Method for preparing carbon nano tube enhanced titanium-base compound material by in-suit reaction

A technology for titanium-based composite materials and carbon nanotubes is applied in the field of in-situ reaction preparation of carbon nanotube-reinforced titanium-based composite materials, which can solve the problems of poor uniform dispersion of carbon nanotubes, poor structural integrity, and pollution of titanium matrix materials. Avoid the reaction between titanium and carbon, the structure is complete, the effect of uniform dispersion without agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

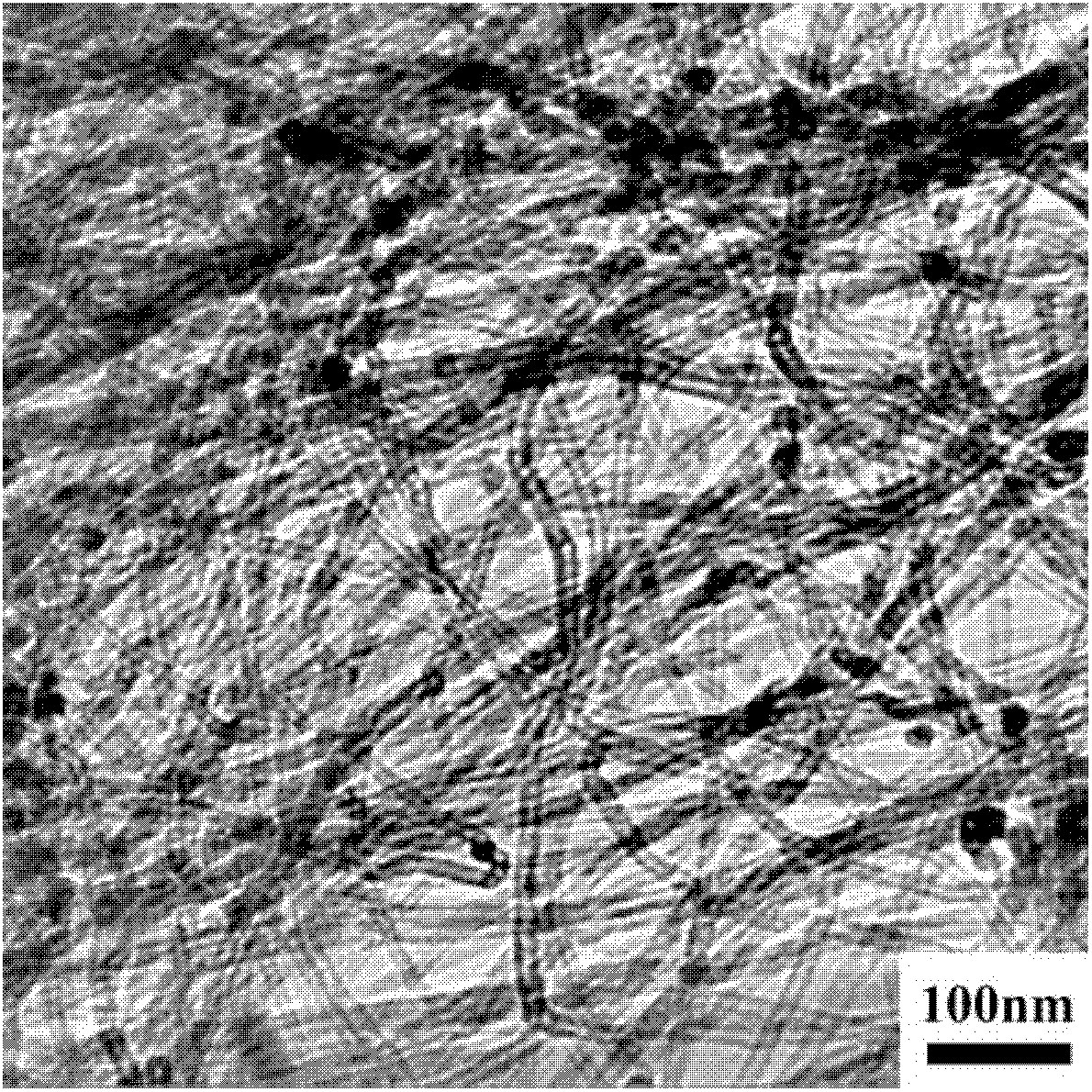

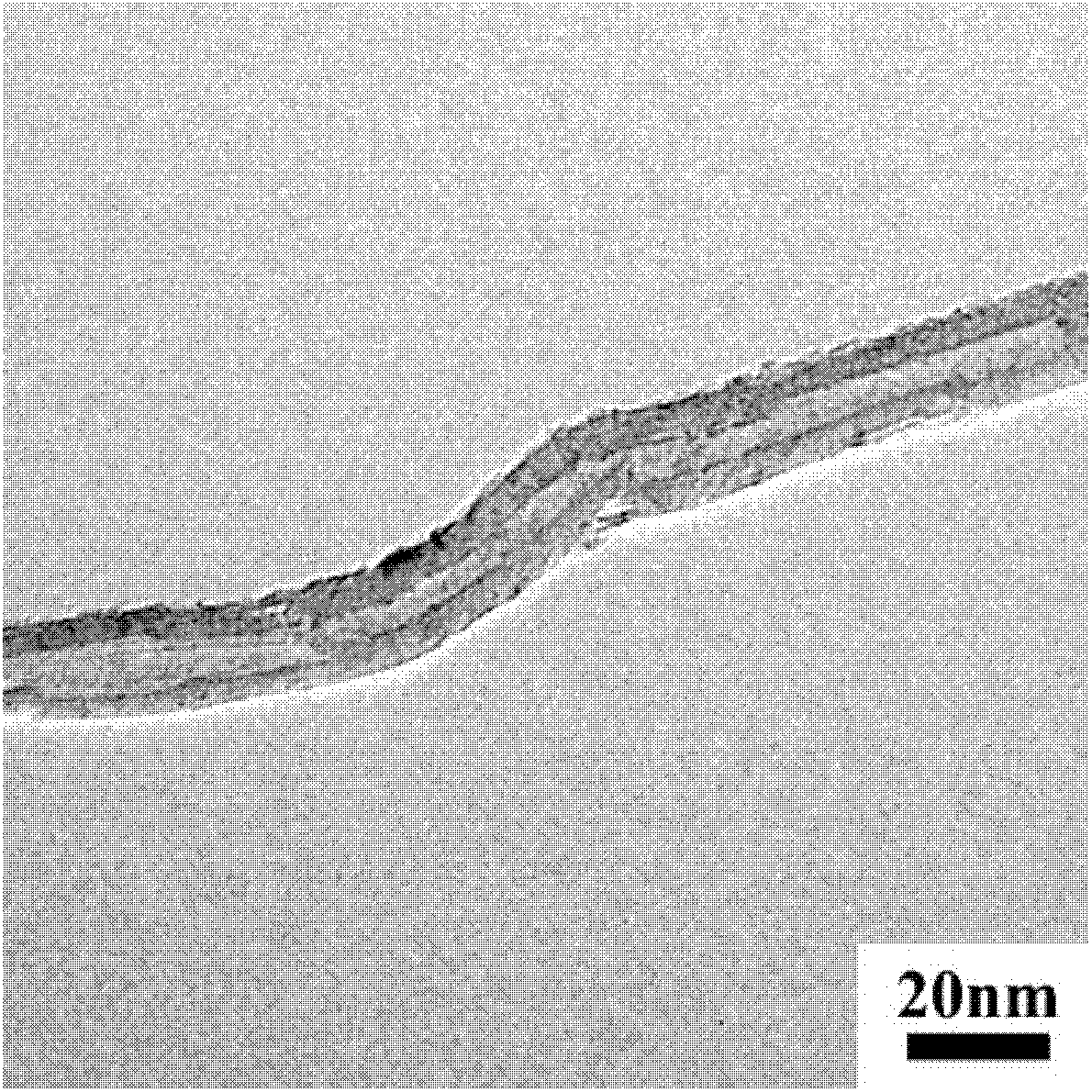

[0014] Specific embodiment one: the method for preparing carbon nanotube reinforced titanium-based composite material by in-situ reaction in this embodiment, proceeds according to the following steps: 1. Nickel nitrate hexahydrate and TiH 2 The powder is added into an ethanol solution with a volume concentration of 95% in a weight ratio of 0.143:1 to obtain a mixed solution. The concentration of nickel nitrate hexahydrate in the mixed solution is 0.1mol / L, stirred for 1 hour, and then heated to 80°C and stirred to mix The solution is evaporated until the weight ratio of Ni and Ti is 0.03:1, that is, Ni-TiH 2 Composite powder; Two, the Ni-TiH obtained in step one 2 Spread the composite powder evenly in the quartz boat, put the quartz boat into the plasma-enhanced chemical vapor deposition equipment, evacuate to 5Pa, and inject H 2 , H 2 The flow rate is 20sccm, the working pressure is 200Pa, then the temperature rises, and the working temperature reaches 500-550°C within 20 m...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 2, the working temperature reaches 500°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment is different from Embodiment 1 in that: in step 2, the working temperature reaches 550°C. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com