Base cloth for filter material and method of manufacturing the same

A technology of filter material and base cloth, which is applied in the field of base cloth, can solve the problems that affect the filtration efficiency and resistance of filter materials, be easily damaged, and increase the emission concentration, etc., and achieve the effect of superior drug resistance and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

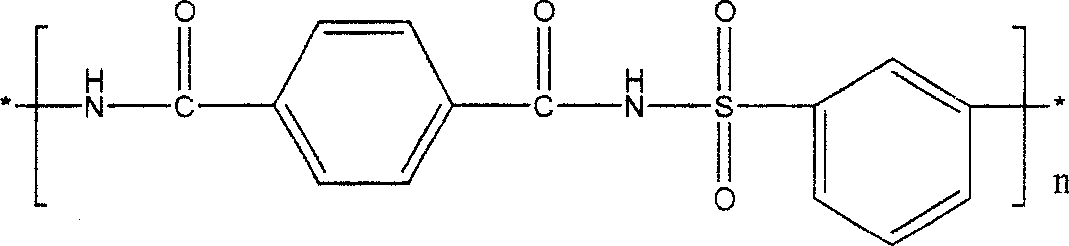

[0043] A kind of production method of filter material base cloth, select polyester fiber (or meta-aramid fiber, para-aramid fiber, polyphenylene sulfide fiber, polyimide fiber, carbon fiber, polytetrafluoroethylene Vinyl fiber, sulfonamide fiber) are used as the fibers to form the warp and weft yarns of the base fabric. The warp and weft yarns are single threads (or strands), and the warp and weft yarns are twisted through the conventional spinning process. The twist is 250T / M~800T / M (for example 250T / M, 500T / M, 800T / M), the fineness is 400Denier~900Denier (for example 400Denier, 700Denier, 900Denier), and the grammage is 100g / m by weaving loom 2 ~150g / m 2 (Example 100g / m 2 、130g / m 2 , 150g / m 2 ) base fabric, when weaving, the warp density is controlled to be 28 / 2.54cm~33 / 2.54cm (for example, 28 / 2.54cm, 30 / 2.54cm, 33 / 2.54cm), and the weft density is 10 Roots / 2.54cm~17 strands / 2.54cm (for example, 10 strands / 2.54cm, 14 strands / 2.54cm, 17 strands / 2.54cm); during the weaving...

Embodiment 2

[0046] The selected polyester fiber yarn is a composite yarn made of polyphenylene sulfide yarn and sulfonamide yarn through a doubling process, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com