Beam-film double island structure micro-pressure high-overload sensor chip

A sensor chip, high overload technology, applied in the direction of microstructure technology, microstructure devices, piezoelectric devices/electrostrictive devices, etc., can solve the problem that cannot meet the requirements of accurate measurement in the aerospace field and Pa-level micro-pressure measurement in the aerospace field needs, can not adapt to the working environment in the aerospace field and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

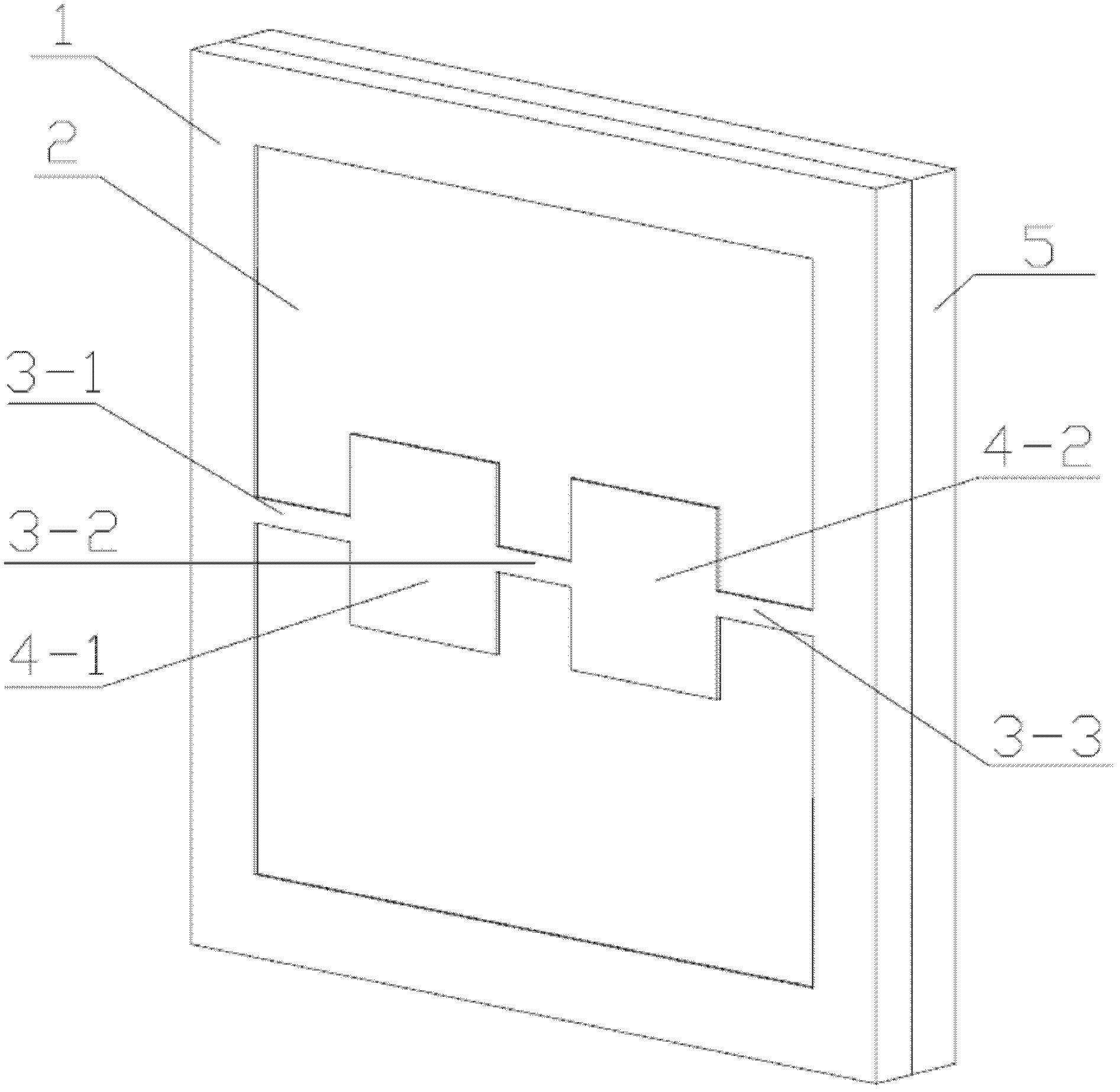

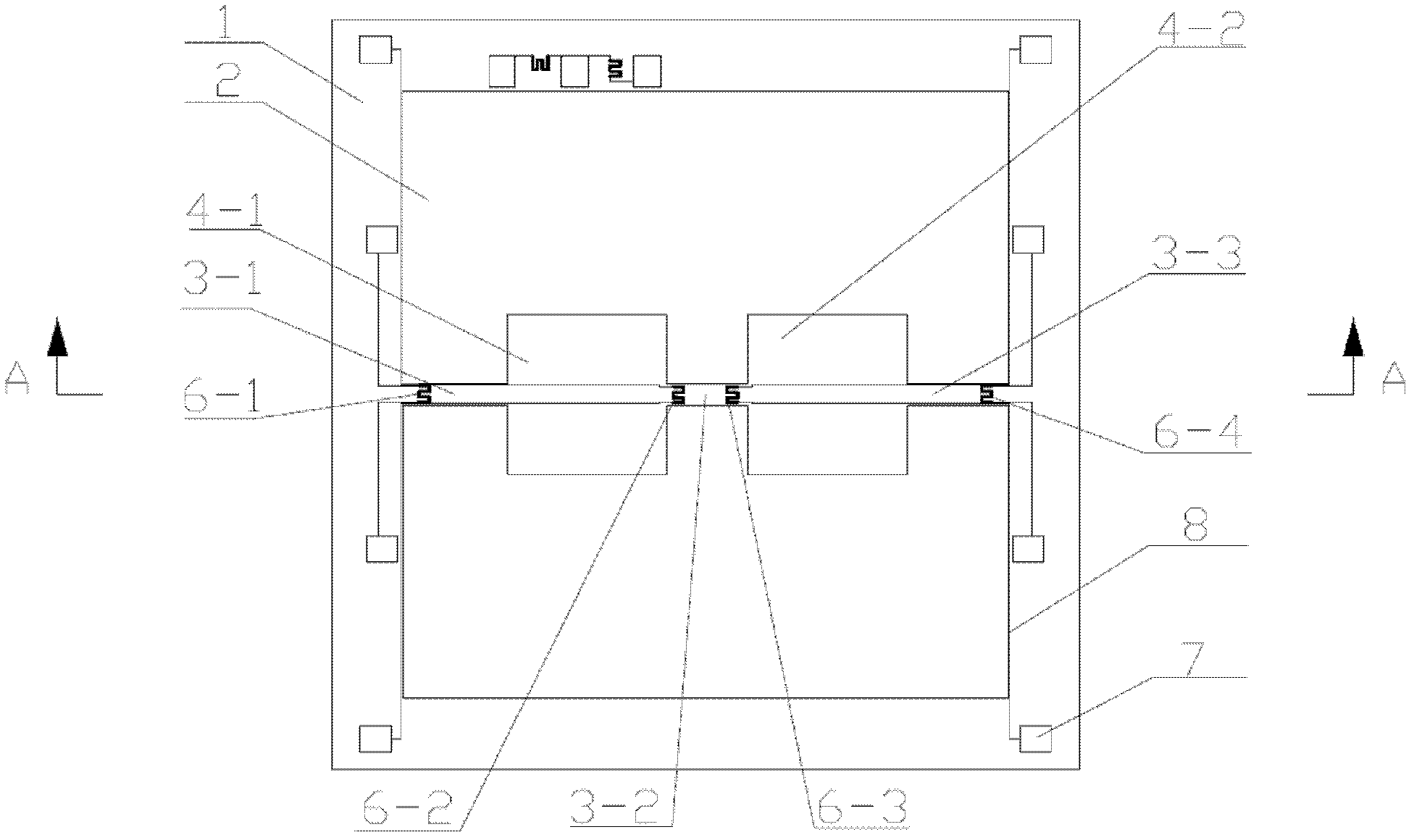

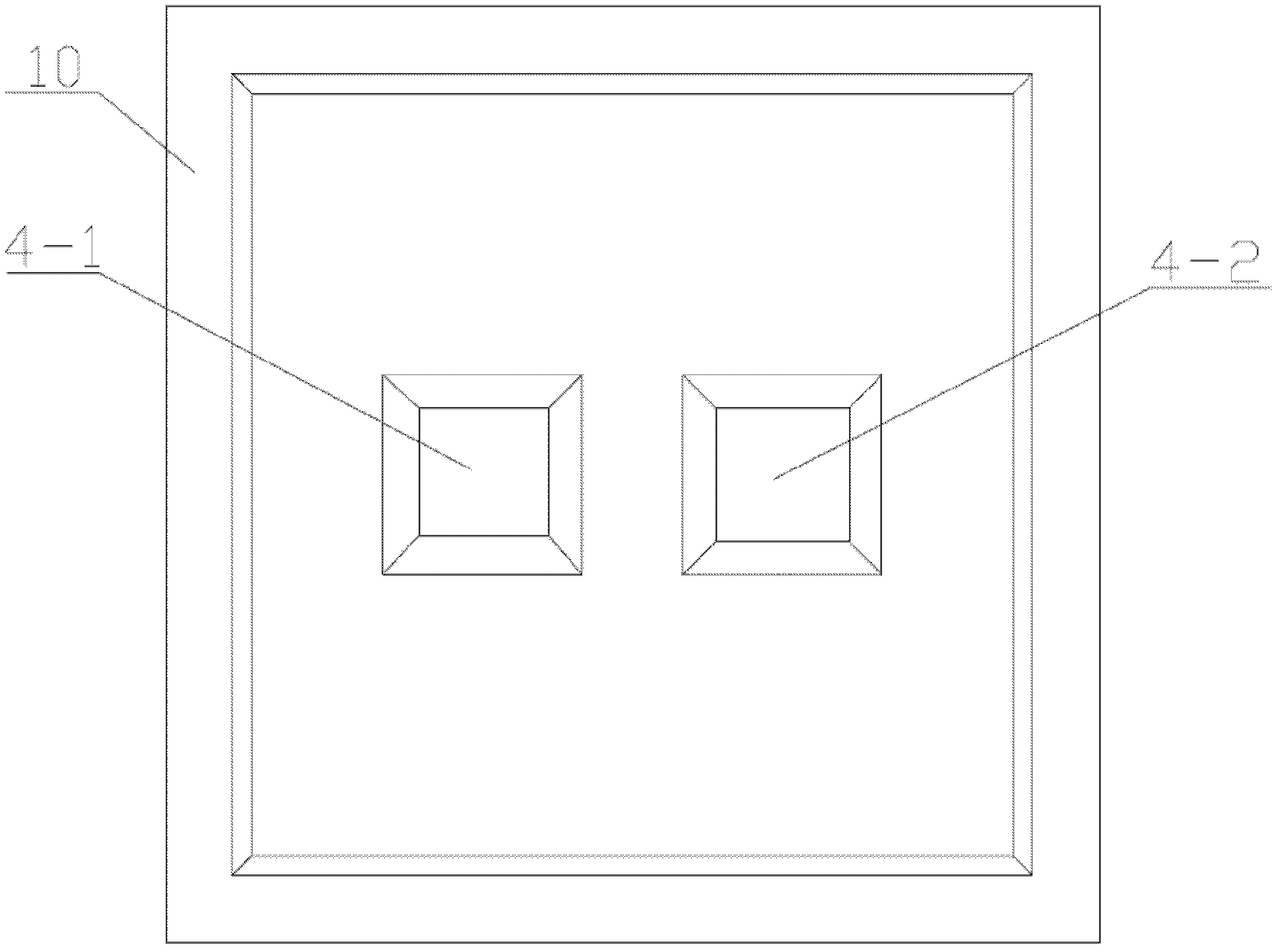

[0022] refer to figure 1 and figure 2 , a beam-membrane double-island structure micro-voltage high-overload sensor chip, comprising a silicon substrate 1 on which two mass blocks 4-1, 4-2 and three single beams 3-1, 3-2, 3 are processed -3, the first mass 4-1 is connected to the silicon substrate 1 through the first single beam 3-1, the second mass 4-2 is connected to the silicon substrate 1 through the third single beam 3-3, and the first mass 4 -1 and the second mass block 4-2 are connected through the second single beam 3-2, and the silicon substrate 1, mass blocks 4-1, 4-2 and three single beams 3-1, 3-2, 3- The space surrounded by 3 is processed into a thin film 2 of 10-30 μm, and the back side of the silicon substrate 1 is bonded to the Pyrex7740 glass 5, refer to image 3 , Figure 4 and Figure 5 , the back of the mass blocks 4-1, 4-2 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com