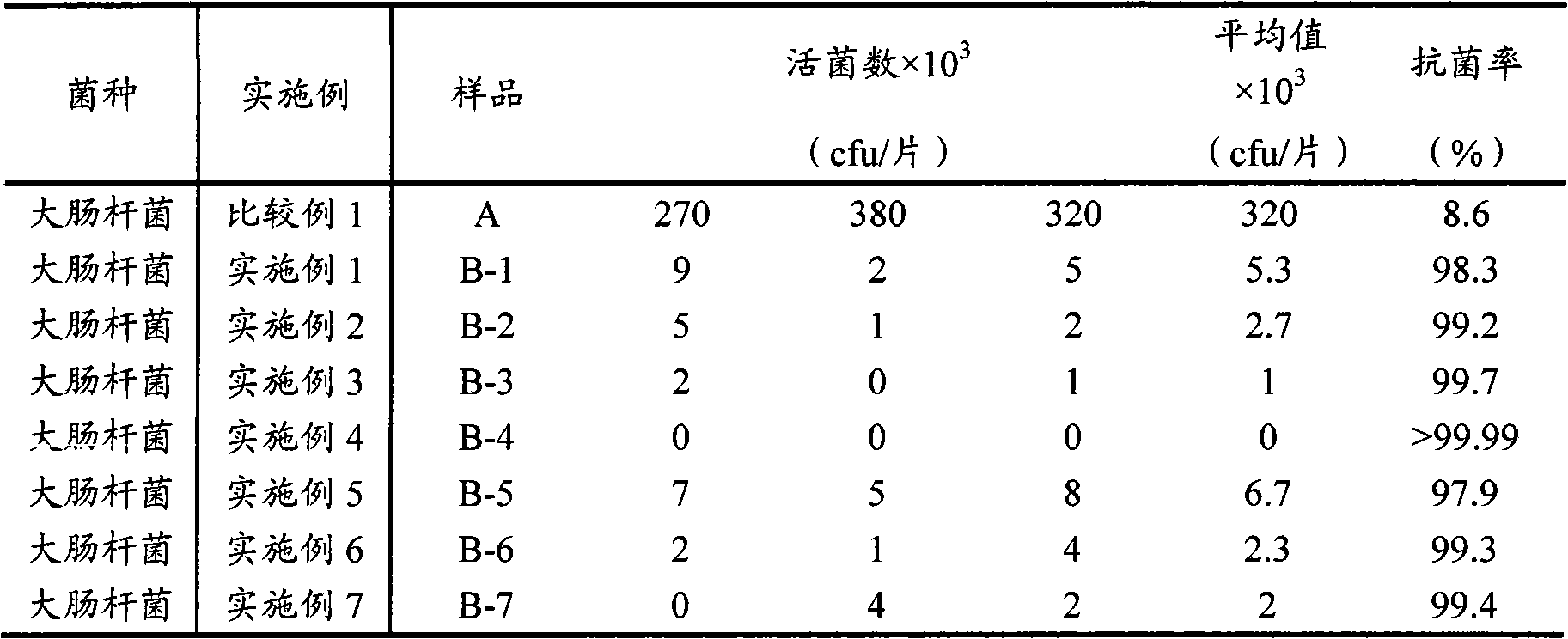

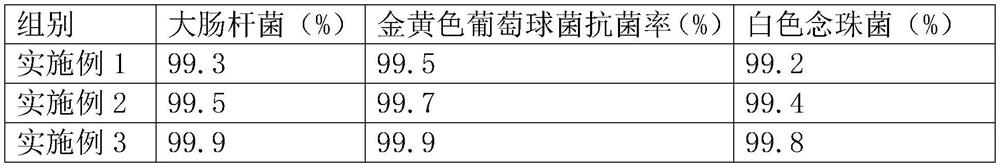

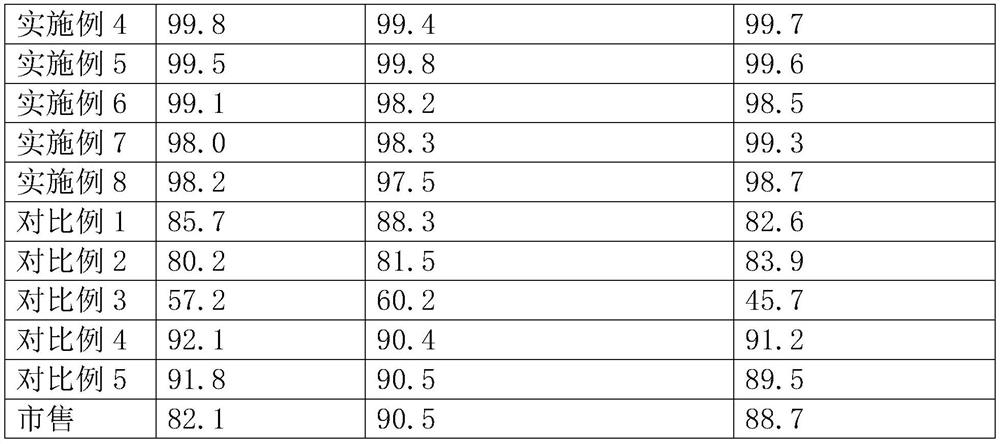

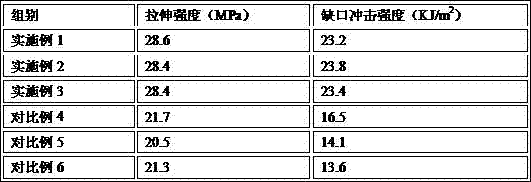

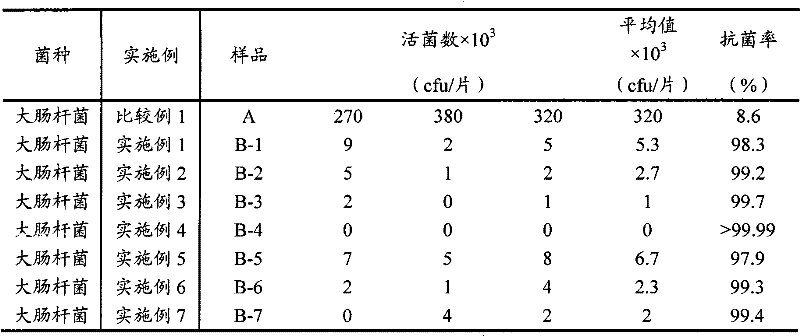

LDPE (low-density polyethylene) antibacterial plastic and preparation method therefor

The invention relates to an LDPE (low-density polyethylene) antibacterial plastic and a preparation method therefor. The antibacterial plastic is prepared from the following components in parts by weight: 100-150 parts of LDPE, 3-5 parts of isothiazolinone, 2-5 parts of polyhexamethyleneguanidine, 2-5 parts of betaine, 2-5 parts of nano-zinc oxide powder, 3-5 parts of nano-titanium dioxide, 0.5-2 parts of zinc stearate, 0.5-2 parts of white oil, 0.5-5 parts of a coupler, 0.5-2 parts of oleamide, 0.1-1 part of an ethylene-octene copolymer, 0.5-1 part of an antioxidant, 0.1-3 parts of a styrene-maleic anhydride random copolymer and 0.5-2 parts of a plasticizer. The antibacterial plastic is excellent in mechanical property and processing performance and good in flame retardancy, has good antibacterial property and can be used for plastic products such as plastic films, packaging bags and the like.

Owner:SHENZHEN BOXINMEI NANOMETER TECH CO LTD

Feed sweetener

ActiveCN102028098AIncrease feed intakeIncrease production capacityAnimal feeding stuffAccessory food factorsSucroseDecomposition

The invention discloses a feed sweetener which is prepared by mixing the following components in parts by weight: 25-70 parts of soluble saccharin, 5-70 parts of maltodextrin, 1-10 parts of sweet taste intensifier, 0.01-0.1 part of ethyl maltol and 0.01-0.1 part of ethyl vanillin, wherein the sweet taste intensifier is one of Acesulfame-K, sucralose, alitame and D-tryptophan or a mixture formed by mixing Acesulfame-K, sucralose, alitame and D-tryptophan according to any ratio. The sweetener enables animals to truly and effectively taste all the components, thereby increasing the feed intakes of the animals and improving the production performance of the animals. The sweetness of the sweetener is 150-500 times higher than that of sucrose, and the sweetener has sucrose-like fragrance and mouth feel, thereby reducing the additive amount of the sweetener in the feed and lowering the culture cost. The sweet taste intensifier in the invention has good stability, and the decomposition temperature is higher than the preparation temperature, so that the sweet taste intensifier can not be decomposed in the sweetener preparation process and the feed granulating process, thereby ensuring that the sweet taste is true and effective.

Owner:CHONGQING MINTAI NEW AGROTECH DEV GRP CO LTD

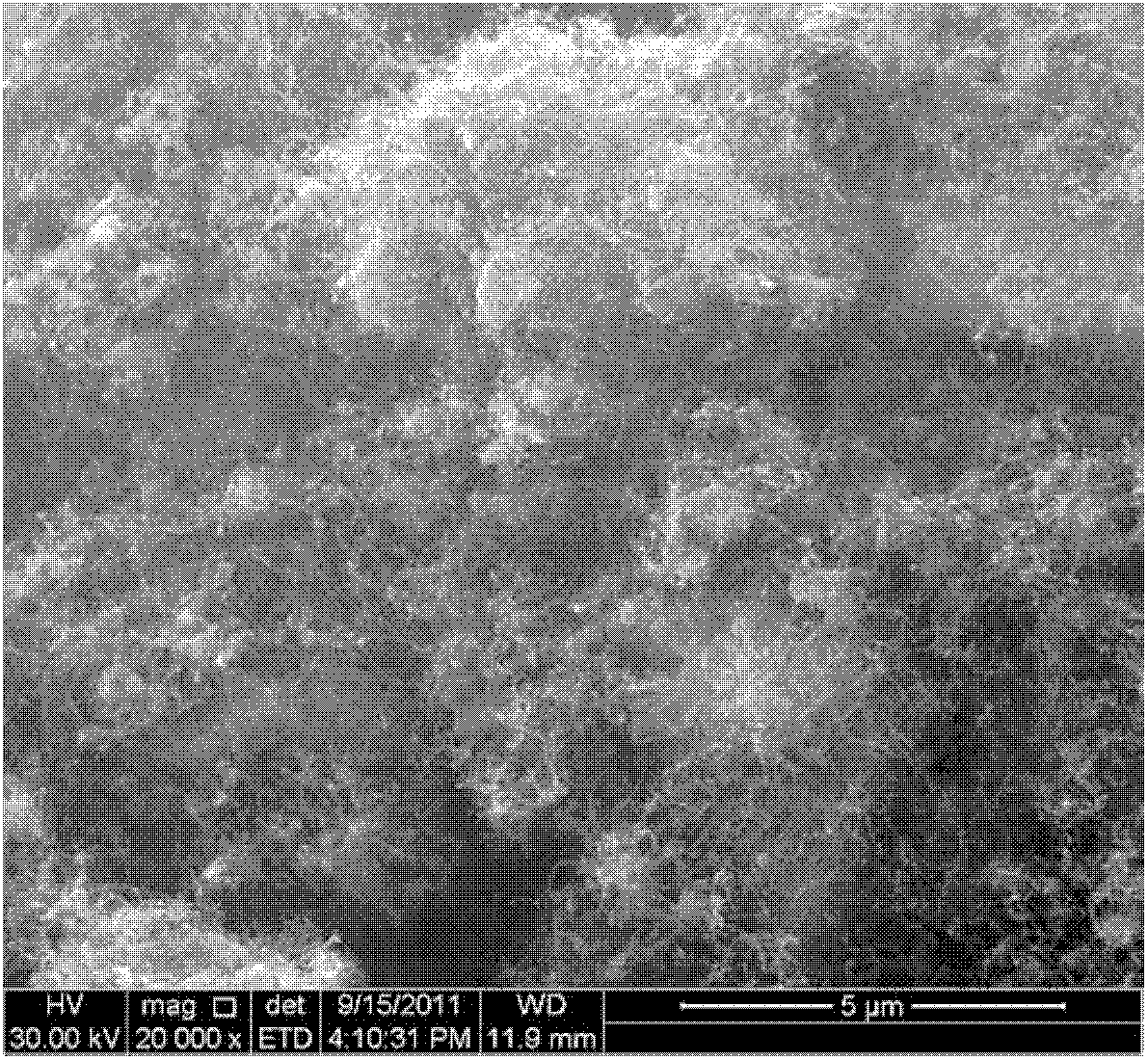

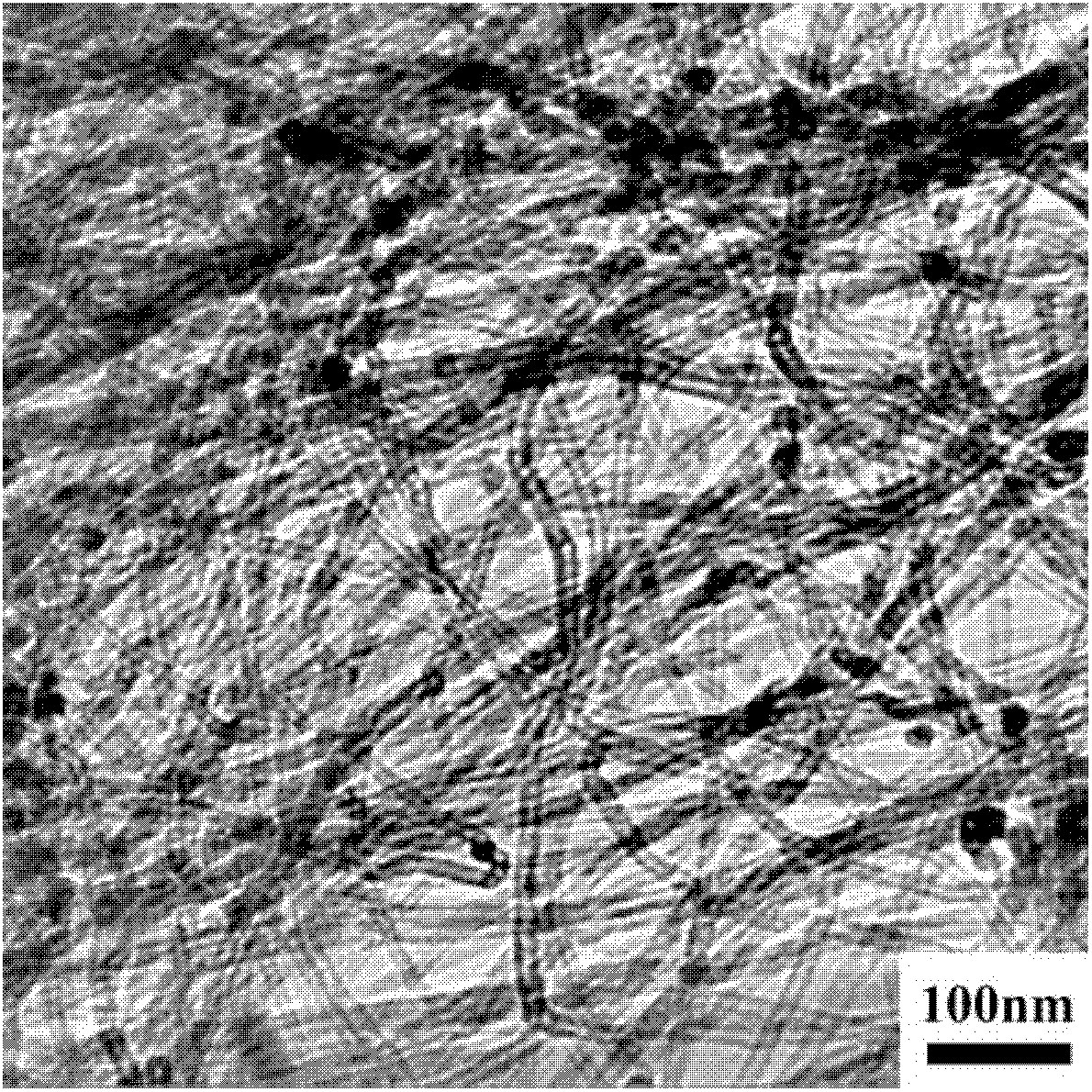

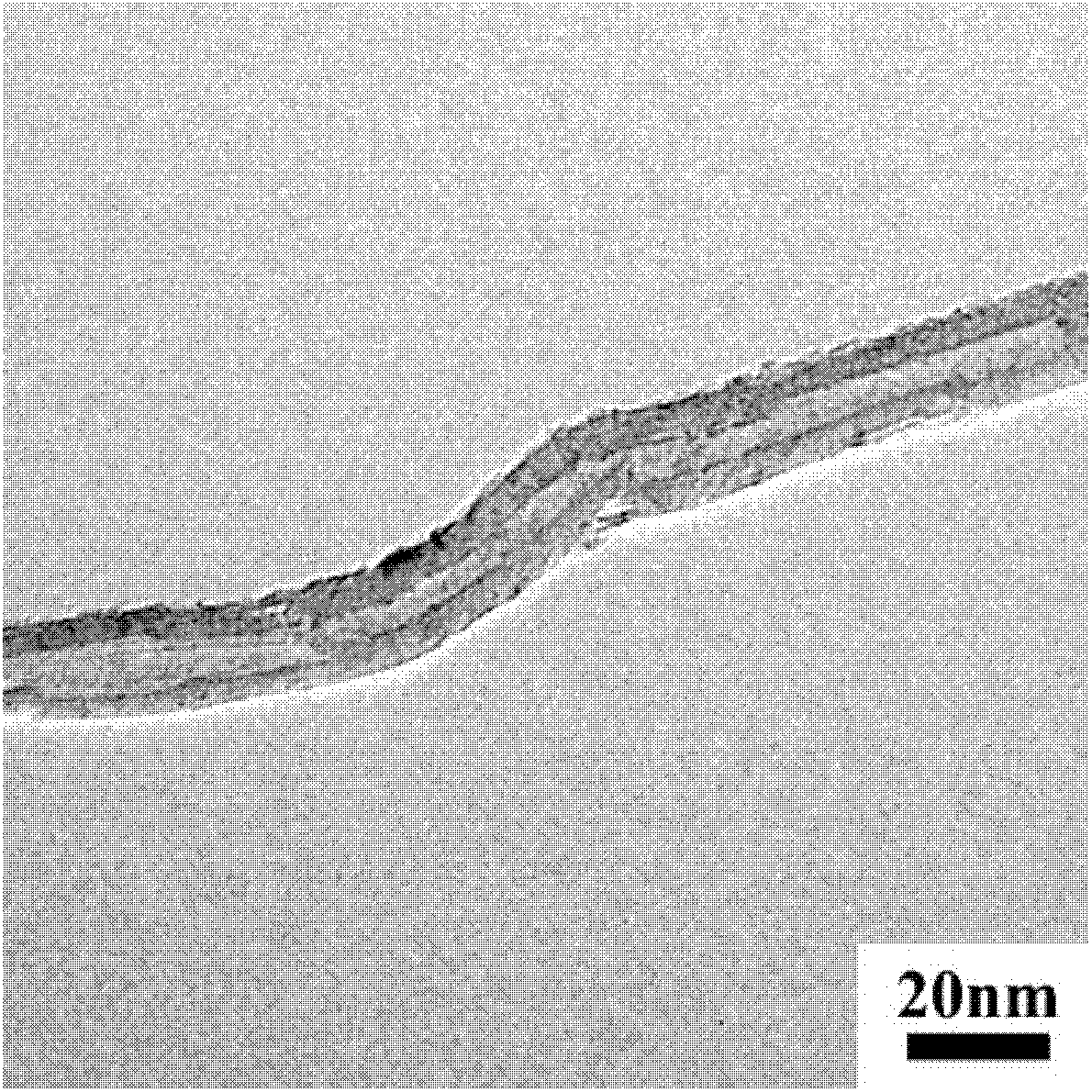

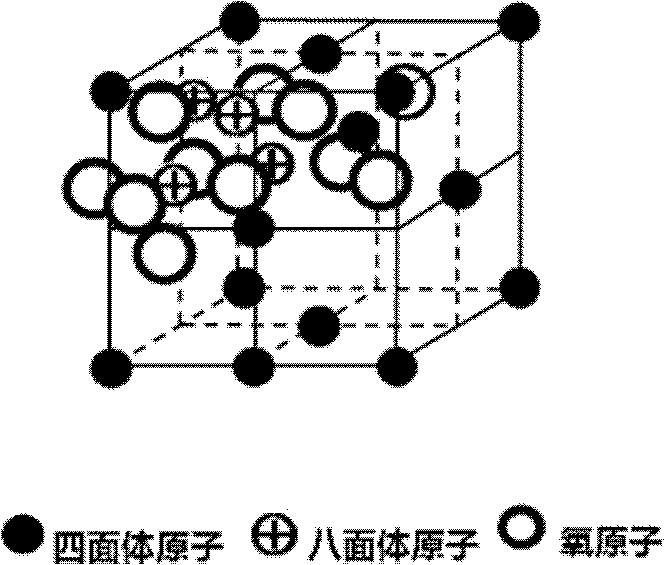

Method for preparing carbon nano tube enhanced titanium-base compound material by in-suit reaction

The invention relates to a method for preparing a carbon nano tube enhanced titanium-base compound material by in-suit reaction in order to solve the problems of low uniform dispersion and low structural completeness of a carbon nano tube in the conventional method for preparing the carbon nano tube enhanced titanium-base compound material and pollution to the titanium-base material caused by reaction of a carbon group and a titanium base body. The method comprises the following steps of: adding nickel nitrate hexahydrate and TiH2 powder into an ethanol solution, stirring and evaporating to obtain Ni-TiH2 compound powder; paving the Ni-TiH2 compound powder in a quartz boat, putting the quartz boat into deposition equipment, feeding H2, raising temperature, feeding CH4, and after the deposition is finished, stopping feeding the CH4 so as to obtain carbon nano tube / TiH2 compound power; pressing the carbon nano tube / TiH2 compound power into a block body, sintering, and re-pressing to obtain the carbon nano tube enhanced titanium-base compound material. Carbon nano tubes in the compound material are uniform to disperse and cannot be aggregated; the compound material is high in purity and has a complete structure; and reaction between the titanium and the defected carbon nano tube can be avoided.

Owner:HARBIN INST OF TECH

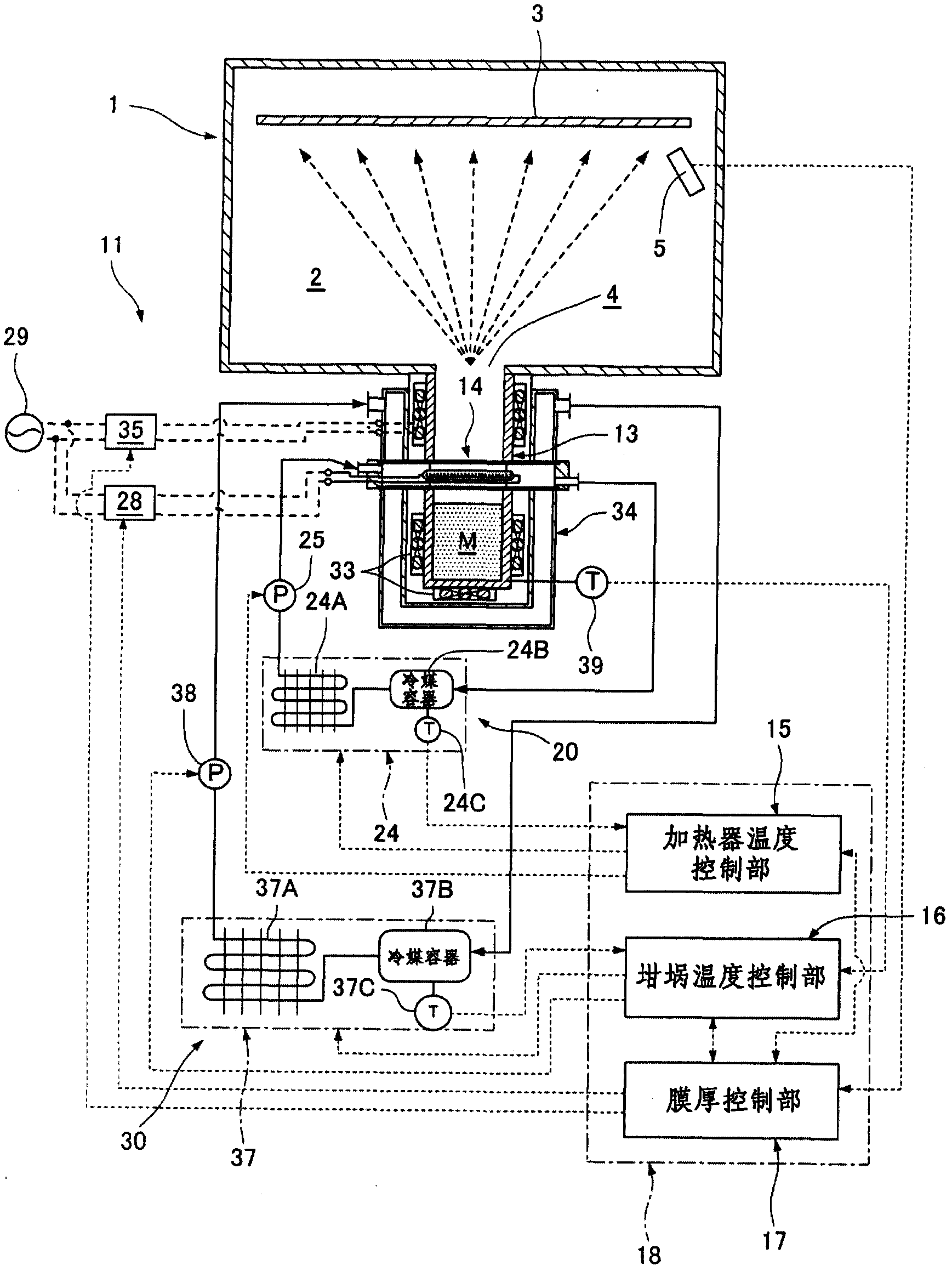

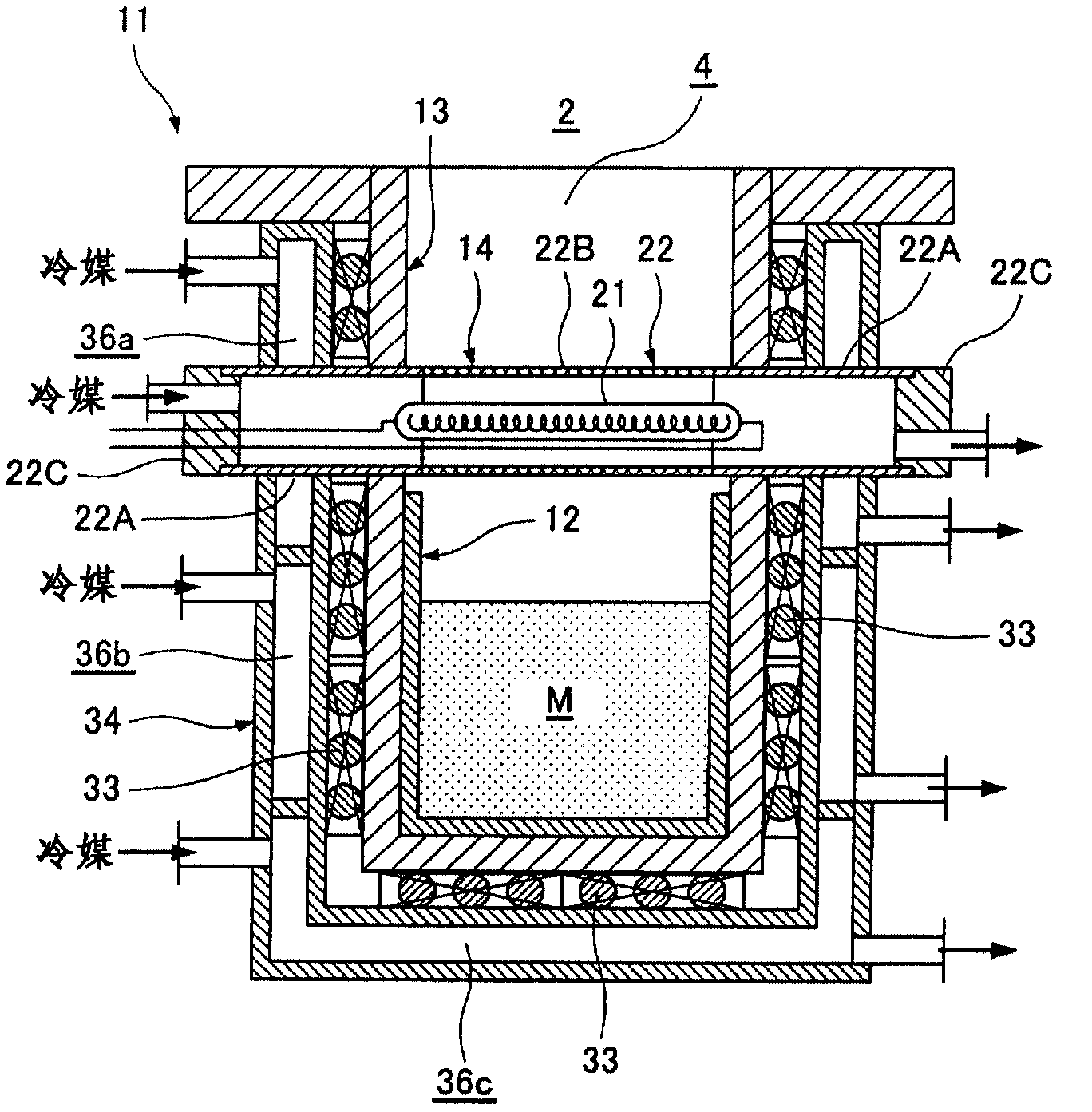

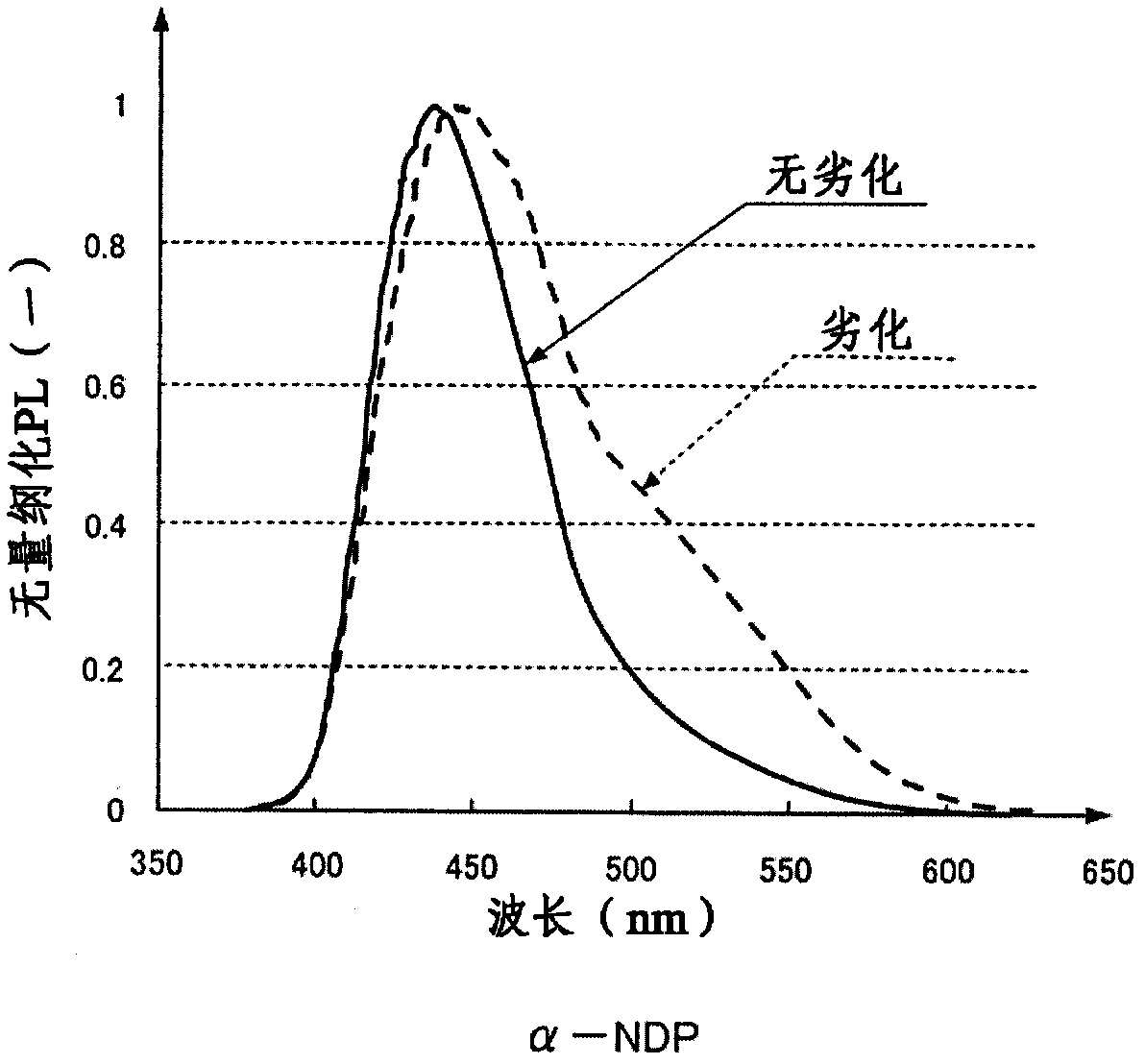

Evaporation or sublimation method and crucible device for evaporation material in vacuum evaporation device

ActiveCN102277557AWill not deteriorateDoes not reduce transmittanceVacuum evaporation coatingSputtering coatingInfraredCrucible

The invention provides an evaporation or sublimation method of evaporation material in a vacuum evaporation unit, and a crucible unit for vacuum evaporation. The units can work continuously for a long term and prevent the degradation of the evaporation material. In a crucible base (13), a radioactive heat source (21) radiating heat waves mainly including infrared ray is disposed in a heat wave transmission tube (22). The heat wave transmission tube (22) is made of material through which the infrared ray can transmit. The heat waves from the radioactive heat source (21) emit on the surface of the evaporation material M in a crucible body (12) and heat the evaporation material to make the surface of the evaporation material M for evaporation or sublimation. Even if the evaporated or sublimated evaporation material M is adhered on the surface of the heat wave transmission tube (22) or the inner surfaces of the crucible body (12) and the crucible base (13), the heat waves can be used to make the evaporated or sublimated evaporation material M for evaporation or sublimation again.

Owner:HITACHI ZOSEN CORP

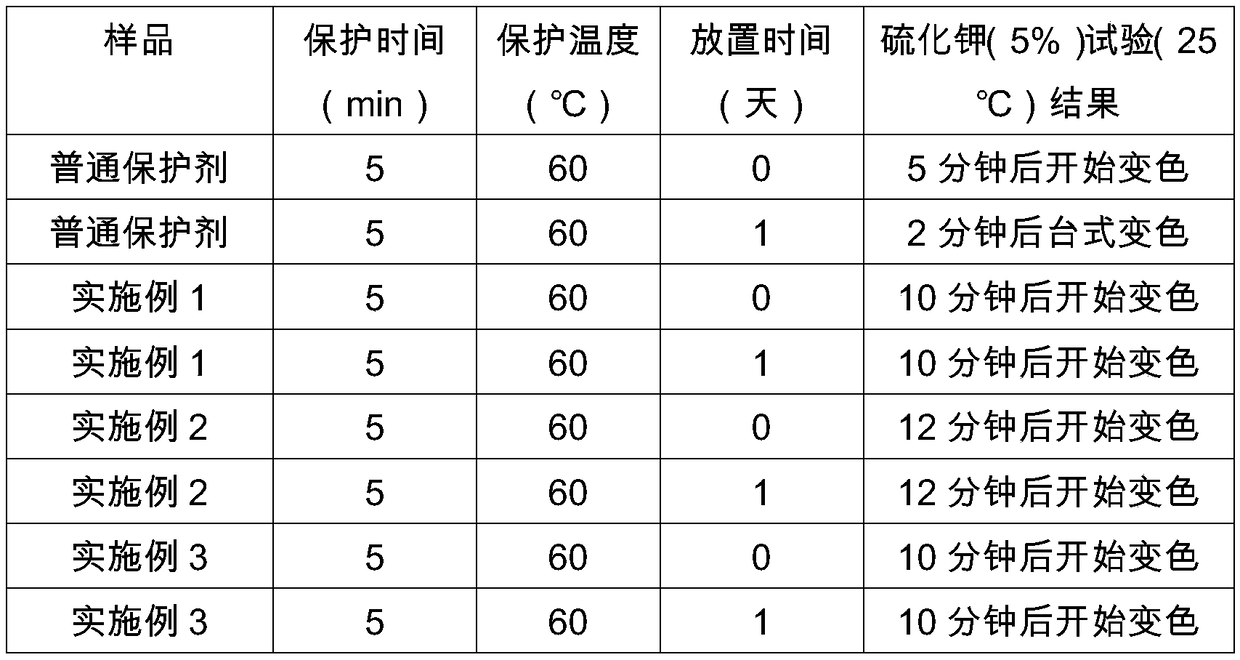

High-stability water-base silver-plating protective agent and preparation method thereof

The invention provides a high-stability water-based silver-plating protective agent. Every liter of the high-stability water-based silver-plating protective agent comprises 40-100 g of octadecanethiol, 4-10 g of trimethyl mercapto phosphate, 100 mg of reduced graphene oxide, 40-100 g of an emulsifier, 10 g of a stabilizer and the balance deionized water. The high-stability water-based silver-plating protective agent adopts the stabilizer and graphene, so that the service life of the protective agent is prolonged, and the corrosion resistance and color change resistance of protected metal are improved; and the surface appearance and performance of the silver-plating layer protected by the protective agent are not affected, a potassium sulfide resistance test of electronic products can be maintained for more than 12 minutes, and the protection time is greatly prolonged.

Owner:SUZHOU HIYIE CHEM CO LTD

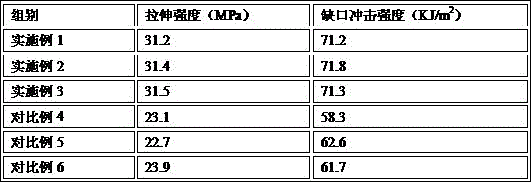

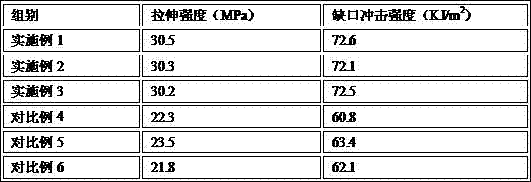

PP antibacterial plastic and preparation method thereof

The invention relates to PP antibacterial plastic and a preparation method thereof. The antibacterial plastic is prepared from, by weight, 100-150 parts of polypropylene, 3-5 parts of dodecyl trimethyl ammonium chloride, 2-5 parts of chitosan, 2-5 parts of glycine betaine, 2-5 parts of nano zinc oxide powder, 3-5 parts of nano calcium oxide, 0.5-2 parts of zinc stearate, 0.5-2 parts of white oil, 0.5-5 parts of a coupling agent, 0.5-2 parts of nonylphenol polyoxyethylene ether, 0.1-1 parts of ethylene-1-octene copolymer, 0.5-1 part of antioxidant, 0.1-3 parts of styrene and maleic anhydride random copolymer and 0.5-2 parts of plasticizer.The antibacterial plastic is good in mechanical property and processability, good in flame retardancy, good in antibacterial performance and capable of being used for plastic thin films, pipes, plates and various plastic products.

Owner:广州美泰包装科技有限公司

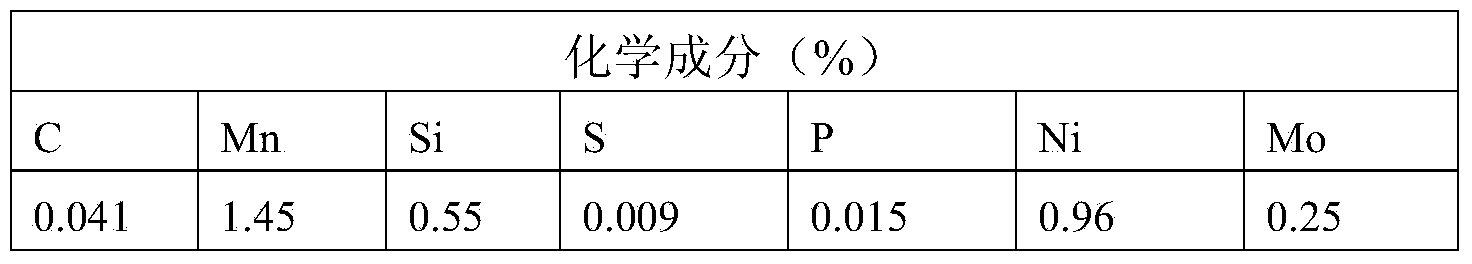

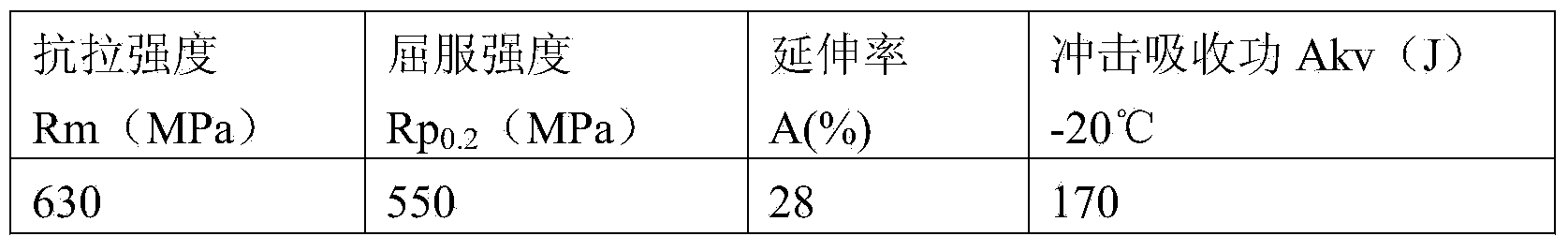

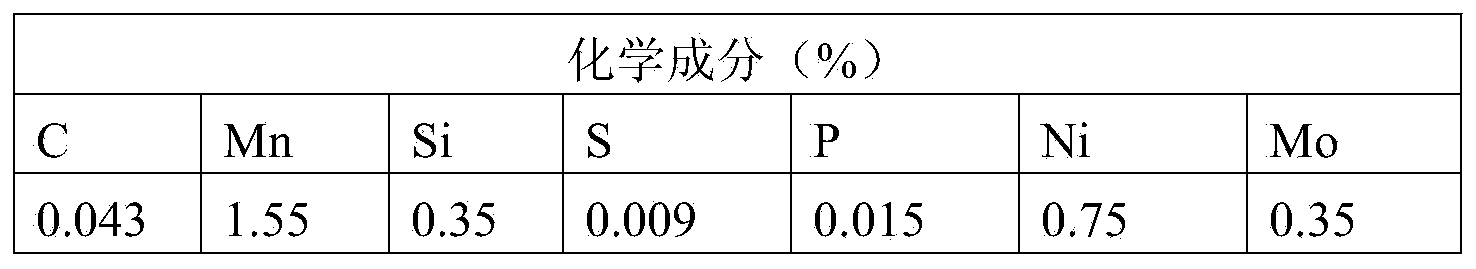

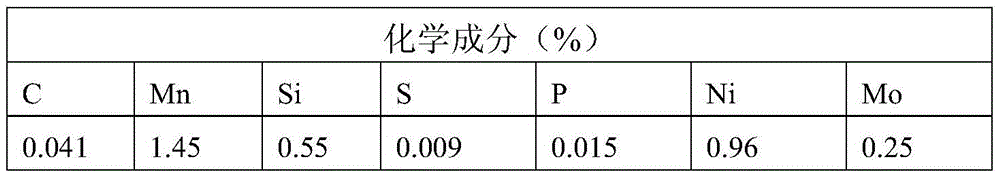

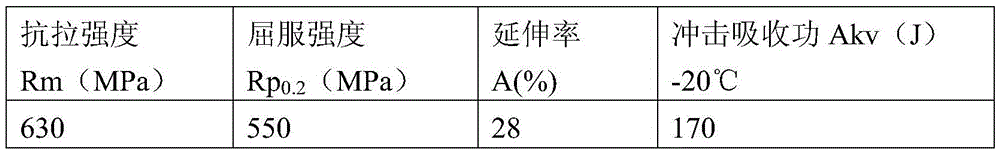

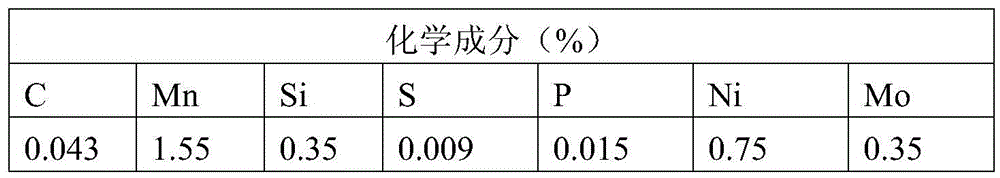

Ultralow-hydrogen high-toughness welding rod for welding of water-diversion steel penstock in hydropower station

ActiveCN103921019ASolving recipe problemsImprove dehydrogenation capacityWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention provides an ultralow-hydrogen high-toughness welding rod for welding of a water-diversion steel penstock in a hydropower station. A coating of the welding rod comprises, by mass, 40%-50% of marble, 2%-4% of dolomite, 18%-30% of fluorite, 2%-6% of quartz, 1%-3% of dehydrated feldspar, 1%-3% of zircon sand, 2%-4% of potassium titanate, 3%-6% of atomized ferrosilicon, 4%-8% of electrolytic manganese, 7%-12% of ferrotitanium, 1%-3% of light rare earth silicon iron, 0.5%-1.0% of ferromolybdenum, 2%-4% of nickel powder, and 0.5%-1.0% of rare earth fluoride. All the components are mixed according to the ratios to form the coating of the welding rod, potassium and sodium mixed water glass is added, an H04E welding core is coated with the mixture through a welding rod pressure coater, and the coated welding core is dried and shaped to form the electric welding rod. The deposited metal diffusible hydrogen content of the welding rod is 1.8 ml / 100 g, the low temperature impact toughness at minus 20 DEG C is stabilized within the range from 160 J to 180 J, and the welding requirement of the water-diversion steel penstock in a 610 MPa hydropower station can be met.

Owner:HUBEI CHUANWANG SPECIAL WELDING MATERIALS

Long-acting broad-spectrum antibiotic polypropylene plastic and method for preparing the same

ActiveCN101550250ADecomposition will notImprove the bactericidal effectSodium PyrithioneEconomic benefits

The invention discloses a long-acting broad-spectrum antibiotic polypropylene plastic, composed by components of following weight parts: polypropylene 100 parts, zinc pyrithione 0.5 to 5 parts, antioxidant 0.5 to 2 parts, dispersant 1 to 2 parts. The invention also discloses prepartion method of the long-acting broad-spectrum antibiotic polypropylene plastic. The benefical effects of the invention is reflected in: excellent high temperature resistant performance, high efficiency broad-spectrum antibiotic, simple and convenient operation, low cost and good economic benefit.

Owner:浙江石油化工有限公司

Preparation method for superfine zirconium powder

InactiveCN104289709AReduce surface activityInhibition of growth behaviorCoatingsZirconium hydrideMicro nano

The invention relates to a preparation method for superfine zirconium powder, in particular to a technical method utilizing a sodium salt and / or potassium salt to coat zirconium hydride to prepare micro-nano-scale zirconium powder, and belongs to the technical field of superfine metal powder. The technical method comprises the following steps: taking the sodium salt as a coating agent, mixing the zirconium hydride particles with the coating agent according to a mass ratio of (5-15):1, conducting wet grinding and vacuum drying to obtain the superfine zirconium powder of which surface is coated with the coating agent uniformly, dehydrogenizing in a vacuum environment at 550-680 DEG C, and conducting wet grinding dispersion and elution on the product to remove the coating agent so as to obtain the superfine zirconium powder, wherein the vacuum degree is controlled at 0.05-0.1 Pa in the dehydrogenation process. The preparation method disclosed by the invention is simple in preparation technology, convenient to control, and safe in operation technology; the obtained product is good in quality; the preparation method facilitates industrialized application.

Owner:CENT SOUTH UNIV

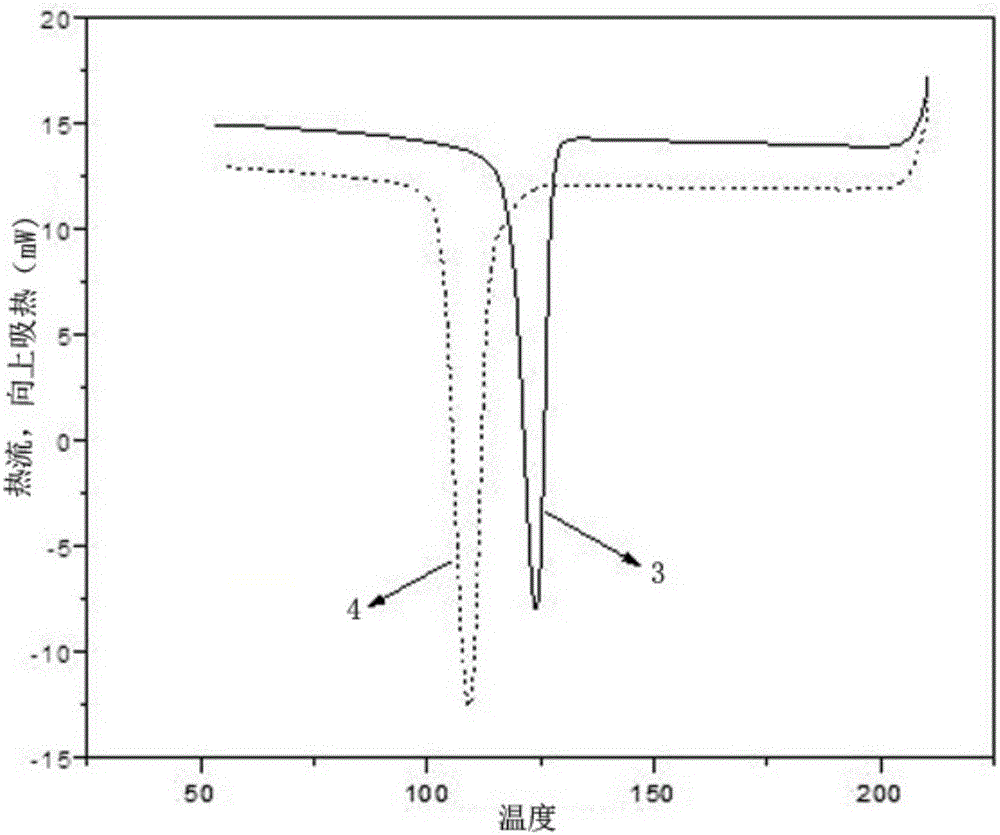

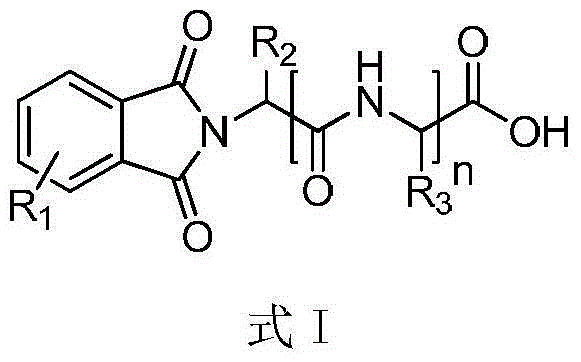

Imide polypropylene beta crystalline form nucleating agent and preparation method thereof

ActiveCN105061404AEasy to disperseRaise the crystallization temperatureOrganic chemistryDecompositionPolypropylene

The invention discloses an imide polypropylene beta crystal form nucleating agent. The agent has a structural general formula I, wherein n ranges from 0 to 20; R1 is nitryl, hydroxyl, amino, halogen or alkyl; R2 is one of the following three groups: H, alkyl and a group containing carboxyl, hydroxyl, halogen or heteroaromatic rings; and R3 is one of the following three groups: H, alkyl and a group containing carboxyl, hydroxyl, halogen or heteroaromatic rings. The invention also discloses a preparation method of the imide polypropylene beta crystal form nucleating agent. The imide polypropylene beta crystal form nucleating agent disclosed by the invention has the characteristics of high efficiency, easy diffusion, and green and non-toxic properties; the beta crystal content reaches 81%; the decomposition temperature is high and the nucleating agent cannot be decomposed under the condition that polypropylene is normally heated; the diffusion effect is good, and the performance of the polypropylene is obviously improved even if the additive amount is small.

Owner:广东炜林纳新材料科技股份有限公司

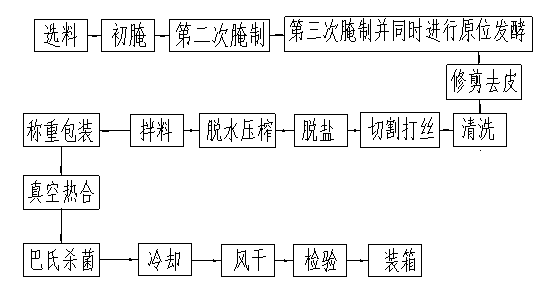

Method for employing in-situ fermentation technology to produce tuber mustard

The invention discloses a method for employing an in-situ fermentation technology to produce tuber mustard, and relates to a foodstuff processing method. The method comprises the following steps: selecting raw materials, performing first preserving, performing second preserving, performing third preserving and in-situ fermentation, trimming and peeling, cleaning, cutting and forming strips, desalinating, dewatering and squeezing, blending with materials, weighing, performing vacuum packaging, performing pasteurization, cooling, performing air drying, examining and cartonning. Compared with the prior art and methods, the preserving time of the tuber mustard produced by employing the in-situ fermentation technology is shortened to about 5.5-6.5 months from original about 6-9 months, and the produced tuber mustard is relatively mellow and pure in flavor and relatively good in quality, and is fresh, fragrant, crisp and tender.

Owner:NANXI SANJIANG FOOD

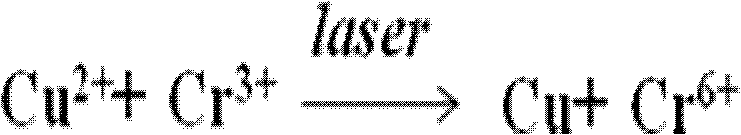

Modified resin composition, preparation method thereof and application thereof

The invention discloses a modified resin composition. The composition is prepared with 35-95% resin matrix, 0-60% additive and 5-15% laser sensitive additive, wherein the laser sensitive additive is preferably made of copper-manganese (iron) and / or copper-manganese (zinc iron). In the preparation process of the modified resin, the laser sensitive additive does not resolve, the resin matrix does not resolve either, non-laser sensitive additive can release copper metallic element to form a active center under the function of a laser, however no poisonous metal generates, and thus the modified resin is safe and environmental. According to the modified resin composition, a preparation method thereof and an application thereof, doping modification technique is applied in the laser sensitive additive for the first time, and thus the performance of a modified resin composition deposited metal film is improved.

Owner:KINGFA SCI & TECH CO LTD +1

HDPE (High-Density Polyethylene) antibacterial plastic and preparation method thereof

The invention relates to HDPE (High-Density Polyethylene) antibacterial plastic and a preparation method thereof. The antibacterial plastic is prepared from the following ingredients in parts by weight: 100-150 parts of HDPE, 3-5 parts of dodecyl trimethyl ammonium chloride, 2-5 parts of polyhexamethylene guanidine, 2-5 parts of glycine betaine, 2-5 parts of nano-zinc oxide powder, 3-5 parts of tourmaline powder, 0.5-2 parts of zinc stearate, 0.5-2 parts of white oil, 0.5-5 parts of coupling reagent, 0.5-2 parts of dibenzylidene sorbitol, 0.1-1 part of ethylene-octylene copolymer, 0.5-1 part of antioxygen, 0.1-3 parts of random copolymer of styrene and maleic anhydride and 0.5-2 parts of plasticizer. The antibacterial plastic disclosed by the invention has the advantages of good mechanical property, processability, flame retardant property and antibacterial property, and can be used for plastic films, tubular products, panels and various plastic products.

Owner:广东辉源卫浴科技有限公司

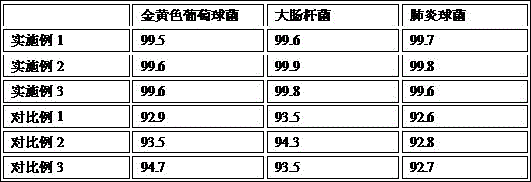

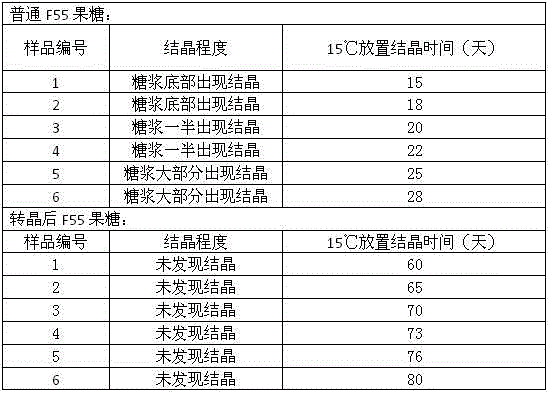

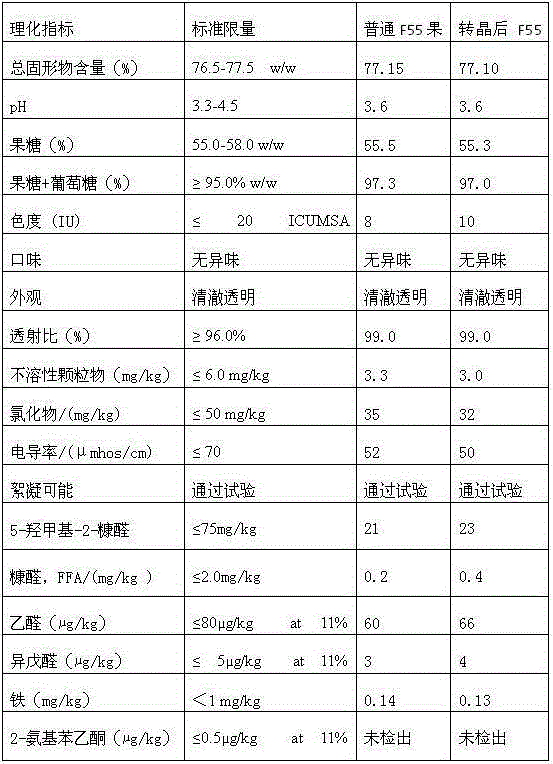

Crystallization resisting method for F55 high fructose corn syrup

InactiveCN104651540AQuality is not affectedSimple process controlFructose productionGlucose productionProduction lineHigh-fructose corn syrup

The invention discloses a crystallization resisting method for F55 high fructose corn syrup, belonging to the field of corn in-depth processing. In a production line of the F55 high fructose corn syrup, a crystal transformation tank is arranged behind a third refining procedure, the F55 crystal transformation subjected to refining of a third ion exchanging system in the third refining process is kept in the crystal transformation tank at 80 DEG C for 20 minutes, and then the F55 crystal transformation enters a third evaporation procedure. The crystallization resisting method has the advantages that the production method is simple, the operation is easy, the influence on F55 crystal transformation process is small, and the method is suitable for industrial production. The investment cost is low, the crystallization time of the produced F55 high fructose corn syrup at a low temperature can reach 70 days, physicochemical indexes of the crystallization resisting F55 high fructose corn syrup are all within the standard range, and the crystallization resisting F55 high fructose corn syrup has no obvious difference with ordinary F55 high fructose corn syrup.

Owner:JILIN COFCO BIOCHEM

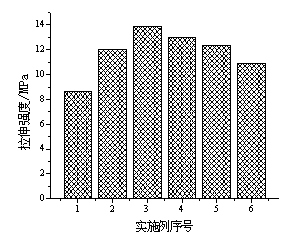

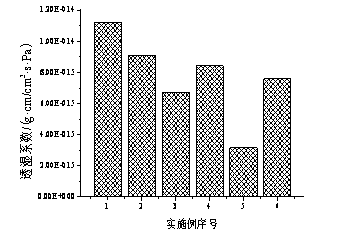

Sustained-release antioxidant packaging film for food and preparation method thereof

ActiveCN103435894AGuarantee green safetyControl Oxidative DeteriorationFlat articlesMasterbatchPolymer science

The invention relates to a sustained-release antioxidant packaging film for food and a preparation method thereof. A film substrate of the packaging film is formed by blending 50-80 parts by weight of HDPE (High-Density Polyethylene) and 20-50 parts by weight of EVA (Ethylene-Vinyl Acetate Copolymer) while adding 5-12.5 parts by weight of diatomite and 0.75-1.25 parts by weight of quercetin. The preparation method comprises the steps: (1) uniformly mixing an HDPE master batch and an EVA master batch, and plasticating; (2) sprinkling diatomite on a roller-wrapped blending thin sheet, plasticating for 6-8 minutes, sprinkling quercetin, and plasticating for 6-8 minutes; (3) carrying out roller release, tiling on a flat plate in single layer, cooling, and then cutting; (4) carrying out hot pressing; (5) carrying out pressure forming, thereby obtaining the packaging film. The packaging film disclosed by the invention has sustained release antioxidant performance, so that the effective utilization ratio of an antioxidant can be increased obviously; meanwhile, the packaging film has good mechanical properties and dampness and oxygen barrier performance; the condition that the packaging film prepared by the method disclosed by the invention has a higher antioxidant retention ratio can be guaranteed.

Owner:JIANGNAN UNIV

Sports effervescent tablet and preparation method thereof

InactiveCN109527325ALighten the burden of carryingEasy to carrySugar food ingredientsInorganic compound food ingredientsSodium bicarbonateAdditive ingredient

Belonging to the technical field of sports drink, the invention discloses a sports effervescent tablet and a preparation method thereof. The sports effervescent tablet comprises the following raw materials by mass fraction: 30%-52% of citric acid, 15%-30% of sodium carbonate, 3%-8% of lactose, 1%-5% of glucose, 3%-24% of fruit powder, 1%-4% of sorbitol, 0.5%-3% of food essence, 0.3%-3% of a sweetening agent, 0.5%-2% of edible salt, 0.5%-2% of potassium chloride, and 0.0001%-0.0003% of vitamin B. The invention mainly uses a special formula proportioning way for electrolyte, vitamin and saccharides, and fuses the effervescent tablet technology to invent the solid drink conducive to supplementing the human body needed nutrients by the sports group. Specifically, a disintegrating agent employssodium carbonate to replace the traditional sodium bicarbonate serving as an alkaline foaming agent, thus increasing the product stability and greatly reducing the economic loss.

Owner:江苏汉典生物科技股份有限公司

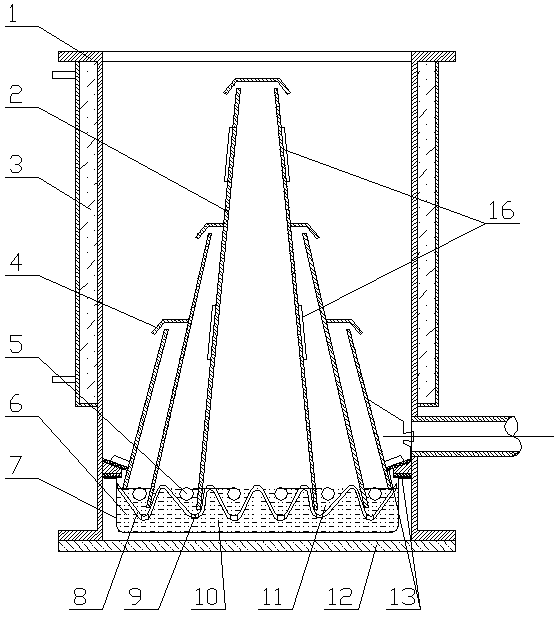

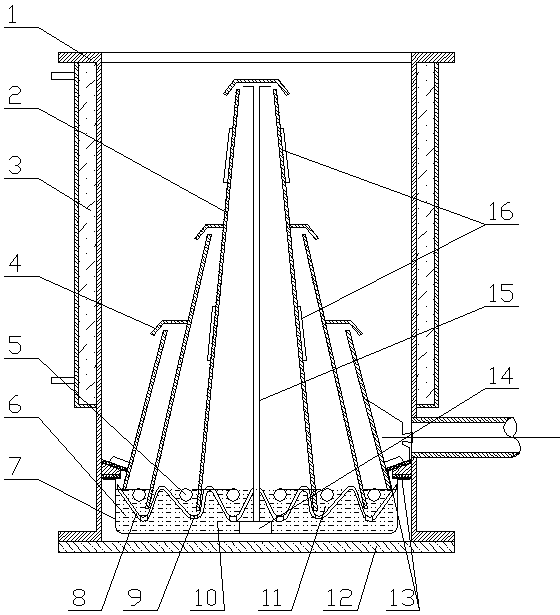

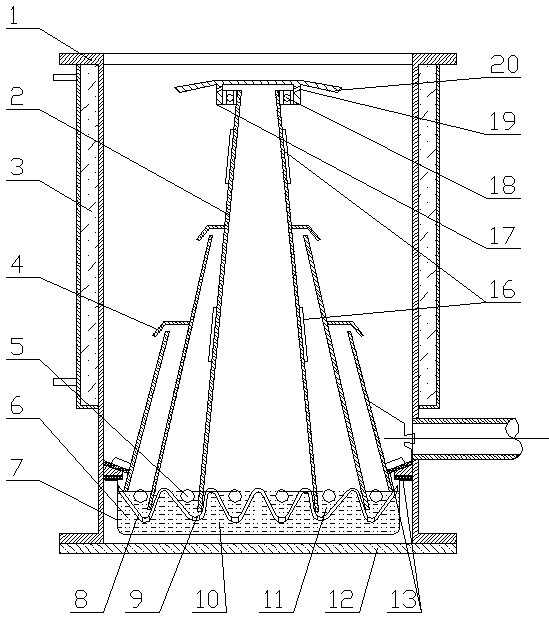

Floating heating type rapid start diffusion pump

ActiveCN108691819AReduce the temperatureTemperature low to highMachines/enginesDiffusion pumpsControl systemEvaporation

The invention provides a floating heating type rapid start diffusion pump. The floating heating type rapid start diffusion pump comprises a pump body, pump oil, a pump core, an evaporation system, a cooling system, an injection system and a control system. A floating heating manner is adopted for the evaporation system. The evaporation system comprises an evaporator, a heater and a temperature measurement and control element. The evaporator is provided with a heating area and an oil storage area, the heating area and the oil storage area are separated through a middle partition plate and communicate with each other through oil holes in the partition plate. The heater is arranged in the heating area and heats the pump oil in the heating area so that the pump oil can be evaporated instantlyto become steam. The heater is fixed to the middle partition plate, the middle partition plate can float on the pump oil, and the heating area can always keep constant and unchanged within a normal pump oil range. A heating device is arranged on or around a steam guide pipe in the injection system, the temperature of the pump core and the steam can be increased, the rate and kinetic energy of theinjected steam are increased, and rapid start of the diffusion pump can be realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

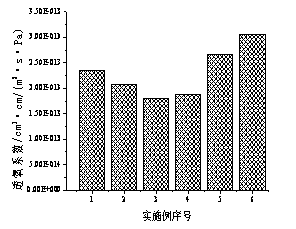

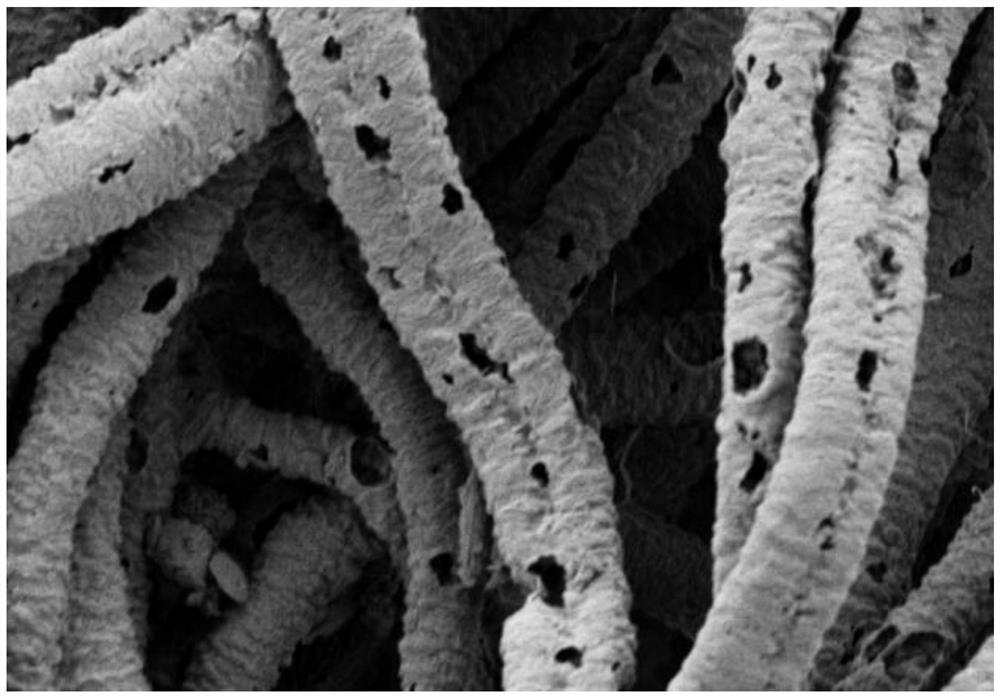

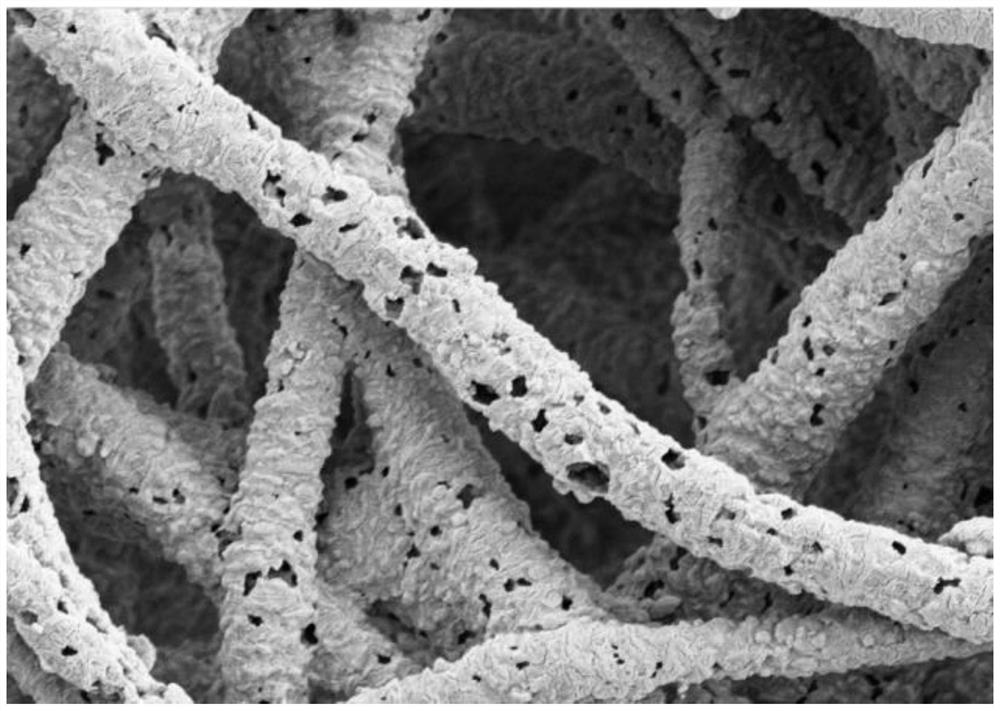

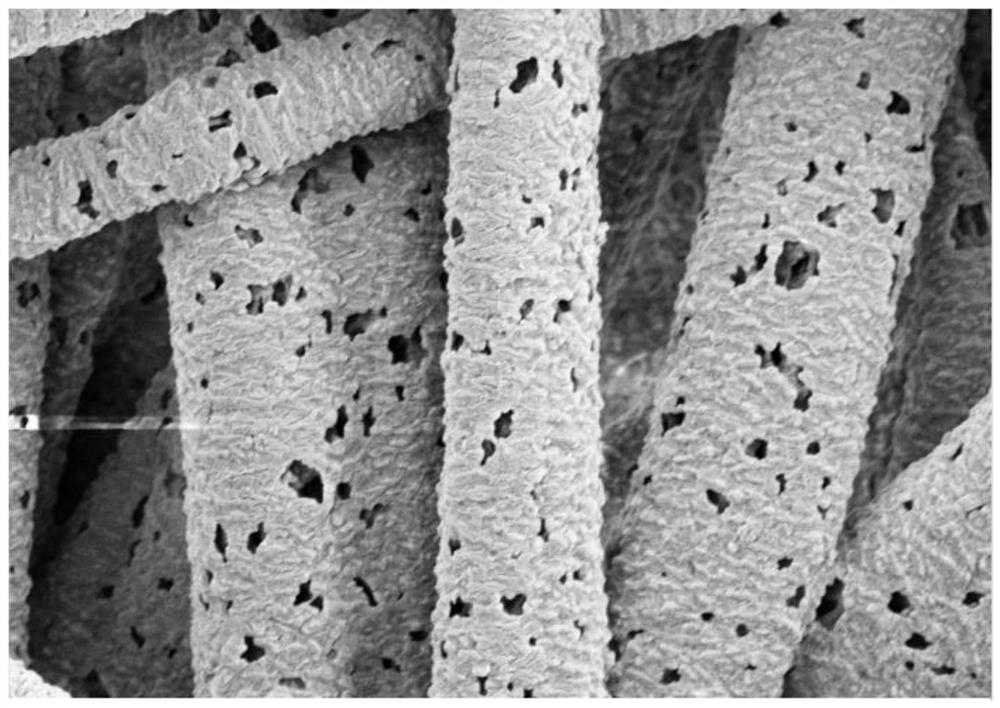

Preparation method of polytetrafluoroethylene fiber with porous structure

PendingCN112160039ADecomposition will notImprove fiber performanceArtificial filament recoveryTextile/flexible product manufacturePoly ethyleneNanofiber

The invention relates to the field of micro-nano fiber preparation, and aims to provide a preparation method of polytetrafluoroethylene fiber with a porous structure. The preparation method comprisesthe following steps of dissolving polyvinylpyrrolidone and polytetrafluoroethylene emulsion in deionized water, and stirring at room temperature to form a homogeneous solution; performing standing anddefoaming; adding the obtained spinning solution into a spinning device, and preparing micro-nano fiber through an electrostatic centrifugal spinning process; calcining the micro-nano fiber at the temperature of 360 DEG C in a nitrogen atmosphere; and carrying out dipping treatment in water, taking out the fiber, and drying the fiber to obtain the micro-nano fiber containing the microporous structure. According to the preparation method, the polytetrafluoroethylene fiber with the porous structure can be obtained by utilizing the high-temperature difficult-to-decompose property and the water-soluble property of the polyvinylpyrrolidone. The prepared product can improve the specific surface area and porosity of an original fiber material, can effectively improve the permeability, hydrophobicity and other properties of a fiber membrane, and has great application prospects in the fields of air filtration, oil-water separation, membrane distillation and the like.

Owner:ZHEJIANG SCI-TECH UNIV

A self-cleaning super weather-resistant powder coating and its preparation method

ActiveCN103194140BImprove stabilityProtect against agingPowdery paintsPolyester coatingsPolyesterAging resistance

The invention belongs to the field of powder paints and particularly relates to a self-cleaning super-weather-proof powder paint. The self-cleaning super-weather-proof powder paint comprises a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system in a weight part ratio of 4:1-1:4, wherein the fluorocarbon resin particle system contains TiO2 nano-particles. As carboxyl-terminated polyester is introduced into a pure fluorocarbon paint, the phase separation occurs in a solidification process, and the fluorocarbon resin floats up to the surface of a coating to serve as coating protection and ageing resistance; the carboxyl-terminated polyester and the like and a substrate can be well wetted, so that the coating and the substrate can be well adhered and can hardly crack and spall; as the TiO2 nano-particles only exist in a fluorocarbon phase, the resin on a bottom layer cannot be broken, and the excellent stability of the system is guaranteed; and the TiO2 nano-particles are scattered in a dry blending manner, and the complex preprocessing is avoided, so that the preprocessing process can be greatly shortened, the cost is lowered, and the efficiency is improved.

Owner:NINGBO SOUTH SEA CHEM

Antibacterial HDPE plastic

The antibacterial HDPE plastic is prepared from the following raw materials: an antibacterial agent reinforced HDPE, graphene, bamboo charcoal fibers, a toughening agent, a flame-retardant plasticizer, an antioxidant, methyl silicone oil, polyethylene glycol and a coupling agent. The preparation method is simple, and the prepared antibacterial HDPE plastic has good high temperature resistance, mechanical properties, safety, surface properties and antibacterial properties, and has broad application prospects.

Owner:瑞普环保新材料(广州)有限公司

Dried bamboo shoot fermented sauce, and preparation method thereof

InactiveCN108813555AAvoid bad tastePrevents oxalate from binding to calciumYeast food ingredientsFood ingredient functionsPre treatmentYeast

The invention discloses a dried bamboo shoot fermented sauce, and a preparation method thereof, and belongs to the technical field of food processing. The dried bamboo shoot fermented sauce comprises,by weight, 80 to 100 parts of flour, 50 to 60 parts of fresh bamboo shoot, 20 to 26 parts of peanut, 0.8 to 1 part of yeast, 0.36 to 0.45 part of Aspergillus oryzae, 15 to 20 parts of red date, 10 to12 parts of honey, and an appropriate amount of water. The preparation method comprises following steps: raw material preparation, raw material pre-treatment, dried bamboo shoot processing, starter making, fermentation, blending, and packaging and sterilizing. According to the preparation method, dried bamboo shoot is taken as the raw material, most oxalic acid in bamboo shot is removed, red dateand peanut are added, suitable people range is widened, and edible value is high.

Owner:绩溪县老胡家生态农业专业合作社

Aluminum-containing ferroalloy for steelmaking deoxidizing

The invention discloses a deoxidizing agent for steelmaking, which contains 40% to 70% of aluminum, 0.5% to 20% of tungsten and / or molybdenum, the remaining are iron and unavoidable impurity. The alloy solves the problem of easy pulverization of current aluminum matrix complex deoxidizer.

Owner:谢应凯

A kind of LDPE antibacterial plastic and preparation method thereof

ActiveCN105670092BDecomposition will notImprove the bactericidal effectLow-density polyethyleneBetaine

The invention relates to an LDPE (low-density polyethylene) antibacterial plastic and a preparation method therefor. The antibacterial plastic is prepared from the following components in parts by weight: 100-150 parts of LDPE, 3-5 parts of isothiazolinone, 2-5 parts of polyhexamethyleneguanidine, 2-5 parts of betaine, 2-5 parts of nano-zinc oxide powder, 3-5 parts of nano-titanium dioxide, 0.5-2 parts of zinc stearate, 0.5-2 parts of white oil, 0.5-5 parts of a coupler, 0.5-2 parts of oleamide, 0.1-1 part of an ethylene-octene copolymer, 0.5-1 part of an antioxidant, 0.1-3 parts of a styrene-maleic anhydride random copolymer and 0.5-2 parts of a plasticizer. The antibacterial plastic is excellent in mechanical property and processing performance and good in flame retardancy, has good antibacterial property and can be used for plastic products such as plastic films, packaging bags and the like.

Owner:SHENZHEN BOXINMEI NANOMETER TECH CO LTD

Long-acting broad-spectrum antibiotic polypropylene plastic and method for preparing the same

ActiveCN101550250BDecomposition will notImprove the bactericidal effectSodium PyrithioneEconomic benefits

The invention discloses a long-acting broad-spectrum antibiotic polypropylene plastic, composed by components of following weight parts: polypropylene 100 parts, zinc pyrithione 0.5 to 5 parts, antioxidant 0.5 to 2 parts, dispersant 1 to 2 parts. The invention also discloses prepartion method of the long-acting broad-spectrum antibiotic polypropylene plastic. The beneficial effects of the invention are reflected in: excellent high temperature resistant performance, high efficiency broad-spectrum antibiotic, simple and convenient operation, low cost and good economic benefit.

Owner:浙江石油化工有限公司

A kind of pp antibacterial plastic and preparation method thereof

Owner:广州美泰包装科技有限公司

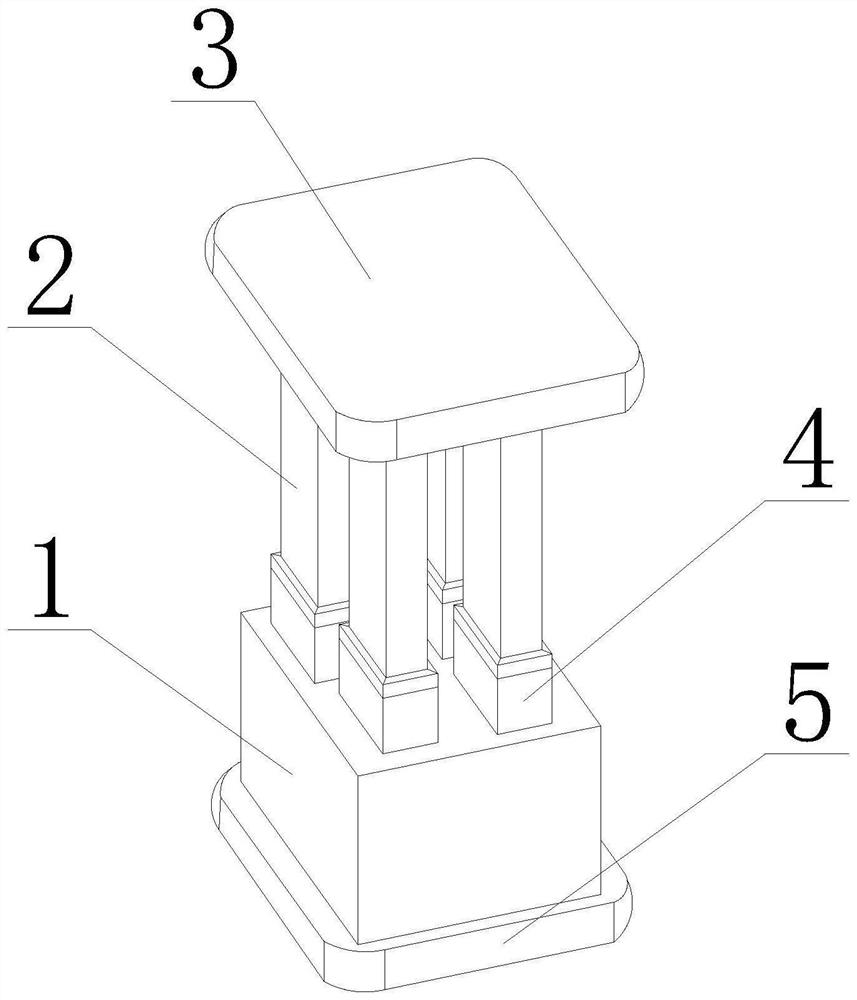

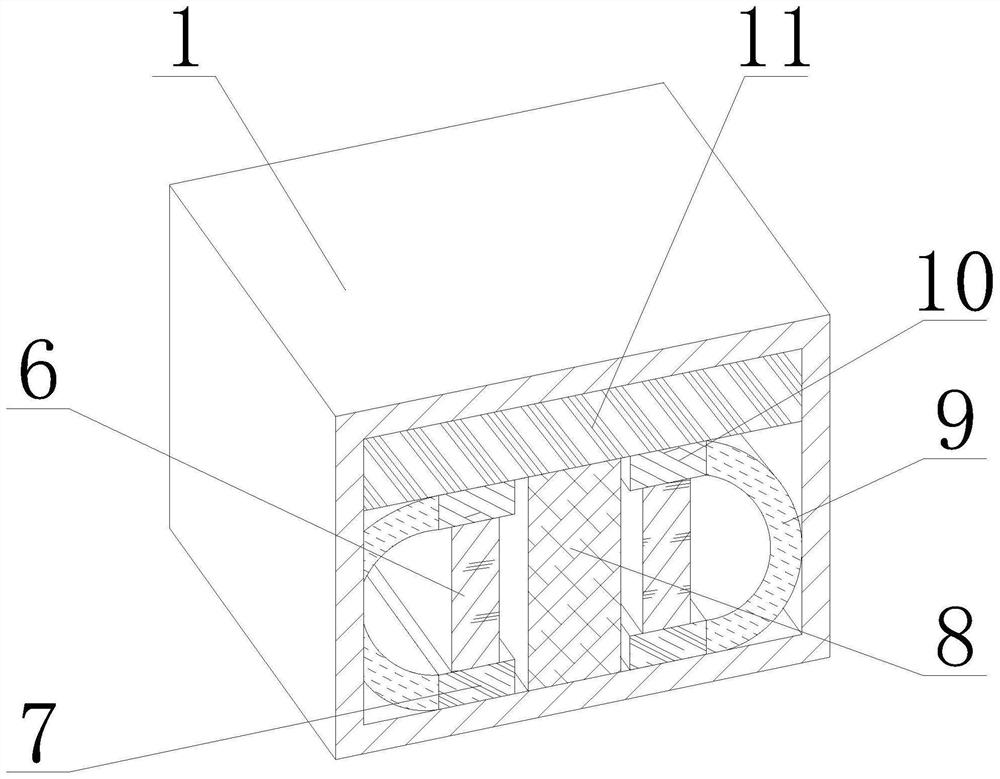

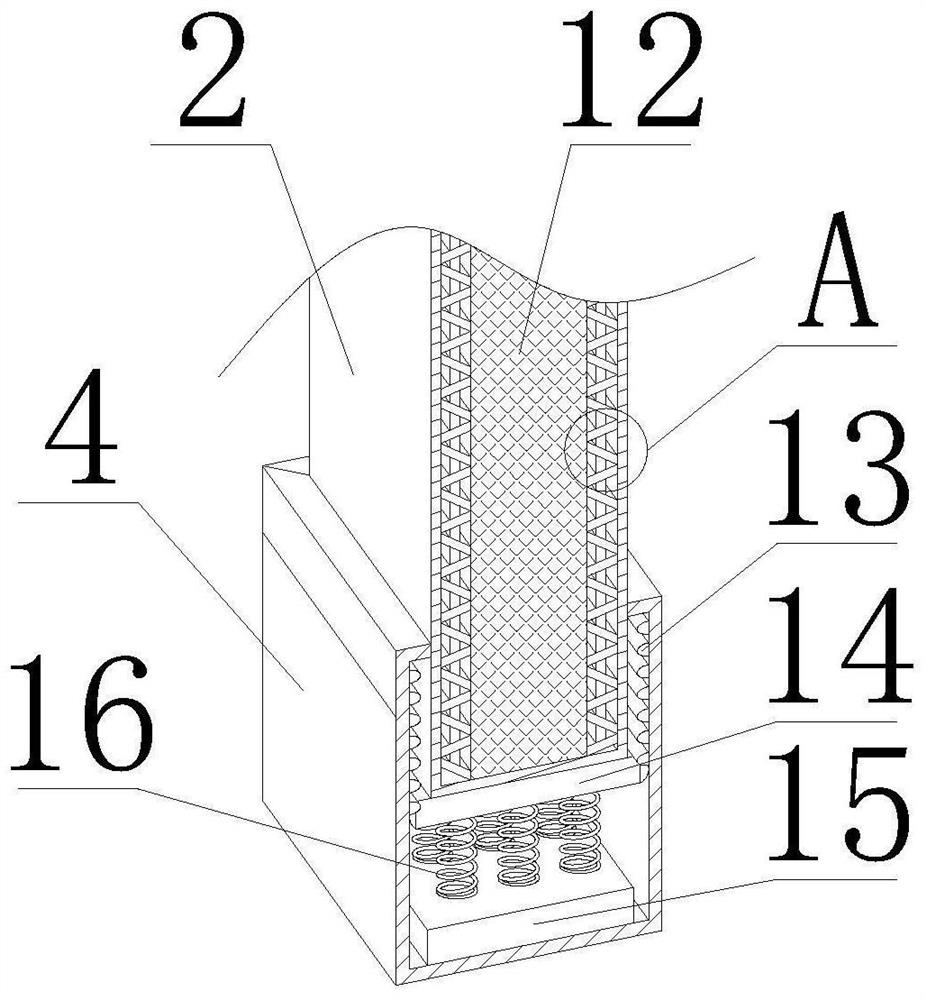

Gravity support for building construction

PendingCN113513188AShock absorptionDecomposition will notVibration suppression adjustmentsShoresArchitectural engineeringSupport plane

The invention discloses a gravity support for building construction, and belongs to the technical field of building construction. The gravity support comprises a gravity support main body, a telescopic support frame, a support top plate, a fixed support table and a main body base table; the top of the main body base table is fixedly mounted at the bottom of the gravity support main body; and the bottom of the fixed support table is fixedly installed on the top of the gravity support main body. The gravity support is ingenious in design, a supporting transmission rod, a transmission rod fixing table, a damping fixing table, a damping semicircular body pipe, a round body pipe connecting piece and a solid body main body supporting shaft are combined, and the problems that when an existing gravity support is used, only a building can be supported, vibration generated in construction cannot be damped, and the building use cannot be effectively helped better is solved, the effect of supporting the building can be achieved, meanwhile, vibration generated in construction can be damped, and more effective help can be provided for building use.

Owner:吴韩

An ultra-low hydrogen high toughness welding rod for welding penstocks in hydropower stations

ActiveCN103921019BSolving recipe problemsImprove dehydrogenation capacityWelding/cutting media/materialsSoldering mediaPotassiumRare earth

The invention provides an ultralow-hydrogen high-toughness welding rod for welding of a water-diversion steel penstock in a hydropower station. A coating of the welding rod comprises, by mass, 40%-50% of marble, 2%-4% of dolomite, 18%-30% of fluorite, 2%-6% of quartz, 1%-3% of dehydrated feldspar, 1%-3% of zircon sand, 2%-4% of potassium titanate, 3%-6% of atomized ferrosilicon, 4%-8% of electrolytic manganese, 7%-12% of ferrotitanium, 1%-3% of light rare earth silicon iron, 0.5%-1.0% of ferromolybdenum, 2%-4% of nickel powder, and 0.5%-1.0% of rare earth fluoride. All the components are mixed according to the ratios to form the coating of the welding rod, potassium and sodium mixed water glass is added, an H04E welding core is coated with the mixture through a welding rod pressure coater, and the coated welding core is dried and shaped to form the electric welding rod. The deposited metal diffusible hydrogen content of the welding rod is 1.8 ml / 100 g, the low temperature impact toughness at minus 20 DEG C is stabilized within the range from 160 J to 180 J, and the welding requirement of the water-diversion steel penstock in a 610 MPa hydropower station can be met.

Owner:HUBEI CHUANWANG SPECIAL WELDING MATERIALS

Diffusion pump capable of achieving rapid starting, floating heating and rotating injection

ActiveCN108691818AReduce the temperatureTemperature low to highMachines/enginesDiffusion pumpsTemperature controlControl system

The invention discloses a diffusion pump capable of achieving rapid starting, floating heating and rotating injection. The diffusion pump comprises a pump body, pump oil, a pump core, an evaporation system, a cooling system, an injection system and a control system, the evaporation system of the pump adopts a heating mode of floating heating, the evaporation system comprises an evaporator, a heater and a temperature measuring and temperature control element, the evaporator is provided with a heating area and an oil storage area, the heating area and the oil storage area are separated through amiddle partition plate and communicate with each other through an oil hole in the partition plate, the heater is arranged in the heating area, and is used for heating the pump oil in the heating areato enable the pump oil to be instantly evaporated to become steam, the heater is fixed on the middle partition plate, the middle partition plate can float in the pump oil, the top of a steam guide pipe in the injection system is provided with a rotating spray head, a series of nozzles are arranged on the periphery of the rotating spray head, when steam is sprayed out of the nozzles, the rotatingspray head can rotate at a high speed, a heating device is arranged on the steam guide pipe or around the steam guide pipe so that the temperature of the pump core and the steam can be improved, and rapid starting of the diffusion pump can be realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

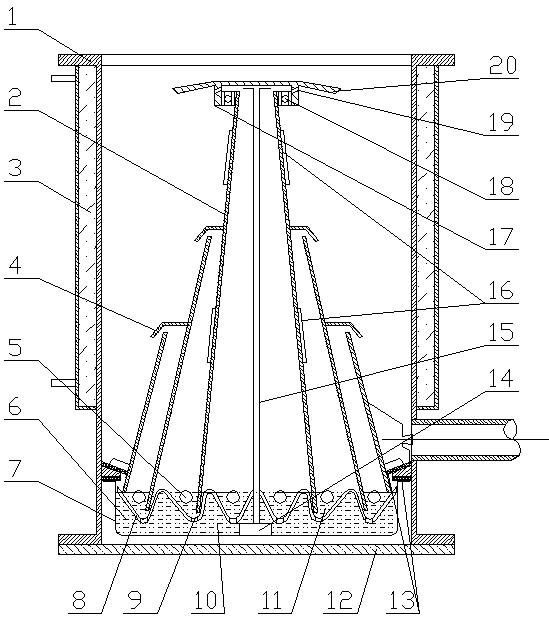

Foamed glass material for purifying water, and preparation method thereof

InactiveCN109650728AIncrease microporosityTo achieve the purification effectGlass shaping apparatusTreatment with microorganism supports/carriersNon toxicityBottle

The invention discloses a foamed glass material for purifying water, and a preparation method thereof. Waste glass bottles undergo a series of treatments through special techniques to form the foamedglass material for purifying water, that is foamed micro-porous silicon pumice with an aperture of 1-4 mm, a water absorption rate of 5-10%, a stress of 1200-3000 N and a specific gravity of 0.5-0.8 g / ml. A foaming mixture is calcined at a high temperature to prepare the foamed glass material, and the foaming mixture includes 90-93 wt% of glass powder, 0.4 wt% of seashell powder having a particlesize of 2-4 mm, 0.6 wt% of seashell powder having a particle size of 1 mm or less and 0.2-1.0 wt% of activated carbon. The foamed microporous silicon pumice has the advantages of durability, high performances, non-toxicity, harmlessness, non-radioactivity, good chemical stability, good corrosion resistance, good weather resistance, insolubility and non-degradability, and the ammonia nitrogen, biochemical oxygen demand, chemical oxygen demand and other indicators of sewage treated with the foamed glass material are significantly reduced.

Owner:深圳市优力凯环保生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com