Special type sludge dewatering extrusion granulator

A technology of sludge dehydration and granulation machine, which is applied in the direction of raw material extrusion granulation, dehydration/drying/thickened sludge treatment, presses, etc., which can solve the problems of high equipment investment and operating costs, and large floor space. Achieve energy saving, large processing capacity, and even water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

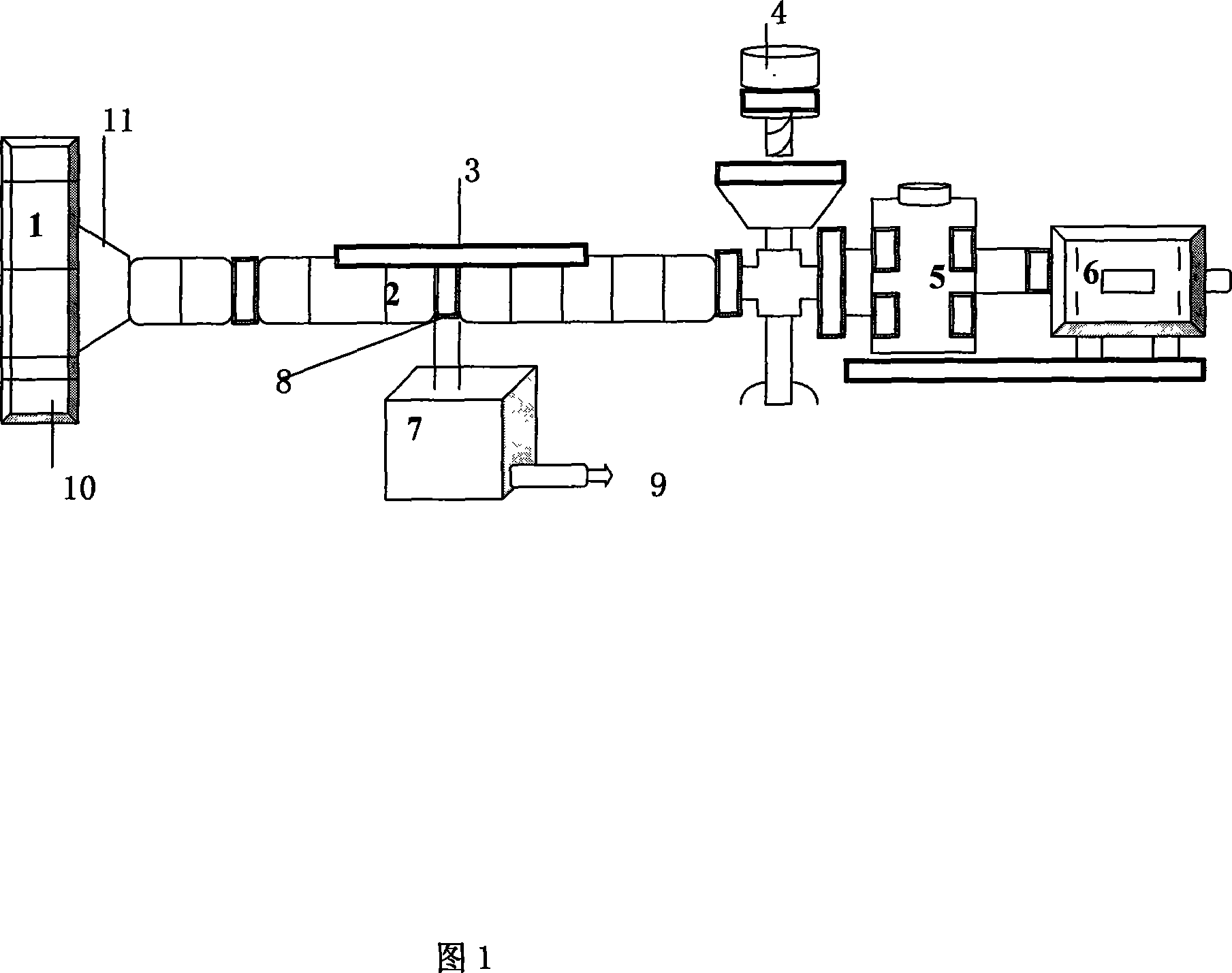

[0016] The special sludge dewatering extrusion granulator is to feed the sludge to the conical single screw and barrel (2) through the sludge feeder (4) for dehydration. The moisture content of the sludge is controlled at a moisture content of 35%. -40%, through (2) connected granulation membrane head (11) and eccentric granulator (1) extrusion cutting granulation is sent out from the discharge port (10), and the moisture detached from the sludge is discharged from the drain ( 8), Negative pressure vacuum (7), discharge of sewage outlet (9), sludge dehydration and granulation in heater (3) specific temperature control, stable feeding in gear box (5), DC motor (6 ) is completed under the stable control, providing a special environment for sludge dewatering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com