Brake disk having a brake disk pot

A technology of brake discs and friction rings, applied in the directions of brake discs, brake components, brake types, etc., can solve problems such as cracks and shielding, and achieve the effect of reducing material stress and avoiding shielding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

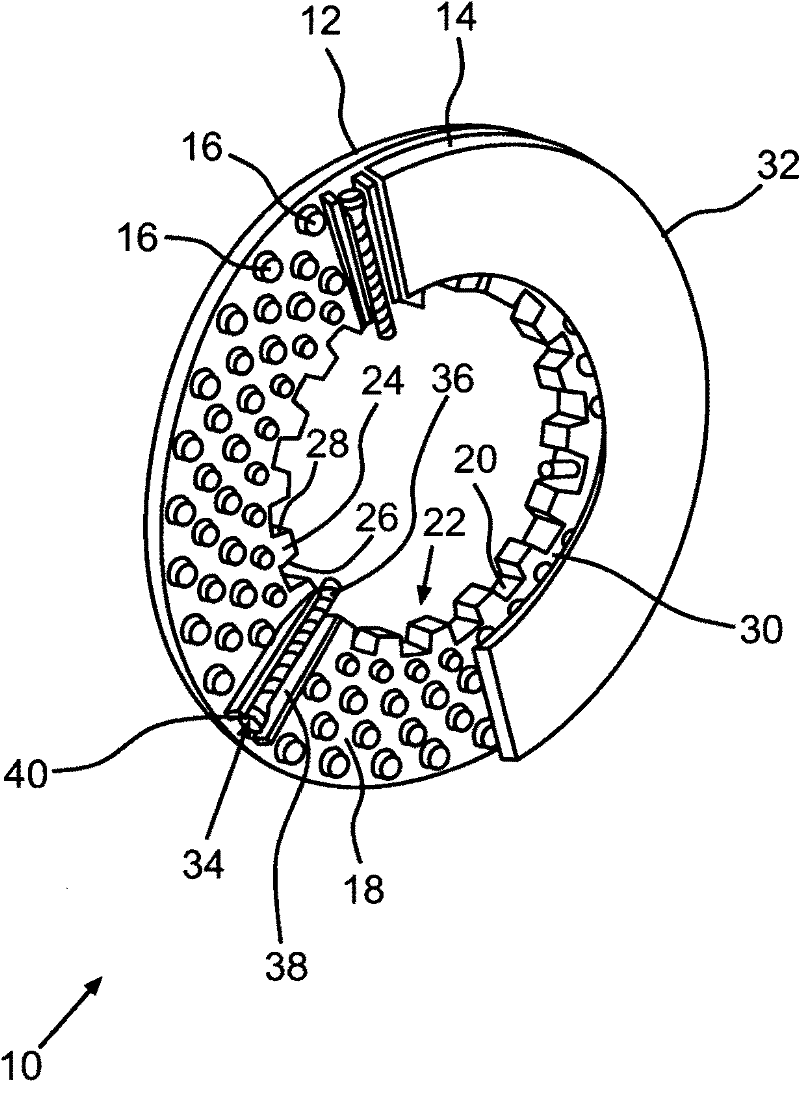

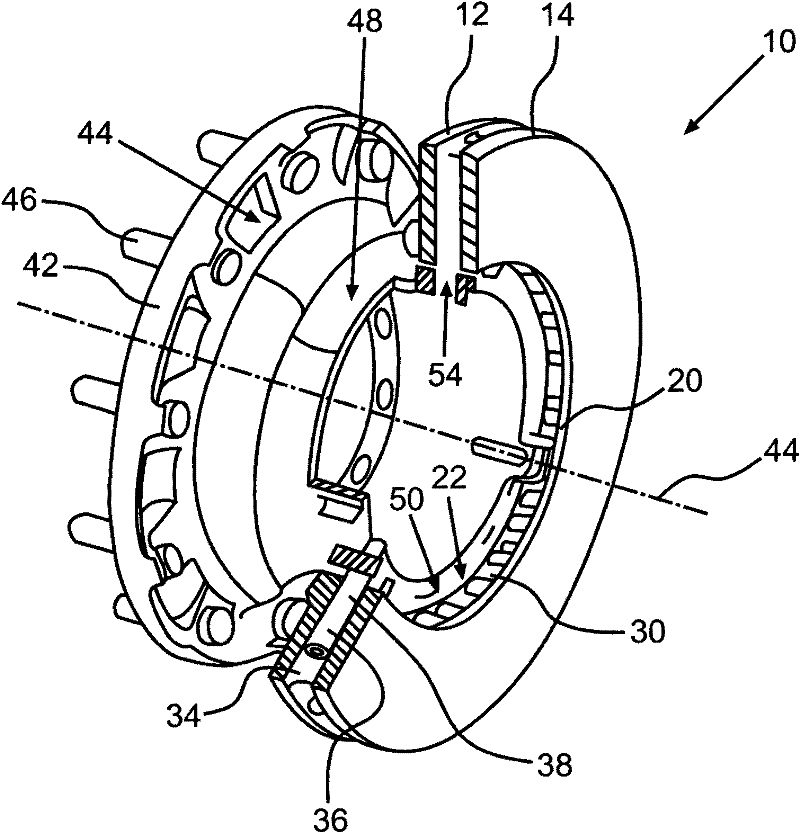

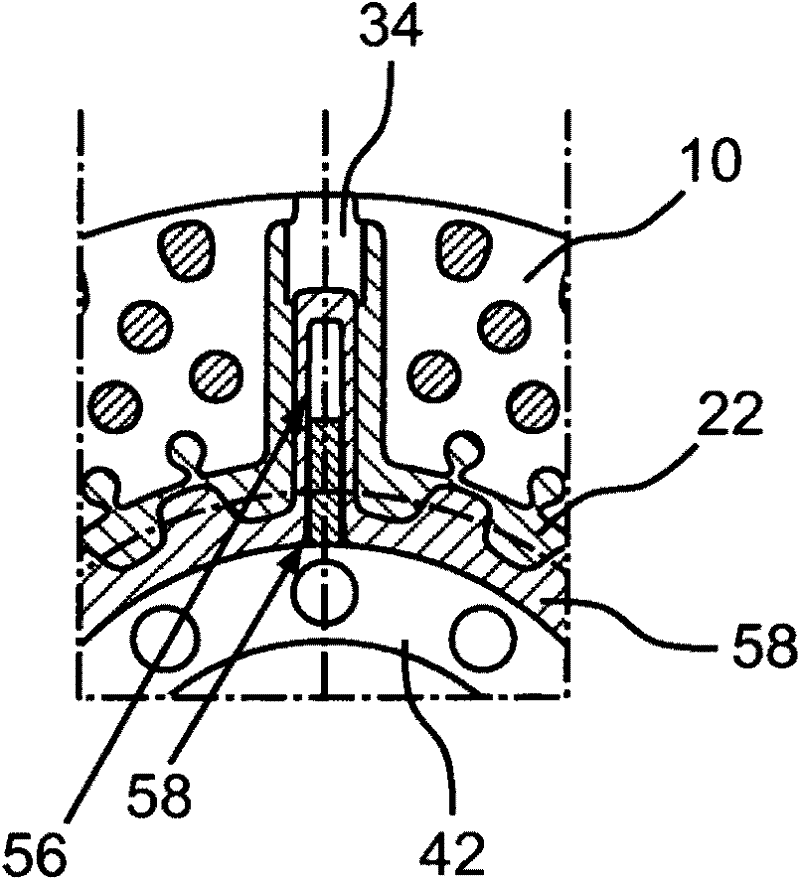

[0022] figure 1 The friction ring 10 shown comprises two friction ring halves 12 and 14 which are connected to one another by spacer lugs 16 , not all of which are shown for the sake of clarity. In this case, the free space 18 between the spacer cam 16 and the friction ring halves 12 , 14 forms an air duct system between the friction ring halves 12 and 14 , which serves for the internal ventilation of the friction ring 10 . In order to connect the friction ring 10 radially to the brake disc cover in a form-fit manner, a toothing 22 surrounding the inner periphery 20 of the friction ring half 12 is formed on the first friction ring half 12 . For the sake of clarity, not all of the teeth 24 of the toothing 22 are designed here as helical teeth, ie the tooth flanks 26 , 28 are designed as planes and at an angle to one another. In the axial direction, a through-opening 30 is formed adjacent to the toothing 22 , which opens the inner circumference 20 of the friction ring 10 into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com