MEMS wafer level vacuum package structure and manufacturing method thereof

A technology of vacuum packaging and manufacturing method, applied in microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems of the vacuum degree of the inner cavity can not be maintained for a long time, the thermal expansion coefficient is inconsistent, and can not meet the high-end devices, etc. Avoid thermal stress, achieve small package size, and design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

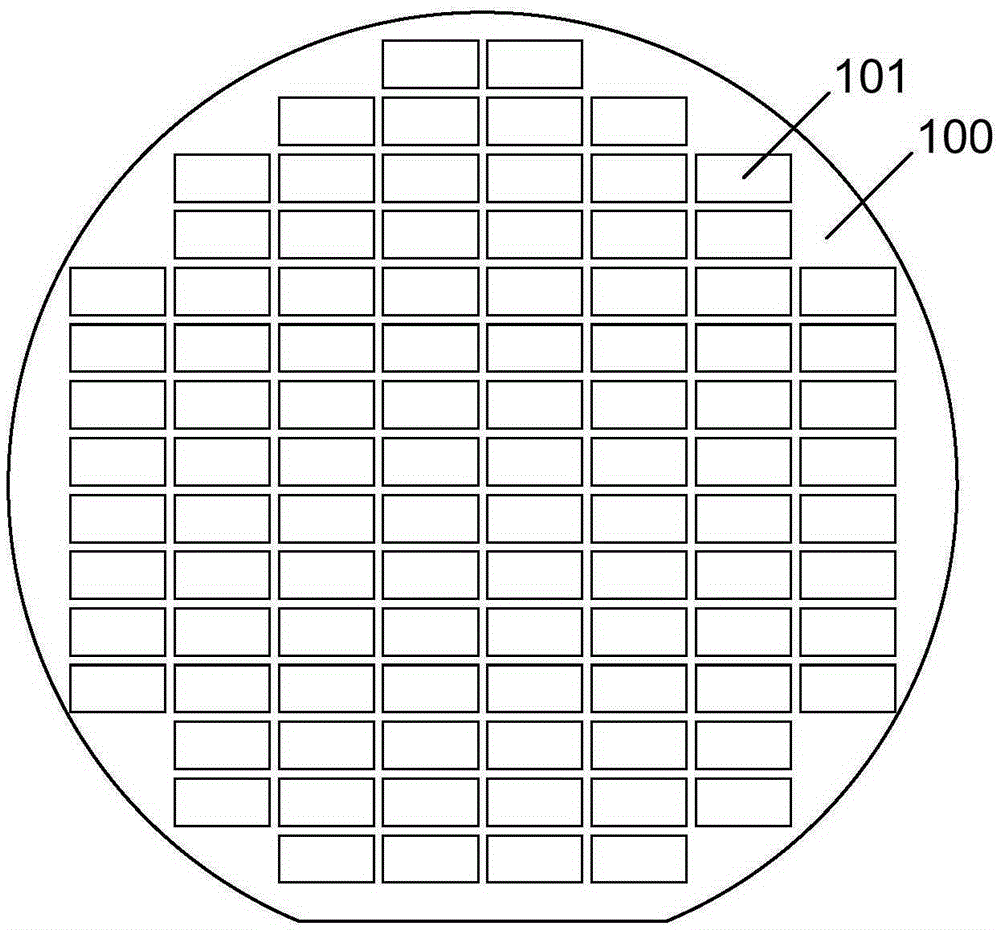

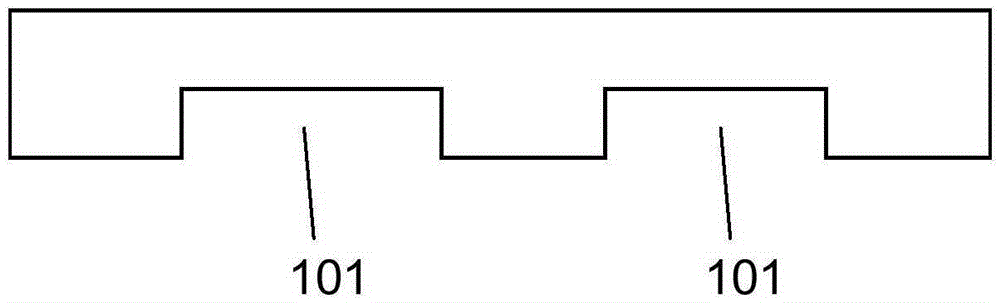

[0046]The present invention proposes a MEMS wafer-level vacuum packaging structure, including a silicon cover 100 and a MEMS wafer 200 with a movable structure 201; the silicon cover 100 is double-sided polished, and the lower surface of the silicon cover 100 is selected as the bonding surface , N grooves 101 for accommodating the movable structure 201 are processed on the bonding surface, and the bottom of the grooves 101 is covered with a layer of getter film; The conductive material 104 made of Cu or Au is filled in the hole 102, and the two ends of the conductive material 104 are respectively flush with the upper and lower surfaces of the silicon cover plate 100; The area other than the groove 101 and the upper surface of the silicon cover plate 100 are all provided with an insulating layer 103, and the material of the insulating layer is SiO 2 or Si 3 N 4 A metal bonding region 105 made of a single-layer or multi-layer AuSn metal thin film material is processed on the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com