Gold-platinum-alladium alloy bonding wire

A palladium alloy and bonding wire technology, which is applied in the field of gold-platinum-palladium alloy bonding wire for halogen-free epoxy resin sealing, can solve the problems of interface degradation, insufficient guarantee of bonding strength, impracticability of practical use, etc., and achieve bondability Good, high tensile strength, stable joint reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

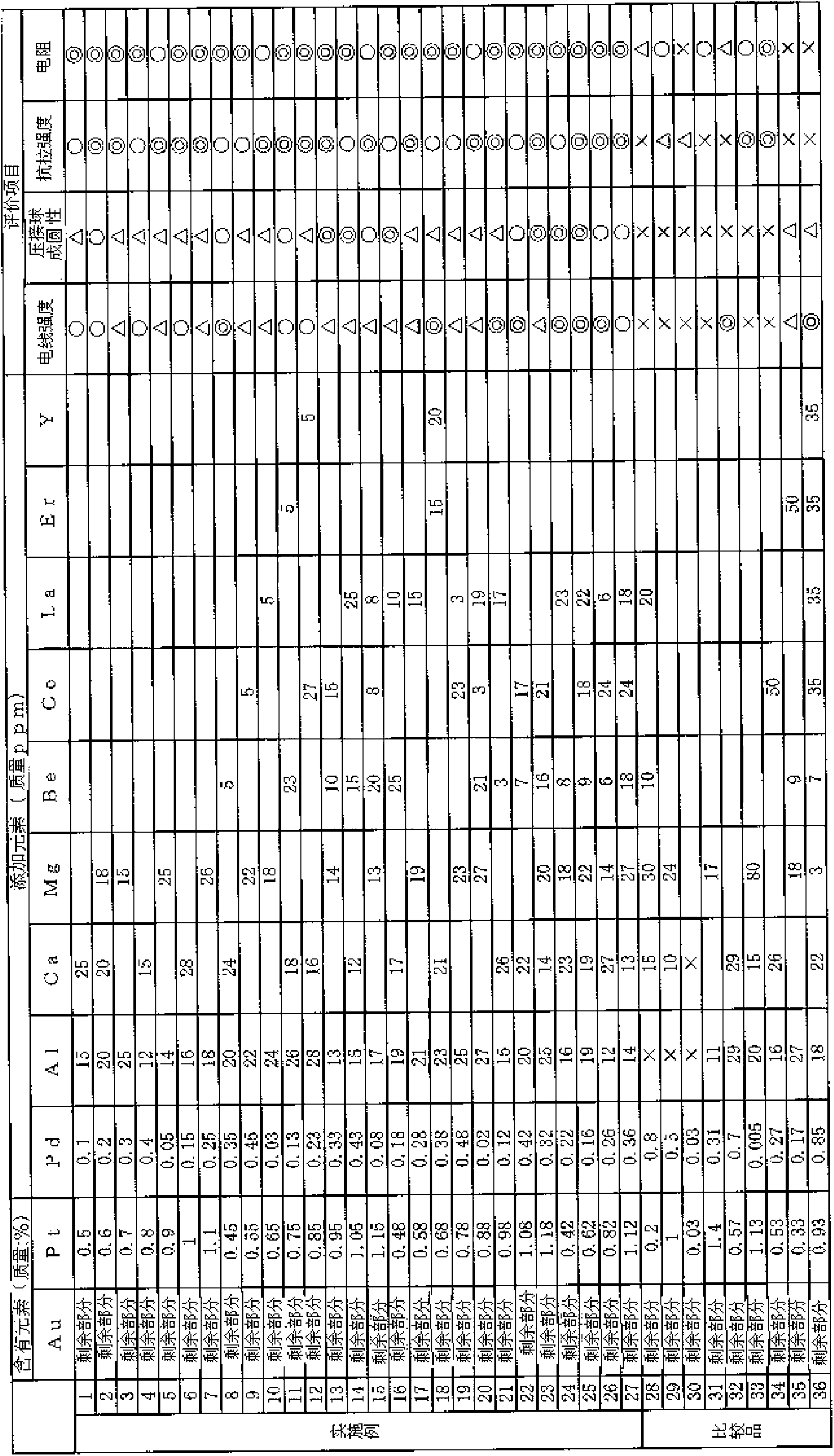

[0035] A gold-platinum-palladium alloy (a gold purity of 99.9999% by mass or more) having the composition shown in the left column of Table 1 was melt-cast, rough-machined, and annealed heat-treated, followed by continuous wire drawing to a final wire diameter of 20 μm , thereby producing gold-platinum-palladium alloy bonding wires (hereinafter referred to as "wires of the present invention") 1 to 27 of the present invention having a wire diameter of 20 μm and gold-platinum-palladium alloy bonding wires of comparative products that do not fall within the composition range of the present invention. Palladium alloy bonding wires and conventional gold-palladium alloy bonding wires (hereinafter all referred to as "comparative wires") 28-36.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com