Piezoelectric film resonance sensor with semi-oval micro flow channel

A resonant sensor, semi-elliptical technology, applied in the field of biochemical sensors, can solve the problems of energy loss, resonance performance, decreased sensing sensitivity and resolution, resonance damping effect, etc., and achieve the effect of high resonance performance and sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

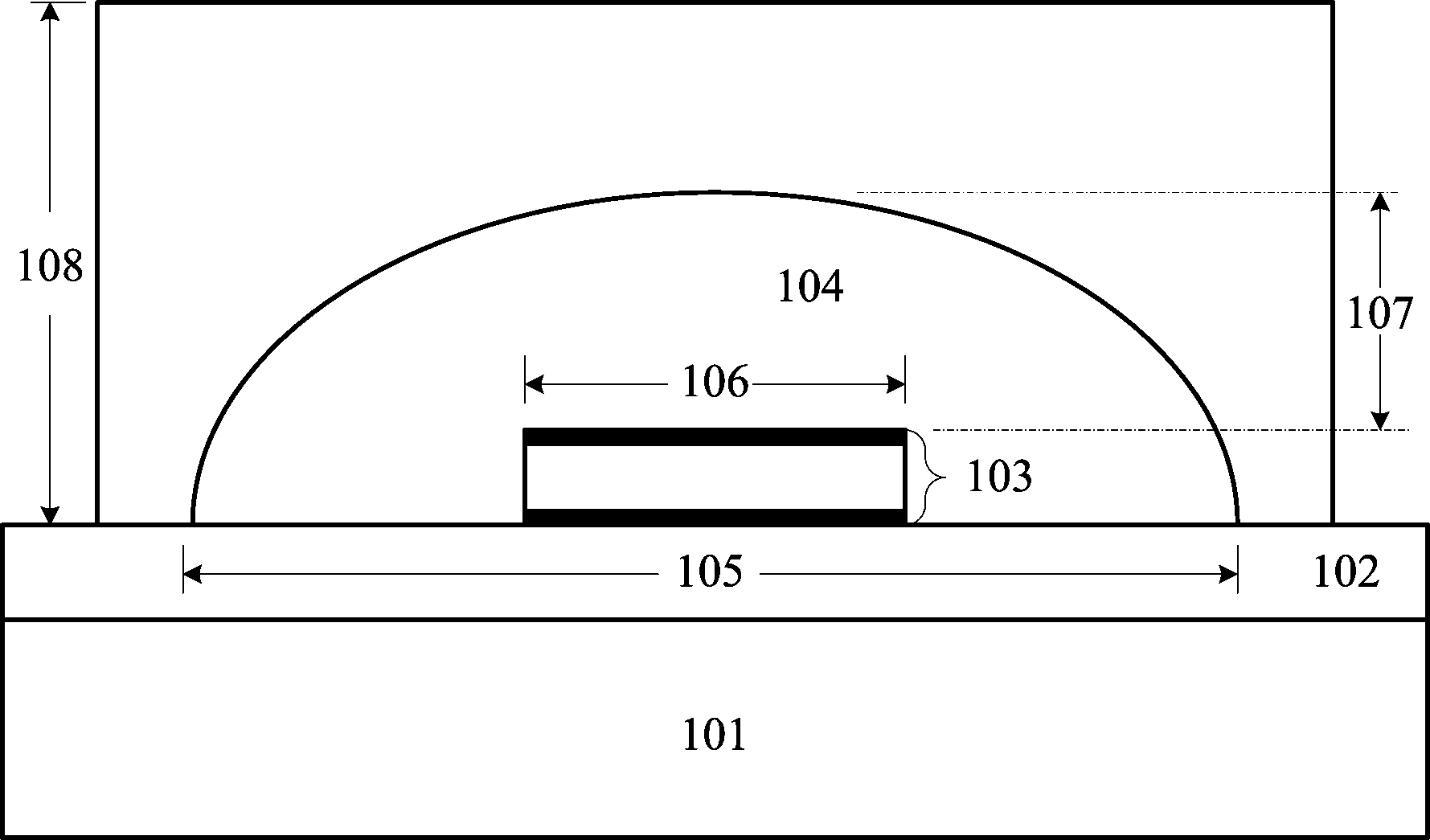

[0031] This embodiment is a piezoelectric thin-film resonant sensor with semi-elliptical micro-channels operating in longitudinal wave mode.

[0032] The device is fabricated on a silicon substrate 101, and an air gap with a thickness of 1 μm is set as the acoustic reflection layer 102 under the piezoelectric stack 103.

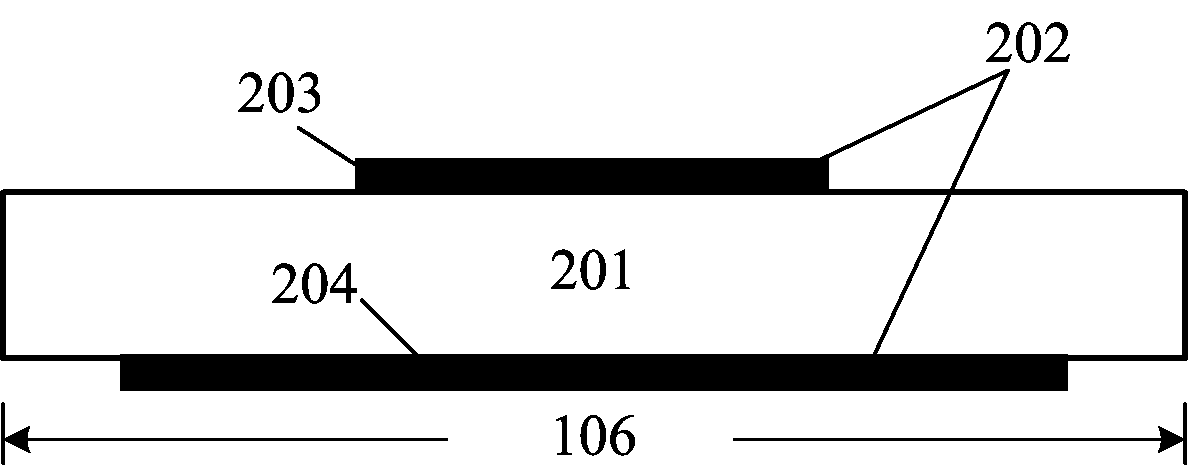

[0033] The length 106 of the piezoelectric stack 103 is 300 microns, and the structure of the piezoelectric stack 103 is as figure 2 Shown. The piezoelectric film 201 is a 2 μm thick aluminum nitride film, and the electrode 202 has a square sandwich structure, clamped on the upper and lower sides of the piezoelectric film 201. The size of the upper electrode 203 is 100 μm×100 μm, and the size of the bottom electrode 204 is 200 μm×200 μm. In the piezoelectric film 201, a longitudinal wave mode acoustic wave resonance of about 2.6 GHz is excited. The construction material of the micro flow channel 104 is polydimethylsiloxane.

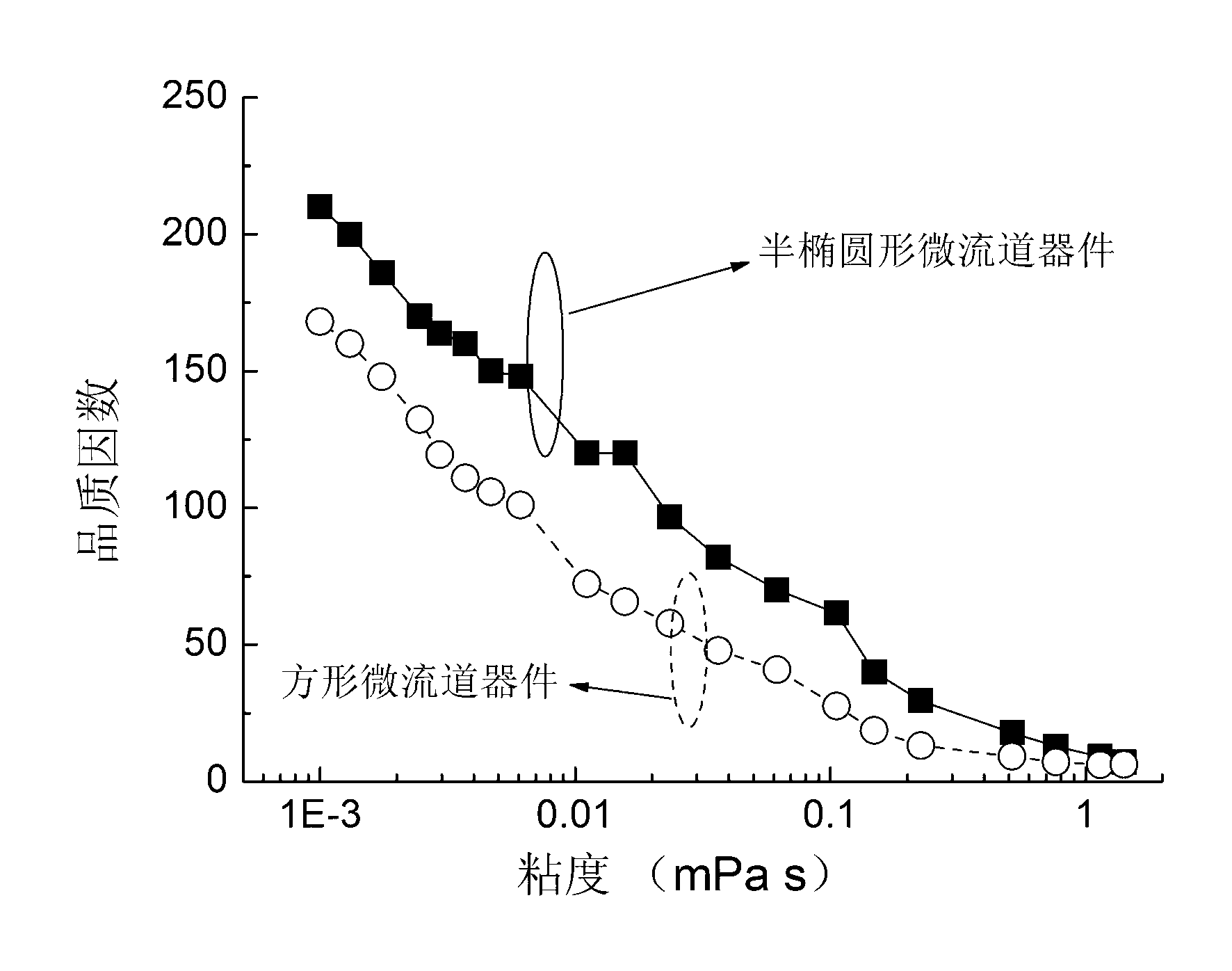

[0034] According to the numerical sim...

Embodiment 2

[0037] This embodiment is a piezoelectric thin-film resonant sensor with semi-elliptical micro-channels operating in shear wave mode.

[0038] The device is fabricated on a silicon substrate 101, and an air gap with a thickness of 1 μm is set as the acoustic reflection layer 102 under the piezoelectric stack 103.

[0039] The length 106 of the piezoelectric stack 103 is 300 microns, and the structure of the piezoelectric stack 103 is as Figure 4 Shown. The piezoelectric film 201 is a 1 micron thick aluminum nitride film, the electrode 202 has a long parallel structure, and the first electrode 301 and the second electrode 302 are both arranged on the upper surface side of the piezoelectric film 201. The size of the first electrode 301 is 150 μm×300 μm, the size of the second electrode 302 is 100 μm×300 μm, and the distance between the two electrodes is 10 μm. In the piezoelectric film 201, a shear wave acoustic resonance of about 3.0 gigahertz is excited. The construction materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com