Modified resin composition, preparation method thereof and application thereof

A technology for modifying resins and compositions, which is applied in the field of modified resin compositions, and can solve the problem of limited heat resistance temperature, no clear mention of complex physical properties, decomposition temperature and clear chemical structure, toxic hexavalent metal chromium ions and other issues to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

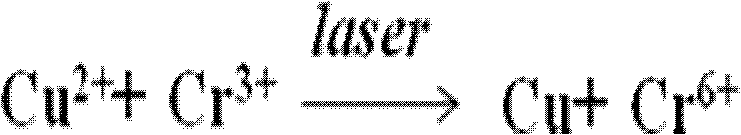

Problems solved by technology

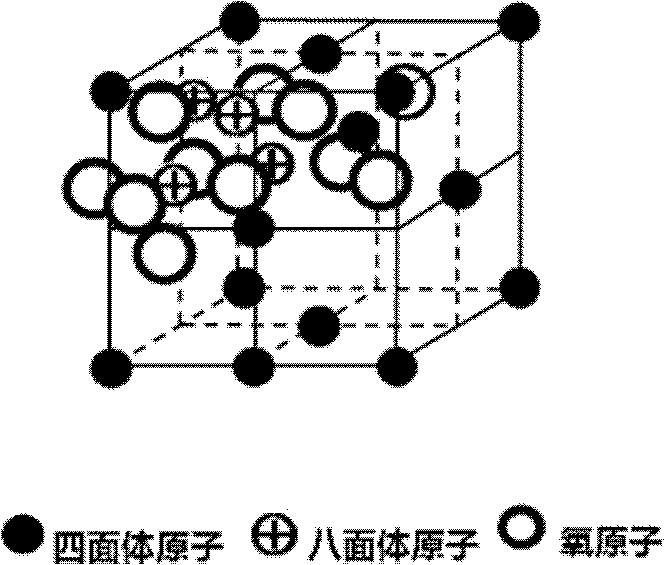

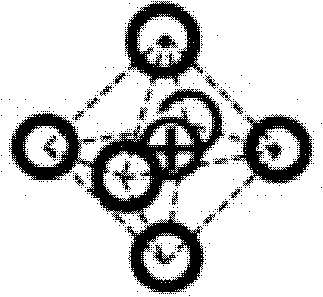

Method used

Image

Examples

Embodiment 1

[0055] A modified resin composition capable of depositing a metal film is prepared by the following method:

[0056] The resin matrix is a PC / ABS alloy, the maximum processing temperature is 250°C, and the resin PC and the resin ABS are pre-mixed uniformly in a ratio of 7:3 by weight. The laser-sensitive additive adopts copper-manganese (iron) type laser-sensitive additive (purchased from Kohler Pigment Co., Ltd.), and the consumption is respectively 3%, 5%, 7%, and 15% of the total mass of raw materials of the modified resin composition; the laser-sensitive additive Alternatively, a copper-manganese (iron-zinc) type laser-sensitive additive (purchased from Kohler Pigment Co., Ltd.) is used in an amount of 7% of the total mass of raw materials of the modified resin composition. The laser-sensitive additive is uniformly mixed with the resin matrix and fed from the main feeding port of the extruder, extruded and granulated to obtain a modified resin composition capable of depo...

Embodiment 2

[0061] A modified resin composition capable of depositing a metal film is prepared by the following method:

[0062] The resin matrix is high-temperature nylon PA10T (Kingfa Technology Co., Ltd.), the maximum processing temperature is 340°C, the content of flat glass fiber (flat ratio 2:1) is 30%, 50%, 60wt%, the content of sodium phosphinate is 14wt%, zinc borate Content 1wt%. The laser sensitive additive adopts copper-manganese (iron) type laser sensitive additive, and the dosage is 3%, 7%, 15% of the total mass of raw materials of the modified resin composition; the laser sensitive additive or adopts copper-manganese (iron-zinc) type laser sensitive additive The additive is used in an amount of 7% of the total mass of raw materials of the modified resin composition. The laser-sensitive additive and the resin matrix are evenly mixed and fed from the main feeding port of the extruder, and the glass fiber is fed from the side feeding port, extruded and granulated to obtain ...

Embodiment 3

[0067] A modified resin composition capable of depositing a metal film is prepared by the following method:

[0068] The resin matrix is thermotropic liquid crystal polymer LCP (Kingfa Technology Co., Ltd.), the maximum processing temperature is 360°C, and the amount of talcum powder added is 30%, 40%, and 60wt%. The laser sensitive additive adopts copper-manganese (iron) type laser sensitive additive, and the dosage is 3%, 7%, 15% of the total mass of raw materials of the modified resin composition; the laser sensitive additive or adopts copper-manganese (iron-zinc) type laser sensitive additive The additive is used in an amount of 7% of the total mass of raw materials of the modified resin composition. The laser-sensitive additive and the resin matrix are evenly mixed and fed from the main feed port of the extruder, and the talc powder is fed from the side feed port, extruded and granulated to obtain a modified resin composition capable of depositing a metal film.

[0069...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com