Magentic recording medium for heat assisted recording and method for fabricating same

一种磁记录介质、记录方式的技术,应用在磁记录、磁记录层、数据记录等方向,能够解决磁记录层劣化、不适合实用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

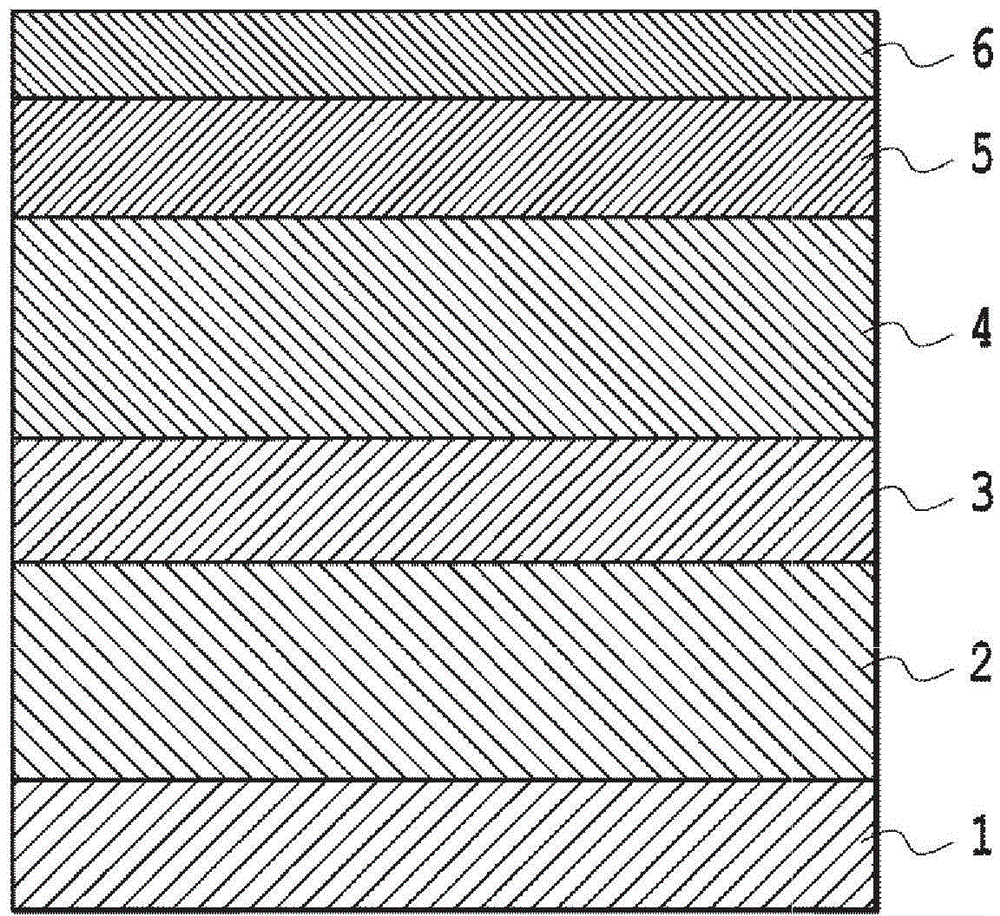

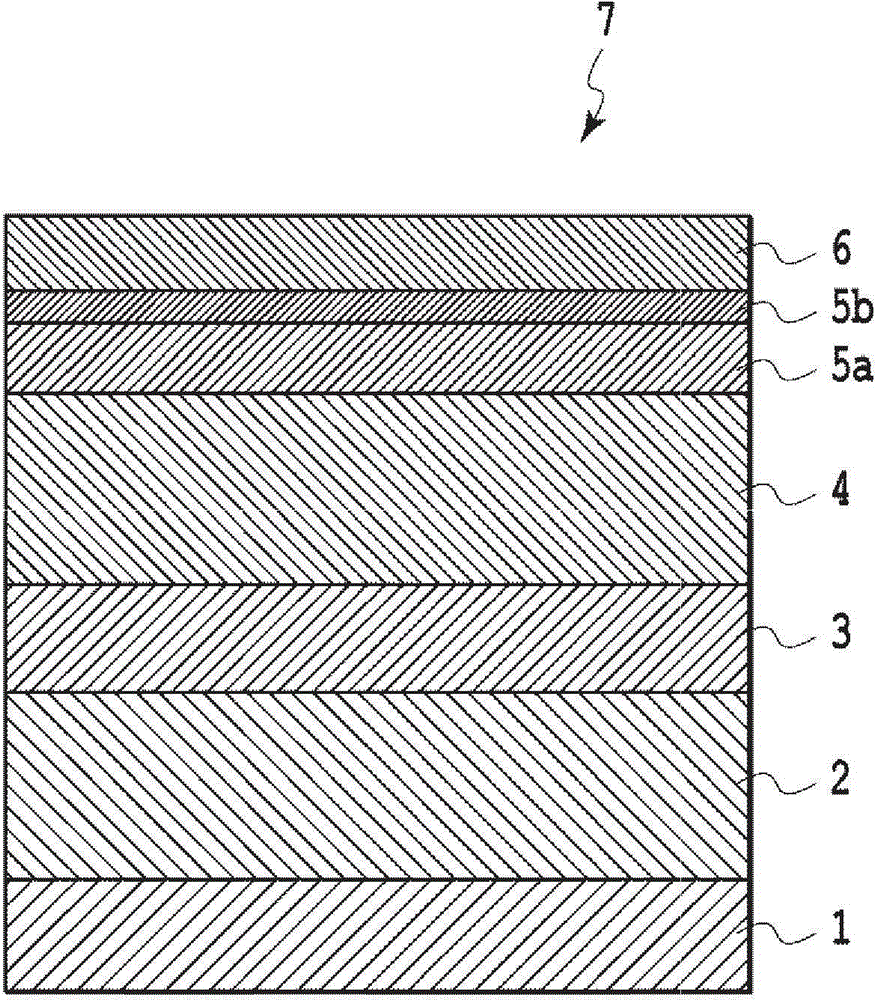

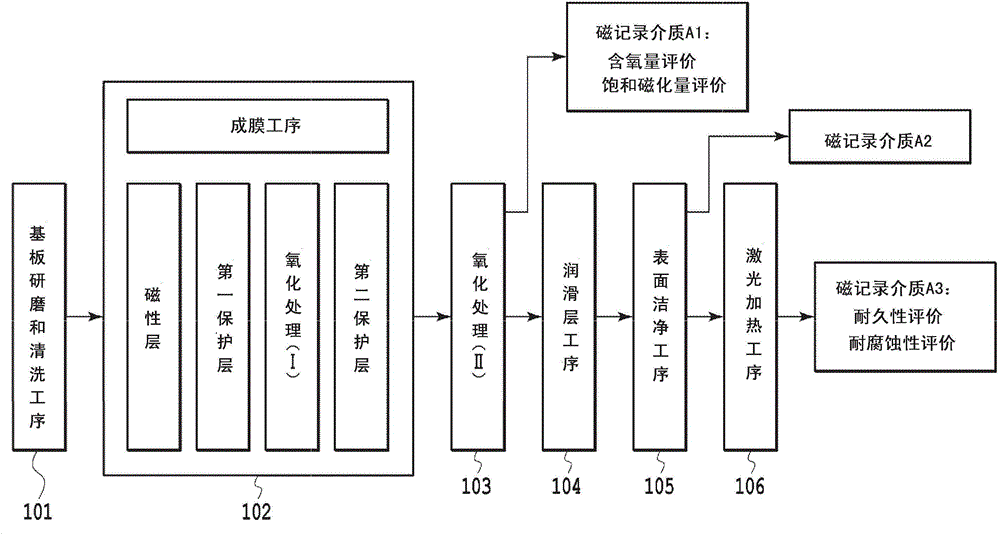

[0054] In embodiment 1, such as figure 2 As shown, a non-magnetic substrate 1, a Co-based soft magnetic substrate layer 2, a base layer 3 made of Ru, CoCrPt-SiO 2 The granular magnetic recording layer 4, the first lower protective layer 5a made of Si, and the first lower protective layer 5a made of SiO 2 A magnetic recording medium consisting of a first upper protective layer 5b, a second protective layer 6 made of DLC, and a lubricating layer (not shown).

[0055] Below, based on figure 1 and figure 2 Examples will be described. As the non-magnetic substrate 1 , a disk-shaped chemically strengthened glass substrate (HOYA Co., Ltd. N-10) with a smooth surface was used. First, the cleaned non-magnetic substrate 1 is introduced into a film forming apparatus. Film formation from the soft magnetic substrate layer 2 to the second protective layer 6 is not exposed to the atmosphere, and all film formation is performed in an in-line film formation apparatus.

[0056] In an Ar...

Embodiment 2

[0062] Except for using Al as the material of the first protective layer 5 and changing the film thickness of the second protective layer 6 to 2.0 nm, 1.5 nm, 1.0 nm, and 0.5 nm, it was prepared in the same manner as in Example 1, and evaluated. The results are shown in Table 2.

Embodiment 3

[0064] Except having used Cu as the material of the 1st protective layer 5, and having set the film thickness of the 2nd protective layer 6 to 2.0 nm, 1.5 nm, 1.0 nm, and 0.5 nm, it produced similarly to Example 1, and evaluated it. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com