Evaporation or sublimation method and crucible device for evaporation material in vacuum evaporation device

A technology for vapor deposition materials and crucibles, which is applied in the field of crucible devices for vacuum vapor deposition, can solve the problems of complicated devices, reduced quality of vapor deposition materials, and adverse effects on film formation, and achieves a simple structure and the effect of preventing deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

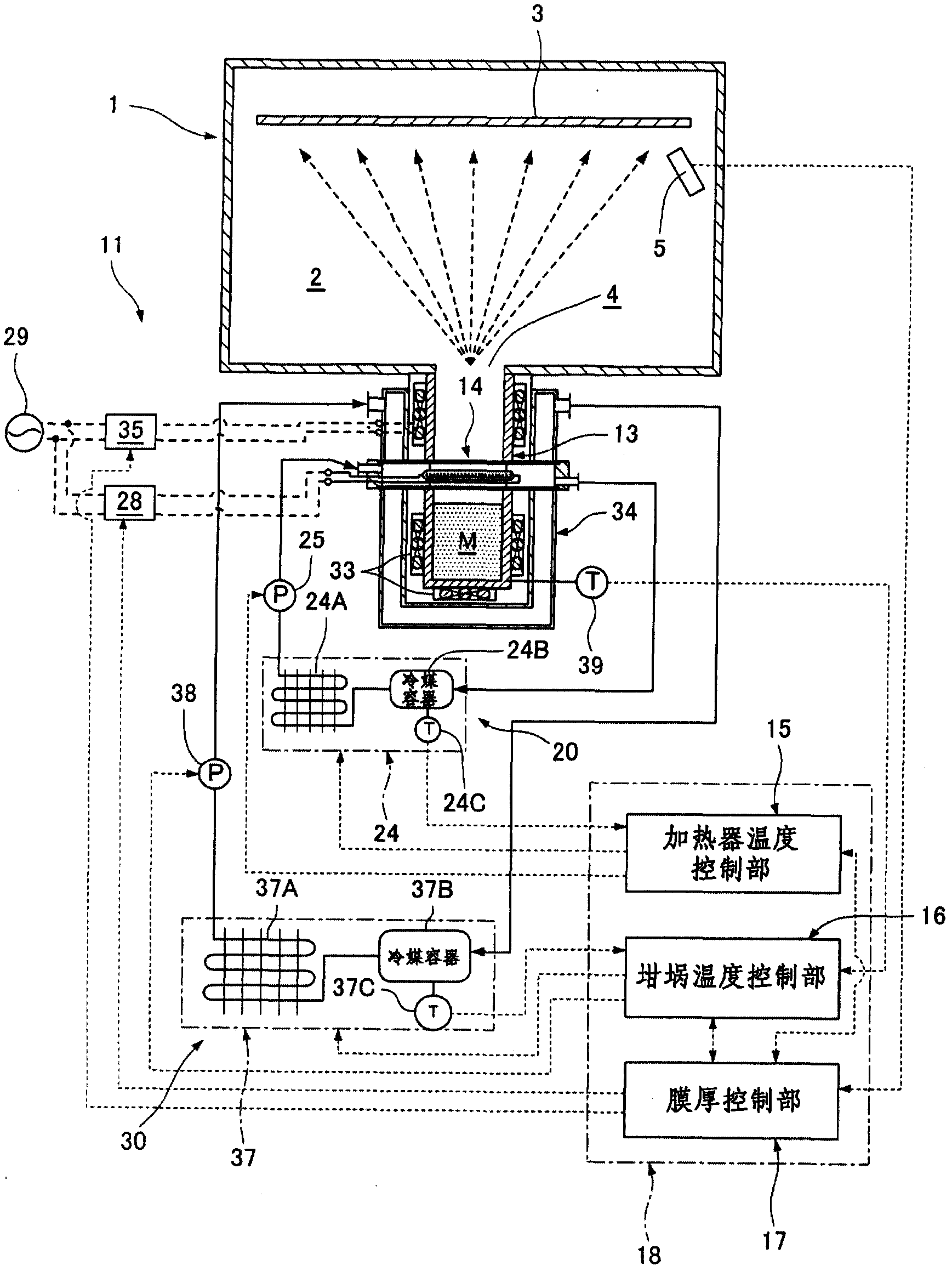

[0074] Such as figure 1 As shown, the vacuum evaporation device is an upper deposition structure. In the upper deposition type vacuum evaporation device, in the upper part of the inner side of the vacuum evaporation chamber 2 formed by the vacuum container 1, the substrate 3 as the member to be evaporated is arranged by means of a holding member (not shown). A material discharge port 4 is provided at the bottom. Furthermore, a material evaporating device 11 is provided outside the vacuum container 1 for heating, evaporating and sublimating the evaporation material M, and the material evaporating device 11 communicates with the material discharge port 4 . An opening with an opening and closing door for allowing the substrate 3 to enter and exit is also formed in the vacuum container 1 , which is not shown in the figure.

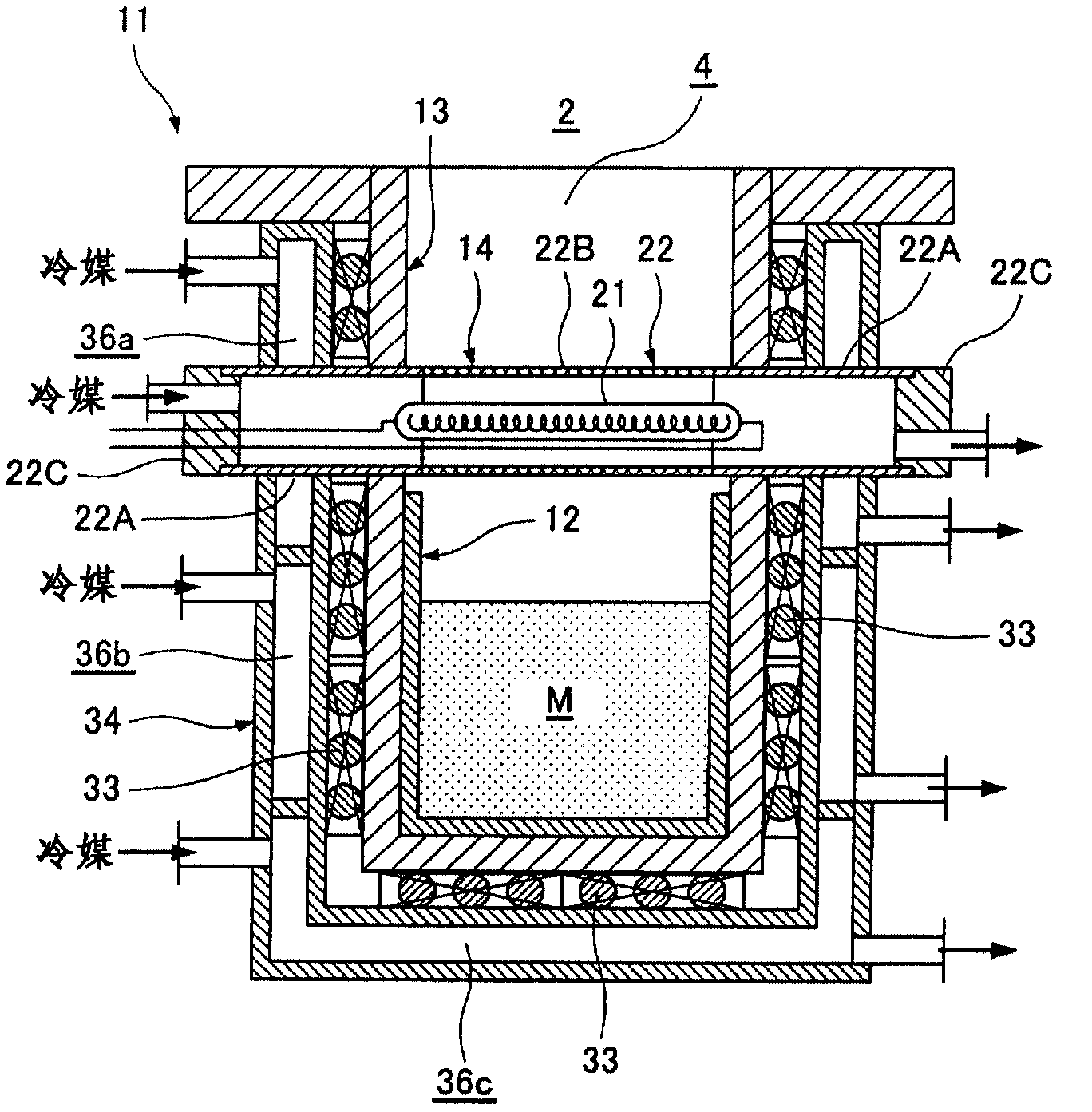

[0075] Such as figure 2 As shown, the crucible arranged on the material evaporation device 11 includes: a crucible main body 12, which is used to accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com