Packaging method for short wavelength LED

A technology of light-emitting diodes and packaging methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as product life impact, thermal stress reduction, and epoxy resin's inability to withstand UV light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

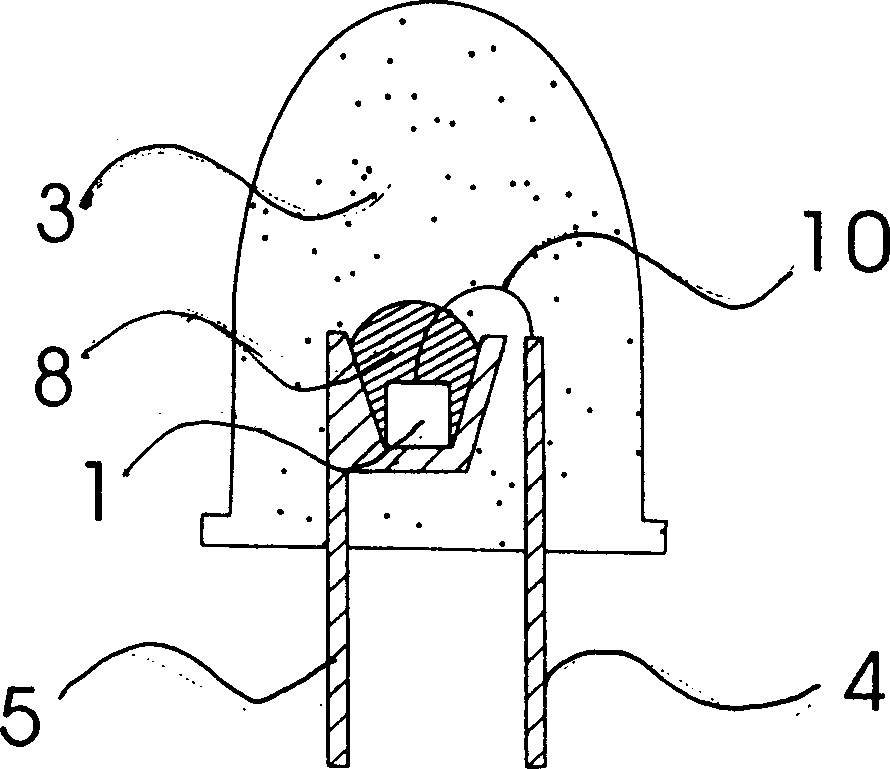

[0019] Generally, LED sealant is made of organic materials, which cannot withstand high temperature and ultraviolet light. Silicone can withstand high temperature of about 200°C, and it is also unable to withstand ultraviolet light. The "liquid glass glue" used in the present invention is different from ordinary glass that needs to be heated to be liquid. It is a liquid colloid at room temperature, which can be applied by dispensing or coating, and becomes a solid glass after heating and hardening. , whose main component is silicon dioxide (SiO 2 ). At present, there are two kinds of liquid glass, one is water glass (Water Glass), the main component is Na 2 o 2 , SiO 2 , another kind of liquid glass (Heatless Glass) invented by the Japanese without heating, the main component is silicon dioxide (SiO 2 ), silicon dioxide is an inorganic glass material with high temperature resistance and short wavelength UV resistance.

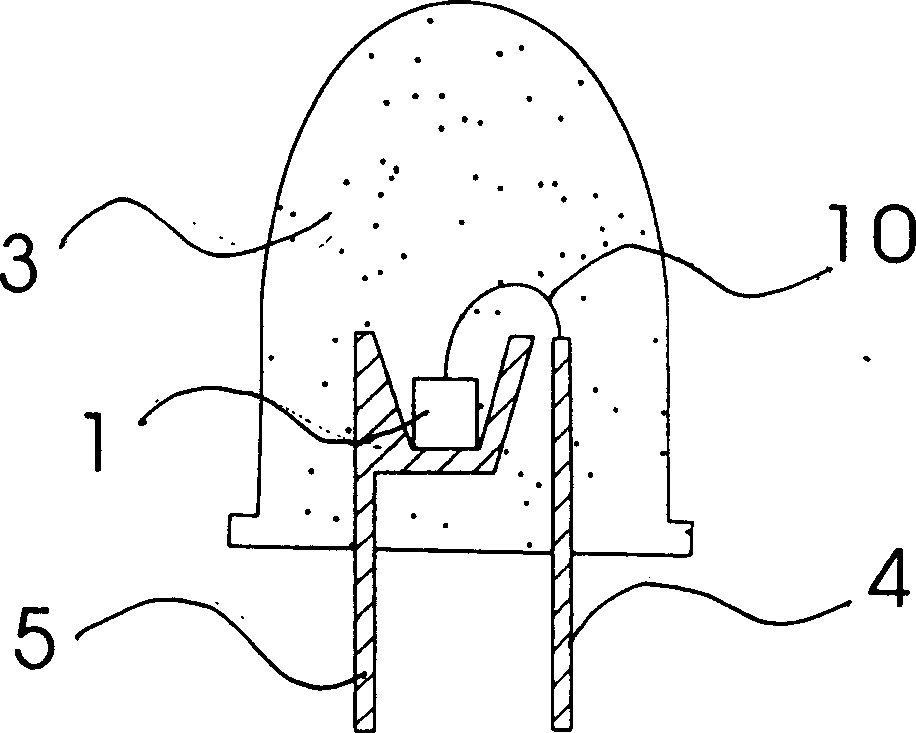

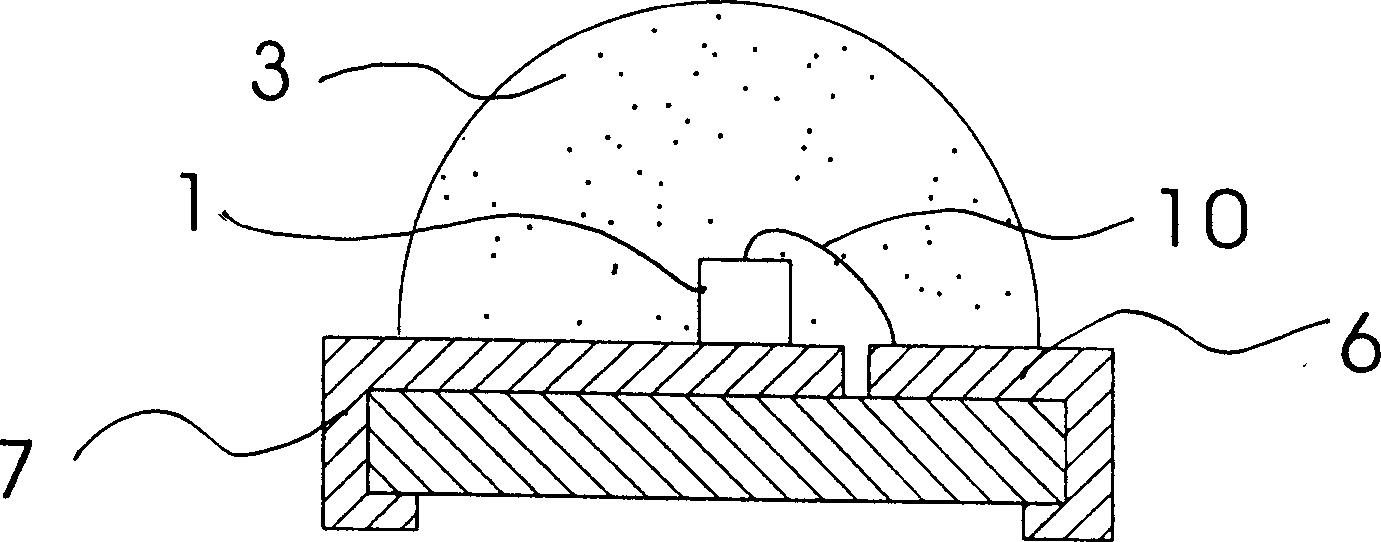

[0020] "Short-wavelength light-emitting diode packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com