Patents

Literature

55results about How to "Improve resonance performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

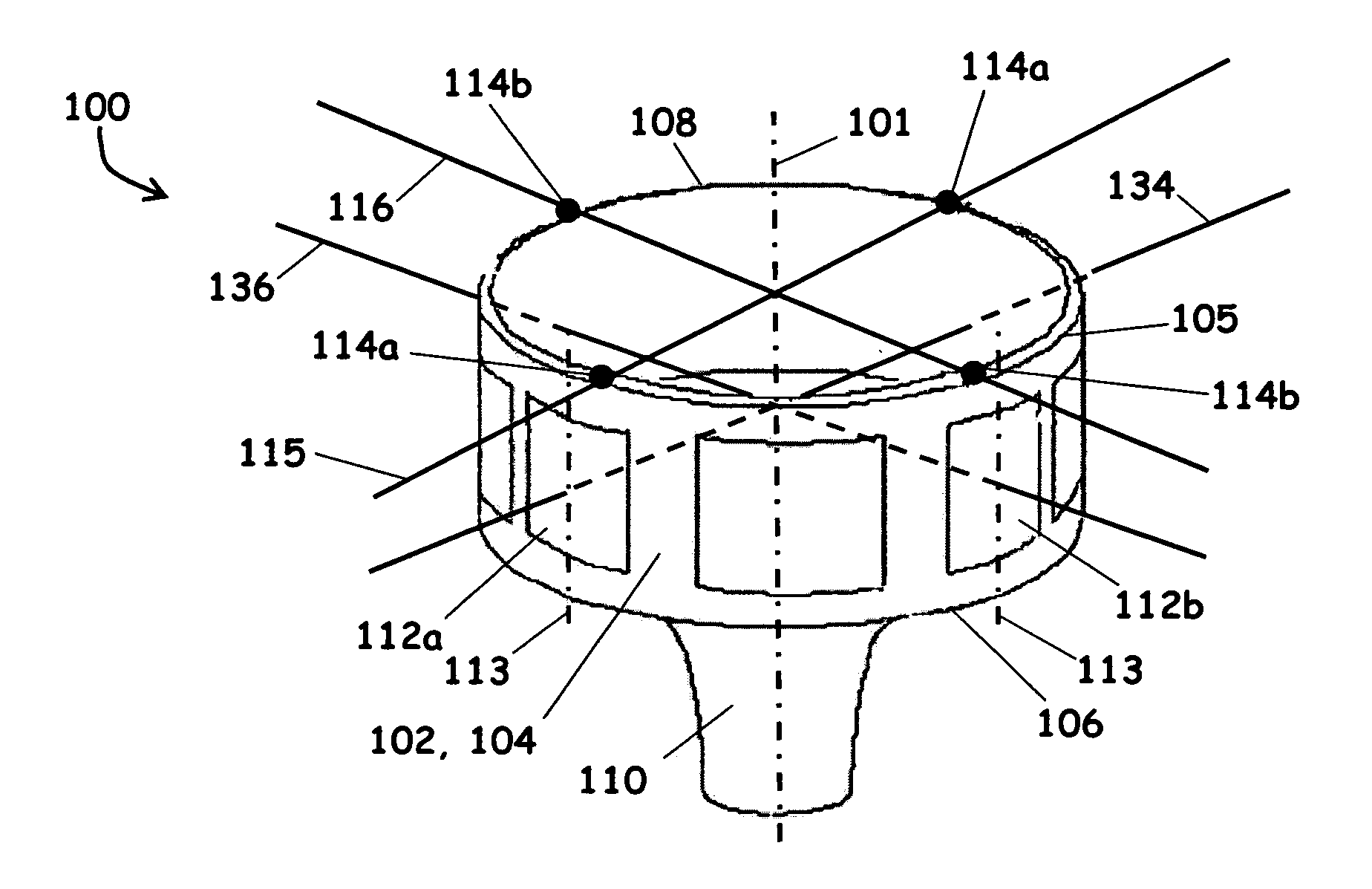

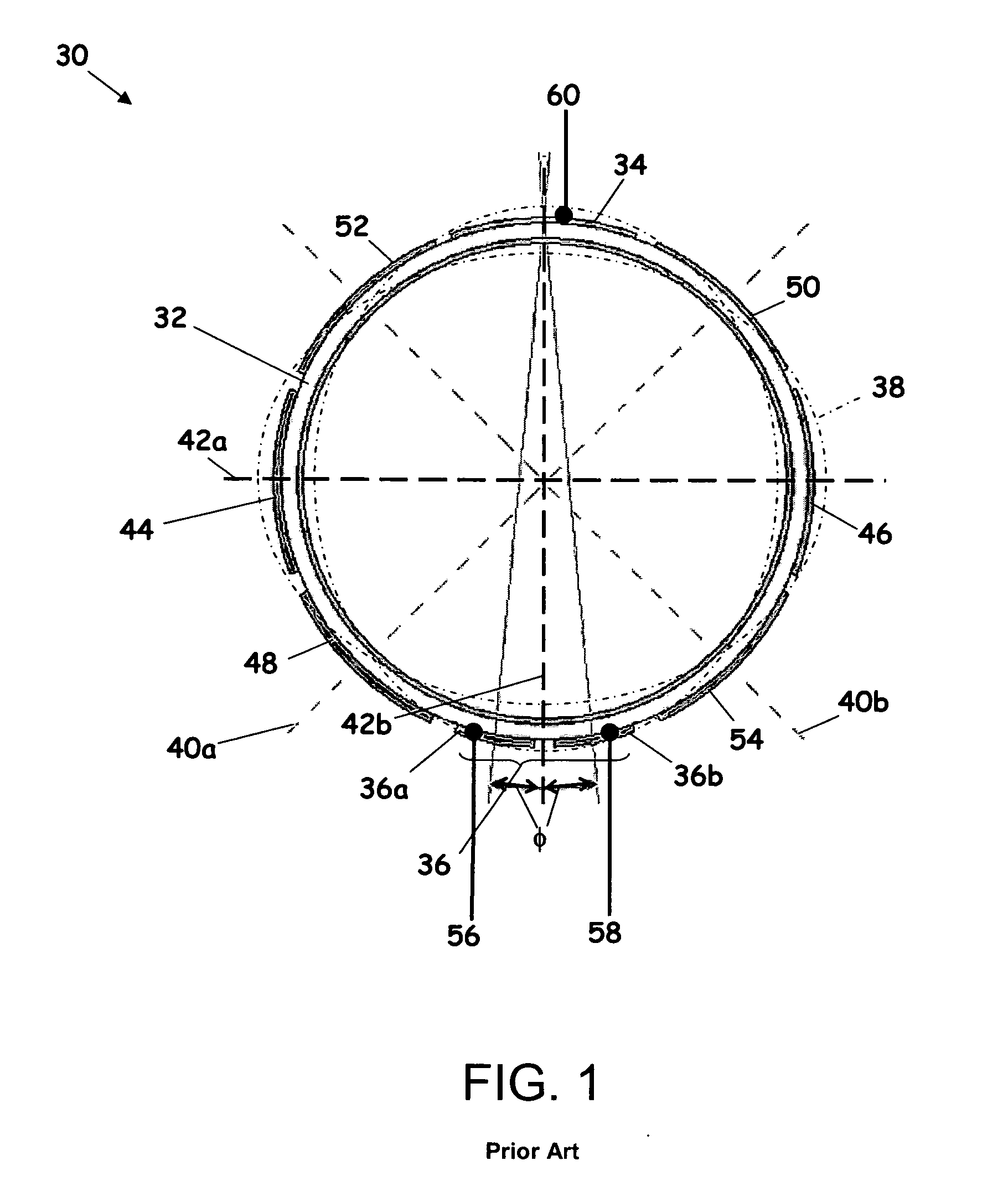

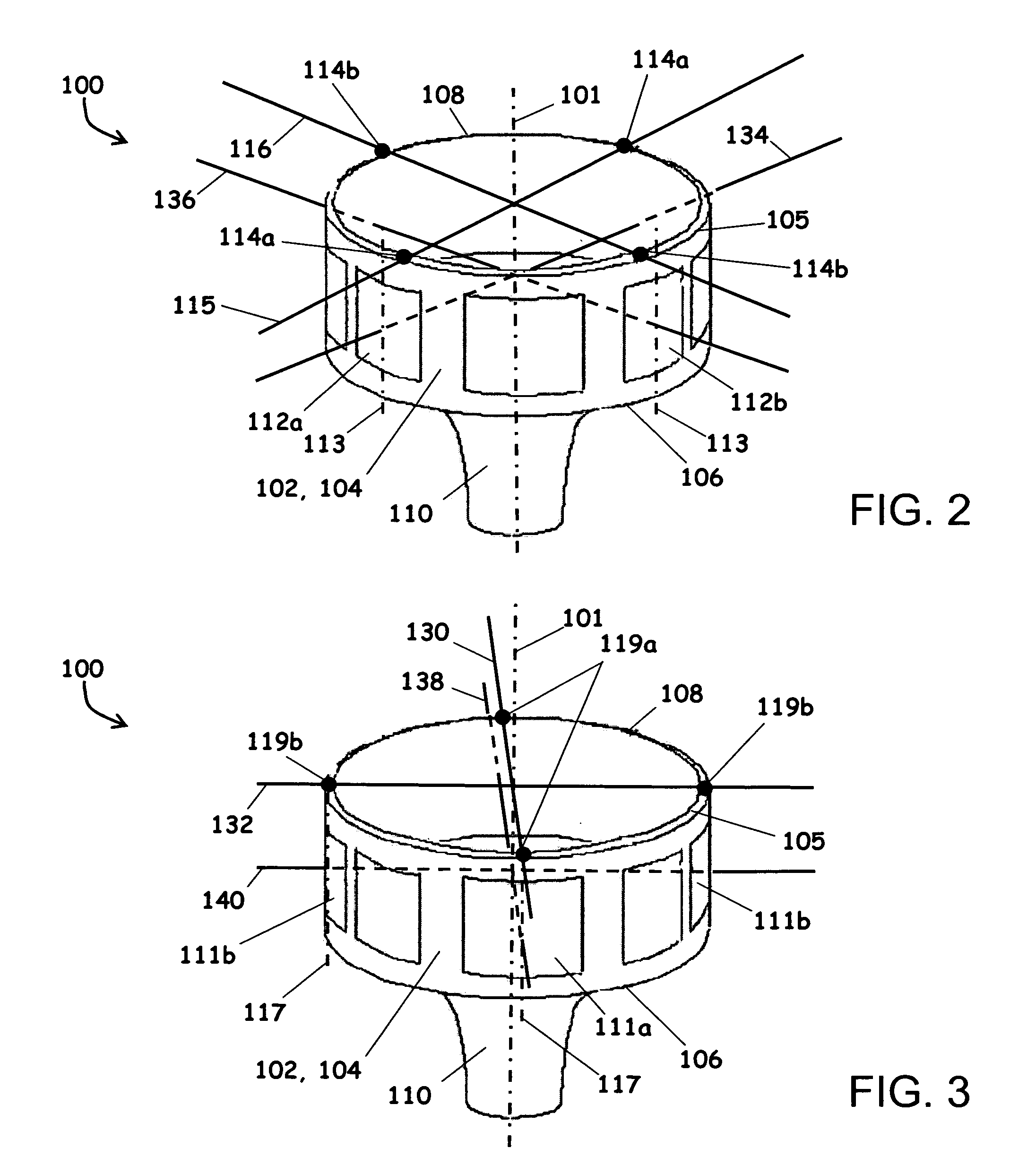

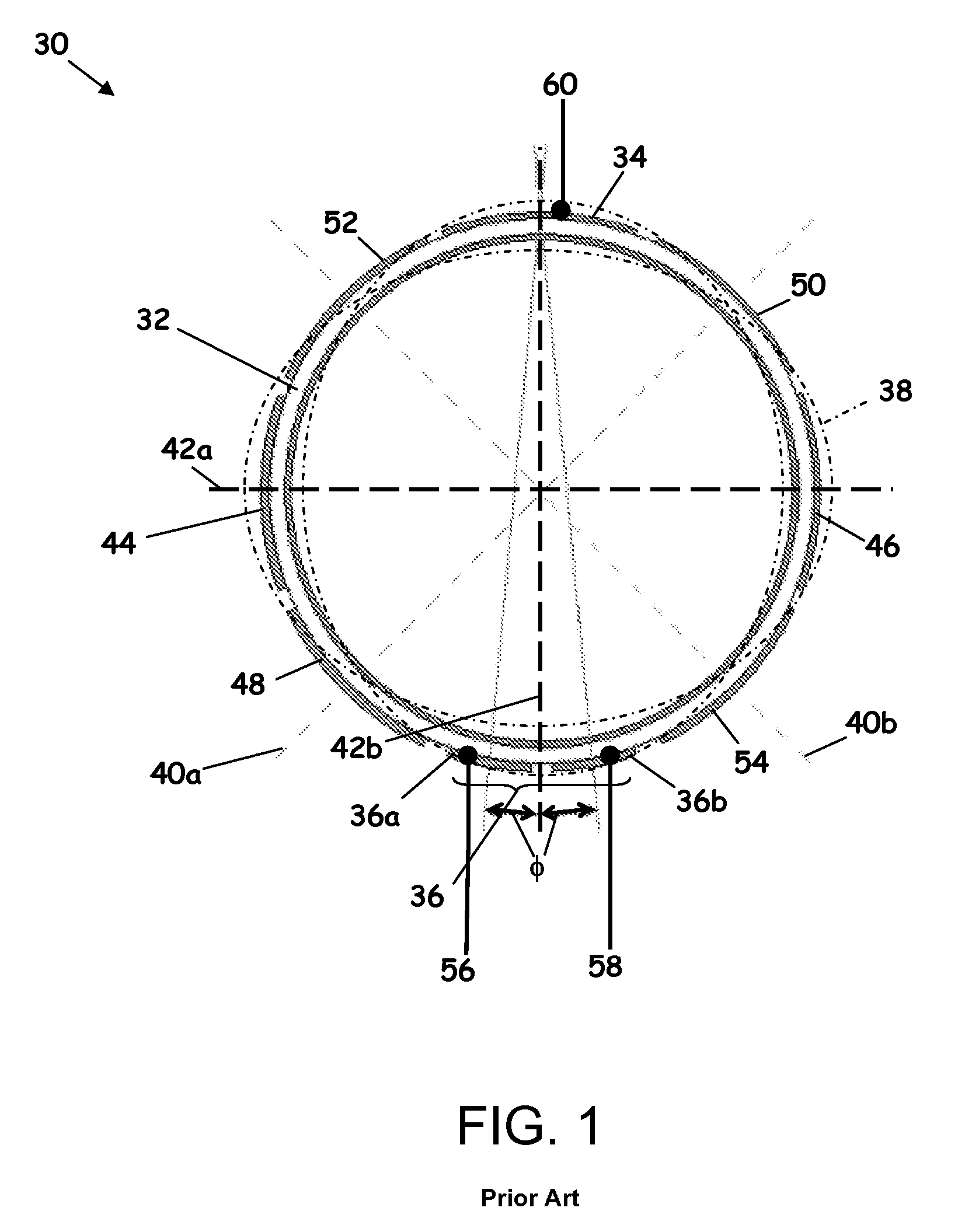

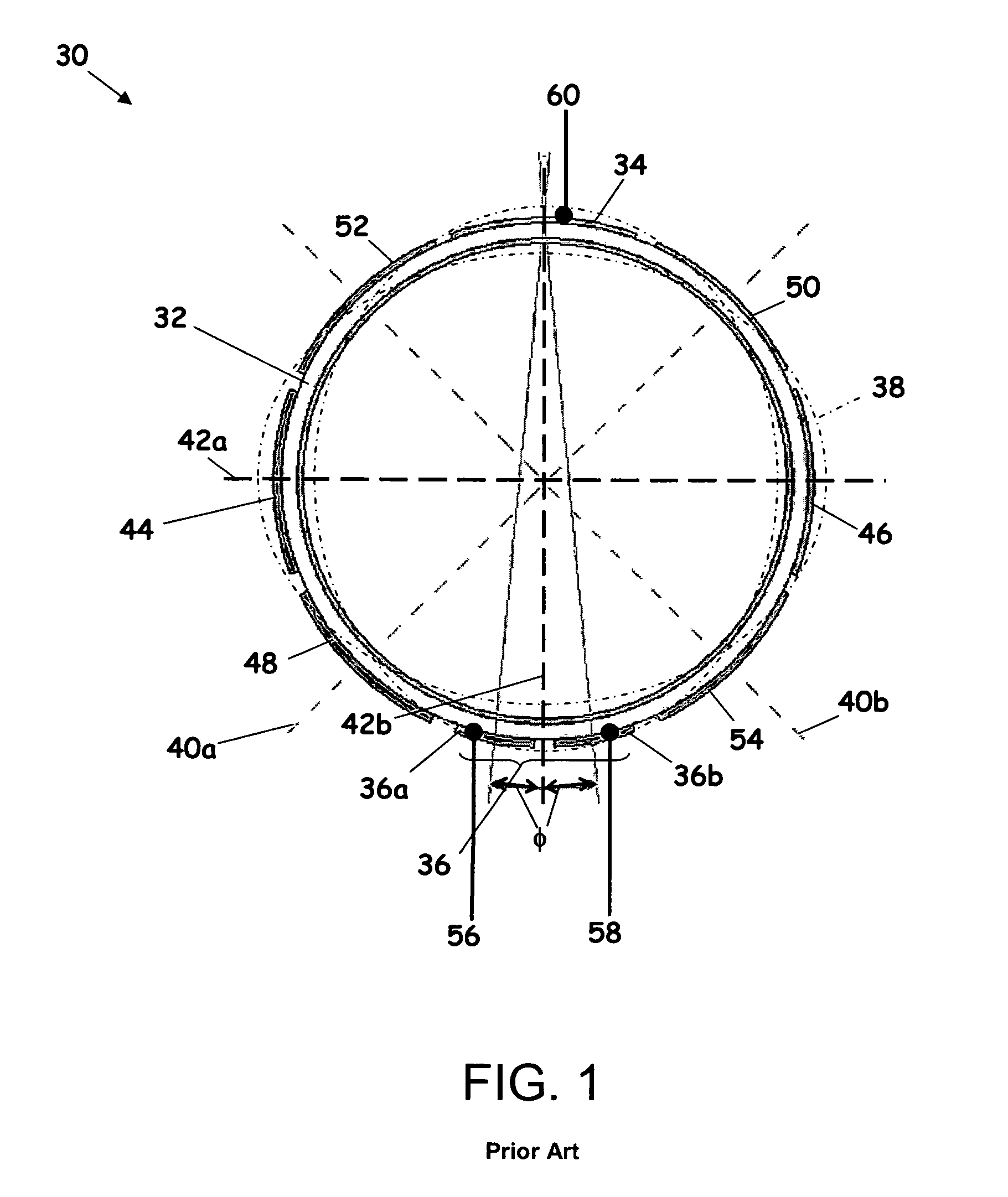

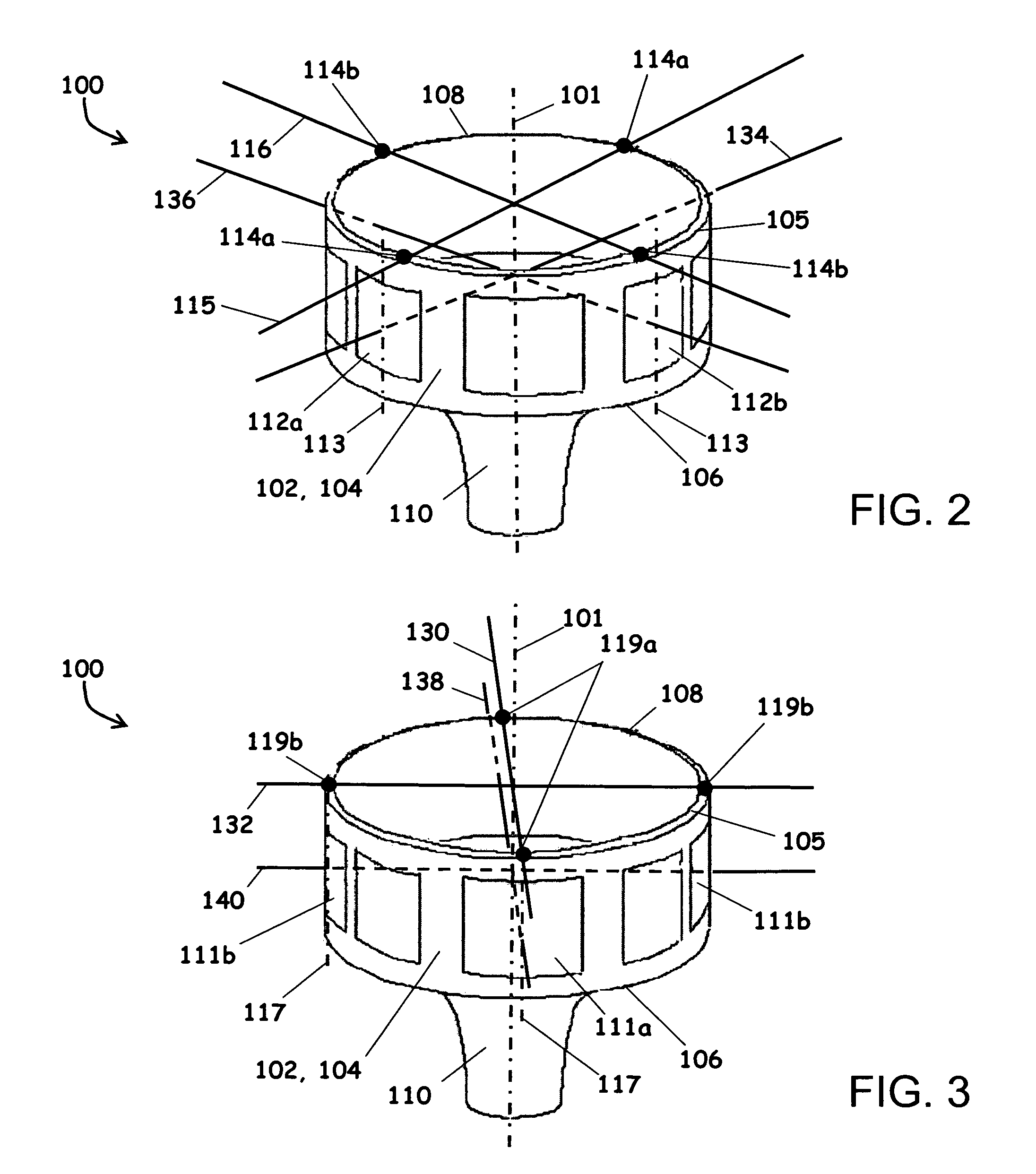

Vibrating inertial rate sensor utilizing skewed drive or sense elements

InactiveUS20070240508A1Good symmetryImprove resonance performanceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeEngineering

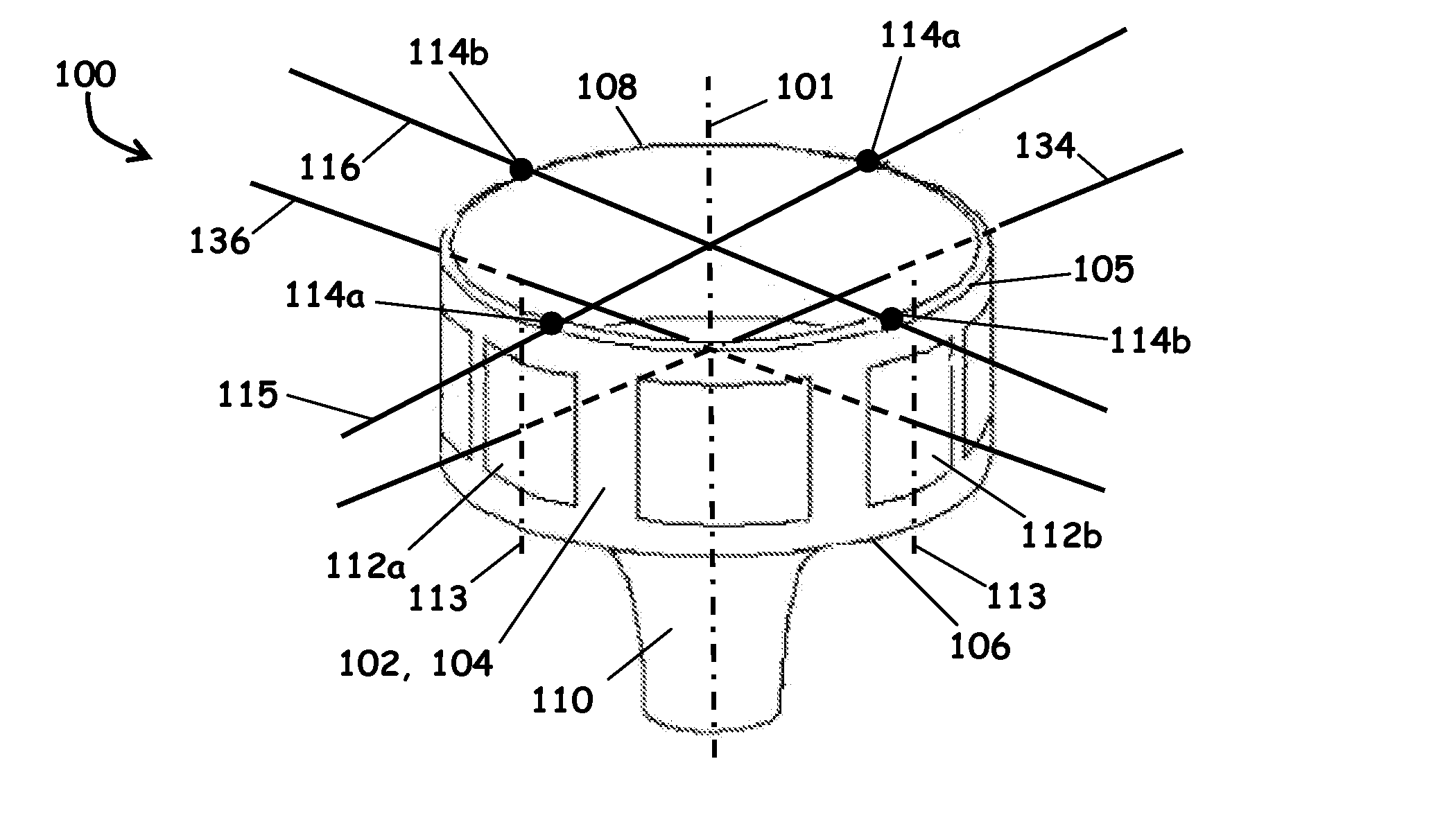

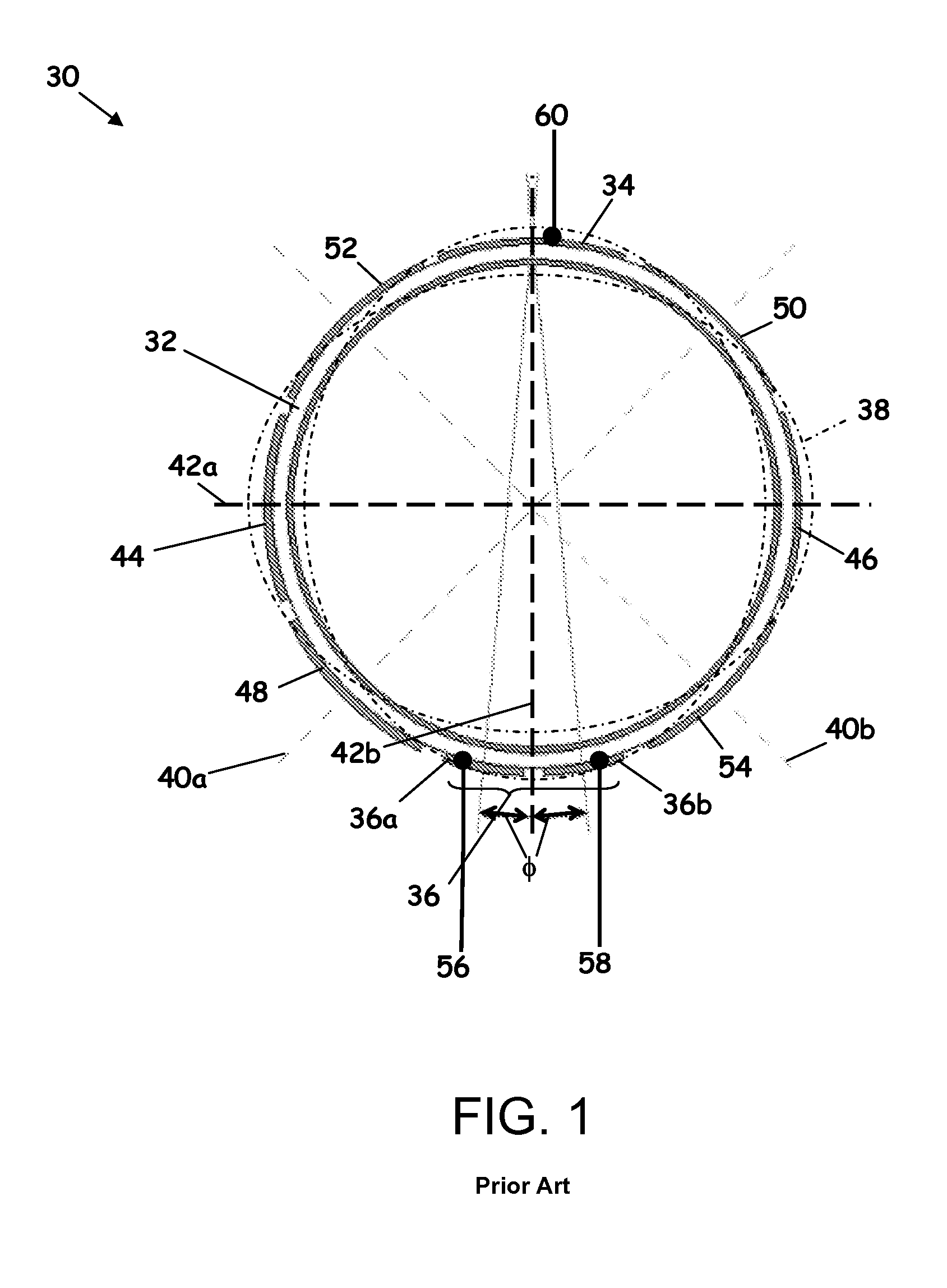

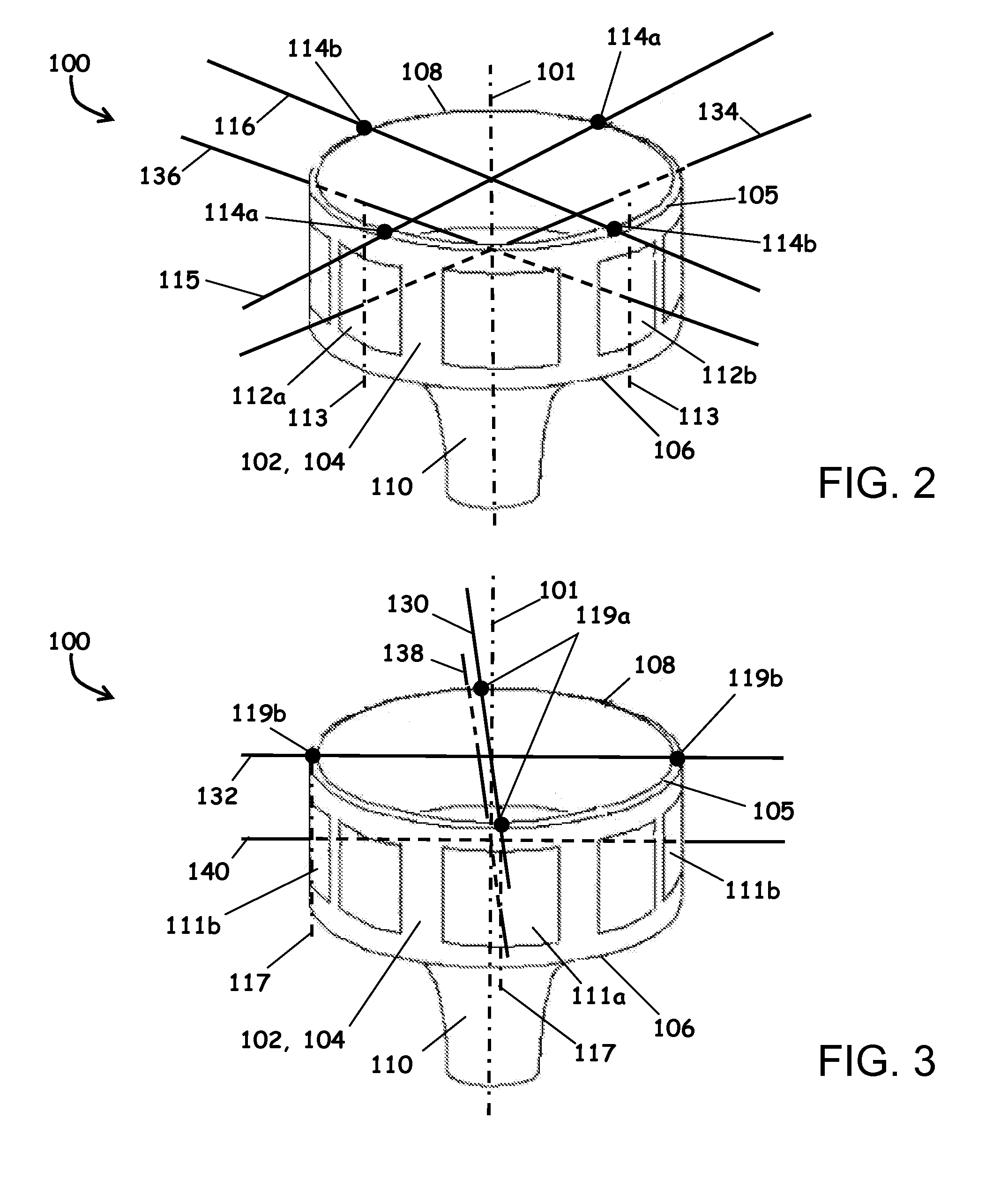

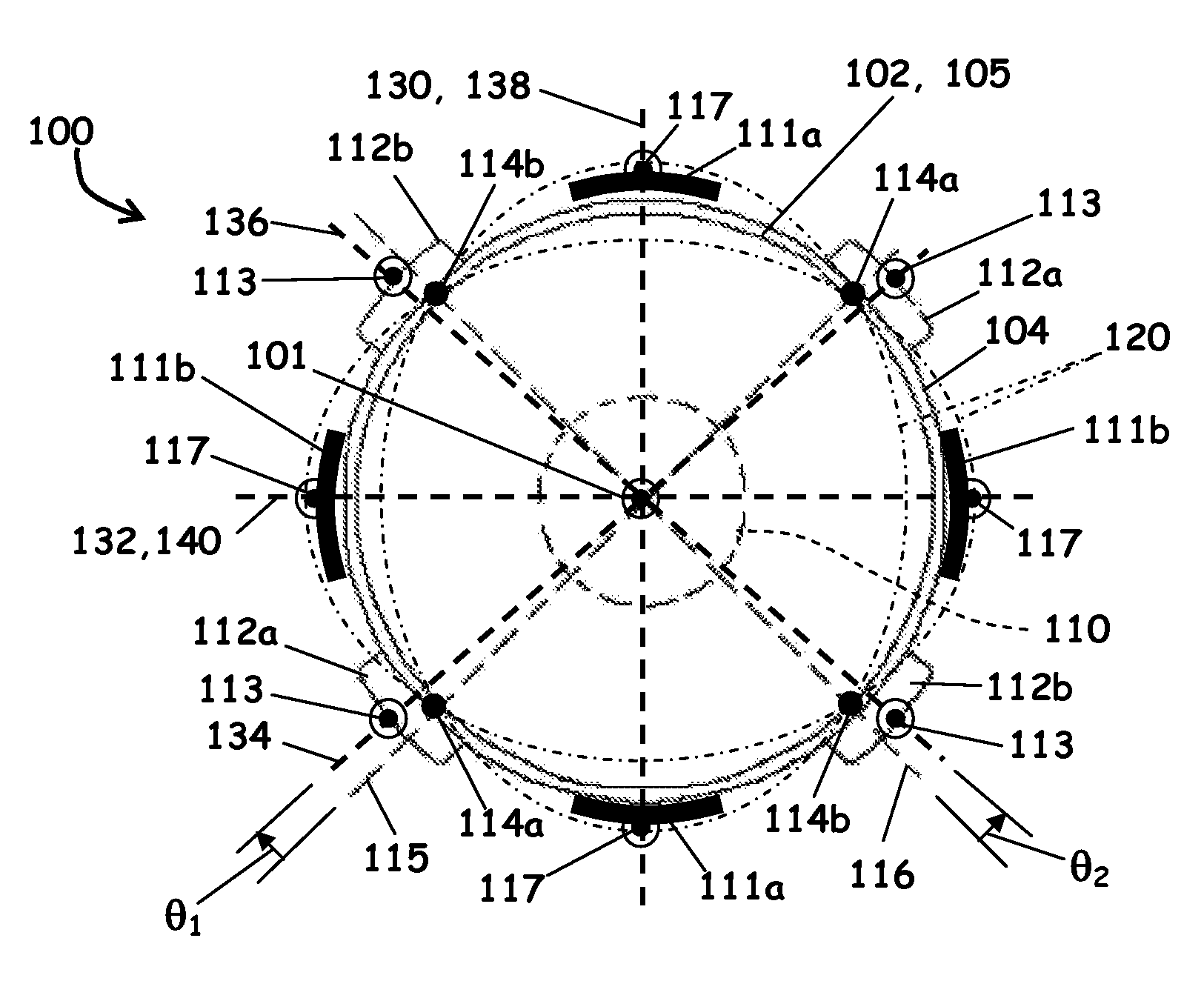

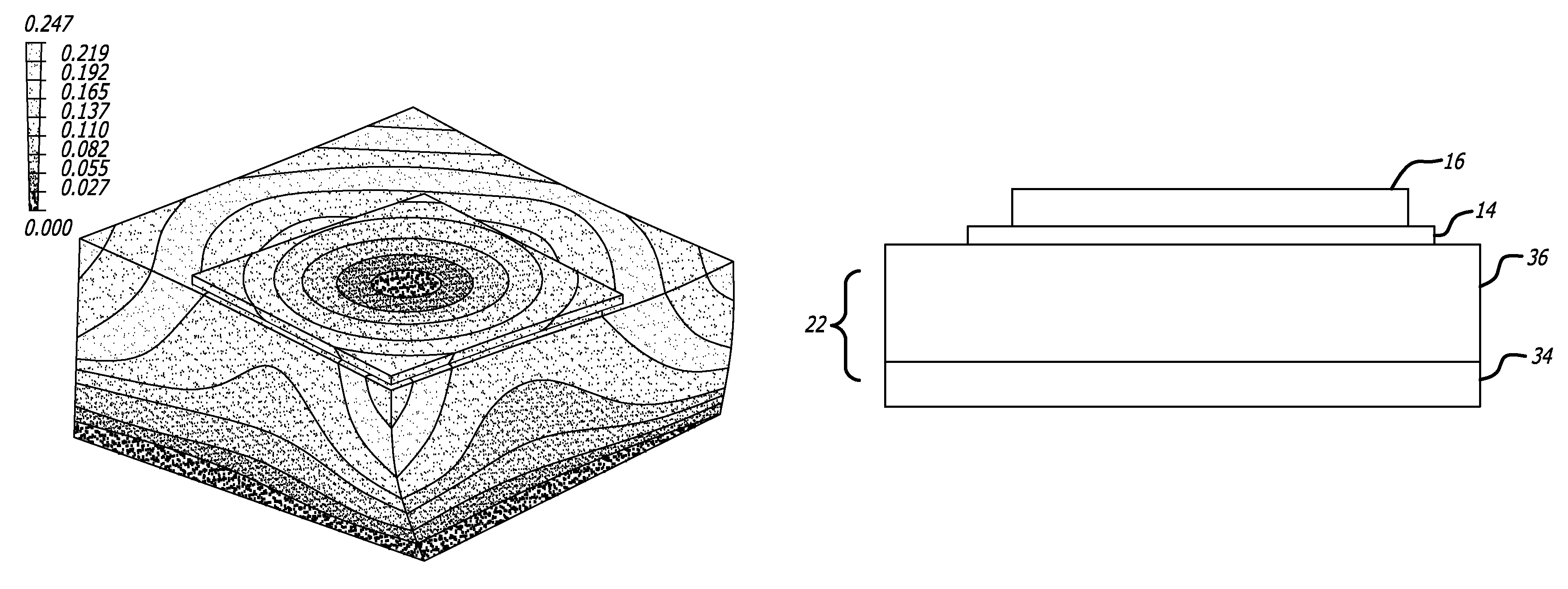

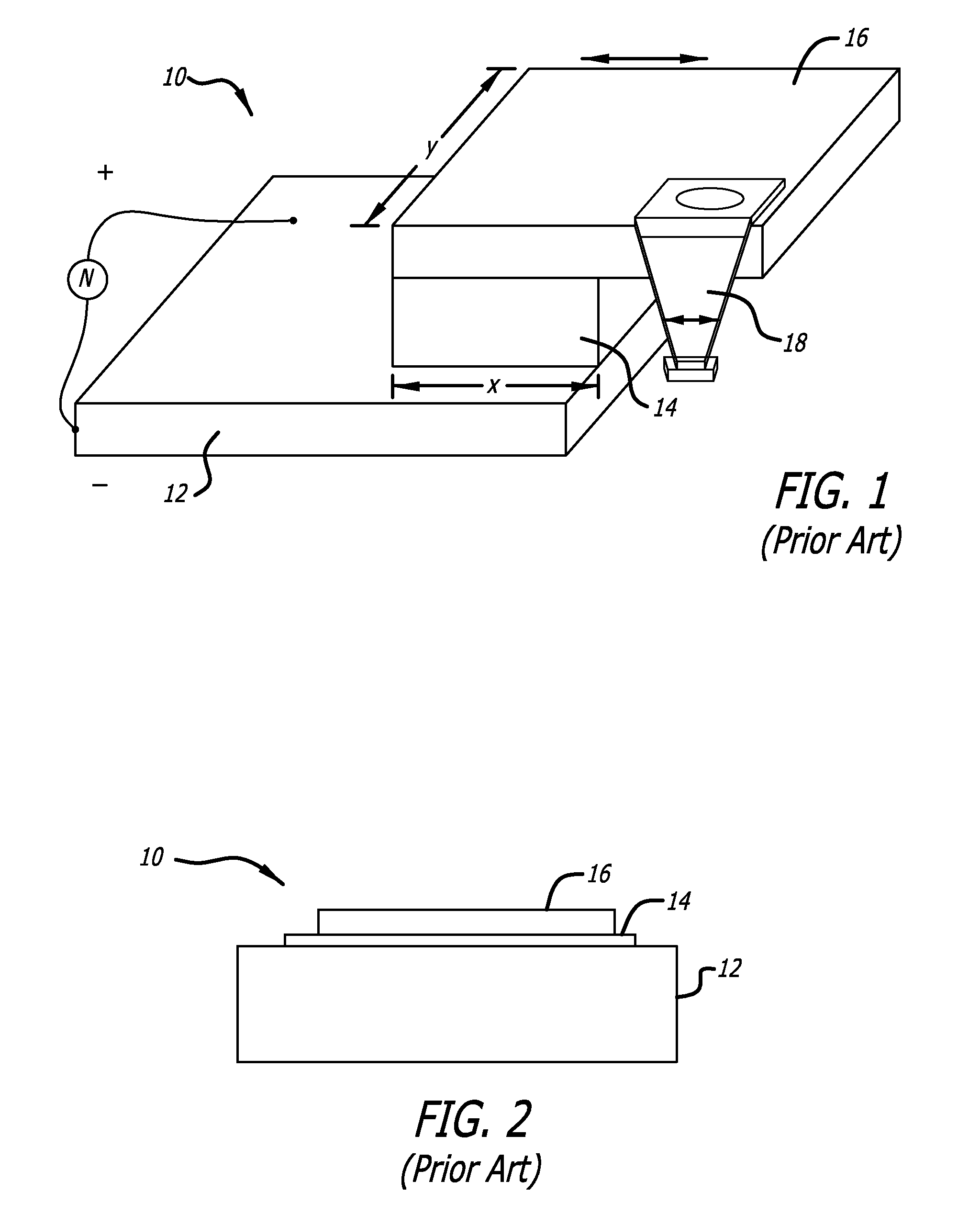

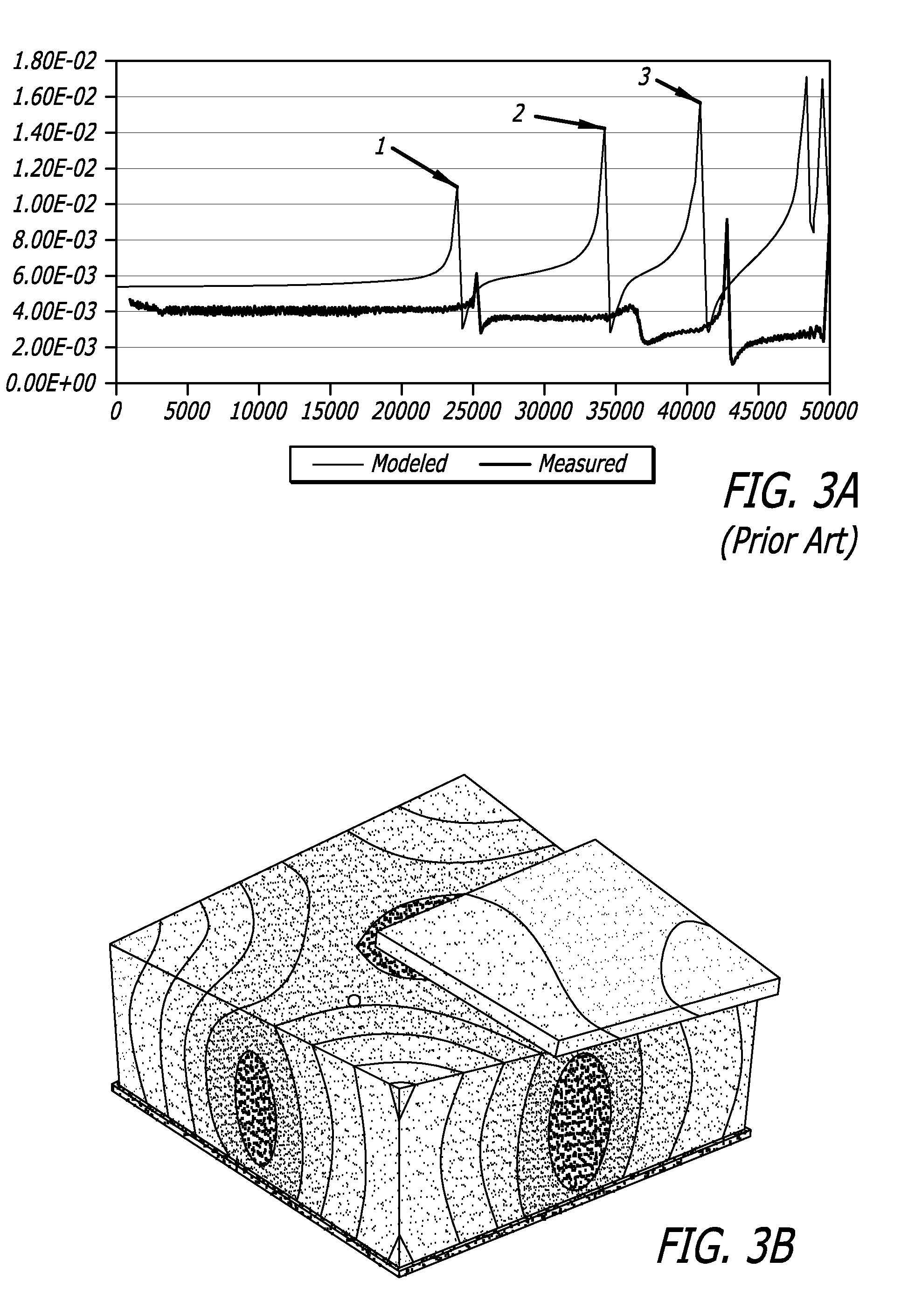

A vibrating inertial rate sensor has sense elements that operate on axes that are rotationally skewed from a node reference axis, enabling both a rate sense and a drive sense determination. Alternatively, the skew may be applied to rotationally offset the drive elements from antinode reference axes to affect active torquing of the gyroscope. The skewed sensing scheme may be applied to vibratory systems having one or more node axes. The skewed drive scheme may be applied to vibratory systems having two or more node axes to affect active torquing.

Owner:WATSON INDUSRIES

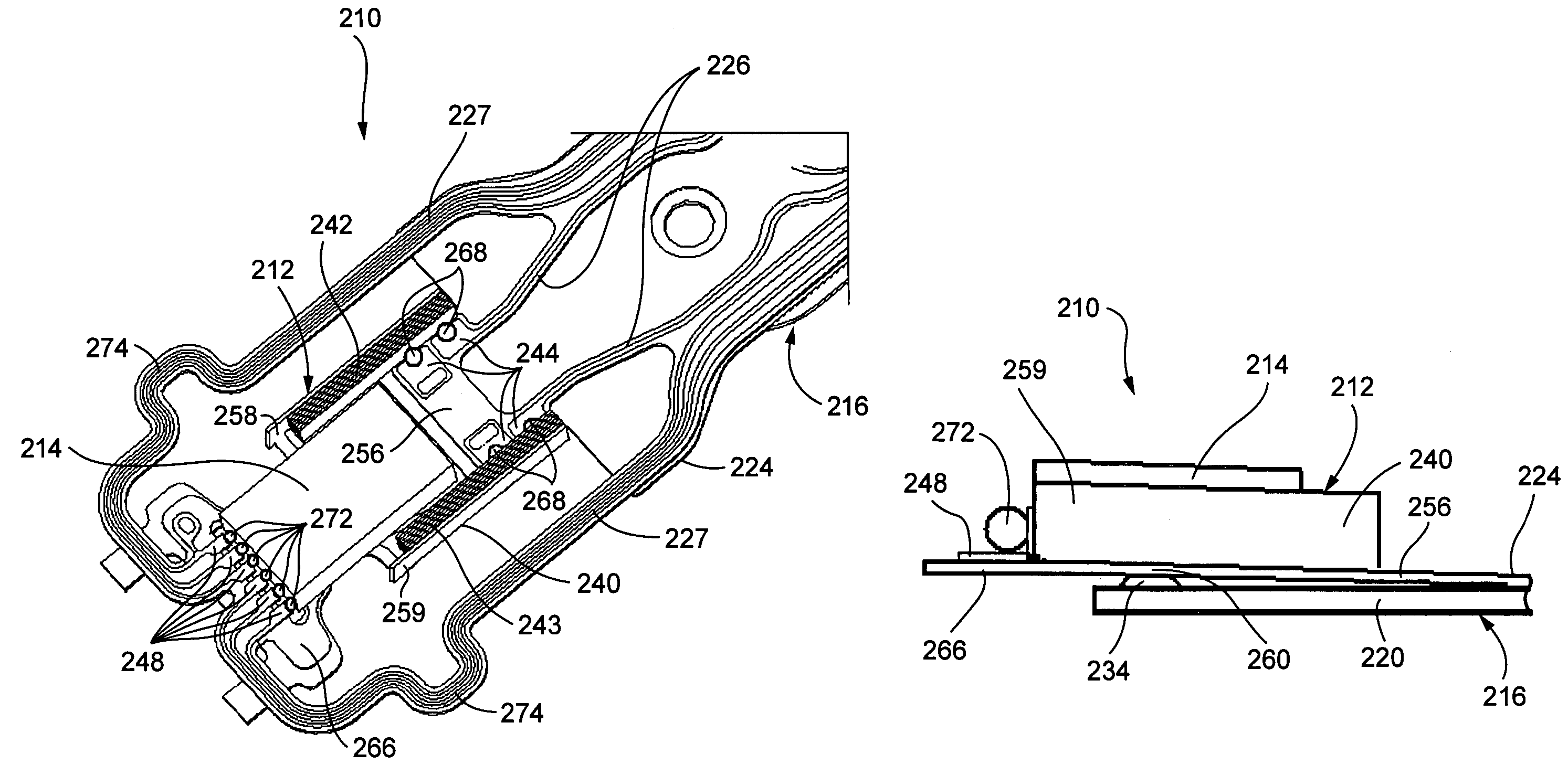

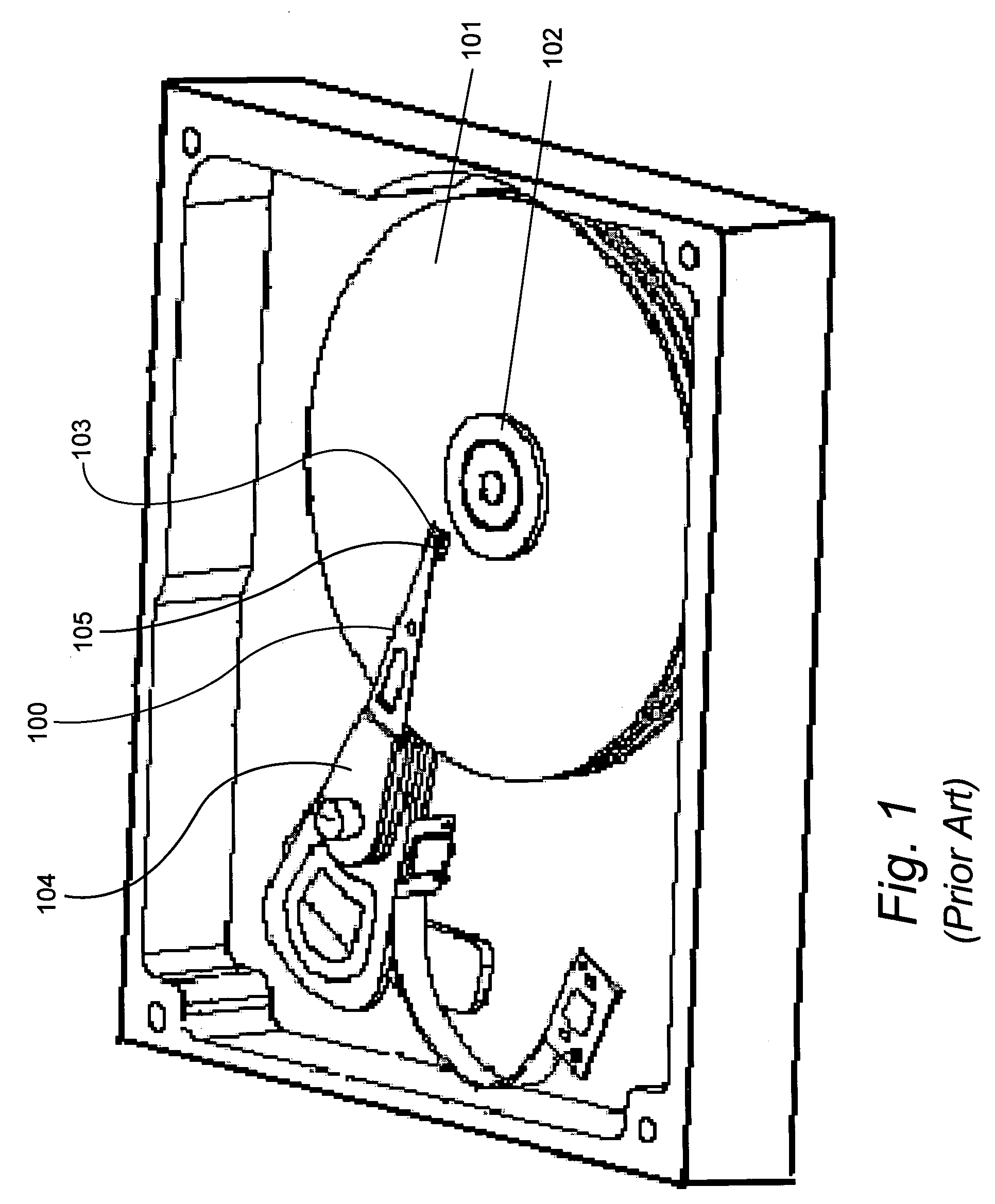

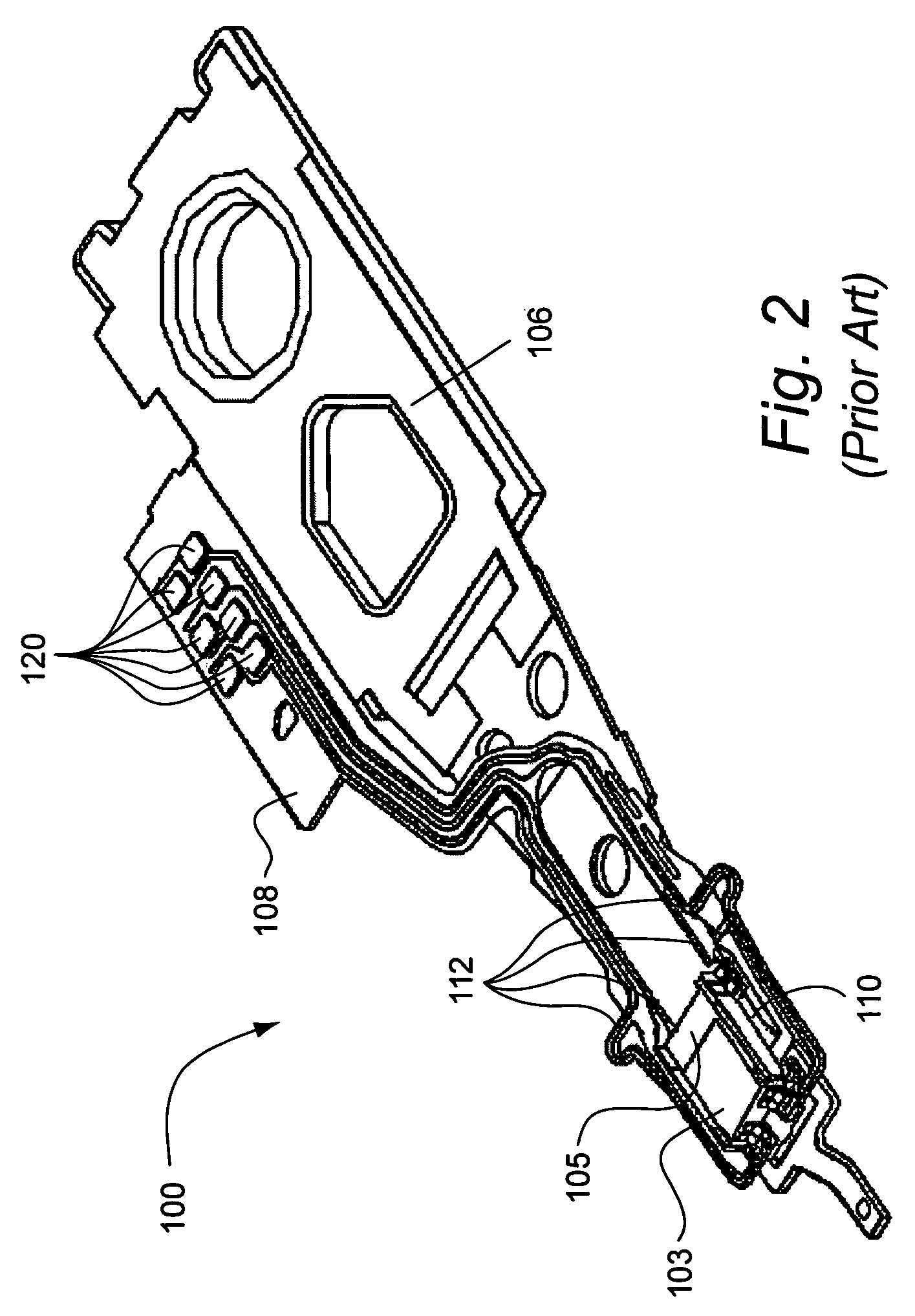

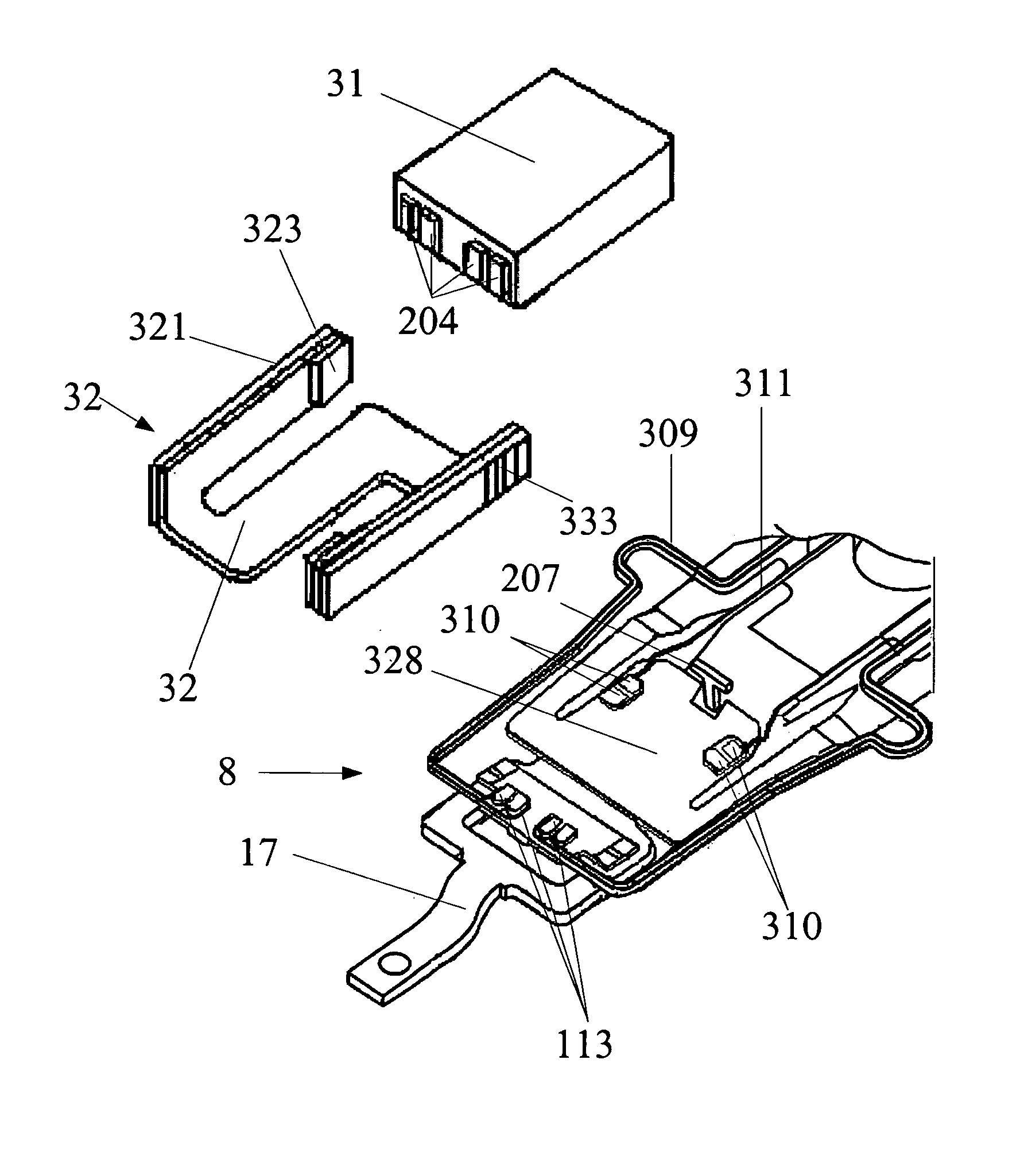

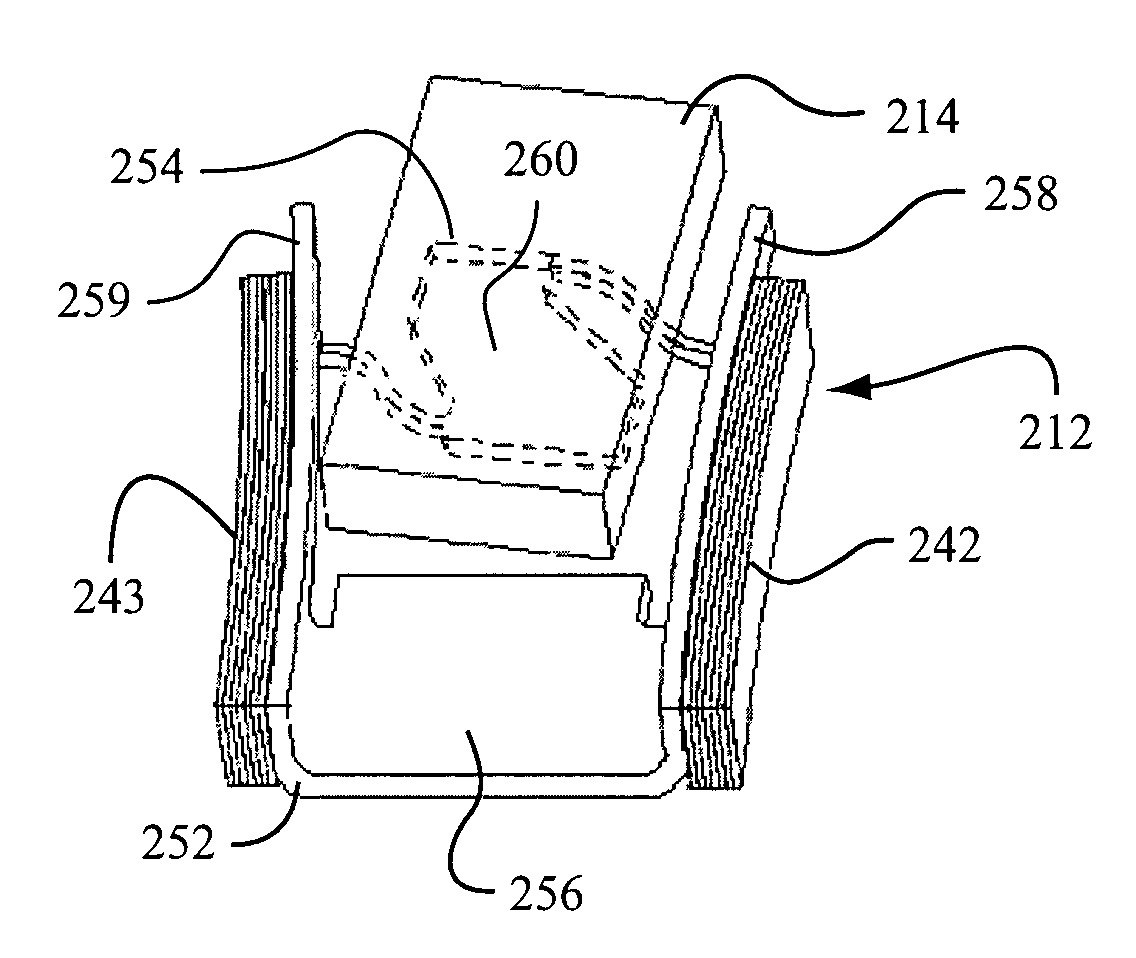

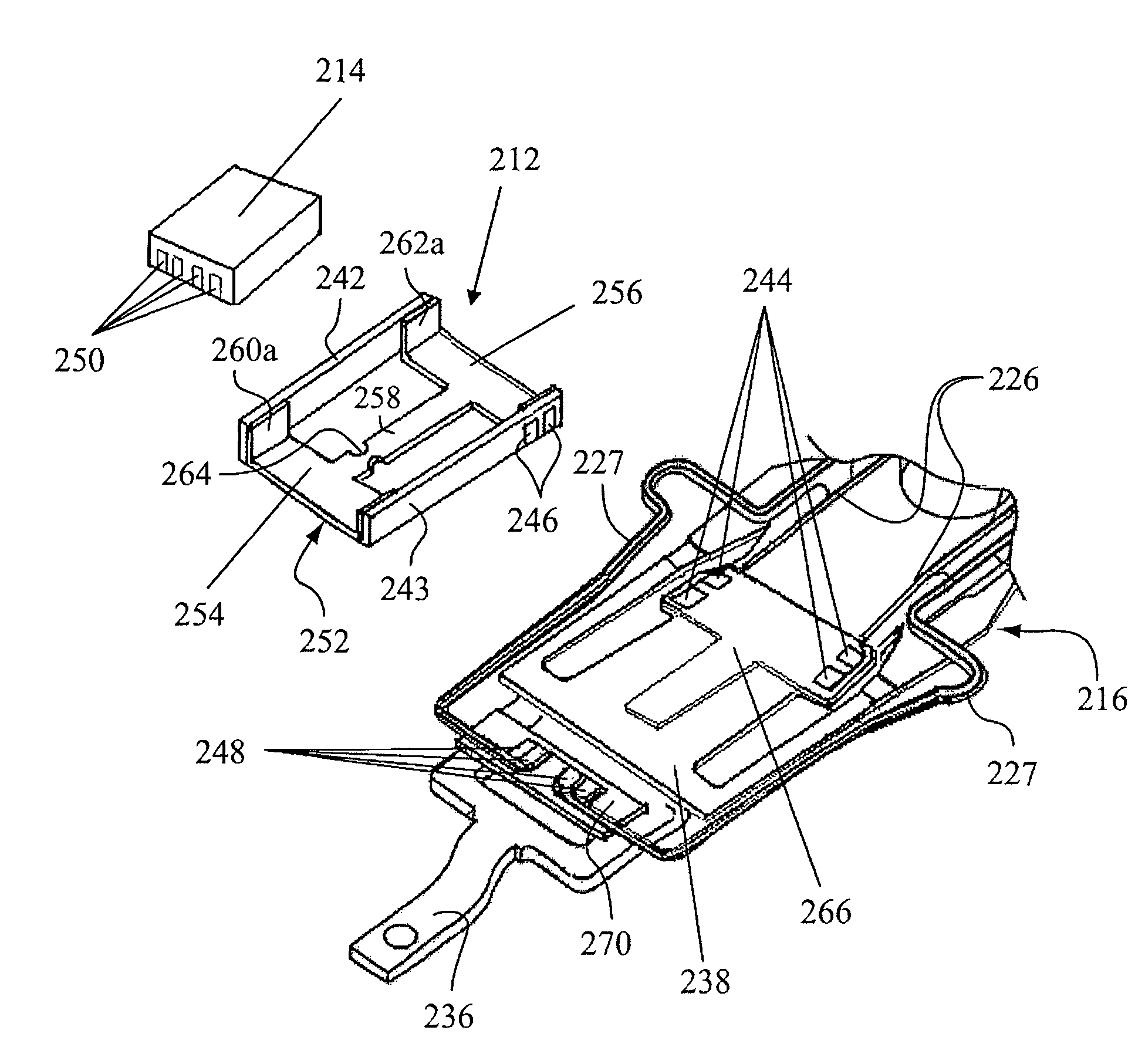

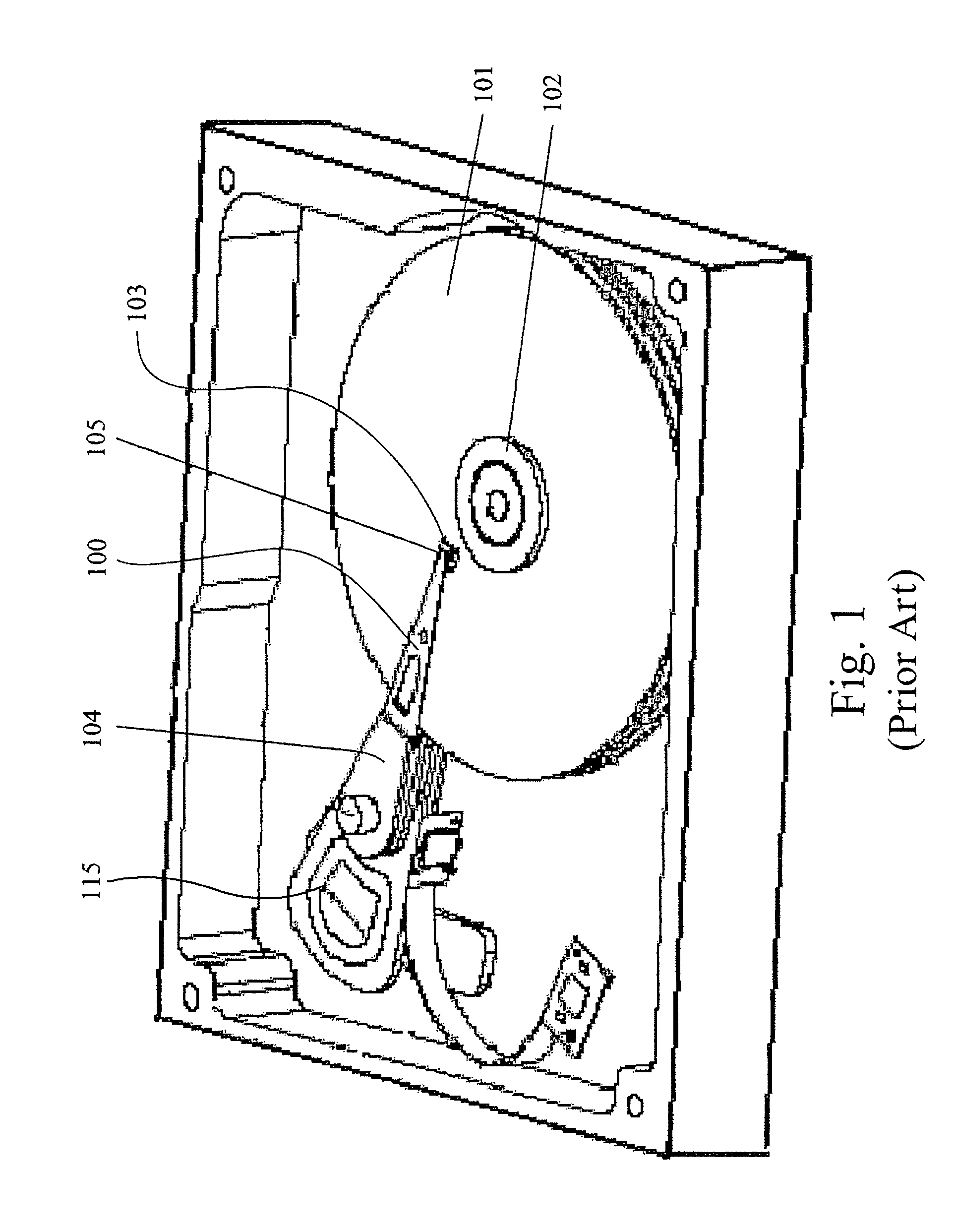

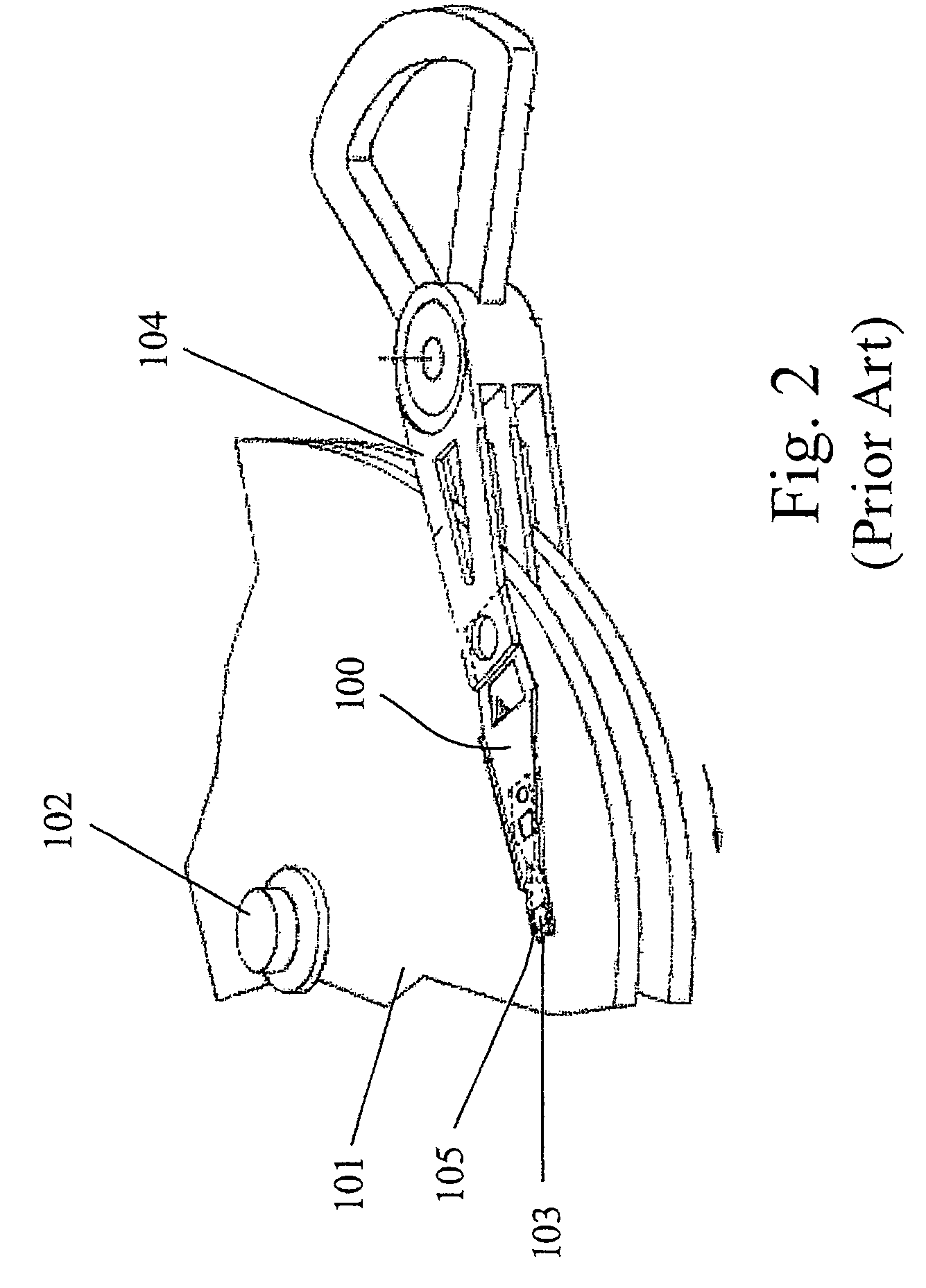

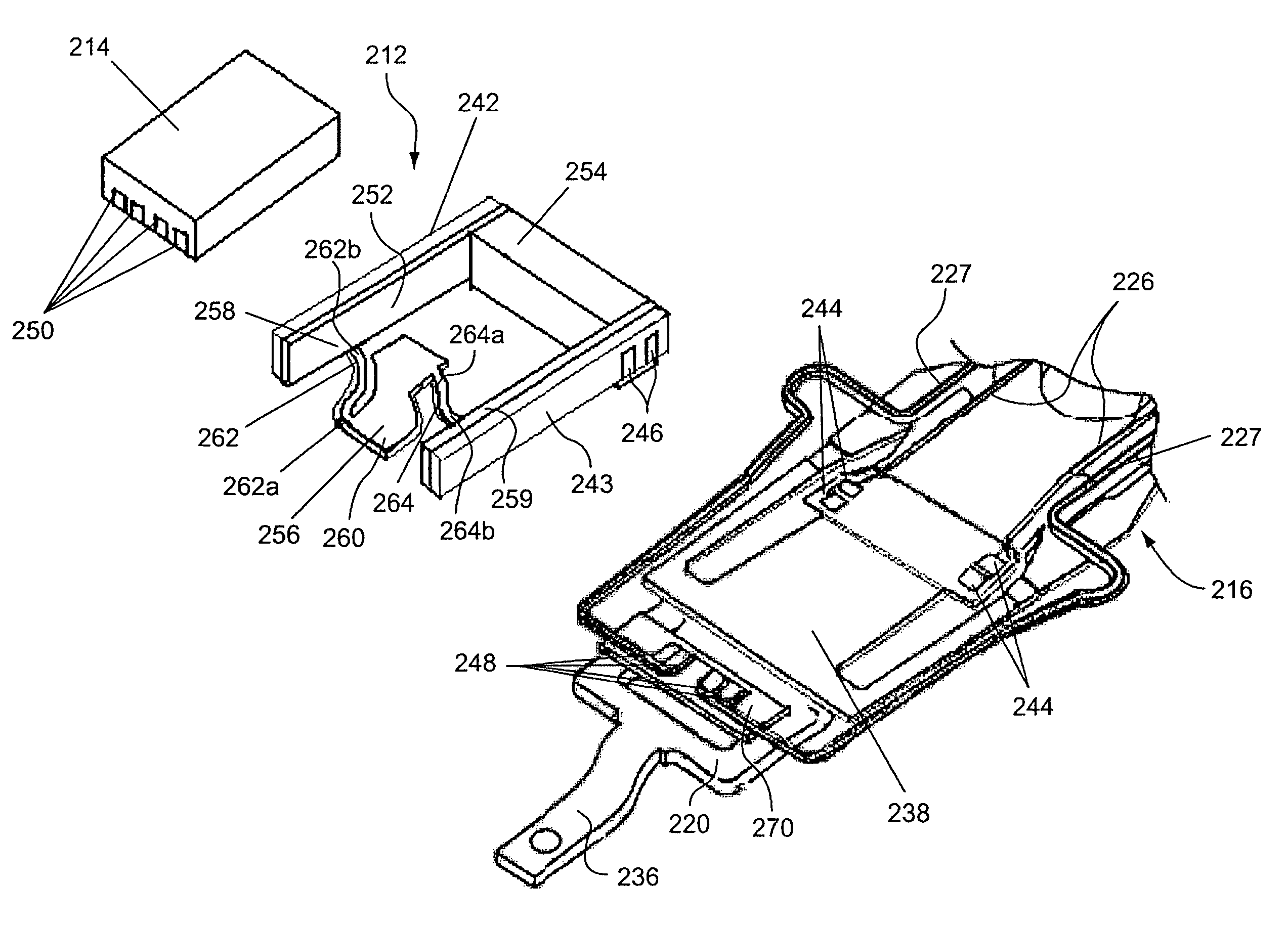

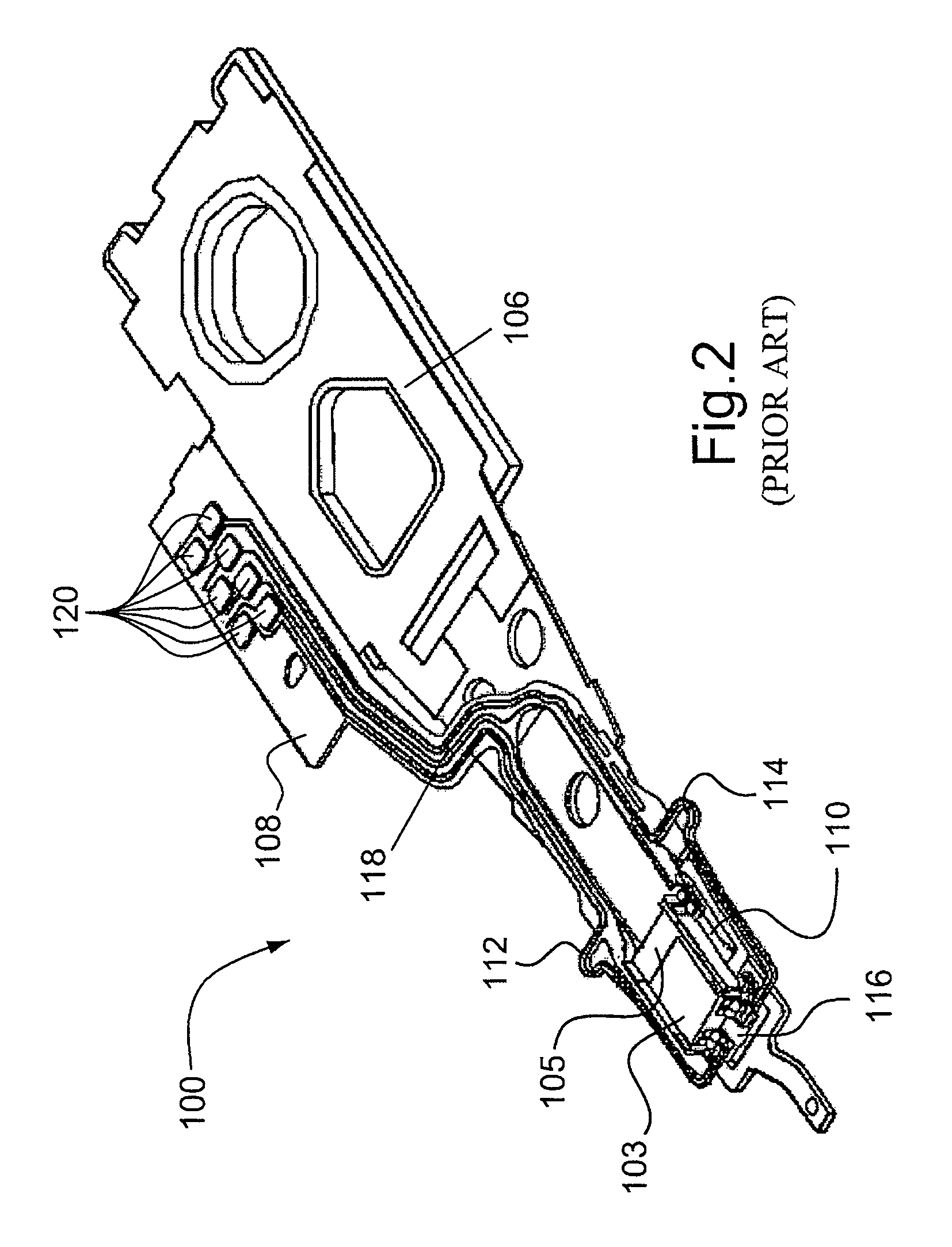

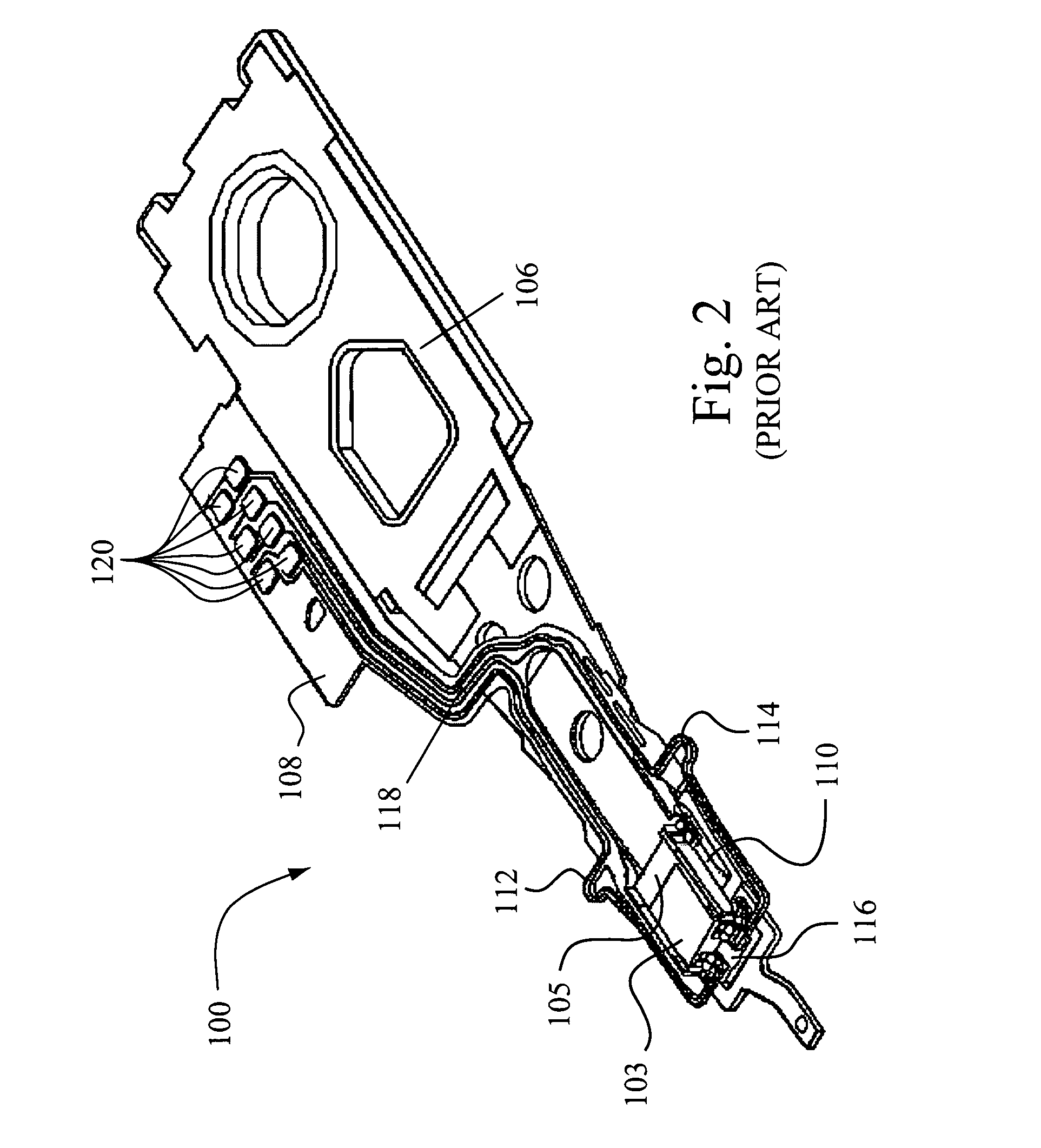

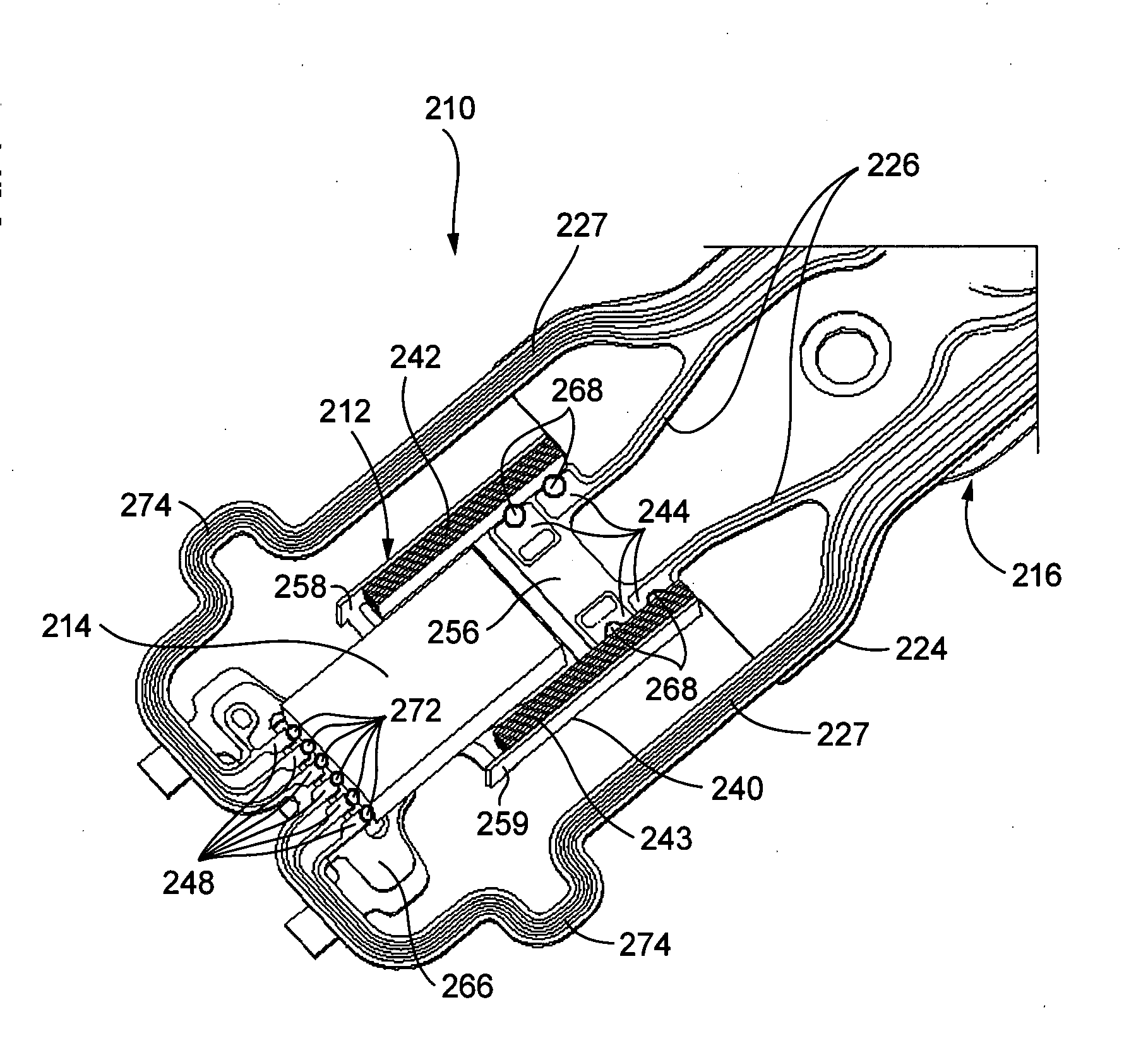

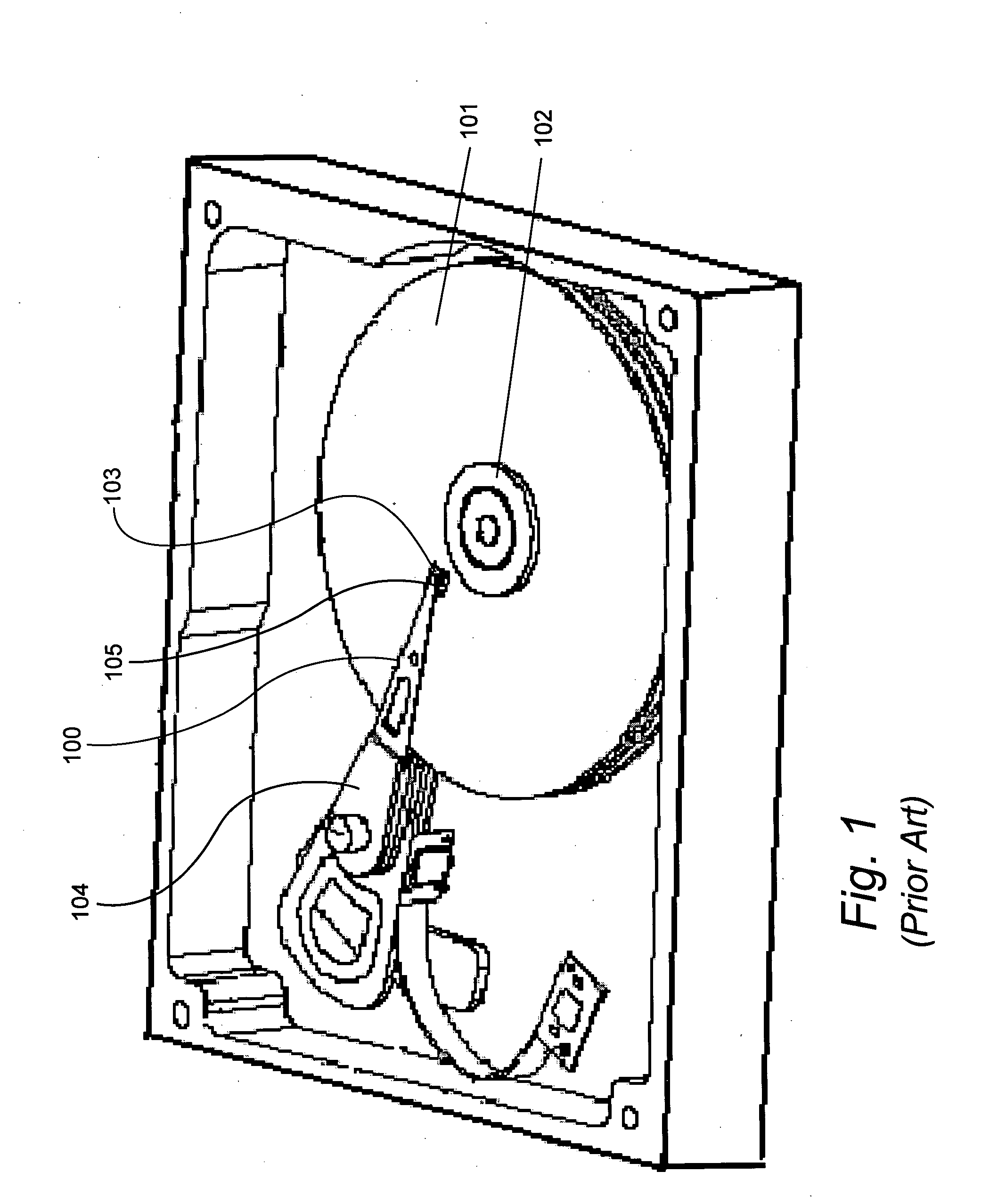

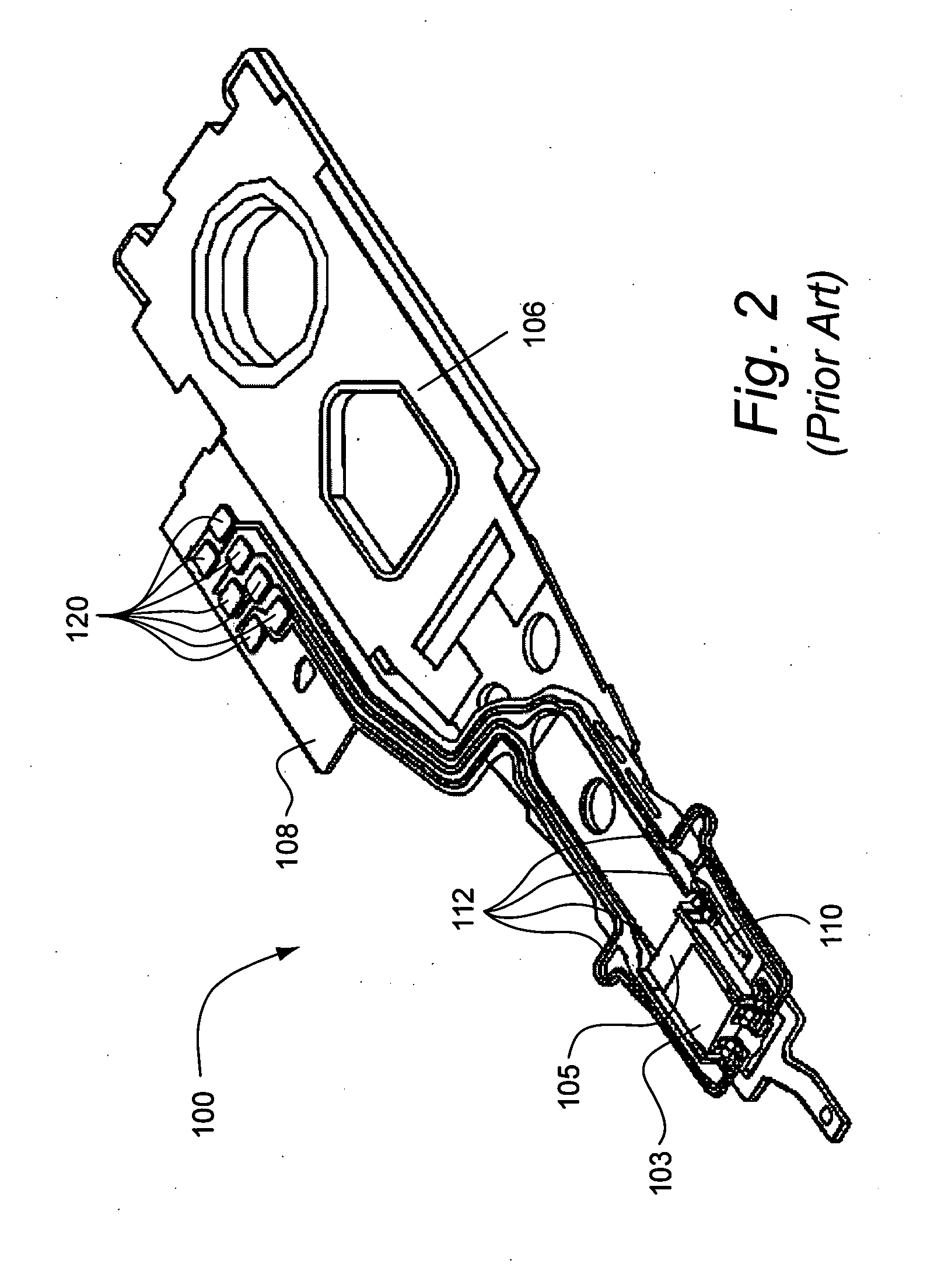

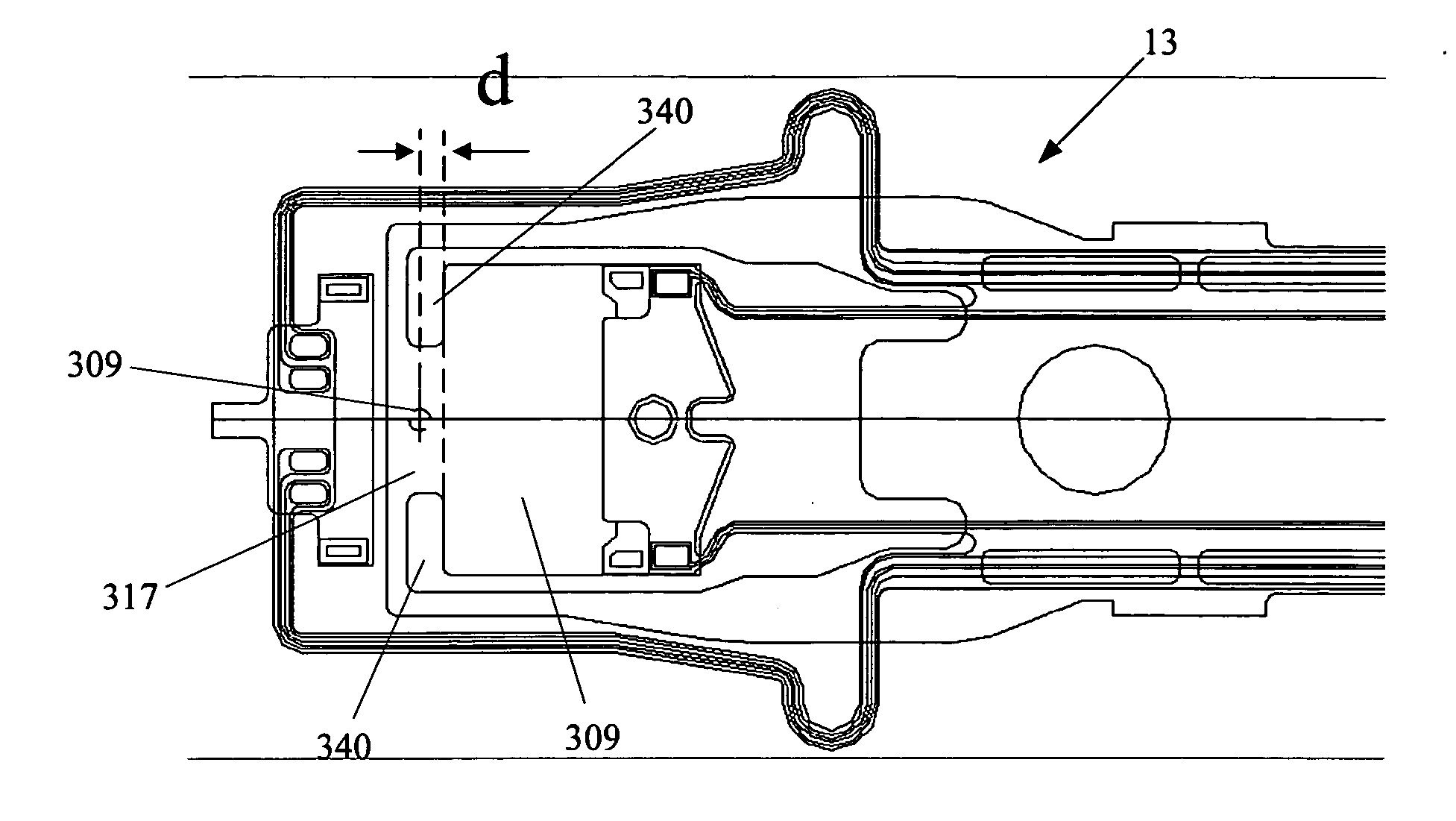

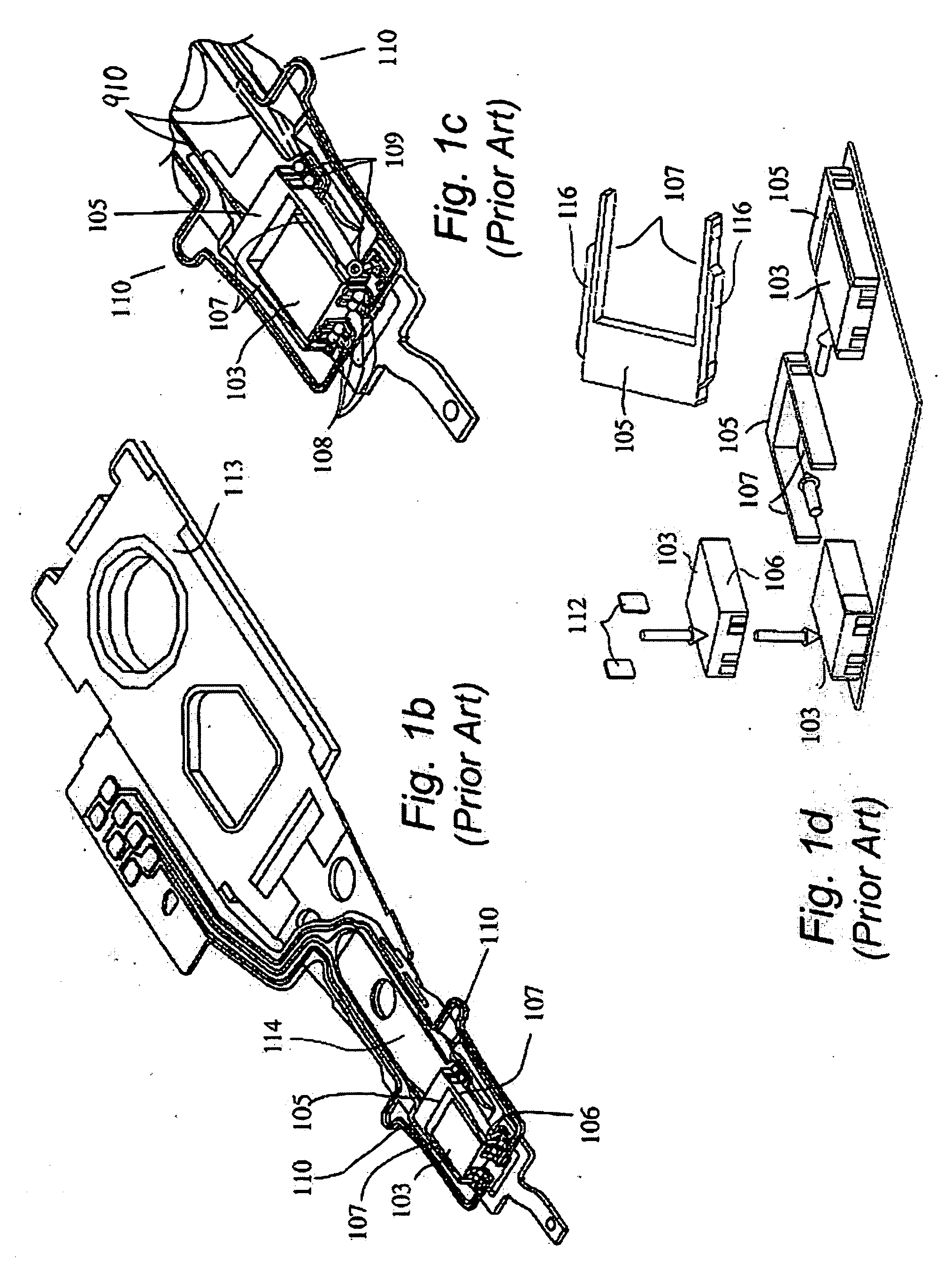

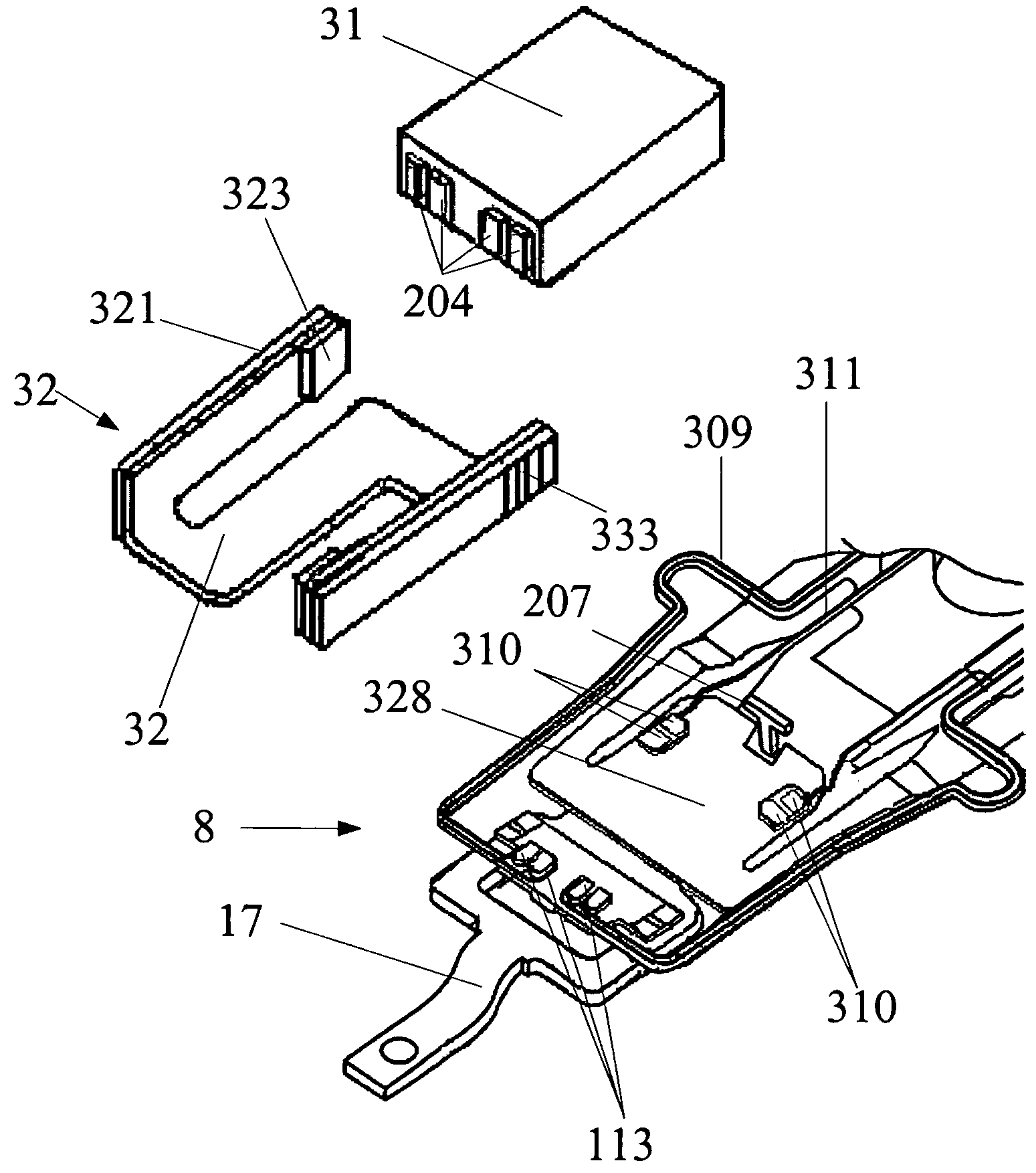

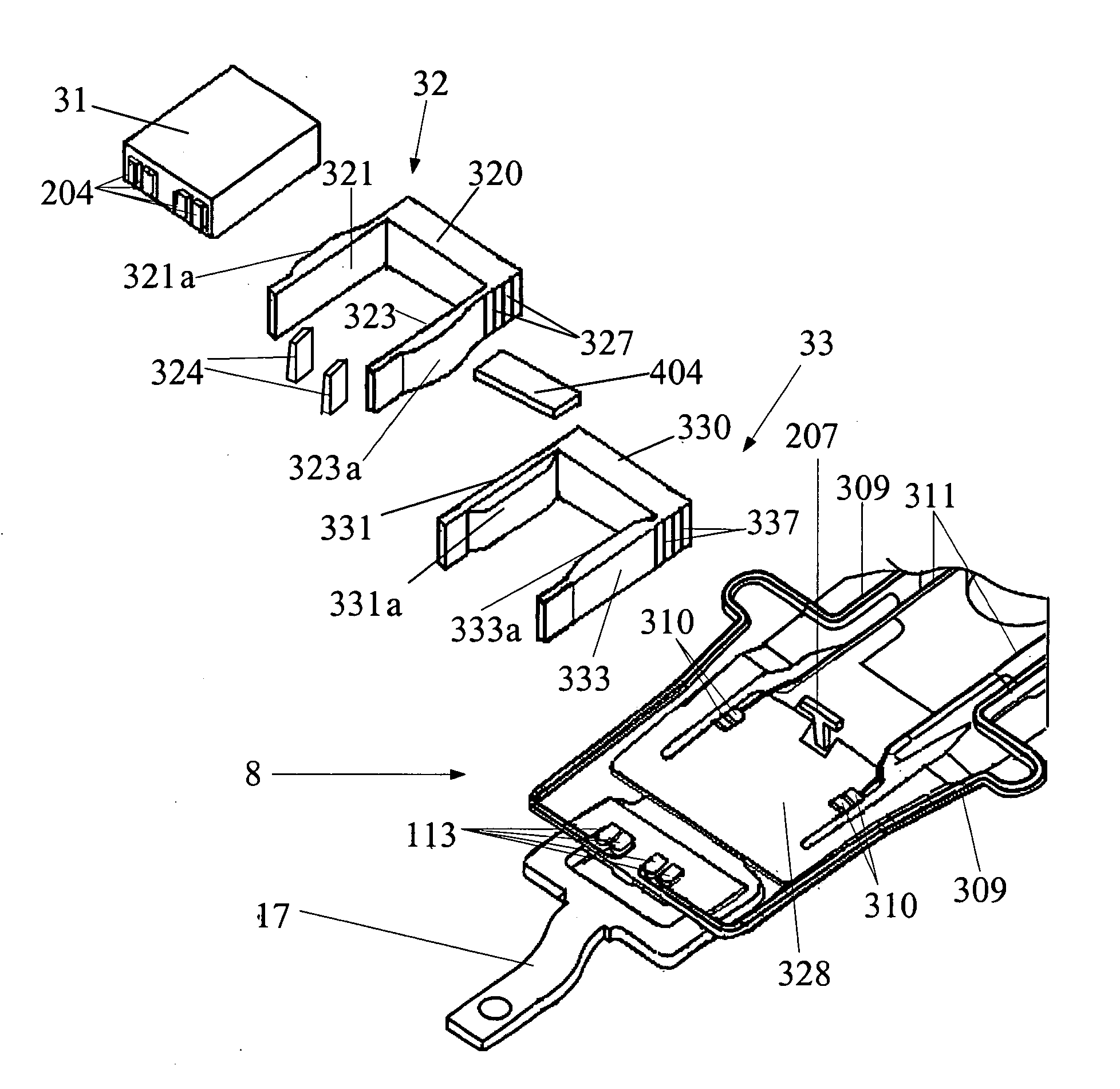

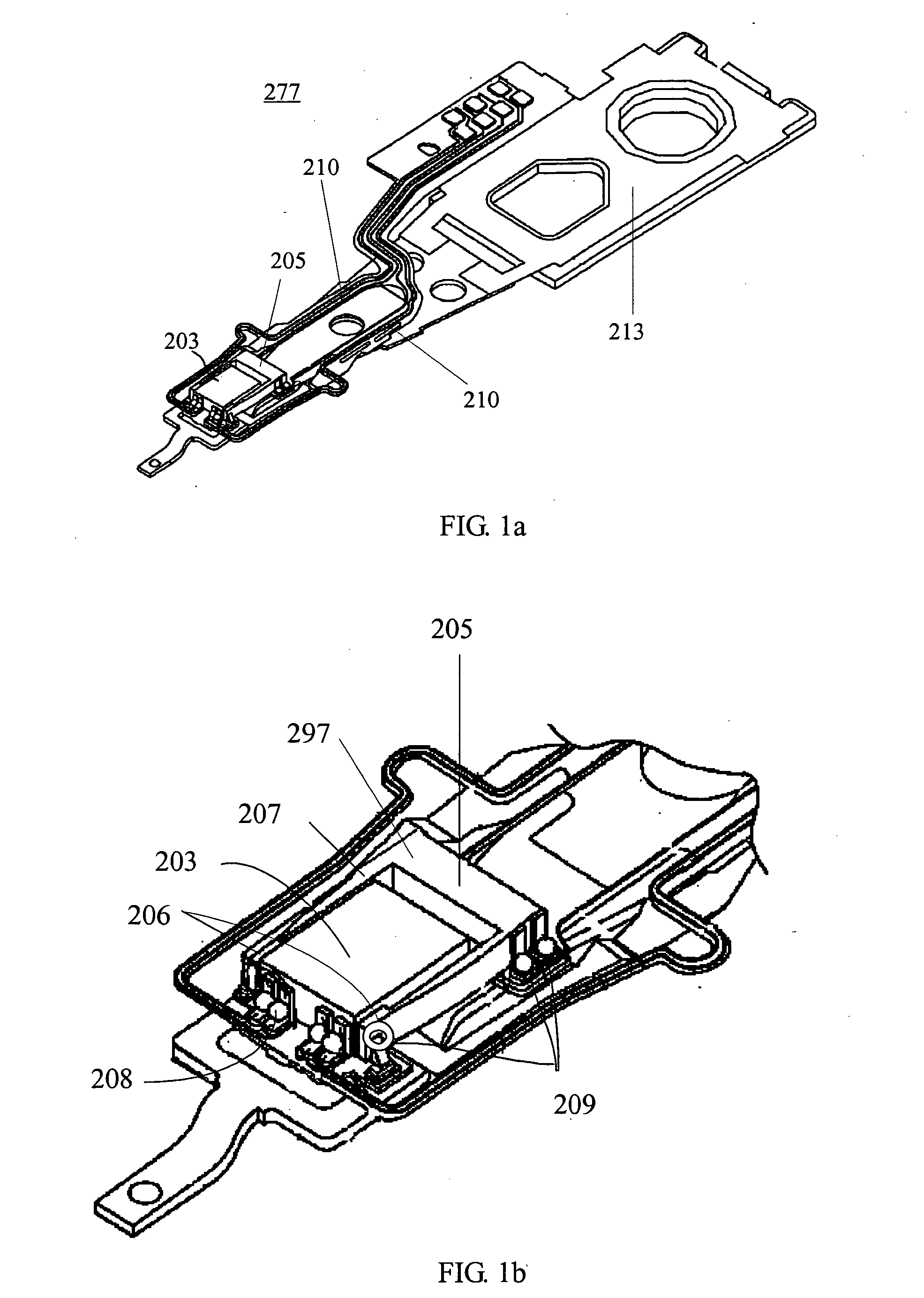

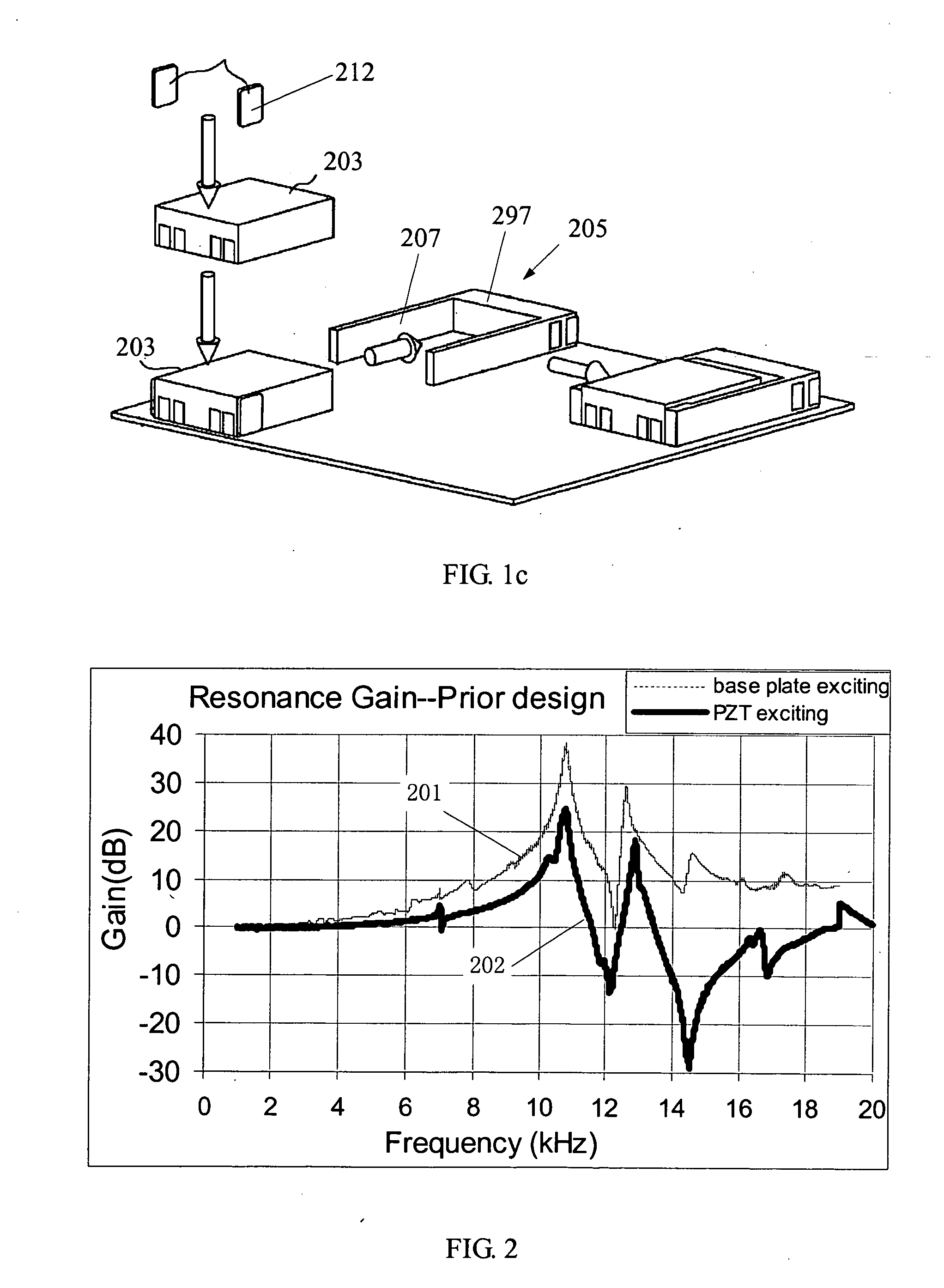

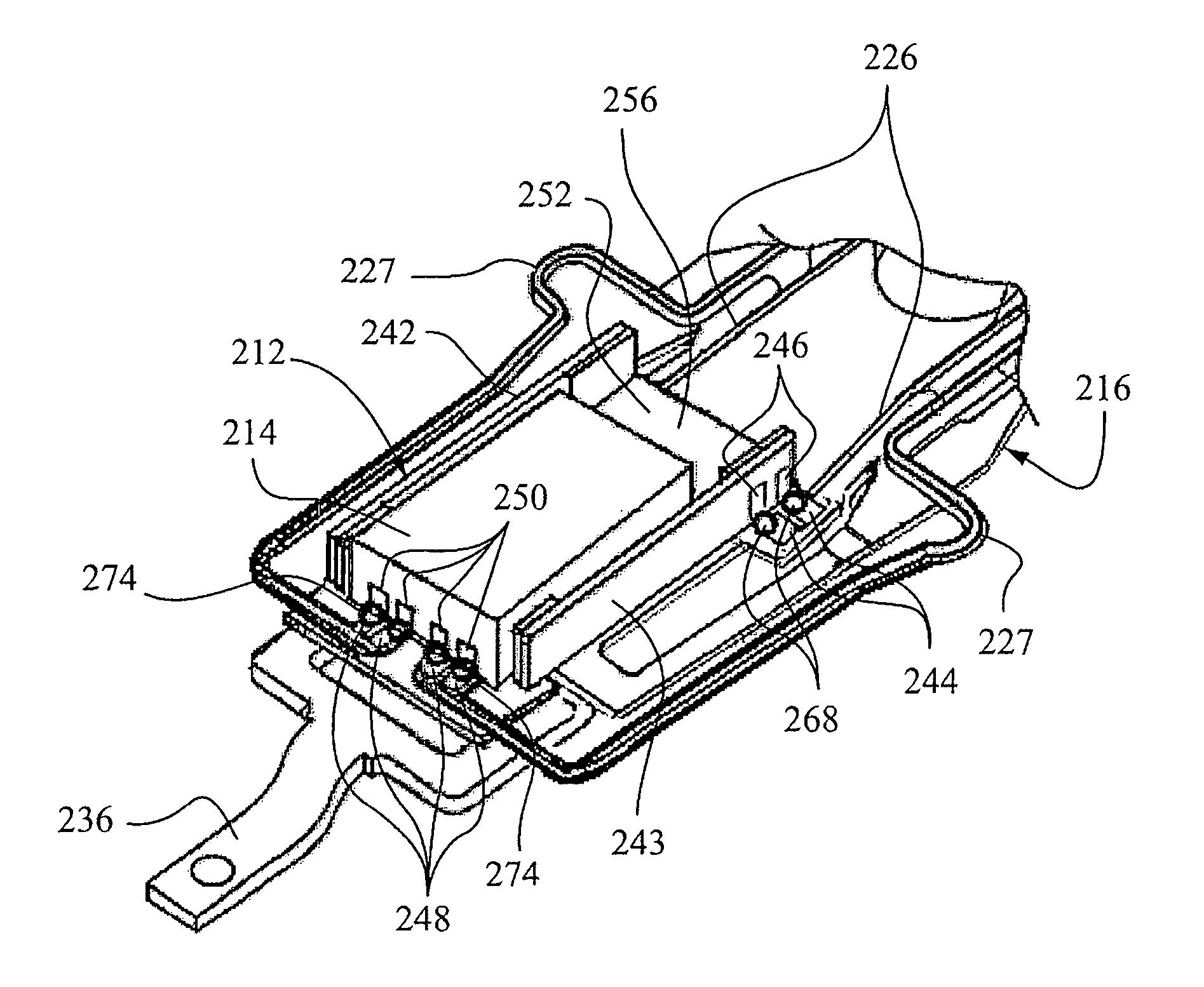

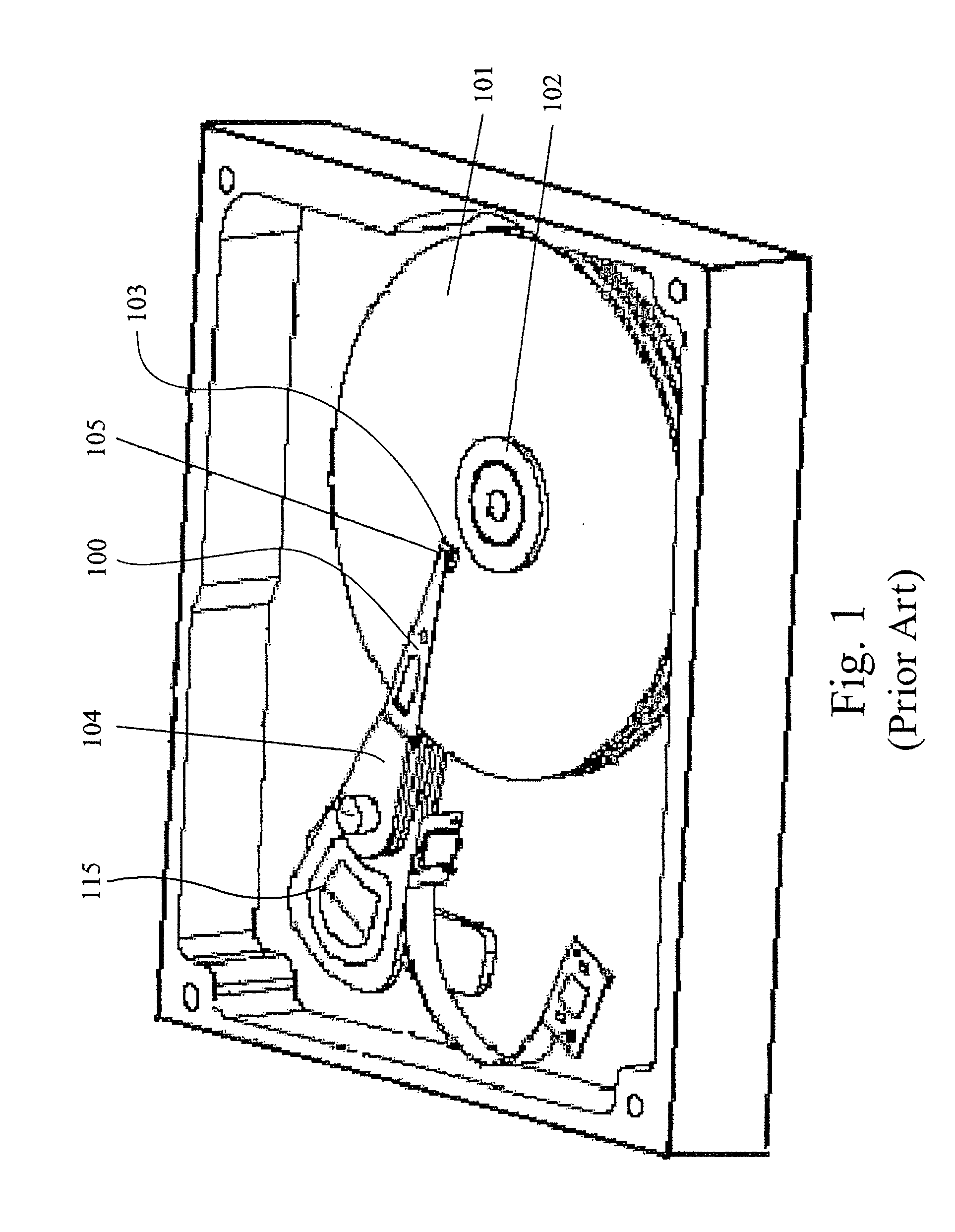

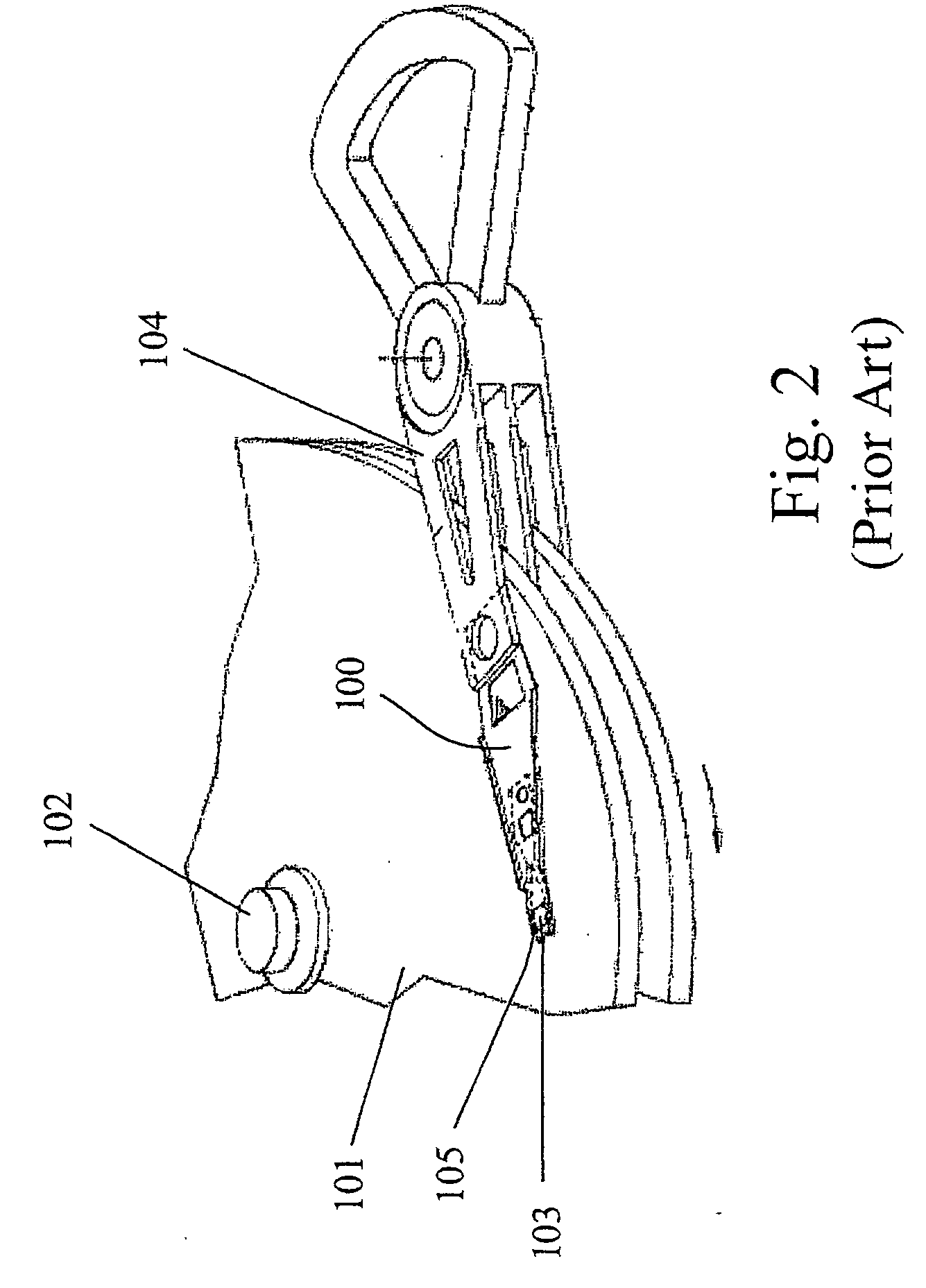

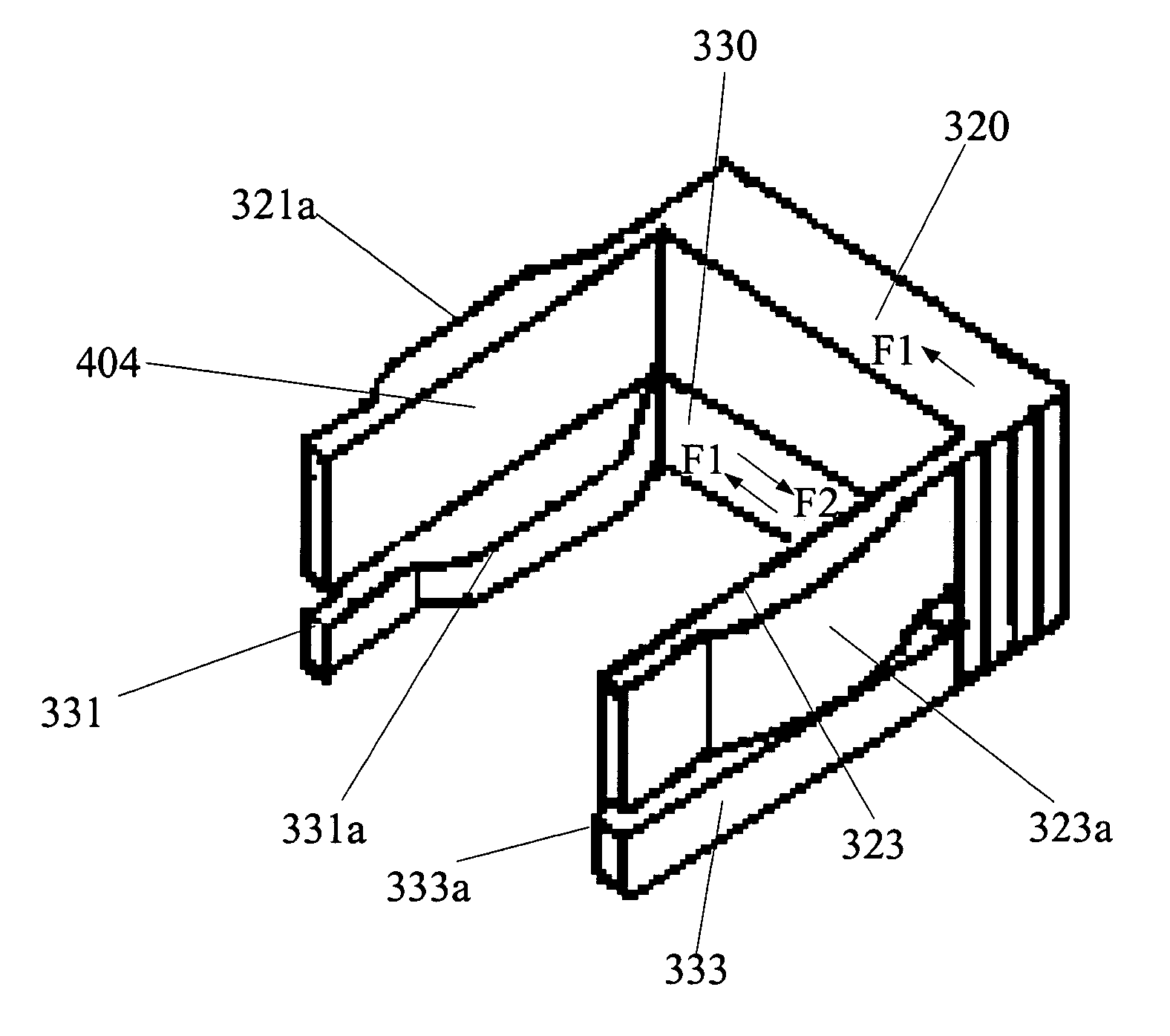

Rotational micro-actuator integrated with suspension of head gimbal assembly, and disk drive unit with the same

InactiveUS7719798B2Improve resonance performanceArm with actuatorsRecord information storageMicro actuatorEngineering

A micro-actuator for a head gimbal assembly includes a metal frame including a bottom support integrated with a suspension flexure of the head gimbal assembly, a top support adapted to support a slider of the head gimbal assembly, and a pair of side arms that interconnect the top support and the bottom support. The top support includes a rotatable plate, connection arms that couple the rotatable plate to respective side arms, and an electrical pad support plate that supports bonding pads. A PZT element is mounted to each of the side arms. Each PZT element is excitable to cause selective movement of the side arms.

Owner:SAE MAGNETICS (HK) LTD

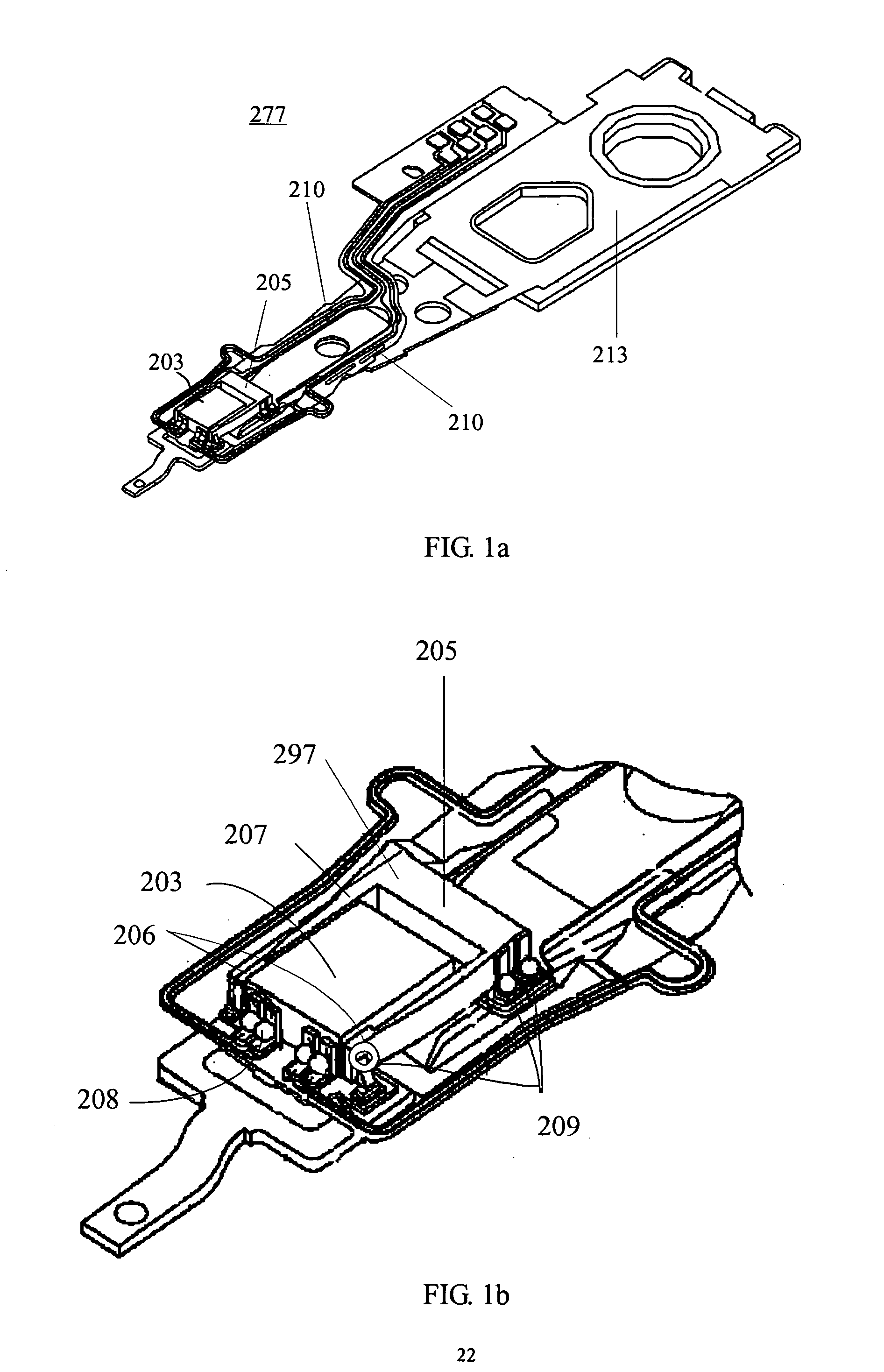

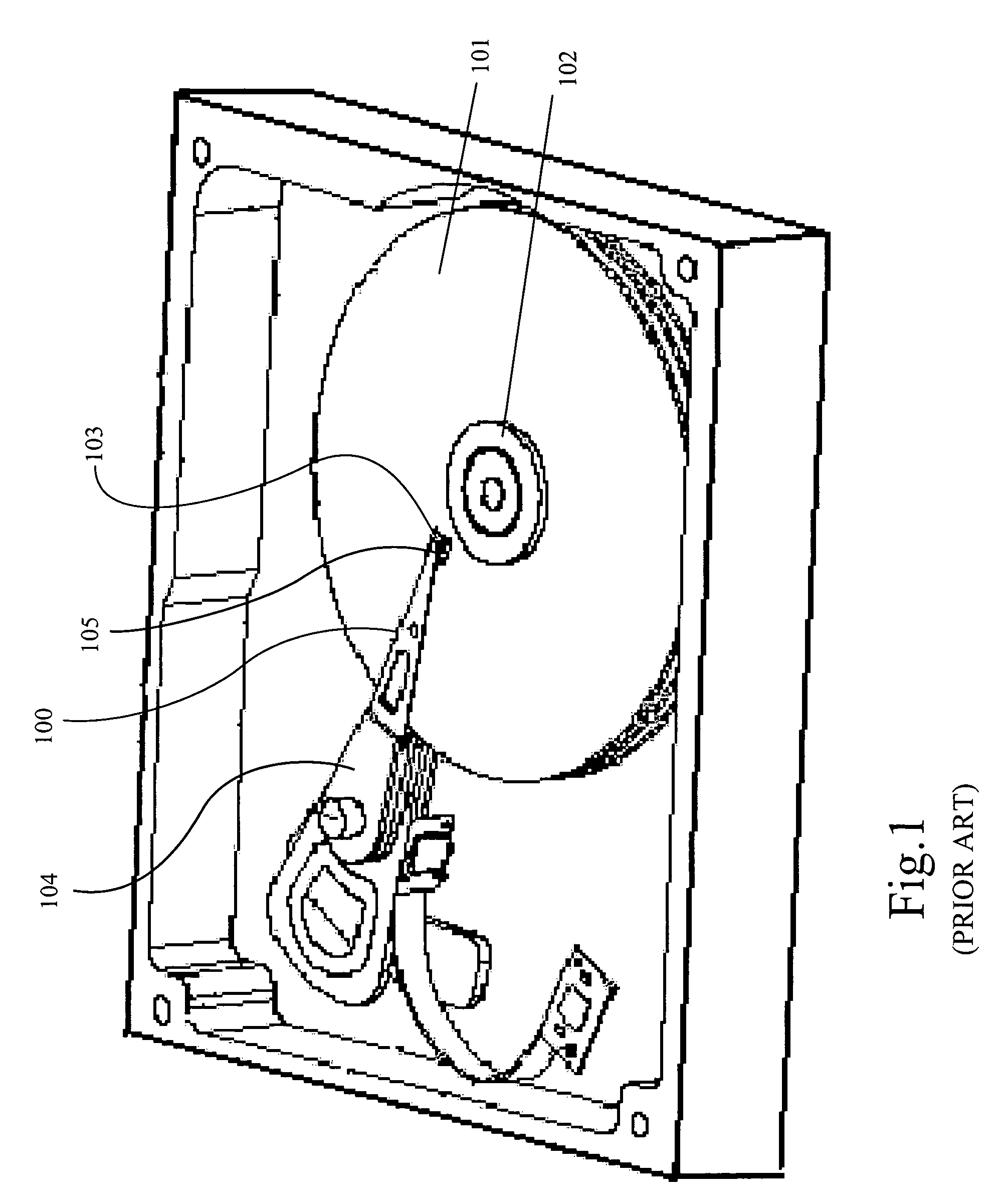

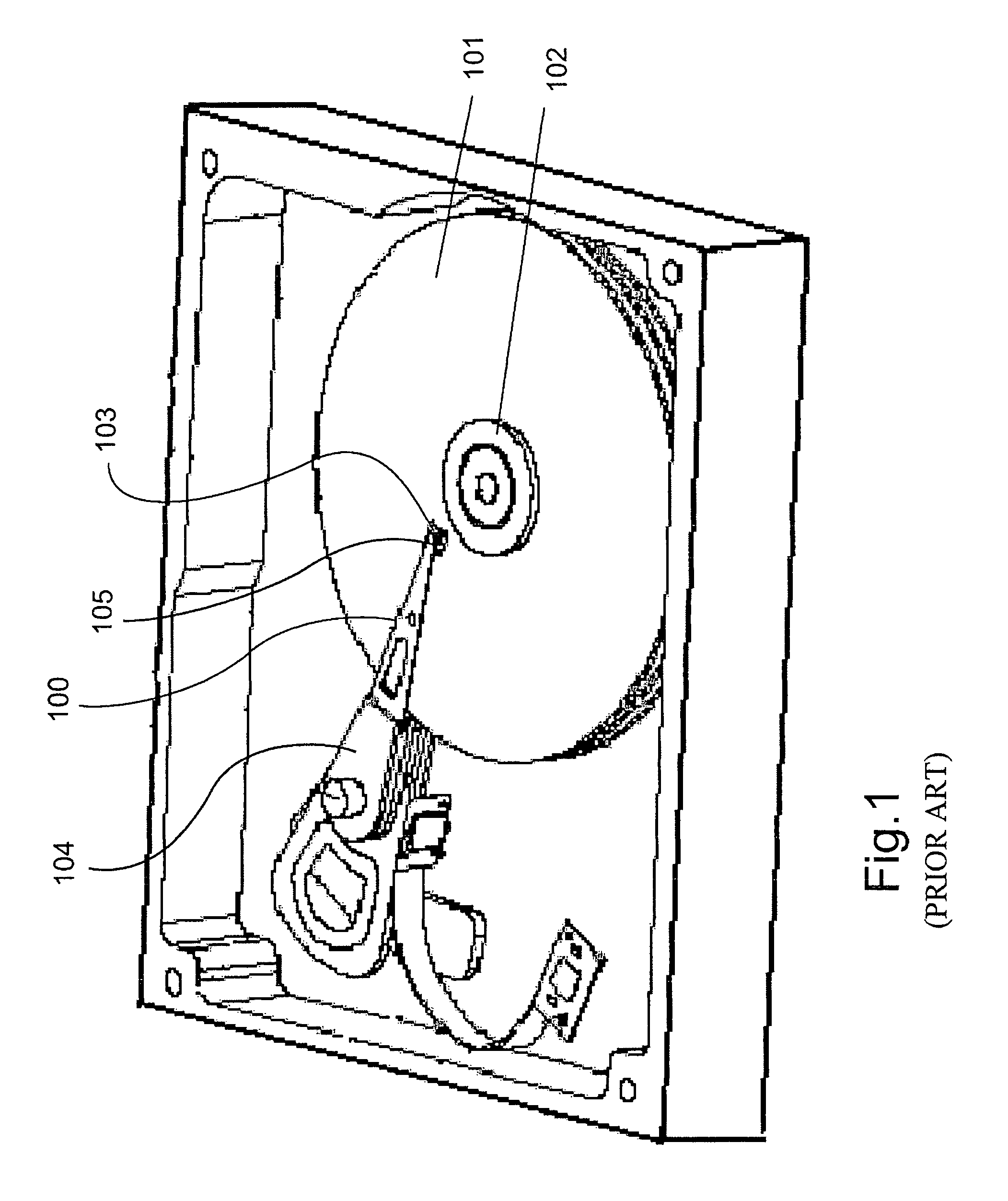

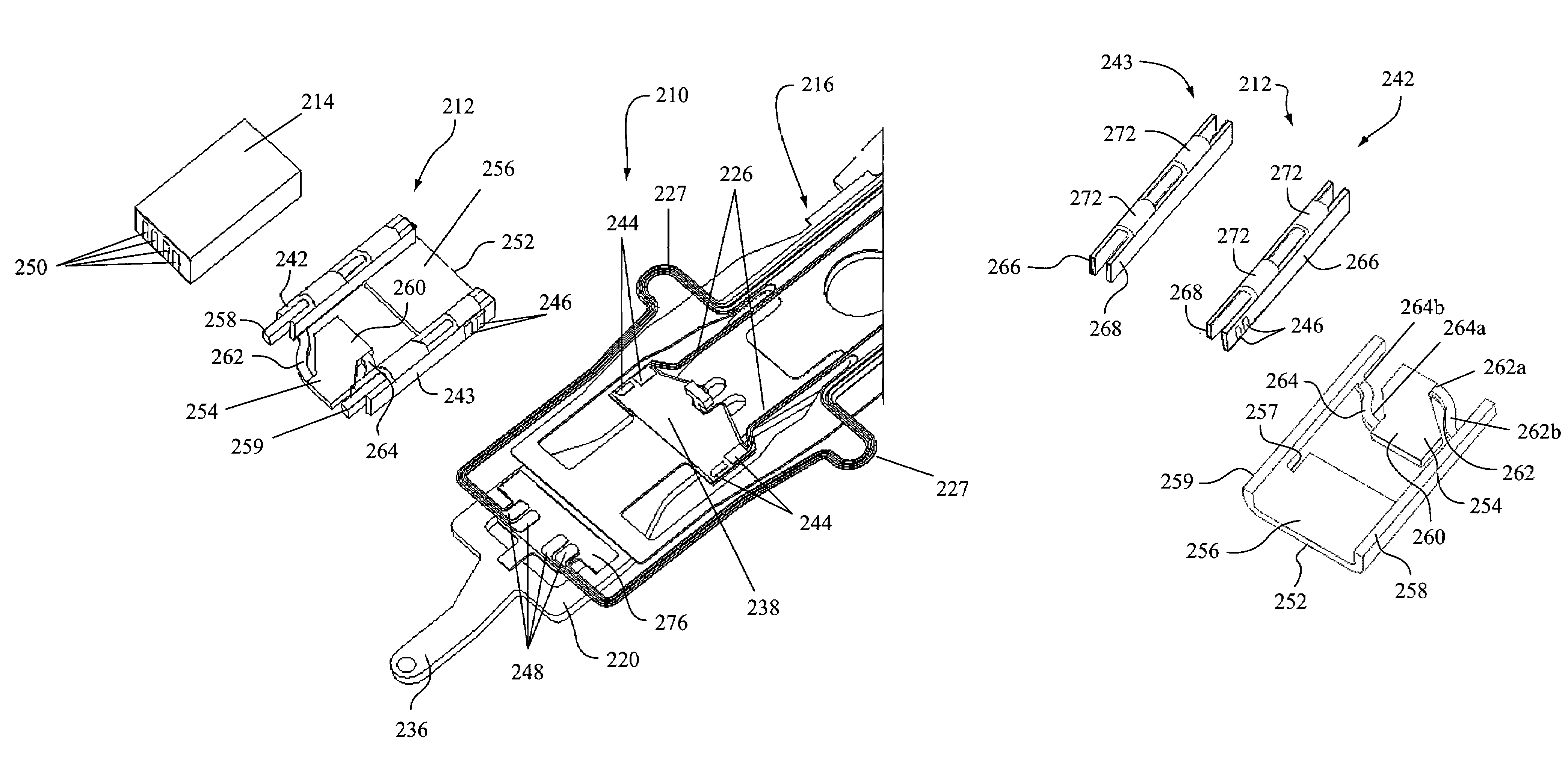

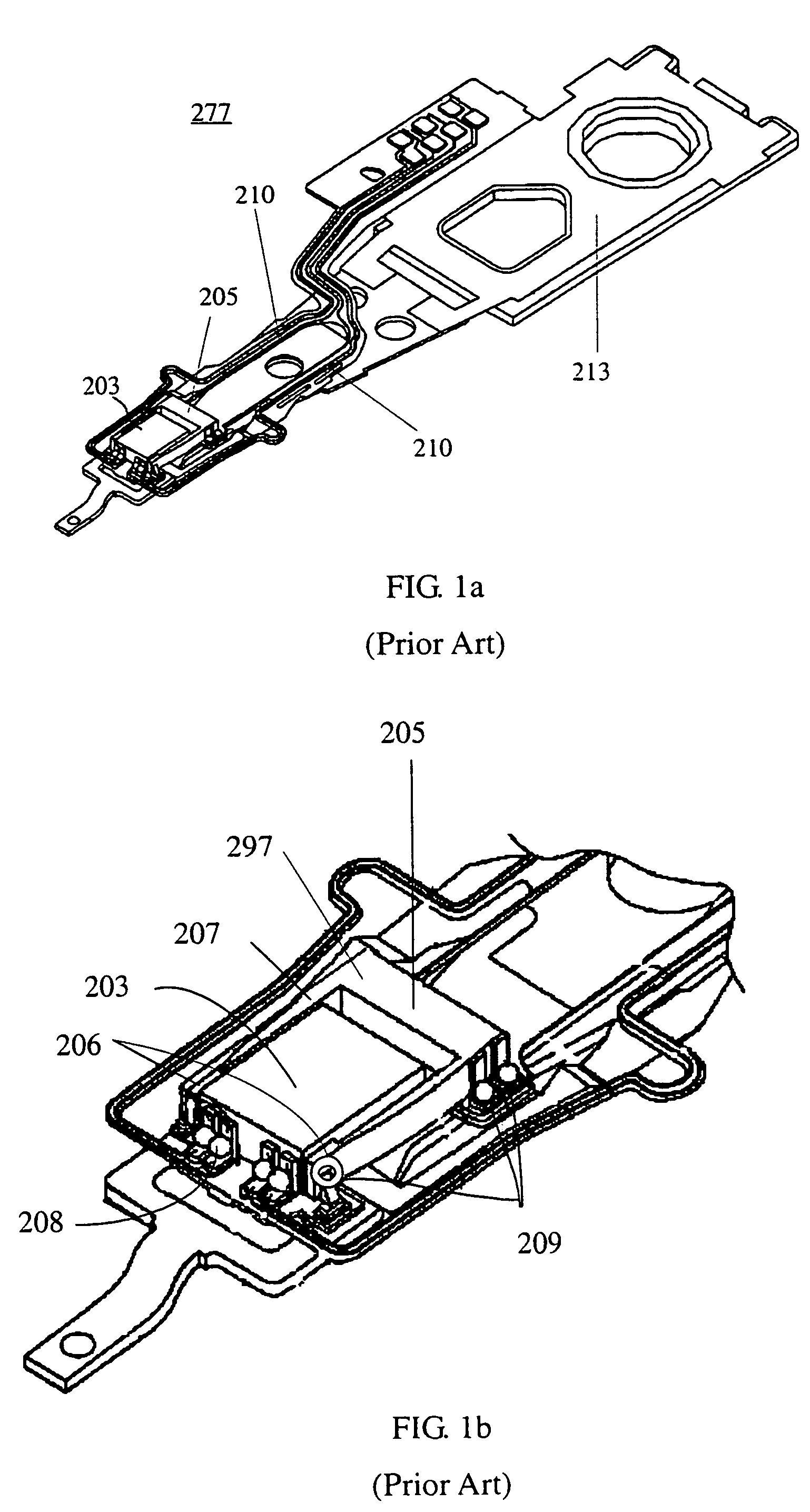

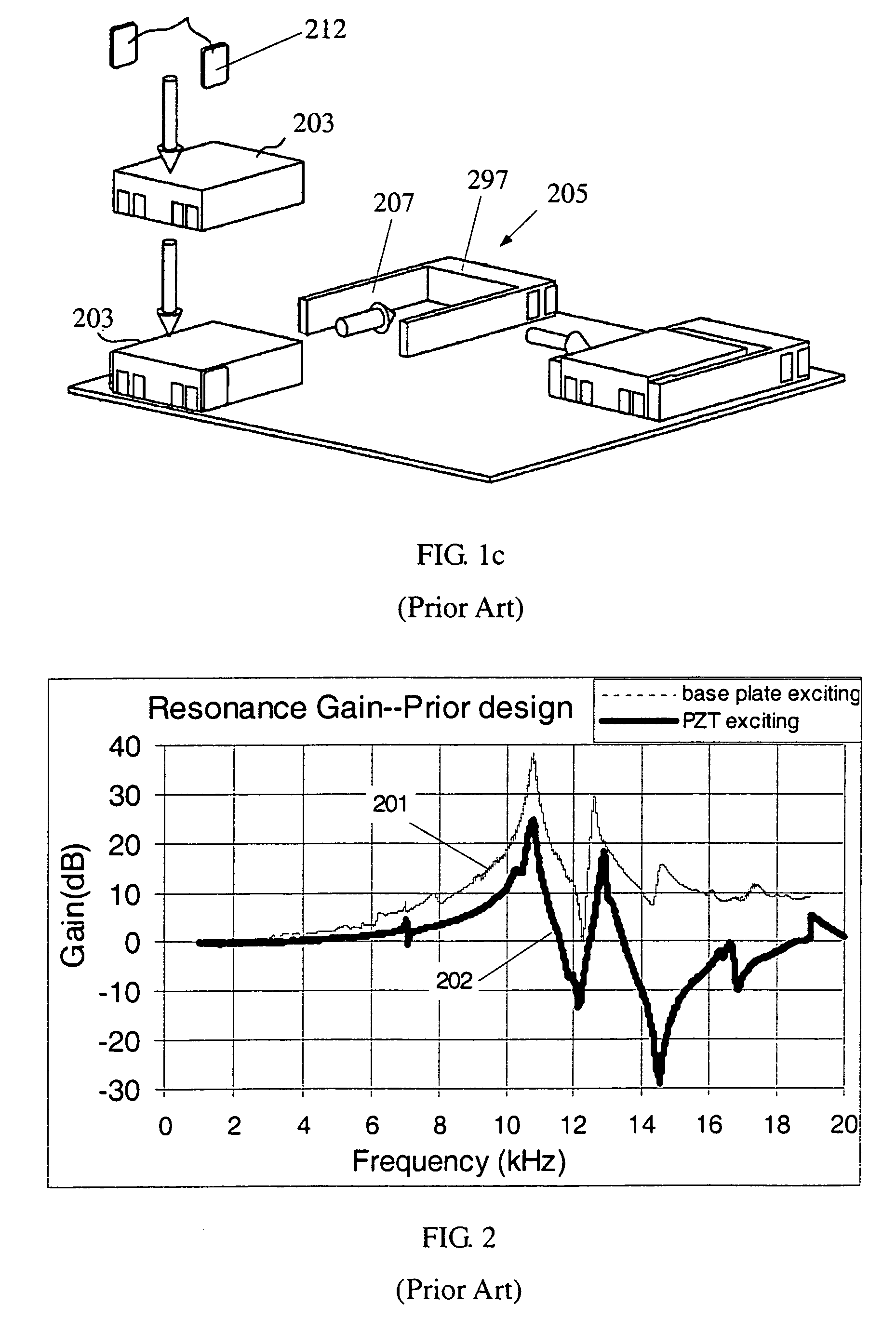

Micro-actuator, head gimbal assembly, and disk drive unit with the same

InactiveUS20060050442A1Fine head position adjustmentImprove resonance performanceDisposition/mounting of recording headsRecord information storageMicro actuatorCantilever

A head gimbal assembly includes a slider, a rotatable micro-actuator and a suspension to load the slider and the rotatable micro-actuator. The rotatable micro-actuator horizontally rotates the slider with a central portion of the slider as an axis, which includes a bottom plate to be connected with the suspension, two arm plates symmetrically disposed on the bottom plate with a central portion of the bottom plate as symmetry point and at least one piezoelectric pieces to be connected with the arm plates. Selectively, the amount of the arm plates can be four and four piezoelectric pieces to be connected with the four arm plates, respectively.

Owner:SAE MAGNETICS (HK) LTD

Rotational micro-actuator with a rotatable plate, head gimbal assembly and disk drive device with the same

InactiveUS7768746B2Improve resonance performanceRecord information storageAlignment for track following on disksMicro actuatorMetal framework

A head gimbal assembly includes a micro-actuator, a slider, and a suspension that supports the micro-actuator and the slider. The micro-actuator includes a metal frame including a top support to support the slider, a bottom support to connect to the suspension, and a pair of side arms that interconnect the top support and the bottom support. The top support includes a rotatable plate and connection arms that couple the rotatable plate to respective side arms. A PZT element is mounted to each of the side arms. Each PZT element is excitable to cause selective movement of the side arms. The suspension includes a load beam having a dimple that engages and supports the rotatable plate in use.

Owner:SAE MAGNETICS (HK) LTD

Vibrating Inertial Rate Sensor Utilizing Split or Skewed Operational Elements

InactiveUS20070256495A1Improved rate sense senseImproved sense drive sense signalAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAxis–angle representationGyroscope

A vibrating inertial rate sensor has operational elements that define axes that are rotationally offset or “skewed” from a node or anti-node reference axis. The skew may be relative to separate node or anti-node reference axes, or take the form of an element that is “split” about the same node axis. Both the drive signal and the sense signal may be resolved from a common set of sensing elements. The drive elements may also operate on a skewed axis angle to rotationally offset the vibration pattern to affect active torquing of the gyroscope. Skewed drive elements may be combined with skewed or split elements on the same device. The skewed sensing scheme may be applied to vibratory systems having one or more node axes. The skewed drive scheme may be applied to vibratory systems having two or more node axes to affect active torquing.

Owner:WATSON INDUSRIES

Vibrating inertial rate sensor utilizing split or skewed operational elements

InactiveUS7617727B2Improve featuresIncrease ratingsAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeDriven element

A vibrating inertial rate sensor has operational elements that define axes that are rotationally offset or “skewed” from a node or anti-node reference axis. The skew may be relative to separate node or anti-node reference axes, or take the form of an element that is “split” about the same node axis. Both the drive signal and the sense signal may be resolved from a common set of sensing elements. The drive elements may also operate on a skewed axis angle to rotationally offset the vibration pattern to affect active torquing of the gyroscope. Skewed drive elements may be combined with skewed or split elements on the same device. The skewed sensing scheme may be applied to vibratory systems having one or more node axes. The skewed drive scheme may be applied to vibratory systems having two or more node axes to affect active torquing.

Owner:WATSON INDUSRIES

Vibrating inertial rate sensor utilizing skewed drive or sense elements

InactiveUS7526957B2Good symmetryImprove resonance performanceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeControl theory

A vibrating inertial rate sensor has sense elements that operate on axes that are rotationally skewed from a node reference axis, enabling both a rate sense and a drive sense determination. Alternatively, the skew may be applied to rotationally offset the drive elements from antinode reference axes to affect active torquing of the gyroscope. The skewed sensing scheme may be applied to vibratory systems having one or more node axes. The skewed drive scheme may be applied to vibratory systems having two or more node axes to affect active torquing.

Owner:WATSON INDUSRIES

Miro-actuator, head gimbal assembly, and disk drive unit with the same

InactiveUS7474512B2Improve resonance performanceRecord information storageAlignment for track following on disksRotational axisMicro actuator

A micro-actuator for a head gimbal assembly includes a support frame including a bottom support adapted to be connected to a suspension of the head gimbal assembly, a top support adapted to support a slider of the head gimbal assembly, and a leading beam that couples the bottom support and the top support. The leading beam includes weak points or notches that allow the top support to rotate about a rotational axis in use. A first PZT element is mounted between first sides of the top and bottom supports, and a second PZT element is mounted between second sides of the top and bottom supports. The first and second PZT elements are excitable to cause selective rotational movement of the top support about the rotational axis in use.

Owner:SAE MAGNETICS (HK) LTD

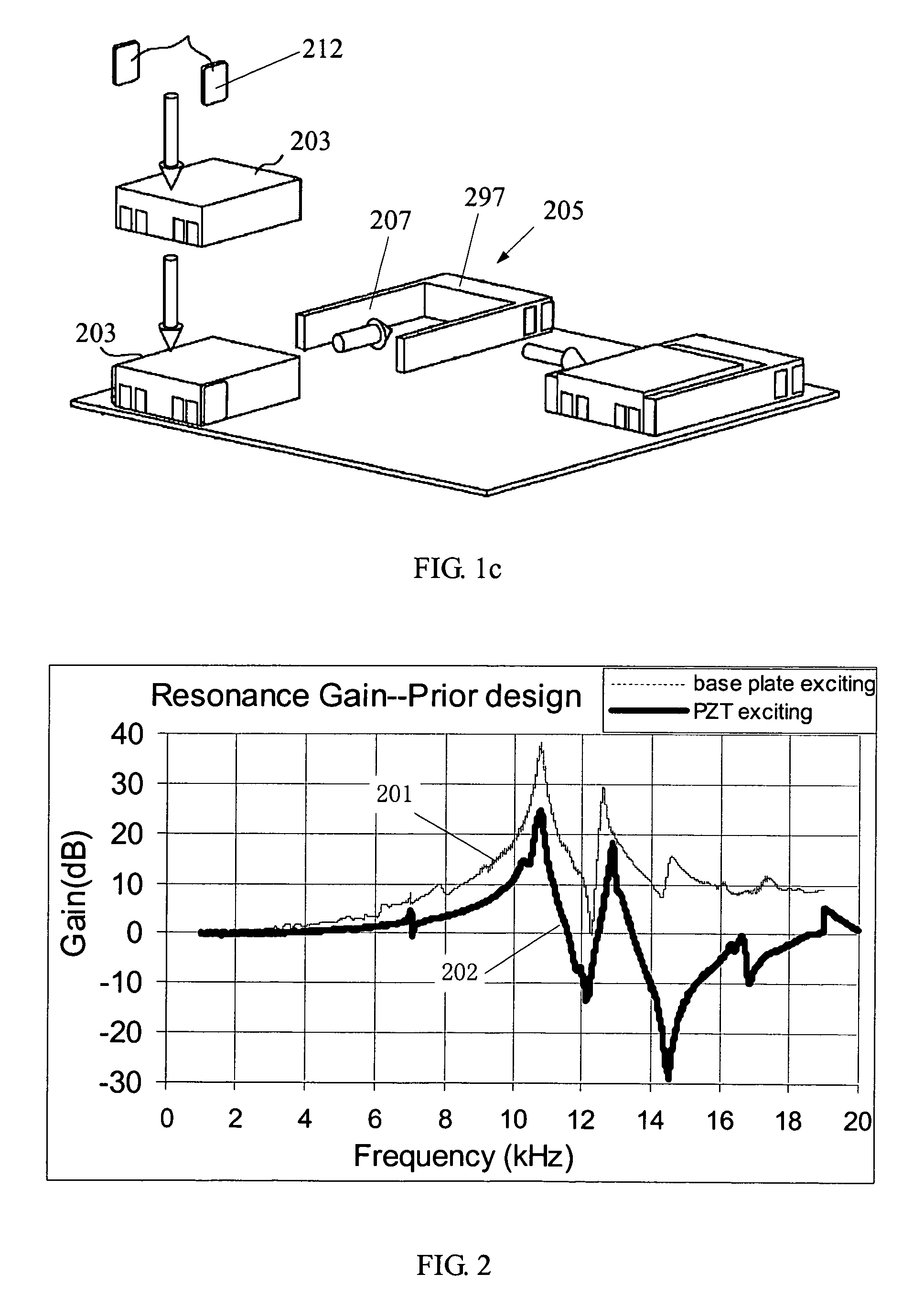

Head gimbal assembly apparatus having an actuator mounted on a mounting plate comprising a ceramic sub-plate formed on a stainless steel mounting plate

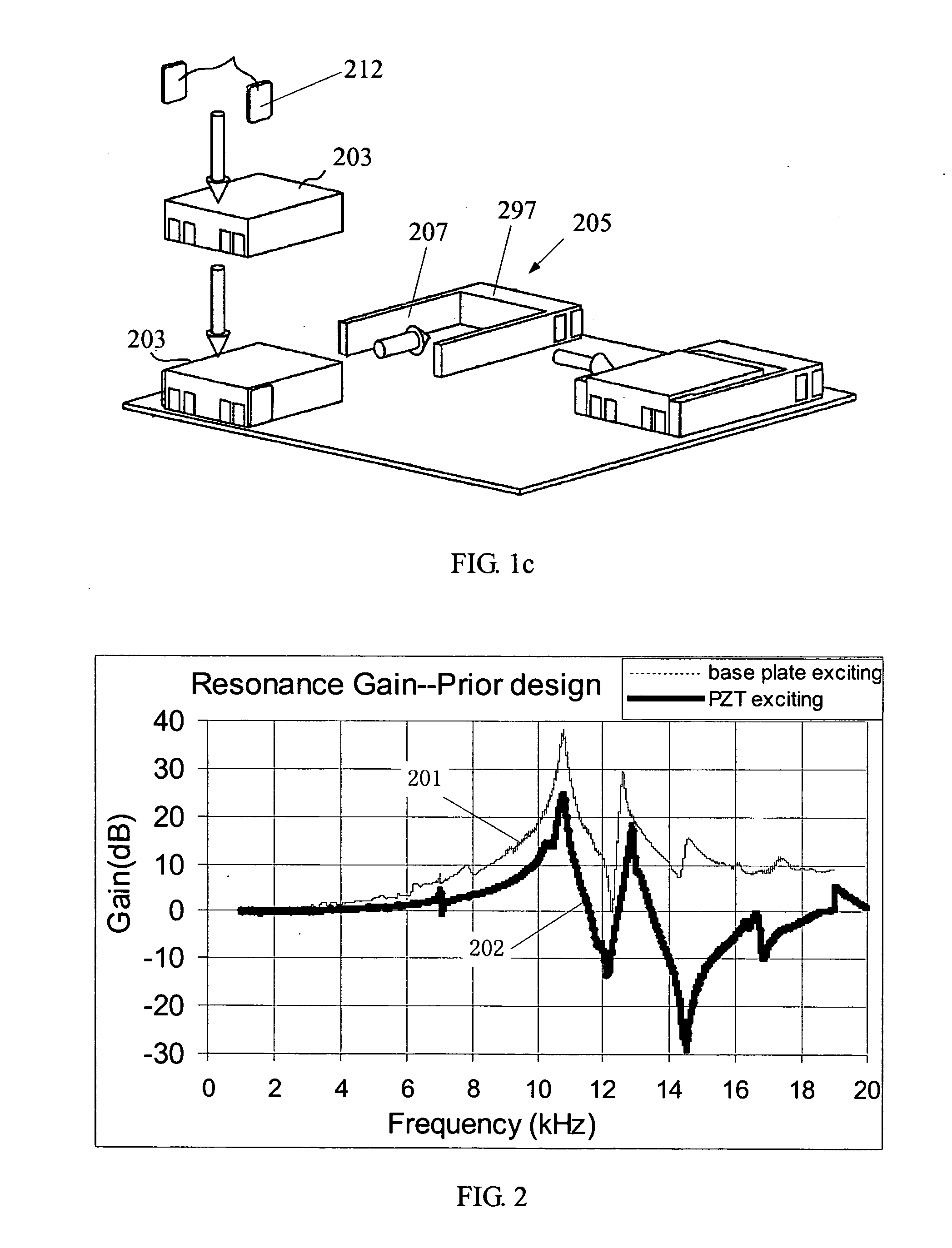

ActiveUS8148791B1Accurate resonance testingExtends usable test frequency rangeDriving/moving recording headsArm with actuatorsDensity ratioResonance

A test assembly for a disk drive suspension head gimbal assembly includes a steel mount plate and a mount sub-plate of a material such as silicon carbide having a modulus of elasticity to density ratio that is significantly higher than the ratio for stainless steel. Preferably the mount plate and the mount sub-plate taken together have a first resonant shear frequency of greater than 50 KHz, which is generally greater than the frequency range of interest for testing head gimbal assemblies. The high modulus of elasticity to density ratio helps to ensure that any shear mode resonances of the test assembly occur at frequencies that are higher than the frequencies of interesting for head gimbal assembly shear resonance testing purposes.

Owner:MAGNECOMP

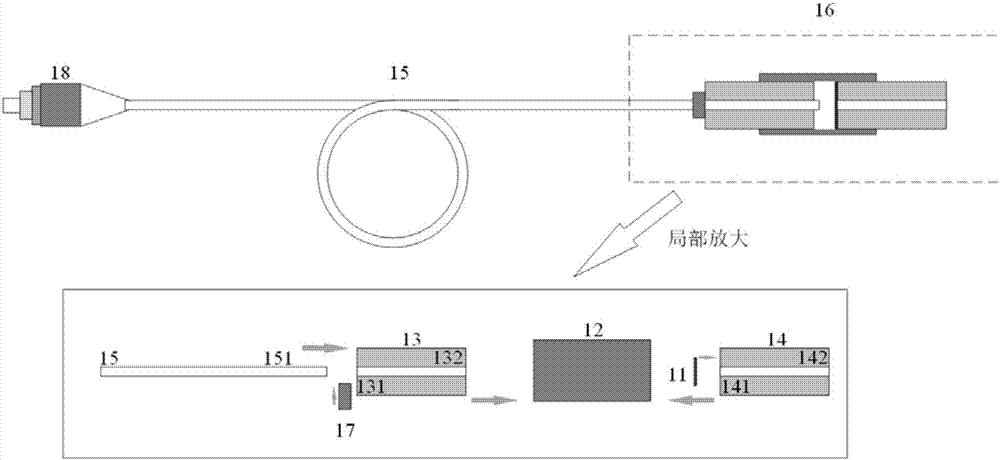

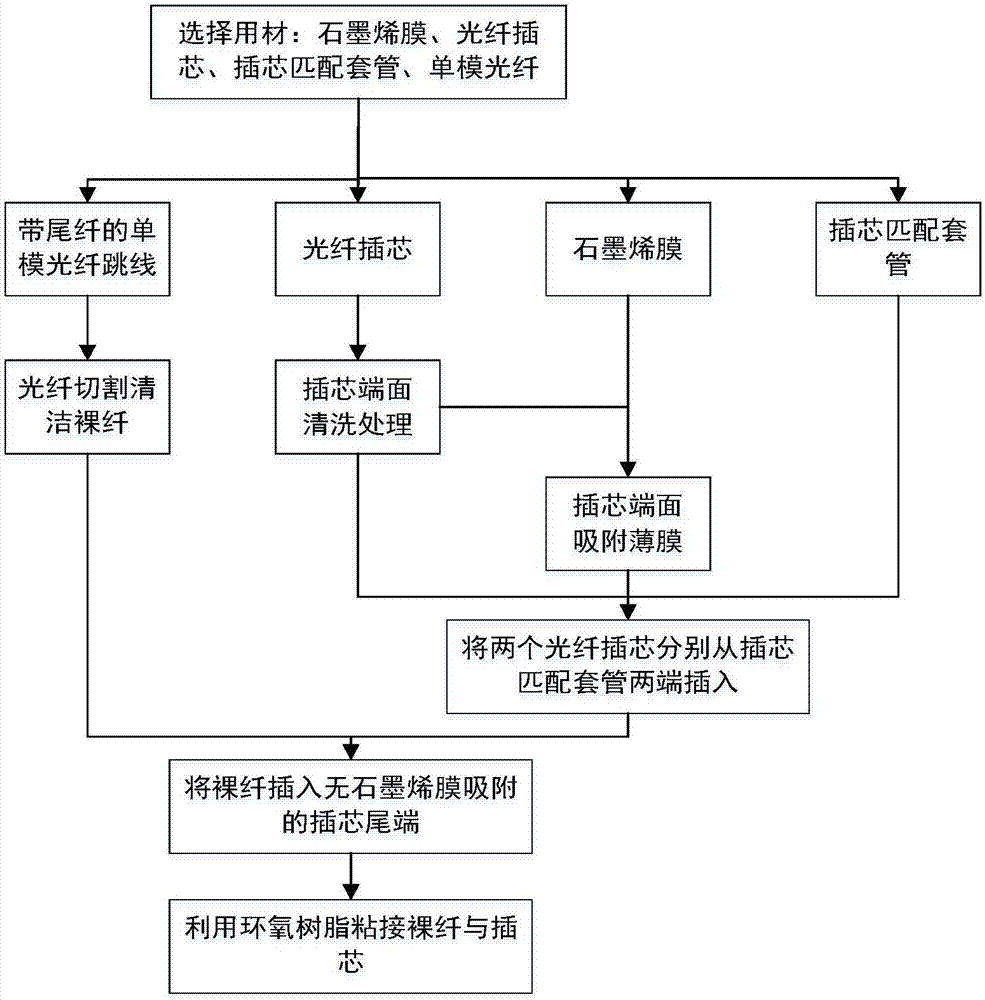

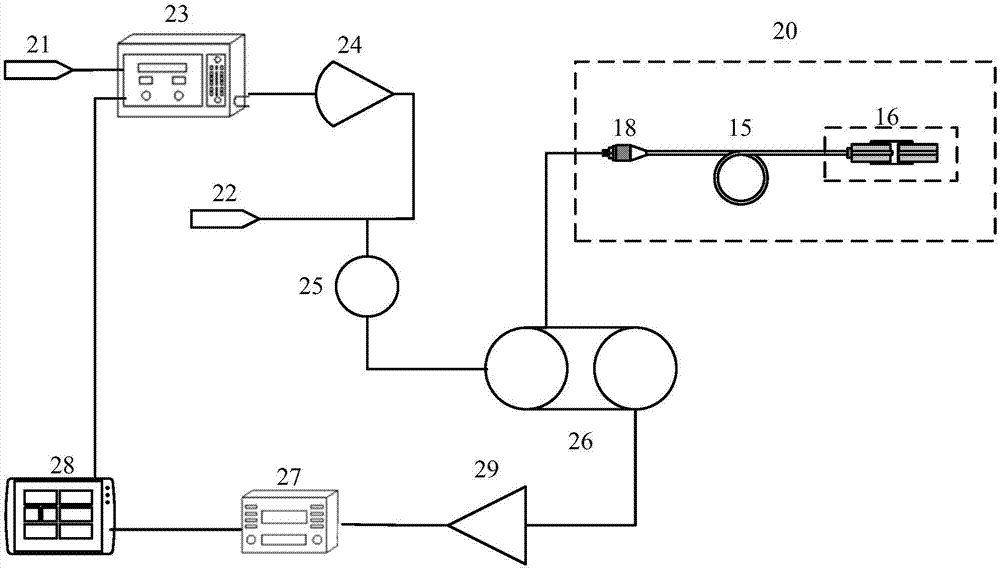

Graphene membrane fiber Fabry-Perot resonator and excitation/vibration pickup detection method thereof

ActiveCN106908092AImprove resonance performanceWith online measurementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberLight energy

The invention discloses a graphene membrane fiber Fabry-Perot resonator and an excitation / vibration pickup detection method thereof. The resonator is manufactured based on a graphene membrane and the principle of fiber Fabry-Perot interference optics. The graphene membrane is used as resonant material, and membrane excitation and vibration pickup can be realized by using fiber conduction laser. According to the excitation method, the graphene membrane is periodically irradiated by light intensity modulated laser, the graphene membrane absorbs light energy and converts the light energy into mechanical energy to generate forced vibration so that excitation of the graphene membrane resonator can be realized. According to the vibration pickup method, the acquired interference signals are demodulated based on the principle of Fabry-Perot interference, and the frequency change information of the interference light signals is acquired so that measured detection related to the frequency quantity can be realized. The resonator has the advantages of easy manufacturing, high sensitivity, small size, low power consumption, quasi-digital signal output, online measurement and electromagnetic interference resistance so that the resonator can perform detection of pressure, temperature, humidity and other physical quantities and gas quantities, biomass and other parameters and can be applied to the field of aerospace, biomedicine and industrial control.

Owner:BEIHANG UNIV

Rotational PZT micro-actuator with a rotatable plate

InactiveUS7538984B2Improve resonance performanceRecord information storageAlignment for track following on disksMicro actuatorEngineering

A micro-actuator for a head gimbal assembly includes a metal frame, PZT elements, and a rigid beam. The metal frame includes a top support adapted to support a slider of the head gimbal assembly, and a pair of side arms extending vertically from respective sides of the top support. The top support includes a rotatable plate and connection arms that couple the rotatable plate to respective side arms. A PZT element is mounted to each of the side arms. Each PZT element is excitable to cause selective movement of the side arms. The rigid beam is mounted between the side arms at an end opposite the top support.

Owner:SAE MAGNETICS (HK) LTD

Micro-actuator and head gimbal assembly for a disk drive device

InactiveUS7417831B2Improve resonance performanceTrack finding/aligningFluid-dynamic spacing of headsMicro actuatorMetal framework

A micro-actuator for a head gimbal assembly includes a metal frame including a bottom support adapted to be connected to a suspension, a top support adapted to support a slider, and a pair of side arms that interconnect the bottom and top supports. The side arms extend vertically from respective sides of the bottom and top supports. A PZT element is mounted to each of the side arms. Each PZT element includes two PZT portions supported by a PI substrate base. The PI substrate base includes one or more bridges that physically and electrically couple the two PZT portions. The bridges are bendable so that the two PZT portions sandwich the respective side arm when mounted thereto.

Owner:SAE MAGNETICS (HK) LTD

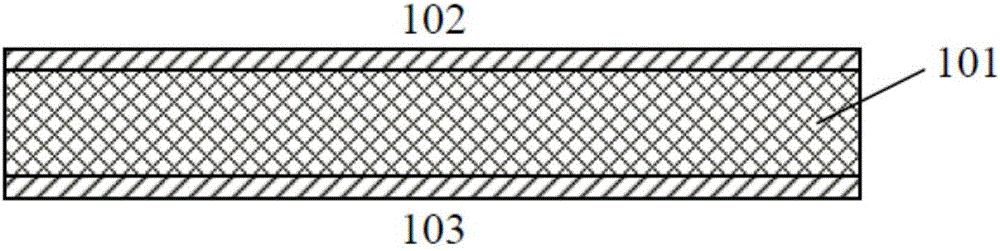

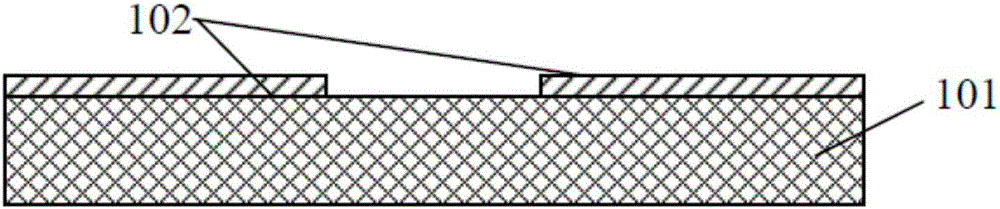

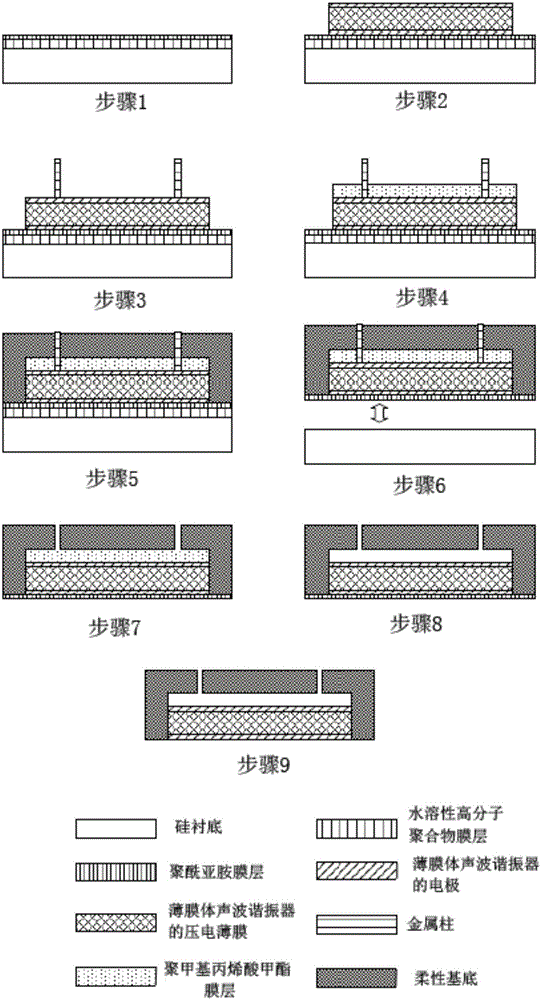

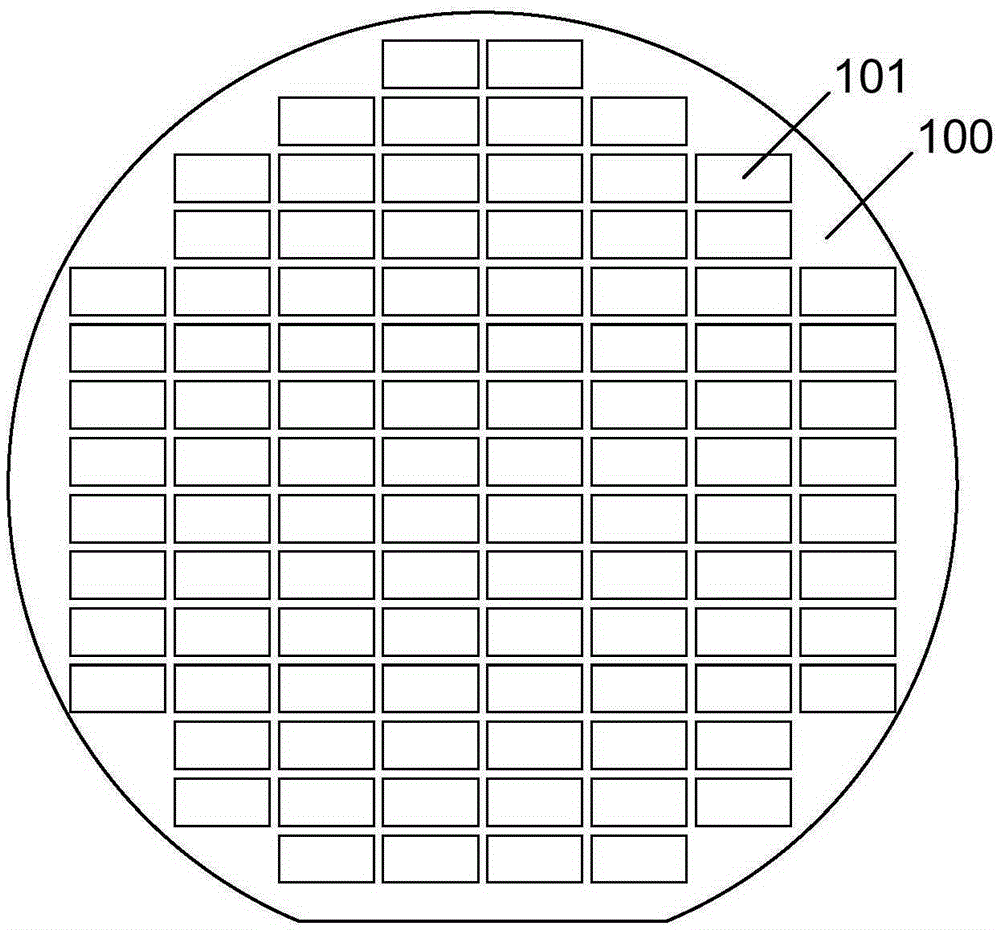

Method of manufacturing film bulk acoustic resonator on flexible substrate

ActiveCN106788318AImprove resonance performanceGuarantee processing qualityImpedence networksThin-film bulk acoustic resonatorPolymethyl methacrylate

The invention discloses a method of manufacturing a film bulk acoustic resonator on a flexible substrate. The method comprises the following steps: selecting a silicon substrate, and orderly coating a water soluble polymer film layer and a polyimide film layer on the silicon substrate; manufacturing the film bulk acoustic resonator above the polyimide film layer; manufacturing a metal post at the top face of an upper electrode of the film bulk acoustic resonator; coating a polymethyl methacrylate film layer at the at the top face of the upper electrode of the film bulk acoustic resonator; coating glue of a used flexible substrate on the silicon substrate and curing the glue; placing the whole finished structure in water to separate the polyimide film layer from the silicon substrate; using corrosive liquid to remove the metal post; placing the above structure into an acetone solution, dissolving the polymethyl methacrylate film layer, and forming an air gap; and removing the polyimide film layer below the film bulk acoustic resonator. By using the method of the invention to manufacture the film bulk acoustic resonator on the flexible substrate, the resonance performance of a device can be enhanced and the processing quality of the device can be guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH

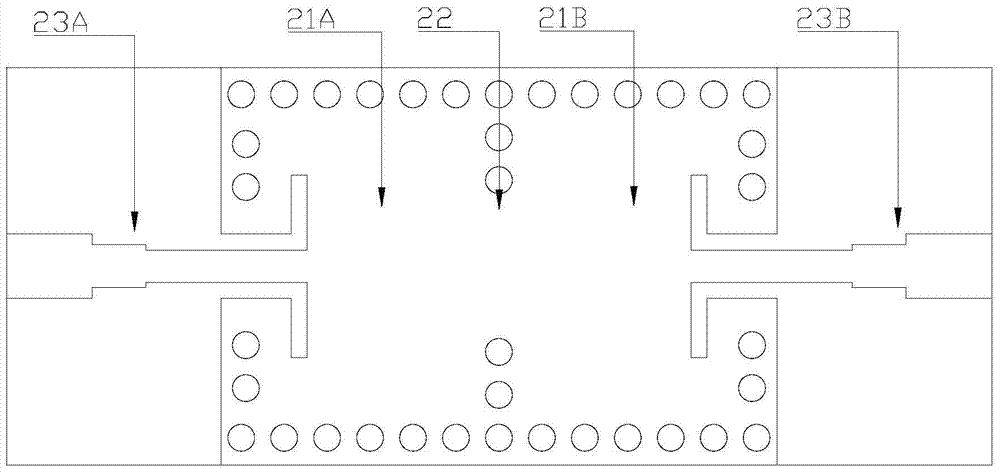

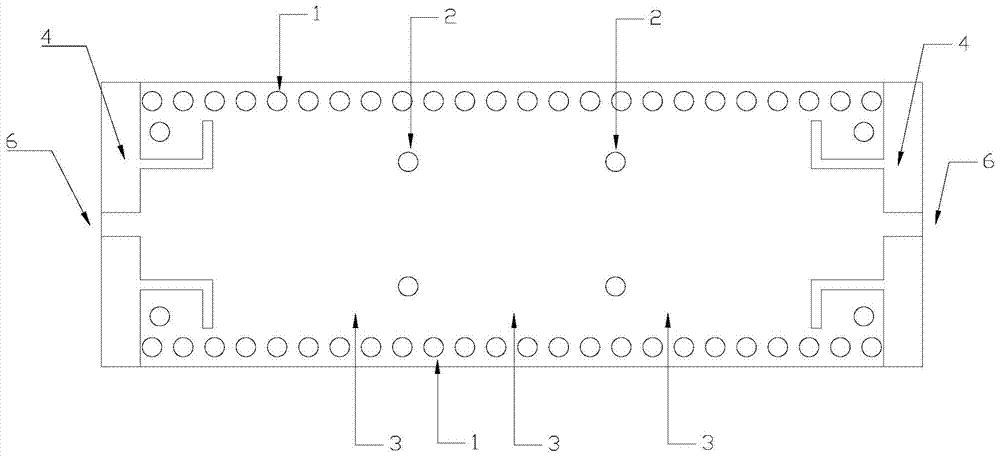

Dielectric waveguide filter with defected ground loaded on magnetic coupling structure

ActiveCN103682534AGood out-of-band rejectionBroaden the field of applicationWaveguide type devicesDielectric substrateTransmission line

Provided is a dielectric waveguide filter with a defected ground loaded on a magnetic coupling structure. A row of metallized through holes is punched in each of two sides of a dielectric substrate, electromagnetic waves are limited to be spread in an area between the upper and lower metal surfaces of the dielectric substrate and the two rows of metallized through holes, and a dielectric waveguide transmission line is formed; two pairs of left-right symmetrical metallized through holes are formed in the formed dielectric waveguide transmission line and are perpendicular to the horizontal center line, the dielectric waveguide transmission line is divided into three parts which form dielectric waveguide resonant cavities, and the two pairs of left-right symmetrical metallized through holes form the magnetic coupling structure; double L-shaped transition structures are loaded from an input / output microstrip line to the upper layer metal surface of the dielectric waveguide transmission line to form transition from the microstrip line to the dielectric waveguide, and meanwhile a defected ground structure is loaded on the lower layer metal surface of the dielectric waveguide resonant cavities adjacent to the double L-shaped transition structures. The dielectric waveguide filter has the advantages of low insertion loss and high out-of-band rejection, and can be applied to fields such as the radio frequency front end, image rejection and spurious suppression.

Owner:SPACE STAR TECH CO LTD

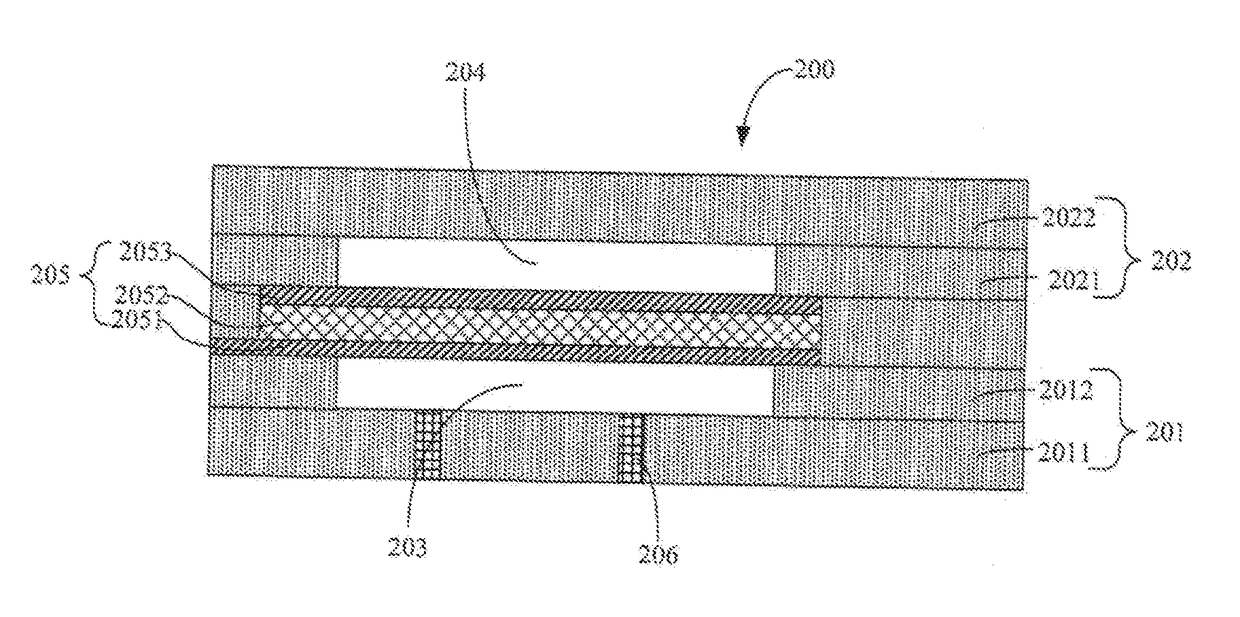

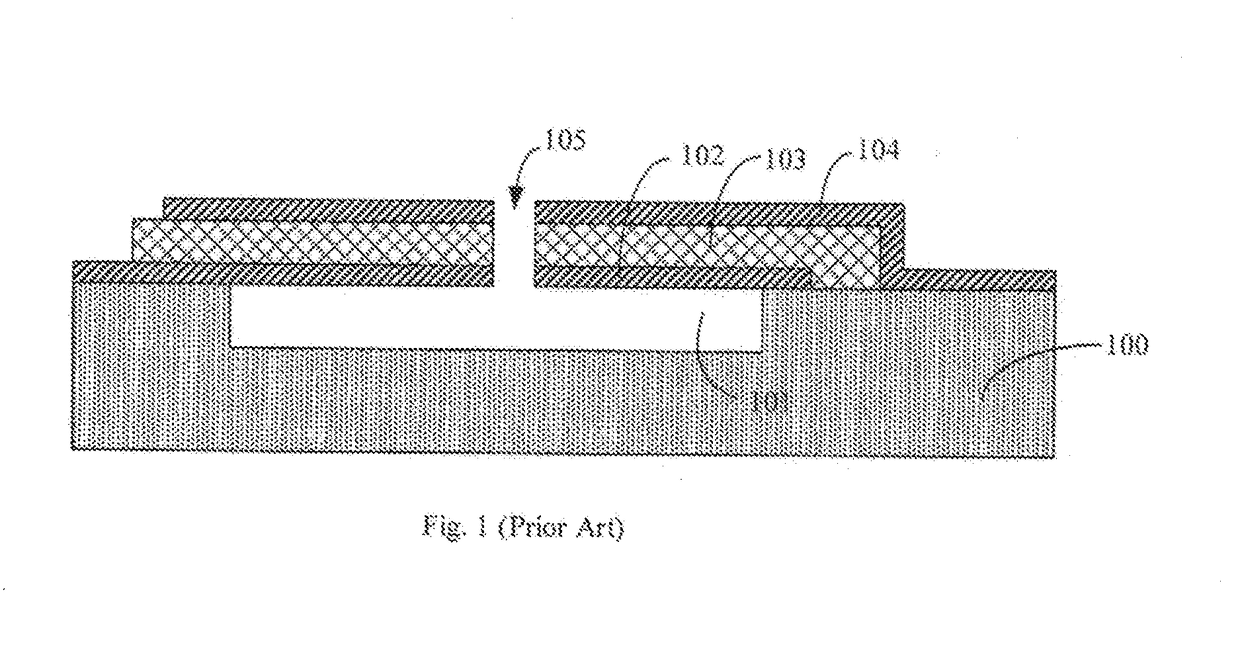

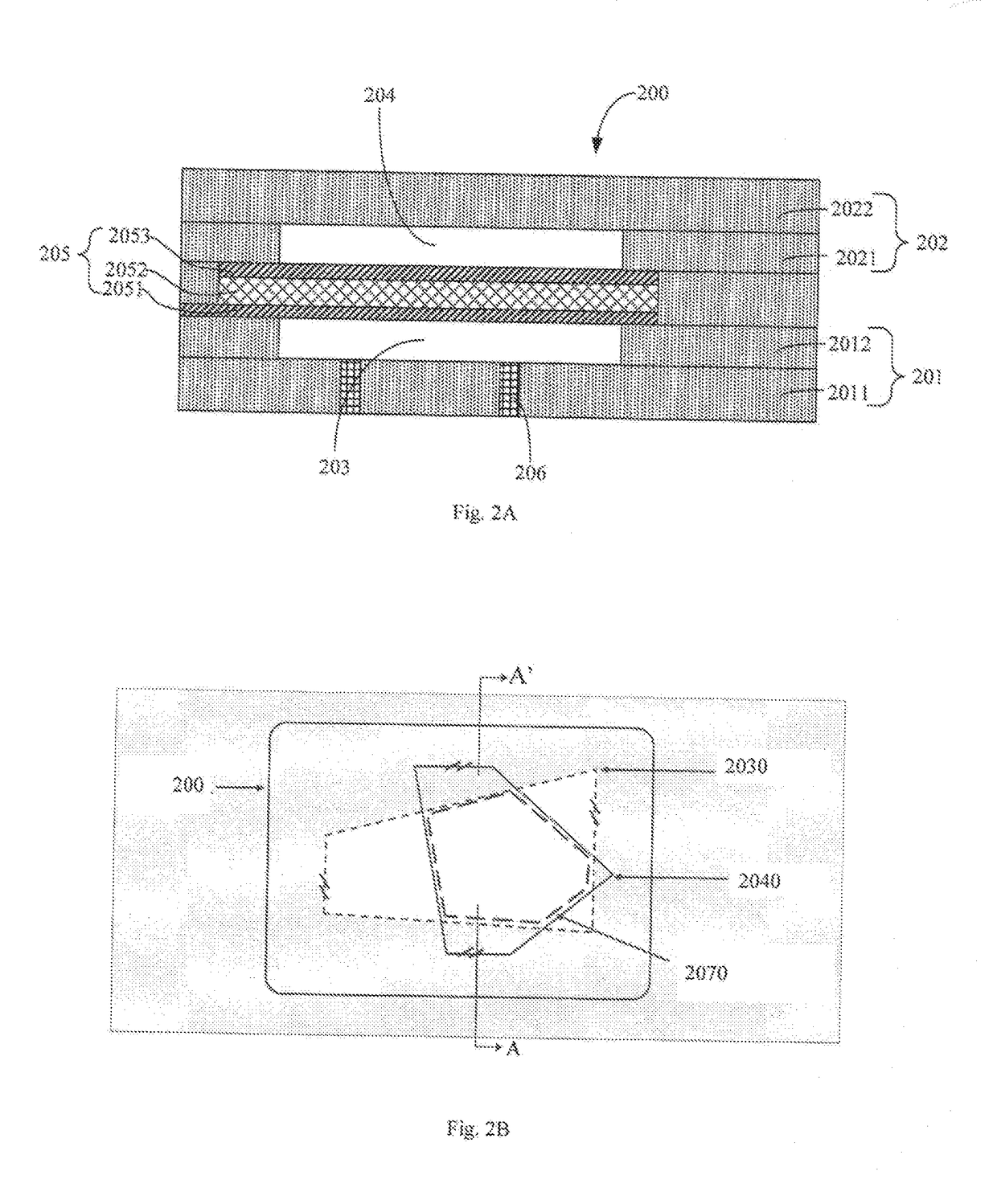

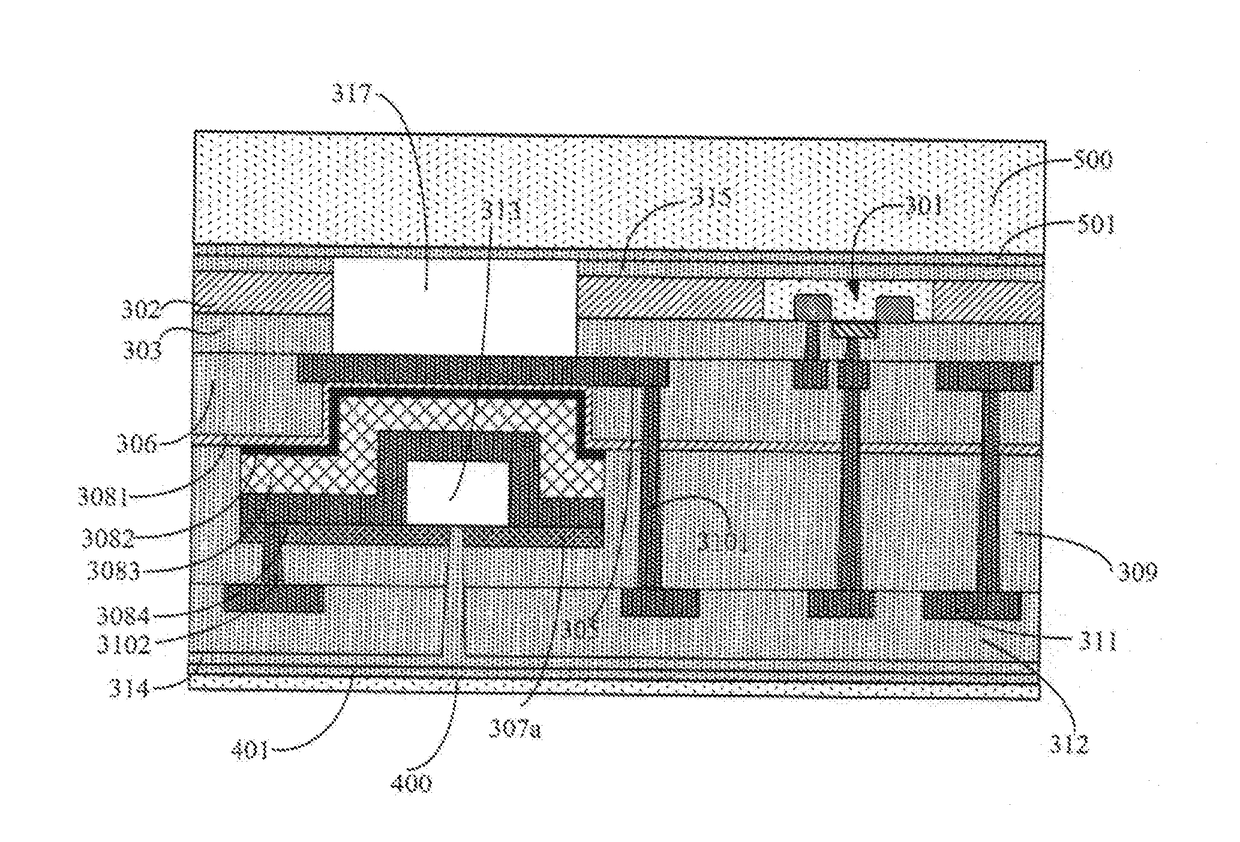

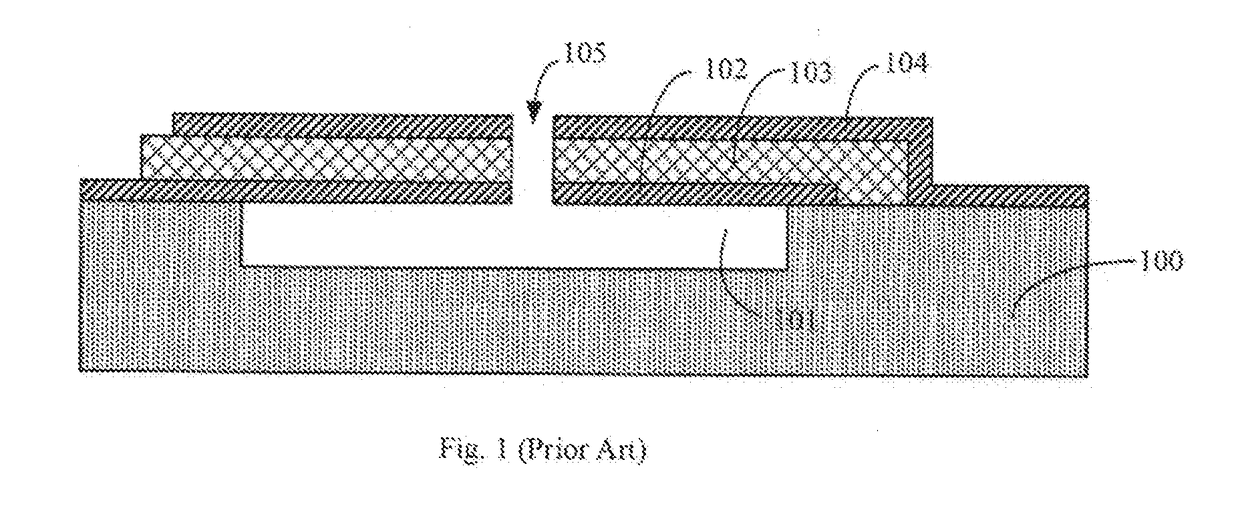

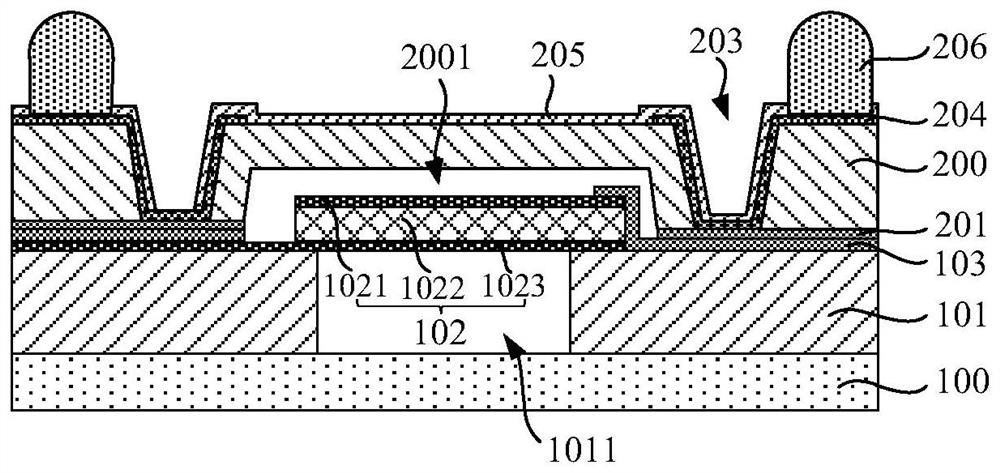

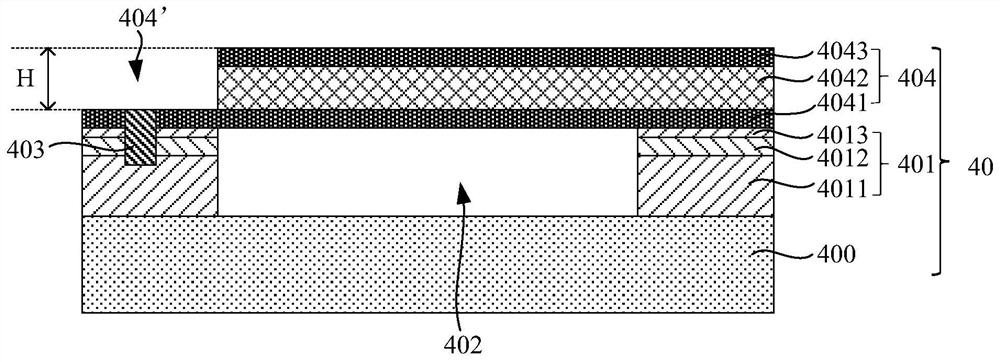

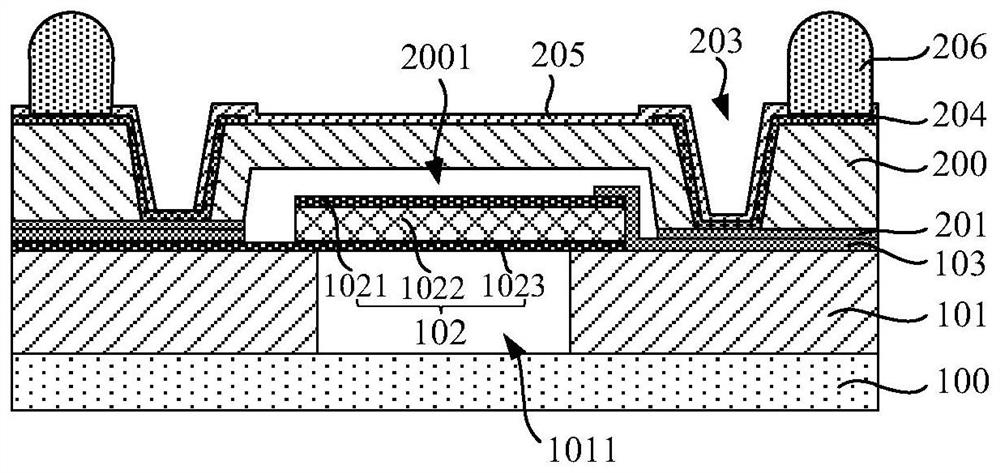

Thin-film bulk acoustic resonator, semiconductor apparatus comprising of such an acoustic resonator, and manufacture thereof

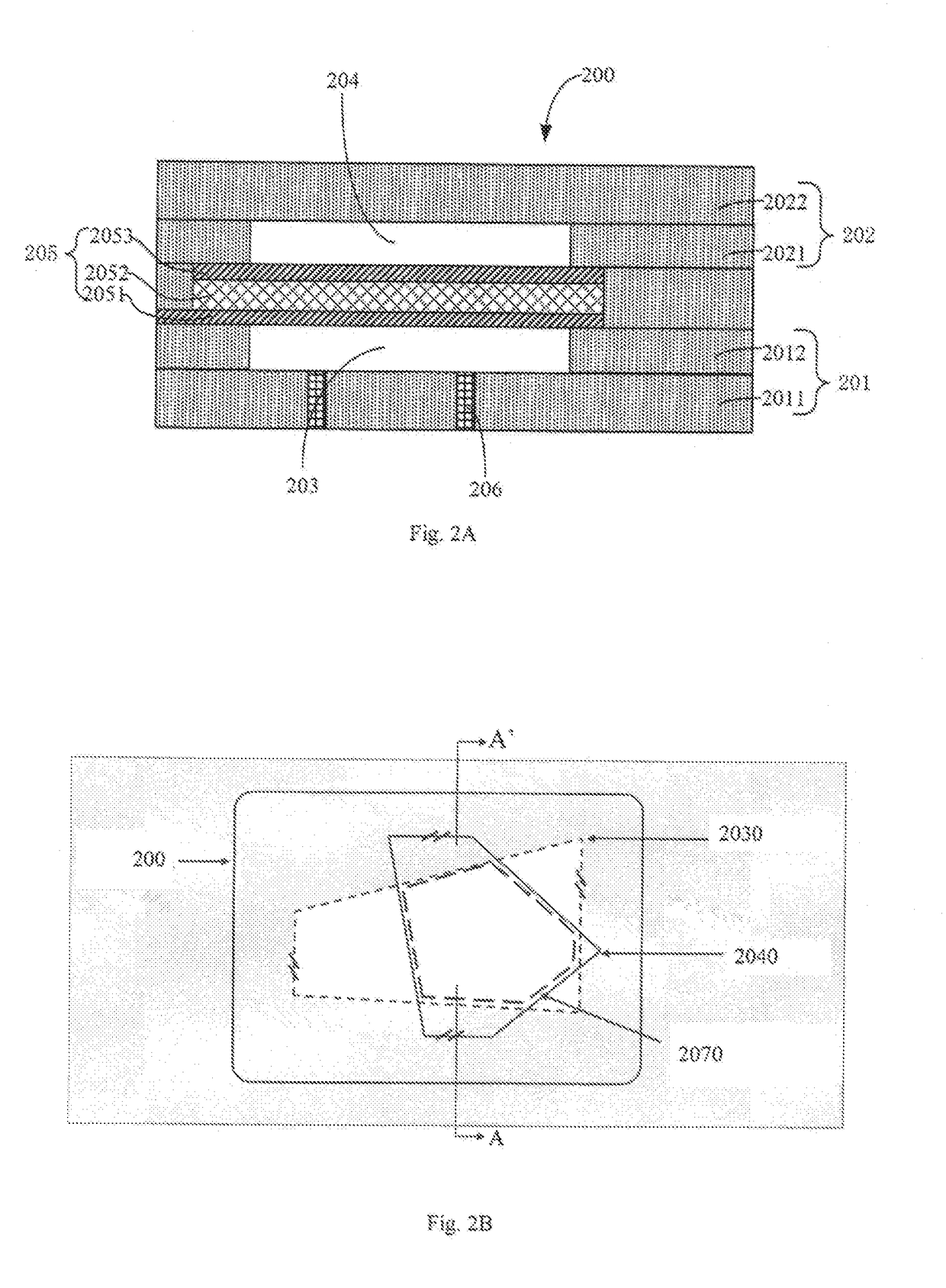

ActiveUS20170264263A1Improve resonance performanceImpedence networksSolid-state devicesThin-film bulk acoustic resonatorAcoustic wave

A thin-film bulk acoustic resonator, a semiconductor apparatus including the acoustic resonator and its manufacturing methods are presented. The thin-film bulk acoustic resonator includes a lower dielectric layer, a first cavity inside the lower dielectric layer, an upper dielectric layer, a second cavity inside the upper dielectric layer, and a piezoelectric film that is located between the first and the second cavities and continuously separates these two cavities. The plan views of the first and the second cavities have an overlapped region, which is a polygon that does not have any parallel sides. The piezoelectric film in this inventive concept is a continuous film without any through-hole in it, therefore it can offer improved acoustic resonance performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

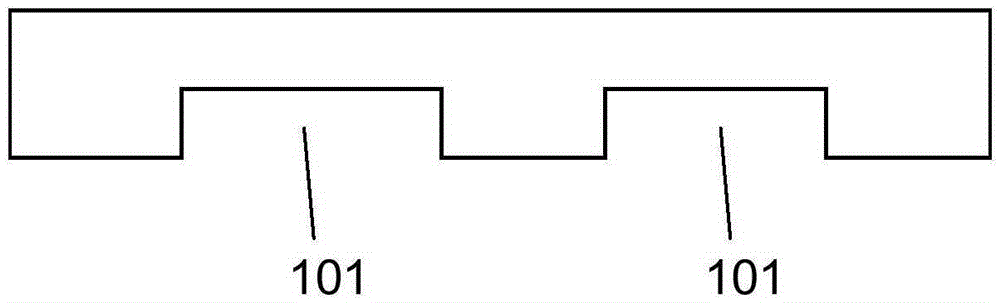

MEMS wafer level vacuum package structure and manufacturing method thereof

InactiveCN105293420AAvoid contaminationImprove resonance performanceDecorative surface effectsSolid-state devicesLead bondingWafer dicing

The invention provides an MEMS wafer level vacuum package structure and a manufacturing method thereof. The package structure comprises a silicon cover plate and an MEMS wafer with a movable structure, wherein a vertical through hole is formed on the cover plate, the through hole is internally filled with a conductive material, a bonding surface of the cover plate is provided with a groove, a layer of getter film is arranged at the bottom of the groove, and the silicon cover plate and the MEMS wafer with the movable structure form the vacuum package structure by wafer bonding. The manufacturing method provided by the invention comprises the following steps: at first, manufacturing the through hole on the cover plate, and filling the conductive material in the hole; and then, forming the groove on the bonding surface, depositing a layer of getter film on the bottom of the groove, depositing a layer of multilayer metal film in a bonding area, and wafer bonding the cover plate with the MEMS wafer with the movable structure in a vacuum environment. According to the MEMS wafer level vacuum package structure provided by the invention, the groove with the getter and the through hole are formed on the silicon cover plate to export an electrode from the closed groove without carrying out wire bonding, so that the procedures are simple, meanwhile, the vacuum maintenance ability in the package structure is improved, contamination of granules to the movable structure during cutting is avoided, and performance of the device is guaranteed.

Owner:BEIJING MXTRONICS CORP +1

Rotational micro-actuator integrated with suspension of head gimbal assembly, and disk drive unit with the same

InactiveUS20070188931A1Improve resonance performanceArm with actuatorsRecord information storageMicro actuatorEngineering

A micro-actuator for a head gimbal assembly includes a metal frame including a bottom support integrated with a suspension flexure of the head gimbal assembly, a top support adapted to support a slider of the head gimbal assembly, and a pair of side arms that interconnect the top support and the bottom support. The top support includes a rotatable plate, connection arms that couple the rotatable plate to respective side arms, and an electrical pad support plate that supports bonding pads. A PZT element is mounted to each of the side arms. Each PZT element is excitable to cause selective movement of the side arms.

Owner:SAE MAGNETICS (HK) LTD

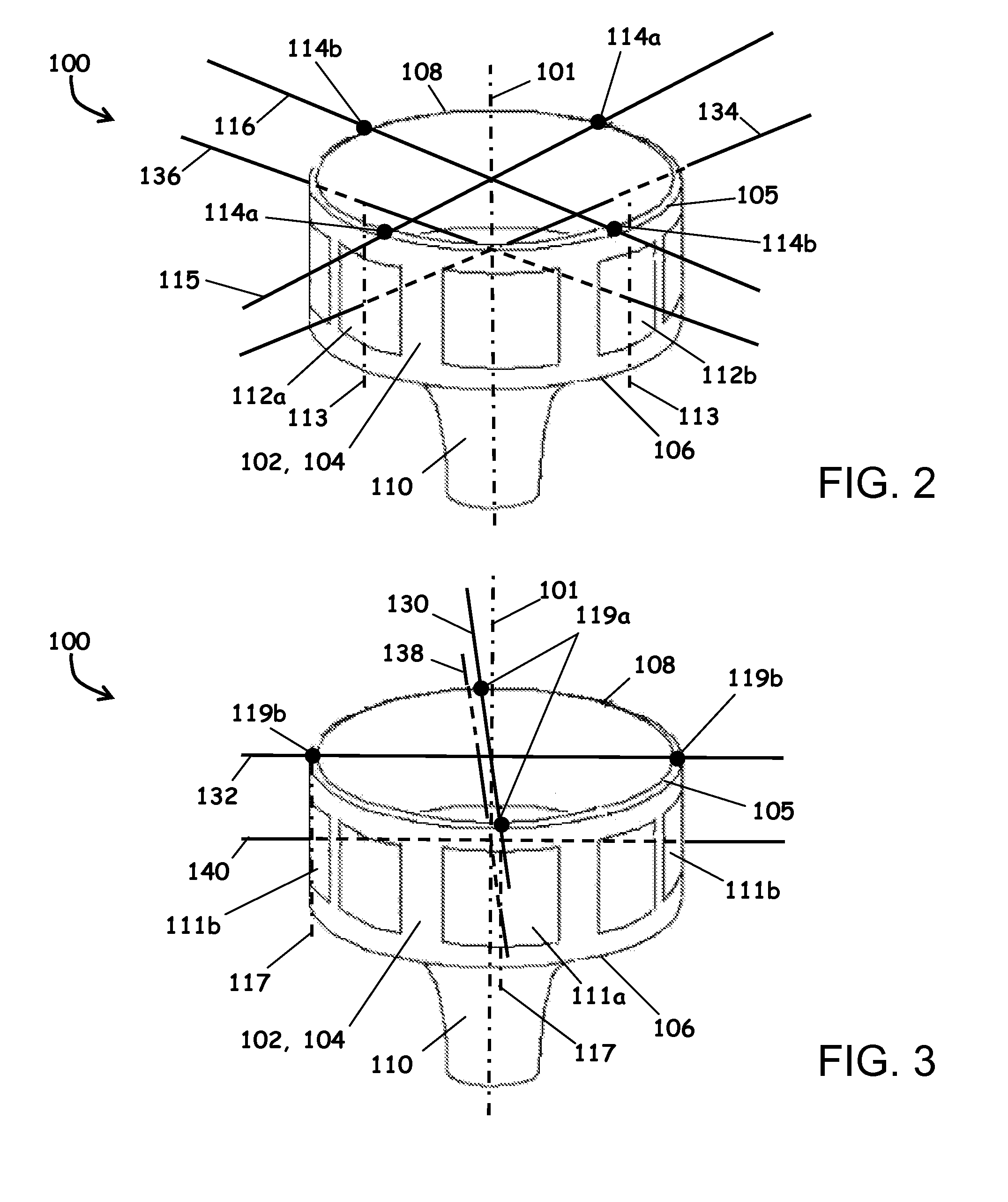

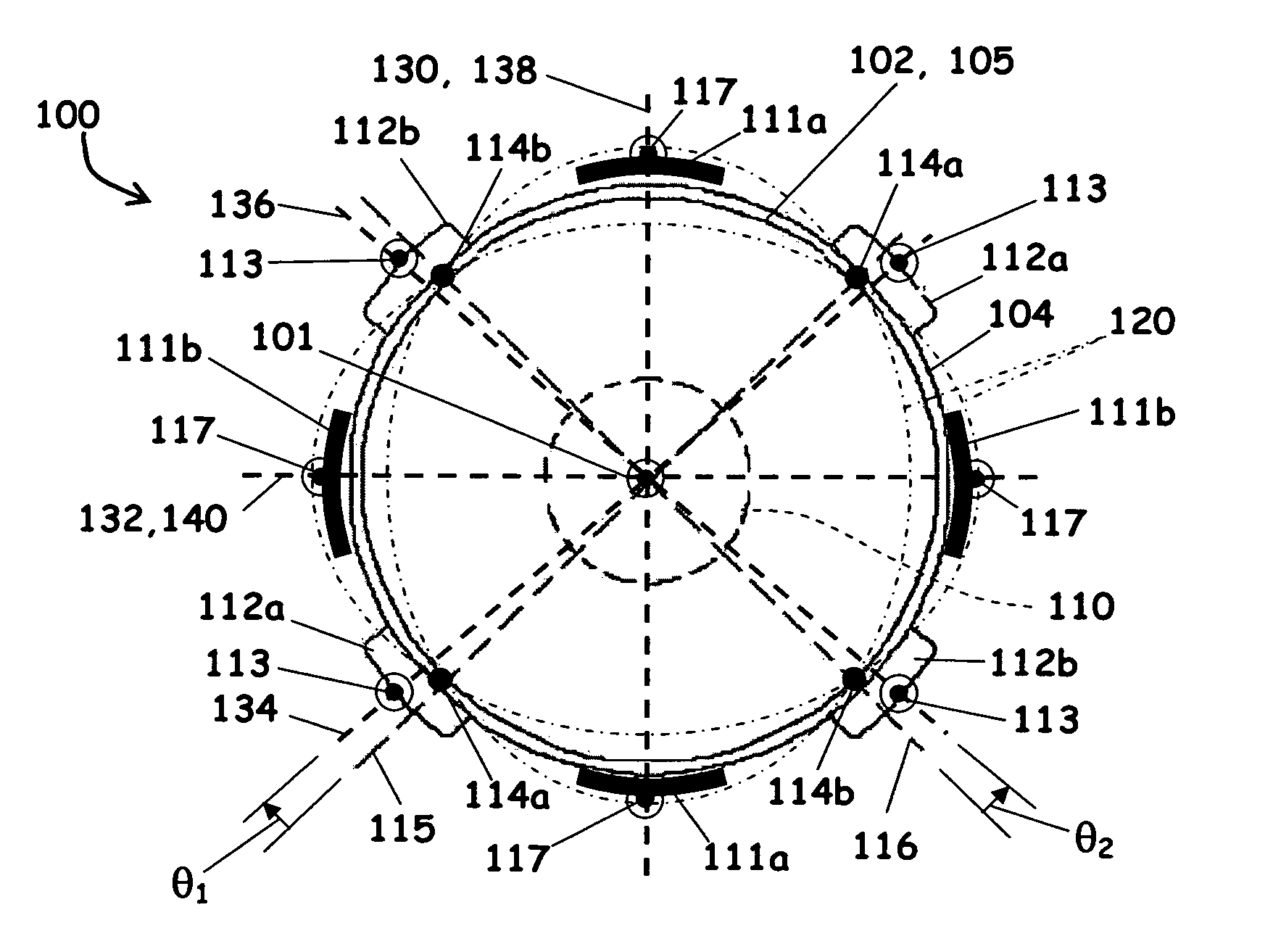

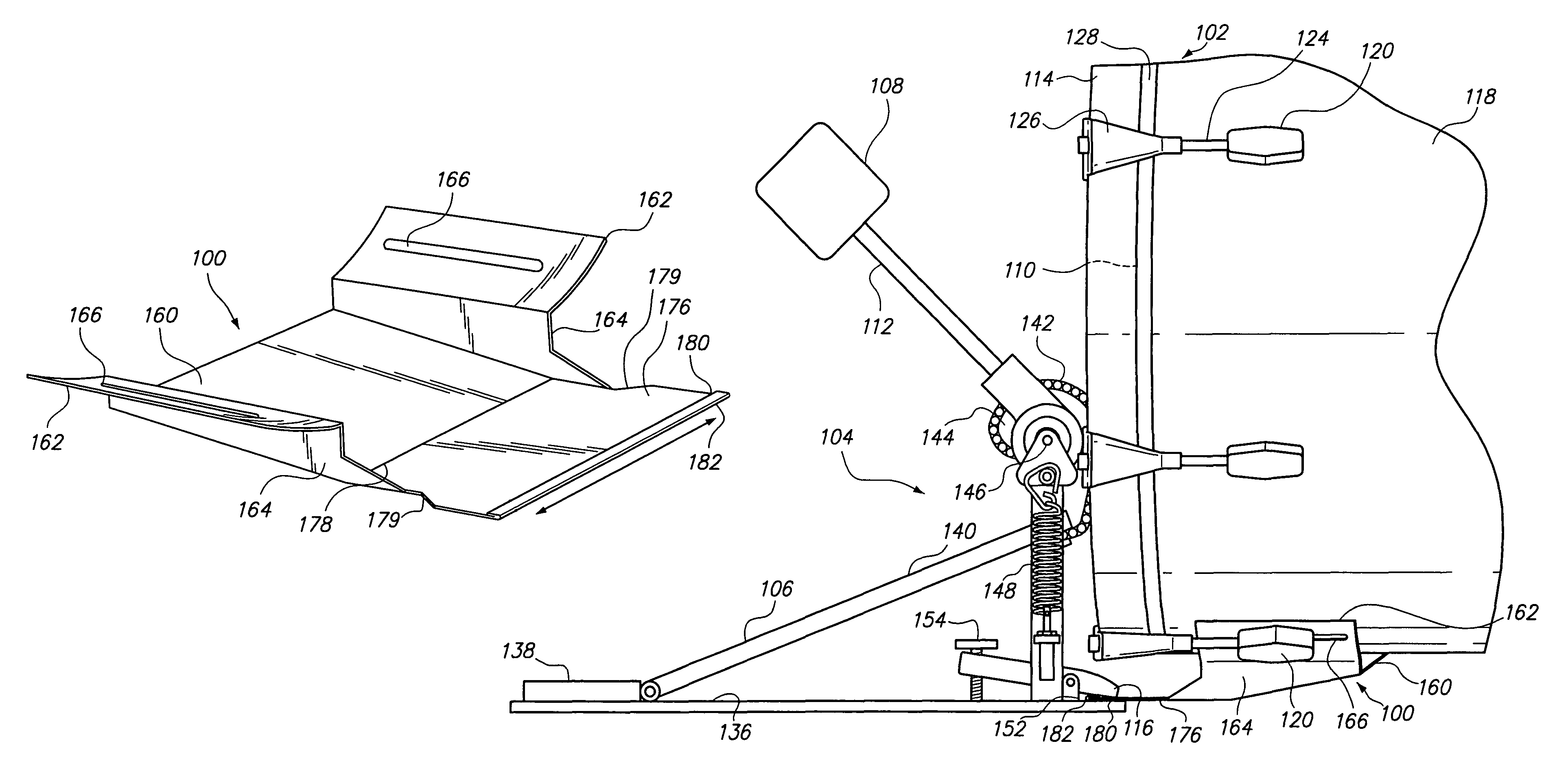

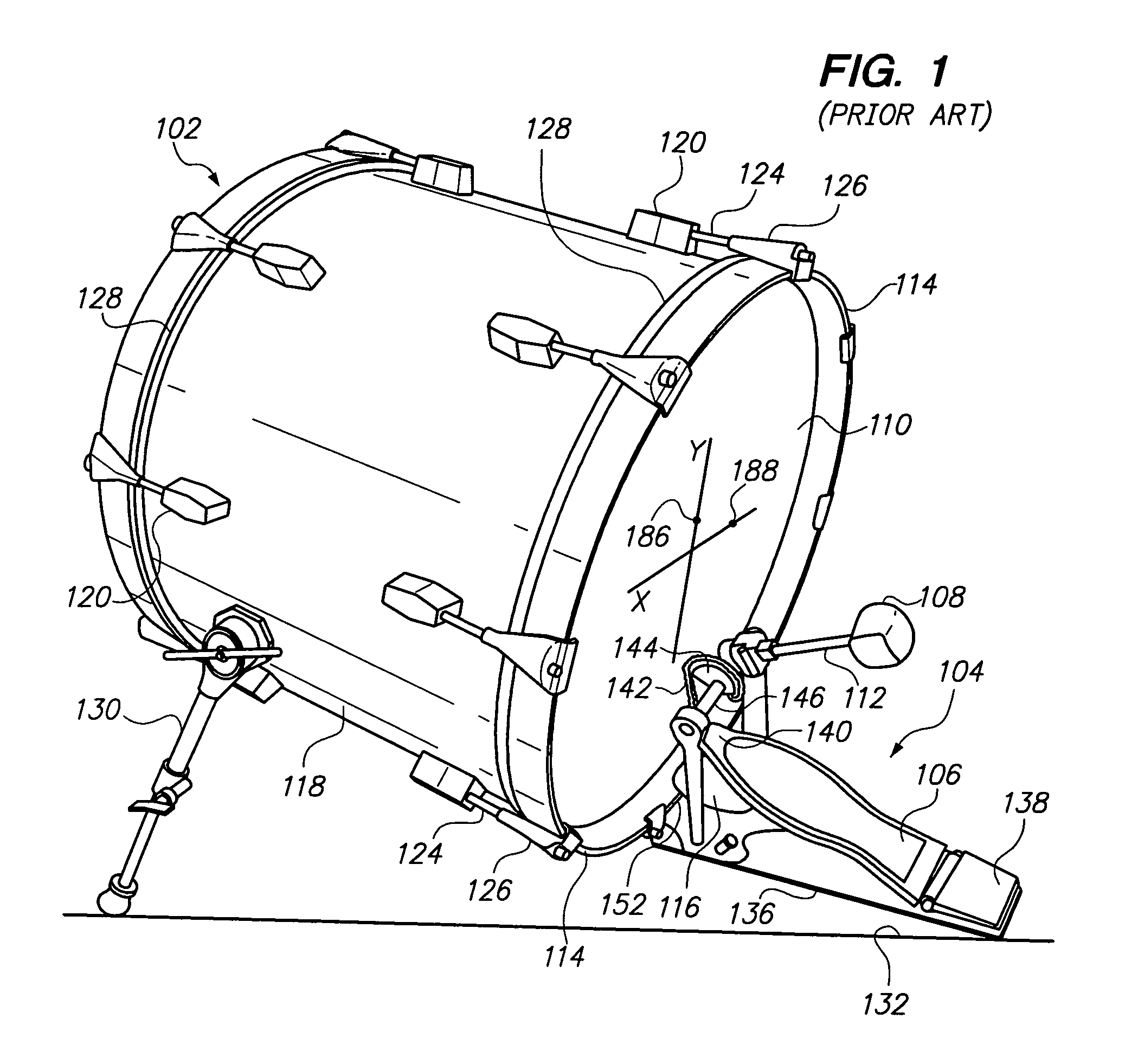

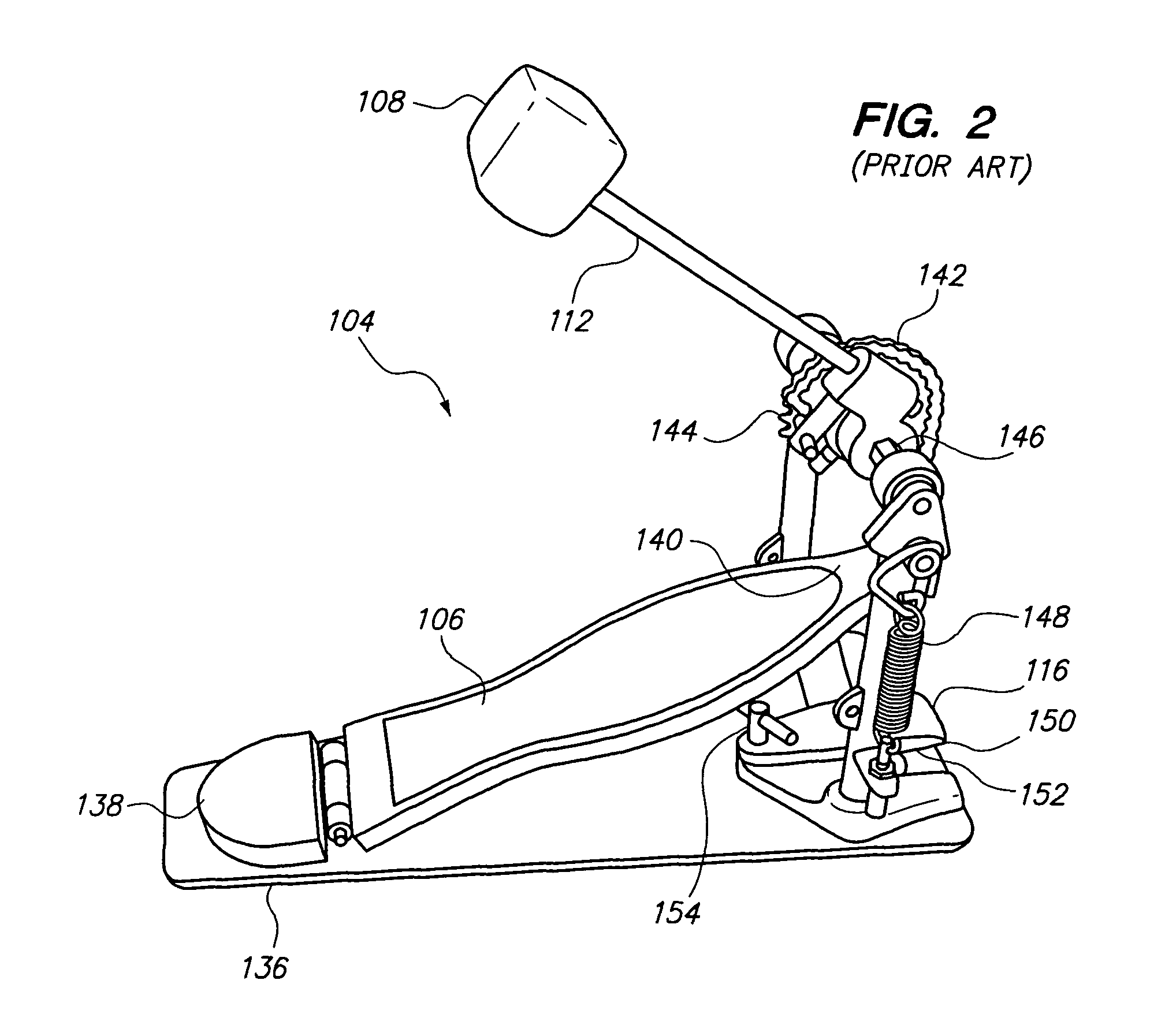

Baseplate for use with bass drum

InactiveUS8022282B1Improve resonance performanceLess distortionPercussion musical instrumentsResonanceEngineering

A baseplate, for use with a bass drum, including a center plate and a pair of wings extending outwardly therefrom. Each wing cradles and is adjustably secured to a lug affixed to a drum shell of a bass drum. A connection plate unitarily constructed with and extending from the center plate includes a terminal end with a lip for adjustably interfacing with a pedal clamp of a drum beater assembly for connecting the drum beater assembly to the bass drum. The pedal clamp is removably connectable to any point along the lip for laterally adjusting the striking point of a beater head onto the bass drum, the bass drum isolated from the pedal clamp for improving the resonance performance thereof, without changing the length of a beater shaft or the feel of the drum beater assembly.

Owner:BURNS NICHOLAS R

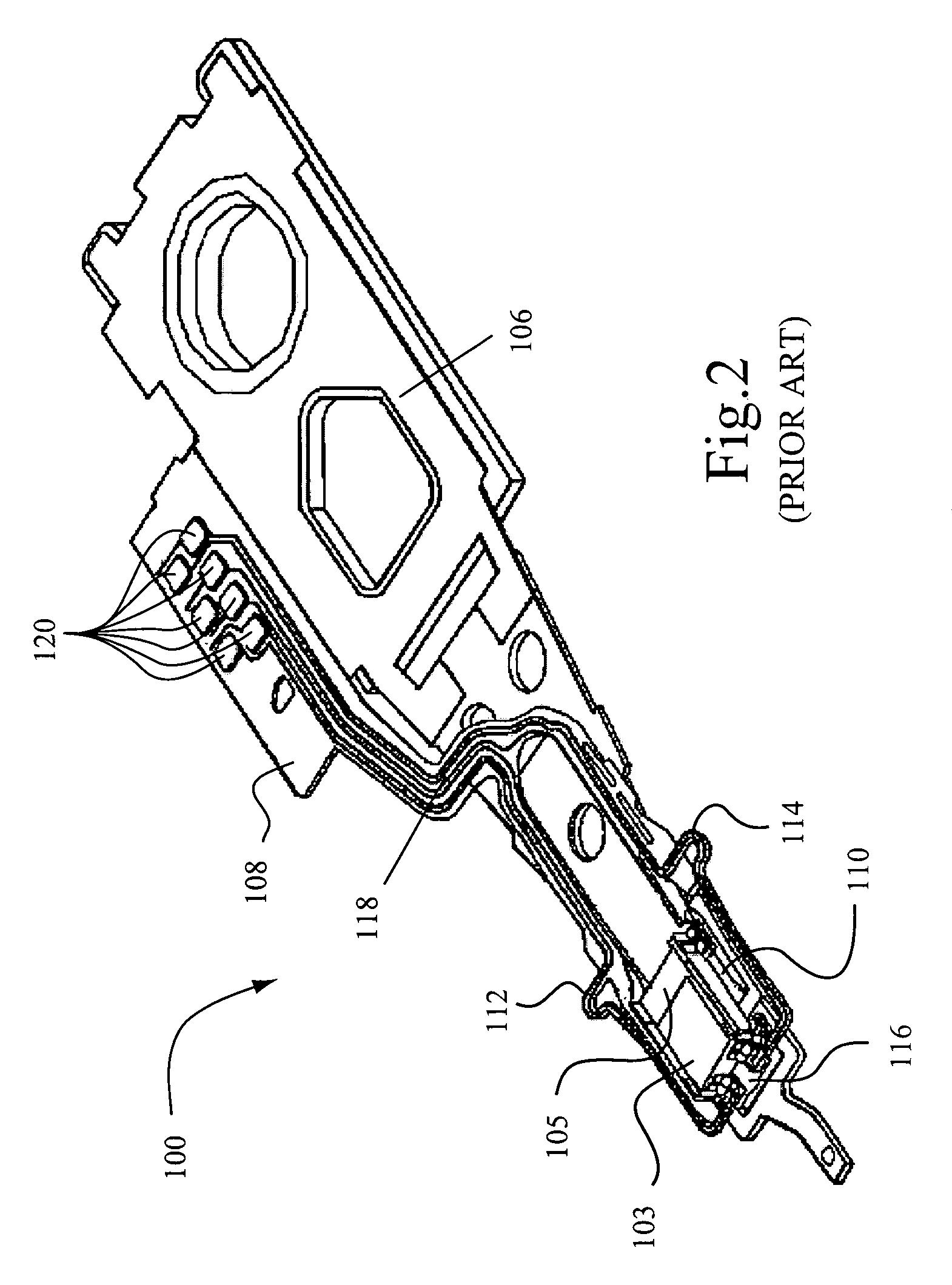

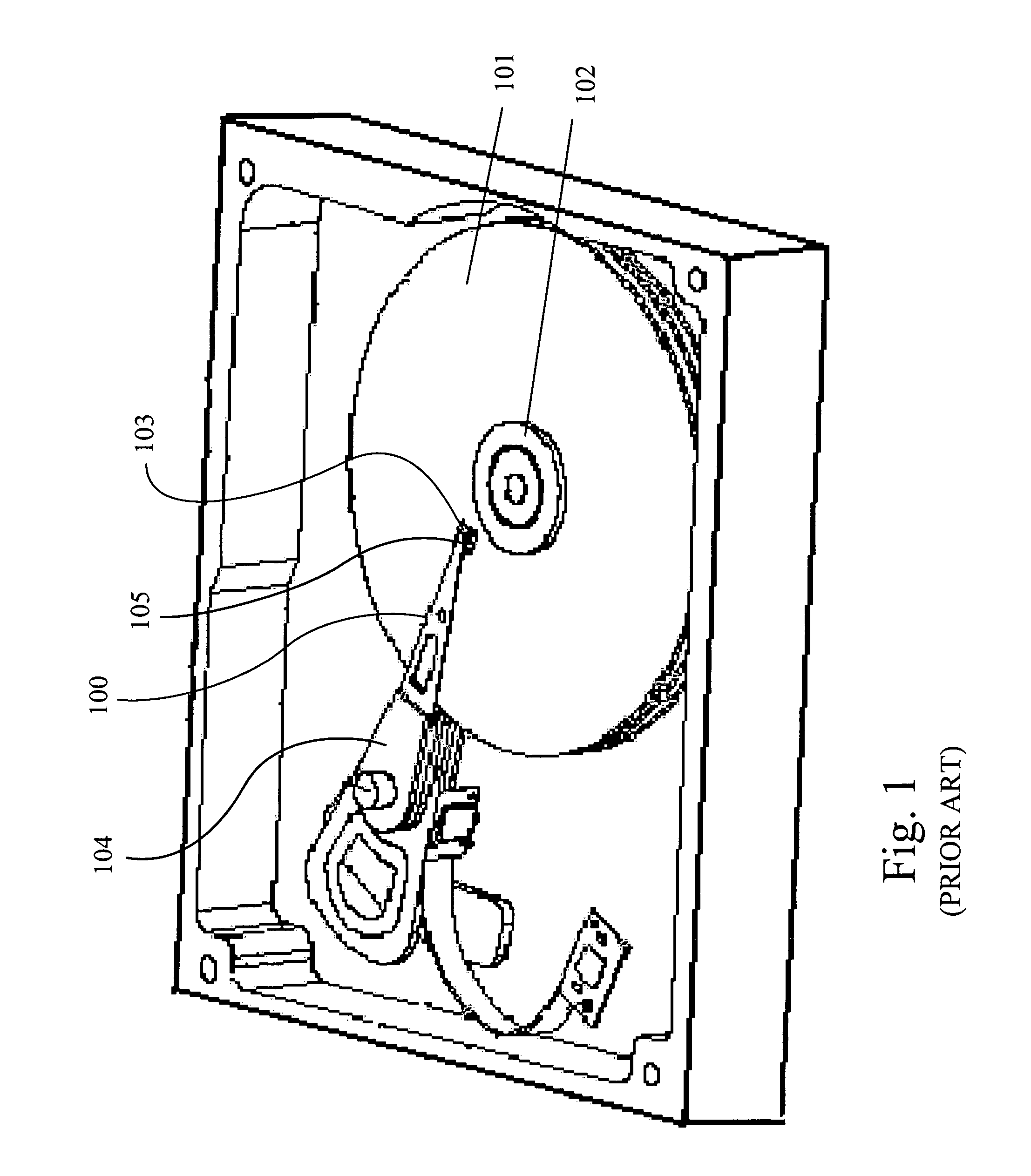

Suspension, head gimbal assembly and disk drive unit with the same

InactiveUS20070115591A1Improve stabilityImprove resonance performanceDisposition/mounting of recording headsRecord information storageControl systemMechanical engineering

A suspension for a HGA of the invention includes a flexure having a plurality of connection pads to connect with a control system at one end and a plurality of electrical multi-traces at the other end; which comprising: a tongue to hold the slider; a suspending portion to suspend the tongue from the flexure; wherein the suspending portion has a narrower width than that of the tongue. The invention also discloses a HGA with such a suspension and a disk drive unit having such an HGA.

Owner:SAE MAGNETICS (HK) LTD

Micro-actuator, head gimbal assembly, and disk drive unit with the same

InactiveUS7312956B2Precise positioningImprove resonance performanceDisposition/mounting of recording headsRecord information storageMicro actuatorEngineering

Owner:SAE MAGNETICS (HK) LTD

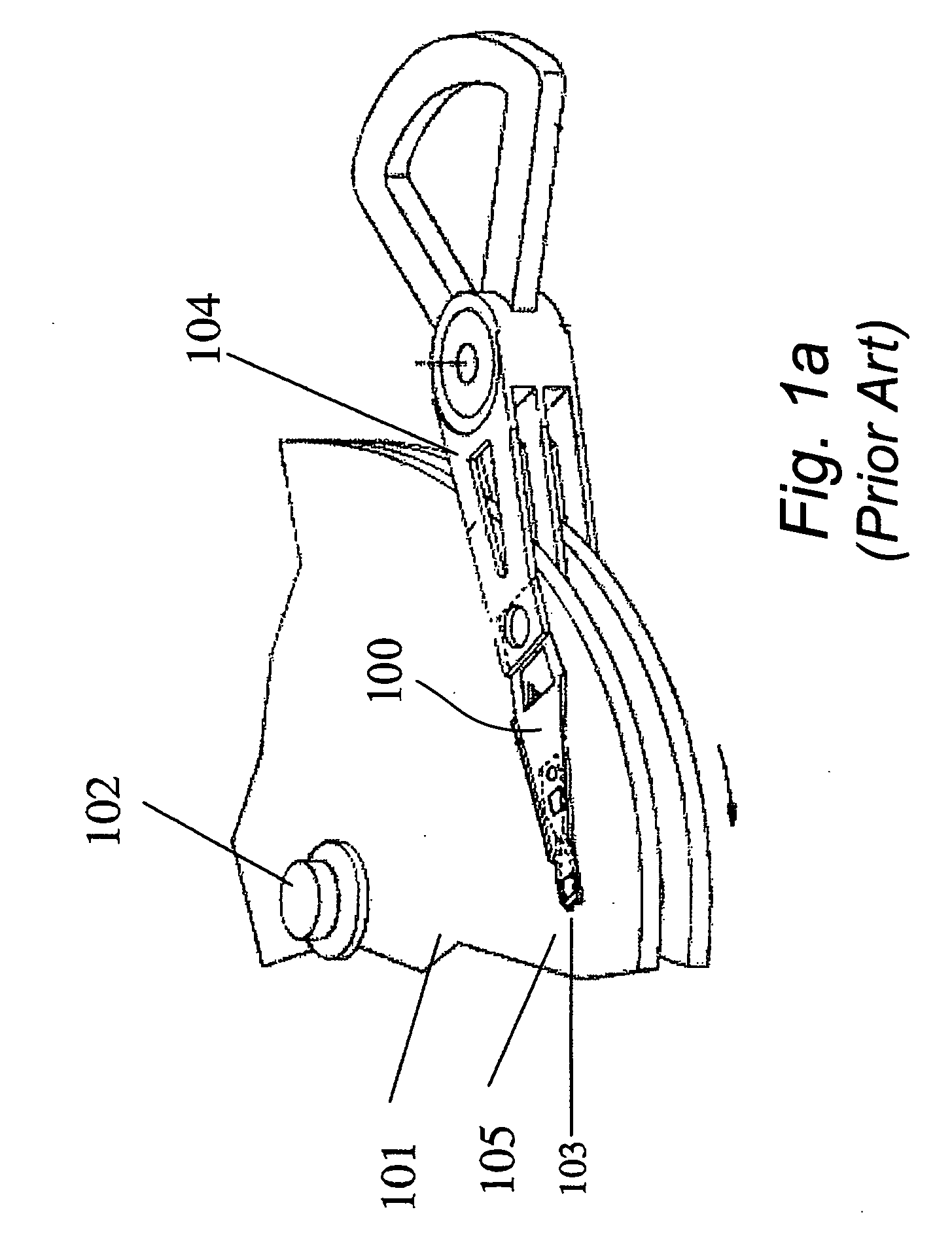

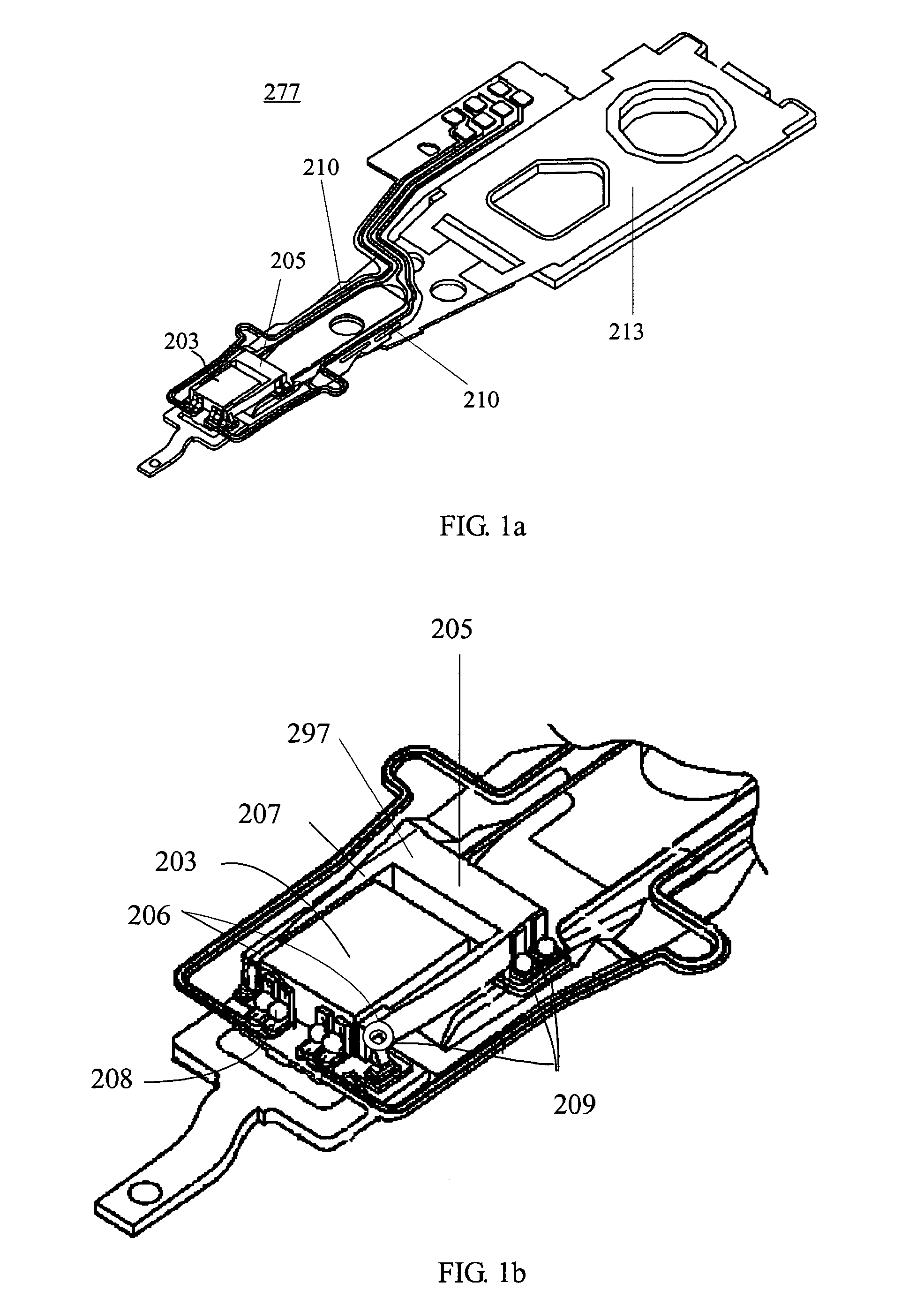

Micro-actuator unit, head gimbal assembly, and disk drive unit with vibration canceller

InactiveUS20060164763A1Good resonance performanceImprove resonance performanceDisposition/mounting of recording headsRecord information storageMicro actuatorGimbal

A HGA of the invention includes a slider, a micro-actuator for adjusting the position of the slider; a suspension to load the slider and the micro-actuator; and a vibration canceller interposed between the micro-actuator and the suspension. The micro-actuator includes a first base-part plate, a pair of actuator side arms extending from the first base-part plate in a first direction, and at least one of side arms has a piezoelectric element thereon. The vibration canceller includes a second base-part plate to connect with the micro-actuator and the suspension; and at least one canceling arm extending from the second base-part plate in the first direction or in a second direction, wherein at least one of canceling arms has a piezoelectric element thereon. The invention also discloses a disk drive with the vibration canceller.

Owner:SAE MAGNETICS (HK) LTD

Micro-actuator, head gimbal assembly, and disk drive unit with the same

InactiveUS20070139823A1Improve resonance performanceRecord information storageAlignment for track following on disksGimbalMicro actuator

A micro-actuator for a head gimbal assembly includes a support frame including a bottom support adapted to be connected to a suspension of the head gimbal assembly, a top support adapted to support a slider of the head gimbal assembly, and a leading beam that couples the bottom support and the top support. The leading beam includes weak points or notches that allow the top support to rotate about a rotational axis in use. A first PZT element is mounted between first sides of the top and bottom supports, and a second PZT element is mounted between second sides of the top and bottom supports. The first and second PZT elements are excitable to cause selective rotational movement of the top support about the rotational axis in use.

Owner:SAE MAGNETICS (HK) LTD

Thin-film bulk acoustic resonator, semiconductor apparatus comprising of such an acoustic resonator, and manufacture thereof

ActiveUS20170264264A1Improve resonance performanceImpedence networksSolid-state devicesThin-film bulk acoustic resonatorAcoustic wave

A thin-film bulk acoustic resonator, a semiconductor apparatus including the acoustic resonator and its manufacturing method are presented. The thin-film bulk acoustic resonator includes a lower dielectric layer, a first cavity inside the lower dielectric layer, an upper dielectric layer, a second cavity inside the upper dielectric layer, and a piezoelectric film that is located between the first and second cavities and continuously separates these two cavities. The plan views of the first and the second cavities have an overlapped region, which is a polygon that does not have any parallel sides. The piezoelectric film of this inventive concept is a continuous film without any through-hole in it, therefore it can offer improved acoustic resonance performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Micro-actuator unit, head gimbal assembly, and disk drive unit with vibration canceller

InactiveUS7433159B2Improve resonance performanceIncrease capacityDisposition/mounting of recording headsRecord information storageMicro actuatorEngineering

A HGA of the invention includes a slider, a micro-actuator for adjusting the position of the slider; a suspension to load the slider and the micro-actuator; and a vibration canceller interposed between the micro-actuator and the suspension. The micro-actuator includes a first base-part plate, a pair of actuator side arms extending from the first base-part plate in a first direction, and at least one of side arms has a piezoelectric element thereon. The vibration canceller includes a second base-part plate to connect with the micro-actuator and the suspension; and at least one canceling arm extending from the second base-part plate in the first direction or in a second direction, wherein at least one of canceling arms has a piezoelectric element thereon. The invention also discloses a disk drive with the vibration canceller.

Owner:SAE MAGNETICS (HK) LTD

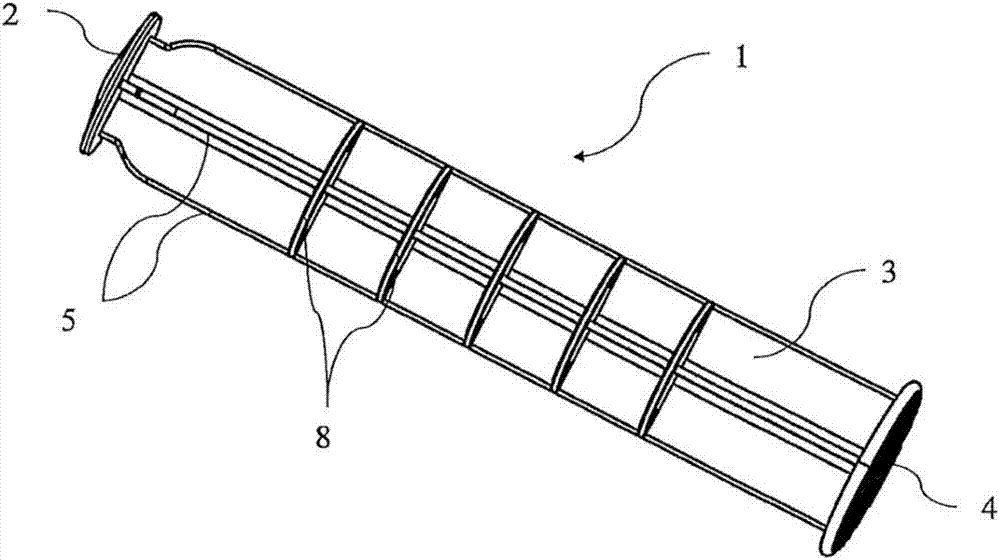

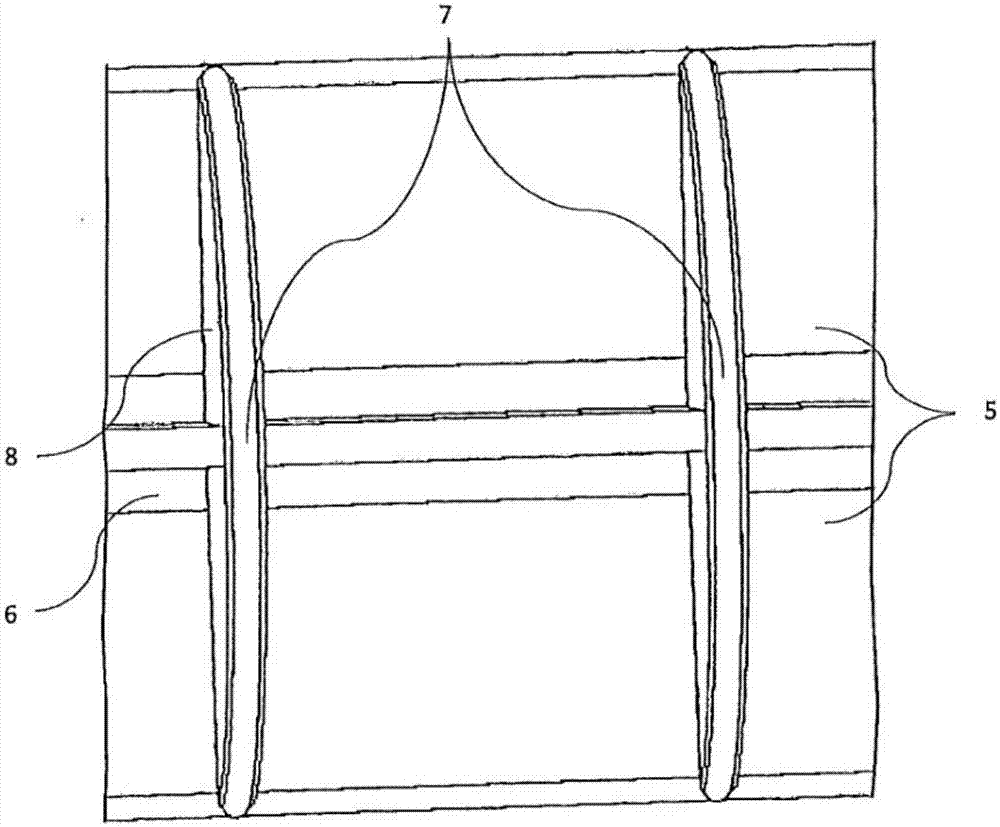

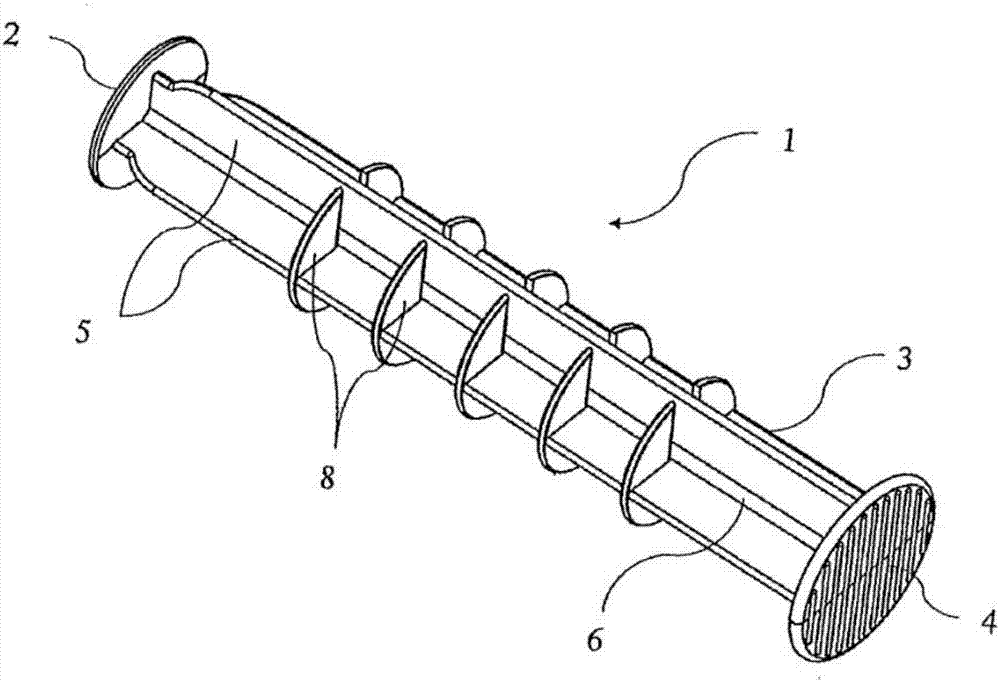

Piston for syringes and syringes

ActiveCN107427636ARealize automatic centering effectReliable shiftAmpoule syringesMedical devicesMechanicsHypodermic Syringes

In a piston for a syringe, in particular an injection syringe, which has a hollow body receiving the piston, comprising a piston head for fluid-tight delimitation of a liquid chamber of the syringe, and a piston rod firmly connected to the piston head and having an actuation portion on which the piston can be actuated for insertion into the hollow body, wherein the piston rod is formed by a plurality of axial webs which extend in the longitudinal direction and which have a radial axial extent outwards from the longitudinal axis and open radially into a common intersection portion receiving the longitudinal axis, wherein at least one free excitation edge protruding radially beyond the radial axial extent is provided on the piston rod, which excitation edge can be brought into engagement with an oscillation exciter of the hollow body upon insertion of the piston, in such a way that an acoustic signal is emitted, provision is made that an oscillation arm body arranged between two axial webs couples the excitation edge to the intersection portion in such a way that, in the event of oscillatory excitation in the axial direction, the oscillation arm body has a radial oscillation arm length, between the excitation edge and the intersection portion, of at least 40% of the radial axial extent.

Owner:OMSI SARL

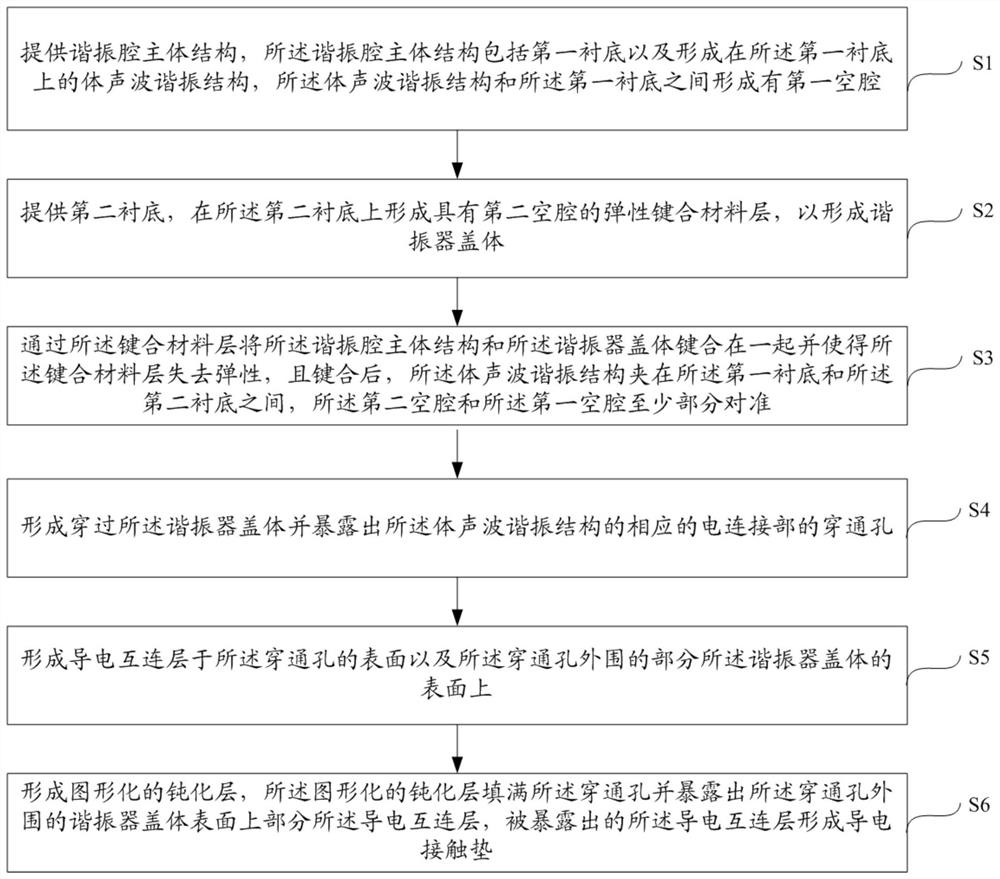

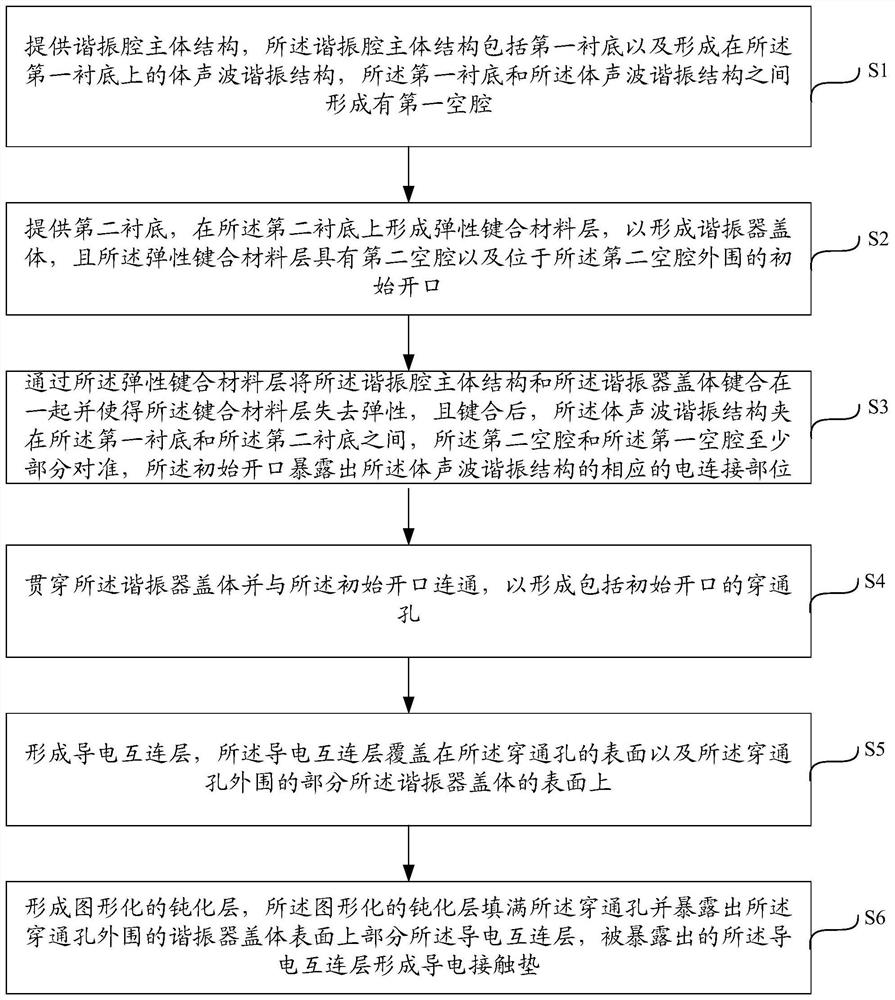

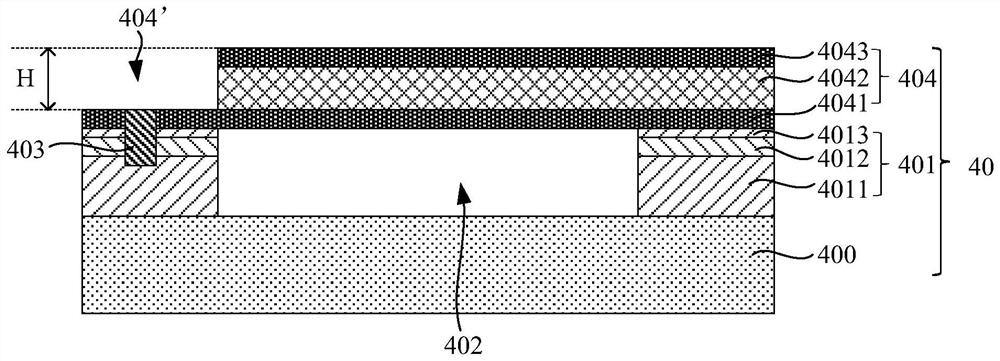

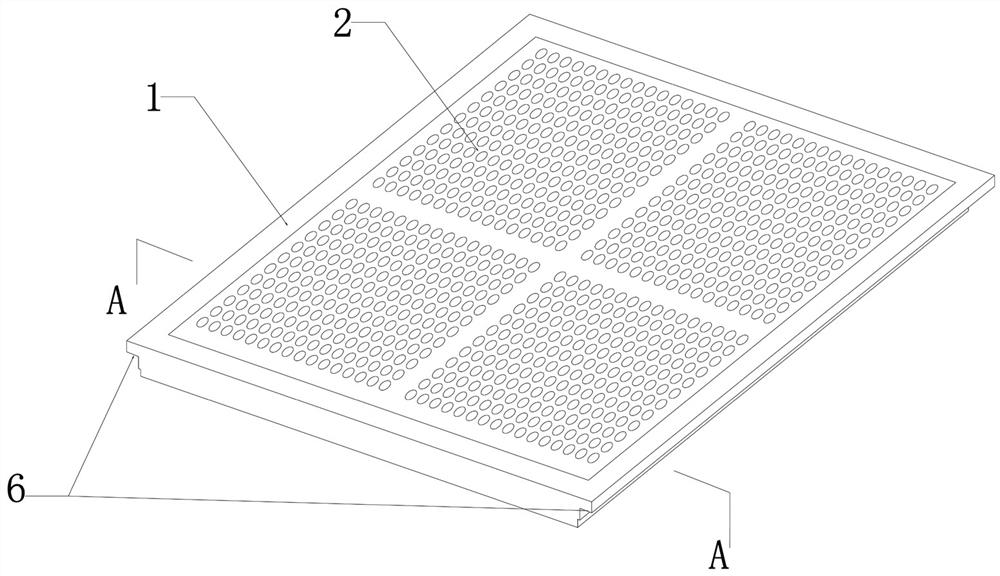

Packaging method and packaging structure of bulk acoustic wave resonator

According to a packaging method and a packaging structure of a bulk acoustic wave resonator provided by the invention, a resonator cover body is manufactured by forming an elastic bonding material layer with a second cavity on a second substrate, then the resonator cover body can be directly bonded with a resonant cavity main body structure through the elastic bonding material layer on the resonator cover body, the elastic bonding material layer loses elasticity, after that, a through hole and a conductive interconnection layer covering the inner surface of the through hole can be formed on the resonator cover body. The process has the characteristics of low cost, simple process and high compatibility with a resonant cavity main body structure process, does not cause the pollution problemof a gold-gold bonding process, and can reduce the influence on a first cavity to the maximum extent; and the elasticity of the elastic bonding material layer can be utilized to tolerate a certain step height difference of the bulk acoustic wave resonance structure in the peripheral area of the first cavity in the bonding process, so that the bonding reliability and stability can be ensured.

Owner:NINGBO SEMICON INT CORP

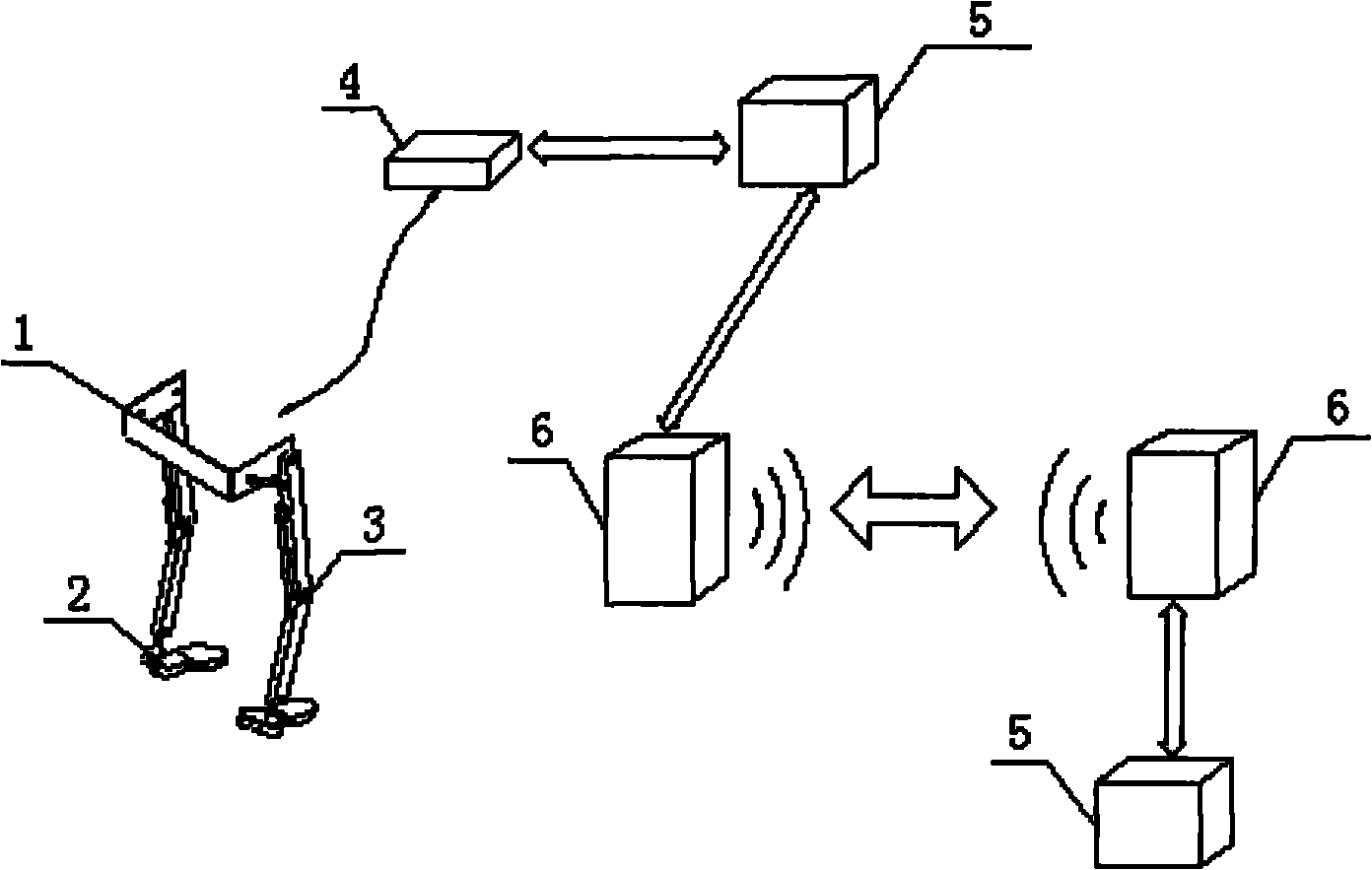

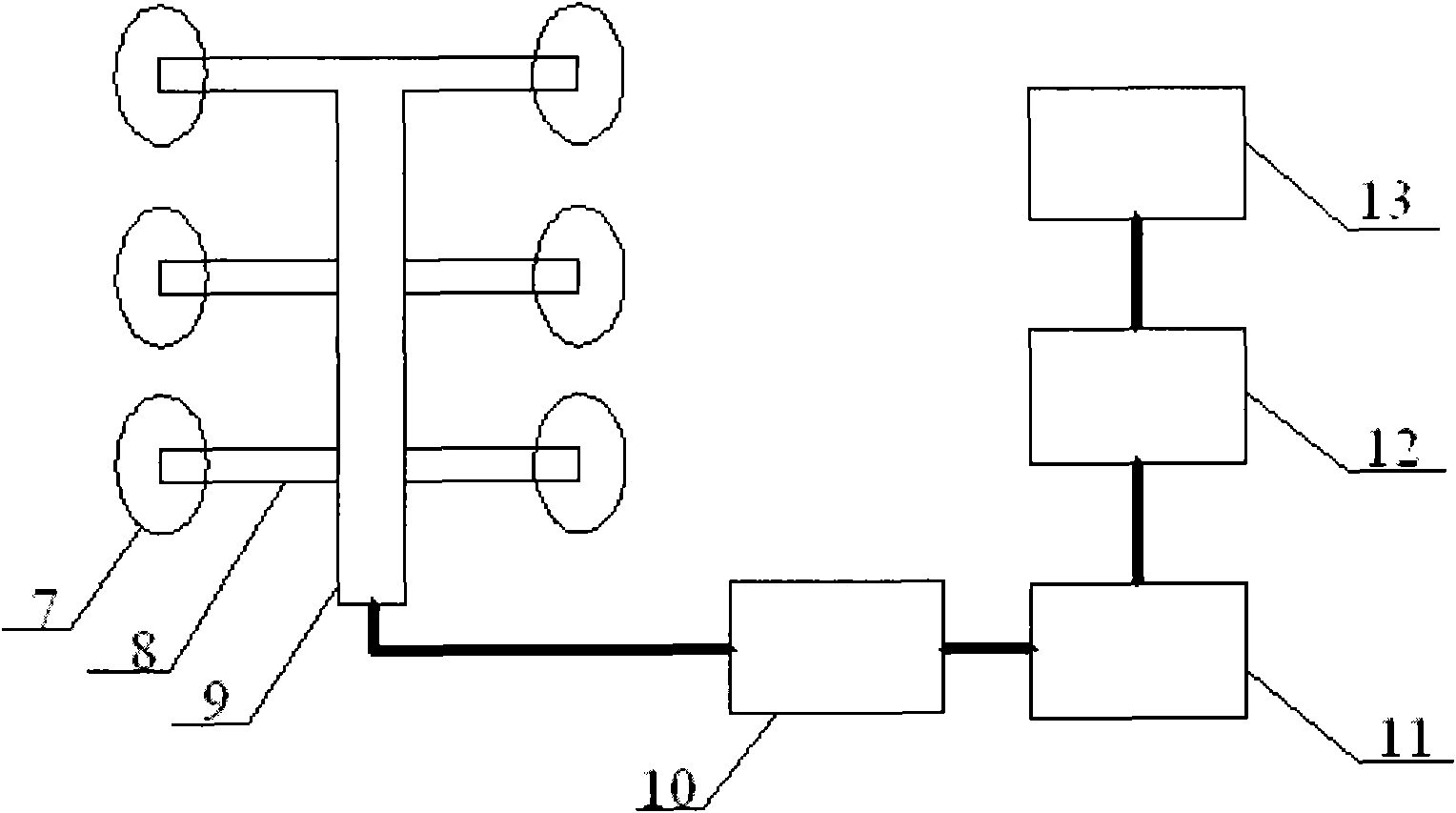

Wireless communication method and device of exoskeleton suit sensing signals

InactiveCN101783065AReduce manufacturing costImprove resonance performanceTransmission systemsFar distanceFiltration

The invention relates to wireless communication method and device of exoskeleton suit sensing signals. The method comprises the following steps of: controlling filtration and threshold triggering modes of a data acquisition module by an intelligent sampling algorithm; transmitting the processed signal data of an exoskeleton suit sensing system to a far-end industrial computer monitoring system in a linking way of a wireless network bridge; and finishing the wireless real-time data transmission of the whole exoskeleton suit sensing signals. The device formed by mounting a pressure sensor at the sole part of the exoskeleton suit body device and mounting an angular displacement sensor at the knee part converts signals acquired by the exoskeleton suit body device into digital signals by the data acquisition module and transmits the signals to the monitoring system of the far-end industrial computer by the special wireless network bridge. The invention has the advantages that the travel range of the exoskeleton suit during a test is widened, the far-distance real-time monitoring is realized, and the device cost is decreased.

Owner:EAST CHINA UNIV OF SCI & TECH

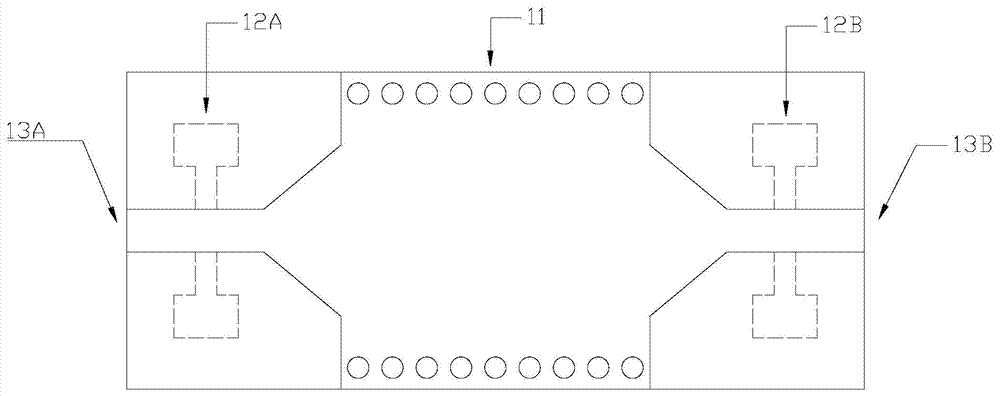

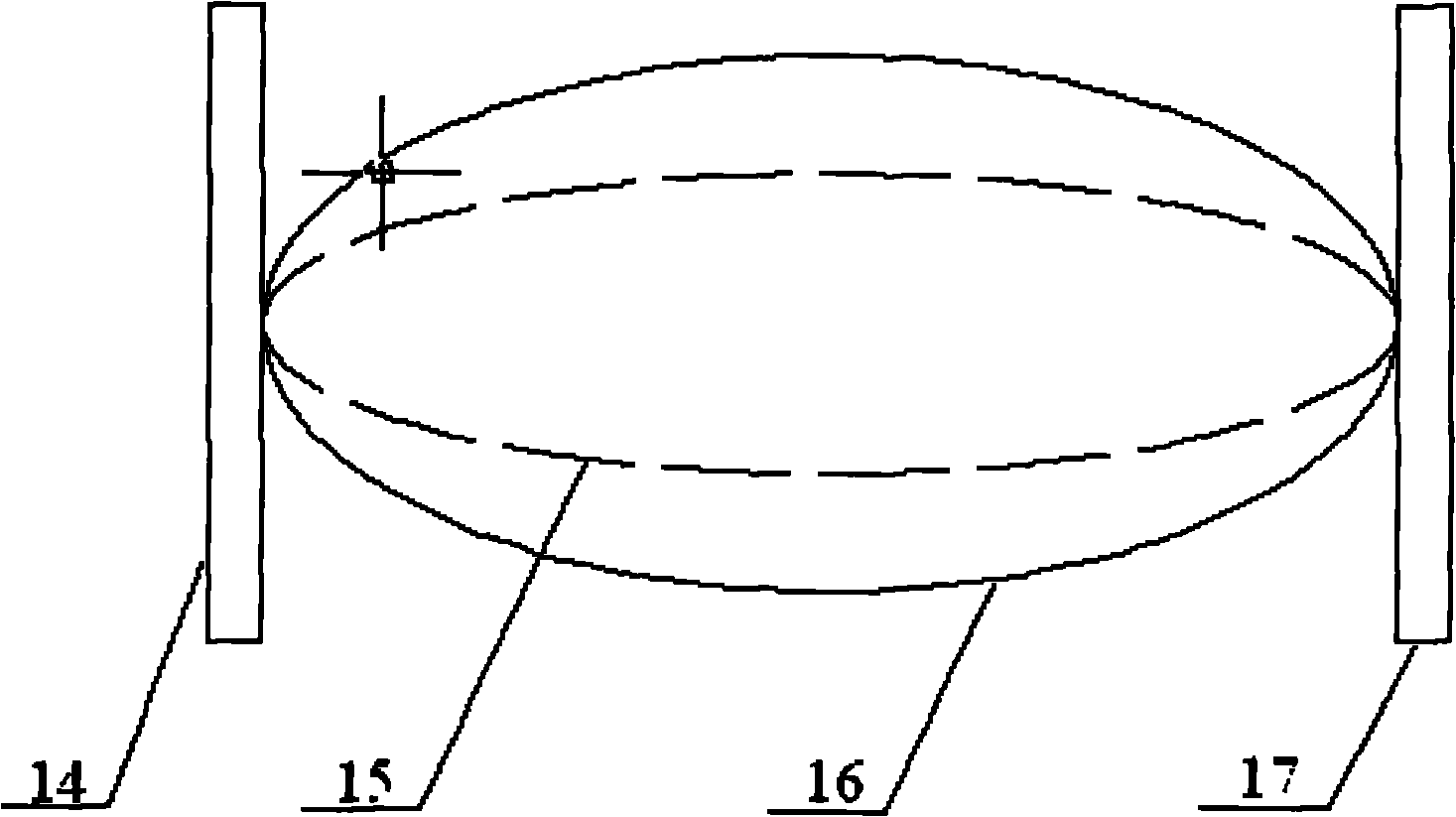

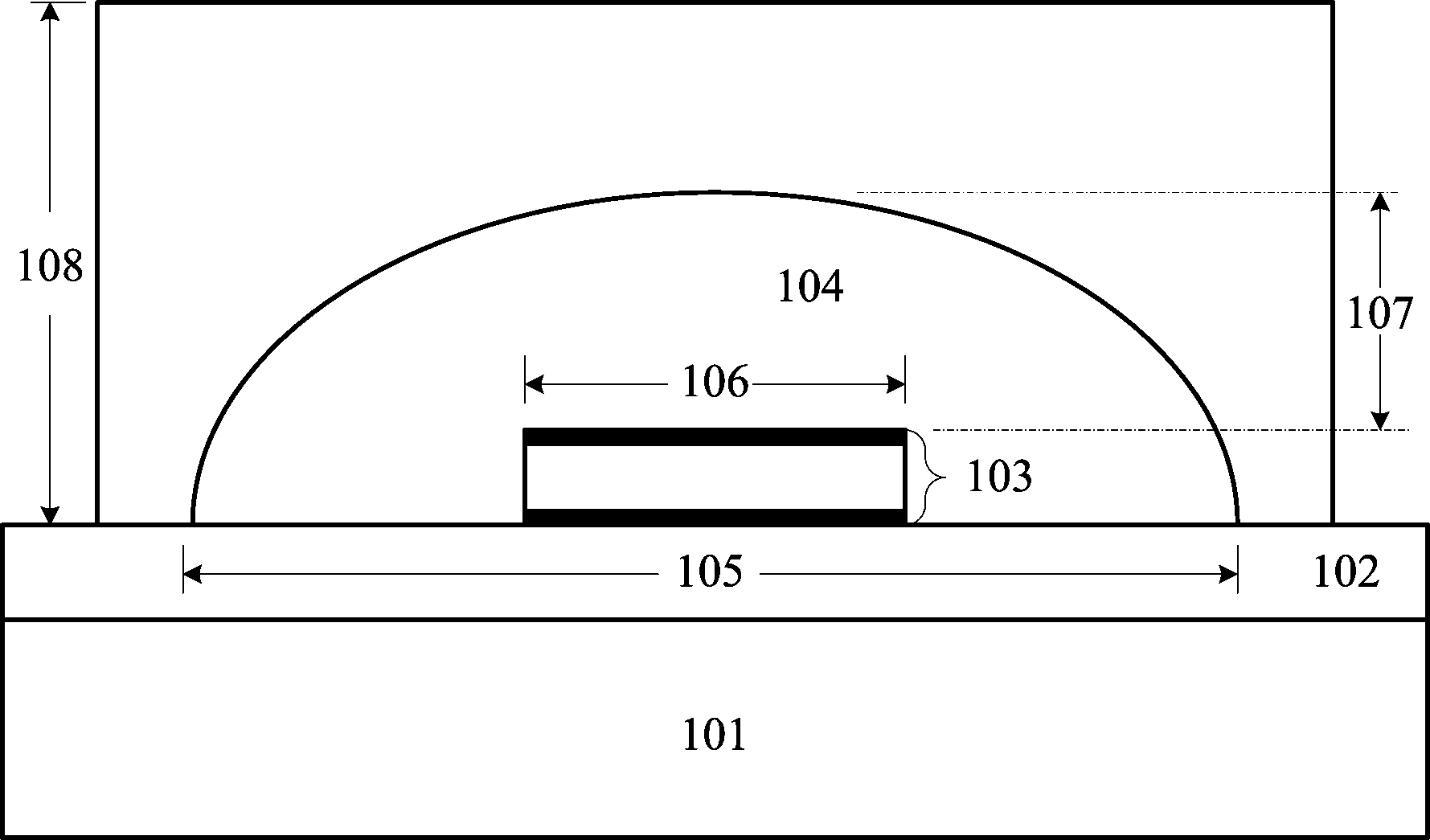

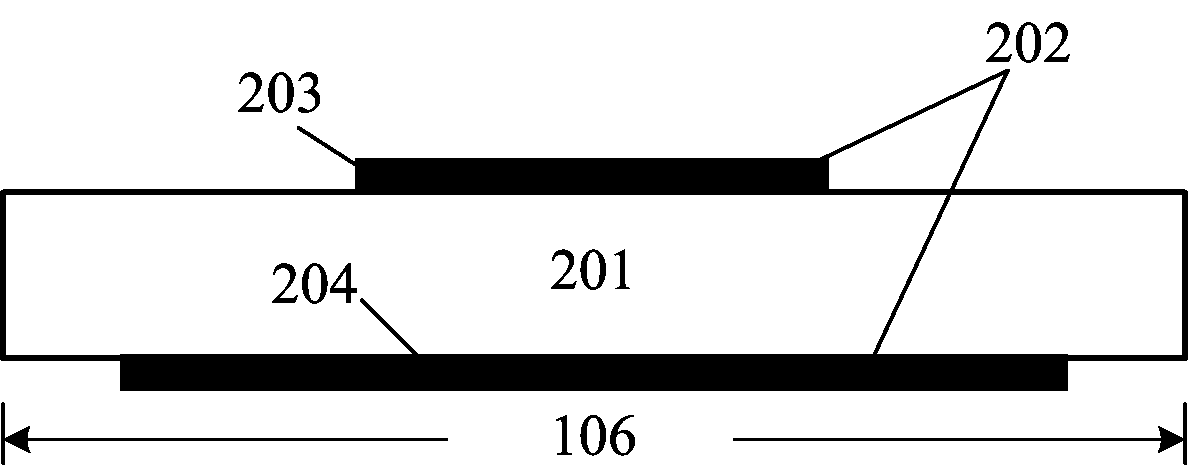

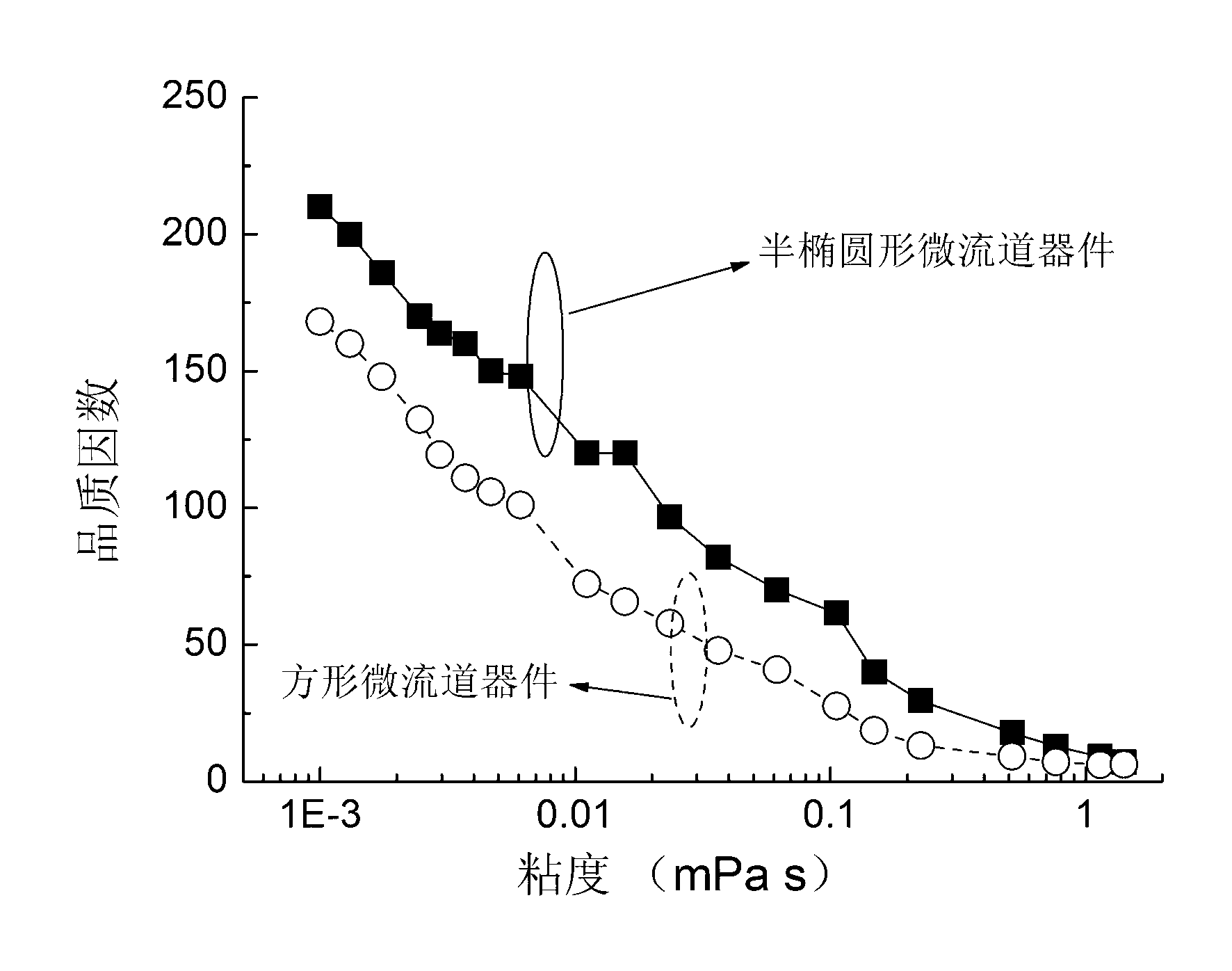

Piezoelectric film resonance sensor with semi-oval micro flow channel

InactiveCN103234562AReduce lossesImprove resonance performanceSpecial purpose recording/indication apparatusElectricitySound wave

The invention discloses a piezoelectric film resonance sensor with a semi-oval micro flow channel. The sensor comprises a substrate, a sound reflection layer, a piezoelectric stack and a micro flow channel which is arranged above the piezoelectric stack. The micro flow channel is made from a thermoplastic high polymer material, the cross section of the micro flow channel is of a semi-oval shape, the center of a horizontal shaft of the micro flow channel is the central point of the piezoelectric stack, and the length of the horizontal shaft is 3-5 times that of the piezoelectric stack. The distance from the highest point inside the micro flow channel to the piezoelectric stack is integer multiple of a half of the stationary wave resonance wave length in the piezoelectric stack, the multiple is in a range of 40-100, and the height of a side wall of the micro flow channel is 5-10 times the distance from the highest point inside the micro flow channel to the piezoelectric stack. Sound wave can be reflected towards the center of the piezoelectric stack by the micro flow channel and the oval interface of a liquid sample in the micro flow channel, thus the loss of sound wave energy is reduced to a certain extent, and the resonance performance and the sensing performance of the sensor are improved.

Owner:SHANDONG UNIV OF SCI & TECH

Packaging method and packaging structure of bulk acoustic wave resonator

ActiveCN112039458AGuaranteed performanceReduce difficultyImpedence networksResonant cavityAcoustic wave

Owner:NINGBO SEMICON INT CORP

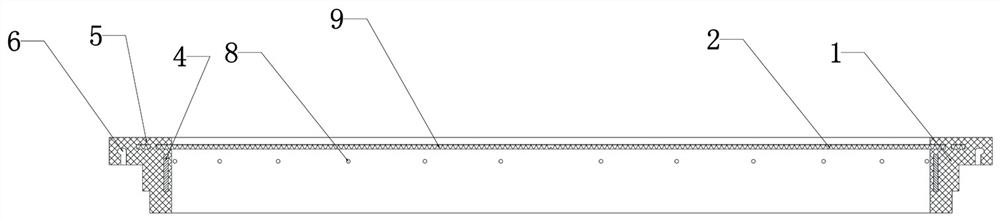

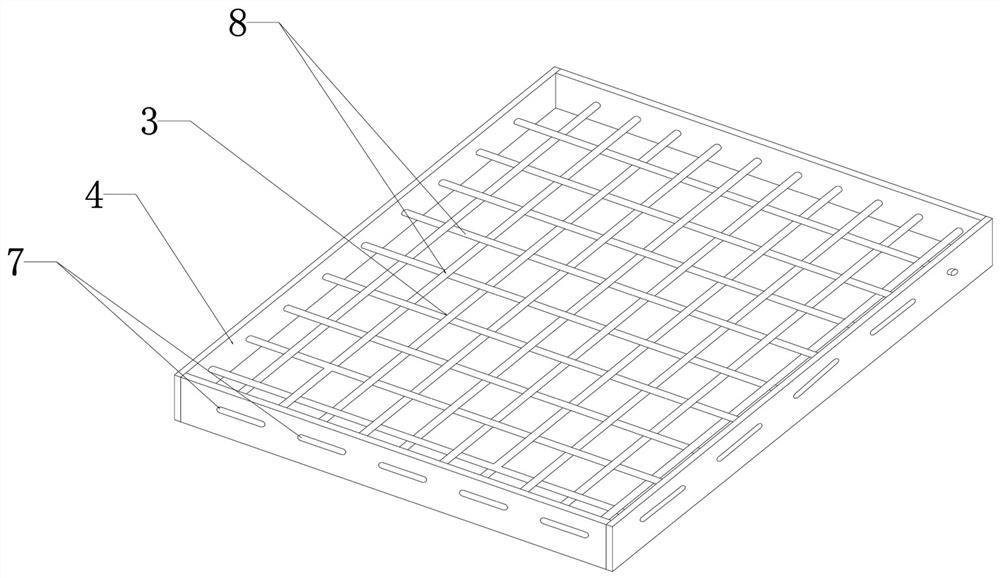

Flexible rubber surface composite screen with supporting net and forming method thereof

PendingCN113385413ADoes not change the installation structureSimple structureSievingScreeningMetal frameworkRubber sheet

The invention discloses a flexible rubber surface composite screen with a supporting net and a forming method thereof, and solves the problems that an existing device blocks holes, is not wear-resistant and is short in service life. The flexible rubber surface composite screen is characterized by comprising a frame body, a screening area and the supporting net; the frame body comprises a metal framework and a polyurethane coating layer; the screening area is formed by punching a flexible rubber plate; the supporting net is of a net-shaped structure formed by weaving warps and wefts through steel wire rope core polyurethane bars in a vertically and horizontally interwoven mode; and the punched rubber screen surface and the metal framework with the woven supporting net are subjected to secondary pouring together in a mold, the framework and the flexible rubber screen surface are connected into a whole through the polyurethane coating layer, and a finished product is obtained through secondary curing. According to the flexible rubber surface composite screen with the supporting net and the forming method thereof, the flexible rubber screen surface, the polyurethane bar supporting net, the metal framework, the polyurethane coating layer and the like are arranged, so that the problem of hole blocking and pasting of fine-fraction materials in a wet and sticky state can be effectively solved, the screening efficiency of the materials under the wet and sticky condition is effectively improved, the labor and maintenance cost is saved, and the production halt loss is reduced.

Owner:ANHUI FANGYUAN YIZHI SCREENING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com