Patents

Literature

92results about How to "Will not deteriorate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

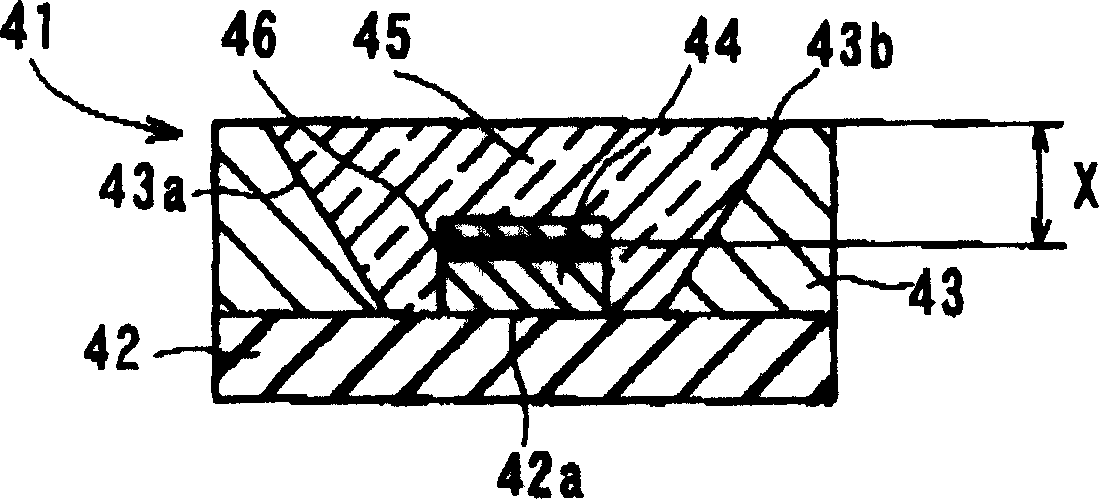

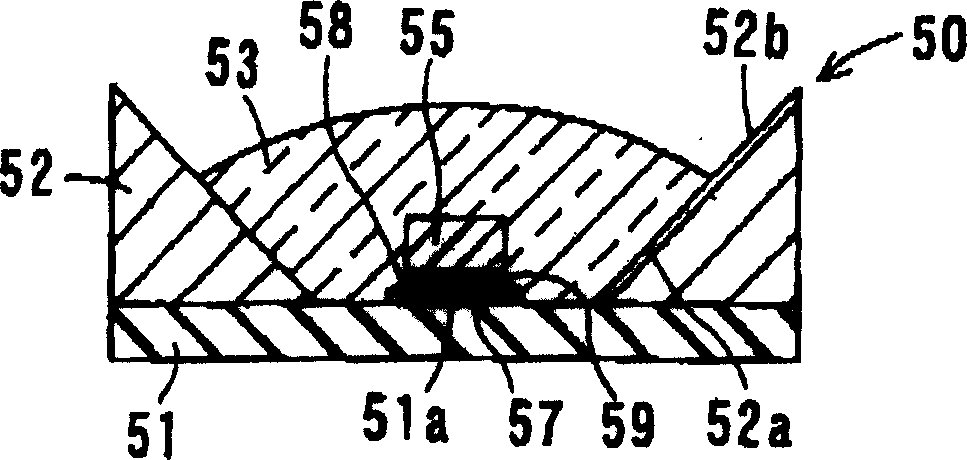

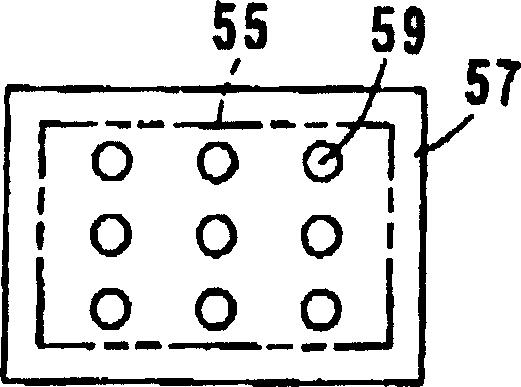

Light-emitting element reception package, light-emitting device and lighting device

InactiveCN1612369ARaise the ratioImprove light outputSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorEffect light

The package has a base body (51) with a mounting portion for mounting a light-emitting unit. A frame body is joined to an outer edge of the body (51) to surround the portion. A wiring conductor has its one end formed on an upper surface of the base body, to electrically connect an electrode of the light emitting unit. The light transmitting unit (53) is inside the frame body to cover the light emitting unit. - Independent claims are also included for the following: - (A) a light-emitting apparatus comprising a package for housing a light emitting unit - (B) an illumination apparatus constructed by setting up a light-emitting apparatus in a predetermined arrangement.

Owner:KYOCERA CORP

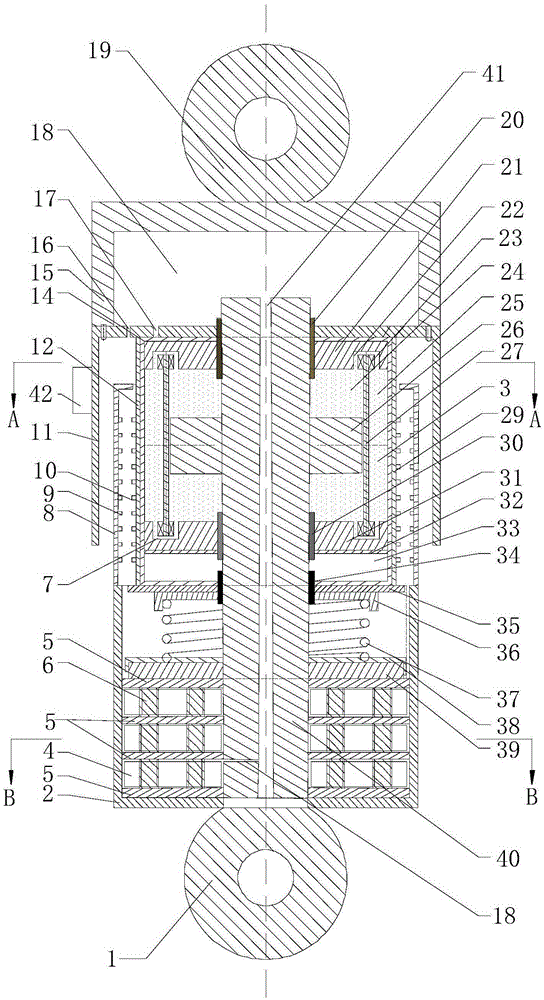

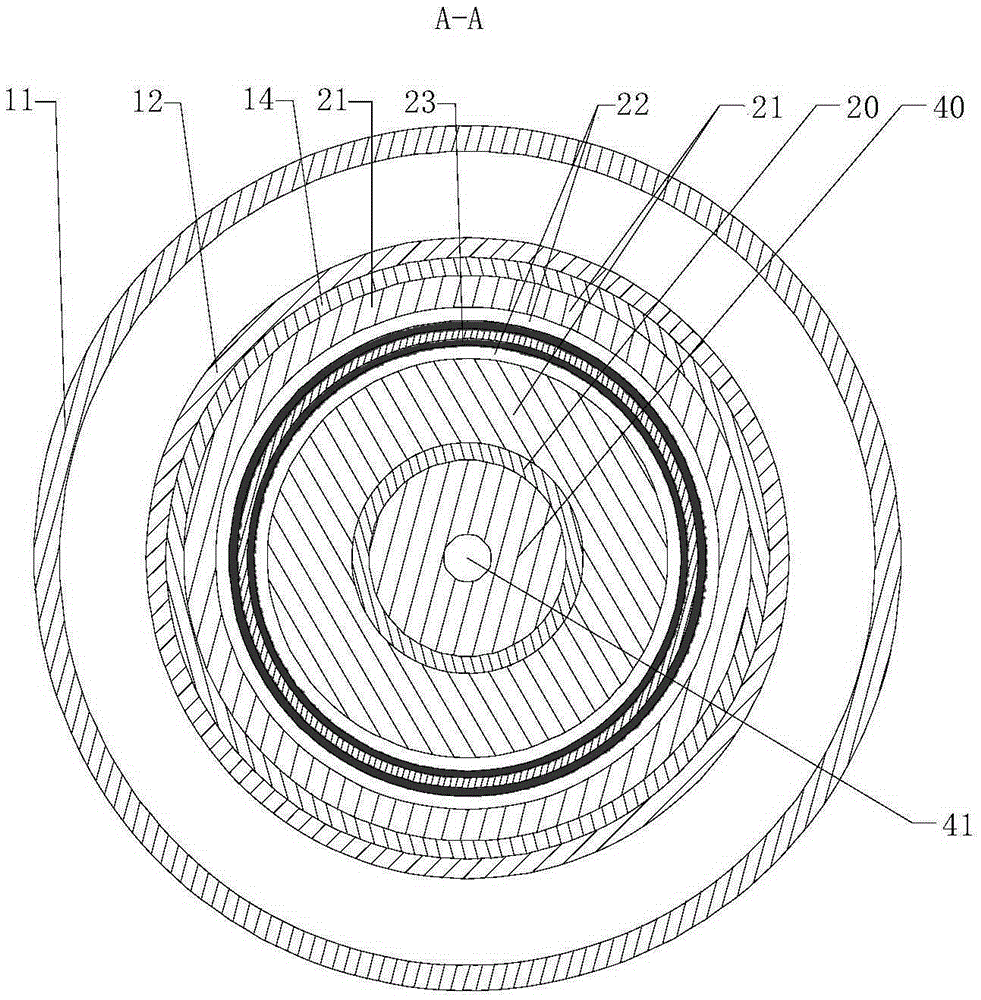

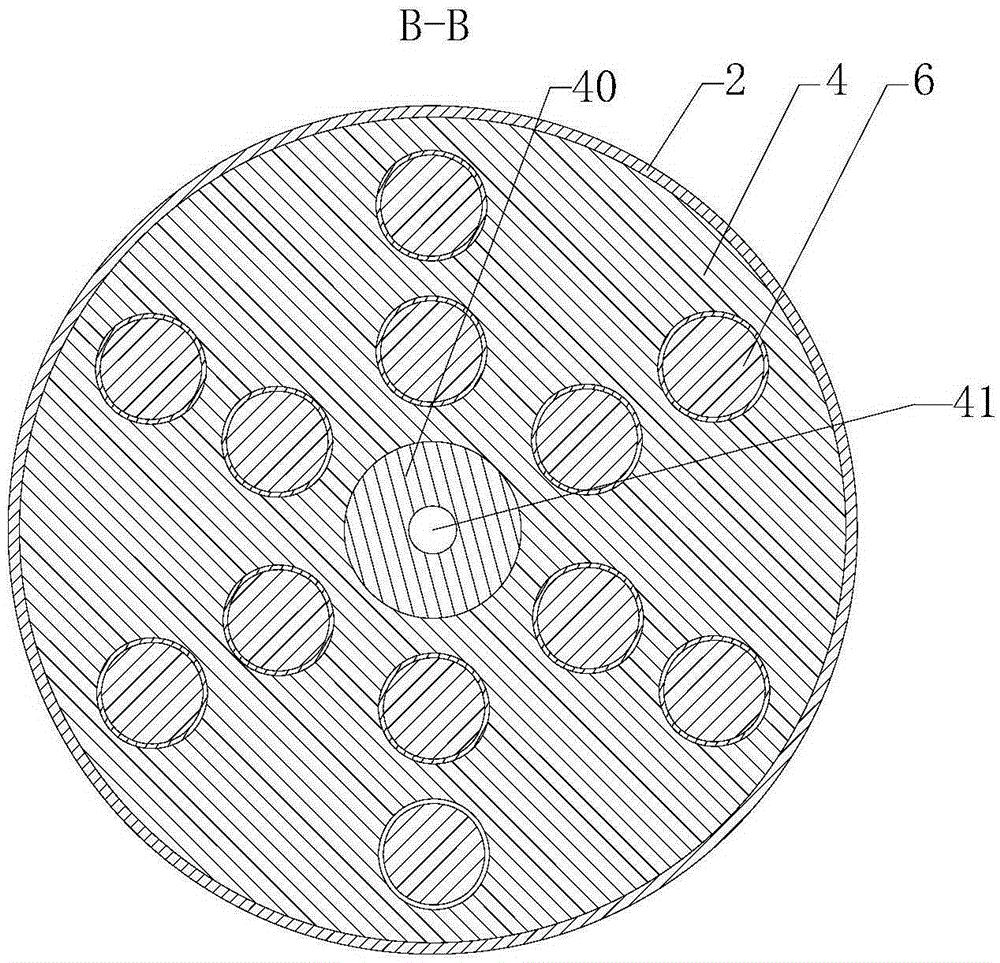

Self-powered vehicle vibration damping device and control method therefor

ActiveCN105351431ACompact structureNovel and reasonable designSpringsNon-rotating vibration suppressionElectricityMagneto rheological

The invention discloses a self-powered vehicle vibration damping device which comprises a vibration damping device body and a vibration damping device controller, wherein the vibration damping device body comprises a first cylinder body, a piston rod, a piezoelectric generating unit, a transmission force spring unit, a magneto-rheological damping unit and an electromagnetic induction unit; the piezoelectric generating unit comprises a plurality of piezoelectric modules, and a plurality of piezoelectric vibrators are inlaid in each piezoelectric module; the transmission force spring unit comprises an upper spring pressing plate, a lower spring pressing plate, a lower spring clamping seat, an upper spring clamping seat and a transmission force spring; the magneto-rheological damping unit comprises an outer cylinder, an inner cylinder, a permanent magnet protecting cover, an upper damp channel, a lower damp channel, a magnet exciting coil and a piston; and the electromagnetic induction unit comprises a leakage-proof magnetic sleeve, a second cylinder body, a permanent magnet and an electromagnetic induction coil. The invention further discloses a control method for the self-powered vehicle vibration damping device. The self-powered vehicle vibration damping device provided by the invention is high in energy-regenerative efficiency, good in work stability, high in reliability, can adjust the damping force in real time, and ensures that a vehicle is in an optimal vibration damping state.

Owner:XIAN UNIV OF SCI & TECH

Method for machining elliptical end socket

InactiveCN103831584AMaterial deteriorationWill not deteriorateHollow articlesAcid washingFree cooling

The invention discloses a method for machining an elliptical end socket. The method includes the following steps that first, discharging is performed; second, welding is performed; third, cold pressing is performed so that preliminary forming is achieved; fourth, end socket pressing is performed, wherein integral forming is performed through pressing so that a semi-finished end socket can be obtained; fifth, cold spinning is performed, wherein the semi-finished end socket is subjected to cold spinning so that final forming is achieved; sixth, heat treatment is performed, wherein the temperature of an empty furnace is raised to 400 DEG C, the end socket is put into the furnace and heated to 500 DEG C to 600 DEG C, the temperature is kept for 20 minutes to 30 minutes, the temperature is lowered to 400 DEG C, and the end socket is taken out of the furnace and naturally cooled; seventh, grooving and grinding are performed; eighth, acid washing is performed, wherein acid wash is evenly smeared onto the whole outer surface of the end socket, preliminary washing is performed, and then the end socket is washed clean with clean water. According to the method, heating is not performed before forming, and materials can not degrade; the cold pressing, the end socket pressing and the cold spinning are adopted for forming, and changes of size can not be caused; a passive film is formed on the surface of the end socket through acid washing; harmful gas and smoke can not be generated.

Owner:宜兴市九洲封头锻造有限公司

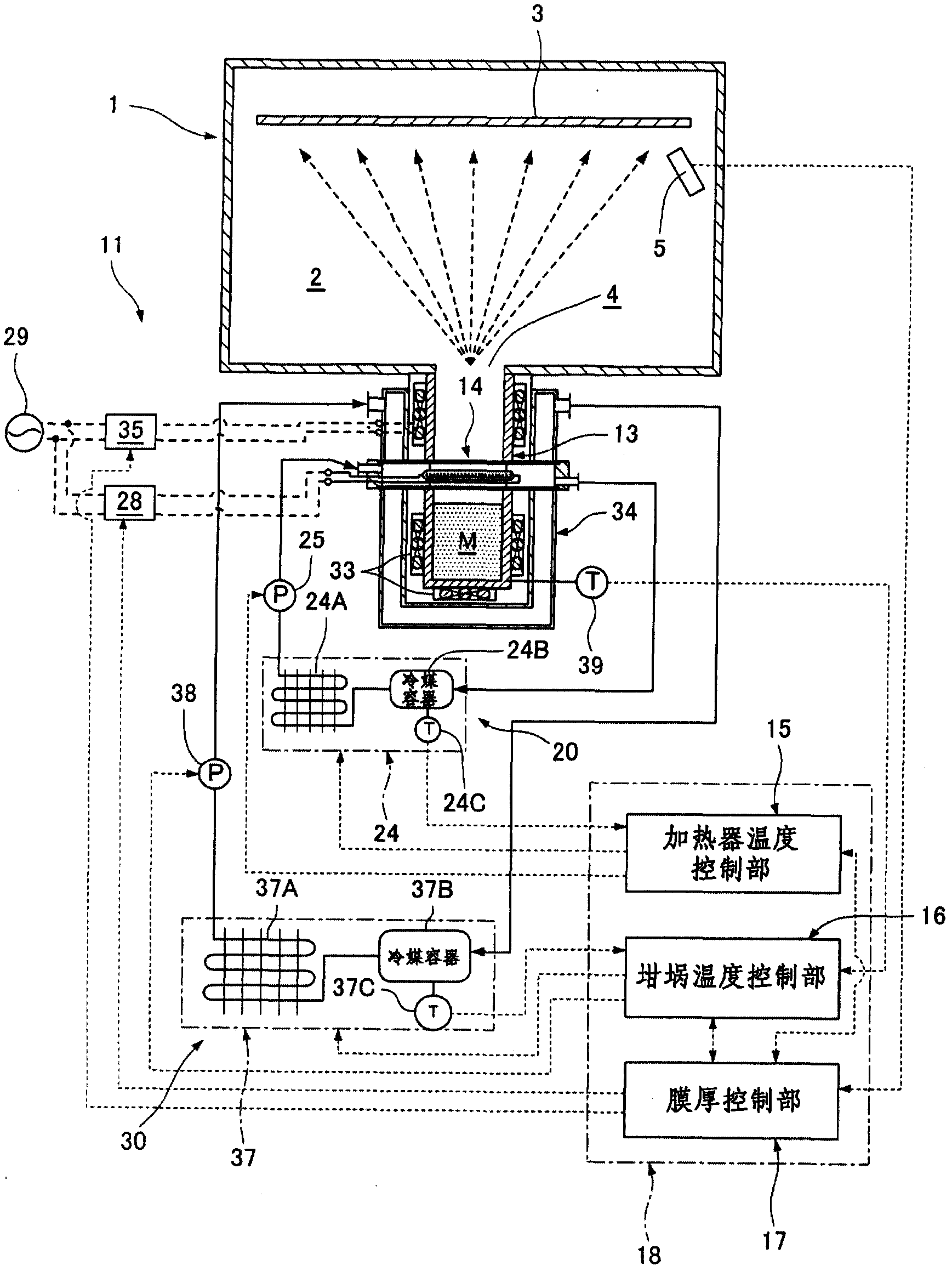

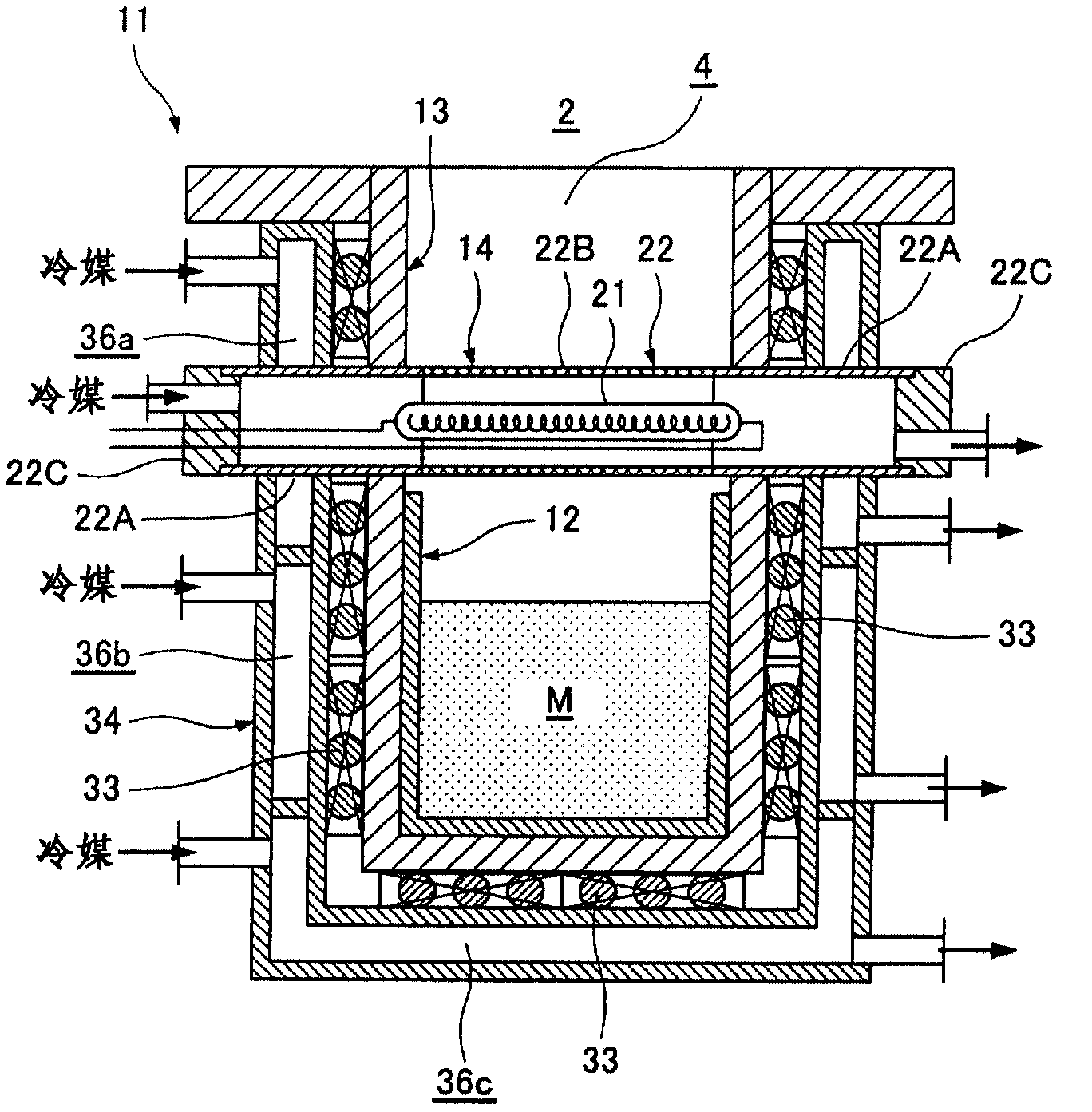

Evaporation or sublimation method and crucible device for evaporation material in vacuum evaporation device

ActiveCN102277557AWill not deteriorateDoes not reduce transmittanceVacuum evaporation coatingSputtering coatingInfraredCrucible

The invention provides an evaporation or sublimation method of evaporation material in a vacuum evaporation unit, and a crucible unit for vacuum evaporation. The units can work continuously for a long term and prevent the degradation of the evaporation material. In a crucible base (13), a radioactive heat source (21) radiating heat waves mainly including infrared ray is disposed in a heat wave transmission tube (22). The heat wave transmission tube (22) is made of material through which the infrared ray can transmit. The heat waves from the radioactive heat source (21) emit on the surface of the evaporation material M in a crucible body (12) and heat the evaporation material to make the surface of the evaporation material M for evaporation or sublimation. Even if the evaporated or sublimated evaporation material M is adhered on the surface of the heat wave transmission tube (22) or the inner surfaces of the crucible body (12) and the crucible base (13), the heat waves can be used to make the evaporated or sublimated evaporation material M for evaporation or sublimation again.

Owner:HITACHI ZOSEN CORP

Base cloth for filter material and method of manufacturing the same

InactiveCN101108288AWill not deteriorateStrong drug resistanceFiltration separationVolumetric Mass DensityFilter material

The invention discloses a cheb used on filtering material and the production method. When the measured pressure of the product is 125Pa according to JIS L 1096 8.27.1A standard, the venting quality value of the cheb is 300cc / cm2 / s to 600cc / cm2 / s; according to JIS L 1096 8. 12. 1A standard, the warp direction of the tensile strength of the cheb is 500N / 5cm to 1000N / 5cm, and the direction of weft is 300N / 5cm to 800N / 5cm. The production method comprises the procedures of choosing warp and weft yarn fiber, weaving and so on; During the process of weaving, the yarn before weaving and the cheb after weaving is processed by heat setting and controls the indexes of warp and weft density, tilter and twist. The invention has good tension strength and venting quality, which improves the filtering performance of the filtering material and prolongs the service life of the filtering material.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

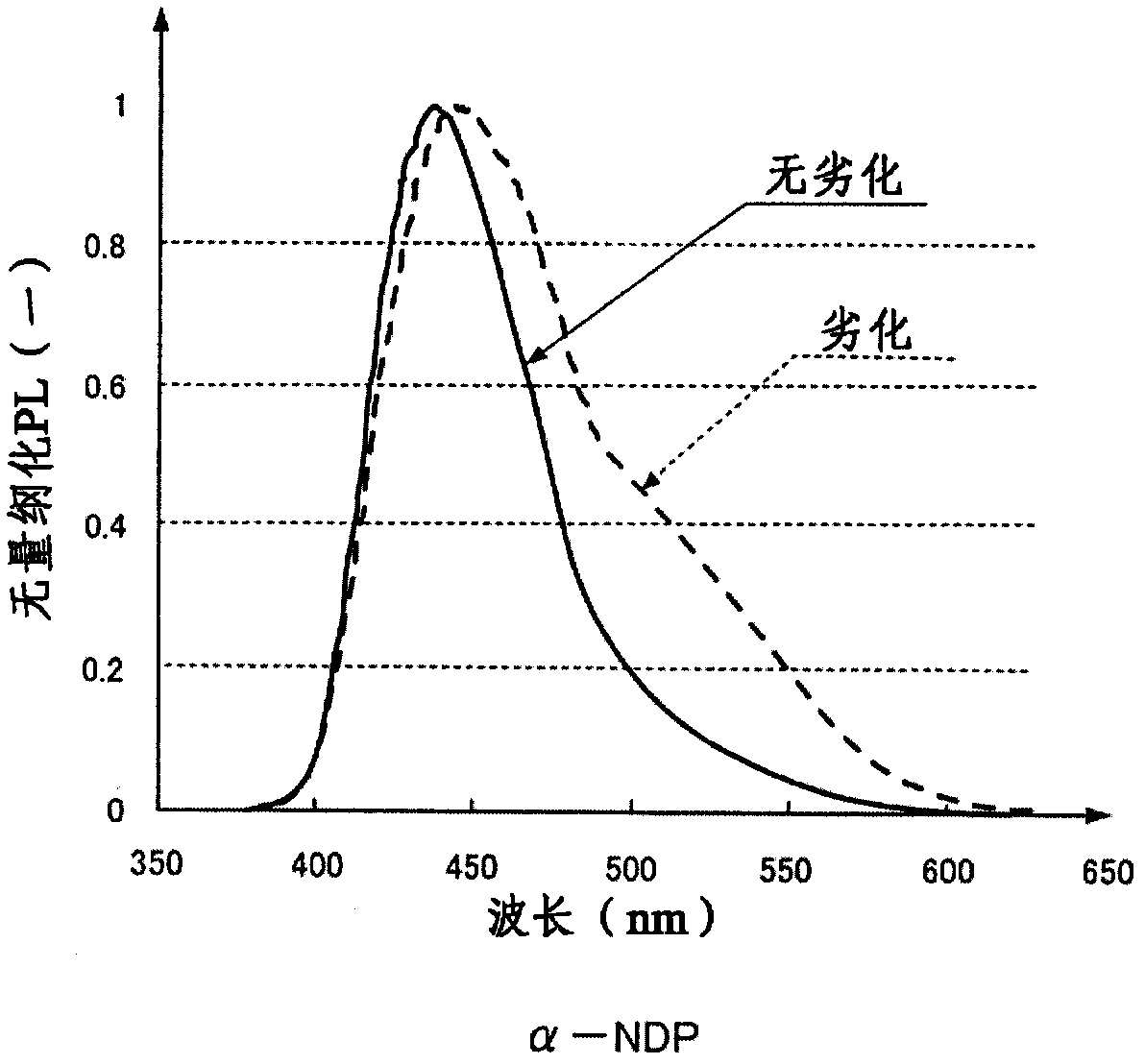

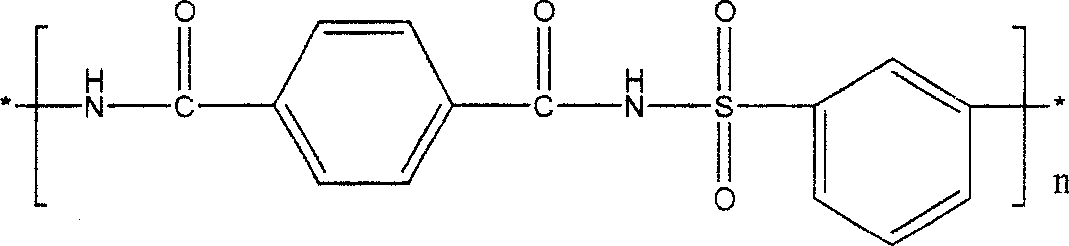

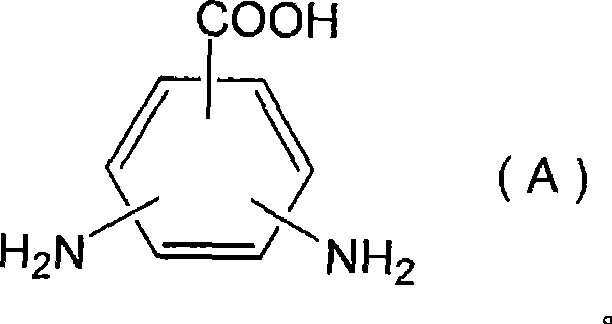

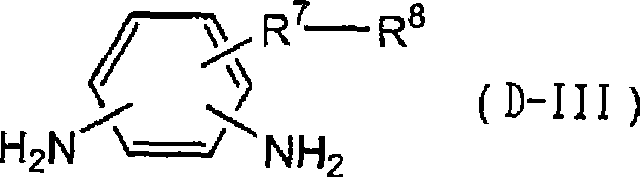

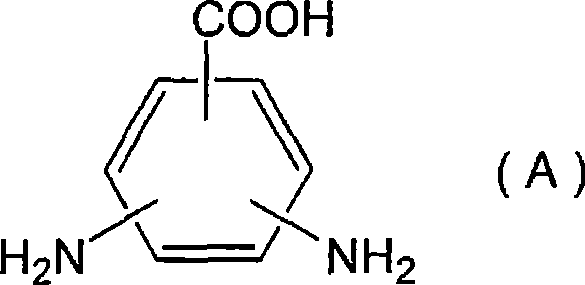

Liquid crystal oriented agent and liquid crystal display element

ActiveCN101452153AImprove heat resistanceWill not deteriorateLiquid crystal compositionsNon-linear opticsLiquid-crystal displayPolyamic acid

The present invention provides a liquid crystal display element forming liquid crystal oriented agent of liquid crystal oriented film with excellent durability to long-time thermal stress, and avoiding deterioration of display capability even after long-time drive. The liquid crystal oriented agent includes a least a polymer selected from polyamic acid produced by reaction between tetracarboxylic dianhydride and diamine of a compound represented by the formula (A) and a matter group composed of polyimide produced by closing-ring dehydration of the polyamic acid, the liquid crystal display element includes a liquid crystal film formed with the liquid crystal oriented agent.

Owner:JSR CORPORATIOON

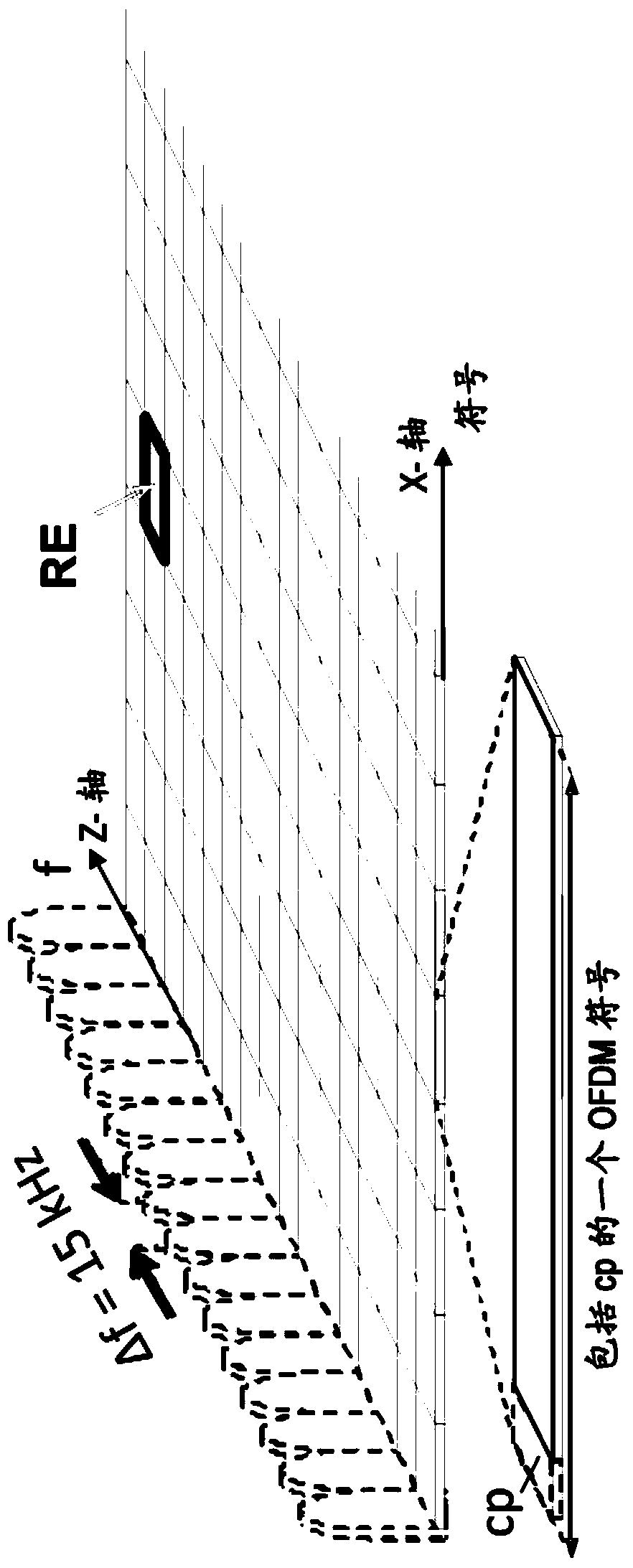

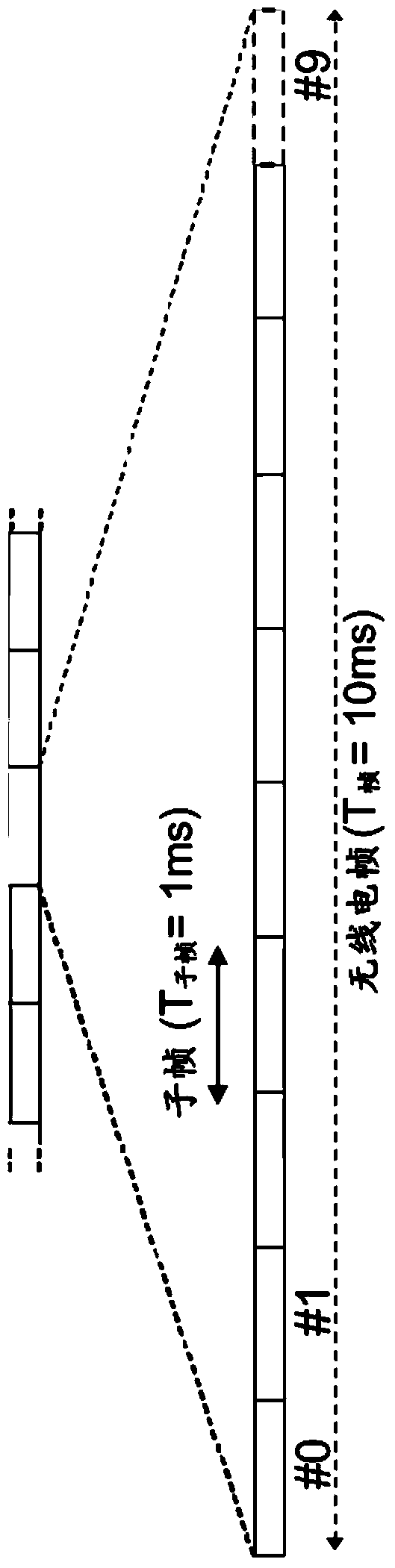

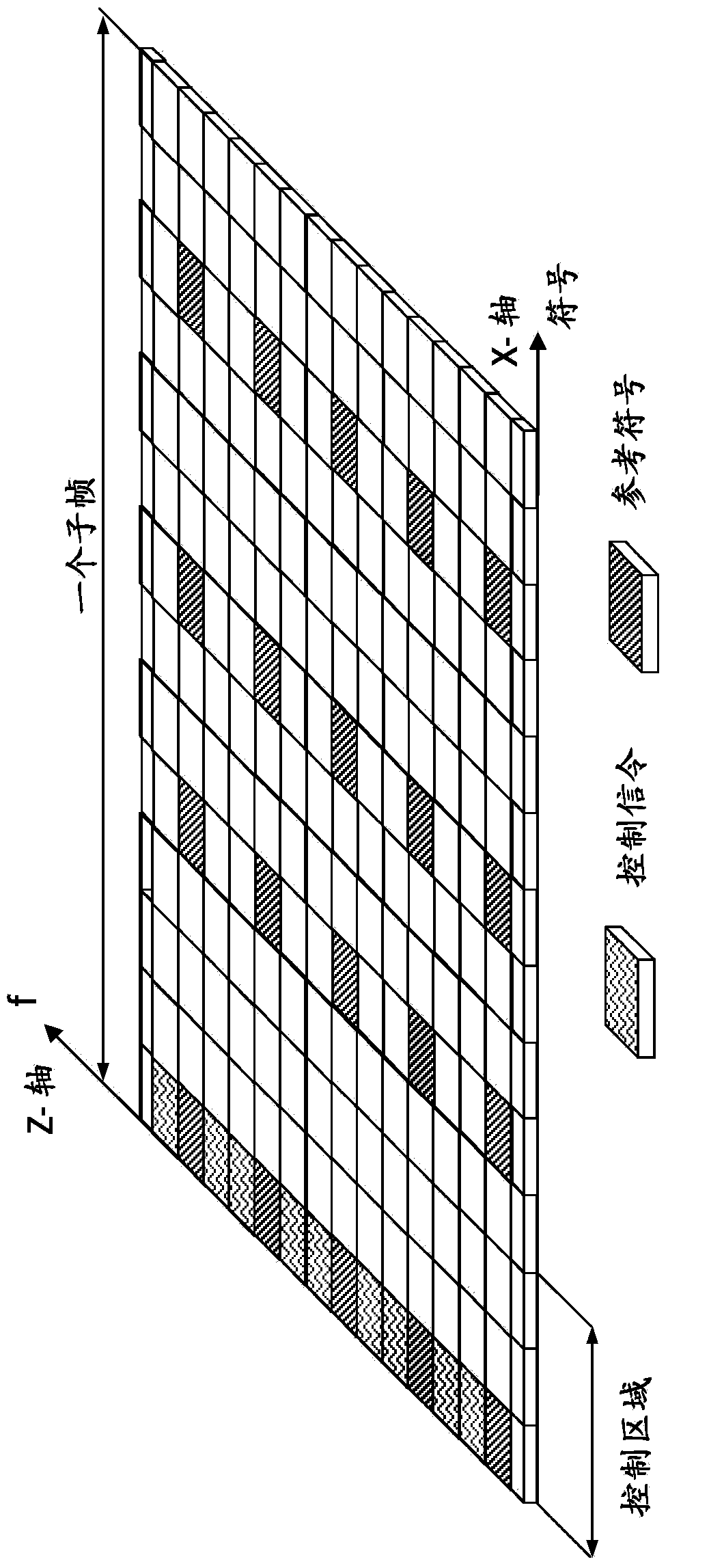

Method and apparatus for transmit timing adjustment

ActiveCN104094548AWill not deteriorateSynchronisation arrangementSignal allocationCell basedReal-time computing

A method in a user equipment (121) for adjusting a transmit timing of uplink transmissions to a network node (110) in a telecommunications system (100) is provided. The user equipment (121 ) is configurable with more than one aggregated serving cells. The more than one aggregated serving cells are divided into one or more groups of serving cells based on a timing advance value of each of the aggregated serving cells. The one or more groups of serving cells each comprises a timing reference serving cell. The reception timing of a downlink transmission from a timing reference serving cell is used as a timing reference for the transmit timing of uplink transmissions for the serving cells in the group of serving cells comprising the timing reference serving cell, respectively. The user equipment (121) determines a change to a second timing reference serving cell in a group of serving cells, which second timing reference serving cell is different from a first timing reference serving cell currently being used as the timing reference serving cell for the group of serving cells. Then, the user equipment (121) applies an incremental adjustment of the transmit timing of uplink transmissions for the serving cells in the group of serving cells with respect to a timing reference based on the reception timing of a downlink transmission from the second timing reference serving cell in the user equipment (121). A user equipment, a method in network node and a network node are also provided.

Owner:TELEFON AB LM ERICSSON (PUBL)

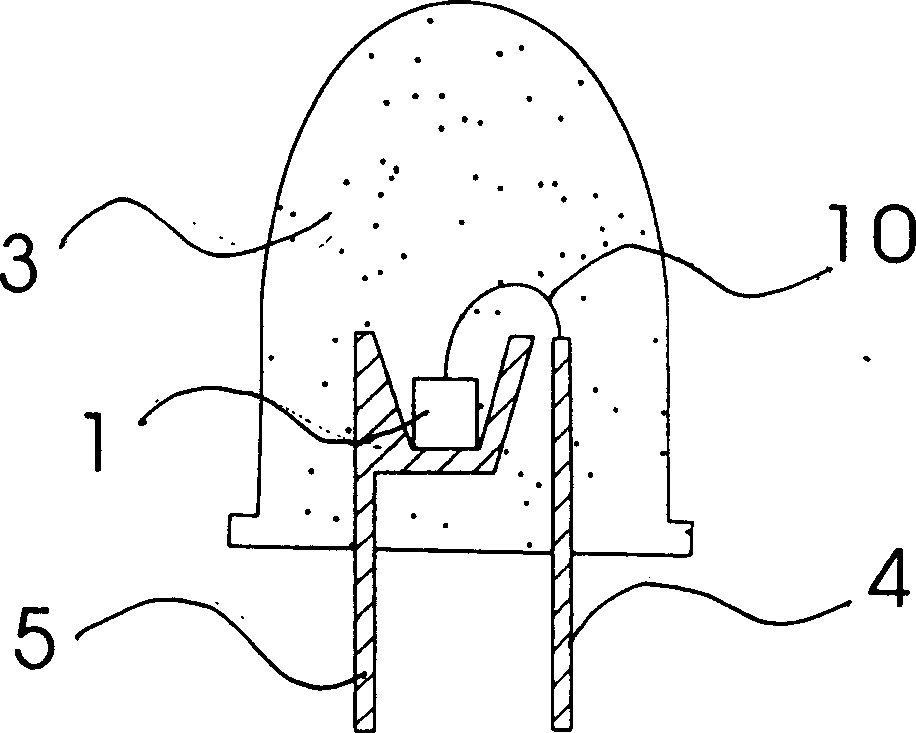

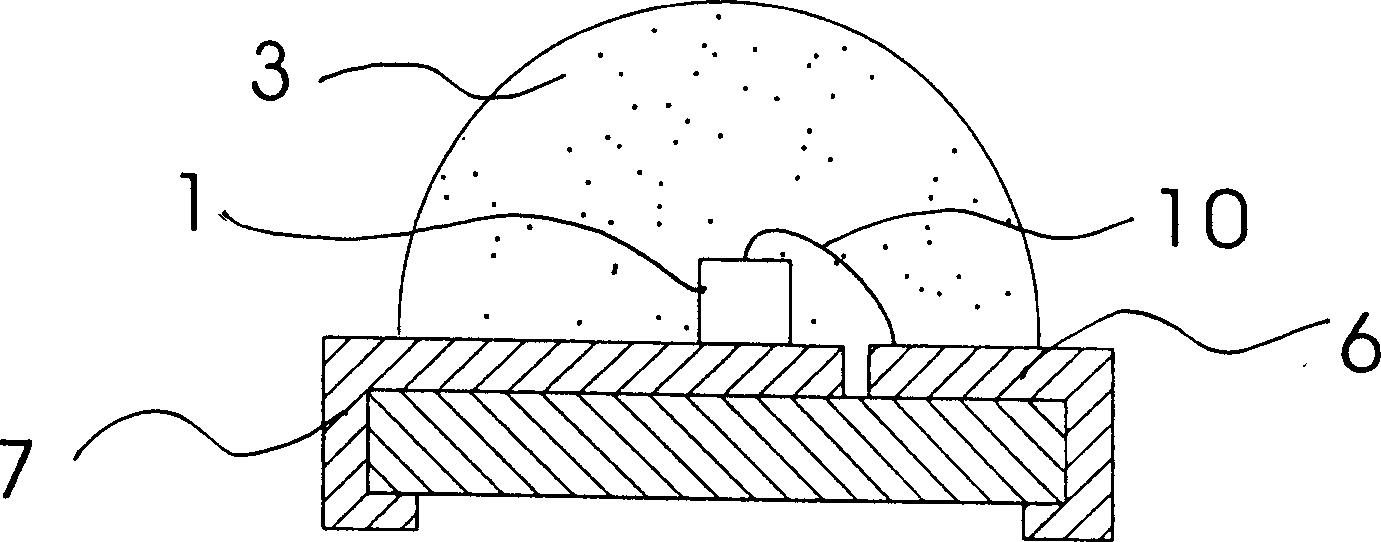

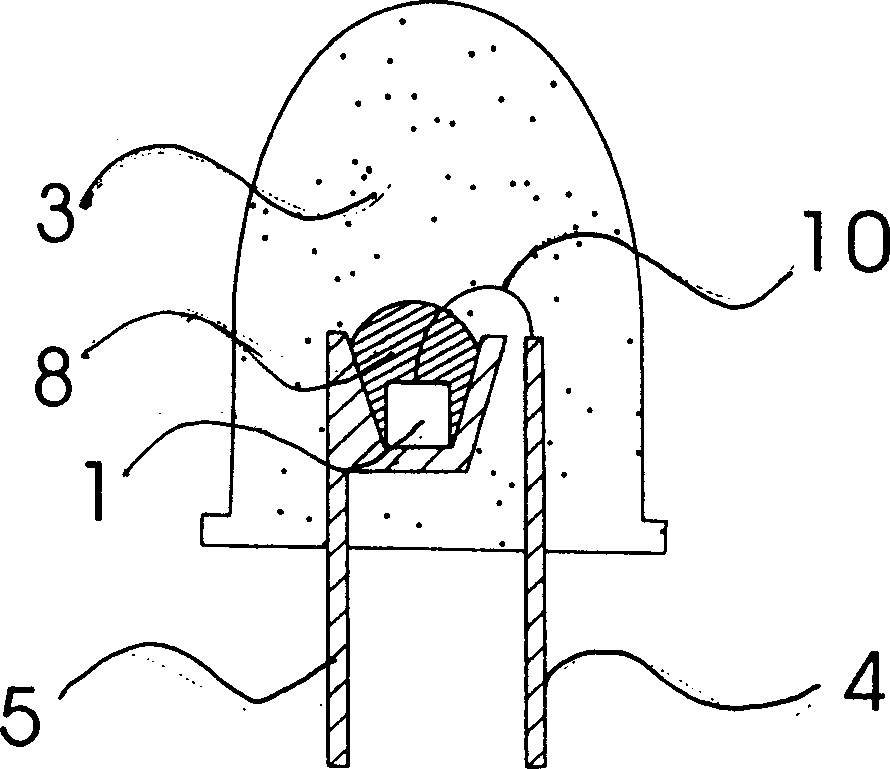

Packaging method for short wavelength LED

A method for packaging the short-wavelength LED includes coating a layer of liquid-state inorganic glass resin on the LED crystal cell and then pouring epoxy resin for packaging it. It can prevent the external epoxy resin layer from being poor under the action of high temp and short wavelength radiation, so improving the brightness and service life.

Owner:SOLIDLITE CORP

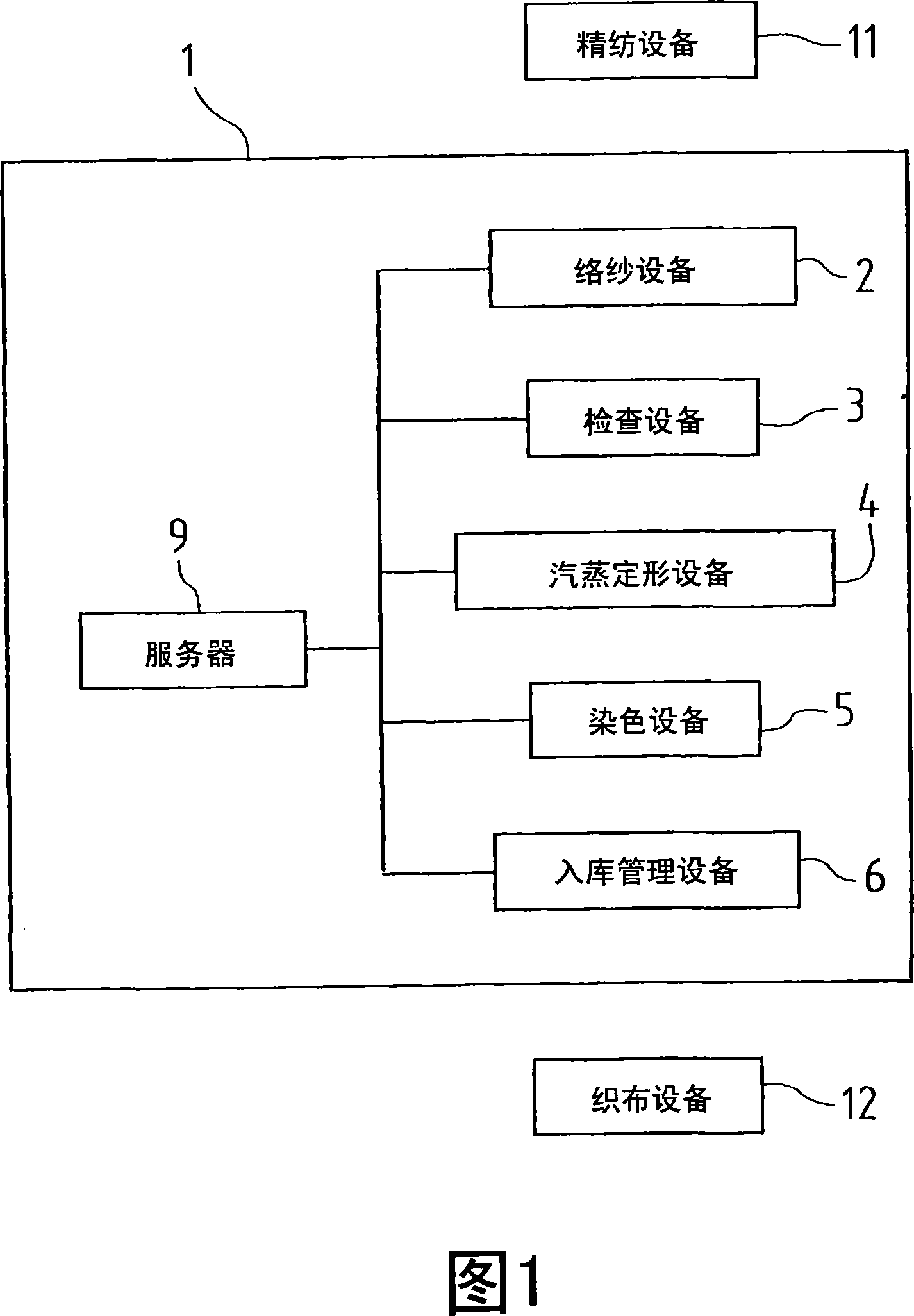

Take-up tube of wound yarn package and device for managing wound yarn package

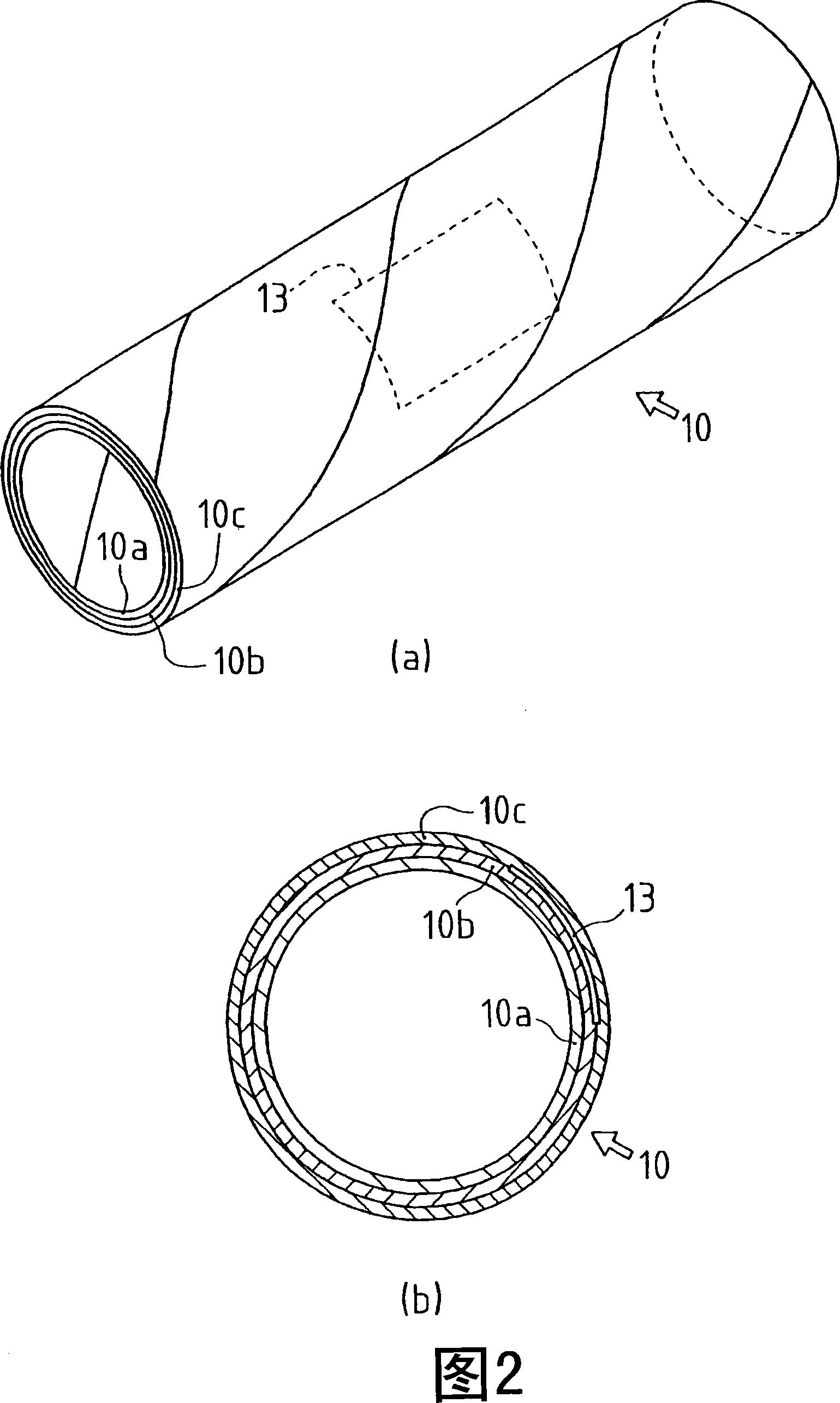

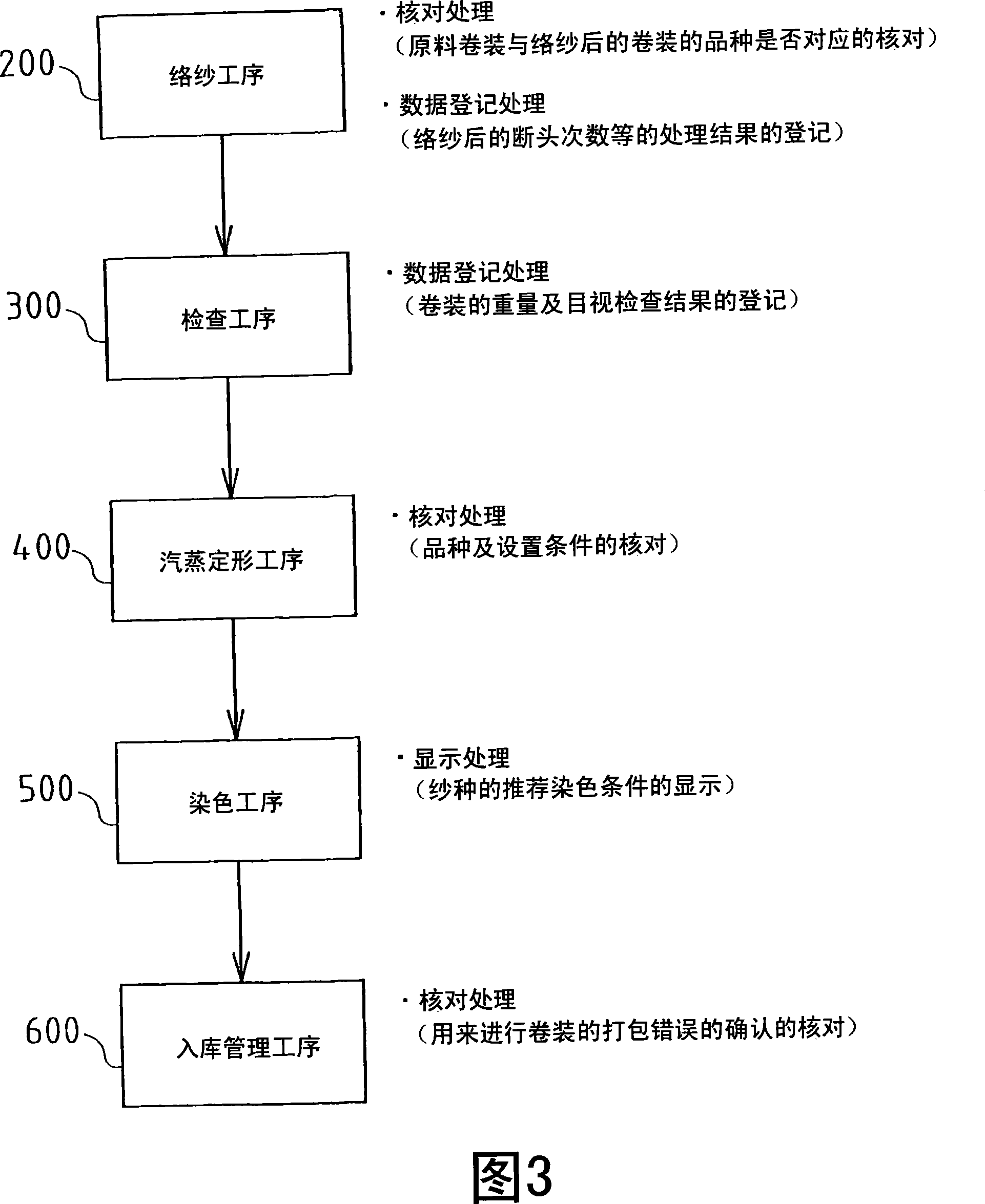

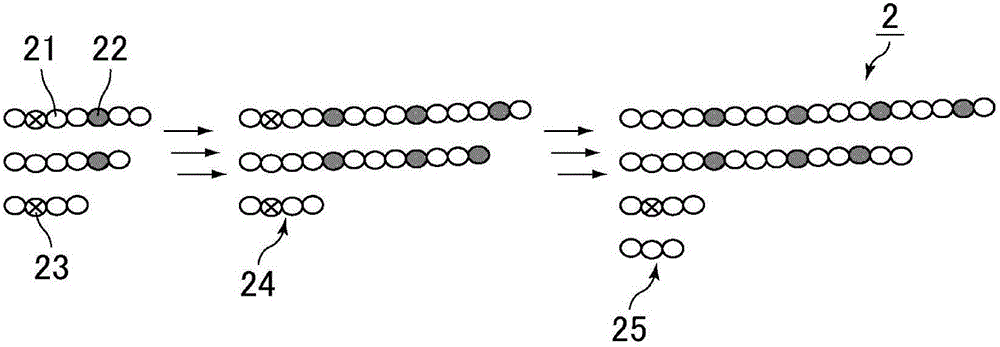

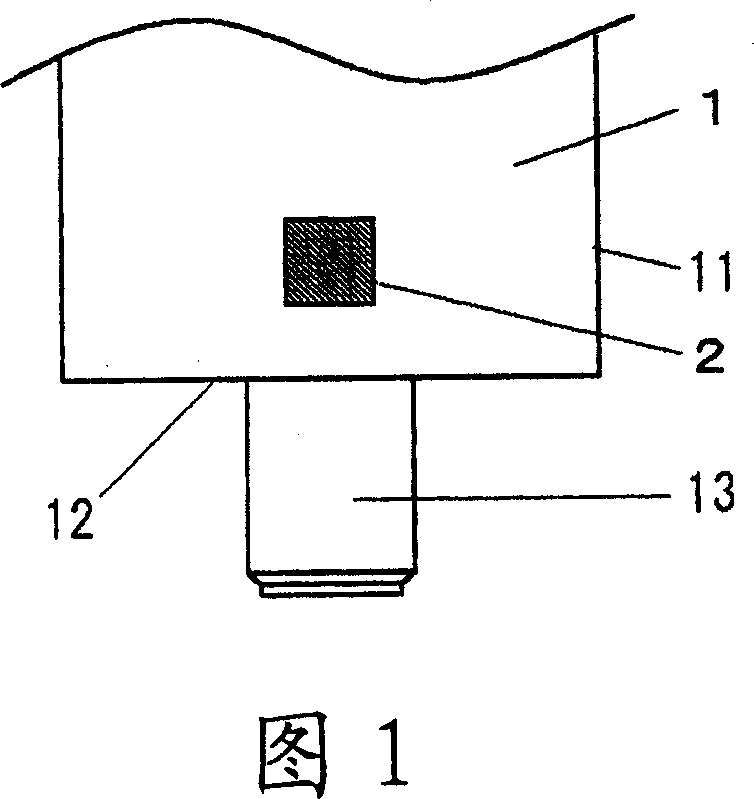

In the structure in which a barcode is pasted or the date is directly printed on the paper tube, the barcode may peel off or the printed characters may be scratched and become difficult to see during the delivery of the package. On the other hand, if a storage mechanism for identification information such as a barcode is provided on a pallet separate from the package, management of the package becomes complicated. The bobbin (10) as the core tube of the bobbin package (8) of the present invention is a paper tube that winds paper to form a tubular paper laminate. Between the middle layer (10b) and the outer layer (10c) ) is embedded with a sheet-like (label-type) storage medium (13).

Owner:MURATA MASCH LTD

A kind of maca freeze-dried powder injection and preparation method thereof

InactiveCN102293808AFor long-term storageWill not deterioratePowder deliveryUrinary disorderAlcoholFreeze-drying

The invention discloses a maca freeze-dried powder injection capable of treating and improving male prostate diseases and a preparation method thereof. Maca is washed first, dried in the sun, coarsely crushed, and then crushed by ultrasonic spray pulverization to form a mist-like ultra-fine state to improve extraction efficiency. Use 95% edible alcohol as an extractant to extract it, refine its active ingredients, and make maca essence. The extraction can be carried out 2-3 times, the essence of 2-3 times of extraction is mixed, the mixed maca essence is firstly filtered and then finely filtered, then sterilized and filled. Freeze-drying is carried out under vacuum conditions, and finally the gland is inspected, printed and packaged to obtain the finished product. Maca dry powder injection is loose and porous, in the form of a sponge, it dissolves quickly and completely after adding water, and almost immediately returns to its original shape. Maca dry powder injection can be stored for a long time without going bad. Inject the active ingredients of Maca directly into the human body to allow the body to absorb it quickly to achieve the best results.

Owner:WUXI LED TRUST PHOTONIC TECH

Deep processing method of animal fat

ActiveCN110079389AHigh nutritional valueWill not deteriorateFatty-oils/fats refiningFatty-oils/fats separationSolubilityNutritive values

The invention discloses a deep processing method of animal fat, and relates to the technical field of animal fat processing. The deep processing method of the animal fat comprises the following steps:dissolving solid animal fat by using a solvent consisting of acetic acid and glycerol; cooling the liquid animal fat in stages; separating saturated stearic acid from oleic acid by using different solubilities and different condensation crystallization temperatures of the saturated stearic acid and the oleic acid in the solvent to increase the content of the oleic acid in the fat; then pressing the obtained crude oil under increased pressure to enable low-melting-point liquid acid to flow out so as to separate saturated fatty acid from unsaturated fatty acid to further increase the content ofthe oleic acid of the animal fat and the content of the saturated fatty acid. In a processing course, the organic solvent is used once only, moreover, the organic solvent is pollution-free and is environmentally friendly, subsequent separation is facilitated due to different condensation points of the acetic acid and the glycerol, the processing temperature is low, the oleic acid cannot be deteriorated or damaged, and thus, the nutritive value of the oleic acid is increased.

Owner:安徽牧洋油脂有限公司

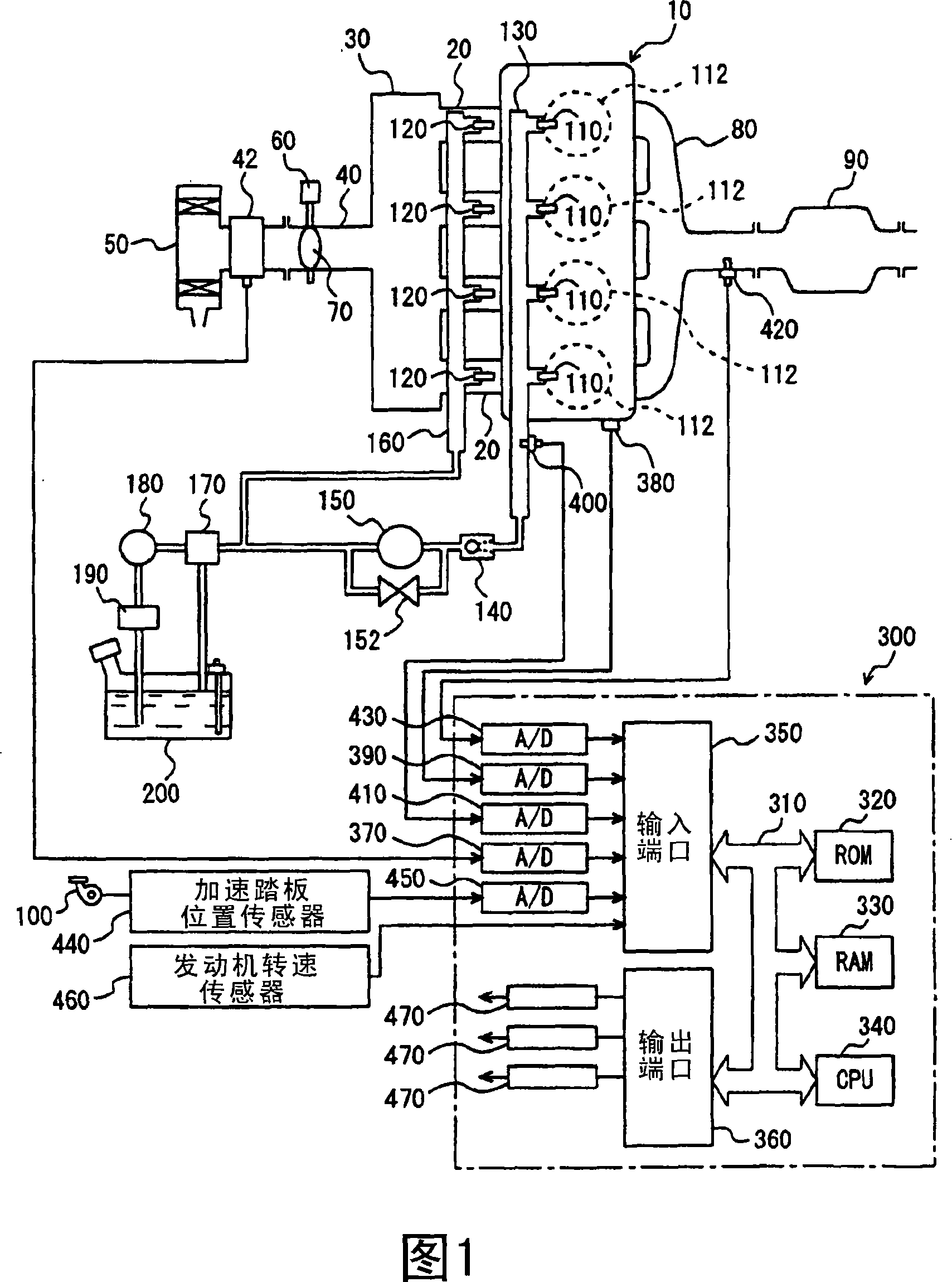

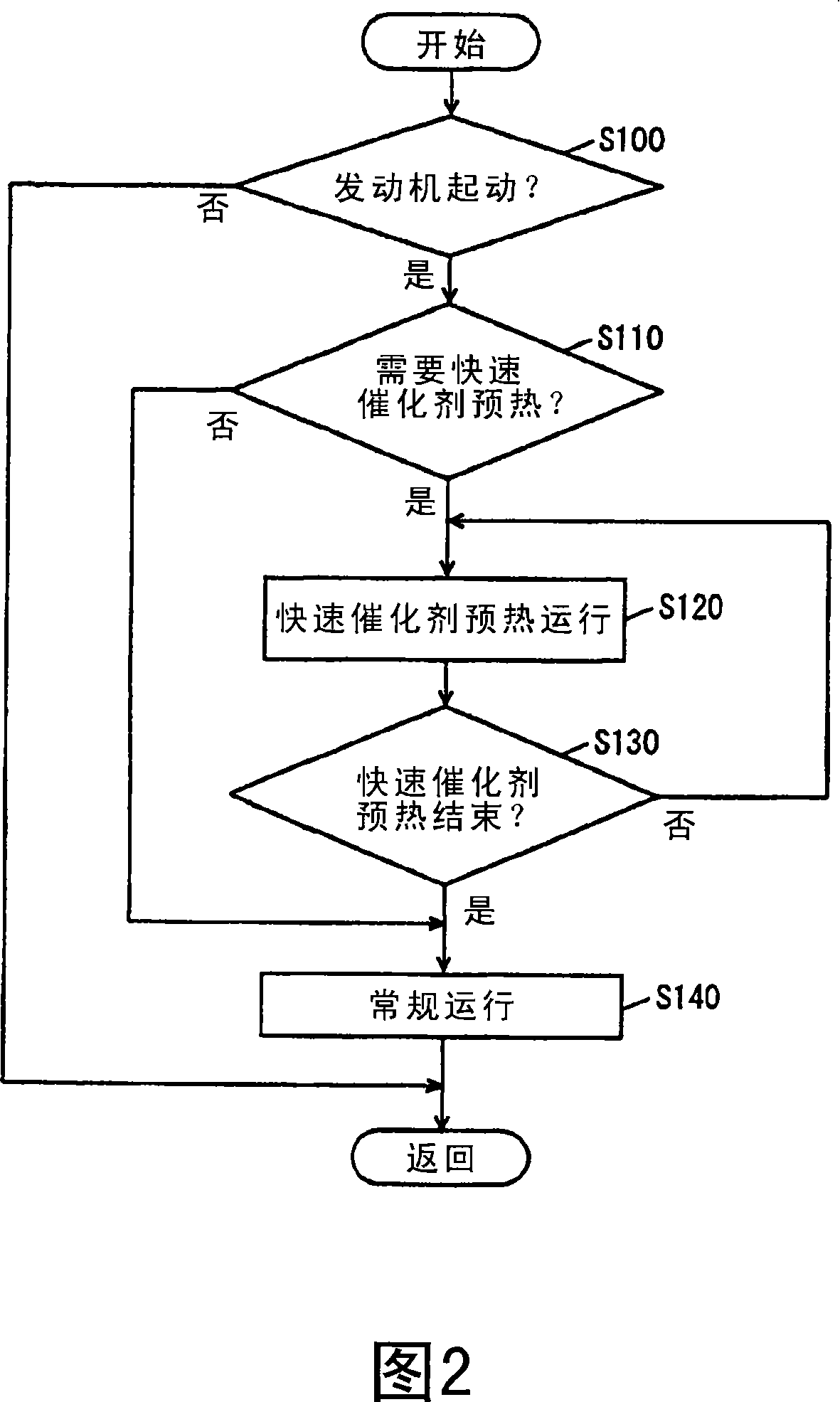

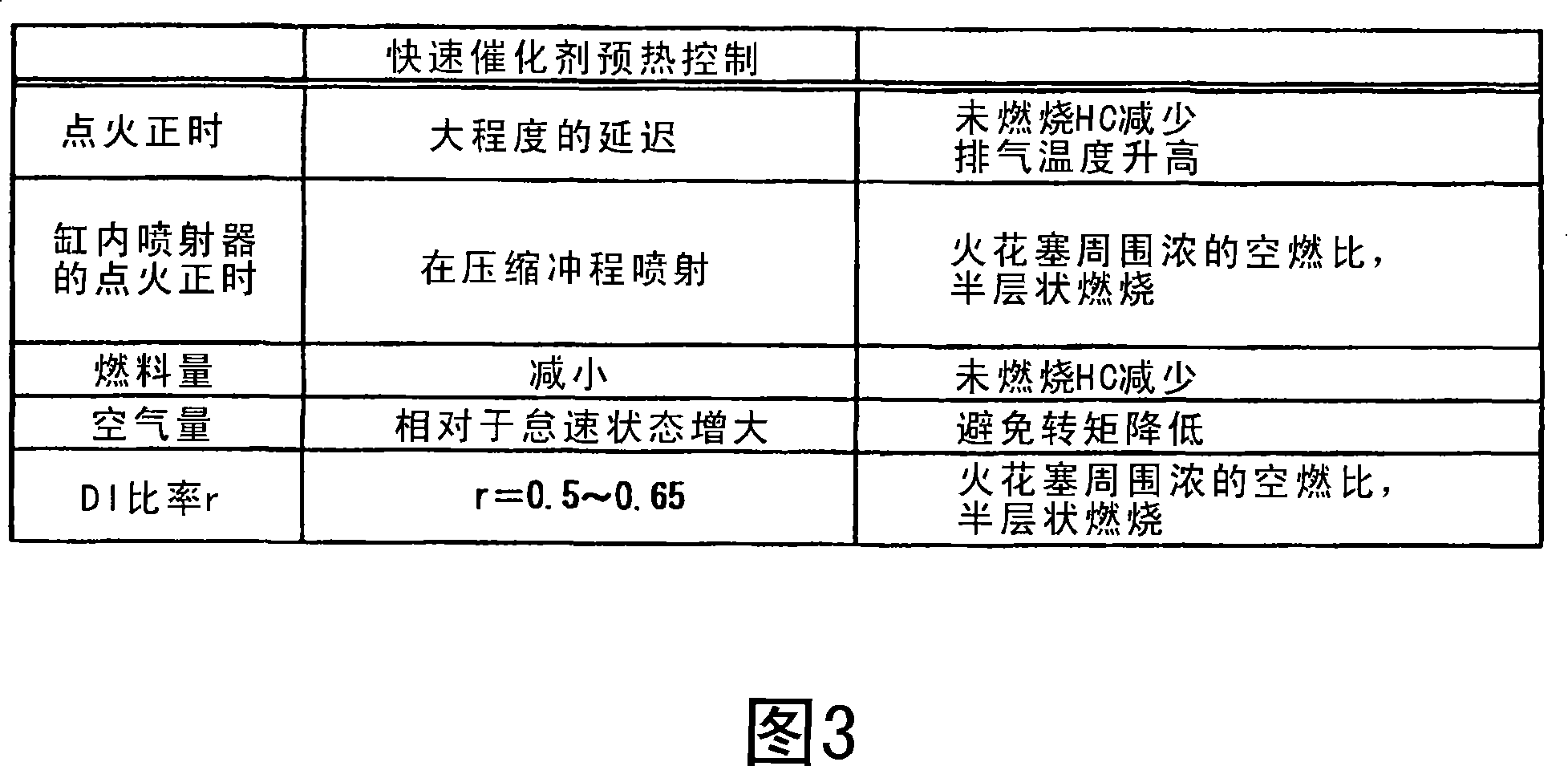

Control apparatus for internal combustion engine

InactiveCN101142387AWarm up fastWill not deteriorateElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

An engine ECU executes a program including the step of performing an operation for rapid catalyst warm-up (S120), under the conditions that an engine is started (YES in S100) and rapid catalyst warm-up is necessary (YES in S110), by setting the ratio of fuel injection by an in-cylinder injector to be equal to or higher than that of an intake manifold injector and retarding the ignition timing to a large degree, and the step of performing normal operation (S140) under the condition that the catalyst is warmed up to be activated (YES in S130).

Owner:TOYOTA JIDOSHA KK

Water-dilutable waterproofing art pigment and preparation method thereof

The invention discloses a water-dilutable waterproofing art pigment, raw materials of which comprise (by weight): 1-5 parts of a cosolvent, 2-9 parts of propylene, 3-7 parts of iron oxide, 5-10 parts of ochre, 3-12 parts of chrome oxide, 1-8 parts of alkylammonium salt, 5-15 parts of calcium carbonate, 1-7 parts of sorbitan ester, 1-6 parts of sodium benzoate and 0.5-1.2 parts of carbon black. The added alkylammonium salt, sodium benzoate, zincate, alkyl sulfonate, alcohol ether sulfate and water-soluble polyether all have good hydrophilicity. When the pigment is blended with water, the added hydrophilic substances enable the pigment to be easily dissolved. In addition, calcium carbonate, chrome oxide, aluminium powder and the like can enhance stability of the pigment such that the pigment will not be deteriorated or damaged even if stored for a long time.

Owner:隋敏

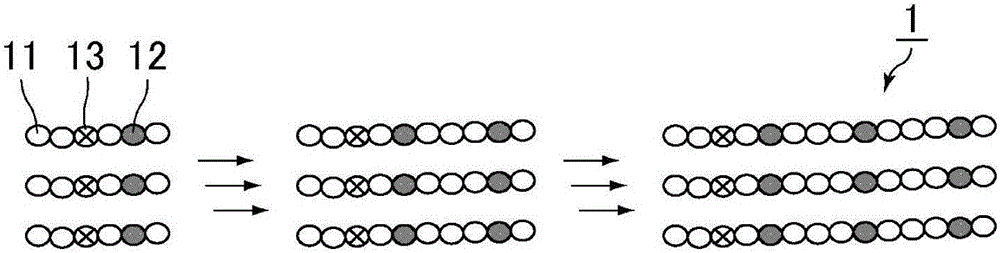

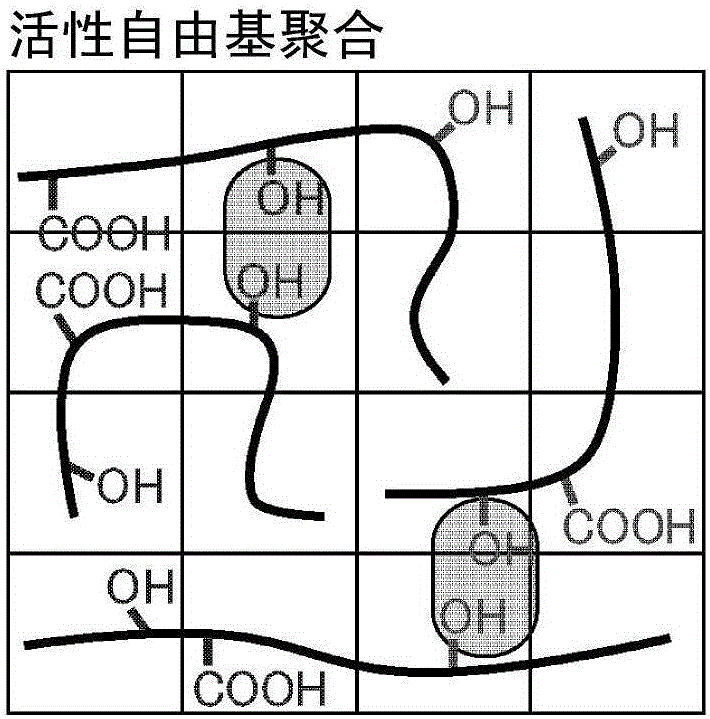

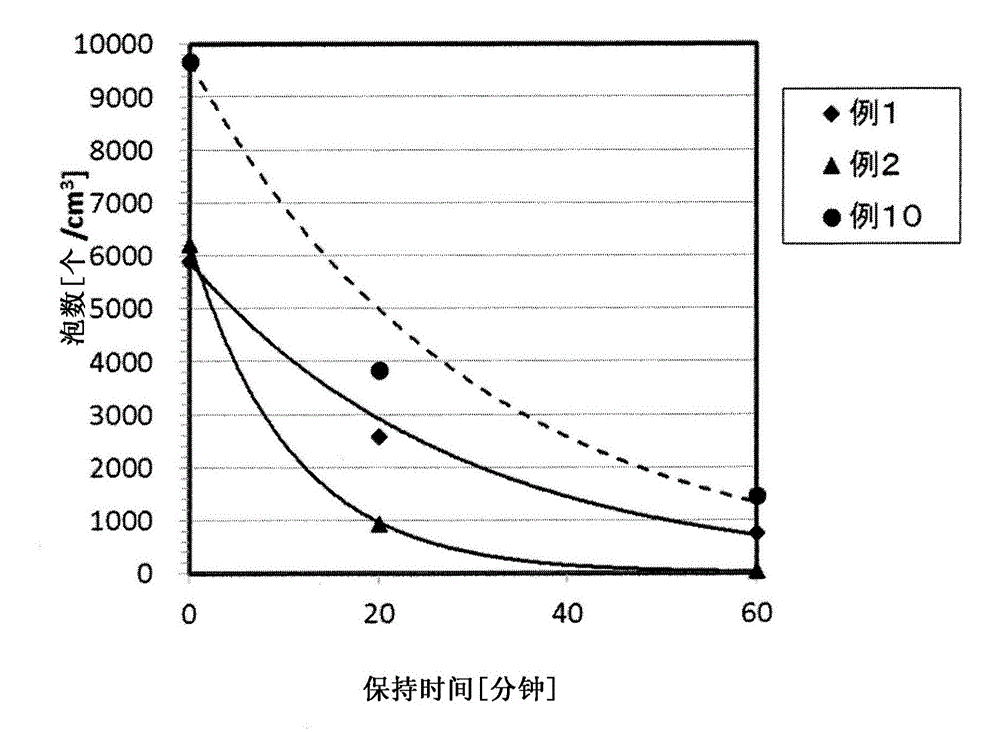

Optical adhesive, optical adhesive tape, and layered body

InactiveCN105683324ANo fogExcellent foam resistanceFilm/foil adhesivesAdhesive articlesMeth-Adhesive

The present invention provides an optical adhesive which does not become clouded even when exposed to high temperature and humidity, which also has excellent antifoaming properties or workability, and which does not degrade a transparent electrode such as one comprising ITO. Another purpose of the present invention is to provide an optical adhesive tape and a layered body manufactured using the optical adhesive. The present invention is an optical adhesive containing: a (meth)acrylic polymer having a molecular weight distribution (Mw / Mn) of 1.05-2.5 obtained by copolymerization by living radical polymerization of a monomer mixture including a) 60-95 parts by weight of alkyl (meth)acrylate having a C1-14 alkyl group, b) 0.1-1 part by weight of a monomer containing a carboxyl group, and c) 10-30 parts by weight of a monomer containing a hydroxyl group, an amino group, or an amide group; and a crosslinking agent; the alkyl (meth)acrylate a) having a C1-14 alkyl group including (meth)acrylate having a bicyclo ring structure.

Owner:SEKISUI CHEM CO LTD

Line control method in optical network and optical network itself

InactiveCN102113275AImprove acceleration performanceWill not deteriorateMultiplex system selection arrangementsStar/tree networksAccess networkSwitching signal

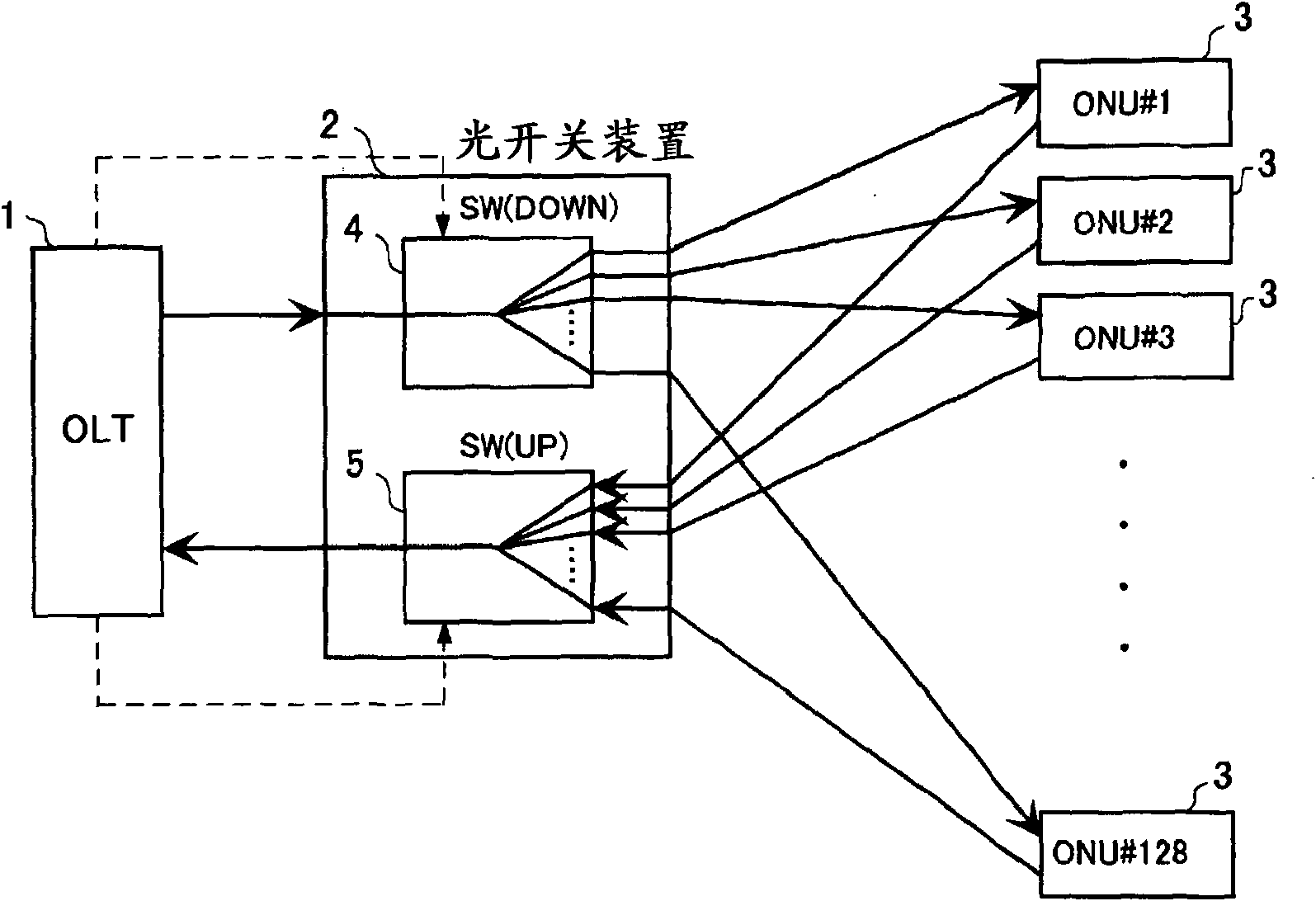

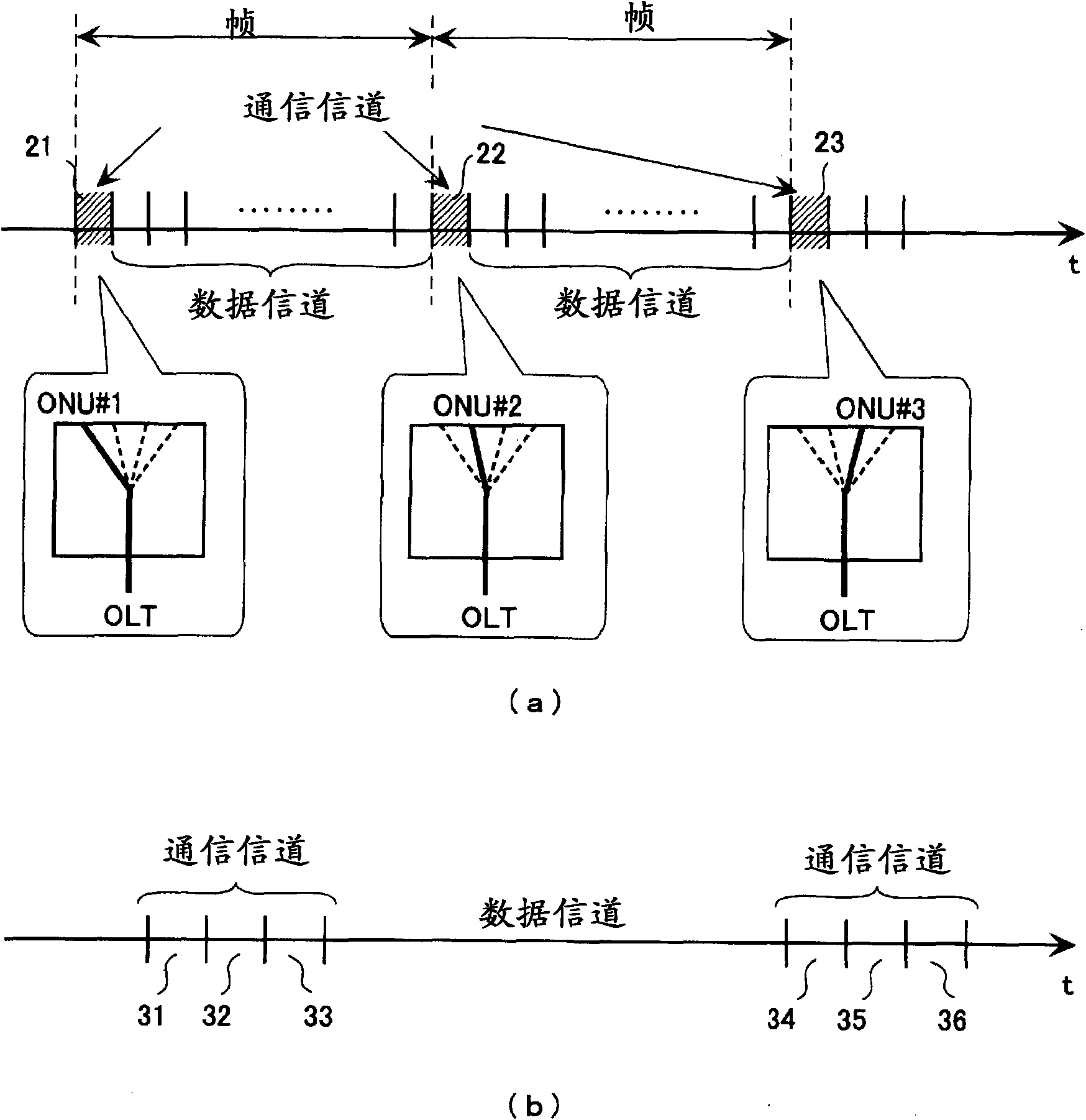

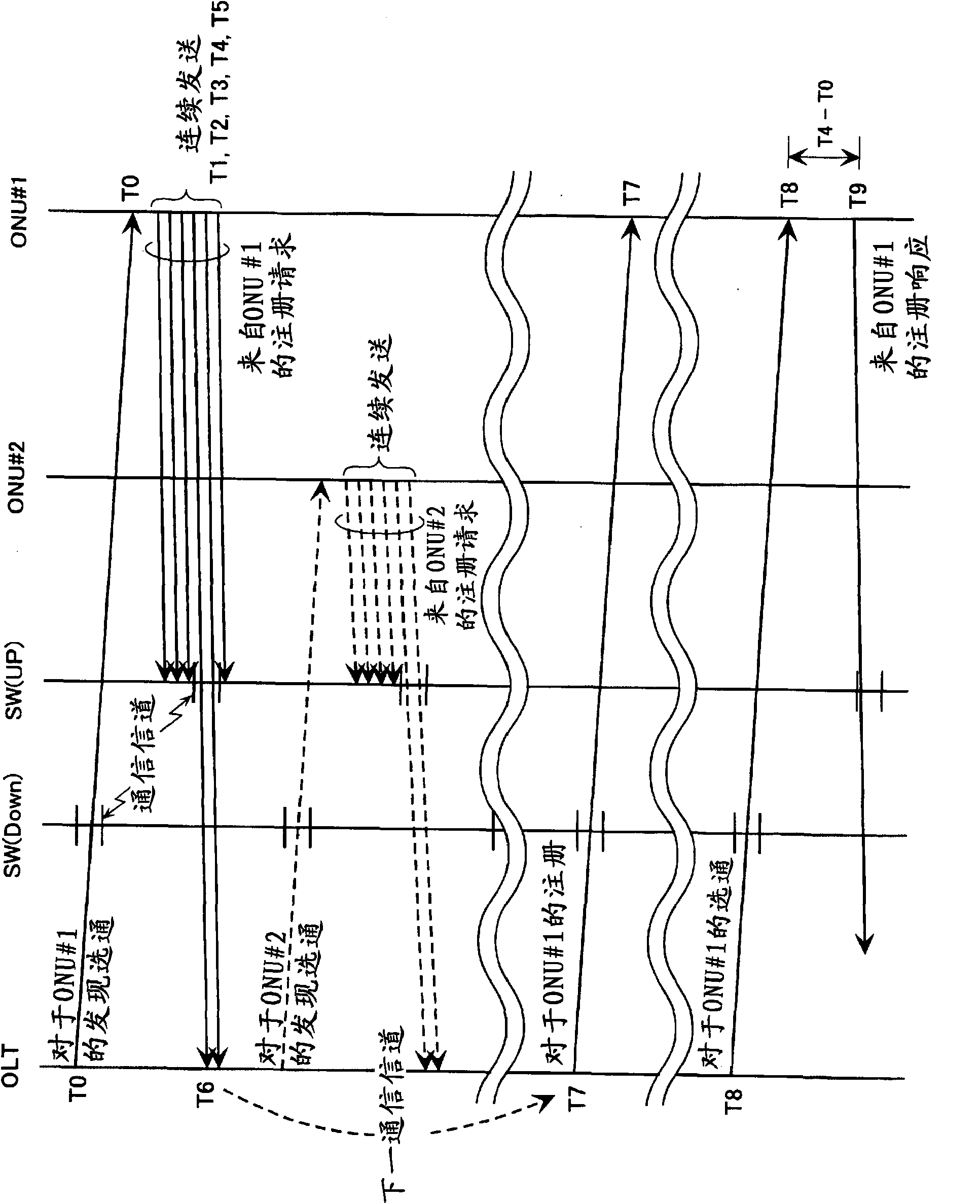

It is possible to establish a communication between an OLT and an ONU in an access network using an optical switch without requiring photoelectrical conversion by an optical switch unit. The OLT successively selects an ONU in slots discretely arranged by controlling a downlink optical switch SW(DOWN) and transmits a Discovery Gate message. The ONU which has received the Discovery Gate continuously transmits a Register Request message. An uplink optical switch SW(UP) successively switches signals from ONU#1 to ONU#128 from one to another in the slots discretely arranged and outputs the signalsto the OLT. Some of the Register Requests transmitted from the respective ONUs reach the OLT through the SW(UP). The OLT decides the ONU transmission timing in accordance with the received Register Request and reports the timing by a Gate message.

Owner:KEIO UNIV

Drilling slurry additive

ActiveCN105492568AReduce adverse effectsImprove heat resistanceDrilling compositionNatural sourceHigh resistance

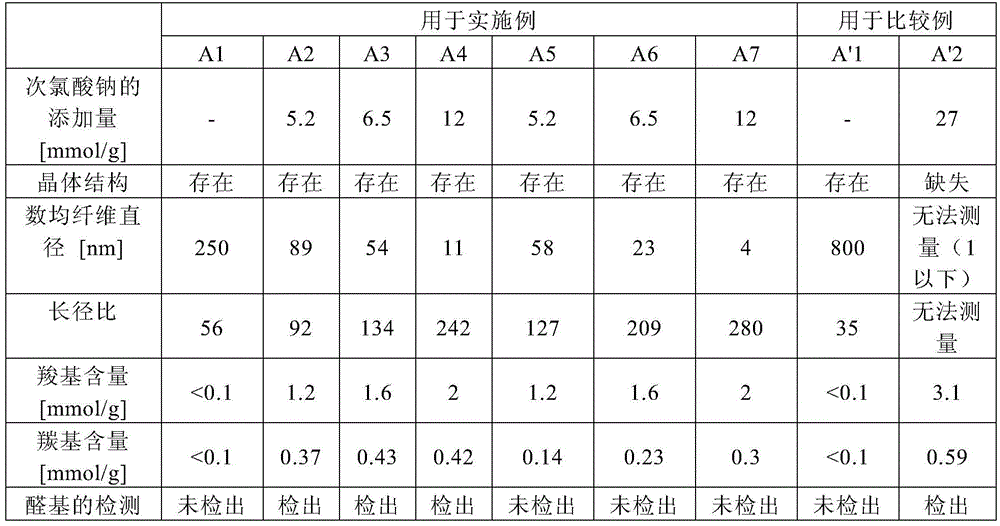

The purpose of the present invention is to provide a drilling slurry additive for use in drilling for petroleum or natural gas or in engineering projects or mining, having high heat resistance and mechanical shear resistance such that viscosity is undegraded under conditions of high temperature and high shear; moreover having high pseudoplastic flow properties, thereby affording high fluidity when discharged; and, being naturally derived, also being highly biodegradable, and having low environmental impact. This drilling slurry additive contains cellulose fibers having a number-average fiber diameter of 2-500 nm, a fiber aspect ratio of 50 or above, and a cellulose type I crystal structure.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Light source device

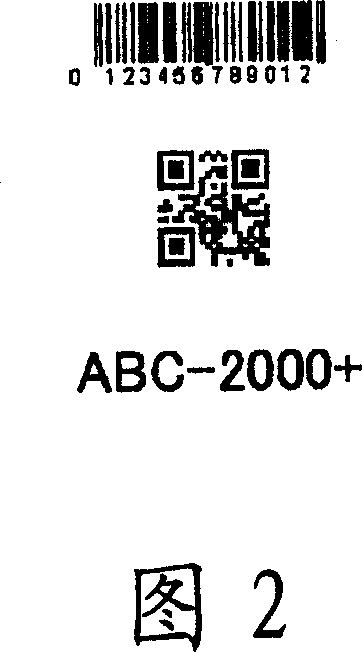

ActiveCN101048027AAccurate readingPrevent intrusionElectrical apparatusPoint-like light sourceData displayGas-discharge lamp

The invention provides a light source device. The said light source device automatically judges whether the discharge lamp mounted on the light source device is proper discharge lamp , if it is the proper discharge lamp, the service mode and service history of the discharge lamp is administered. The discharge lamp comprises: discharge lamp with lamp head (1) and lamp / data displaying part (2) for displaying the lamp / data associated with discharge lamp on the lamp head (1), the said lamp head (1) composed of cylindrical base (11)of large diameter by sealing one end using disck shaped abutting surface (12) and projection (13) of large diameter by interpenetrating the centre of the disck shaped abutting surface and coaxial implanting ; and lamp head seat (3) for holding the lamp head of the discharge lamp and performing power on, with a reading device on the lamp head seat (3) for reading the date of the lamp / data displaying part (2).

Owner:ORC MFG

Cape jasmine leaf dark tea and processing method thereof

InactiveCN106962530AAffect aestheticsKeep active ingredientsPre-extraction tea treatmentFlavorBlood lipids

The invention discloses cape jasmine leaf dark tea and a processing method thereof. Cape jasmine leaf extracts and dark tea leaves are compounded to form cape jasmine leaf dark tea, the weight ratio of the cape jasmine leaf extracts and the dark tea leaves is 1: (5-10), the cape jasmine leaf dark tea is simple in raw material, nutritional components in cape jasmine leaves are furthest kept, taste of the dark tea cannot be changed, and the cape jasmine leaf dark tea is fragrant and sweet in flavor and brilliant yellow in soup and has the functions of clearing heat and removing toxicity and relieving high blood pressure, high blood lipid and high blood sugar when being drank for a long time.

Owner:珠海仙茶美文化产业发展有限公司

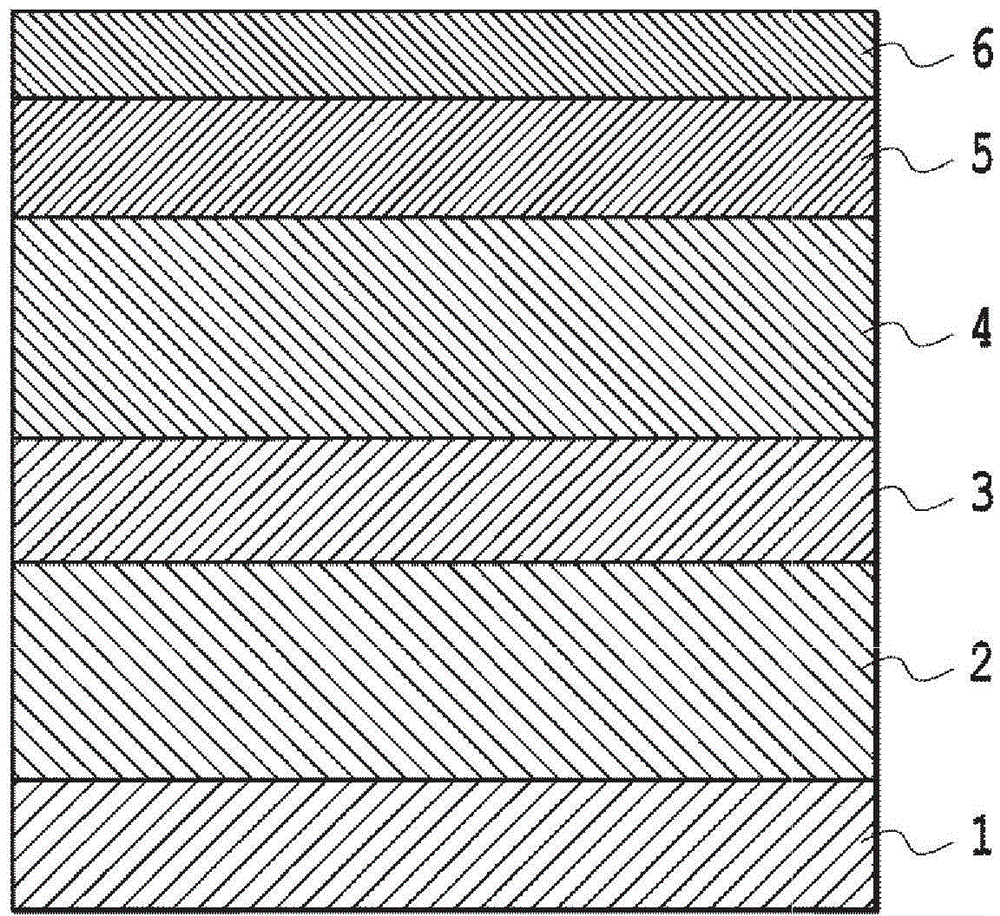

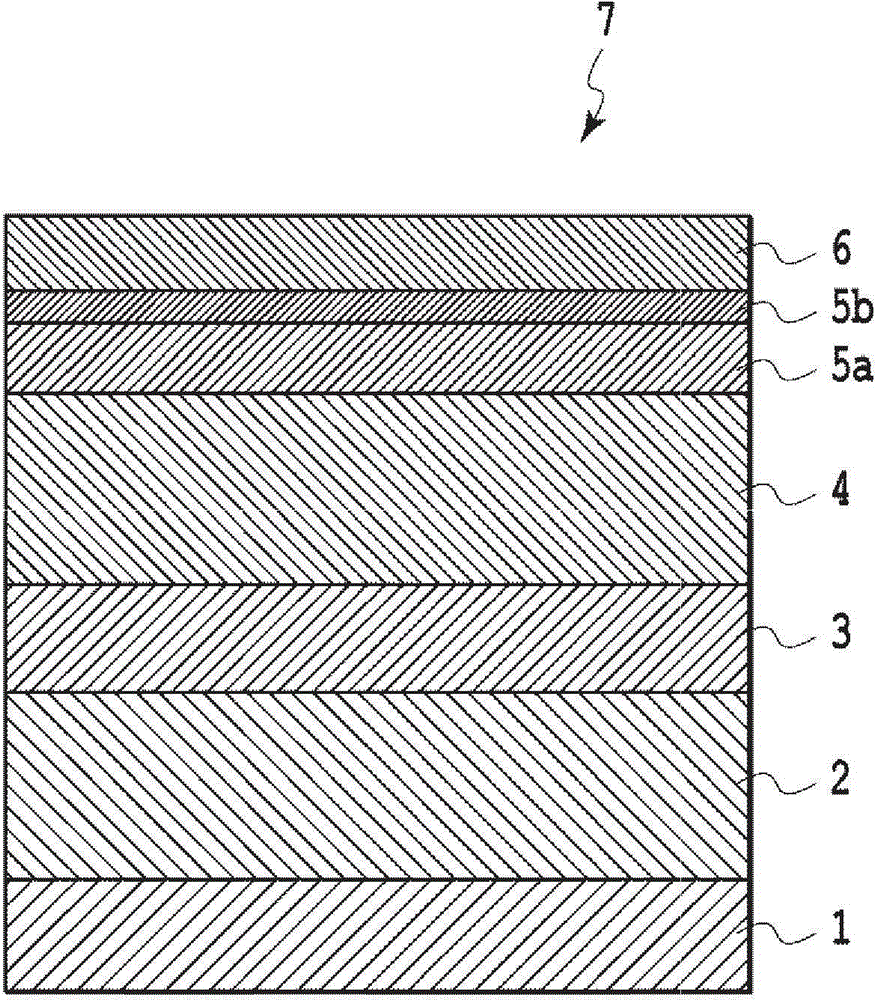

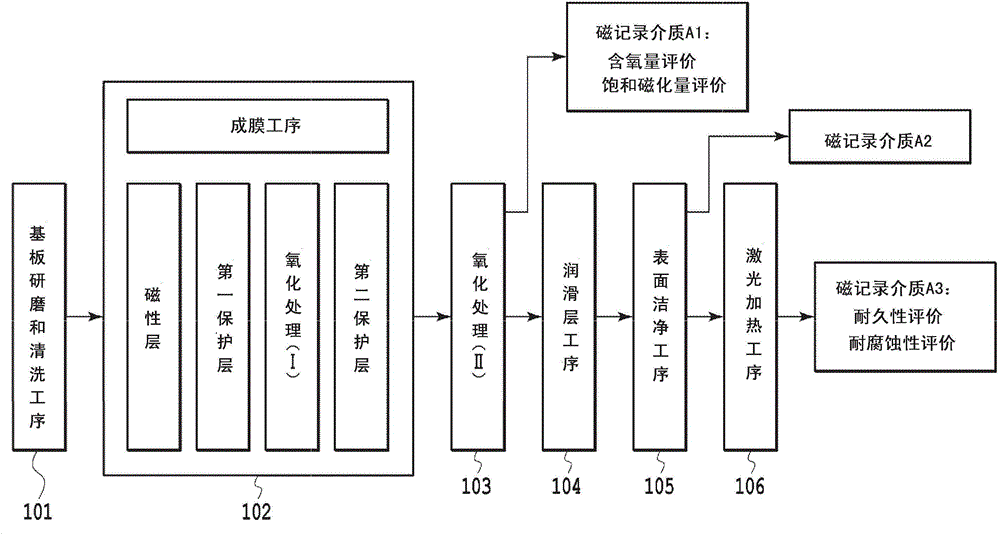

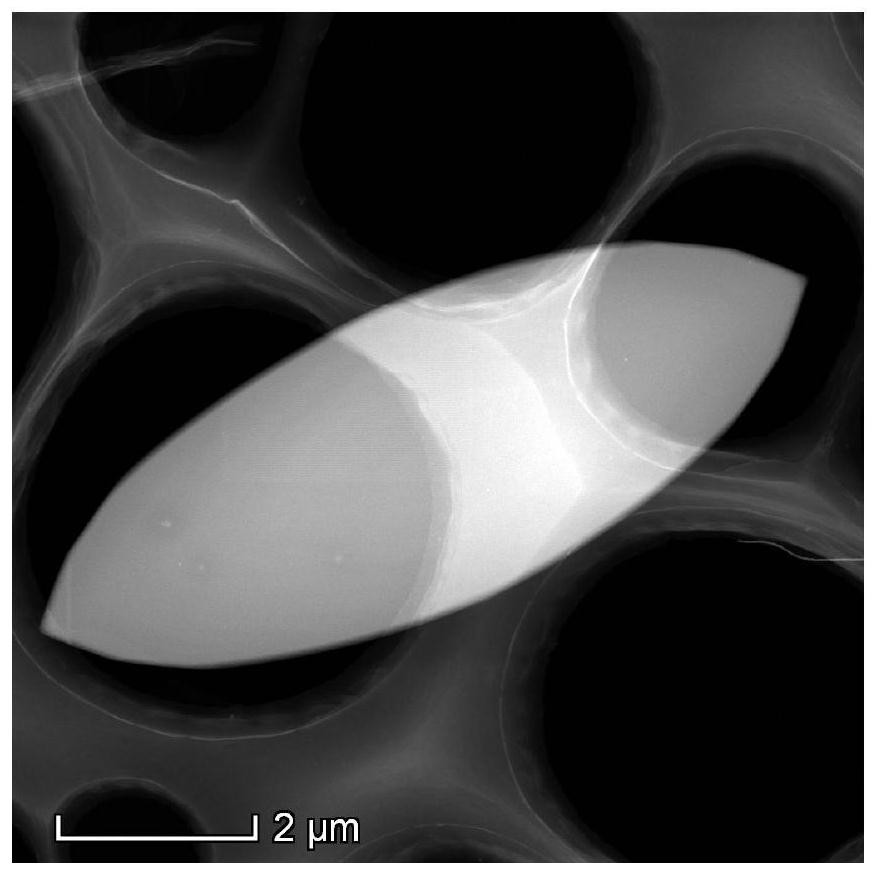

Magentic recording medium for heat assisted recording and method for fabricating same

InactiveCN104685565AWill not deteriorateProtective coatings for layersRecord information storageRecording layerNon magnetic

This magnetic recording medium for heat assisted recording comprises a magnetic recording layer upon a non-magnetic substrate, and a protective layer atop the magnetic recording layer. The protective layer further comprises a first lower protective layer atop the magnetic recording layer, a first upper protective layer atop the first lower protective layer, and a second protective layer atop the first upper protective layer. The first lower protective layer has, as a primary constituent, an element selected from a group which consists of silicon, aluminum, and copper. The first upper protective layer is configured from an oxide of the material of the first lower protective layer.

Owner:FUJI ELECTRIC CO LTD

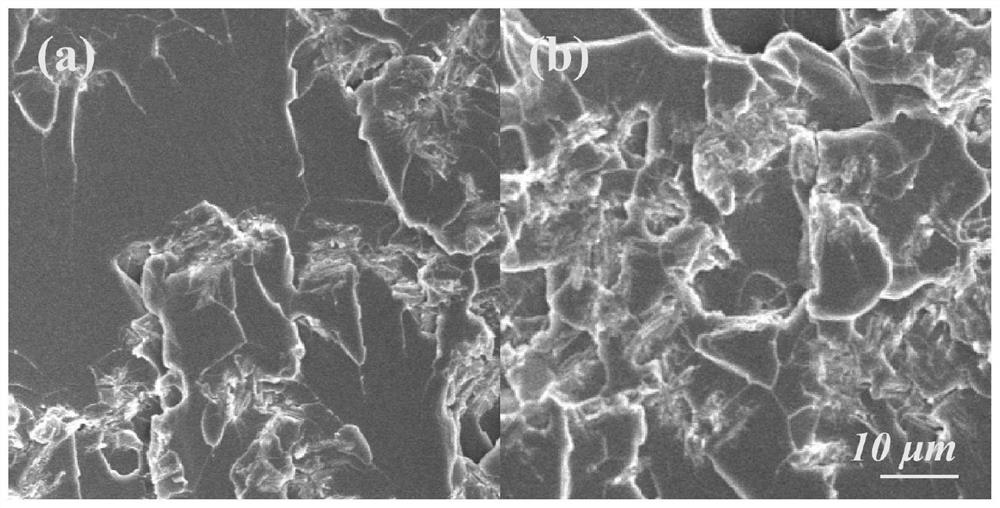

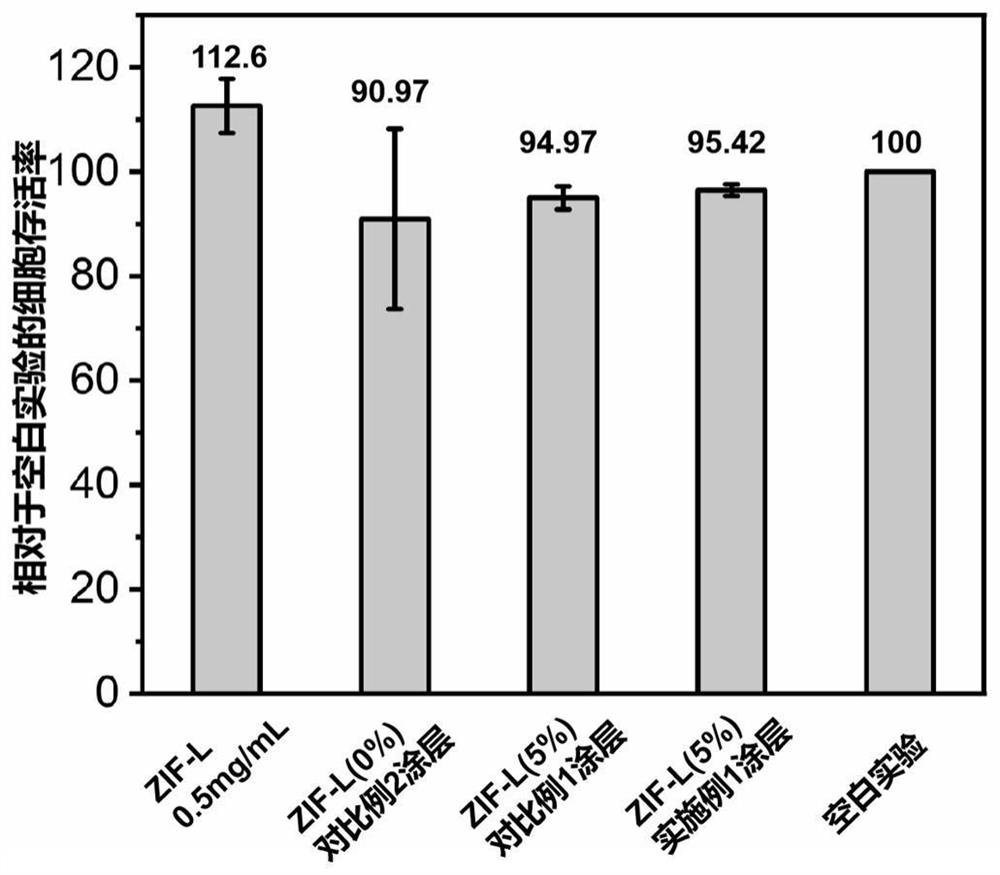

ZIF-L-based epoxy resin composite coating, preparation method and coating product

ActiveCN114133840AGood dispersionGood poisonAntifouling/underwater paintsPaints with biocidesEpoxyMetal-organic framework

The invention relates to an epoxy resin composite coating based on ZIF-L, a preparation method and a coating product, and relates to the technical field of coatings and surface coatings. According to the main technical scheme, the ZIF-L-based epoxy resin composite coating is prepared from two-dimensional metal organic framework material ZIF-L nanoparticles, 8-hydroxyquinoline terminated aniline tripolymer and an epoxy resin coating body. In the ZIF-L-based epoxy resin composite coating, the mass fraction of the two-dimensional metal organic framework material ZIF-L nanoparticles is 0.1-10 wt%, and the mass fraction of the two-dimensional metal organic framework material ZIF-L nanoparticles is 0.1-10 wt%. The mass of the 8-hydroxyquinoline terminated aniline tripolymer is 5 to 50 percent of the mass of the two-dimensional metal organic framework material ZIF-L nano-particles. The invention is mainly used for providing and preparing the ZIF-L-based epoxy resin composite coating with excellent antibacterial, antifouling and anticorrosive properties and a coating product, can prevent gram-negative bacteria and gram-positive bacteria, and has good poisoning and anti-adhesion effects on chlorella, phaeodactylum tricornutum and navicula.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

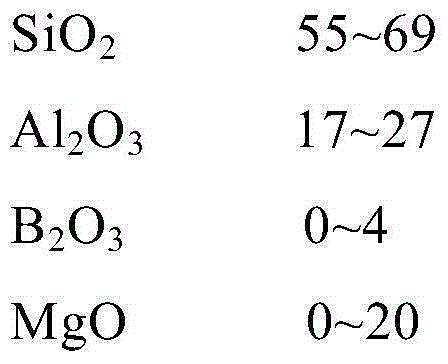

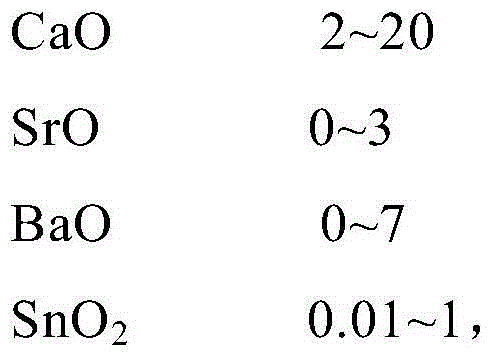

Method for producing alkali-free glass

PROBLEM TO BE SOLVED: To provide an alkali-free glass which has a high strain point, a high Young's modulus and excellent solubility during producing and can be easily subjected to float molding.SOLUTION: There is provided an alkali-free glass which has a Young's modulus of 87 GPa or more, a strain point of 680 DEG C or more and an average thermal expansion coefficient at 50 to 350 DEG C of 3010to 4710 / DEG C, comprises, by mass% on the basis of oxide, 55 to 69 of SiO, 17 to 27 of AlO, 0 to 3 of BO, 0 to 20 of MgO, 2 to 20 of CaO, 0 to 2 of SrO, 0 to 2 of BaO and 0.01 to 1 of SnOand satisfies [SiO]6.7+[AlO]+[BO]4.4-458<=0, in which SiO+AlO+MgO+CaO is 95 or more and MgO+CaO+SrO+BaO is 12 to 2

Owner:ASAHI GLASS CO LTD

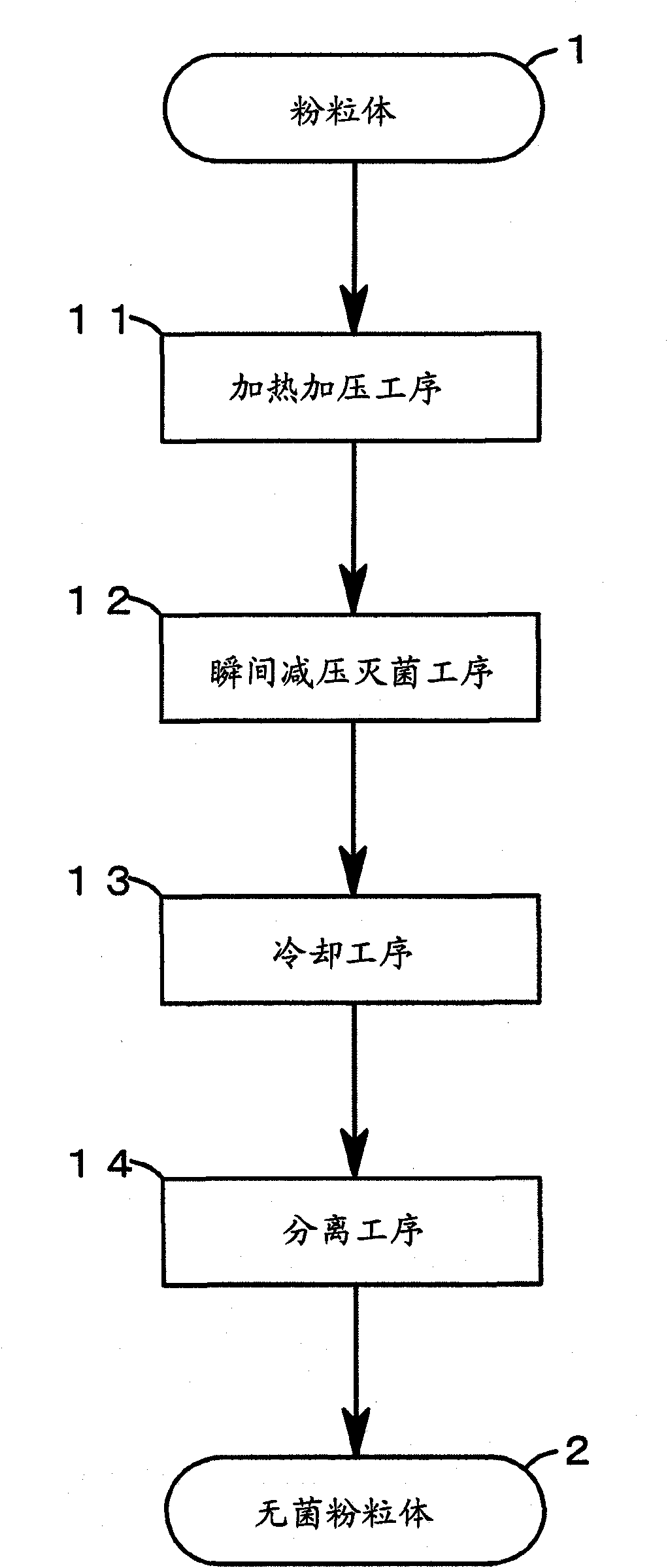

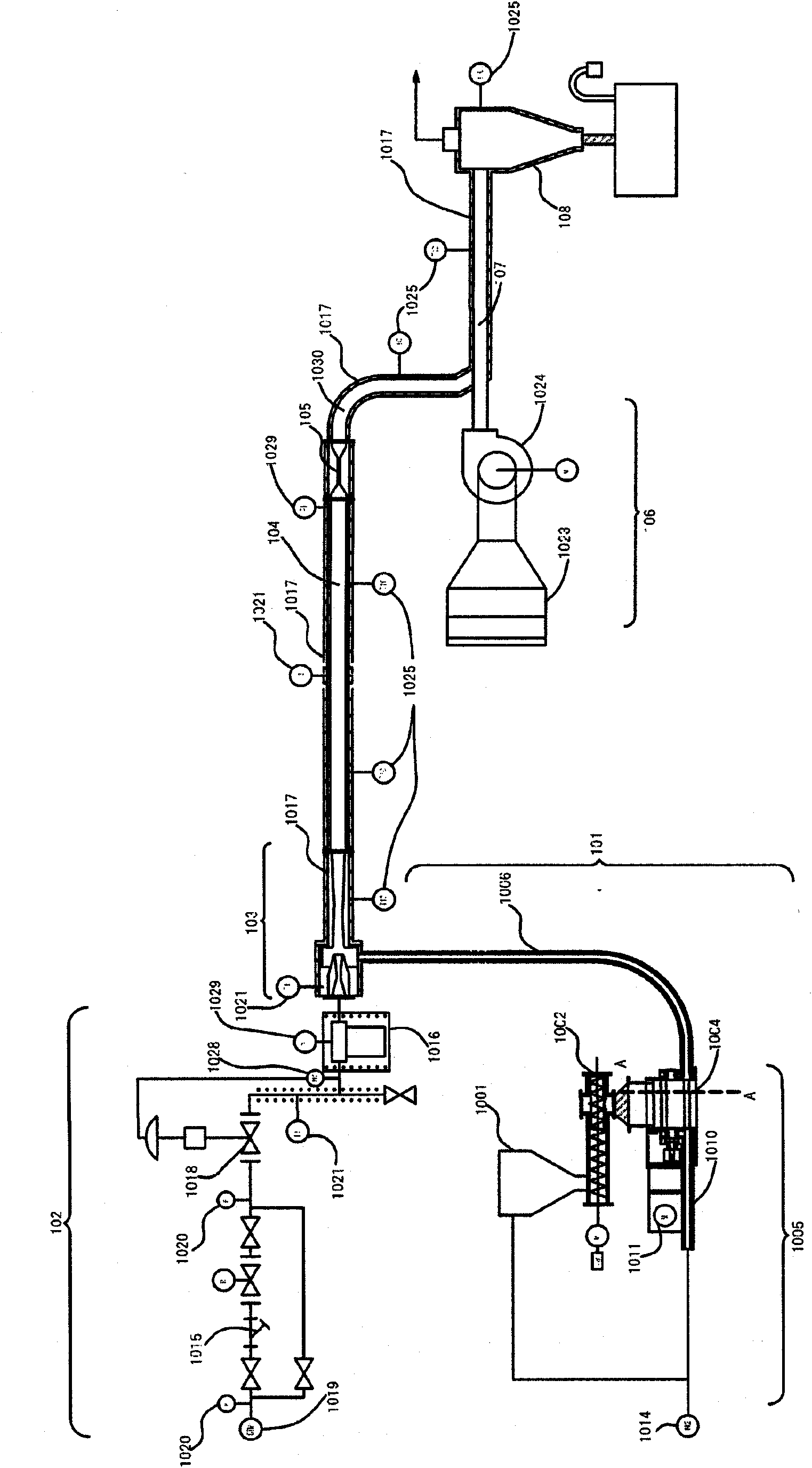

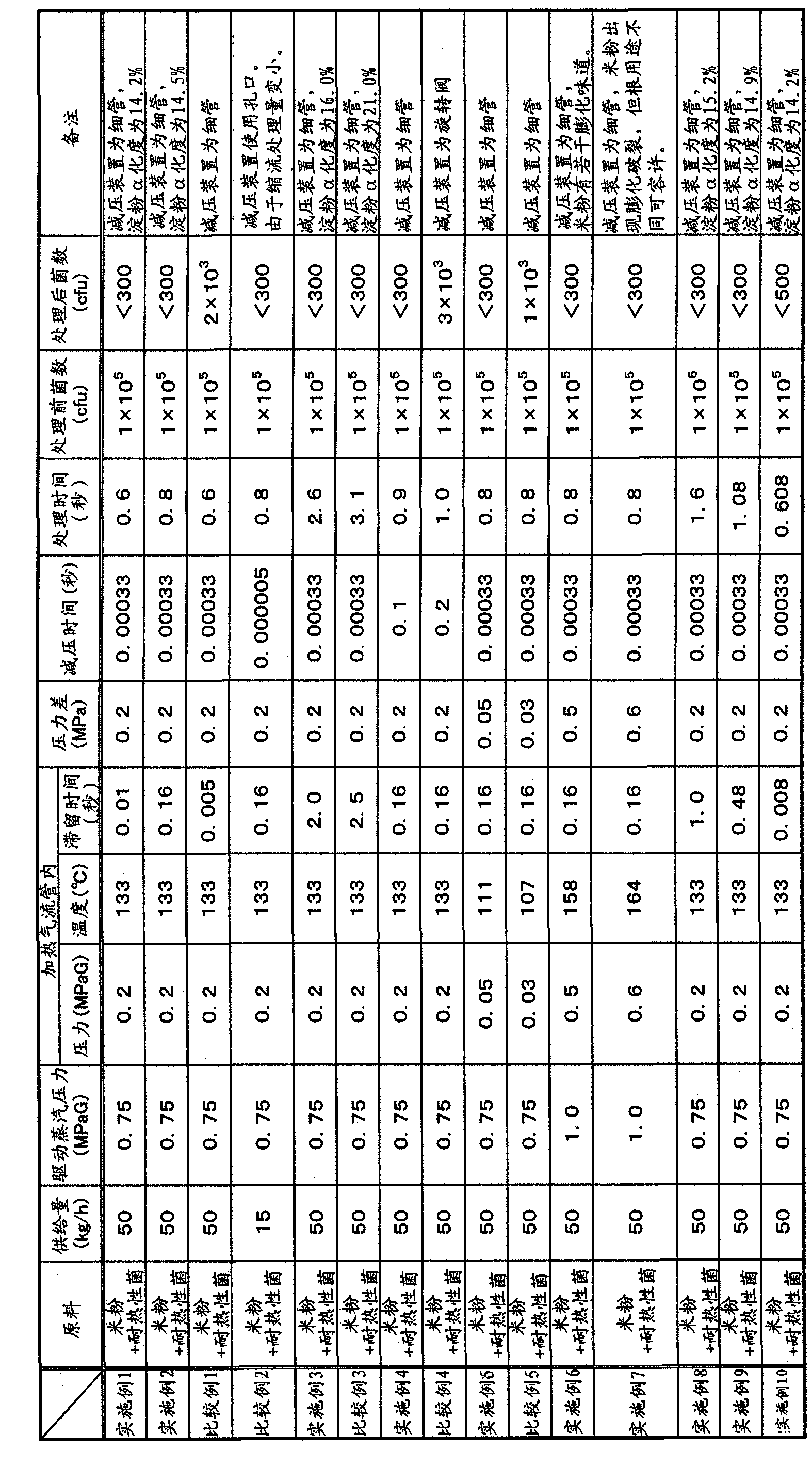

Method for sterilization of powdery or granular substances and apparatus for the sterilization by the method

ActiveCN102046029AImprove sterilizationEasy to sterilizeFruits/vegetable preservation by heatingSeed preservation by heatingProduct gasBiomedical engineering

Provided are a method for the sterilization of powdery or granular substances which can protect powdery or granular substances from quality deterioration caused by heating and which can attain sufficient sterilization effect and a sterilization apparatus suitable for the method. A method for the sterilization of powdery or granular substances, characterized by comprising the heating / pressurizing step of feeding a powdery or granular substance into a heating gas flow pipe kept in a heated and pressurized condition and transferring the powdery or granular substance while bringing the powdery or granular substance into direct contact with a condensable heating gas for 0.008 to 2 seconds in the heating gas flow pipe and the instantaneous vacuum sterilization step of releasing the condensable heating gas and the powdery or granular substance instantaneously into a space having a pressure lower than that in the heating gas flow pipe to boil the water contained in microorganisms adhering to the powdery or granular substance and thus destroy the tissue of the microorganisms; and an apparatus for the sterilization of powdery or granular substances by the method.

Owner:FUJIWARA TECHNO ART CO LTD

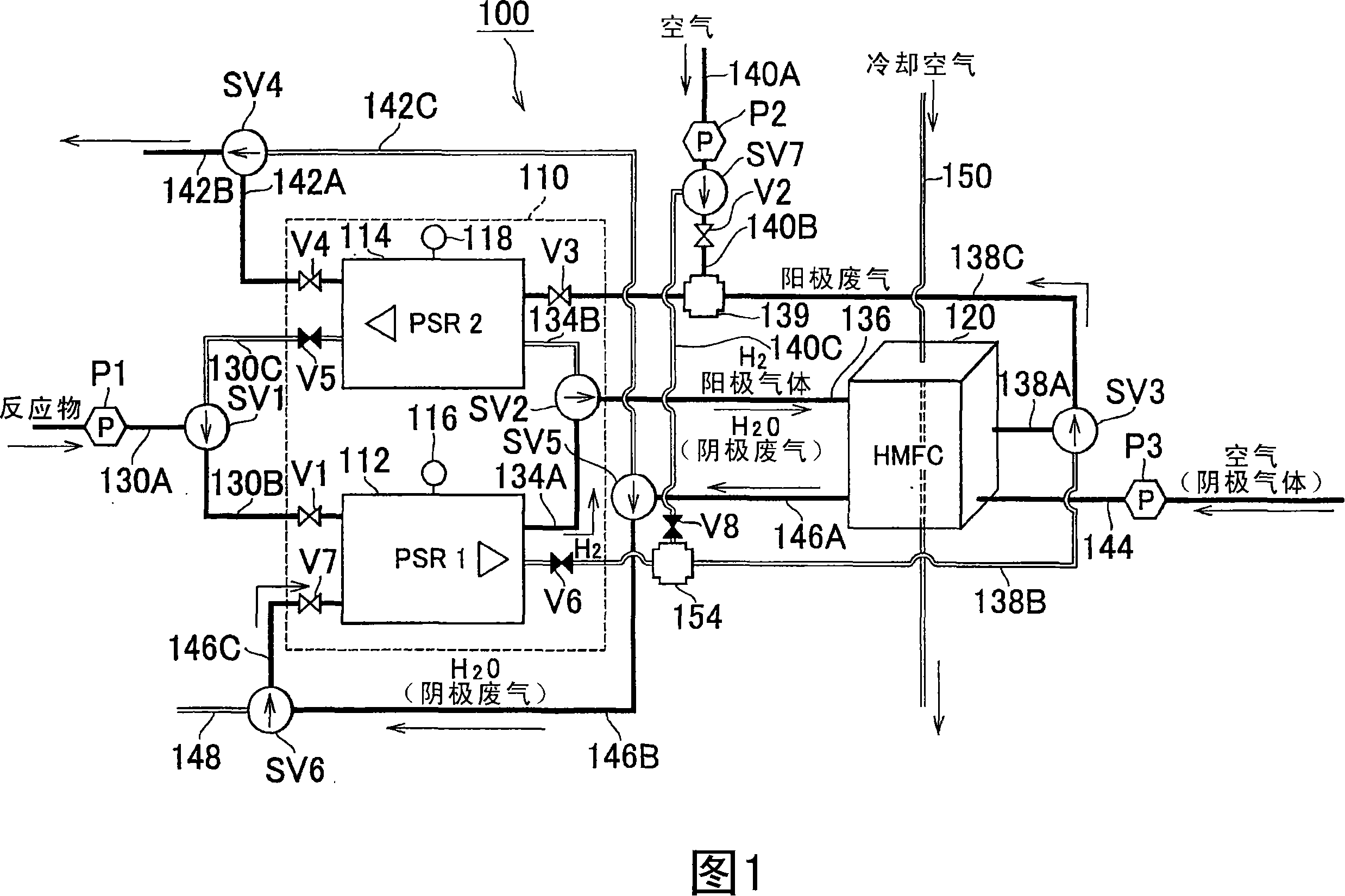

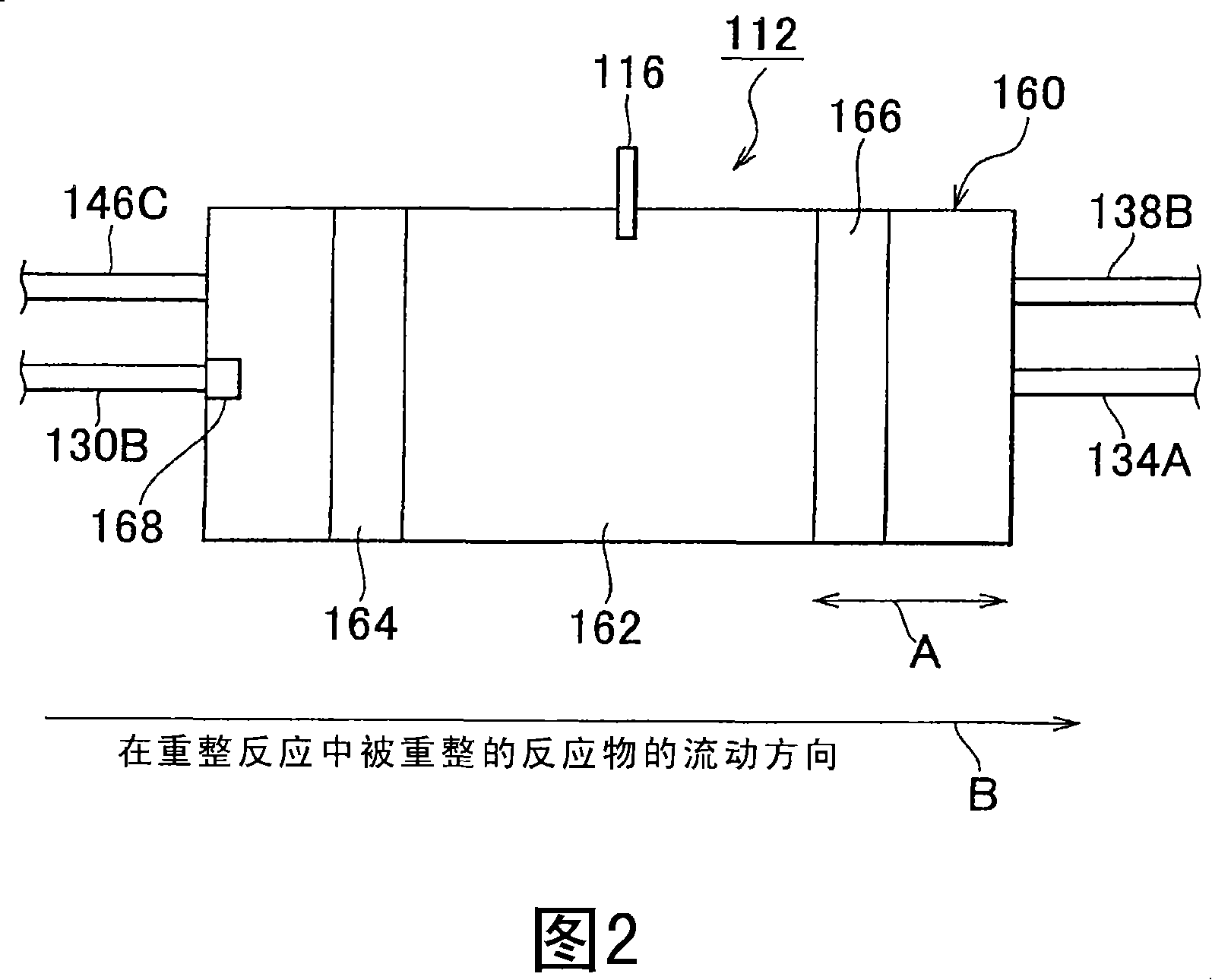

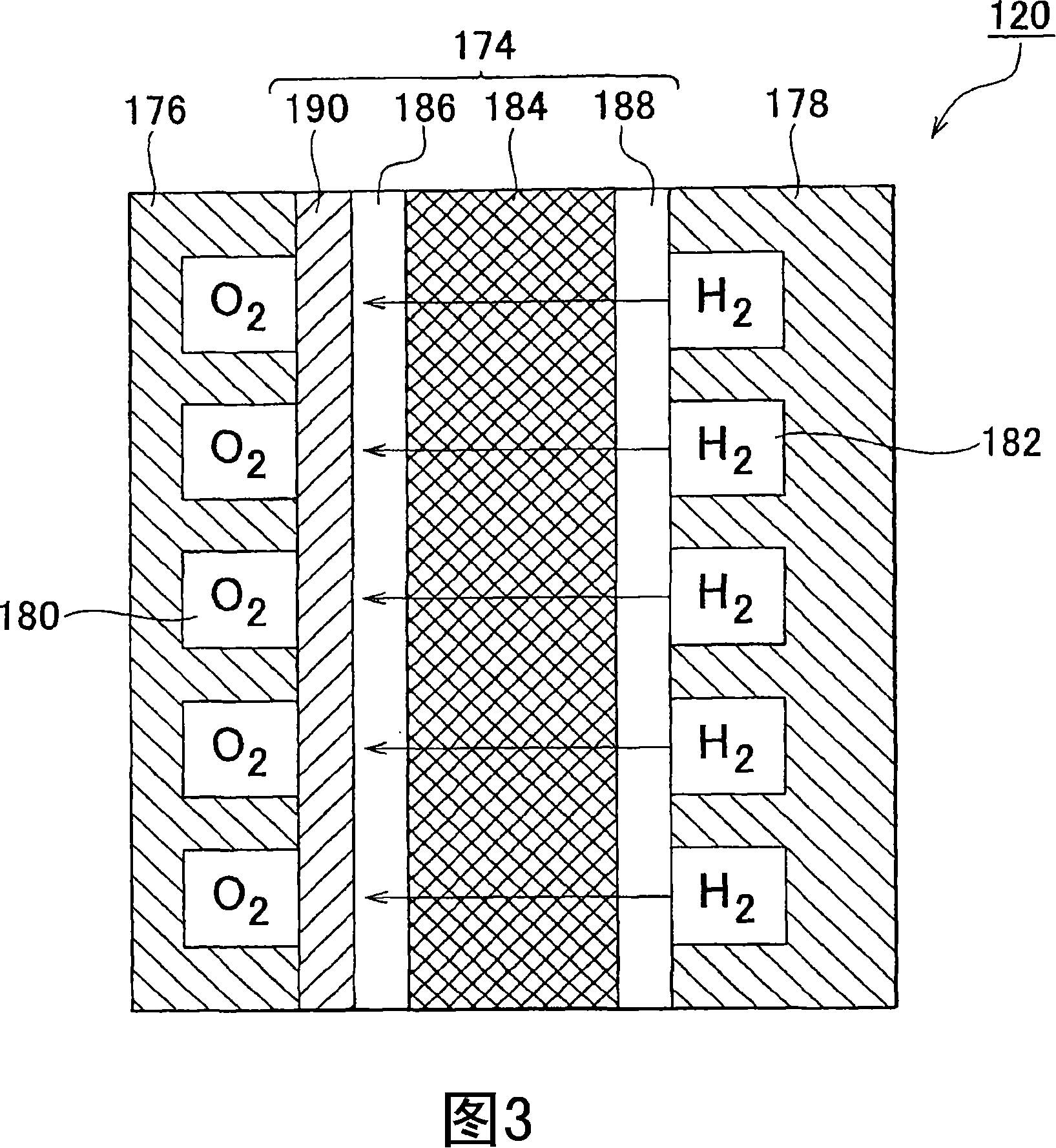

Hydrogen generation device and fuel cell system including same

InactiveCN101151761AWill not deteriorateLess impuritiesHydrogenFuel cell heat exchangeHydrogenFuel cells

A hydrogen generation device (110) includes a catalyst (162); a sulfur-trap member (164); a soot-trap member (166); a pair of reformers (112, 114); and a control portion (170). In each reformer (112, 114), a reforming reaction is carried out to generate hydrogen-containing gas using gasoline and cathode off-gas on the catalyst (162), and an exothermic reaction is carried out to heat the catalyst (162) using anode off- gas and air. The control portion (170) executes a control such that the reactant and the exothermic material are alternately supplied to each reformer (112, 114), whereby the reforming reaction and the exothermic reaction are alternately carried out in each reformer (112, 114). A fuel cell system (100) includes the hydrogen generation device (110).

Owner:TOYOTA JIDOSHA KK

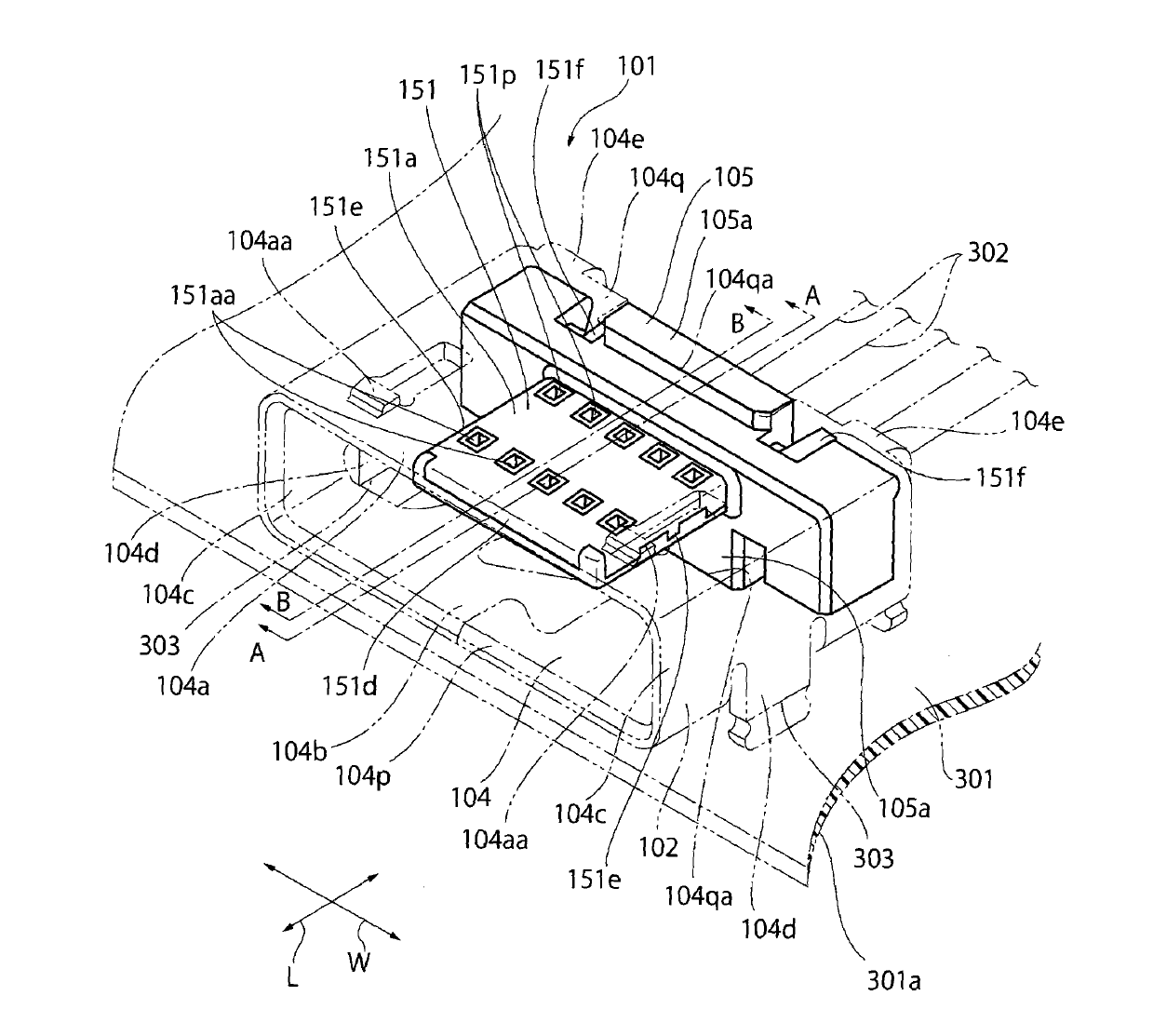

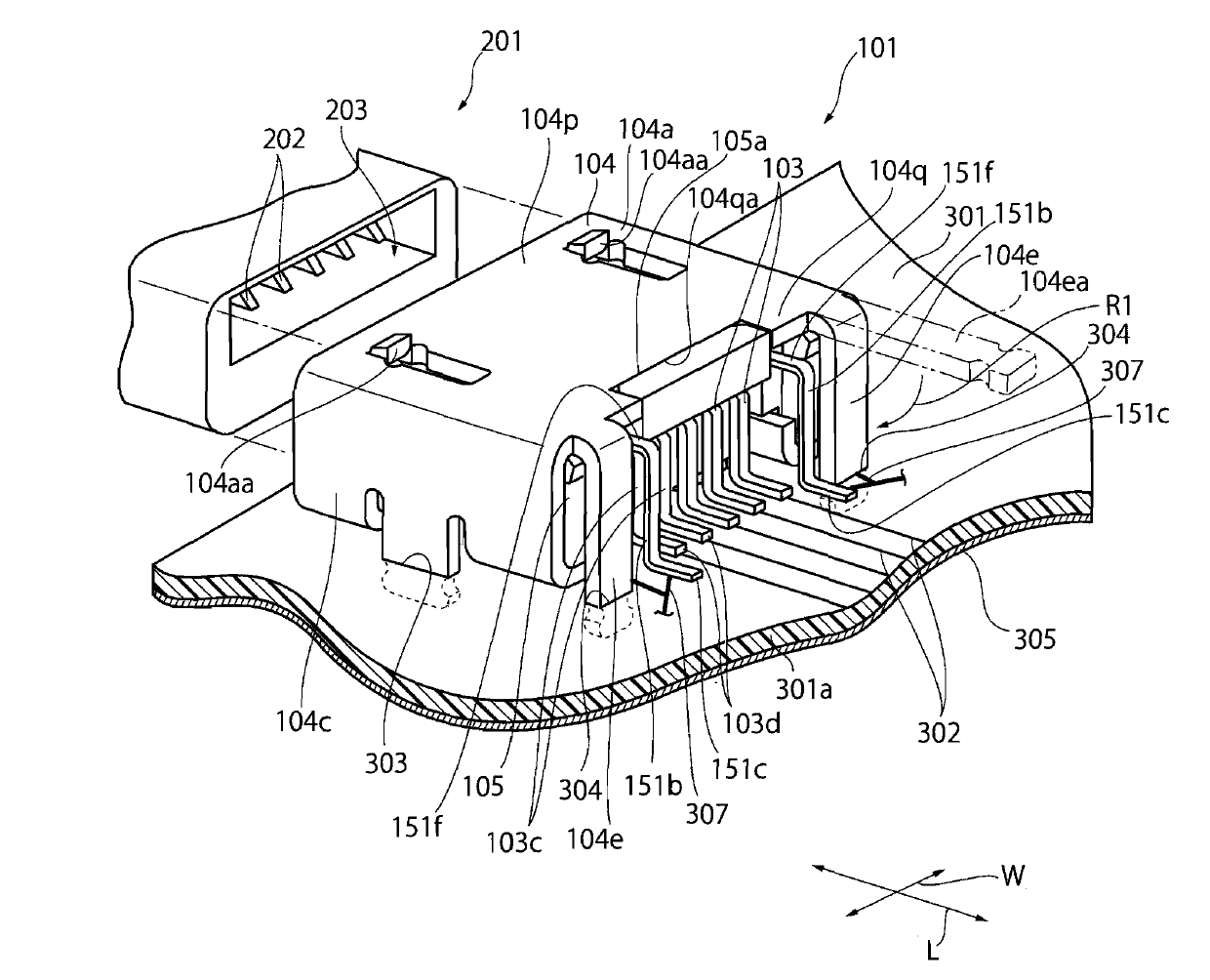

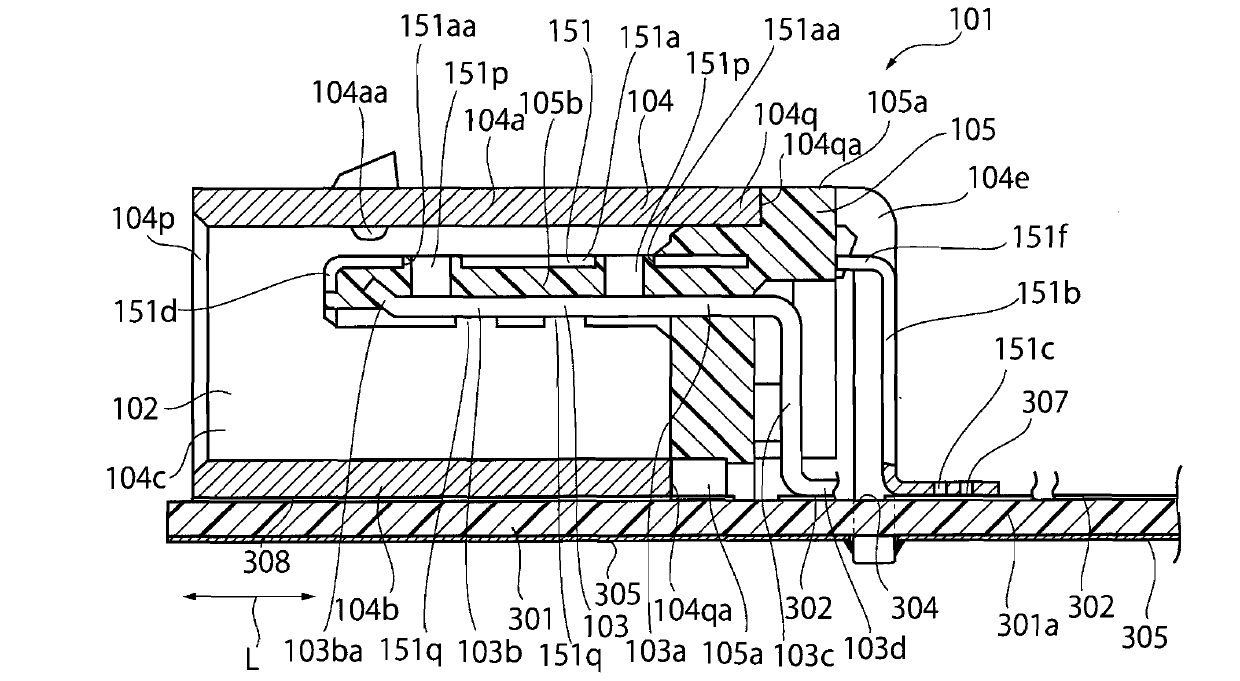

Electric connector

InactiveCN103219612AImpedance control is easyWill not deteriorateCoupling contact membersFixed connectionsElectric signalHigh Frequency Waves

The invention relates to an electric connector. Even when the electric connector is installed on a circuit board, high frequency performance of electric signals is not degraded. A matched connector is installed on an installation part (102) of the electric connector (101). A shade (105) is formed by shaping an insulating resin and is provided with an extending part embedded with an embedding hole of the matched connector when being installed on the installation part. A contact part (103b) of a contact component (103) is contacted with a contact component on a matched side in the embedding hole of the matched connector when being installed on the installation part and is arranged in list on the lower surface of the extending part (105b). A metal piece (151) is fixed on the shade and is grounded through a grounding part (151c). A flat part (151a) arranged on the metal piece is arranged on the upper surface of the extending part and is in parallel with the list of the contact parts (103b) of the contact component.

Owner:SMK CO LTD

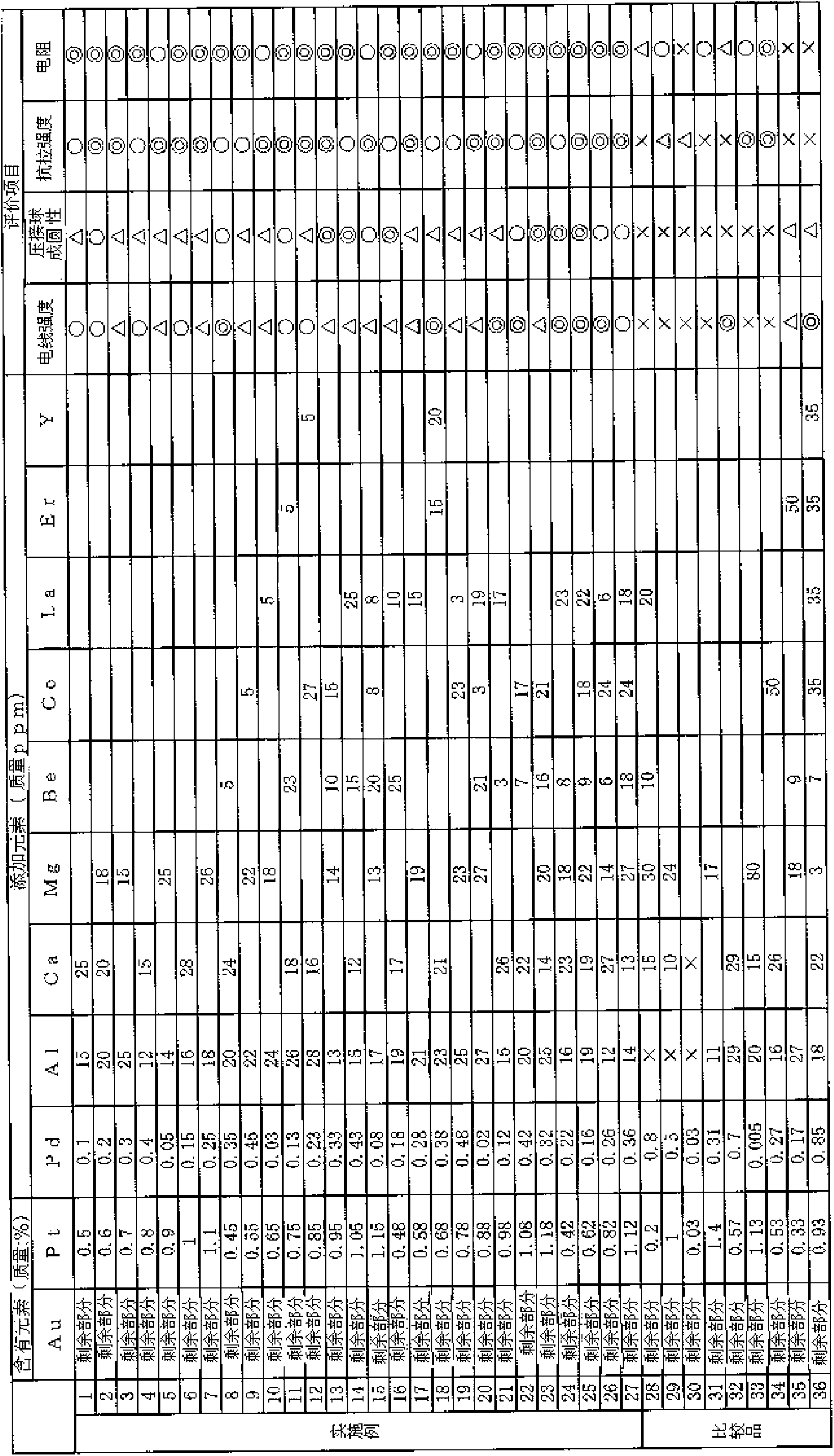

Gold-platinum-alladium alloy bonding wire

ActiveCN103238210AGood bondingEnsure roundnessSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyPlatinum

[Problem] To provide a gold-platinum-palladium alloy bonding wire for vehicle-mounted semiconductors, which exhibits excellent reliability in the connection with aluminum pads, while being highly reliable when left at high temperatures even in cases where an epoxy resin containing no halogen substance is used, thereby capable of maintaining the electrical characteristics after being left at high temperatures. [Solution] A gold-platinum-palladium alloy bonding wire which contains 0.4-1.2% by mass of platinum, 0.01-0.5% by mass of palladium, 10-30 ppm by mass of aluminum and 10-60 ppm by mass of calcium and / or magnesium in total, with the balance made up of gold having a purity of 99.999% by mass or more.

Owner:TANAKA DENSHI KOGYO KK

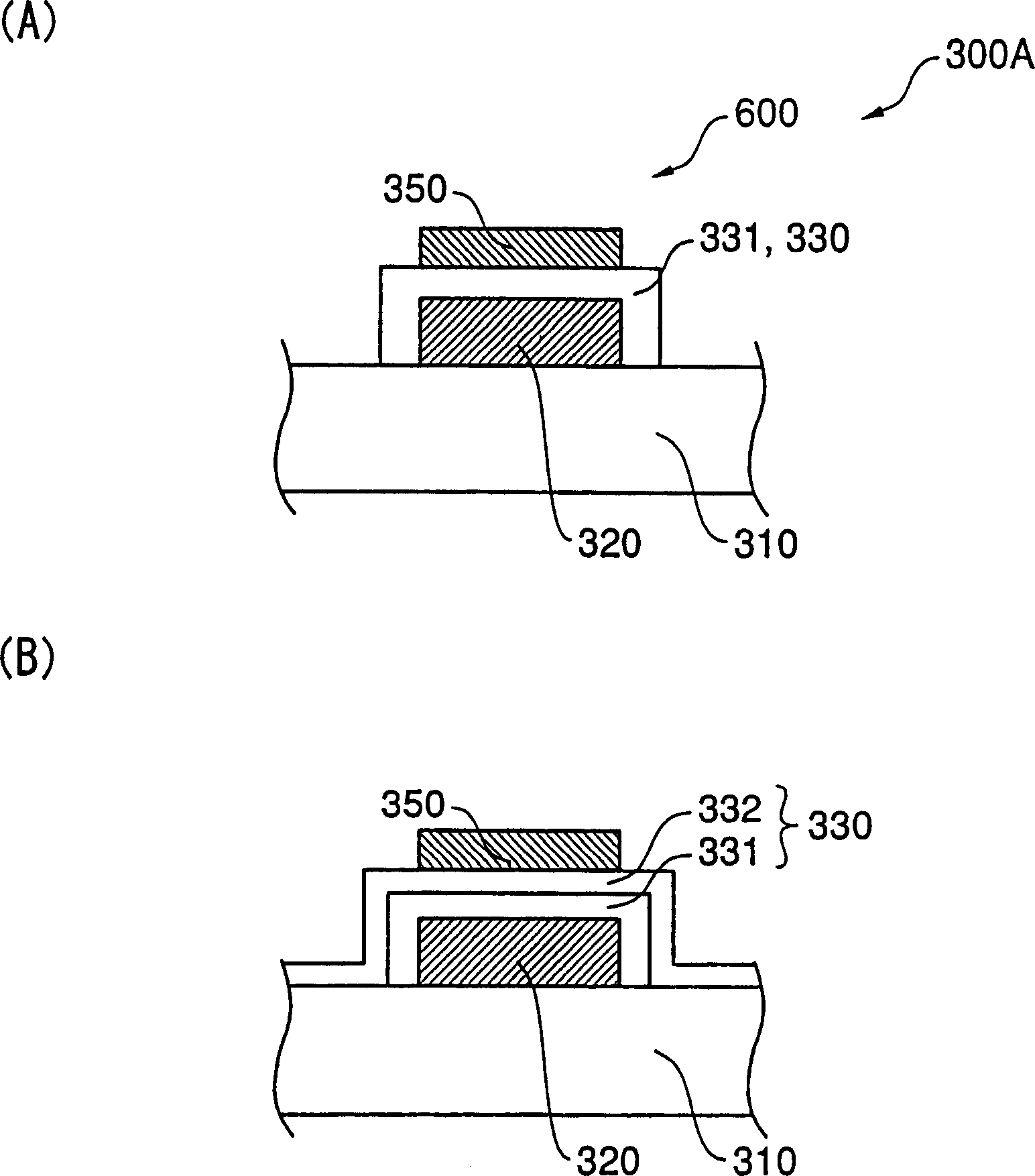

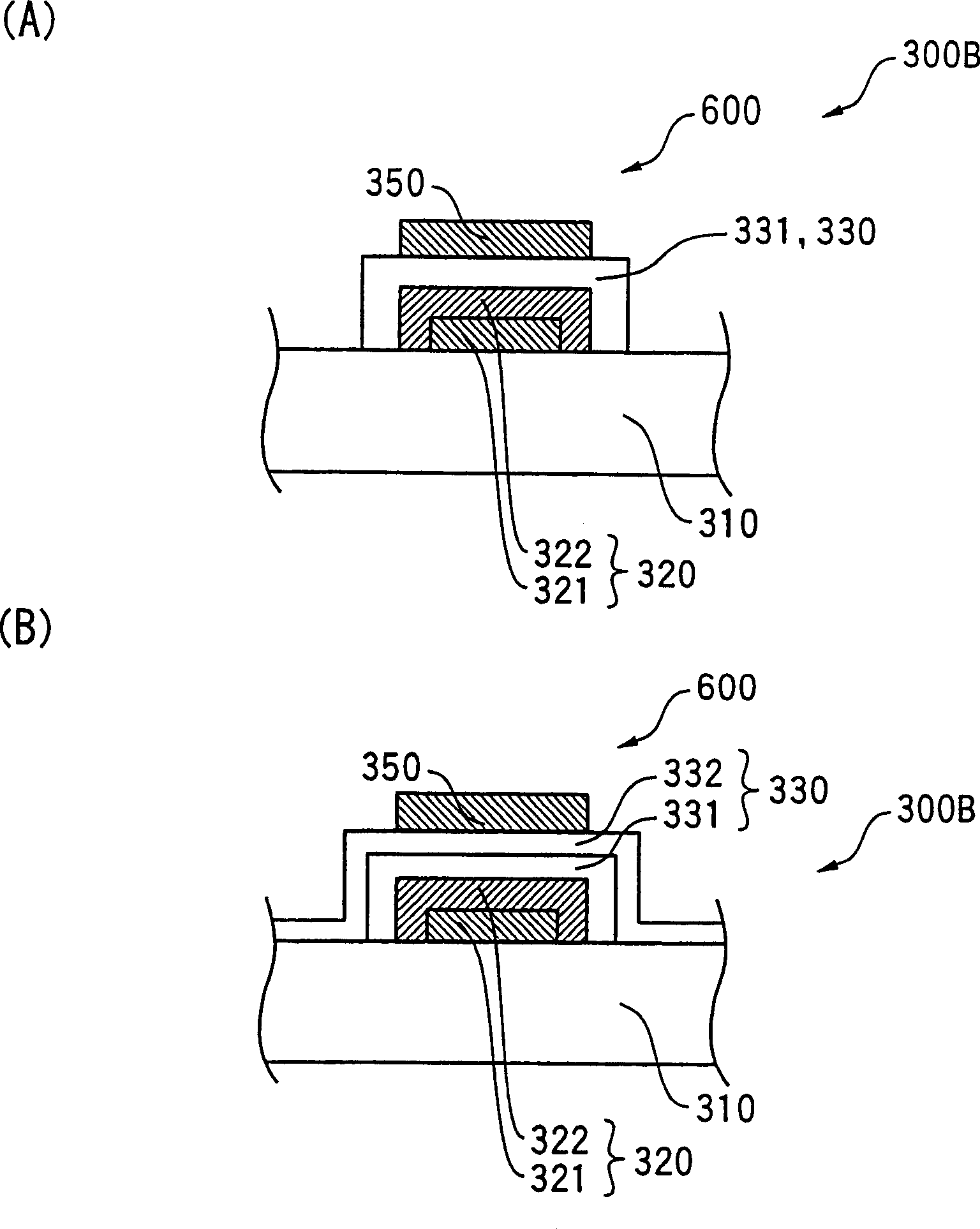

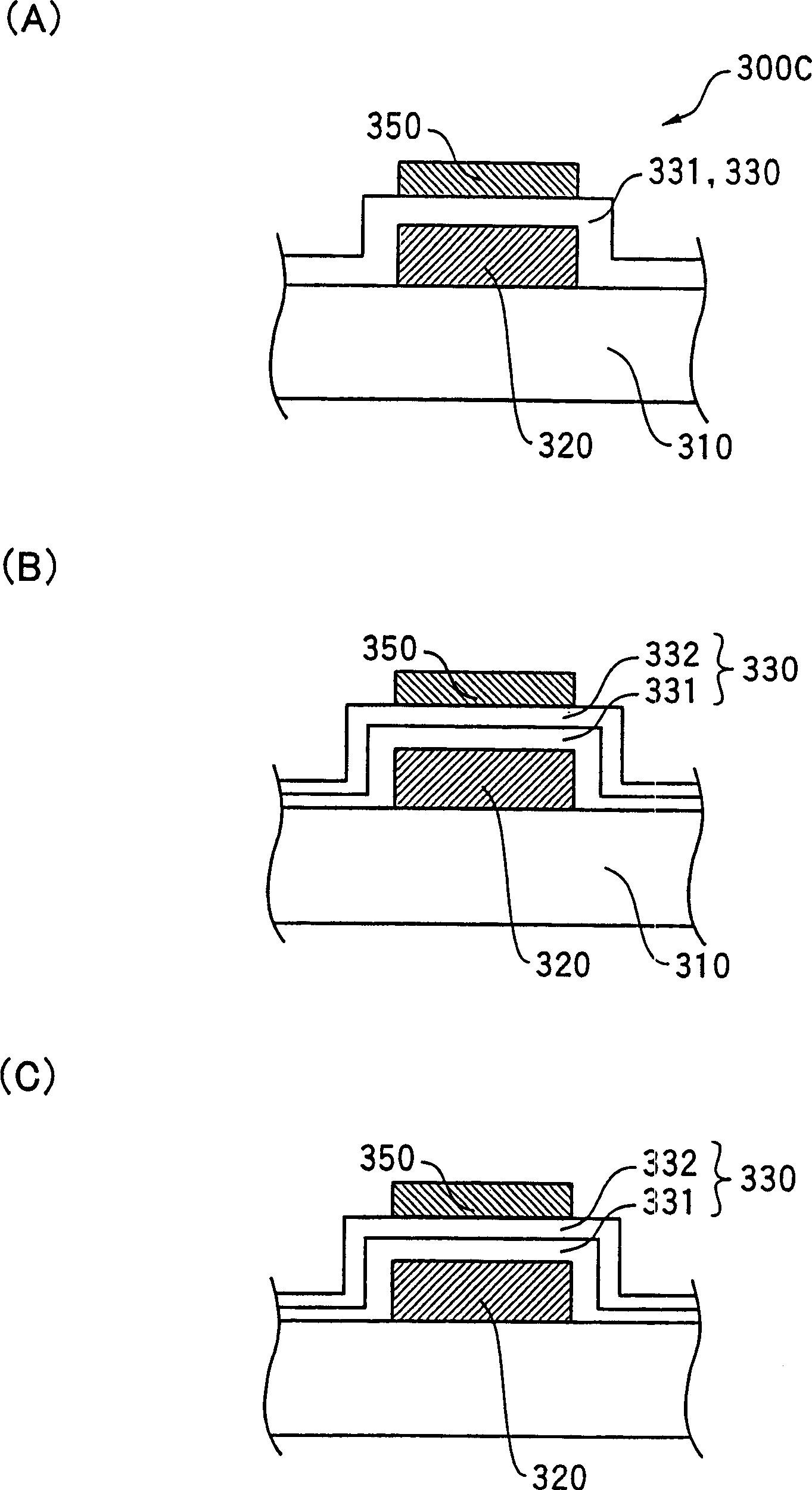

Capacitor, semiconductor device and its manufacture method, electrooptical device and electronic machine

InactiveCN1405805AImprove pressure resistanceImprove uniformityTransistorFixed capacitor dielectricSilicon oxideHigh pressure

A semiconductor device includes a TFT, a diode and a capacitor each having an insulating layer which includes a tantalum oxide film formed by oxidizing a tantalum film at a temperature of 300 DEG C to 400 DEG C and under a pressure of 0.5 MPa to 2 MPa, and a silicon oxide film formed by a CVD method and the like. Therefore, the insulating layer includes the tantalum oxide film produced by high-pressure annealing and thus has high voltage resistance.

Owner:SEIKO EPSON CORP

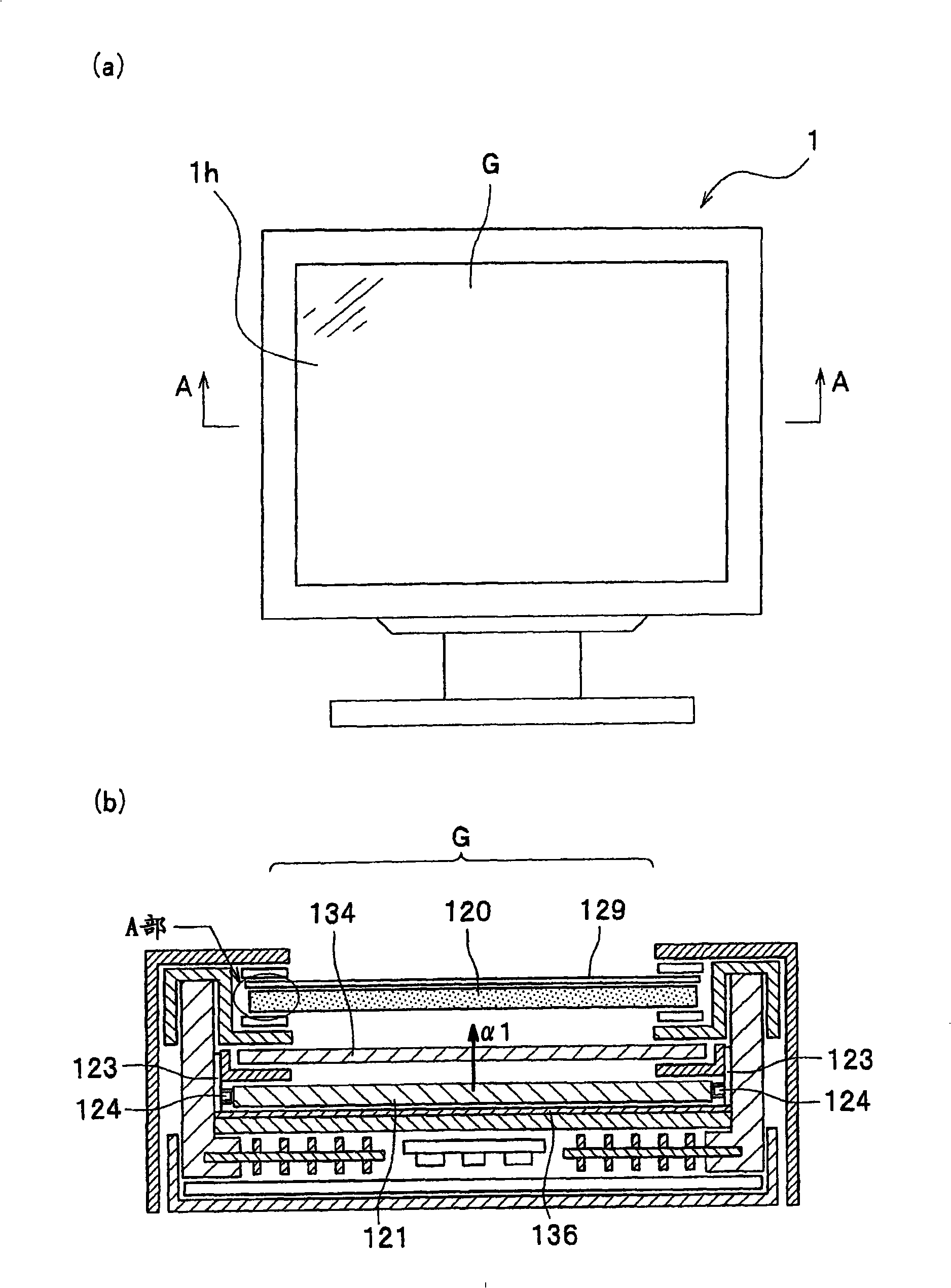

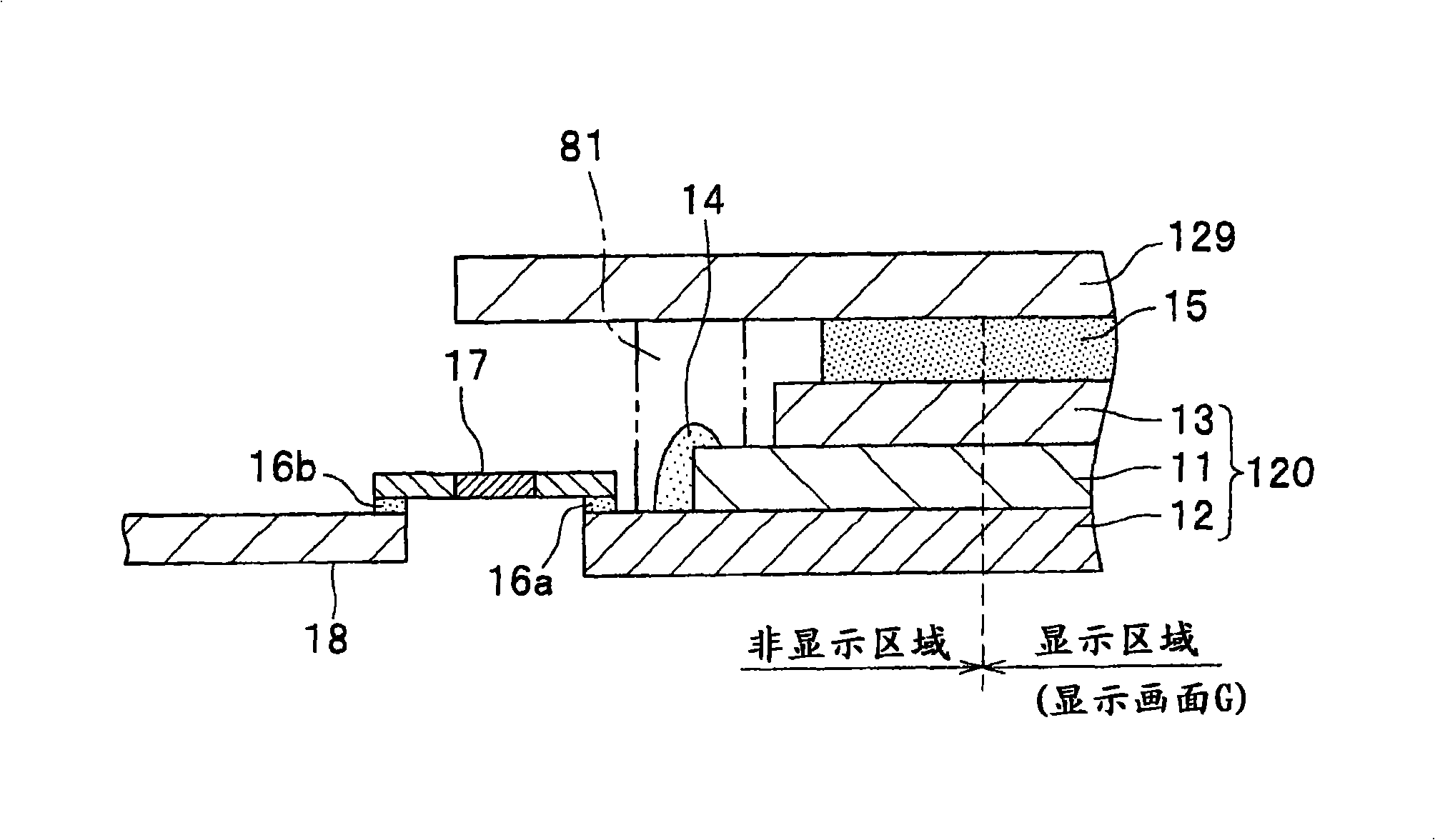

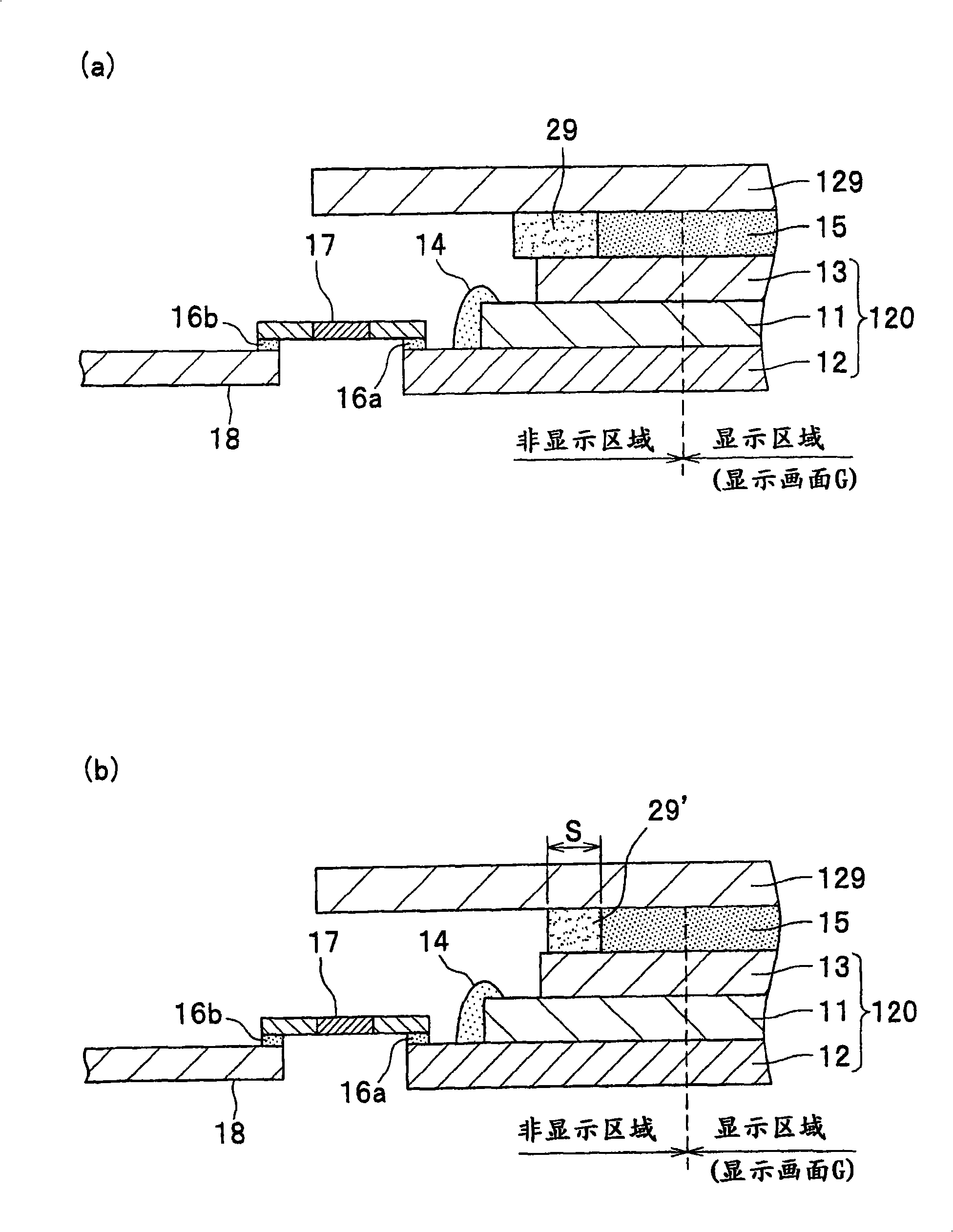

Image display device

ActiveCN101315482APrevent leakagePrevent infiltrationNon-linear opticsElastomerLiquid-crystal display

Owner:JAPAN DISPLAY INC +1

Rehabilitation lyophilized powder injection and its preparation method

InactiveCN1762416AGood removal effectIncrease total content determinationPowder deliveryPeptide/protein ingredientsMedicineFreeze-drying

The invention provides a rehabilitation lyophilized powder injection and its preparation method, which comprises the following constituents (by weight ratio): gen-seng, astragalus root extract and Marine 5-80%, and freeze-drying excipient 20-95%. The preparing process for the gen-seng and astragalus root extract consists of charging water for injection into gen-seng, astragalus root extract and Marine, stirring to dissolve, adjusting pH of the soup to 3.0-7.5 with medicinal alkali, charging freeze-drying excipient, stirring, mixing homogenously, adding water for injection to predetermined volume, carrying out asepsis filtering, split charging, and freeze-drying.

Owner:邹巧根

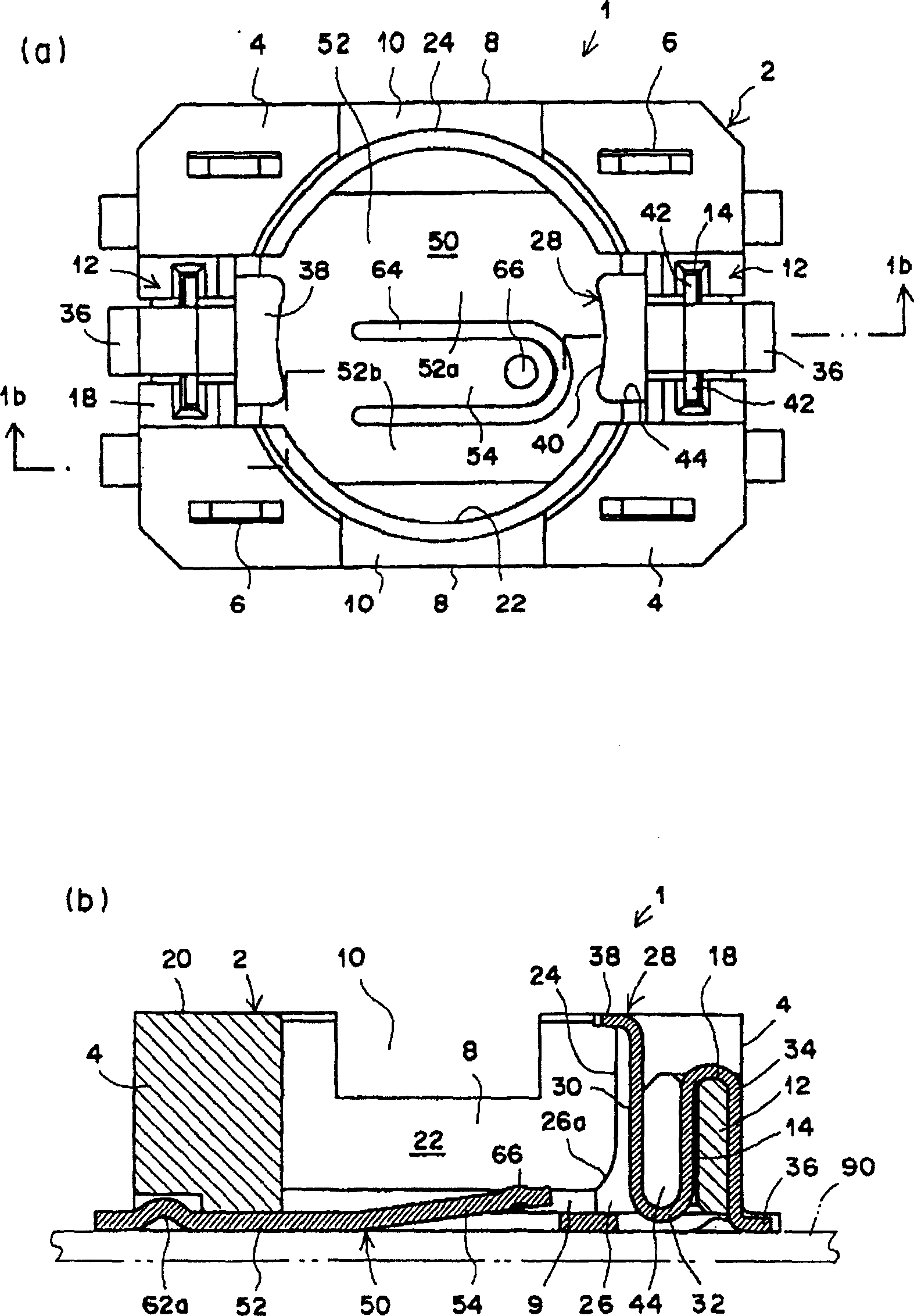

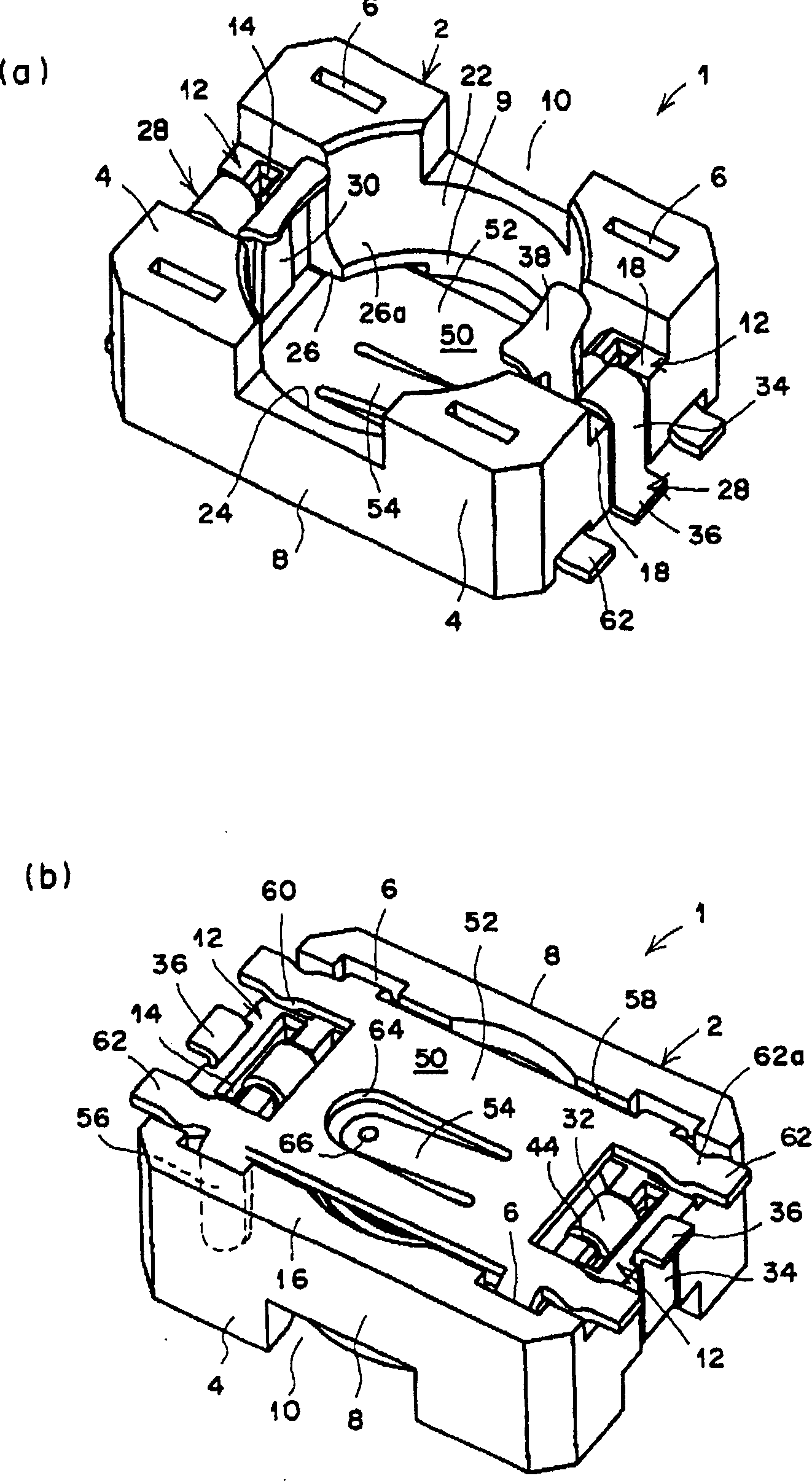

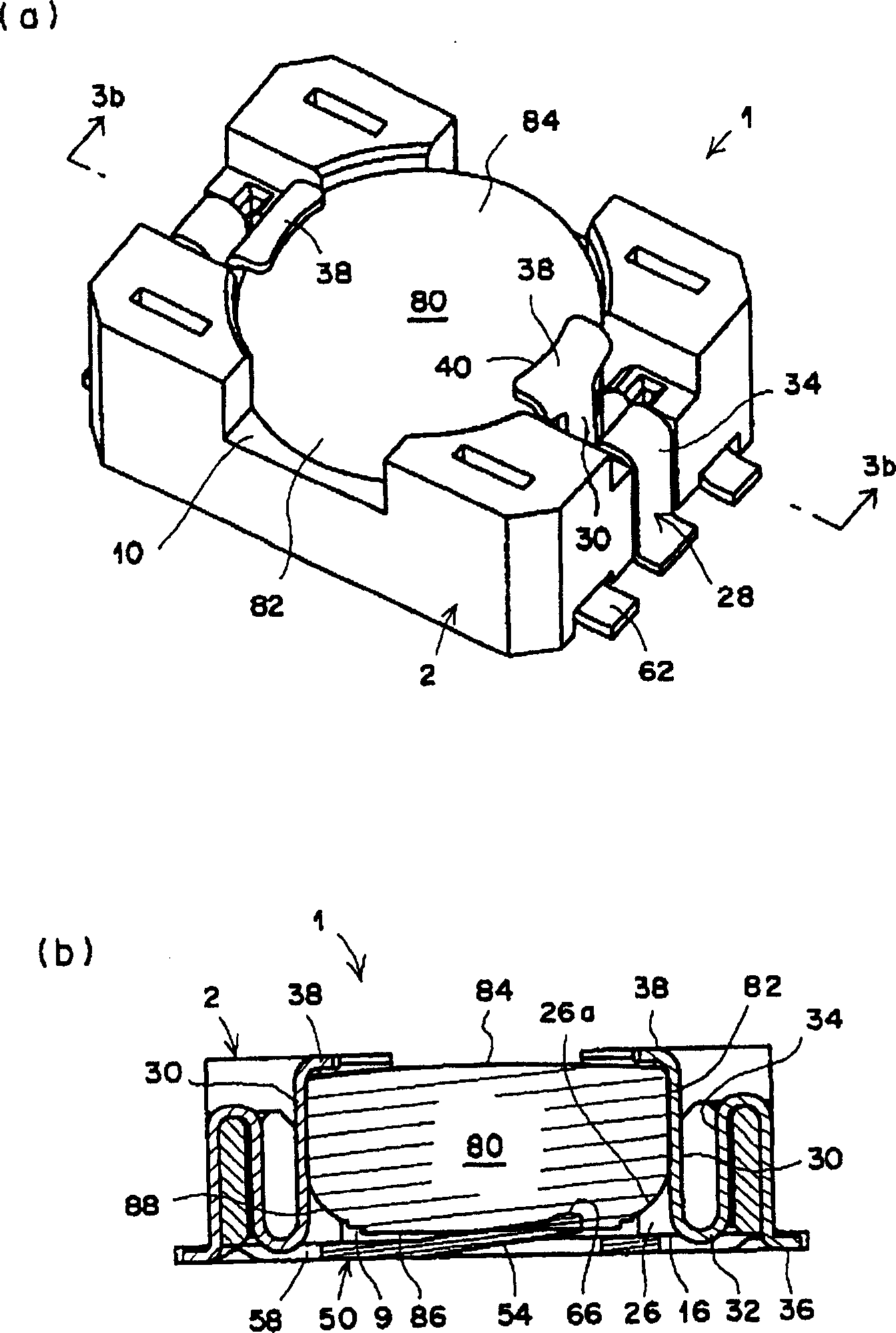

Battery holder for button type battery

InactiveCN1453887AImprove hold reliabilitySpeed up the flowResilient/clamping meansCell component detailsBattery holderEngineering

PROBLEM TO BE SOLVED: To realize a further low height and improve molding performance in a battery holder that is mounted on a substrate. SOLUTION: The battery holder comprises a housing 2, a contact 28, and a contact 50. A housing section 22 which penetrates vertically is formed in the housing 2 and a bottom wall is not formed, and an opening 9 is formed. The battery is housed in the housing section 22 and supported by the battery holder 1 by a pawl 38 of the contact 28 and a protrusion 26 of the housing section 22, and is electrically connected to a spring member 30 of the contact 28 and a contact piece 54 of the contact 50. Since there is no bottom wall and an opening penetrated in vertical direction is formed, the battery holder 1 becomes low height and molding performance is improved as there is no thin bottom wall. COPYRIGHT: (C)2004,JPO

Owner:TYCO ELECTRONICS AMP GMBH

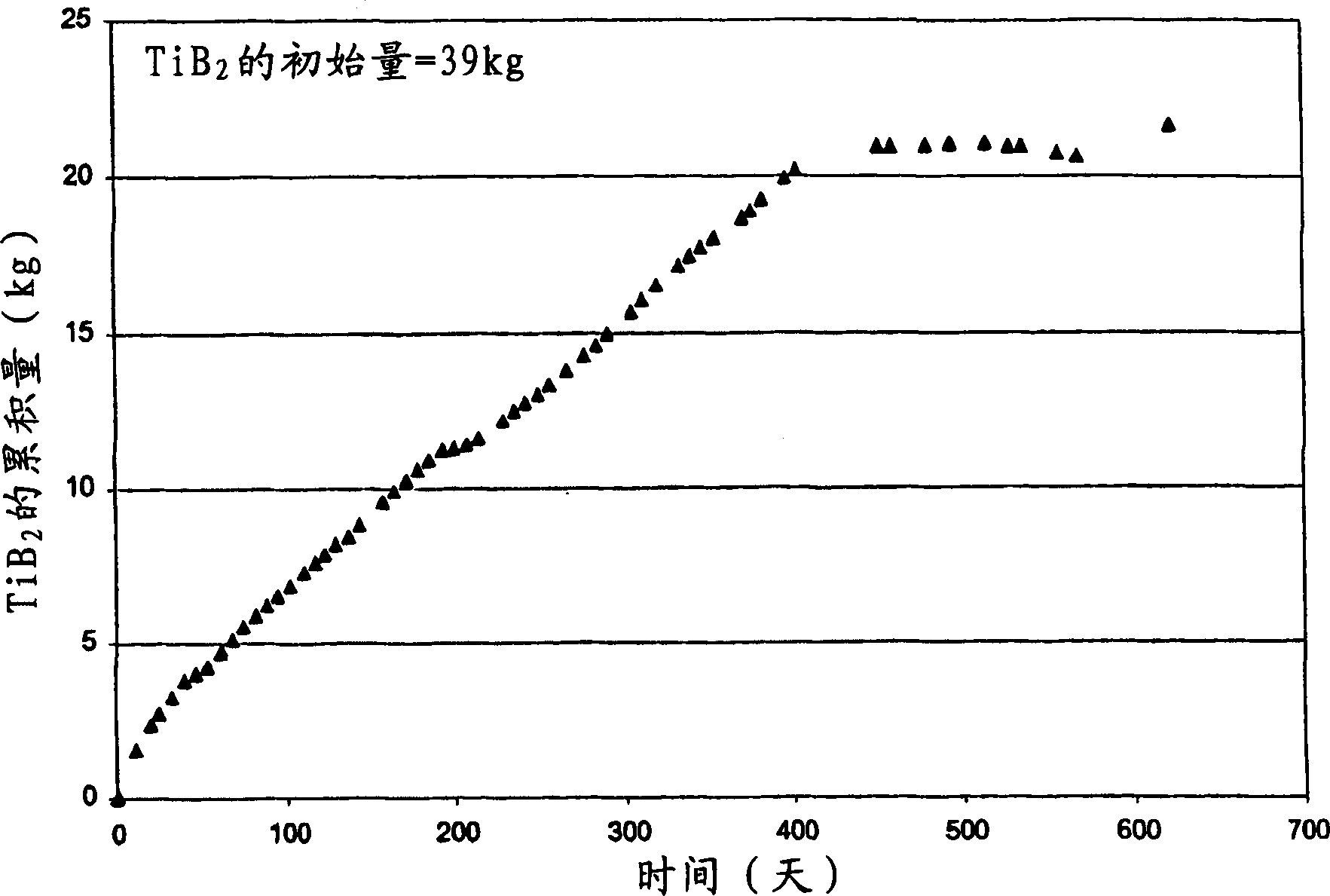

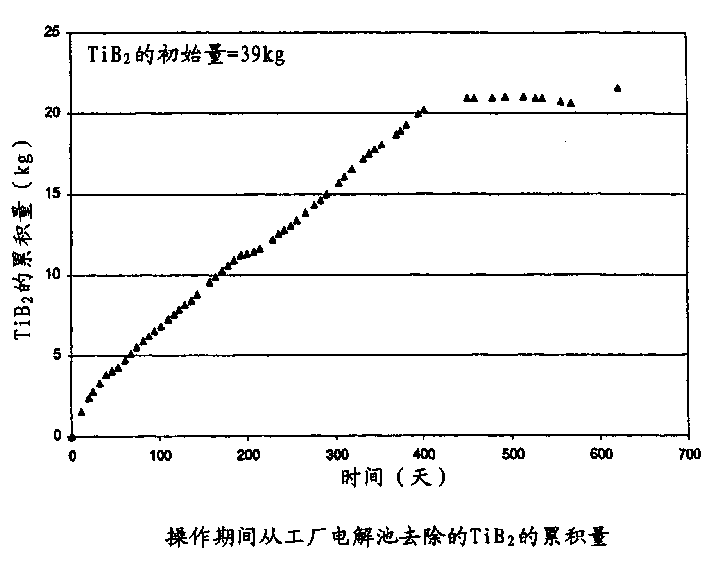

A method for providing a protective coating for carbonaceous components of an electrolysis cell

InactiveCN1401018AWill not deteriorateReduce absorptionLiquid surface applicatorsLiquid/solution decomposition chemical coatingLignosulfonatesRefractory

A method of treating a carbonaceous cell component of an electrolyte cell for the production of aluminum, to impart protection against deterioration during operation of the cell. A liquid suspension of a refractory material dispersed in a lignosulfonate binder solution is prepared and applied as a protective coating to the surface of carbonaceous cell components and allowed to dry.

Owner:ALCAN INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com