Electronic packaging material

A technology of electronic packaging materials and carbon nanotubes, which is applied in the field of material science to achieve the effect of low material cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

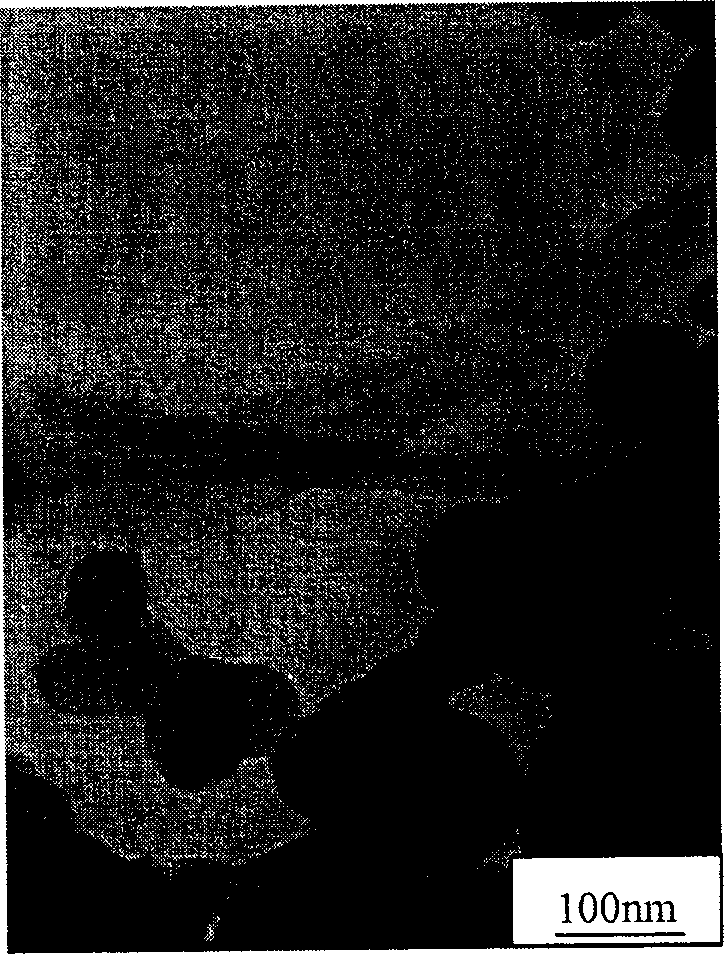

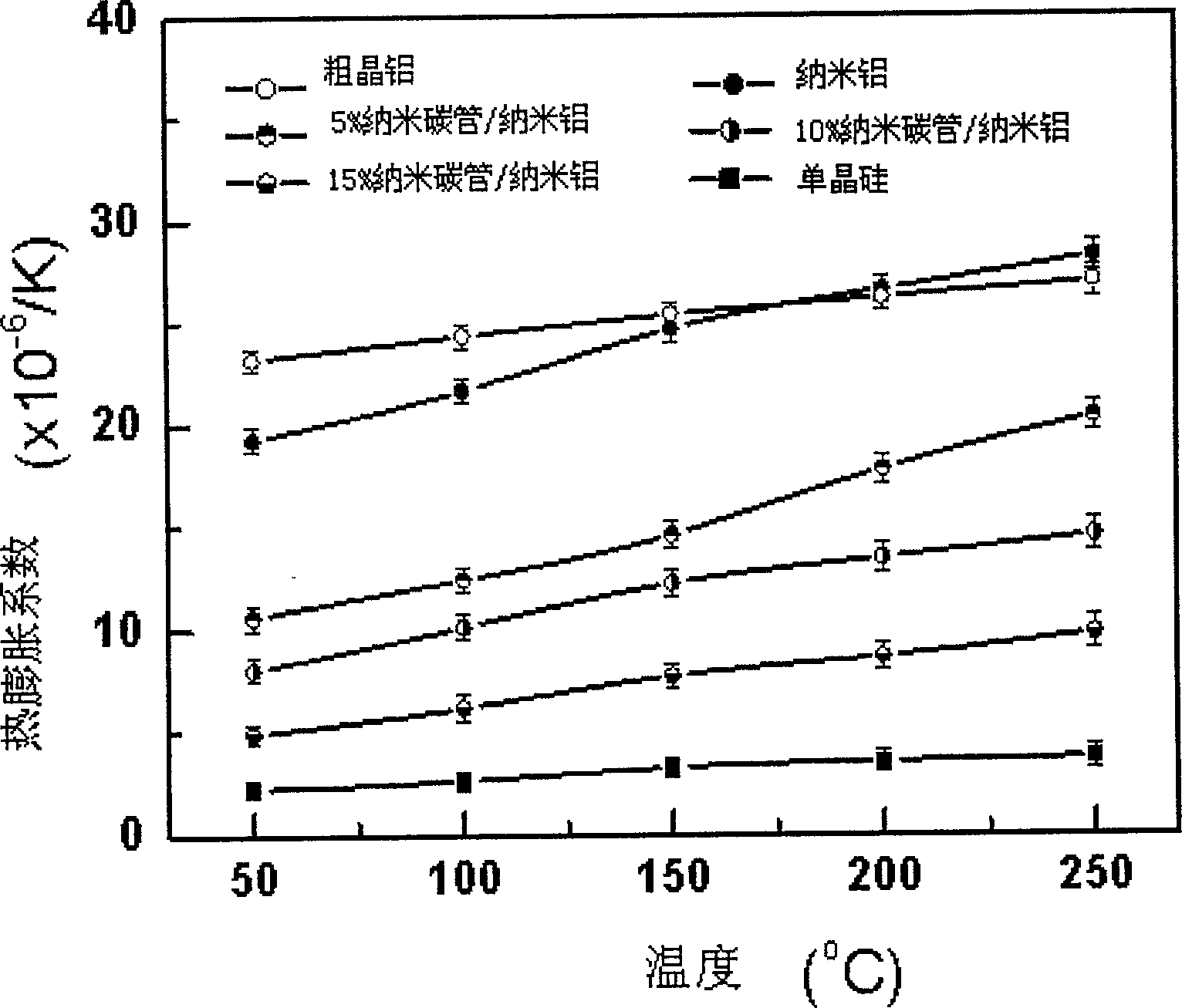

Embodiment 1

[0018] Single-walled carbon nanotubes and nano-Al powders were prepared by semi-continuous hydrogen arc method and active hydrogen plasma evaporation method, and then the purified carbon tubes and nano-Al powders were dispersed and mixed in proportion by wet ultrasonic dispersion. Cold press forming, followed by vacuum hot pressing at 380°C, to prepare a block composite material sample with a carbon tube content of 2.5wt.% and a density greater than 95%. The thermal expansion coefficient of the composite material was tested at 20°C to 250°C to be 11×10 -6 / K~18×10 -6 / K.

Embodiment 2

[0020] Single-walled carbon nanotubes and nano-Al powders were prepared by semi-continuous hydrogen arc method and active hydrogen plasma evaporation method, and then the purified carbon tubes and nano-Al powders were dispersed and mixed in proportion by wet ultrasonic dispersion. Cold press forming, followed by vacuum heat treatment at 380°C, to prepare a block composite material sample with a carbon tube content of 5wt.% and a density greater than 95%. The thermal expansion coefficient of the composite material was tested at 20°C to 250°C to be 8×10 -6 / K~12×10 -6 / K.

Embodiment 3

[0022] Single-walled carbon nanotubes and nano-Al powders were prepared by semi-continuous hydrogen arc method and active hydrogen plasma evaporation method, and then the purified carbon tubes and nano-Al powders were dispersed and mixed in proportion by wet ultrasonic dispersion. After cold pressing and hot pressing at 380°C, a bulk composite material sample with a carbon tube content of 17.5 wt.% and a density greater than 95% was prepared. The thermal expansion coefficient of the composite material was tested at 20°C to 250°C to be 5×10 -6 / K~7×10 -6 / K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com