Patents

Literature

218results about How to "Avoid heat stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

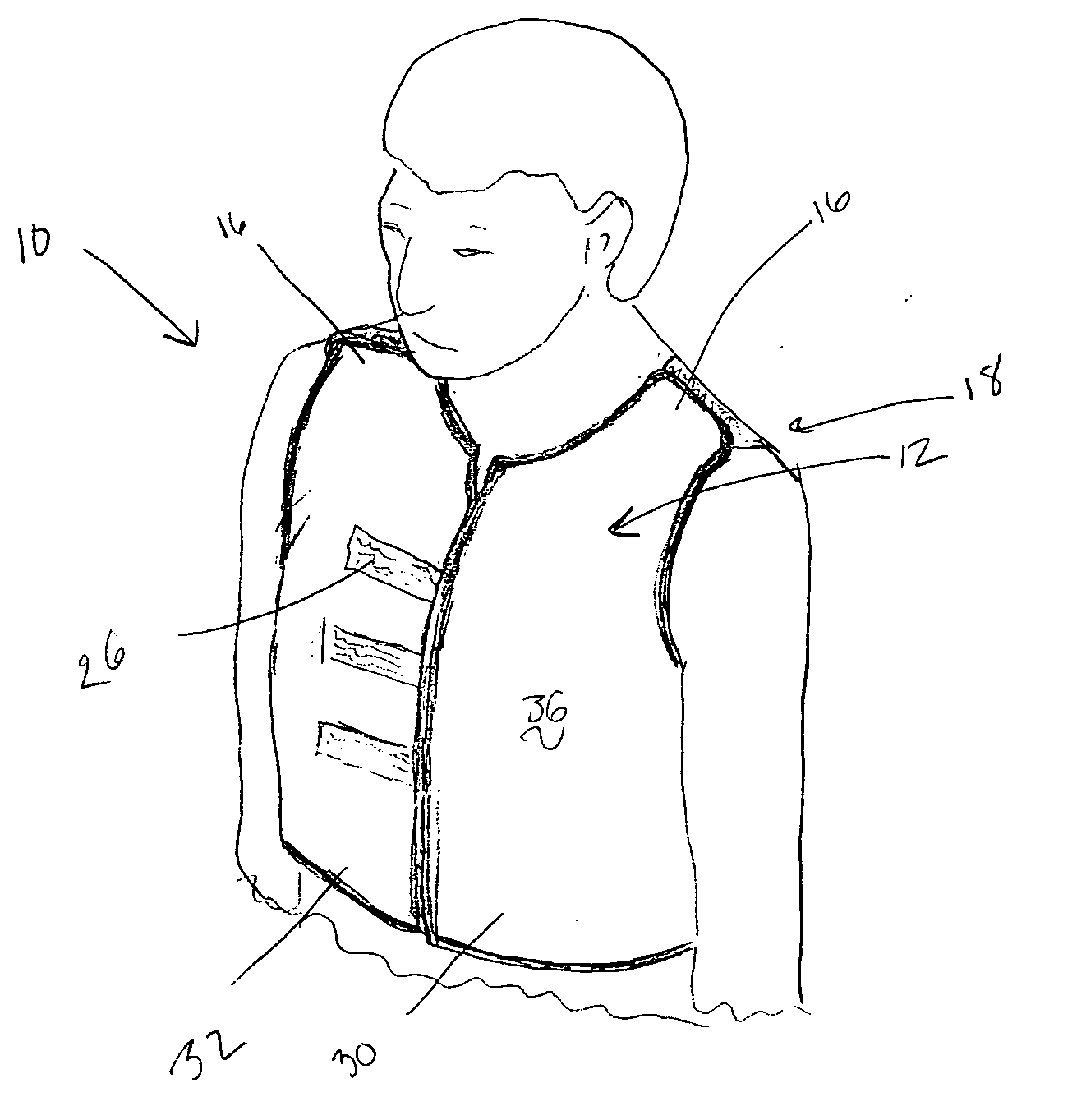

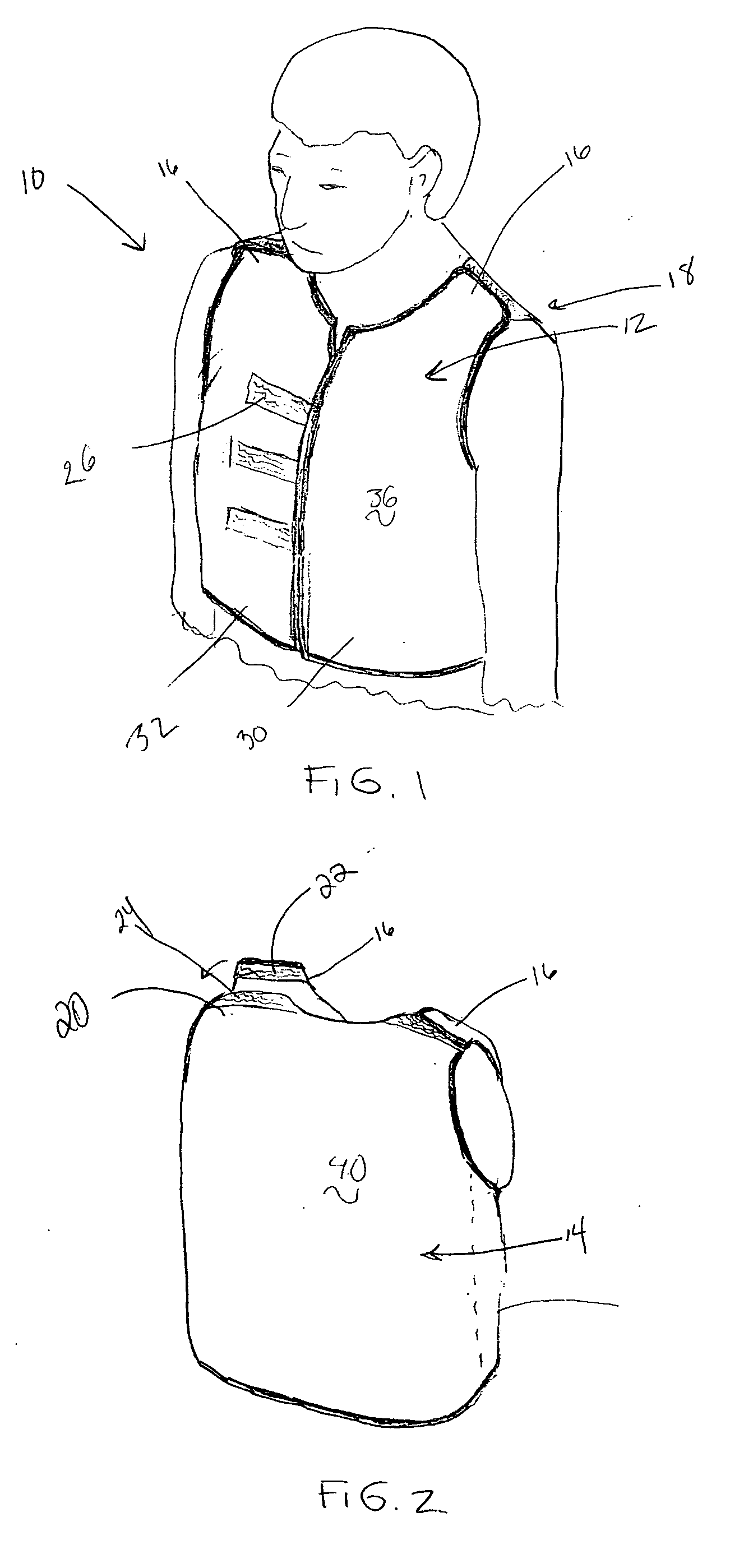

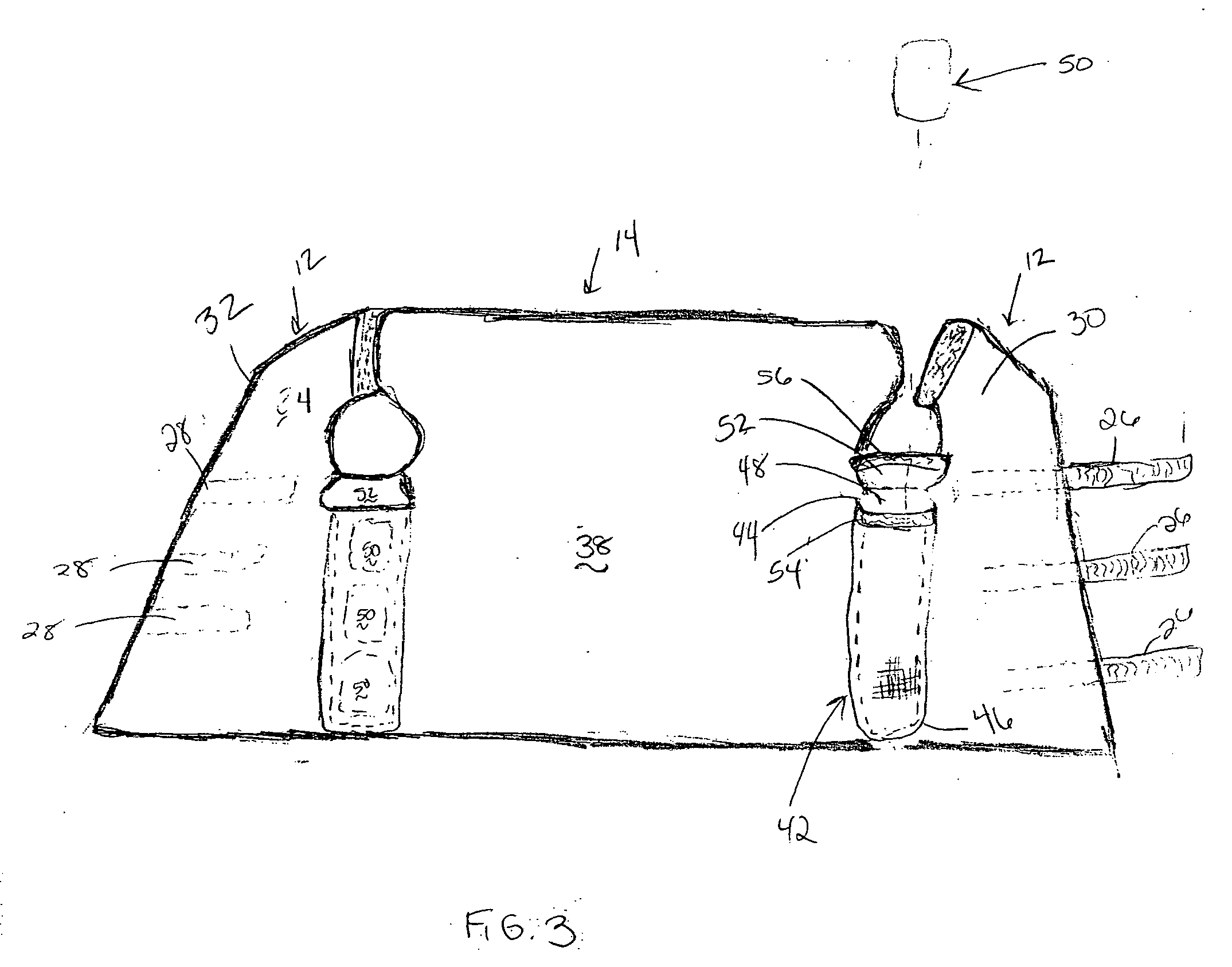

Thermal garment system and method of using the same

InactiveUS20060036304A1More situationAvoid heat stressTherapeutic coolingTherapeutic heatingEngineeringHeat stress

The instant invention comprises a thermal garment system worn by a user to cool the user's upper torso and thereby reducing the incidence of heat stress related injuries. The garment comprising a plurality pockets integrally attached to adapted to receive and support at least one thermal pack therein. The thermal pack comprising a sealed container having flexible walls enclosing a thermal composition and a catalyst adapted to produce an endothermic reaction when desired. The pack includes at least one venting means therein so that the thermal container is more readily capable of being conformed to user's body. The present invention further includes a method for cooling a user's torso and / or body which includes placing the vest around a user's torso, activating the amount of thermal packs believed necessary to produce the desired amount of cooling, and placing the thermal packs into at least one pocket of the vest.

Owner:GEL TECH SOLUTIONS

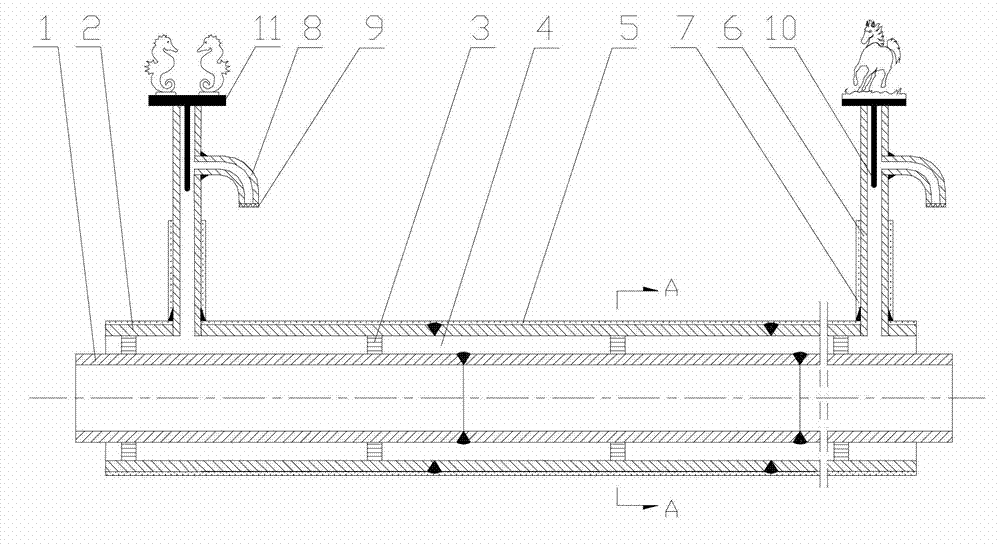

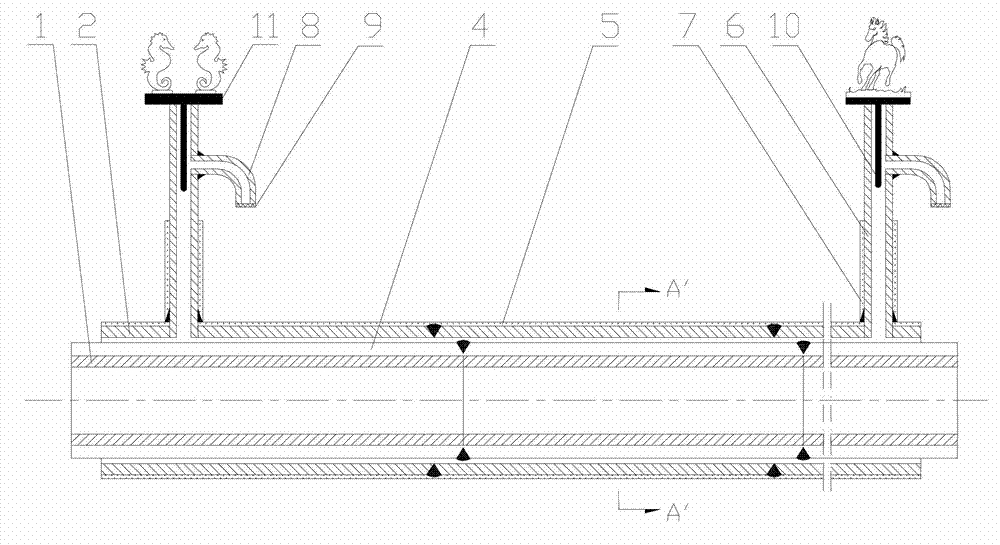

Dual-layer pipe wall composite-type gas pipeline and leakage monitoring method

InactiveCN102758973AQuickly calculate the location of the leakMeet the needs of long-distance transportationDetection of fluid at leakage pointPipe couplingsNitrogenCombustible gas

The invention relates to a dual-layer pipe wall composite-type gas pipeline and a leakage monitoring method for the pipeline, in order to mainly solve the problems that the gas pipeline operation safety in the high-hazard region is insufficient and the leakage point is difficult to confirm. The dual-layer pipe wall composite-type gas pipeline is characterized in that a clearance cavity is arranged between an inner pipe and an outer pipe; nitrogen displacement is carried out in the clearance cavity; the top of the outer wall of the outer pipe is provided with a plurality of vertical branch pipes communicated with the clearance cavity; the top ends of the vertical branch pipes are provided with concrete plates for sealing; the side wall of the outer pipe is communicated with a branch pipe which is bent downward; the tail end of the branch pipe is provided with a pressure blasting plate; the bottom surfaces of the concrete plates are provided with combustible gas probes which extend into the vertical branch pipes and are respectively connected to a combustible gas alarm and an industrial control computer in a remote monitoring room through a simulation signal wire and an RS485 data bus cable; and the industrial contro computer is used for calculating the position of pipeline leakage. The method can be used for determining the leakage point safely and rapidly.

Owner:NORTHEAST GASOLINEEUM UNIV

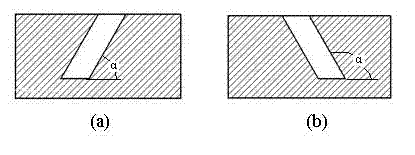

Laser repairing process for automobile mold

ActiveCN102732831ADoes not affect mechanical propertiesHigh hardnessVacuum evaporation coatingSputtering coatingHardnessAlloy

The invention relates to a laser repairing process for an automobile mold. The repairing process comprises the following steps of: (A) processing the surface of the mold, and carrying out detection and analysis on the mold; (B) heating the mold at a low temperature; (C) programming a cavity of a worn part of the mold according to a detection and analysis result of the mold, setting process parameters, and sequentially carrying out laser cladding on edges and corners of the mold and plane parts and step parts on the mold; and (D) detecting, wherein alloy powder adopted by the process comprises the following components in percentage by weight: less than or equal to 0.1% of C, 10-13% of Cr, 1.5-2.5% of B, 1-2% of Si, 0.5-1.2% of Mo, 8-12% of Mn, 6-12% of W, 2.5-15% of TiO and the balance of Fe. The laser repairing process for the automobile mold can be used for carrying out laser cladding on the worn parts and enabling the surface hardness and the sizes of the worn parts to meet a using requirement.

Owner:中科恩吉瑞特(烟台)科技发展有限公司

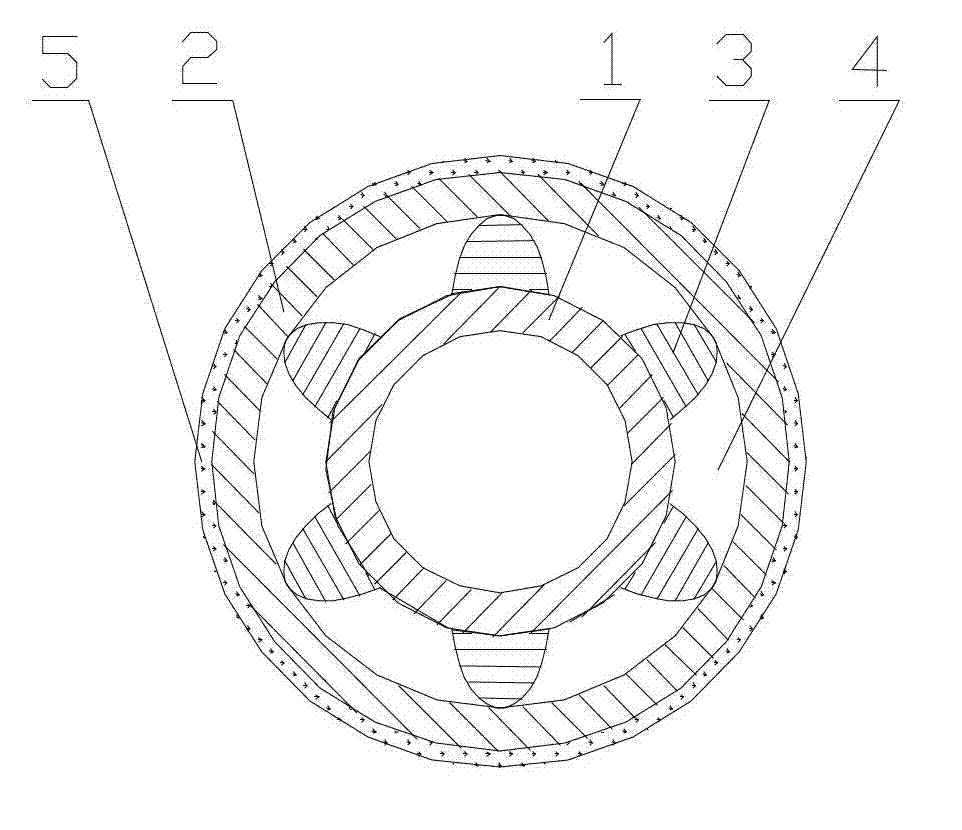

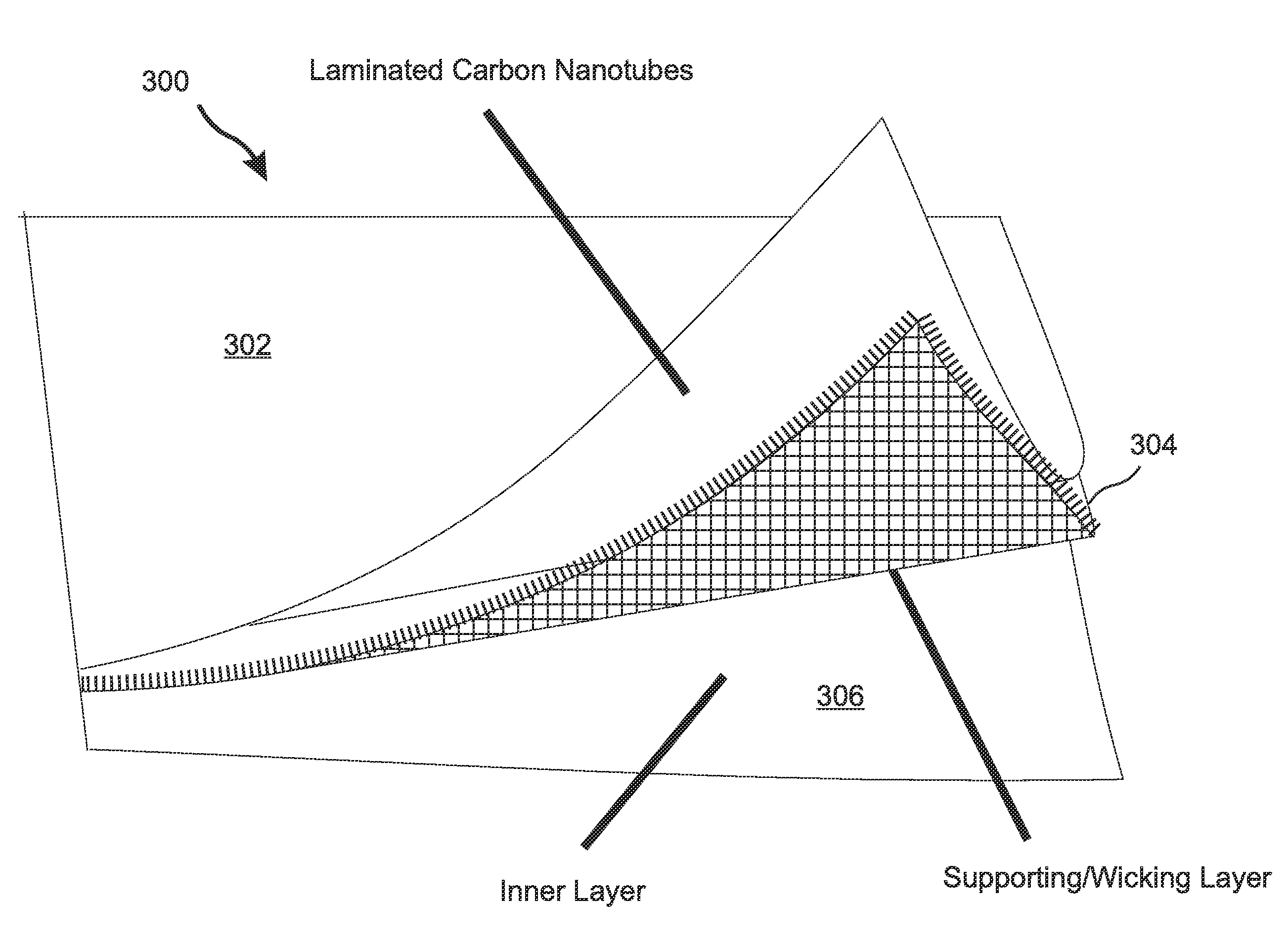

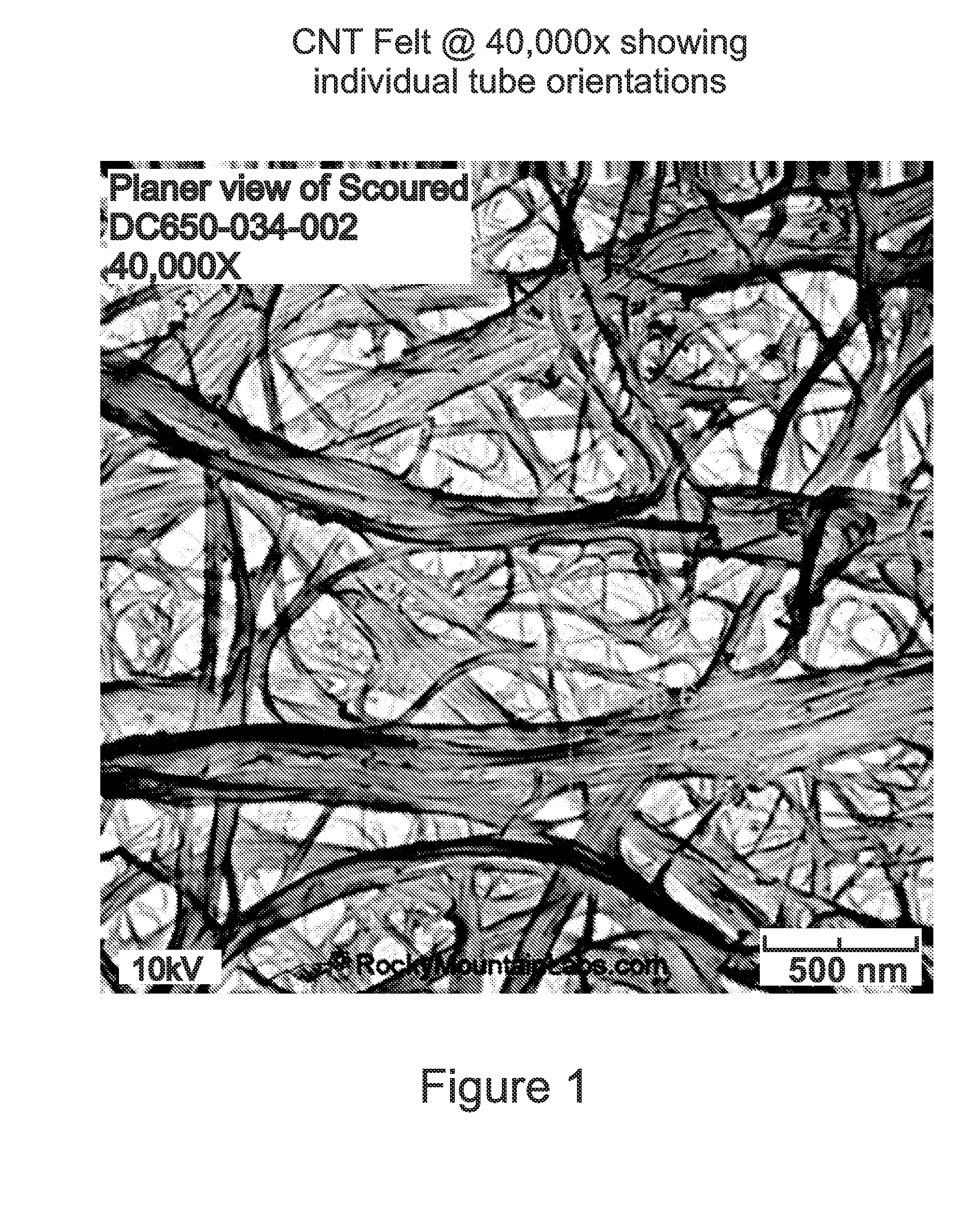

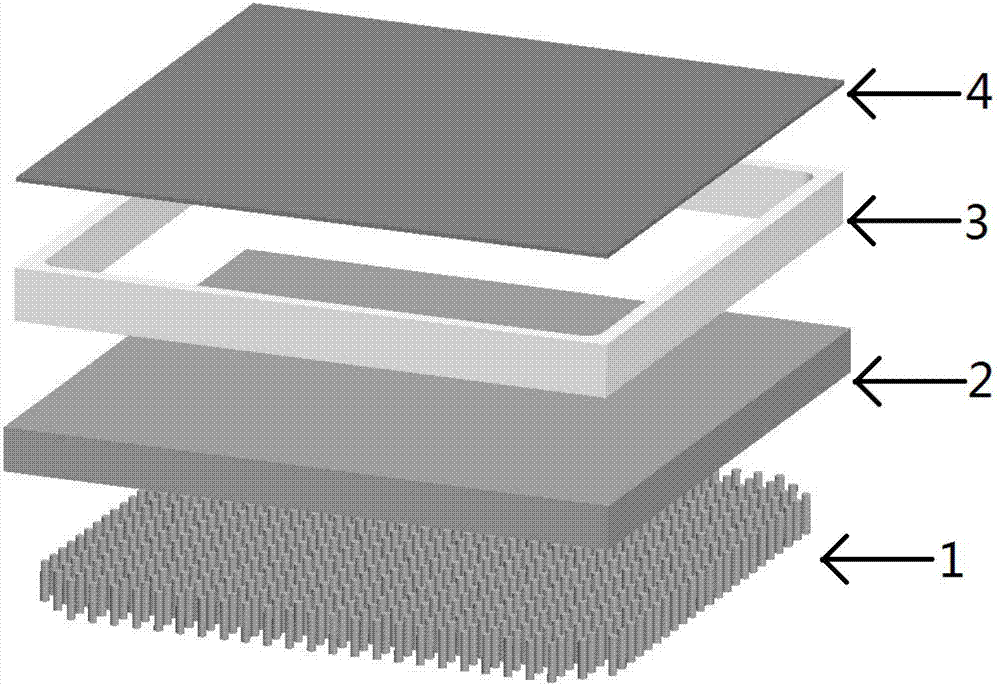

Breathable chembio protection fabric with carbon nanotube physical pathogen barrier

InactiveUS20110123757A1Avoid undue heat stressPrevent penetrationMaterial nanotechnologyLamination ancillary operationsFiberCarbon nanotube

A fabric for use in chemical and biological (CB) protective garments includes at least one felt layer having from 25% to 100% carbon nanotube (CNT) fibers as a breathable physical barrier against toxic chemical droplets and / or pathogens. The felt layers are cleaned and consolidated into a mechanically competent sheet which can form adhesive seams having lapshear greater than the sheet itself. An additional supporting layer can be included. The supporting layer can be a wicking layer which is permeable with a chlorinated or otherwise chemically active solution to establish a reactive chemical barrier, the solution being dispensed on demand from a portable container. Embodiments include a second layer of CNT or of another backing fabric, sandwiching the wicking layer therebetween. Impermeable fluoropolymer seams can divide the fabric into a plurality of CNT / wicking cells. A layer of activated charcoal and / or halamine-forming hydantoin can be included for persistent reactive chemical protection.

Owner:WARWICK MILLS INC

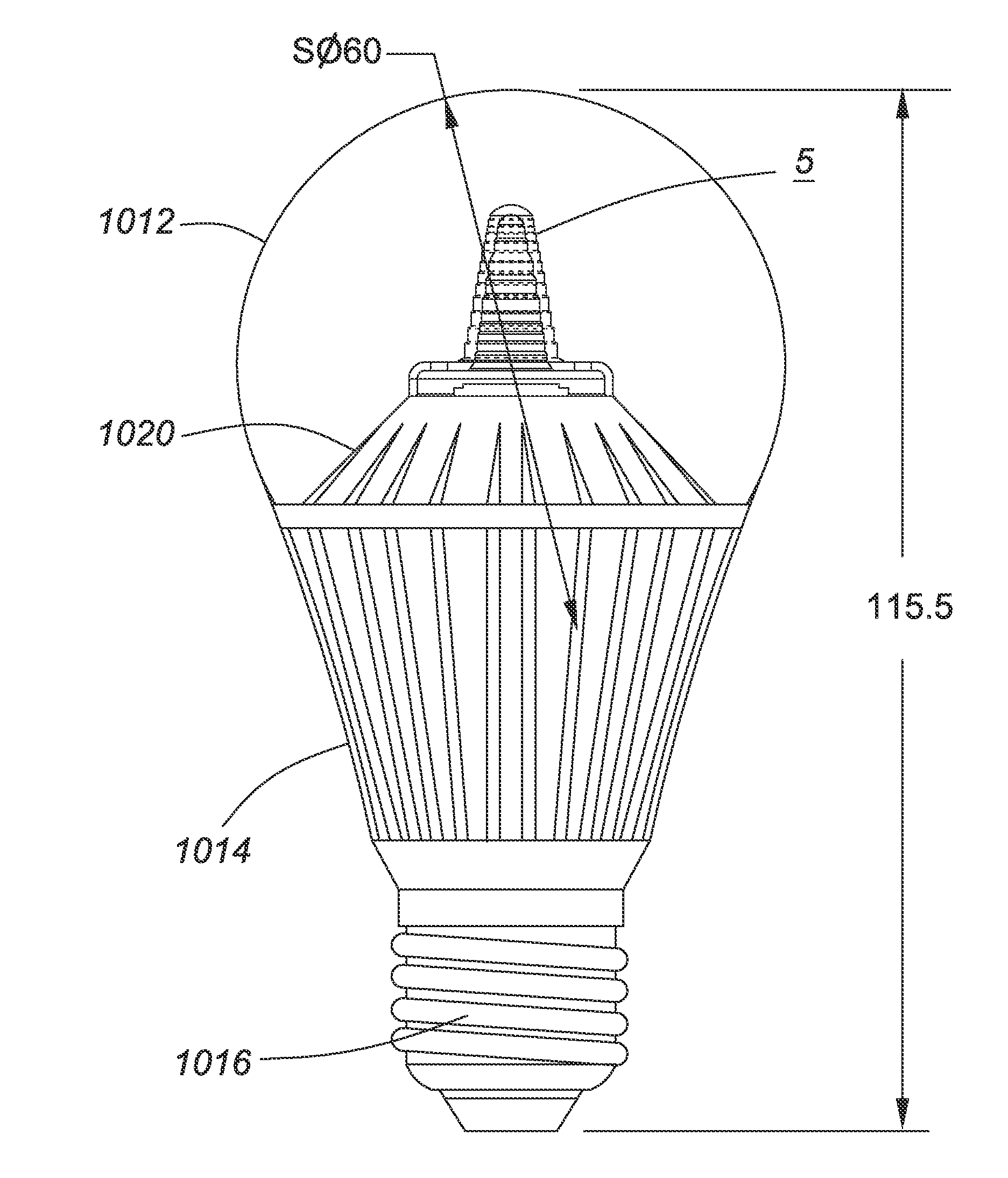

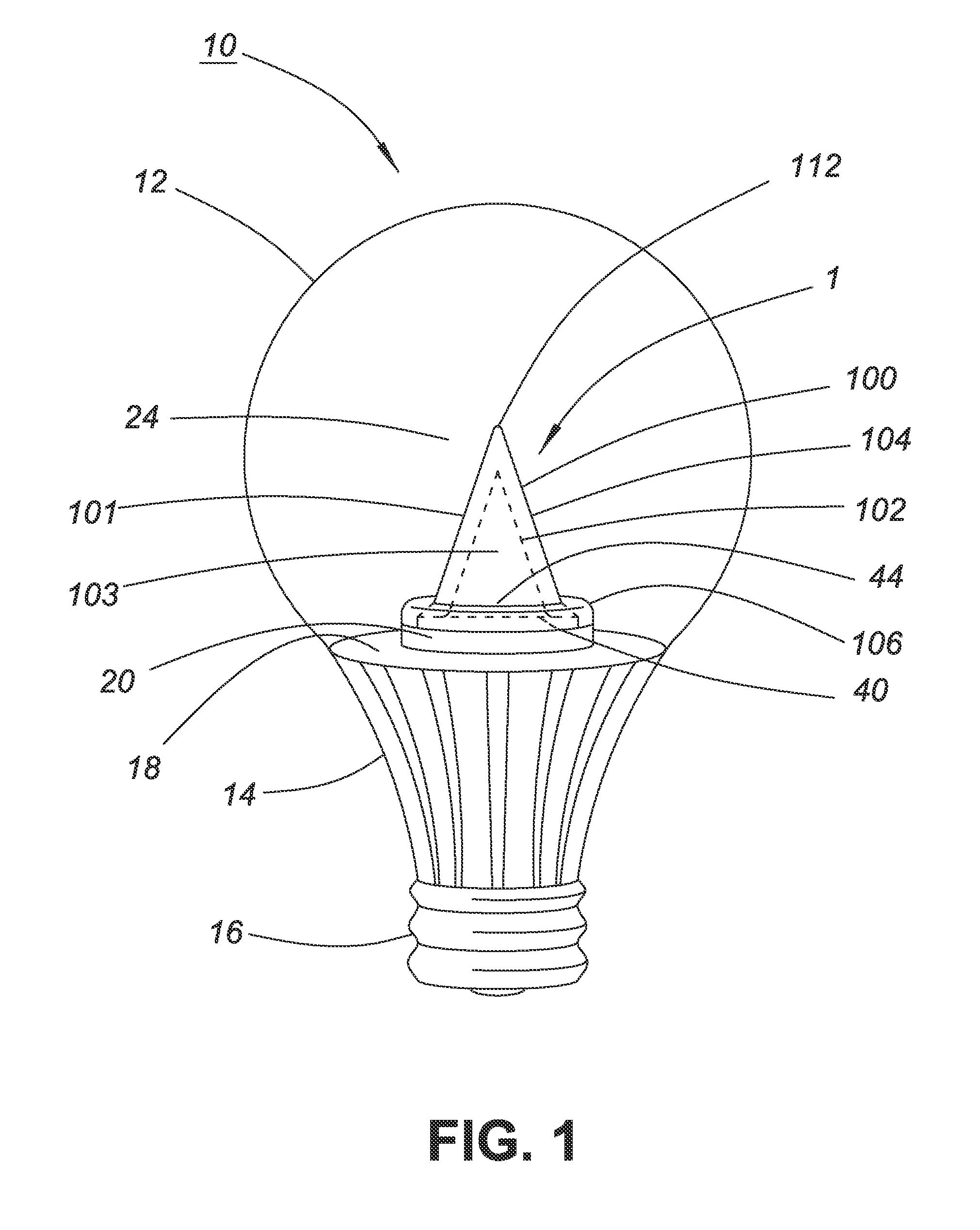

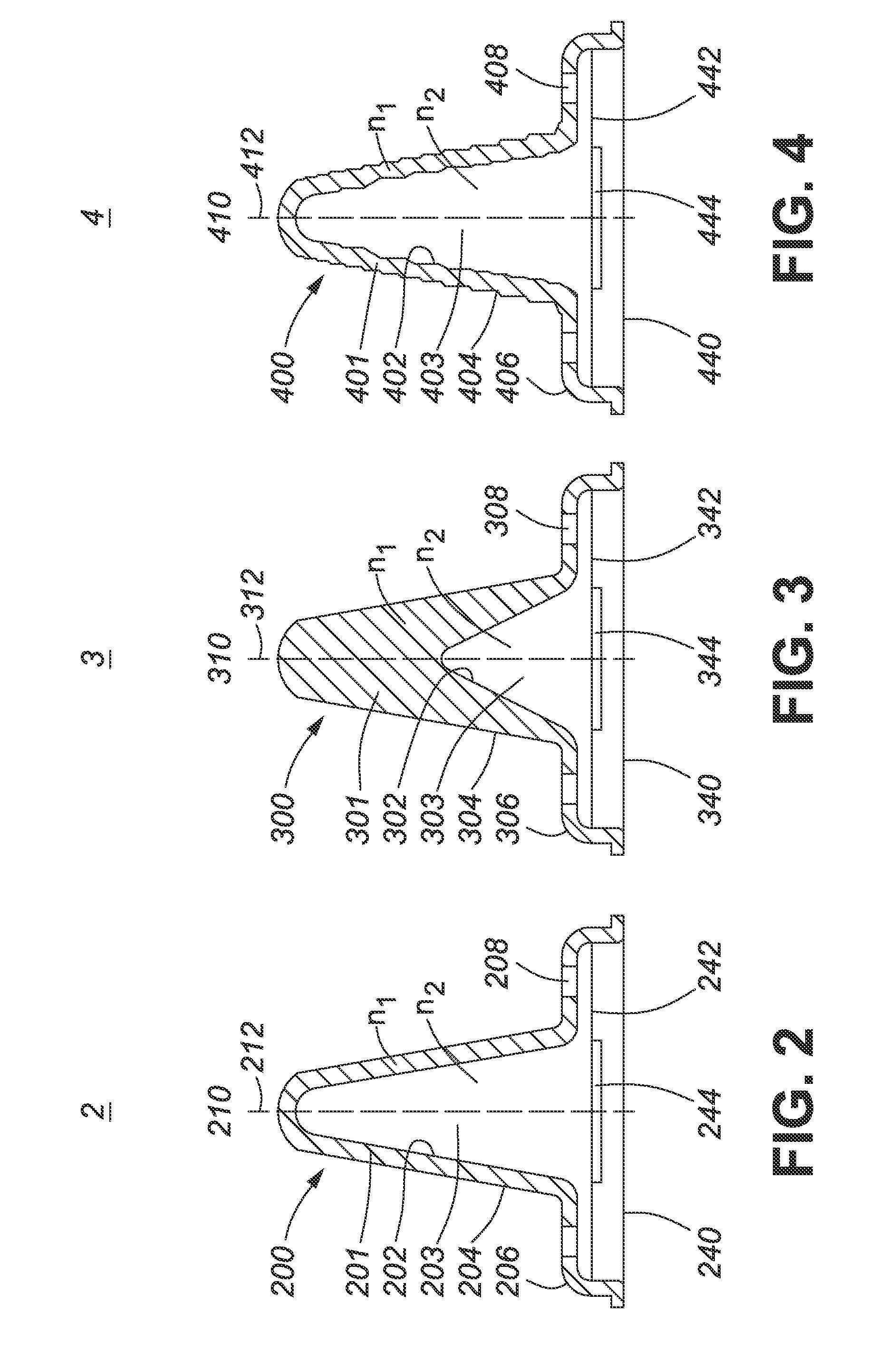

Optical device and system for solid-state lighting

ActiveUS20140268802A1Light weightEasy to shapeLighting heating/cooling arrangementsSemiconductor lamp usageGratingCircular cone

An optical device for transforming an input light distribution from an LED light source to provide an omni-directional output light distribution for solid-state lighting is disclosed. The optical device has a conical form, comprising first and second coaxial cones of different refractive index, defined by coaxial inner and outer cone surfaces, which converge from a cone base to a rounded tip at the apex. Preferably, each of the inner and outer cone surfaces comprises a plurality of conical facets defining a grating structure. The inner cone, i.e. air cavity, is directly coupled to an LED emitter area. Cone angles and spacings of conical facets, defining inner and outer gratings, are tailored to reshape a predetermined input light distribution. Apertures assist in heat dissipation. A lightweight, compact device with high transmission efficiency can be manufactured at low cost by one-step injection molding from an optical-grade polymer, such as PMMA.

Owner:1947796 ONTARIO INC

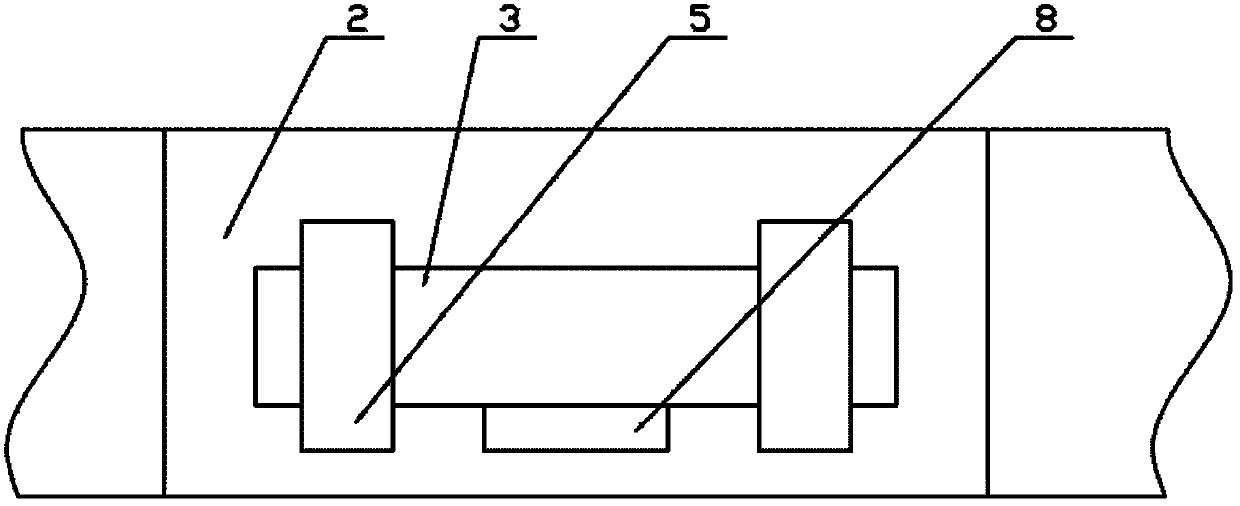

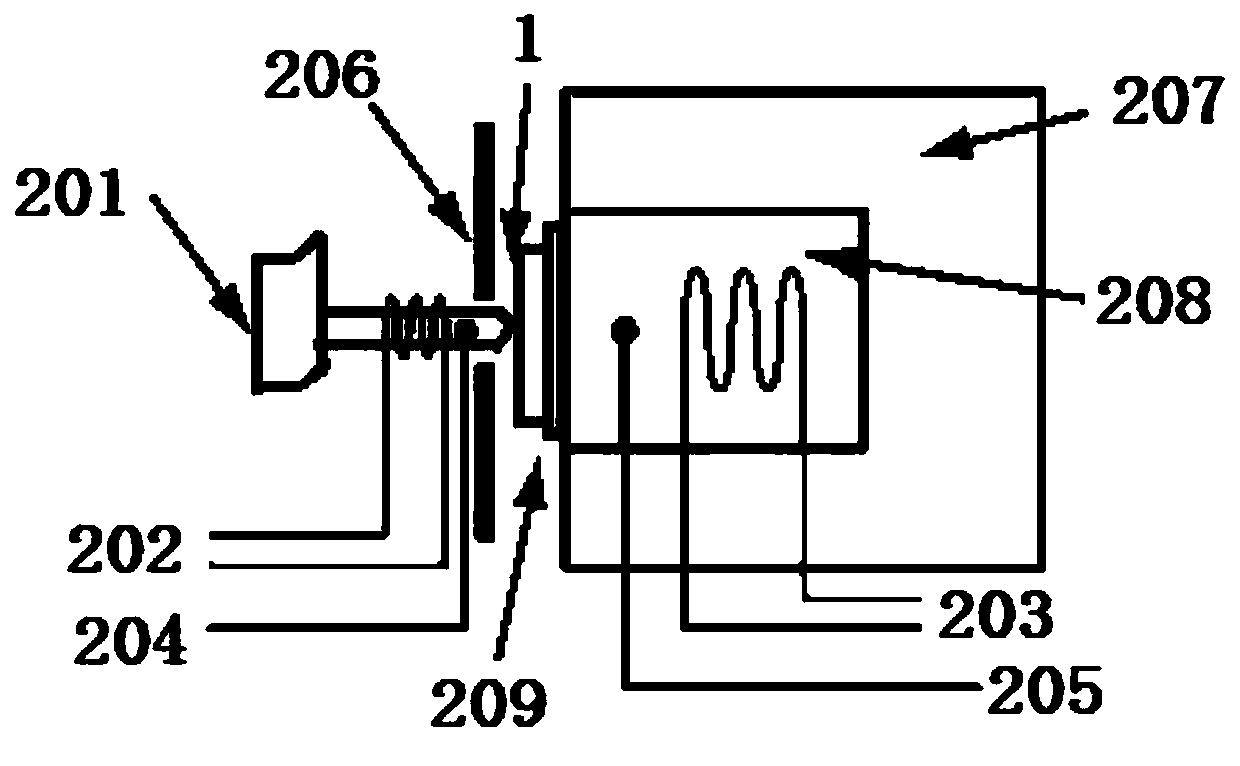

Tensile straightening device for on-line heating and straightening process of magnesium alloy extrusion

The invention discloses a stretching-straightening device for an online heating-straightening process of a magnesium alloy extrusion material, comprising a stretching-straightening device and a heating device. The stretching-straightening mechanism comprises a bracket, a stretching drive mechanism and a clamping drive mechanism. Double rails are arranged on the bracket. The rail is provided with a chuck I and a chuck II which are matched with the surfaces of the rails in a sliding manner. At least one chuck is capable of sliding forward and backward along the rail direction with the action ofthe stretching drive device. The chuck I and the chuck II are used for generating clamping forces via the clamping drive mechanism respectively. The heating device comprises a lifting mechanism and aheating mechanism. The heating mechanism comprises a positive clamping electrode, a negative clamping electrode and a transformer. The lifting mechanism is arranged under the double rails. The heating device of the stretching-straightening device is capable of guaranteeing that the extrusion material is expanded freely during heating without generating heat stress. The bending phenomenon caused by the heat stress and the instability phenomenon caused by the combined action of the heat stress and the self gravity are avoided via effective support during heating.

Owner:重庆昱华新材料科技有限公司

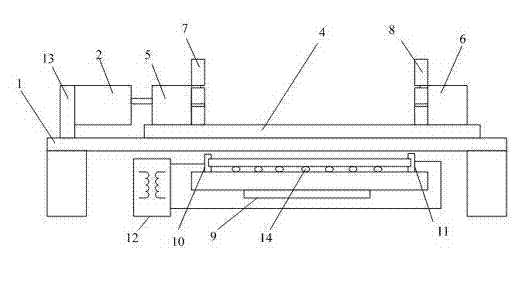

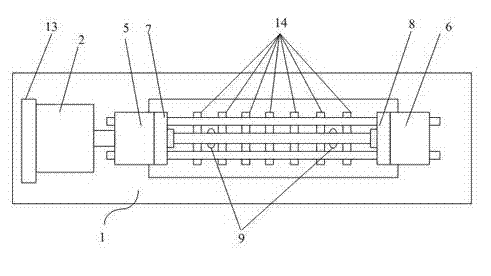

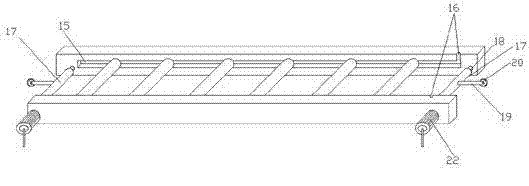

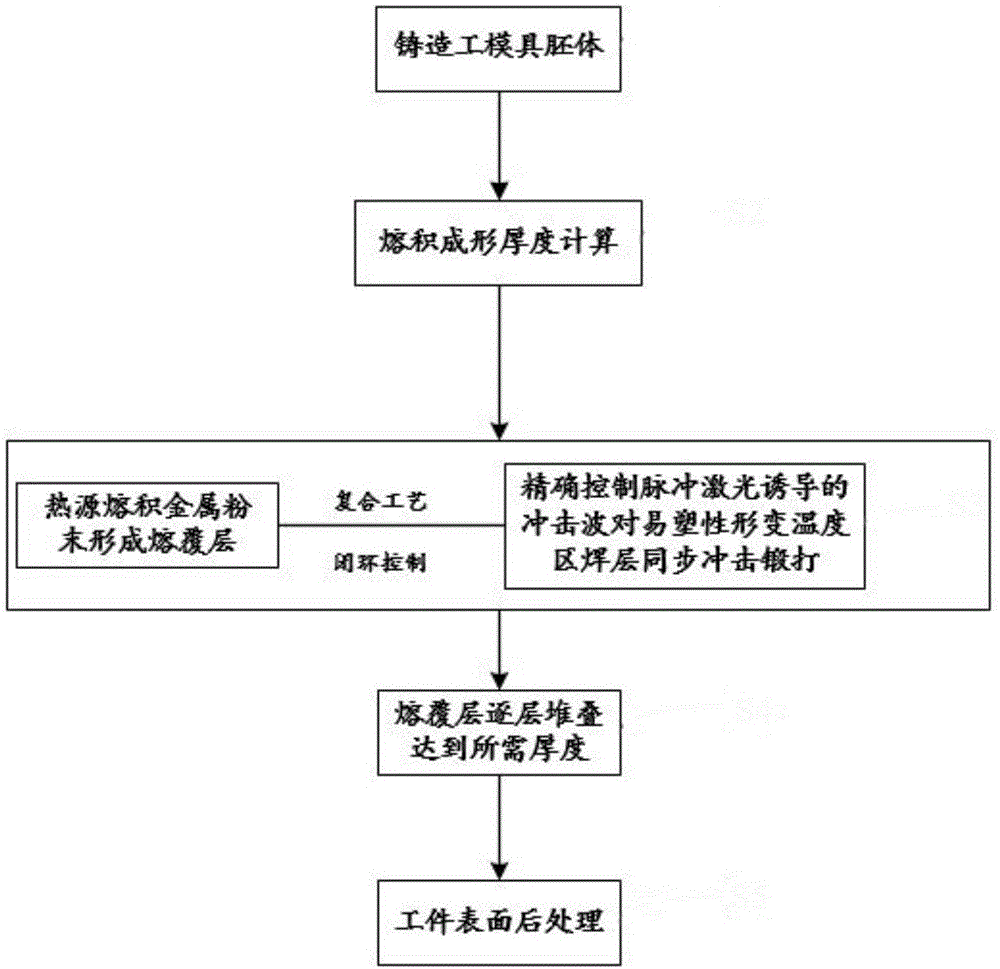

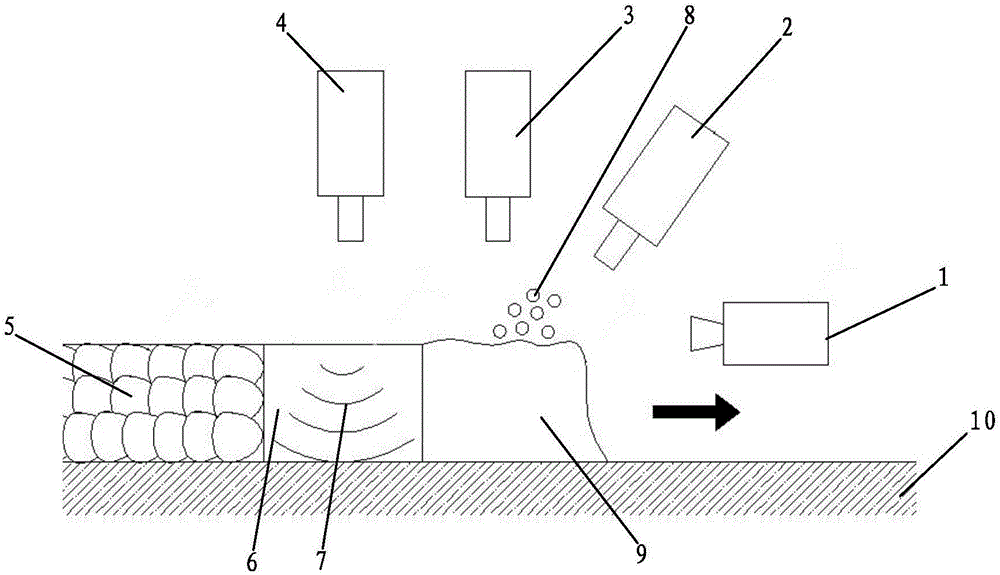

Mould melting-deposition forming and laser impact forging composite additive manufacturing method and device

InactiveCN107520449AQuality improvementImprove efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyMetal powderMetal mold

The invention discloses a mould melting-deposition forming and laser impact forging composite additive manufacturing method. The mould melting-deposition forming and laser impact forging composite additive manufacturing method comprises the following steps that (1) a mould blank body is cast; (2) the melting-deposition forming thickness is calculated; (3) metal powder is subjected to melting deposition through a heat source to form cladding layers, a controller controls a laser generator to conduct impact forging on a melting-deposition metal area at the plastic deformation temperature synchronously, the cladding layers are stacked layer by layer till the thickness of the cladding layers reach the thickness value in the step (2), and thus a workpiece is formed; and (4) the surface of the workpiece is treated. The invention further provides a mould melting-deposition forming and laser impact forging composite additive manufacturing device. The method adopts melting-deposition forming and laser impact forging composite manufacturing, melting-deposition forming and impact forging are conducted simultaneously, parameters are mutually coordinated and restrained in the process, thus, thermal stress, deformation and cracking can be avoided, the microstructure of a metal part is optimized, internal defects of pores, non-fusion, shrinkage porosity and the like are avoided, and the forming quality and efficiency of additive manufacturing of a metal mould are improved.

Owner:GUANGDONG UNIV OF TECH

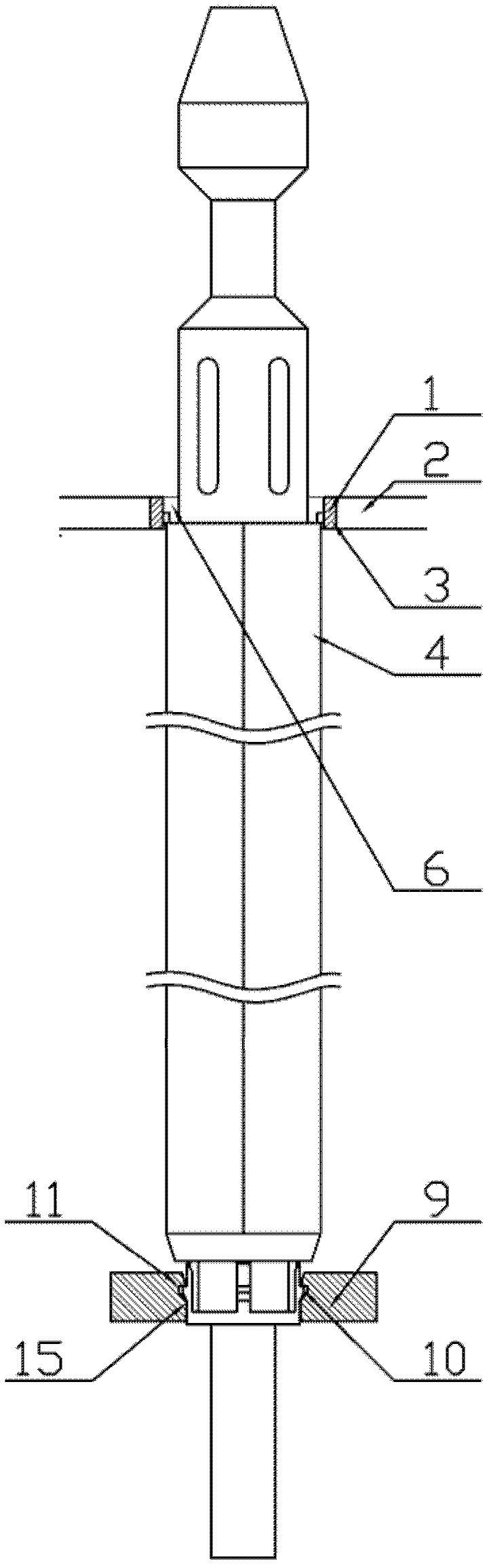

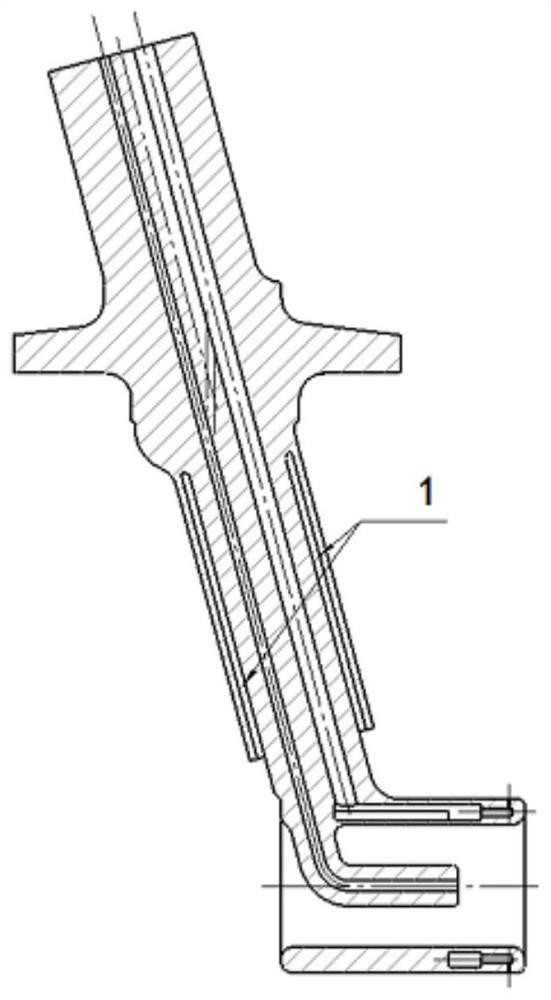

Fuel subassembly fixing device of reloadable liquid heavy metal reactor

InactiveCN102610286AAvoid heat stressRealize online refuelingNuclear energy generationFuel element assembliesNuclear engineeringLiquid state

The invention relates to a fuel subassembly fixing device of a reloadable liquid heavy metal reactor, which consists of an upper grid tray of a reactor core, a fuel assembly and a lower grid tray of the reactor core. The main body of the fuel assembly is hexagonal, wherein the upper part of the fuel assembly extends into a honeycomb structure of the upper grid tray of the circular reactor core and is supported by a double-bump spring on the inner wall of the honeycomb structure. A slipknot is arranged at a pin of the fuel assembly to hook a circular groove of an installation hole of the upper grid tray of the reactor core to form lower constraint. The device has the functions of fixing the fuel assembly of the reactor and fixing the assembly, prevents the fuel elements from shuttling in the liquid heavy metal reactor and can reload the reactor online.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

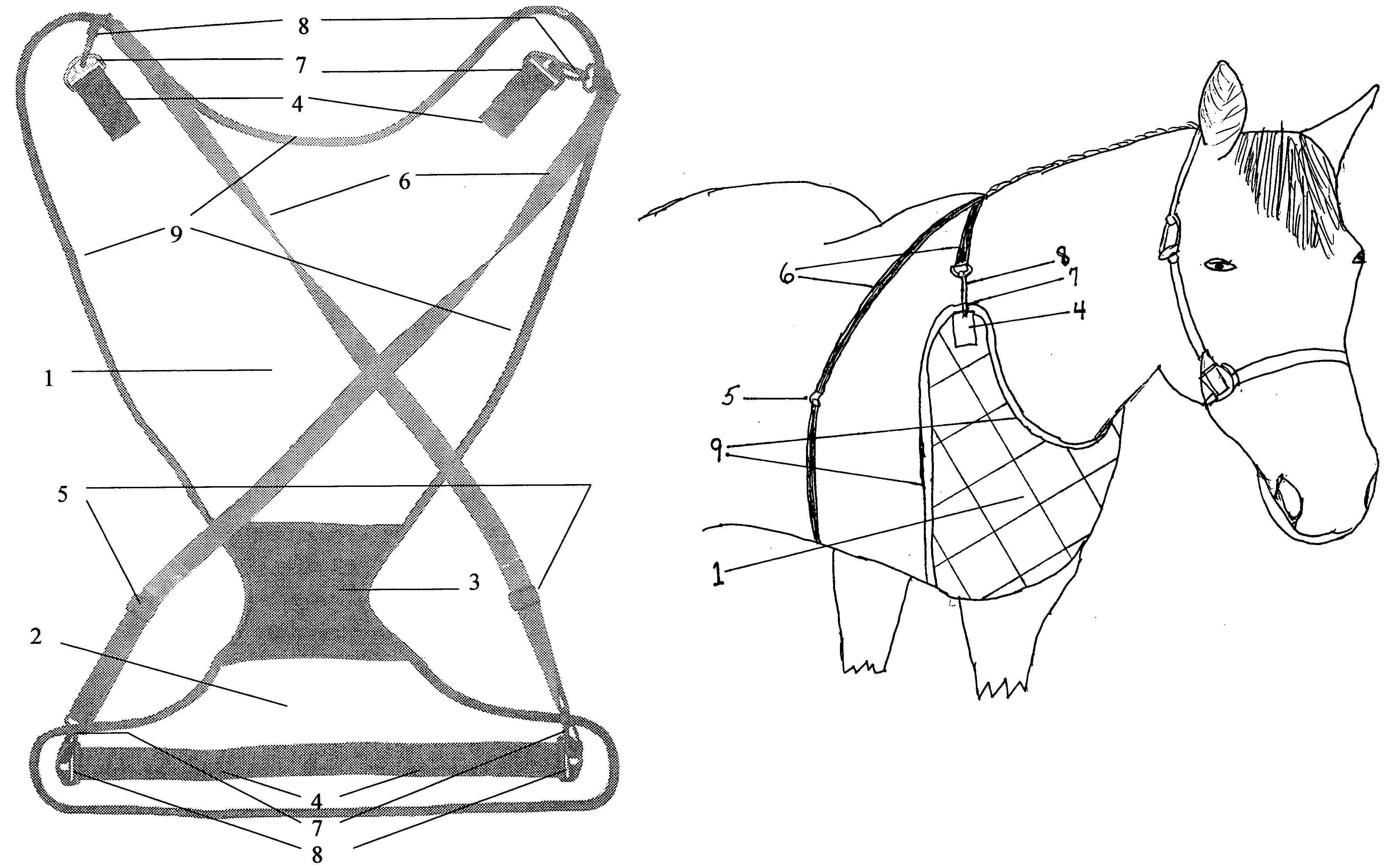

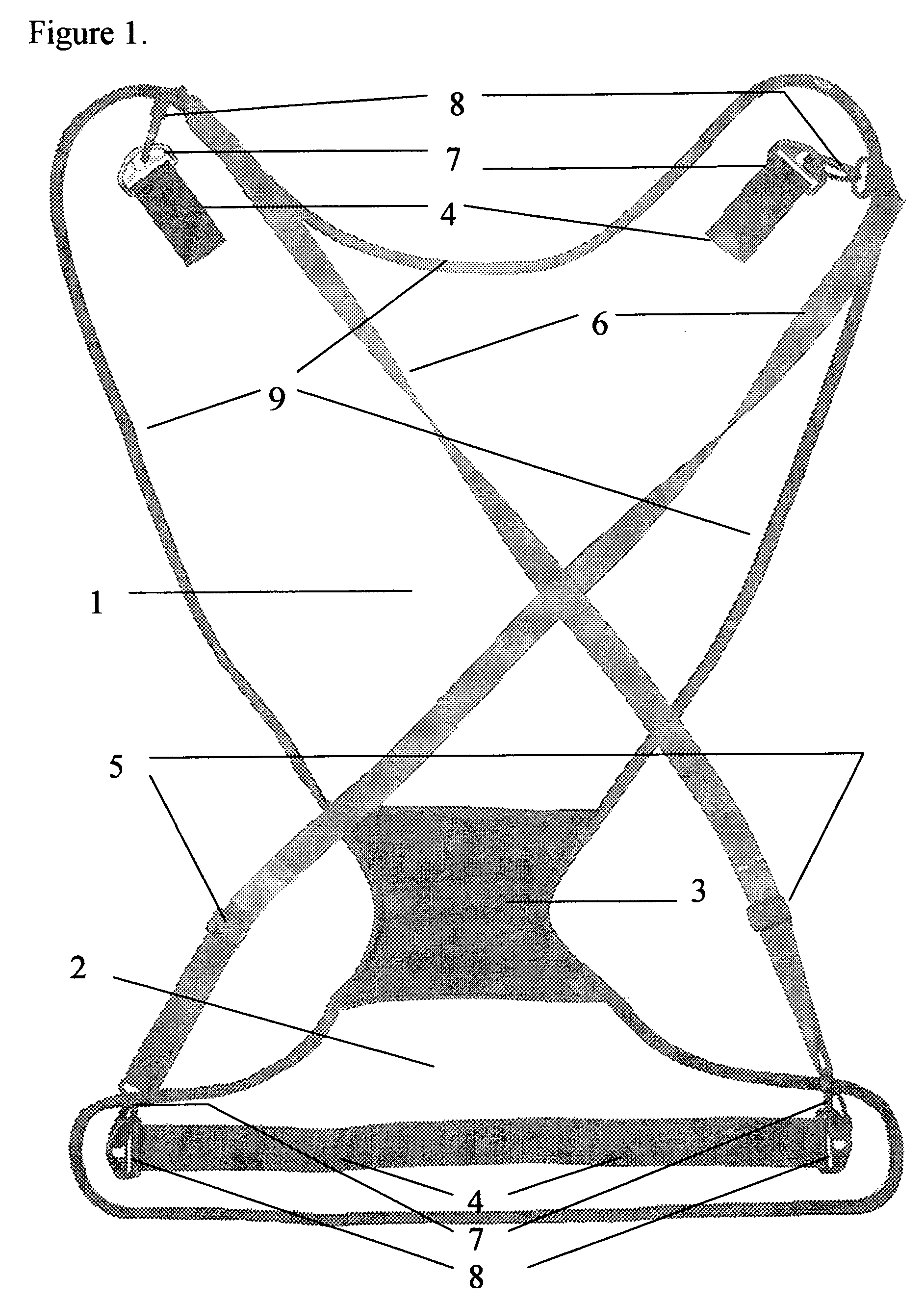

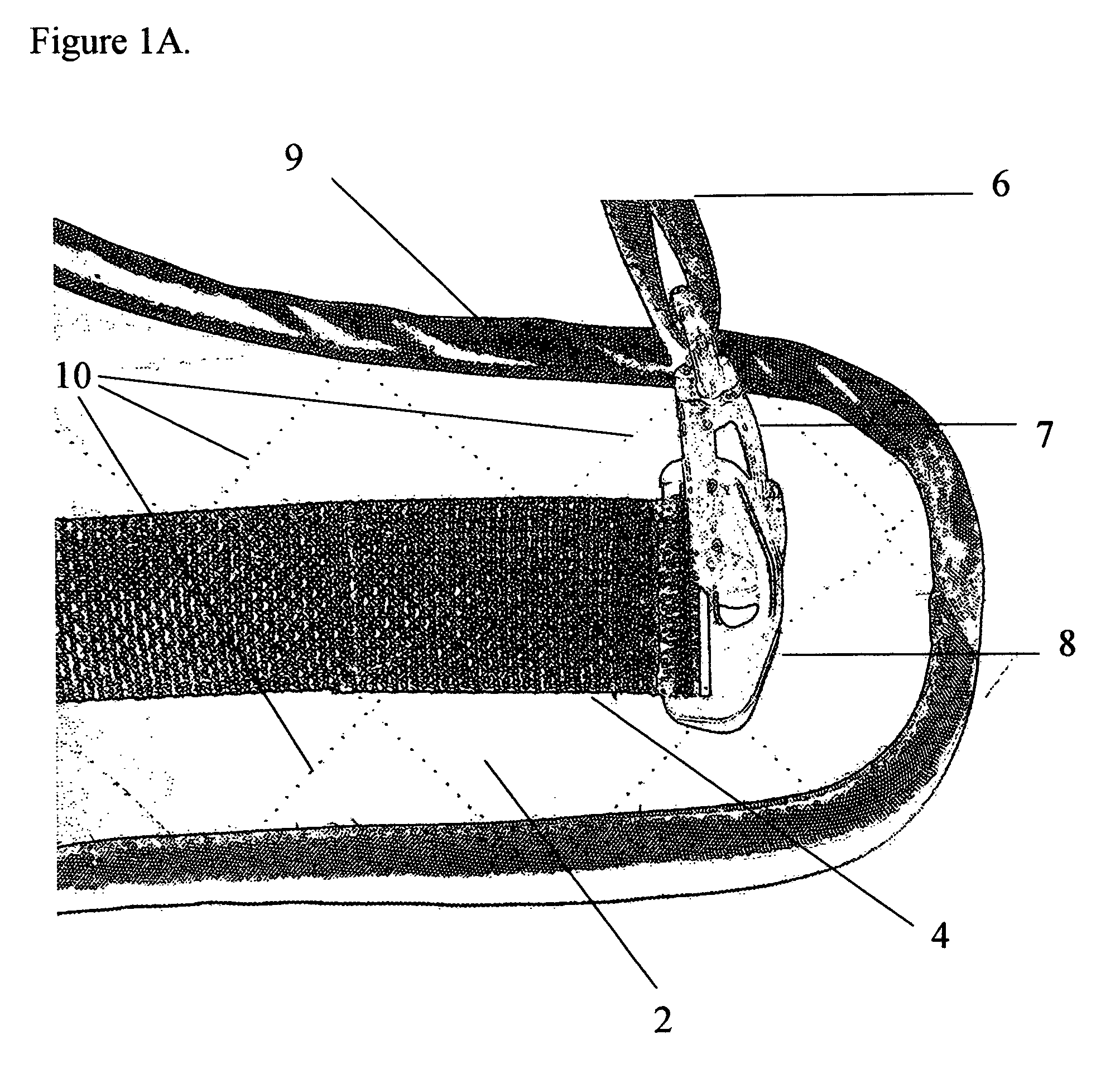

Animal cooling vest

The present invention is a water-absorbent animal cooling vest made with an inner core of woven, hydrophilic / hydrophobic polymer embedded fabrics (PEF) enclosed inside two exterior (a wicking fabric inside to the body and a breathable fabric outside to the air) fabric shells attached to the animal by criss-crossing two double-ended, elastic and adjustable hook straps over the rear of the animal's neck, which straps are then attached to sewn-on loops on the upper and lower parts of the vest. The vest is soaked in approximately 3-16 ounces of water (depending on the size of the vest and the size of the animal for which is to be used) for 3-15 minutes (again depending on size of vest) before use, thus allowing the inner core to absorb the water. This process begins the vest's evaporative process. The internal core fibers of the vest absorb many times its weight in water. Excess water is wrung out of the vest prior to installation. The cooling evaporative process lasts for several hours based on ambient temperature, activity and level of exertion of the animal. The purpose of the vest is to promote absorption of moisture and body heat from the animal into the vest and enhance the natural evaporative cooling process to reduce body temperature and heat stress, which can lead to heat stroke, a significant cause of death for equines and other four-legged domestic animals. The animal cooling vest may be reactivated by simply re-immersing in water for a short period and reinstalling. The animal cooling vest may be machine washed and dried and is re-useable. Due to the flexible characteristics of the fabric materials comprising the vest and the method of strapping the vest to the animal, the vest shapes closely to the animal's body for maximum direct contact to the critical chest area of the body while allowing complete freedom of movement.

Owner:JACKSON SUSAN M +1

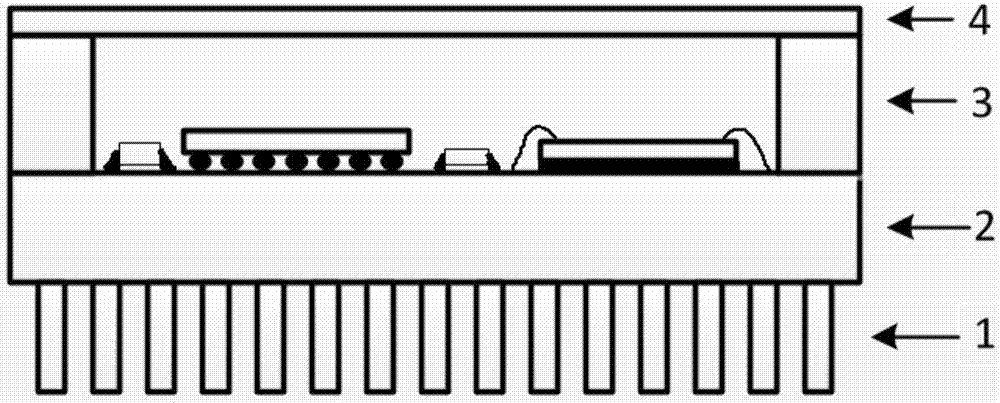

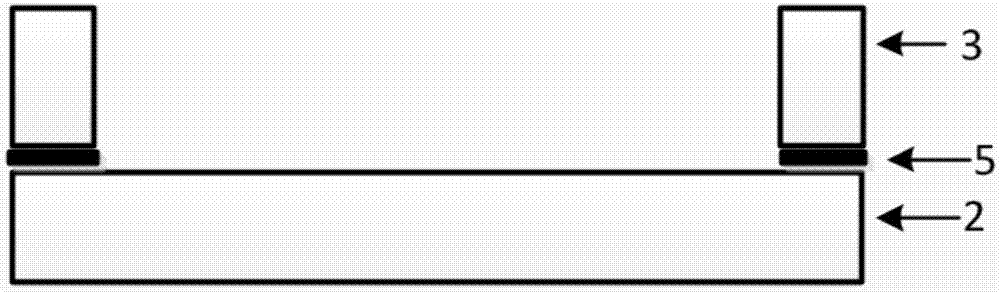

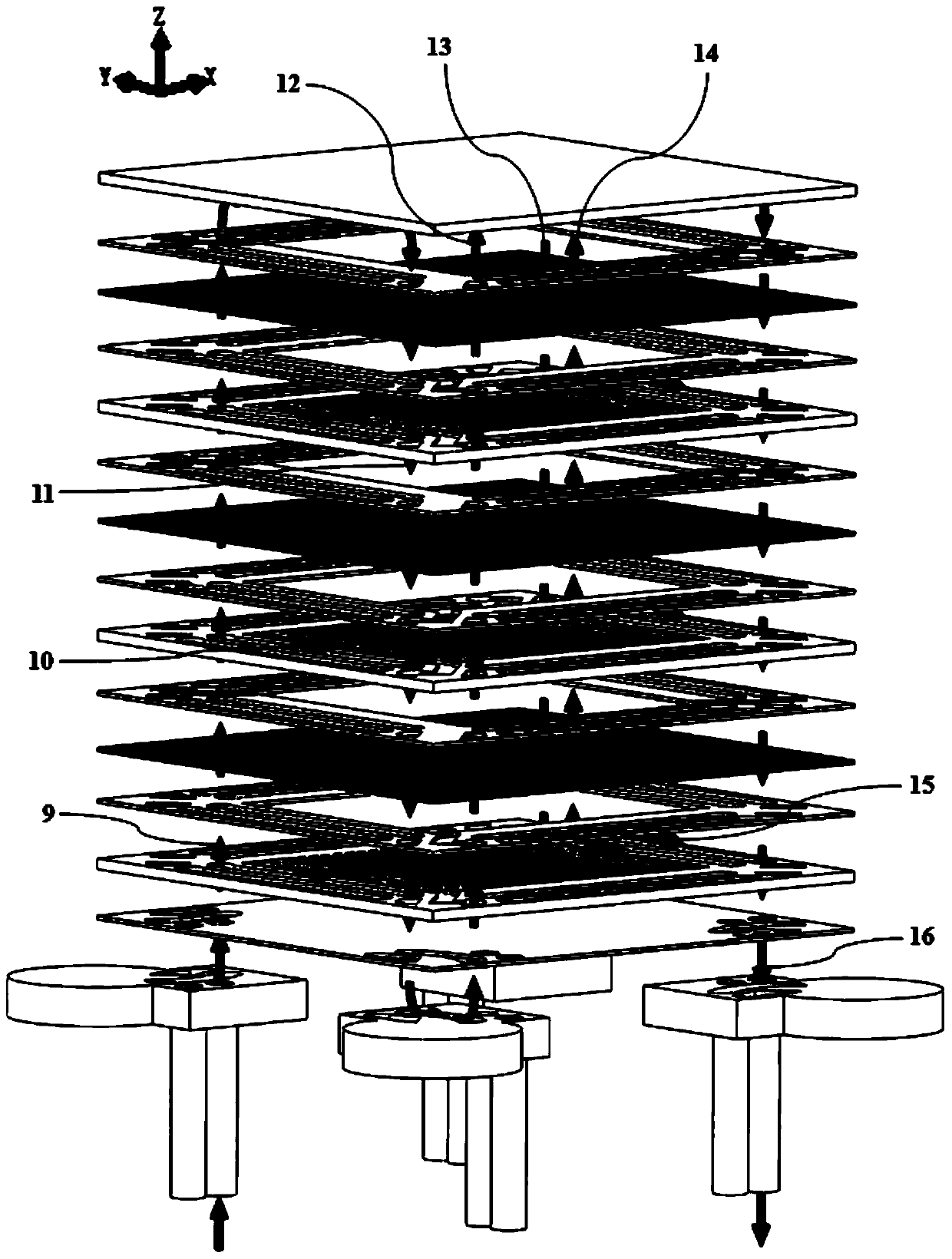

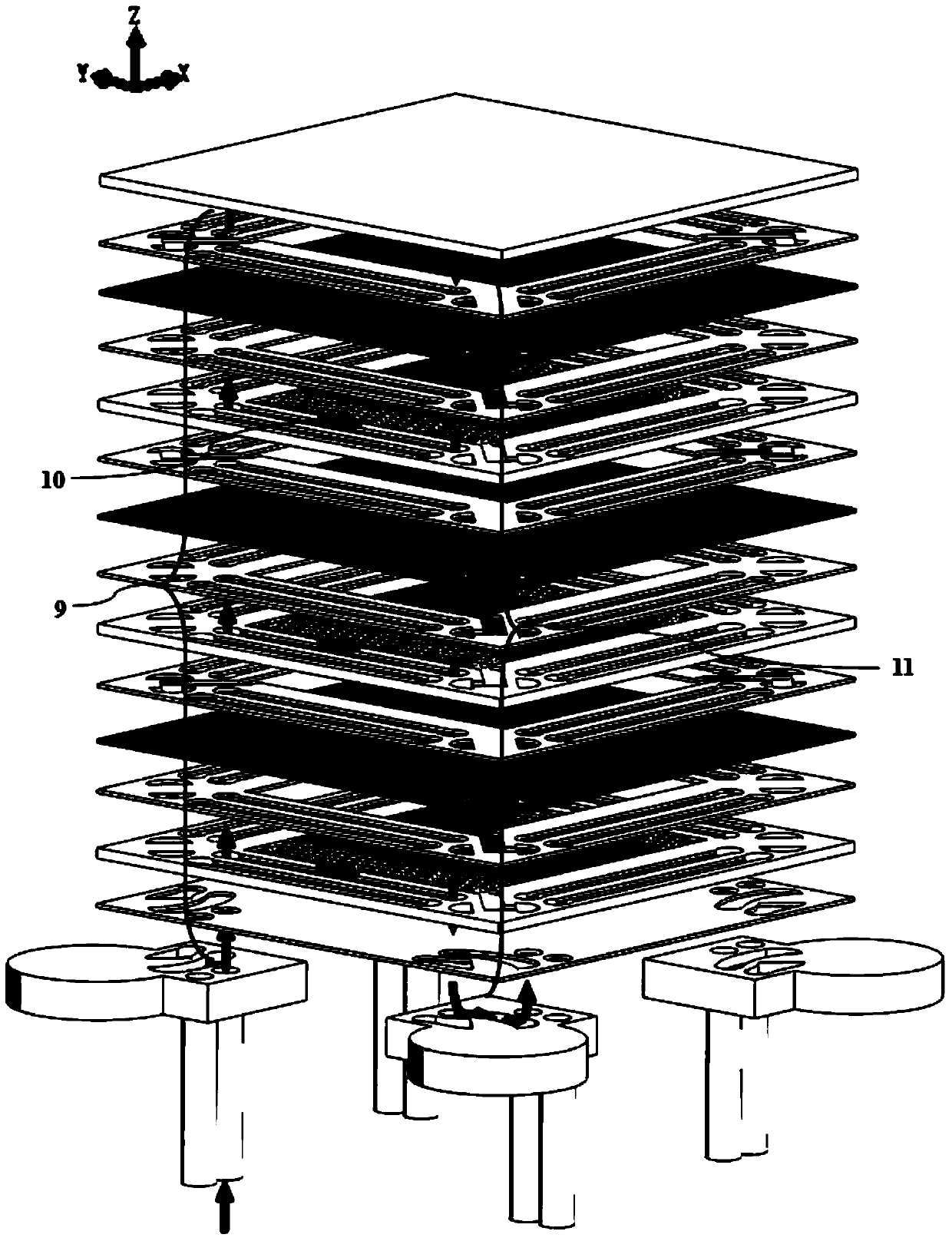

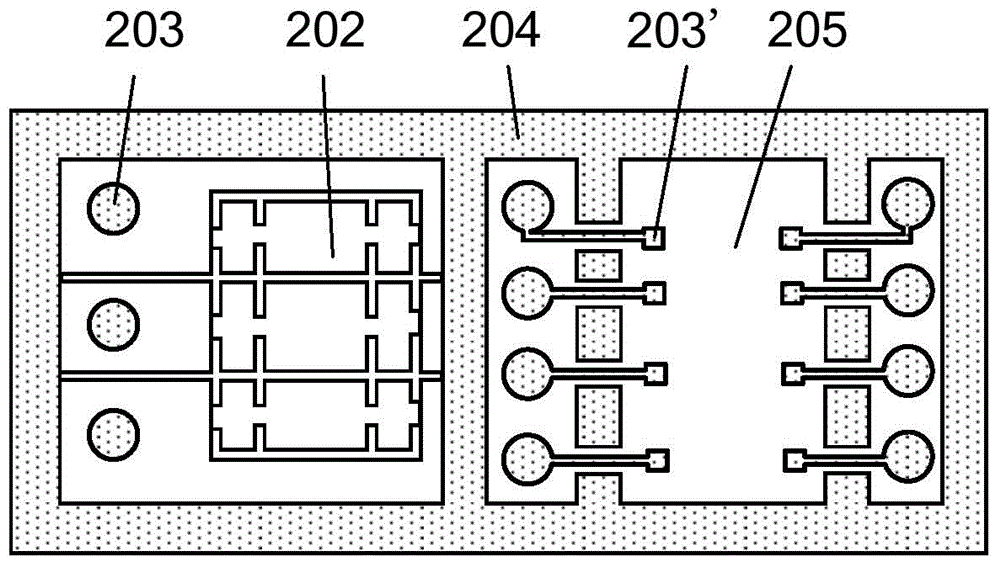

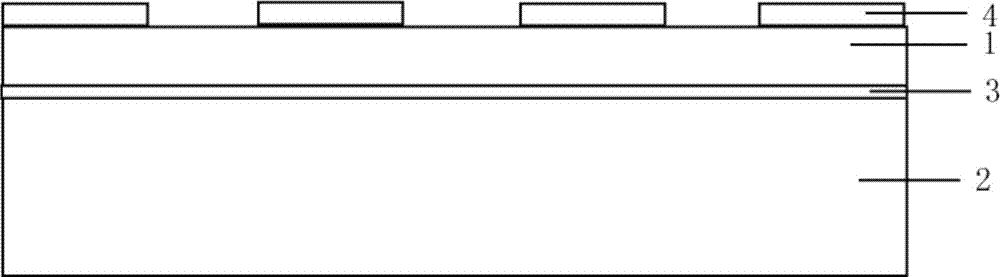

LTCC-based CGA integrated packaging structure and realization method thereof

ActiveCN107301982AAchieve weldingHigh densitySemiconductor/solid-state device detailsSolid-state devicesSystem integrationShape change

The invention discloses an LTCC-based CGA integrated packaging structure and a realization method thereof. An LTCC technology and a CGA technology are combined, and a CGA array is manufactured on the bottom surface of an LTCC substrate by adopting a tool through a welding mode; the LTCC is used as an interconnecting substrate, a packaging body and a passive element integrated carrier of the module at the same time; and the whole region or a partial region on the substrate is welded with a metal surrounding frame, and airtight packaging in the metal surrounding frame region can be realized through parallel seam welding or laser melting seaming ways. The packaging structure is mainly used for the field of system integration as a packaging platform; by adoption of the CGA, high-reliability interconnection between the module and the exterior is realized, so that large module packaging dimensions can be realized; by adoption of the LTCC, integration of active devices and passive elements can be realized at the same time, so that system integrated density is greatly improved; by virtue of the high-precision welding of the metal surrounding frame, high packaging efficiency is realized; due to the position and shape changes of the metal surrounding frame, different applications of electromagnetic shielding, airtightness and the like can be realized; and in addition, the packaging structure has high fundamentality and expandability.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Chicken feed

InactiveCN105166482AImprove protein qualityIncrease the ratio of calcium hydrogen phosphateAnimal feeding stuffChemistryAutumn season

The invention discloses a chicken feed. The chicken feed comprises the following raw materials in parts by weight: 140-210 parts of bean meal, 500-600 parts of corn, 50-100 parts of stone powder, 0.2-0.5 part of vitamin, 2-3 parts of micromineral, 10-50 parts of calcium hydrogen phosphate, 0.5-1 part of active dry yeast, 0.1-0.4 part of table salt, 5-10 parts of vegetable oil, 0.2-0.5 part of choline chloride, 1-1.5 parts of earthworm powder, 2-5 parts of pine straw powder, 1-2 parts of additives and 1.4-2 parts of traditional Chinese medicine. The chicken feed is capable of improving resistance and reducing disease rate of laying hens in the spring and autumn seasons; moreover, the chicken feed is capable of greatly raising egg production of the laying hens.

Owner:广西南宁劲能农业科技有限公司

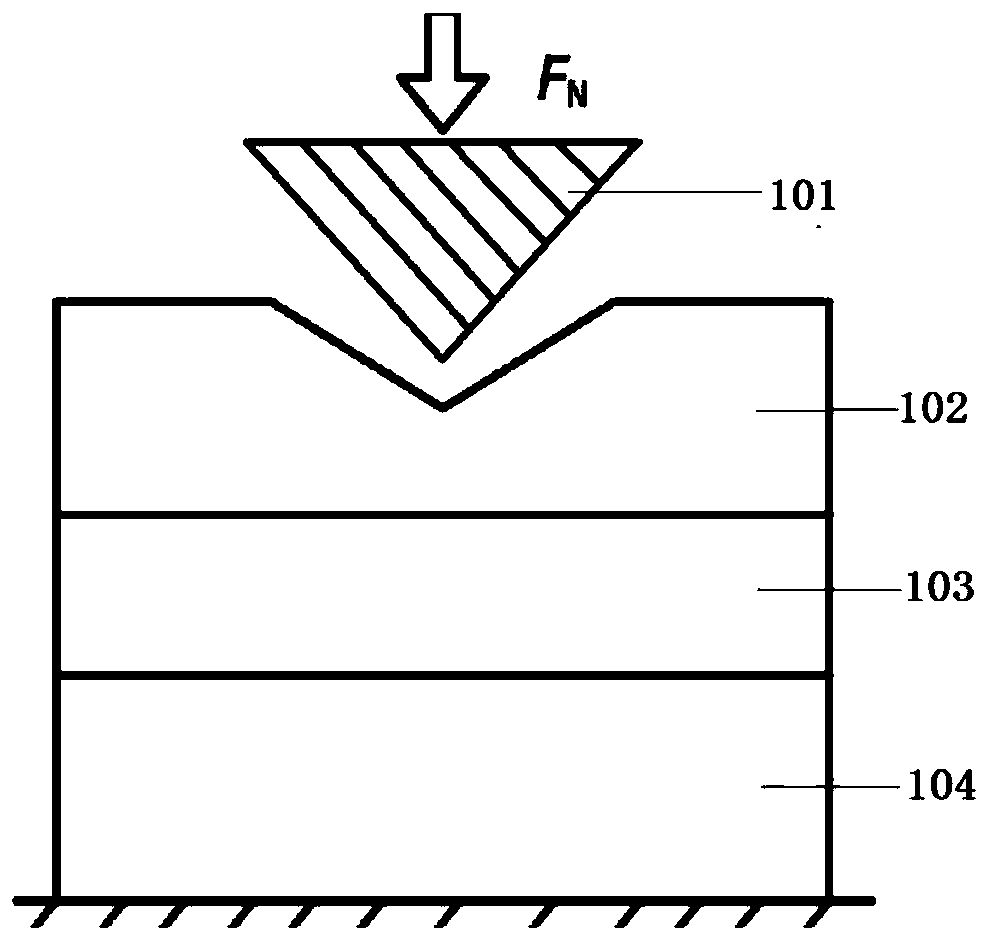

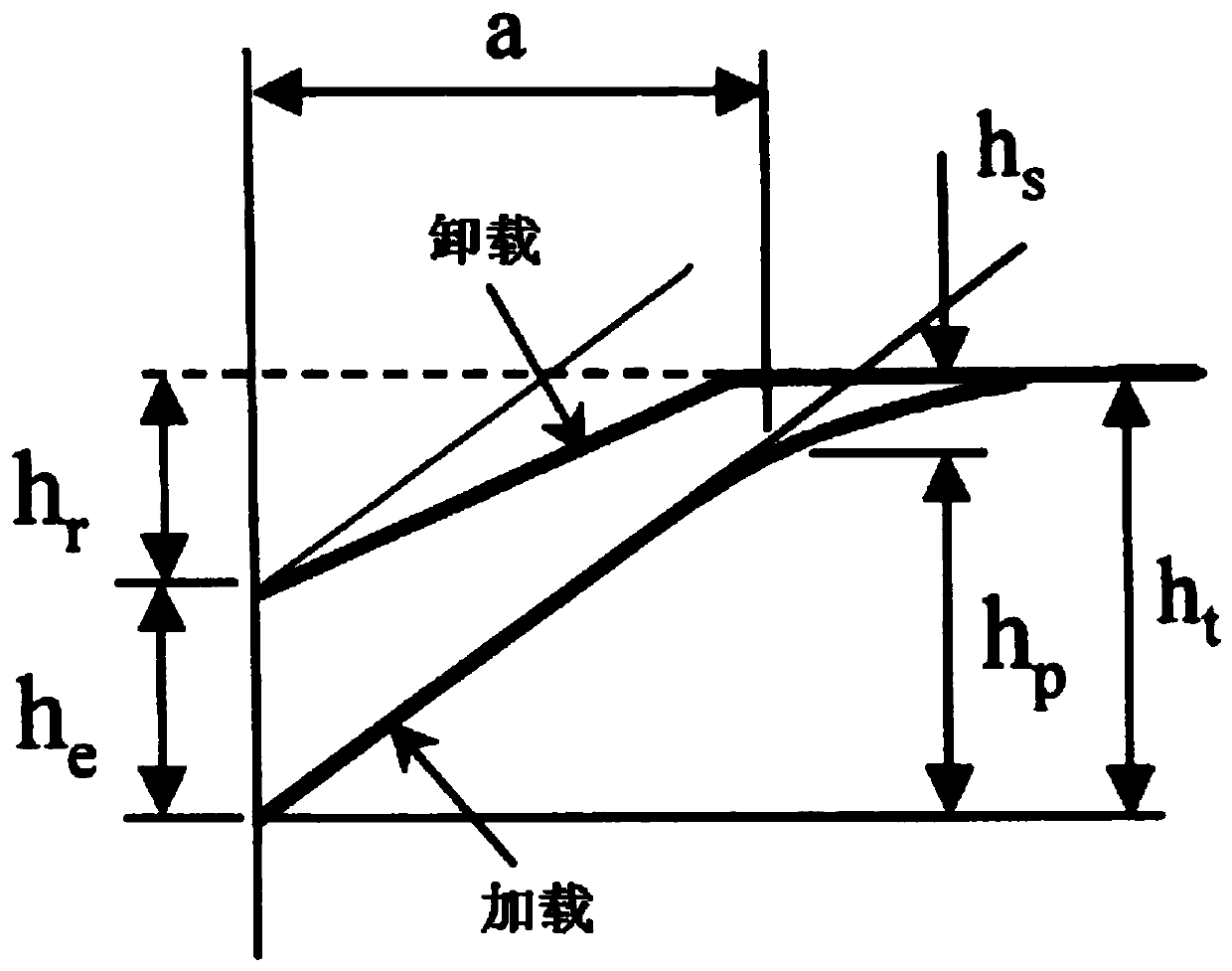

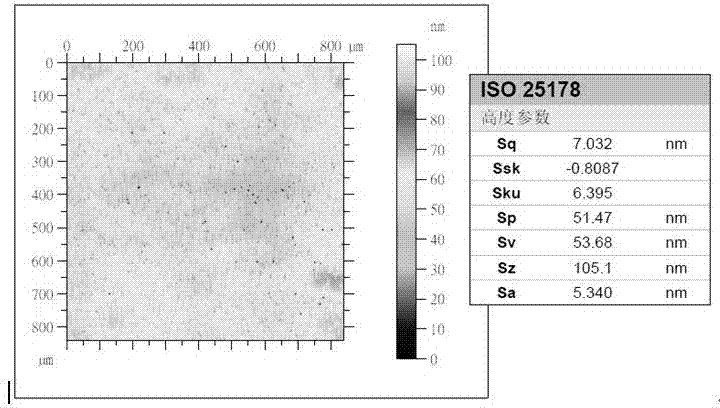

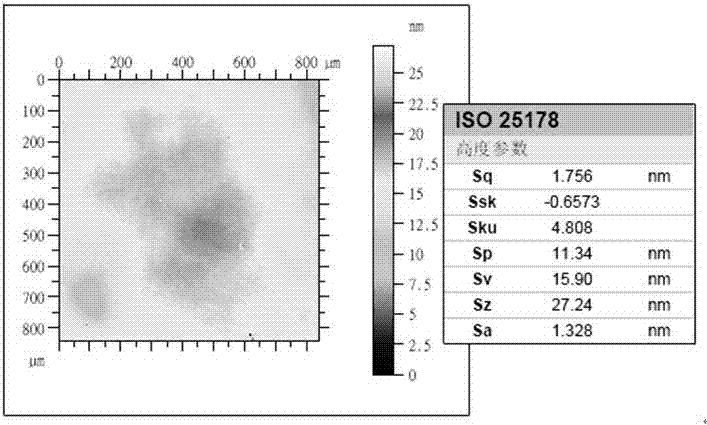

Method for testing nano-indentation of coating property

InactiveCN110031349ATemperature won't changeGuaranteed accuracyInvestigating material hardnessCoated surfaceIndentation testing

The invention discloses a method for testing a nano-indentation of a coating property. The method comprises the following specific steps of fixing a sample on a sample holder of a nano-indentation test system; regulating the temperature of the sample and a pressure head by using a temperature module, so that the sample and the pressure head are kept at a target temperature; applying and unloadinga load on the coating surface according to the set, and synchronously recording the depth of the indentation to obtain a load-depth curve; and calculating mechanical parameters of the coating based onthe load-depth curve. The temperature module enables the pressure head and the sample to reach the target temperature and maintain the target temperature and then an indentation test is carried out,so that the temperature of the sample, the pressure head and a contact point during the measurement process is ensured to be not changed, the load-depth curve of various temperature conditions can beobtained, and mechanical parameters of the coating at various temperatures can be calculated conveniently. Meanwhile, the problems of temperature gradient and thermal stress formed between the sampleand the pressure head are avoided, and the precision of the load-depth curve is effectively guaranteed.

Owner:CASIC DEFENSE TECH RES & TEST CENT

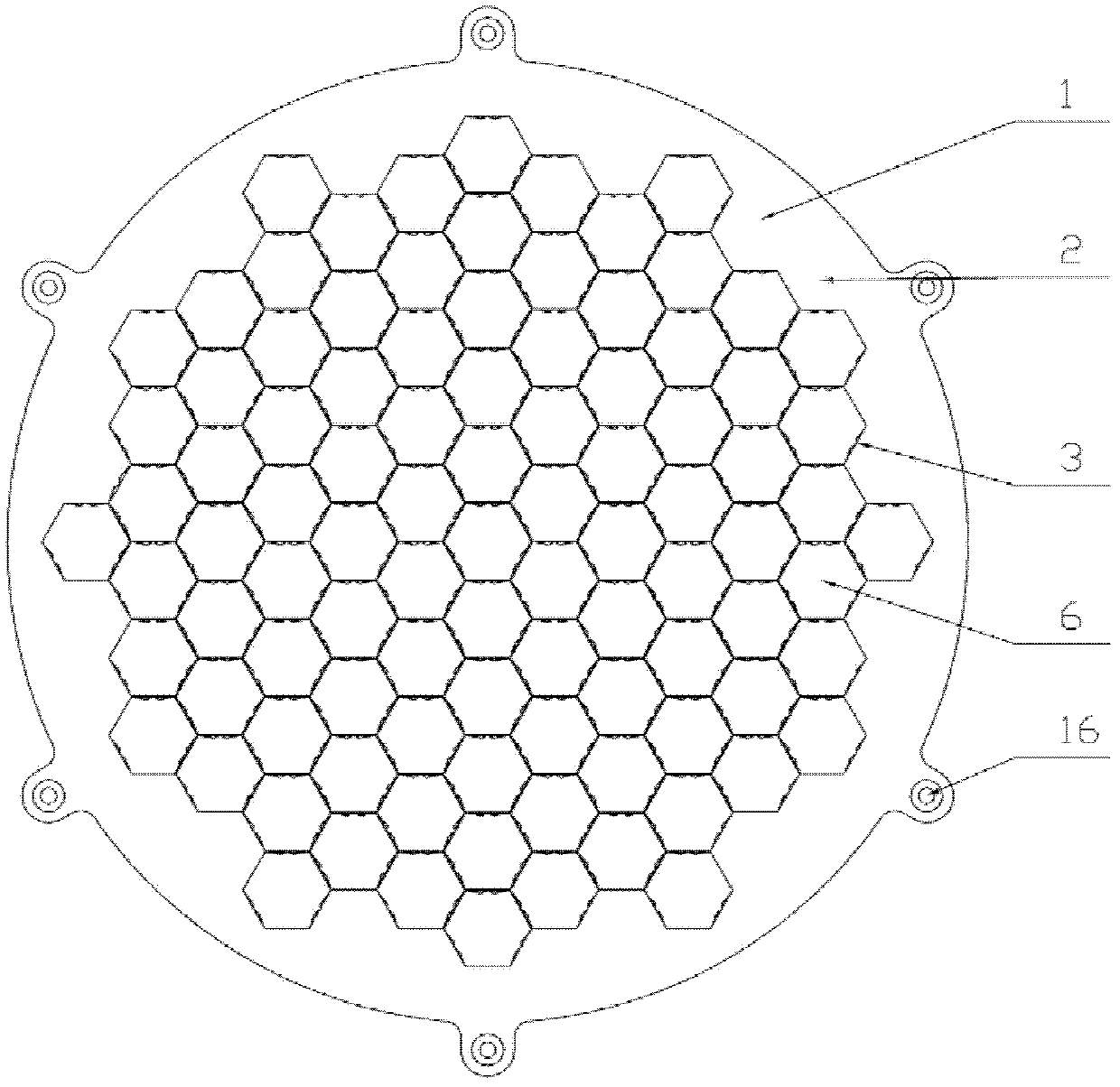

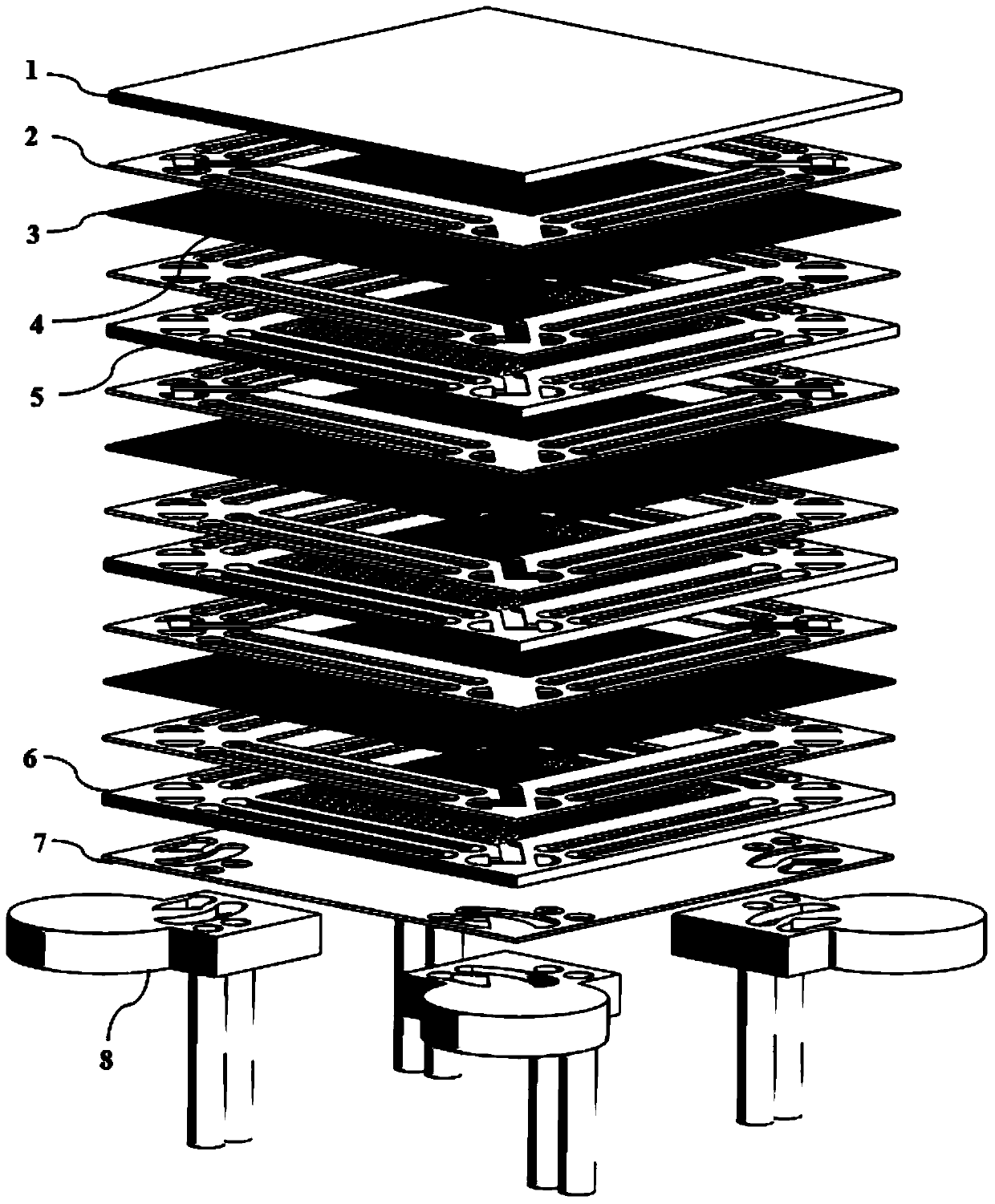

Flat plate type solid oxide fuel battery stack device

InactiveCN104218252AReduce the temperatureFacilitate heat exchangeReactant parameters controlFuel cells groupingFuel cellsAir tightness

The invention discloses a flat plate type solid oxide fuel battery stack device. The flat plate type solid oxide fuel battery stack device comprises bases, single batteries, a single battery frame, a sealing piece, a connector, fuel pipelines and air pipelines, wherein the connector is provided with a battery coverage area and a heat exchange area, and the gas in the fuel pipelines and the air pipelines passes through a main air-intake pipeline, an air-intake collecting pipeline, an air-intake flow allocation pipeline, an exhaust collecting pipeline, an exhaust flow allocation pipeline and a main exhaust pipeline in sequence. The flat plate type solid oxide fuel battery stack device is in favor of the heat exchange between cold fluid and hot fluid and capable of reducing the temperature at a hot fluid outlet end, and the sealing piece is far away from the high temperature area, thereby improving the air tightness of fuel battery stacks and prolonging the service life of the sealing piece.

Owner:JIANGSU UNIV OF SCI & TECH

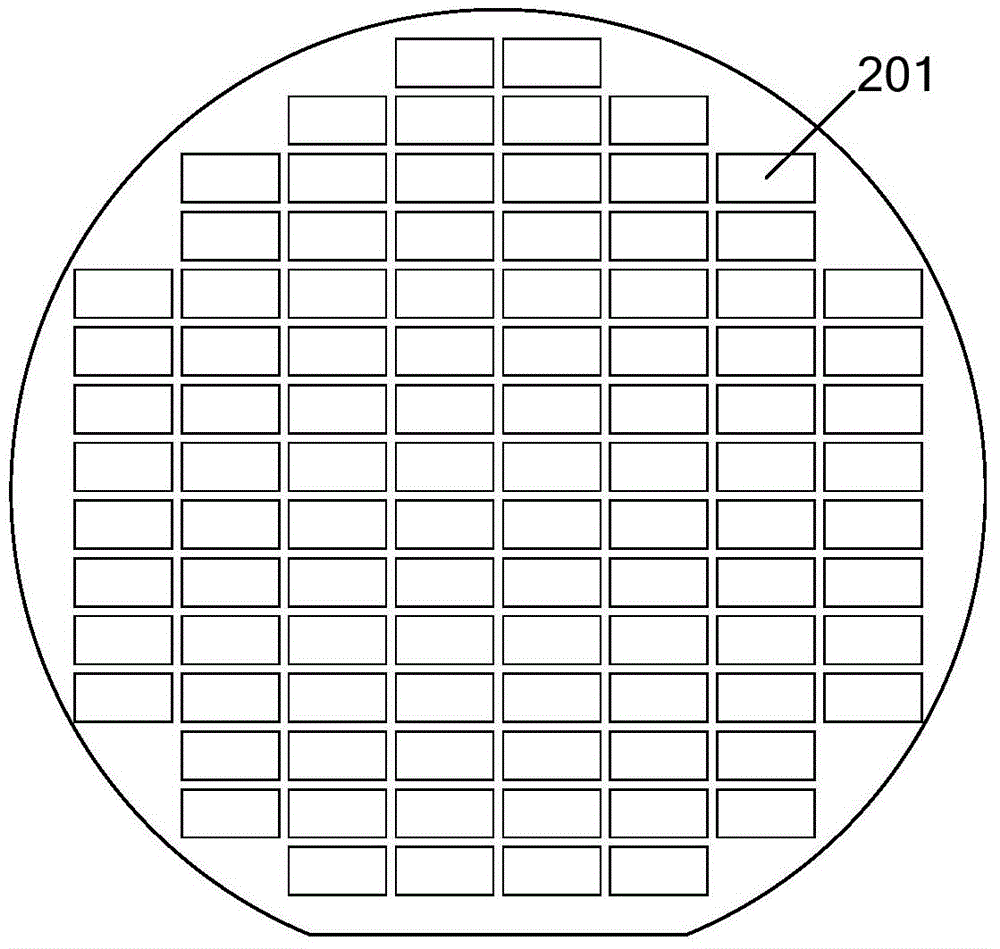

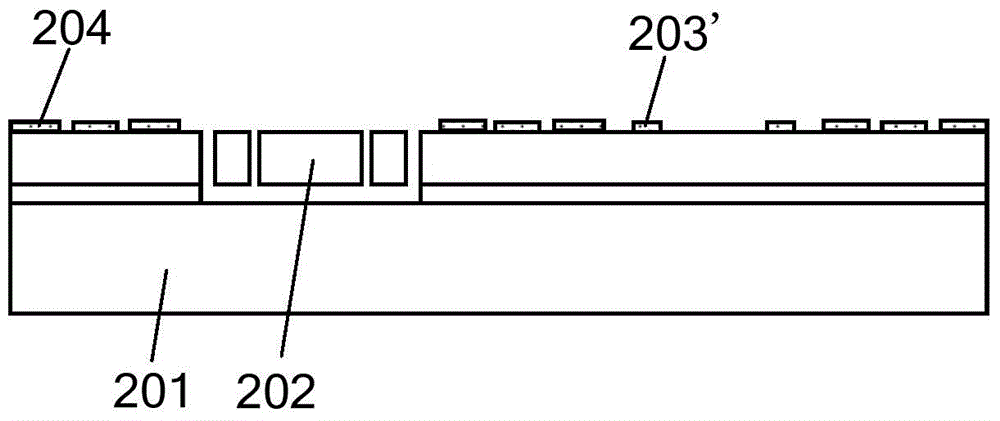

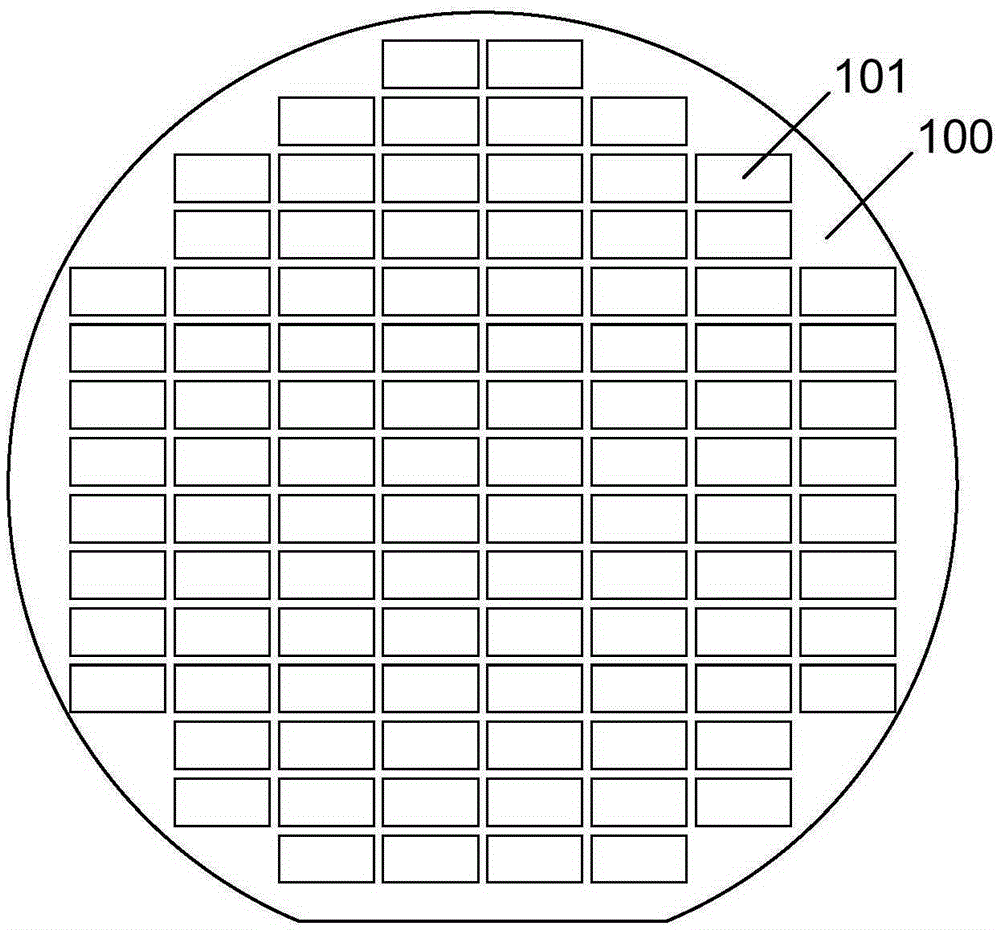

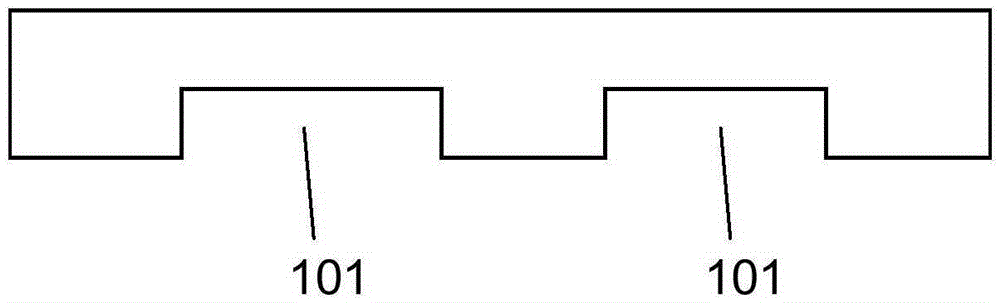

Novel packaging method of MEMS (Micro-electromechanical Systems) structure and processing circuit integrated system

ActiveCN103818874ASimple processGood effectDecorative surface effectsSolid-state devicesEngineeringThermal expansion

The invention relates to a novel packaging method of an MEMS (Micro-electromechanical Systems) structure and a processing circuit integrated system. The method comprises the following steps: (1) preserving a plurality of circuit chip holding areas on each substrate unit of an MEMS wafer, and putting circuit chips on the MEMS wafer to form integration of the MEMS structure with a processing circuit; (2) utilizing a vertical intercoupling technique, using silicon as a cover plate in which a vertical through hole is formed, filling a conductive material into the through hole to form an input port and an output port of the structure; (3) forming a plurality of grooves in the binding surface of the cover plate for providing a vacuum airtight environment necessary for working of an MEMS device and a space required by the circuit, wherein an air sucking agent film inside the cover plate groove is used for maintaining the vacuum degree; (4) performing wafer binding on the cover plate and the MEMS wafer so as to achieve the wafer grade vacuum integrated packaging. The method is not only simple in process, wide in application range and remarkable in effect, but also can avoid thermal stress caused by the coefficient of thermal expansion, and can remarkably improve the temperature coefficient of a device.

Owner:BEIJING MXTRONICS CORP +1

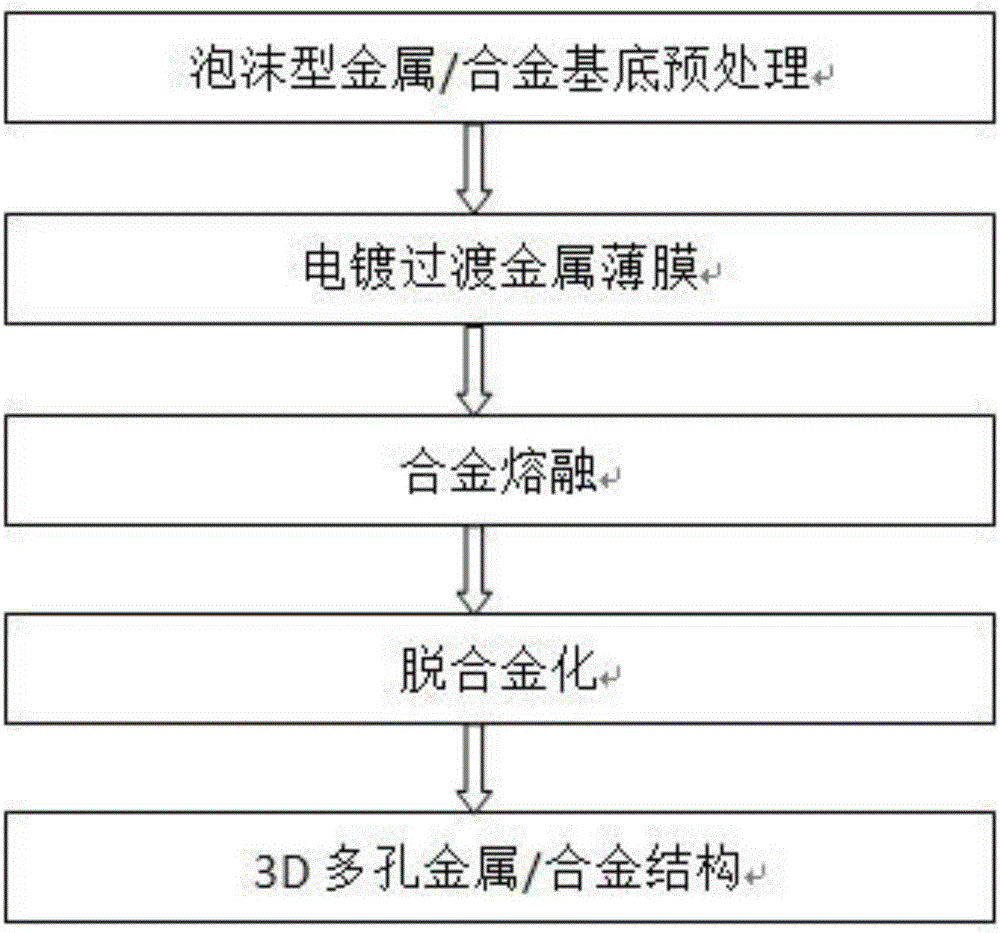

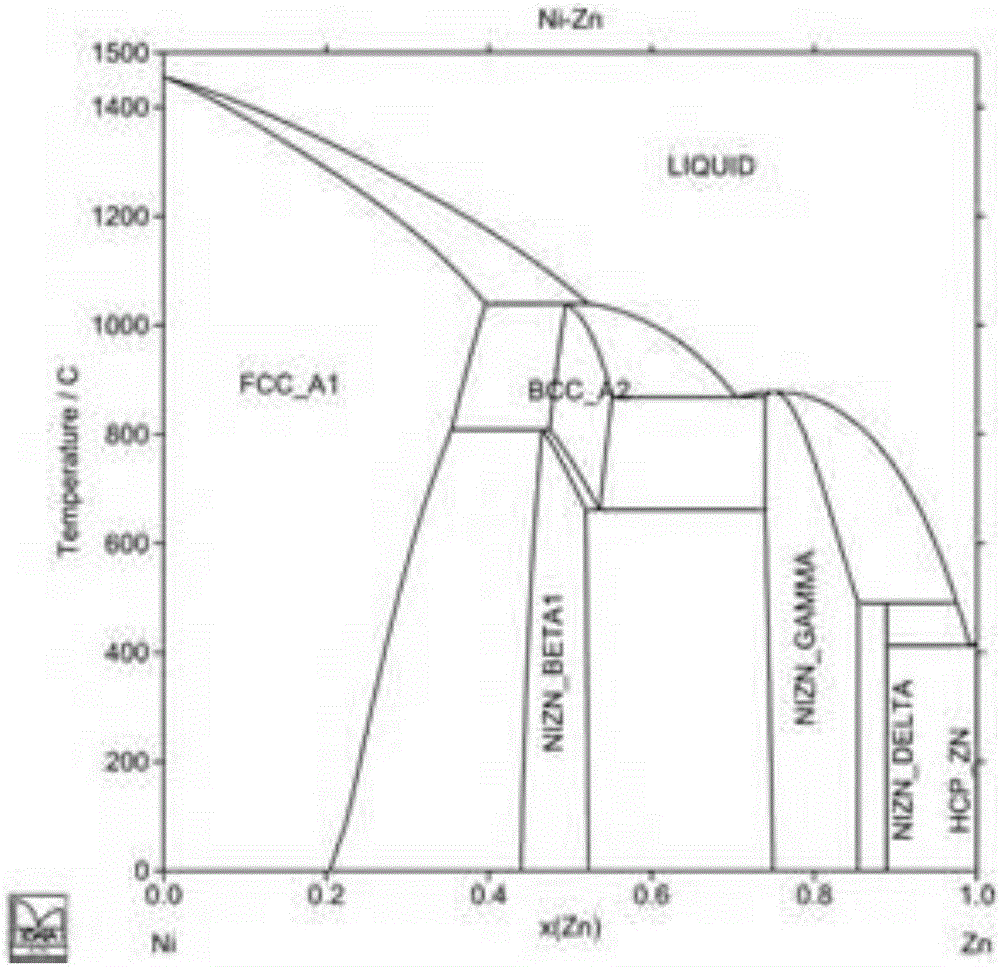

Preparation method for 3D nano porous metal materials

InactiveCN106757234ASolving the Problem of Controlling Aperture SizeUniform and controllable structureAlloy substrateMetallic materials

The invention discloses a preparation method for 3D nano porous metal materials, and mainly solves the problem that metal or alloy prepared in the prior art is large in aperture size, small in specific surface area, low in porosity and difficult to briquette. The implementation scheme of the preparation method for the 3D nano porous metal materials comprises the steps that 1) a foam metal / alloy substrate is subjected to cleaning and activating pretreatment; 2) a transition metal thin film is electroplated on the pretreated foam metal / alloy substrate; 3) the substrate and the transition metal thin film are subjected to alloy melting; and 4) an electrochemical selective corrosion method is adopted for molten alloy, electroplated transition metal in the alloy is corroded, dealloying is carried out, and preparation for the porous metal materials is completed. According to the the preparation method for the 3D nano porous metal materials, the specific surface area and the porosity of the nano-porous metal materials are increased, the aperture size is controllable, and the nano-porous metal materials can serve as a substrate for growing other porous nano-scale structural materials.

Owner:XIDIAN UNIV

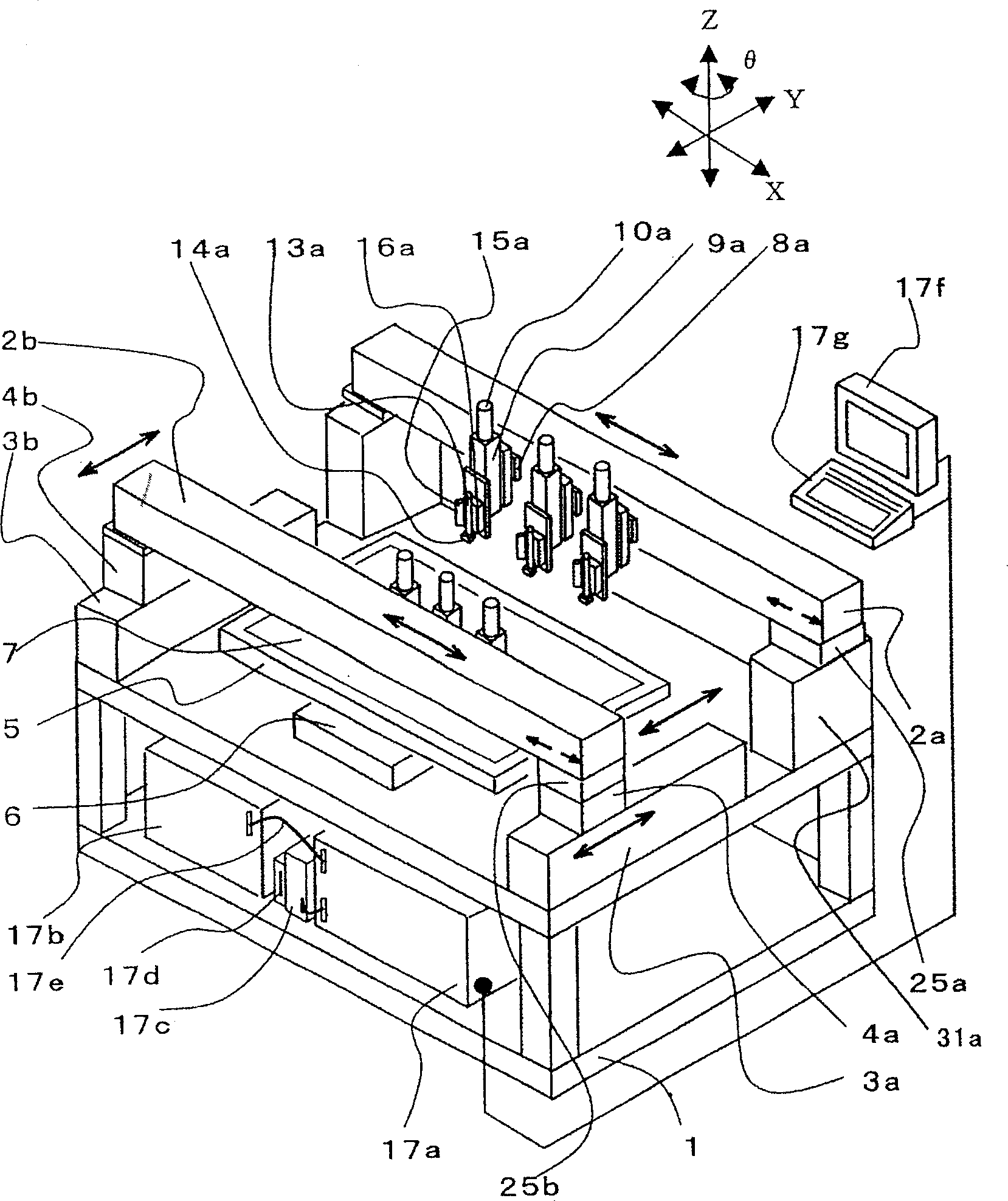

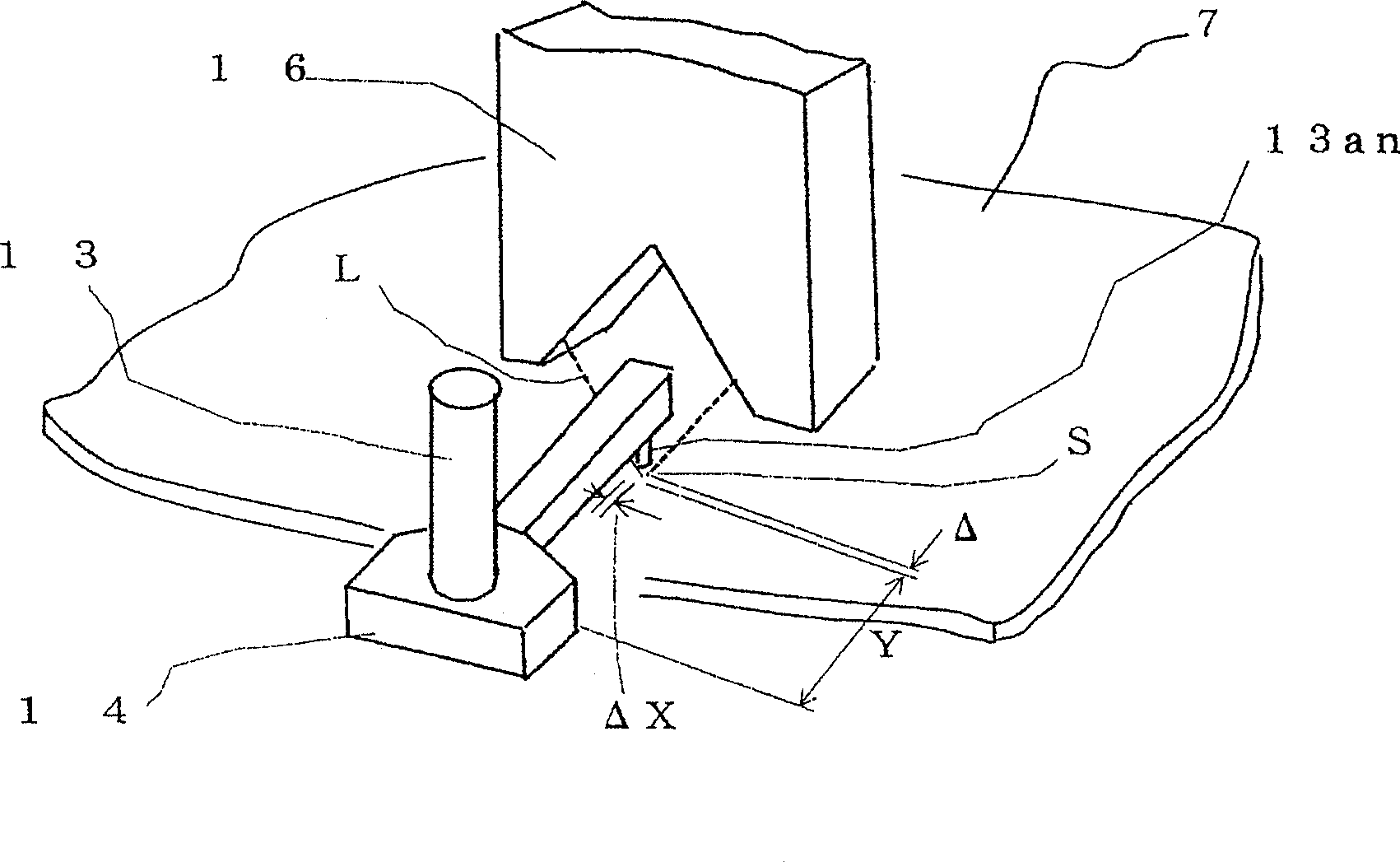

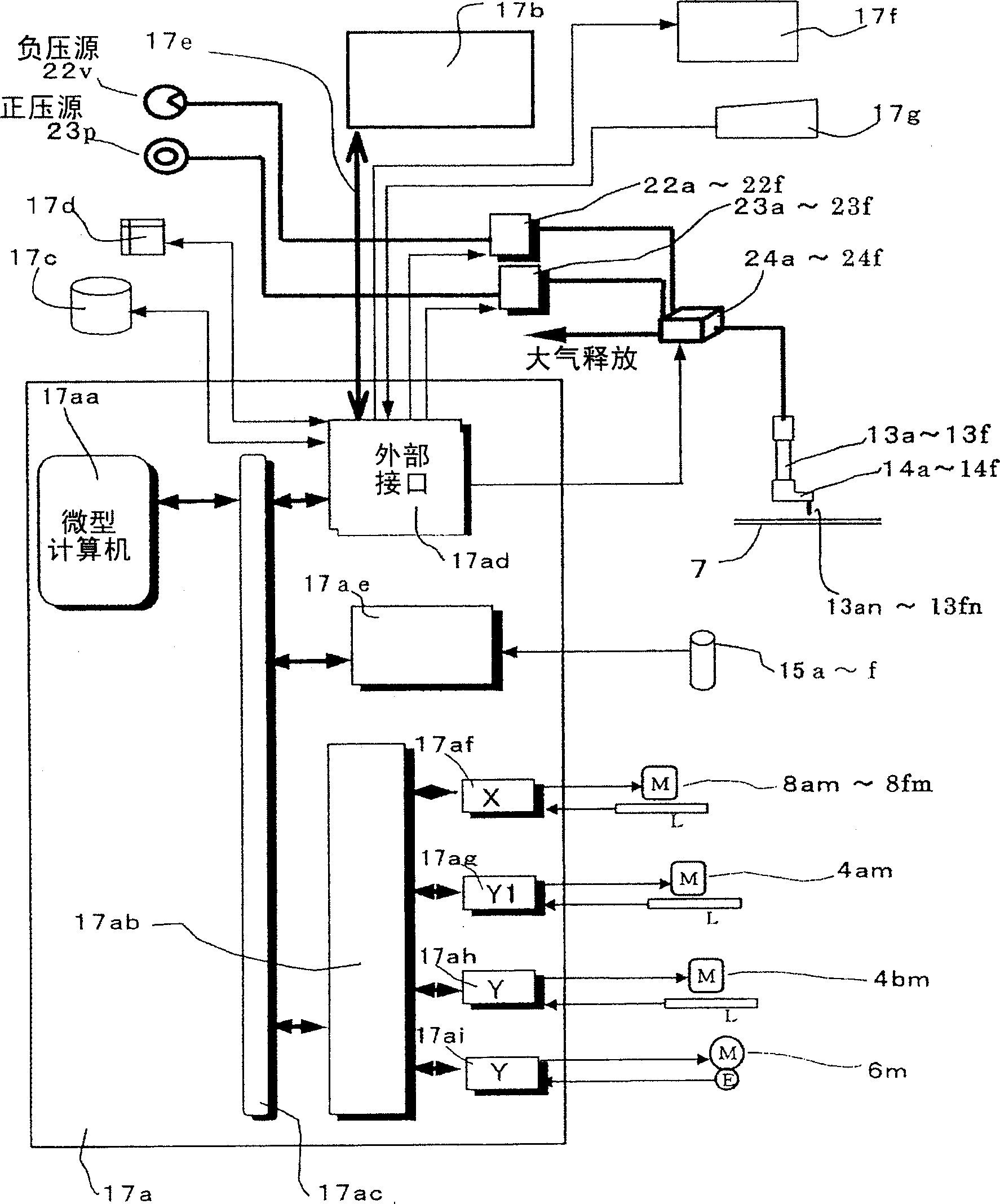

Coating device and method

InactiveCN1748873AAvoid heat stressLiquid surface applicatorsSpraying apparatusPrimary standardEngineering

With the upsizing of devices, a door-shaped framework comprising a plurality of coating heads deforms due to heat expansion and the precision of coating positions is reduced, thus the problem of incapability of precisely coating is raised. Therefore, the invention adopts the technical proposal that: one side of the framework is fixed, the other side of the framework is supported by a straight-action linear guide rail which can be moved along the length direction of the framework, thereby heat stress (the bending of the framework) caused by the heat expansion does not happen in the framework; meanwhile, position deviations of heads caused by the heat expansion are corrected by means of a primary standard calculating heat expansion capacity.

Owner:HITACHI PLANT TECH LTD

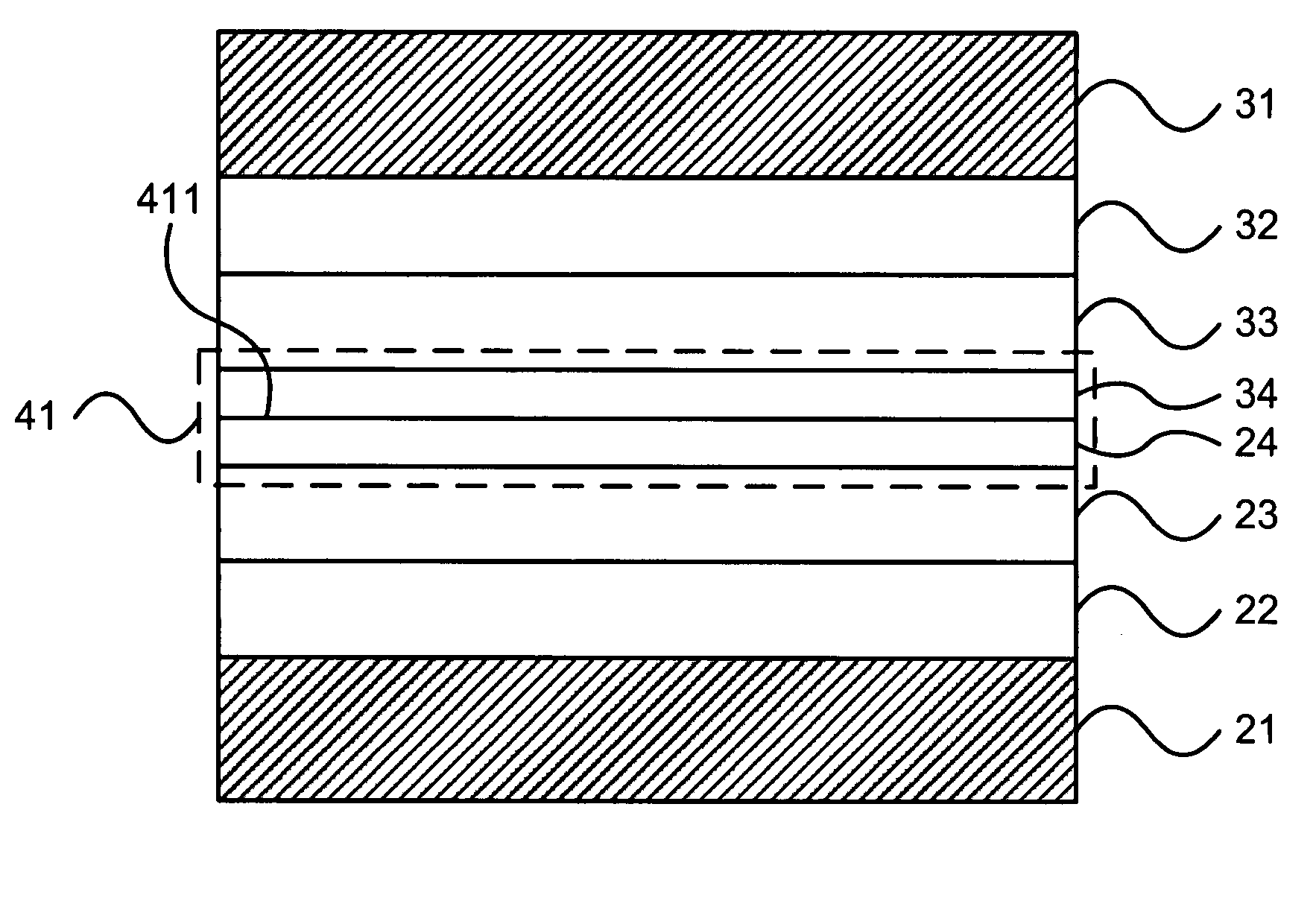

MEMS wafer level vacuum package structure and manufacturing method thereof

InactiveCN105293420AAvoid contaminationImprove resonance performanceDecorative surface effectsSolid-state devicesLead bondingWafer dicing

The invention provides an MEMS wafer level vacuum package structure and a manufacturing method thereof. The package structure comprises a silicon cover plate and an MEMS wafer with a movable structure, wherein a vertical through hole is formed on the cover plate, the through hole is internally filled with a conductive material, a bonding surface of the cover plate is provided with a groove, a layer of getter film is arranged at the bottom of the groove, and the silicon cover plate and the MEMS wafer with the movable structure form the vacuum package structure by wafer bonding. The manufacturing method provided by the invention comprises the following steps: at first, manufacturing the through hole on the cover plate, and filling the conductive material in the hole; and then, forming the groove on the bonding surface, depositing a layer of getter film on the bottom of the groove, depositing a layer of multilayer metal film in a bonding area, and wafer bonding the cover plate with the MEMS wafer with the movable structure in a vacuum environment. According to the MEMS wafer level vacuum package structure provided by the invention, the groove with the getter and the through hole are formed on the silicon cover plate to export an electrode from the closed groove without carrying out wire bonding, so that the procedures are simple, meanwhile, the vacuum maintenance ability in the package structure is improved, contamination of granules to the movable structure during cutting is avoided, and performance of the device is guaranteed.

Owner:BEIJING MXTRONICS CORP +1

Feeding method for sows from pregnancy to parturition

InactiveCN106922603AHeating fastAvoid heat stressFood processingAnimal feeding stuffWeaningWeightlessness

The invention relates to a feeding method for sows from pregnancy to parturition. The method comprises the following steps: preparing feed for sows from pregnancy to parturition and preparing nursing sow feed and restricting feed to pregnant sows; feeding in all following stages including weaning and breeding, feeding in a short term (estrualization), 7days after breeding, 7-100 days after breeding, 95 days after pregnancy to 112 days and sow delivery. The feeding method for sows from pregnancy to parturition has the following beneficial effects: by preparing dedicated feeds for pregnant sows and nursing sows, the sows are processed in different periods; special-purpose microecologics and preventative heat stress can effectively prevent constipation; feed with high content of energy, proteins and unsaturated fatty acid enable sow milk to be sufficient; full nutrition and reduction in weightlessness of a lactation period help promote oestrus of sows; by the method for feeding, a sow can deliver more than 10 piglets weighted average at 1.5 kilograms; after 28 days of weaning, the individual weight of each sow can be up to 8 kilograms; and estrus rate of the piglets within 5 days of sows is up to more than 90%.

Owner:株洲市良强饲料科技有限公司

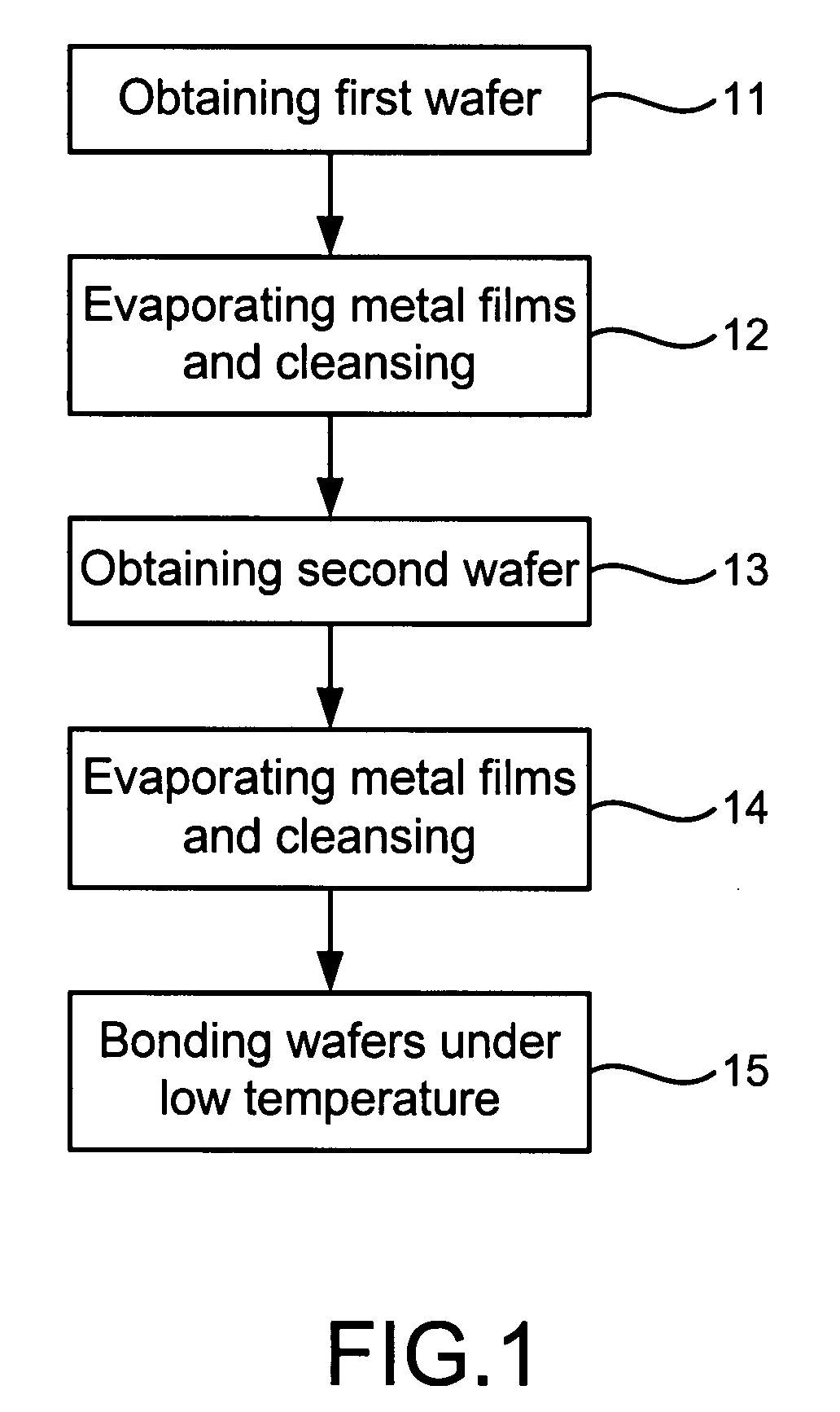

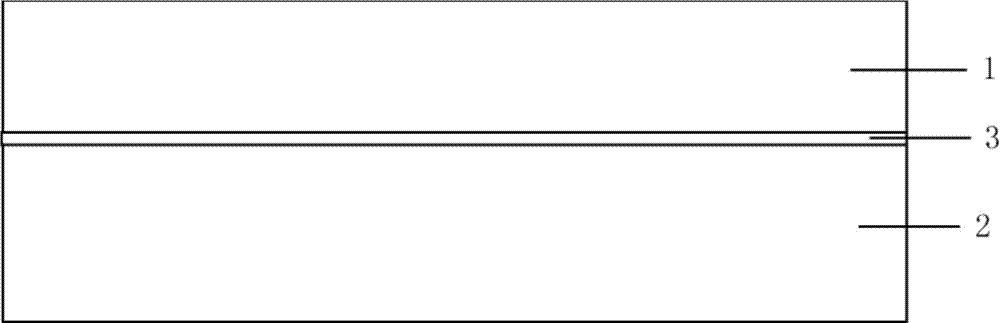

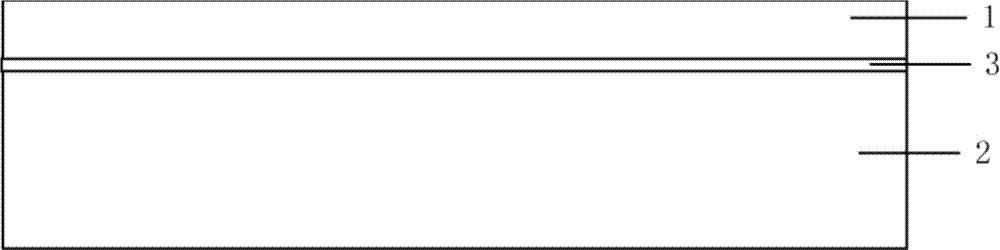

Method of low temperature wafer bonding through Au/Ag diffusion

InactiveUS20080194077A1Avoid heat stressAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingBonding processOptoelectronics

Two wafers are bonded. One wafer has a gold (Au) film on its surface; the other, a silver (Ag) film. The wafers are stuck together for a bonding process between the Au and the Ag films. Thus, an Au / Ag bonding layer is formed. The bonding layer has a high melting point and so is suitable for high-temperature processes. The bonding process also do no harm to devices on the bonded wafer.

Owner:NAT CENT UNIV

Welding method of super-thick steel casting

InactiveCN109108431AEliminate welding residual stressReduces the chance of weld cracksArc welding apparatusFurnace typesLayer removalWelding deformation

The invention discloses a welding method of a super-thick steel casting. Process steps include S1, preparing a joint: an asymmetric X-type groove is adopted; S2, preheating: the front side and the reverse side are uniformly heated, the preheating temperature is set within the range of 150-160 DEG C, and the heating rate does not exceed 100 DEG C / h; S3, back welding: gas shielded welding backingis carried out on flux-cored welding wires for three layers, and fire warming is carried out to remove stress after each weld seam is welded; S4, reverse side air gouging: air gouging back chipping and carburized layer removal are carried out; S5, reverse side back welding: back welding is carried out by three layers after the temperature of the steel casting reaches a preheating temperature according to the method described in the step 2, and fire warming is performed on each weld seam to remove stress; S6, filling and cover surface welding: the front side and the reverse side are welded respectively by one welder simultaneously and symmetrically, and hammering is carried out layer by layer after each layer of weld beads of each weld seam is welded; and S7, 550 DEG C *2h heat treatment after stress removal is carried out immediately after the completion of welding. By means of the method, welding stress and welding deformation can be significantly reduced, and the probability of generating steel casting welding cracks is greatly reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

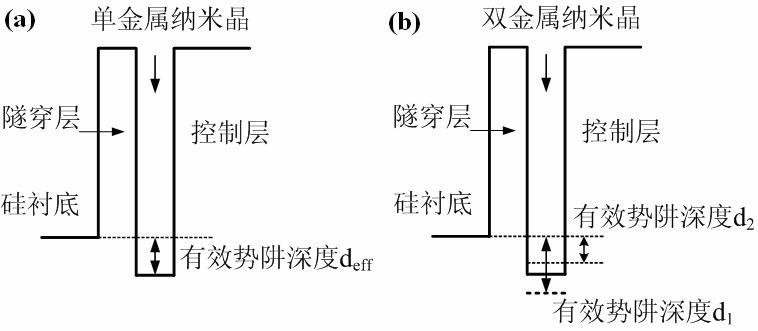

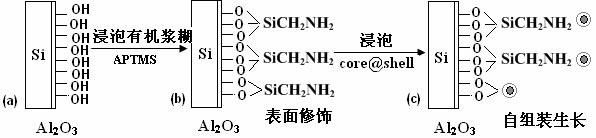

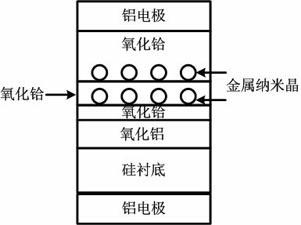

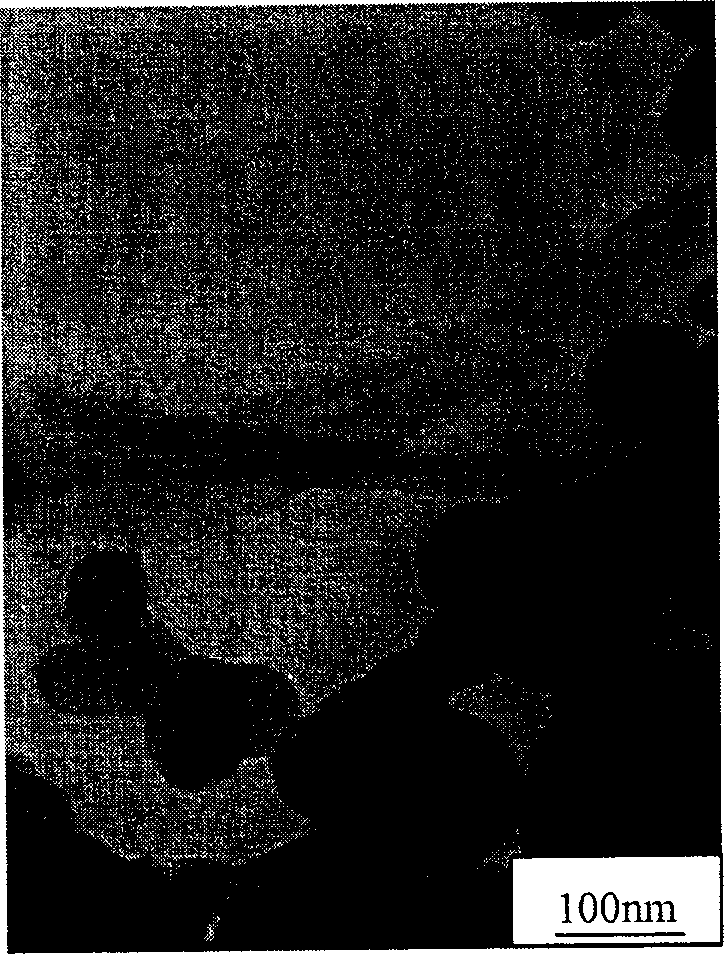

Metal nanocrystalline storage capacitor and preparation method thereof

InactiveCN102184848AReduce energy consumption and costsAvoid heat stressSemiconductor/solid-state device manufacturingSemiconductor devicesWork functionMulti element

The invention belongs to the technical field of semiconductor storage manufacturing, namely a method for preparing a metal nanocrystalline storage capacitor. By the method, a metal nanocrystalline with an adjustable work function can be directly obtained on the surface of Al2O3, HfO2, La2O3 and Nb2O5 films deposited on an atomic layer, or a laminated combination of the Al2O3, HfO2, La2O3 and Nb2O5 films or a multi-element mixed thin film surface at room temperature. By the method, one layer or multiple layers of nanocrystalline can be embedded in the medium film; the layers are completely isolated through the medium film; and the size and distribution of each layer of nanocrystalline are not affected in the subsequent medium film depositing process substantially.

Owner:FUDAN UNIV

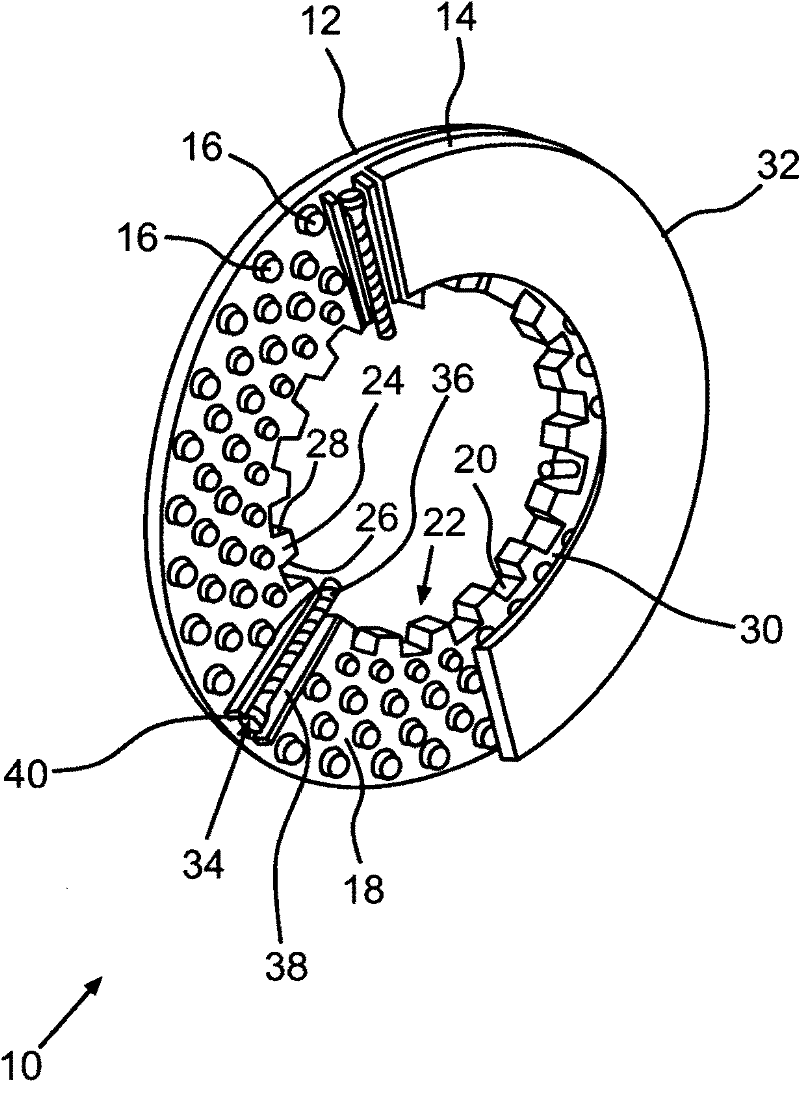

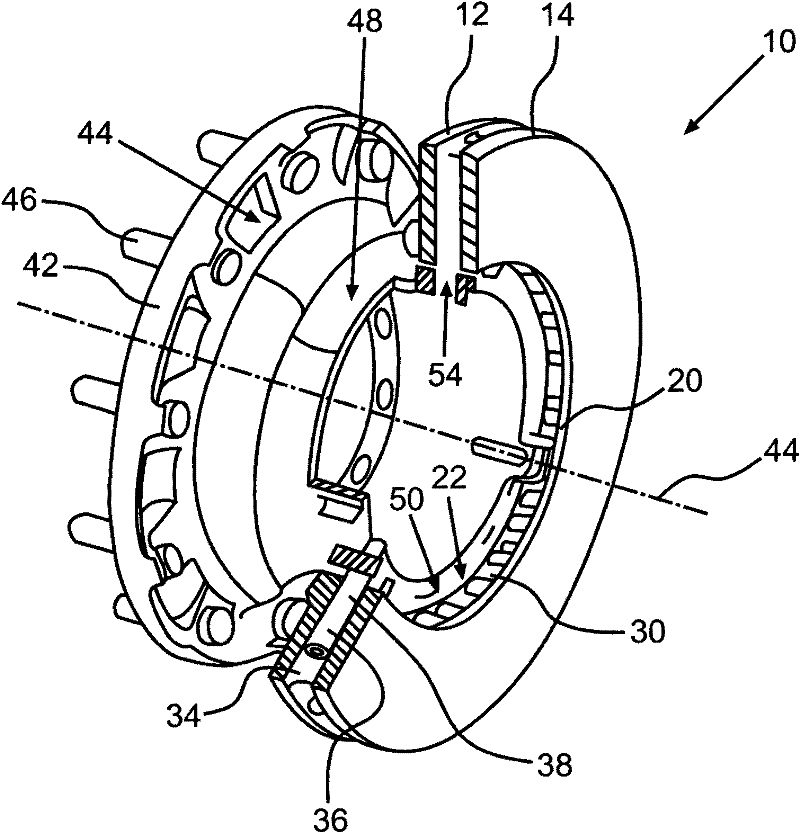

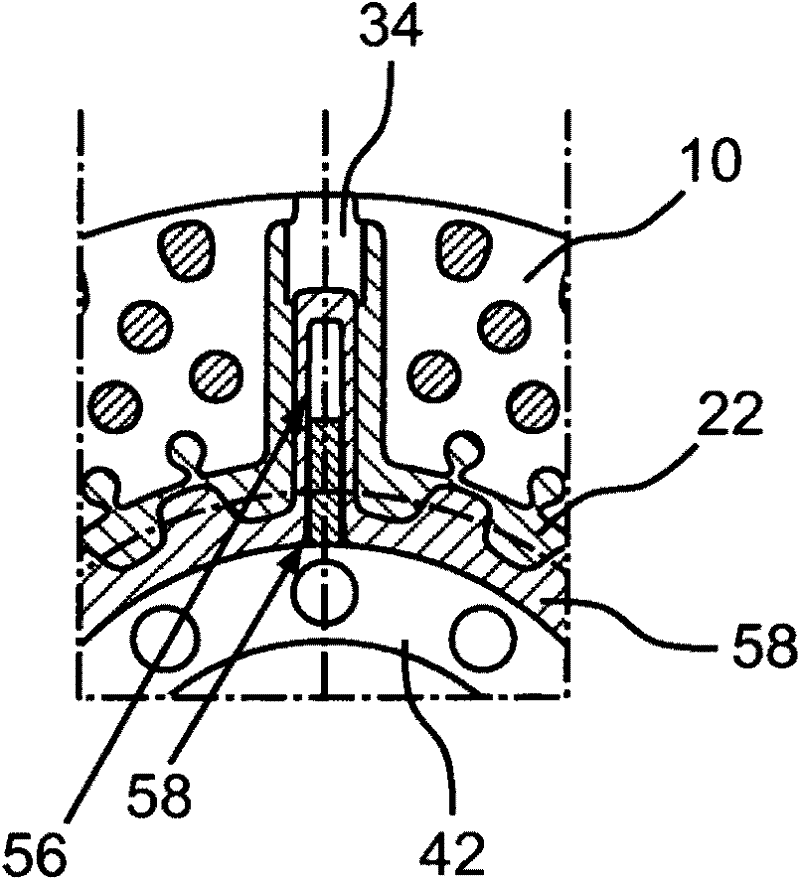

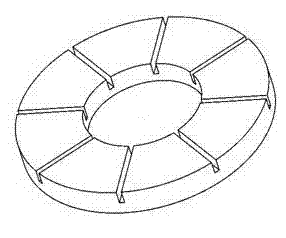

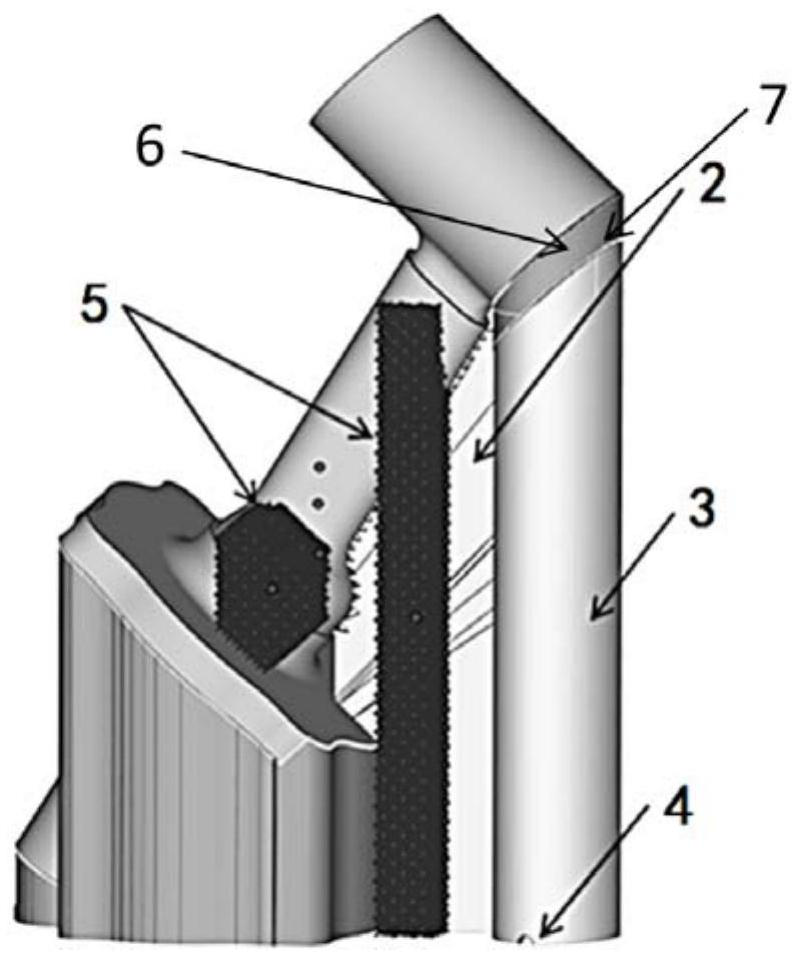

Brake disk having a brake disk pot

The invention relates to a brake disk having a brake disk pot (42) and a friction ring (10) which is positively connected to the brake disk pot via a toothing (50). The friction ring (10) comprises two friction ring halves (12, 14), wherein the toothing extends across only one of the friction ring halves. In this manner it is possible to mount through-passages (30) axially adjacent to the toothing running around the friction ring half on the interior circumference of the friction ring, said passages connecting the interior circumference of the friction ring to an interior ventilation arrangement of the friction ring. In this manner both a good transmission of force and a stable positive connection is ensured between the friction ring and the brake disk pot as is an efficient cooling by means of interior ventilation of the friction ring.

Owner:DAIMLER AG

Electronic packaging material

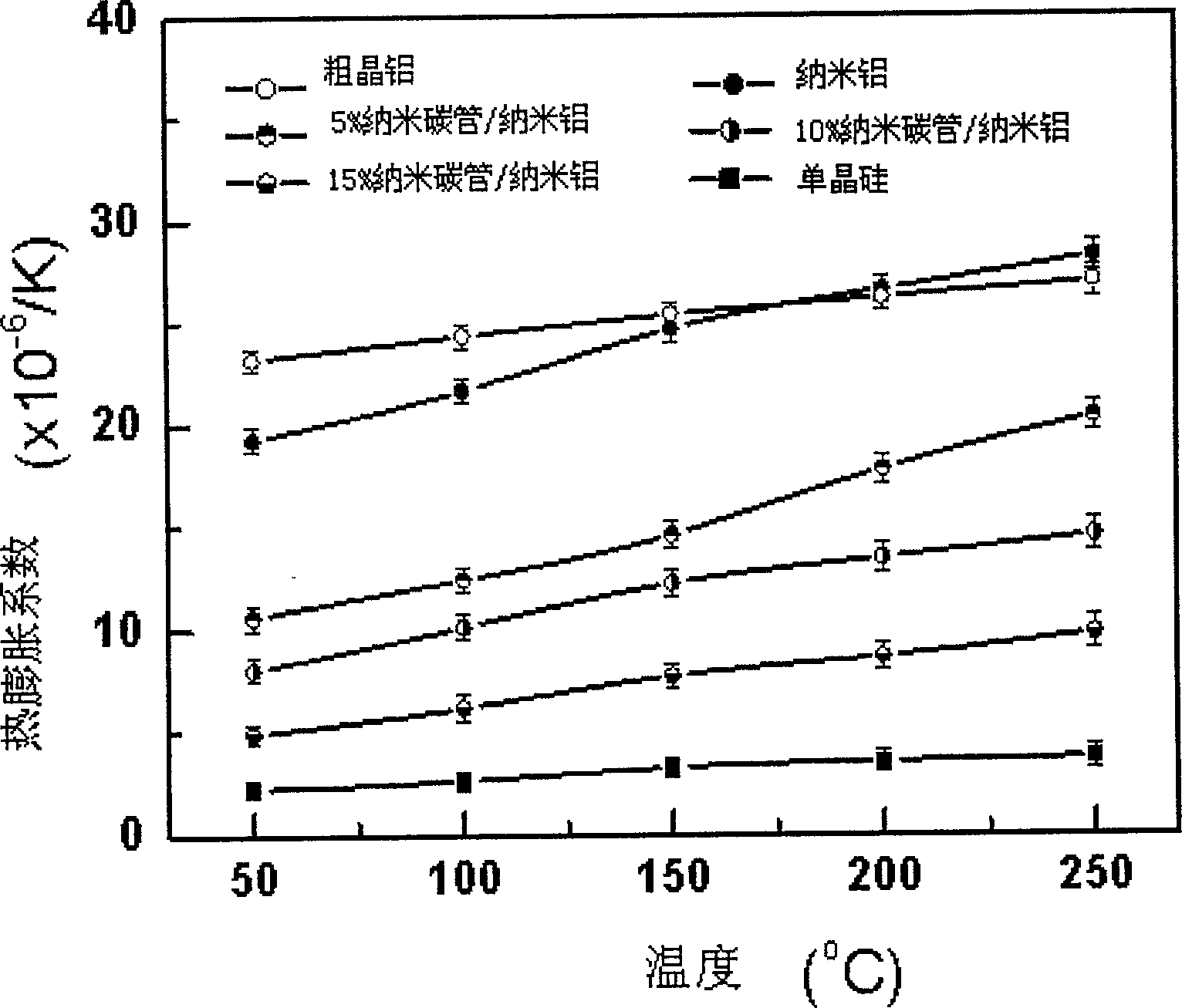

InactiveCN1858143AImprove performanceAvoid heat stressOther chemical processesSemiconductor/solid-state device detailsCarbon nanotubeHeat stress

The electronic packaging material is prepared with nanometer metal as base material and adding carbon nanotube in 0-35 vol%. The base material may be nanometer aluminum. The present invention has the advantages of the synchronous heat expansion with silicon semiconductor to avoid heat stress and heat crack between the silicon semiconductor and packing aluminum material, excellent packaging performance, low cost and wide application.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

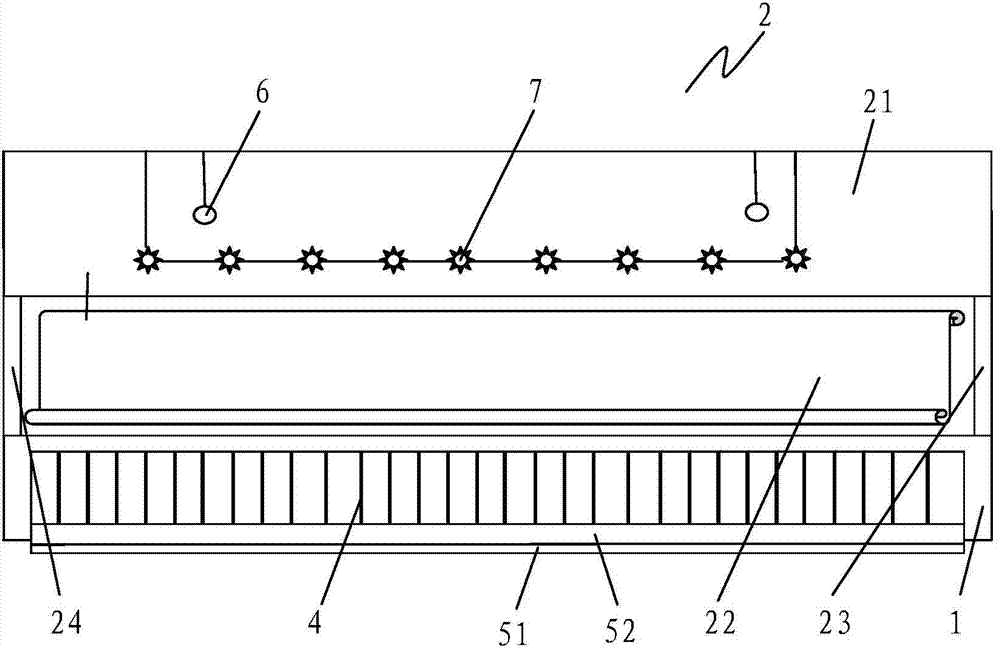

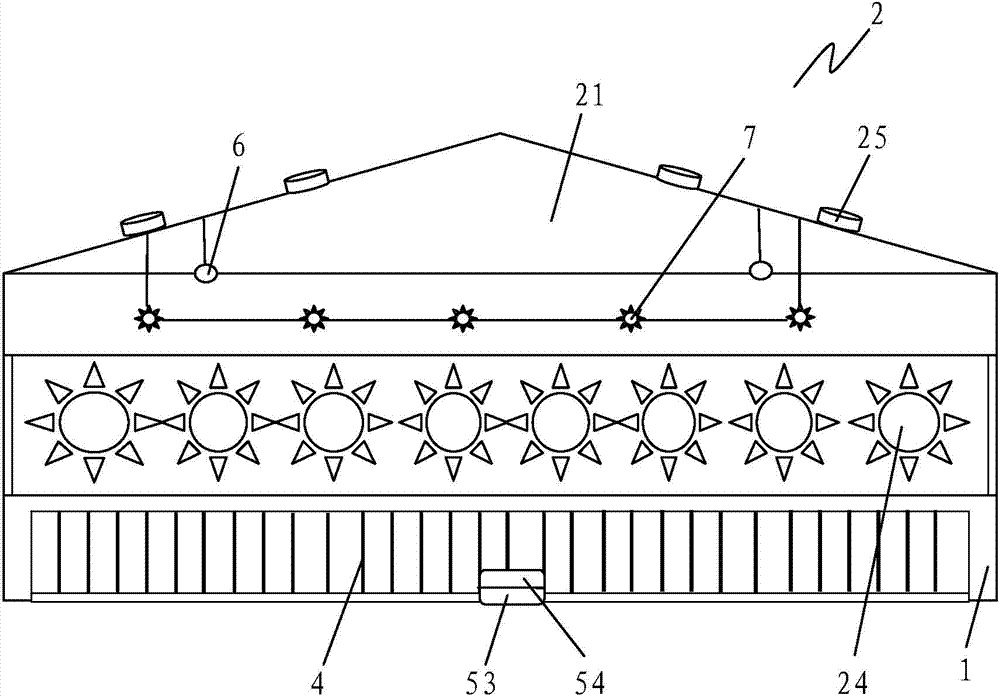

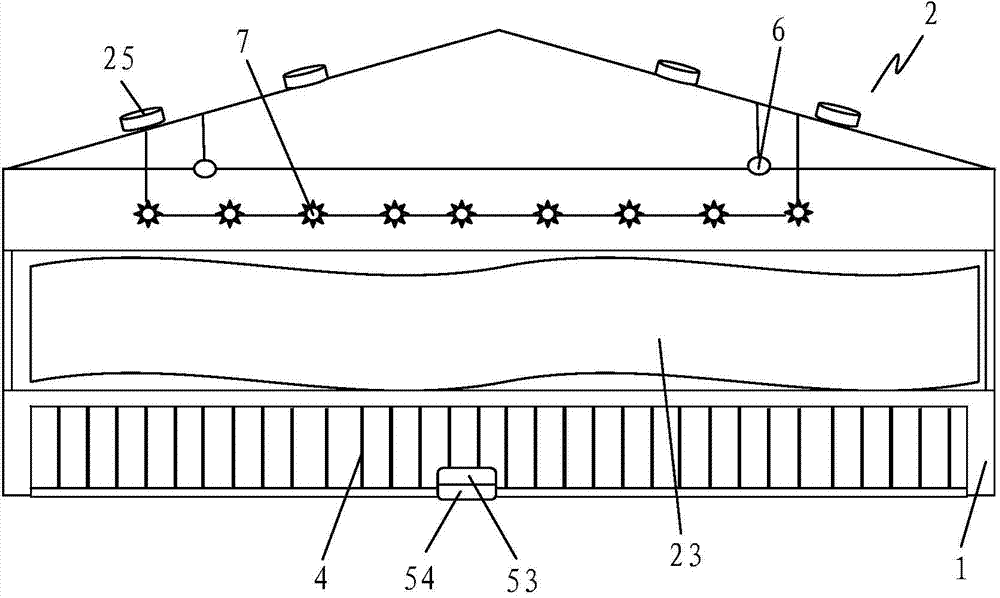

Ecological live pig raising house with microbial fermentation bed and large pen

ActiveCN103749317AReach the purpose of raising pigs in an environment-friendly mannerNo pollution in the processAnimal housingData informationSteel frame

The invention provides an ecological live pig raising house with a microbial fermentation bed and a large pen. The ecological live pig raising house is characterized in that the area of a pig house ranges from 1000 square meters to 2000 square meters, a wall is arranged on the periphery of the pig house in a surrounding manner, and the height of the wall ranges from 0.8m to 1.2m; a steel framed green house of the pig house is erected above the ground surrounded by the wall, shutter fabrics are respectively arranged on two sides of the long edges of the steel framed greenhouse, a wet curtain and a negative-pressure fan are respectively arranged on two sides of the short edges of the steel framed greenhouse, and spraying cooling devices are mounted on the outside of a roof; a sidewalk is arranged in the pig house along the wall on the periphery of the pig house, and the pen is arranged on the inner side of the sidewalk in a surrounded manner; fermentation bed packing, feeding troughs and a water trough are arranged in the pen, axial-flow fans and miniature spraying cooling systems are arranged at certain positions below the roof, and the distances from the certain positions to the roof range from 1.2m to 1.5m; the temperature and the humidity of the inside of the pig house can be automatically regulated according to data information of the brightness, the temperature, the moisture, the humidity, the air quantity and the amount of rainfall of an environment outside the pig house. The ecological live pig raising house has the advantages that the ecological live pig raising house is low in construction cost and suitable for ventilation cooling in summer, has a large raising space and an activity range and can be conveniently mechanically operated, and heat stress of pigs and fighting of individual pigs can be reduced.

Owner:福建省农业科学院农业生物资源研究所

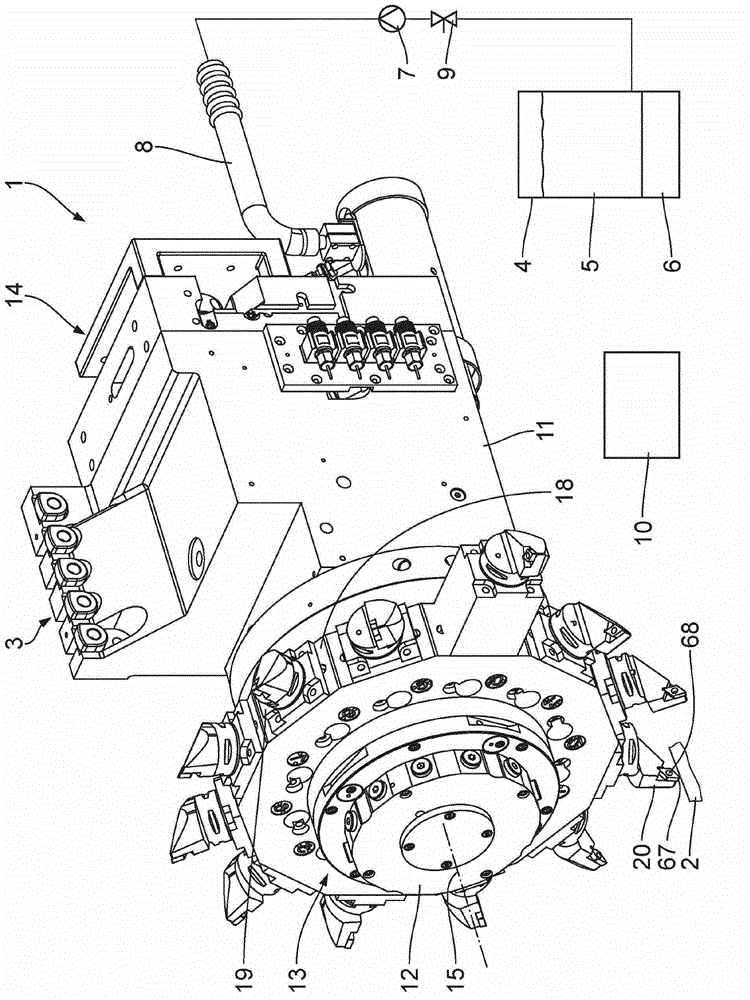

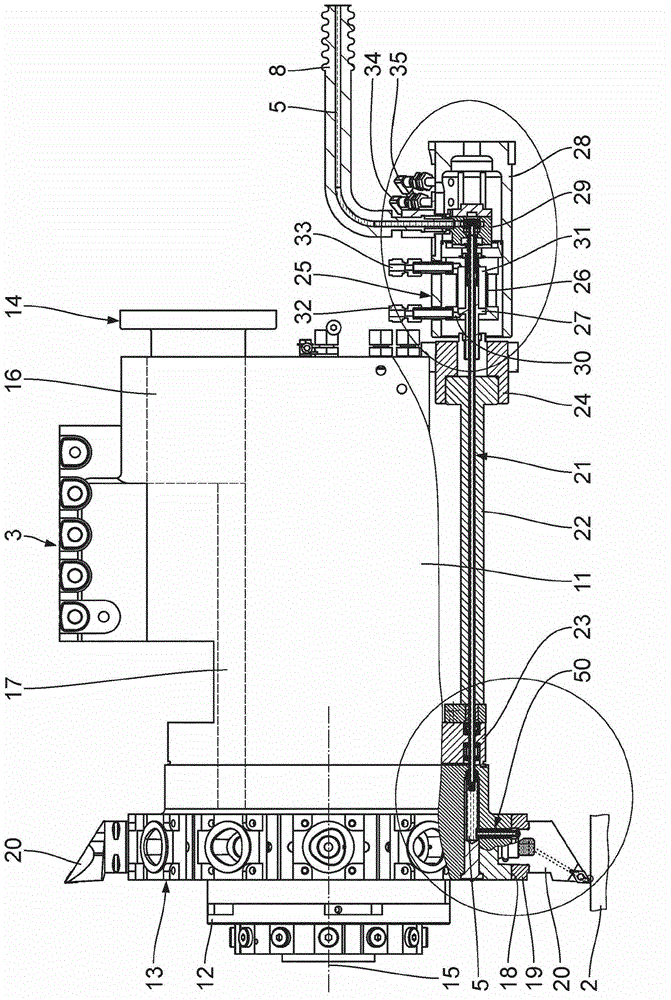

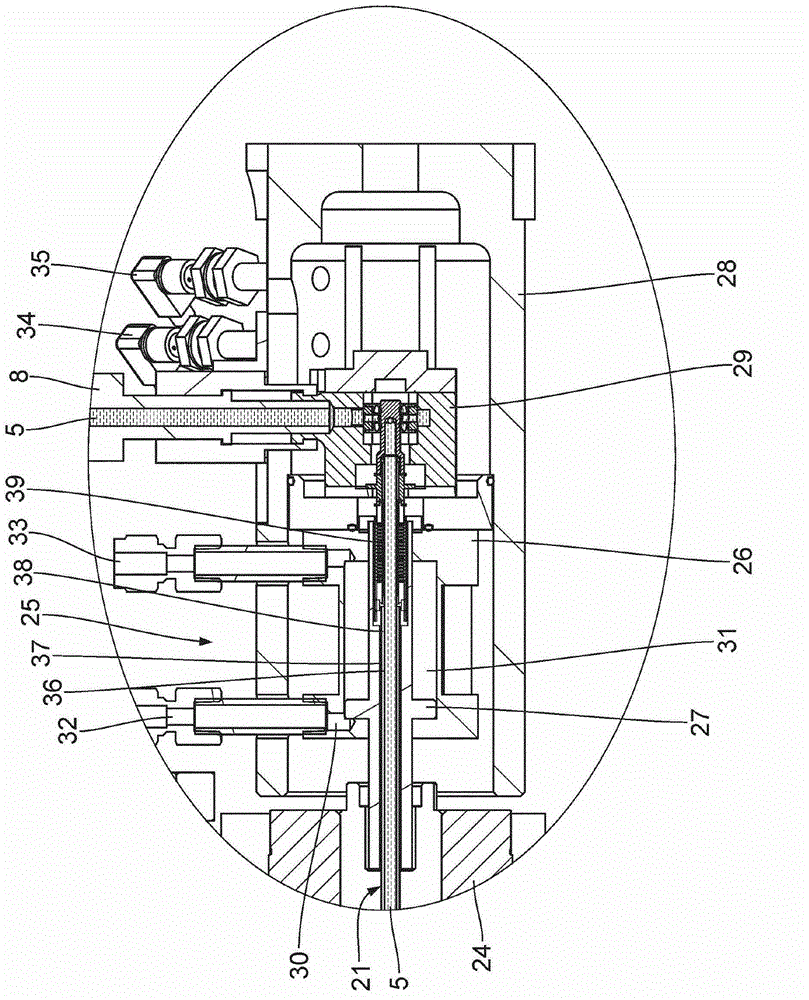

Tool revolver for machining workpieces and a machining system comprising such a tool revolver

InactiveCN103338898AHelp lifeImprove productivityLathesMachine tool componentsRotational axisMachining system

Owner:5ME IP

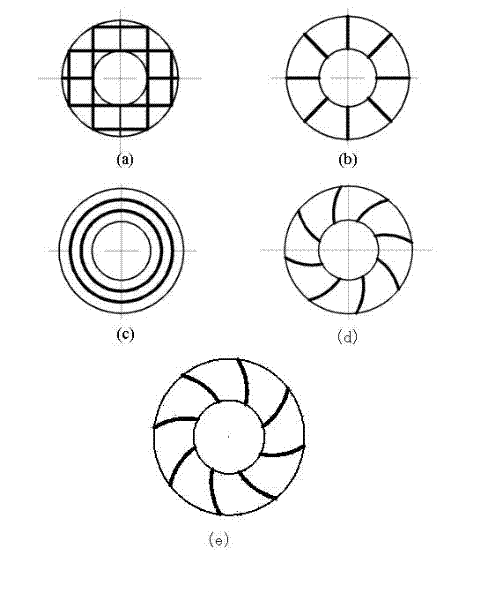

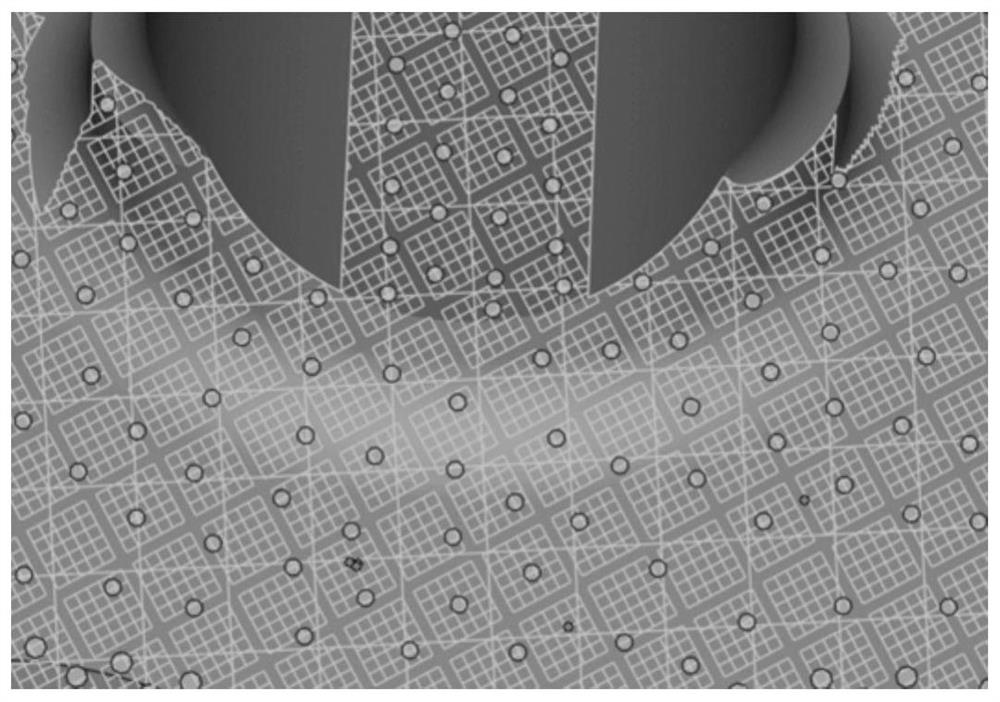

Slotting-type freezing and solidifying grinding material polishing pad and preparation method thereof

InactiveCN102335888AImprove protectionFacilitate the development of new usesFlexible-parts wheelsGrinding devicesPolishingEngineering

The invention discloses a slotting-type freezing and solidifying grinding material polishing pad, which is characterized in that the center of one surface of a polishing pad, which is opposite to a processed workpiece, is provided with a blind hole (1); the periphery of the blind hole (1) is provided with a groove (2); the diameter d of the blind hole (1) is equal to e-r, wherein e in the formula is the eccentricity of the polishing pad, r is the radius of the polished workpiece, the value of the eccentricity is always 20-105mm, the depth of the blind hole (1) is 10-20mm, the depth of the groove (2) is 50-70% of the depth of the blind hole (1), and the width of the groove (2) is 5-10mm. In the slotting-type freezing and solidifying grinding material polishing pad, different types of grooves of different shapes are manufactured on the traditional freezing and solidifying grinding material polishing pad. Various groove shapes are formed mainly by the action of a slotting die. The polishing pad can be used for polishing and machining various thin workpieces, and is especially suitable for machining heat sensitive materials, soft materials, crystal materials and the like, has the advantages of low machining cost, high machining efficiency, strong technical control capability and the like, is simple to manufacture, is environmentally-friendly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Glass corrosion mask layer method

The invention discloses a glass corrosion mask layer method. The method comprises the following steps: a) a silicon chip having a surface oxide layer and glass are subjected to catalysis bonding through hydroxide; b) removing oxide on the upper surface of the silicon chip; c) thinning the silicon chip; d) photoetching the surface of the silicon chip by a photoresist, forming an image required by glass corrosion; e) using DRIE (deep reactive ion etching) anisotropy etching, etching the silicon chip, wherein the etching depth is to a glass layer; f) removing the photoresist on the silicon chip; g ) corroding the glass; and h) removing silicon and silicon oxide on the glass and cleaning to obtain a required glass structure. According to the intention, glass corrosion depth is not restricted, thermal stress due to anode bonding temperature can be avoided, expensive equipment is not required, and operation is simple.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

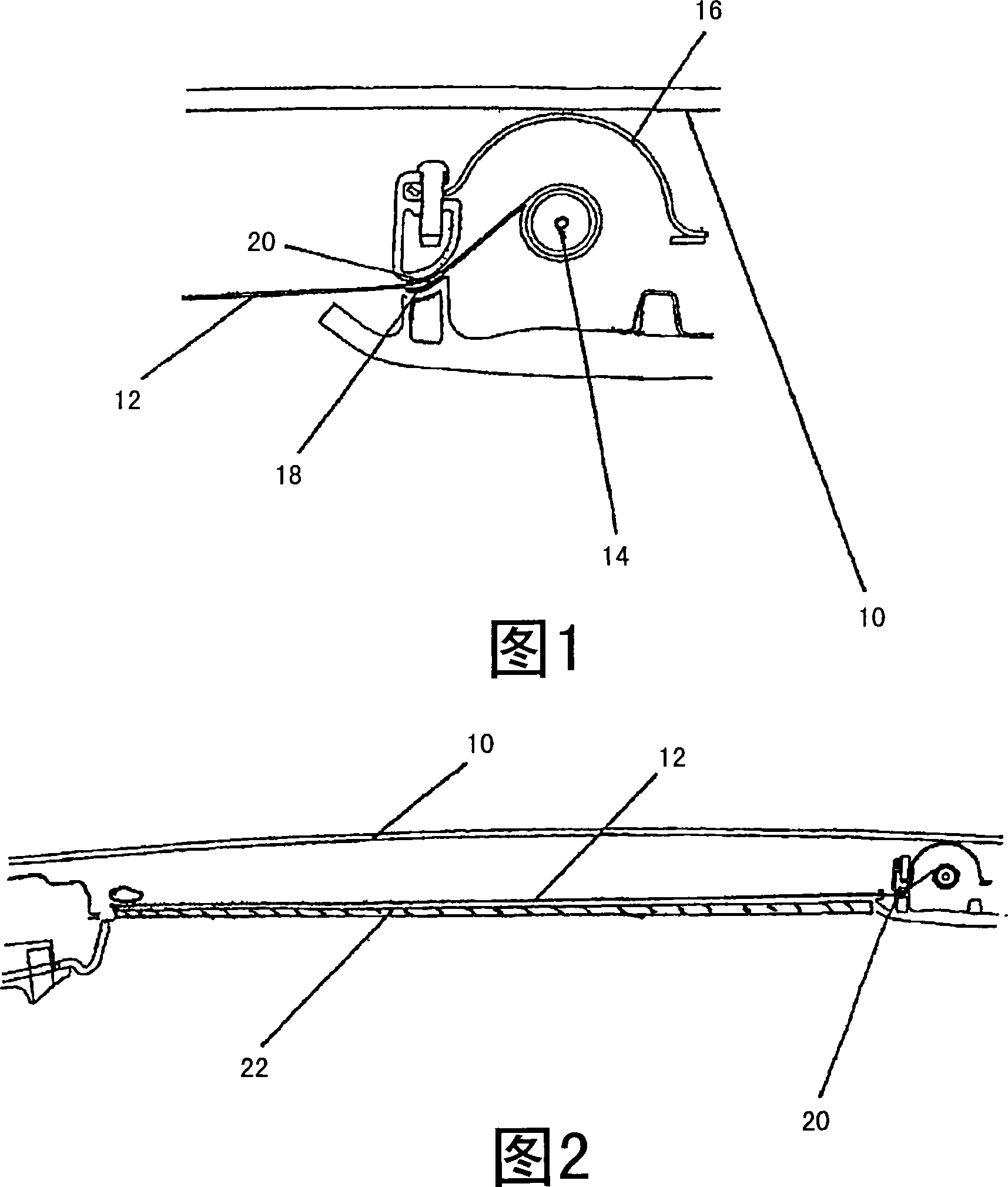

Shade assembly for a transparent bodywork surface of a vehicle

The invention relates to a shade assembly for a transparent bodywork surface (10) of a vehicle, said assembly comprising at least one section of variable light transmission. The assembly comprises at least one film, whose light transmission characteristics can be modified by the application of an electric current. According to the invention, the film forms part of a displaceable window blind web (12). The invention also relates to a vehicle roof comprising a roof opening, which is closed by a transparent pane (10) and can be shaded by a shade assembly as cited in the invention.

Owner:WEBASTO AG

Forming method for selective laser melting forming technology

ActiveCN112496343AReduce porosityReduce defects such as cracksAdditive manufacturing apparatusSelective laser meltingEngineering

The invention discloses a forming method for a selective laser melting forming technology, and belongs to the technical field of additive manufacturing. The forming method comprises the steps of according to the actual design size of a target part, carrying out allowance compensation to optimize a three-dimensional model, and constructing a three-dimensional entity model suitable for selective laser melting forming; according to the obtained three-dimensional entity model, designing and slicing a supporting structure suitable for the target part; after the supporting structure is designed, carrying out process arrangement to form a model file, and slicing the obtained model file; and setting process parameters of the selective laser melting forming technology, and carrying out integrated printing forming, wherein the target part is of a cavity thin-wall structure. Through the forming method, the defect that in the integrated forming process of the part with the cavity thin-wall structure, the part is prone to being scratched by a scraper due to thermal stress can be effectively overcome, and the percent of pass is increased.

Owner:AECC AVIATION POWER CO LTD

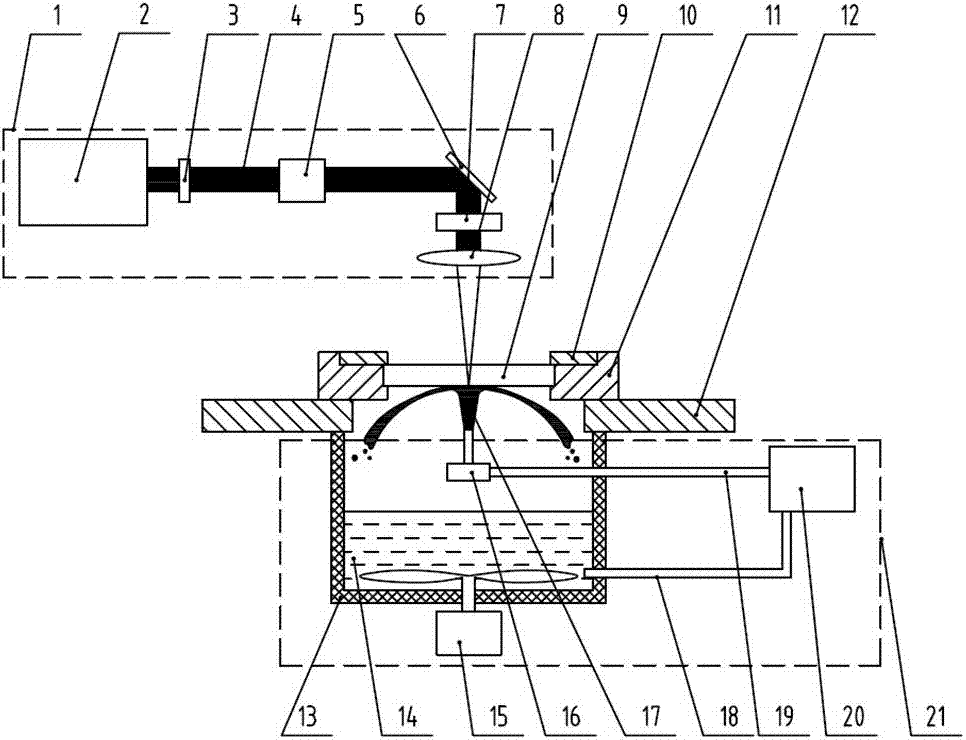

Laser and jet flow compound polishing method and device

ActiveCN108000147AImprove processing efficiencyGood circulation coolingOther manufacturing equipments/toolsLaser beam welding apparatusJet flowLaser beams

The invention discloses a laser and jet flow compound polishing method and device. According to the method and the device, by regulating a focusing lens of a laser polishing module, a laser beam is converged to the surface of a to-be-machined workpiece to form a laser beam focal spot; a jet flow beam generated by conveying a polishing solution through a pressure supply pump, making the polishing solution flow through a nozzle and ejecting out the polishing solution through the nozzle impacts on the surface of the to-be-machined workpiece to form a jet flow beam impacting area; and by means ofa mechanical structure, it is ensured that the laser beam focal spot and the jet flow beam impacting area overlap, and therefore the relative positions of the jet flow beam impacting area, the laser beam focal spot and the to-be-machined workpiece are changed, and the compound polishing process of the surface of the to-be-machined workpiece is completed. By means of the method and the device, thebottleneck problems that in the conventional polishing technology, thermal stress and the machining efficiency are low are solved, the ultra-precision polishing efficiency is improved, and meanwhile the polishing quality is improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com