Patents

Literature

158results about How to "Avoid heat cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

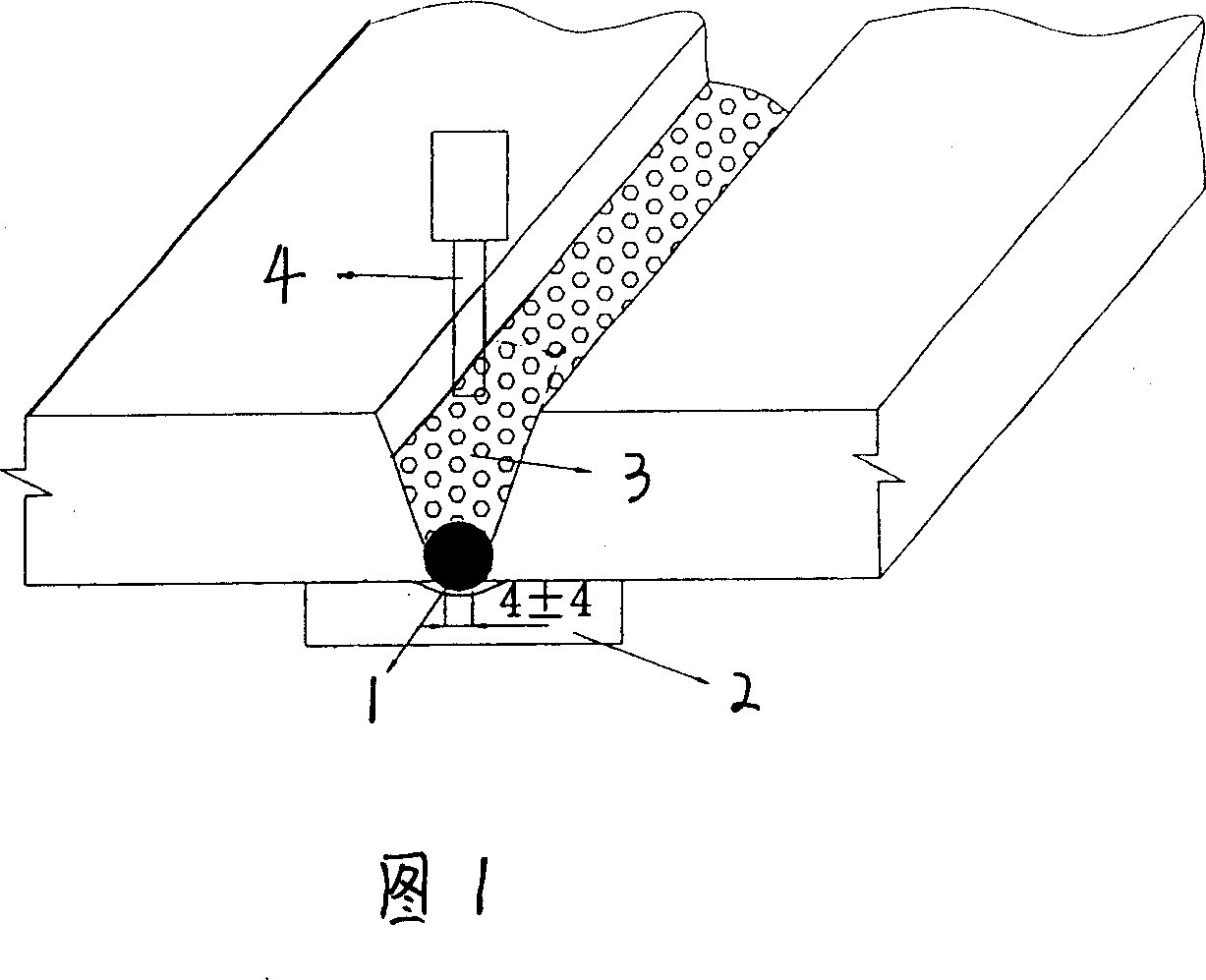

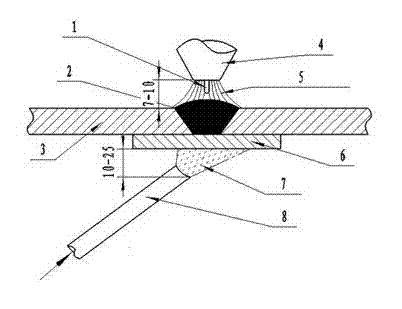

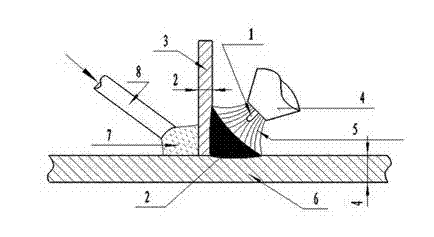

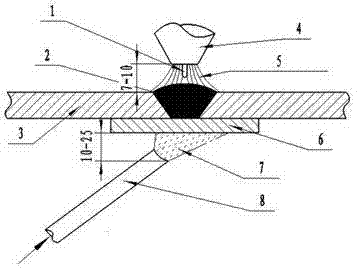

CO2 gas protected single-sided welding and double-sided forming process

ActiveCN1931500AImproved ability to resist tensile stressAvoid heat cracksArc welding apparatusWelding/cutting media/materialsWeld seamSeam welding

The CO2 gas protected single-sided welding and double-sided forming process includes the following steps: cutting bevels in the pieces to be butt welded; spot welding to fix the bevels; adhering ceramic lining to the opposite side of the bevels; filling smashed metal wires in the thickness capable of forming welding seam over 7 mm between the bevels; bottoming welding under the protection of CO2 gas at the welding current of 420-540 A; and 6. the subsequent welding. The present invention has the advantages of double-sided forming via single-sided welding, capacity of preventing heat crack in large current condition, and no weld penetration.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

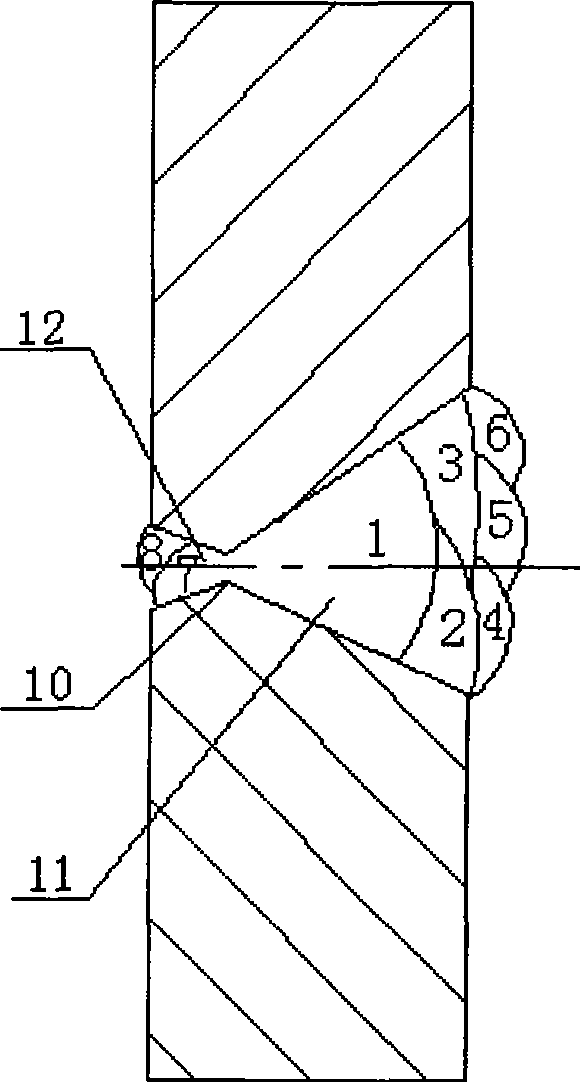

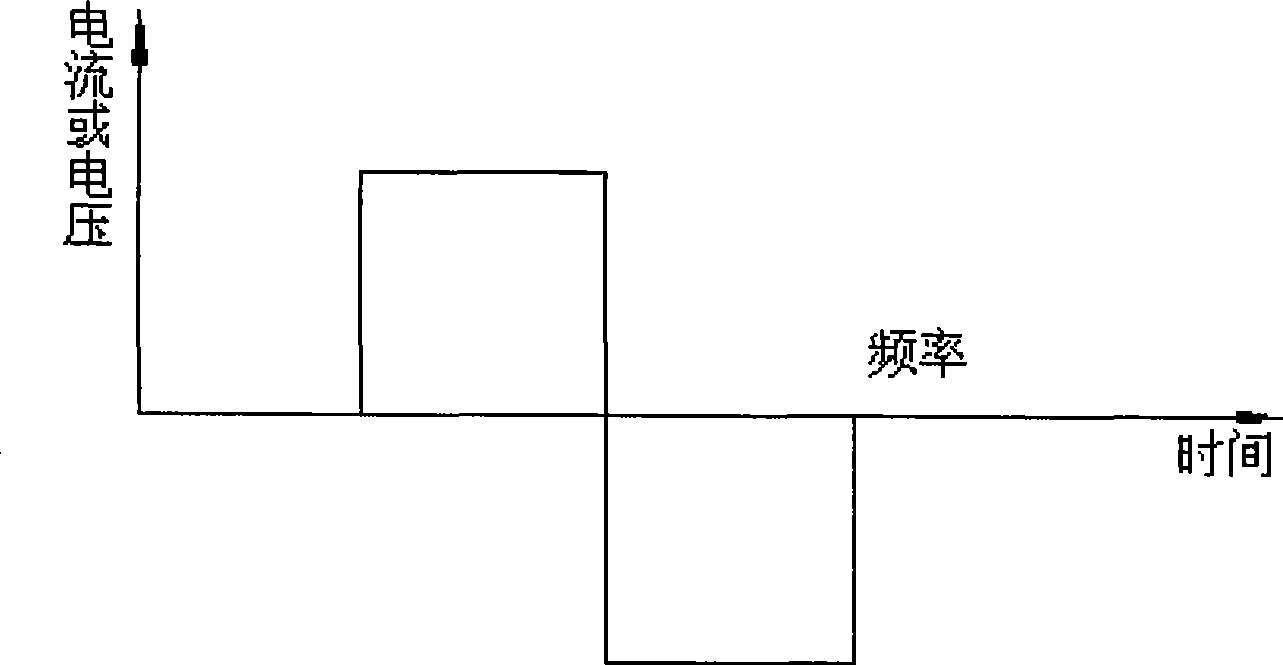

Welding process of large-sized liquefied natural gas storage tank

InactiveCN101412136AEasy to shapeReduce Rooting WorkloadArc welding apparatusDomestic vesselsNatural gas storageEngineering

The invention relates to a method for welding a large liquified natural gas storage tank. The method uses alternating rectangular wave current for welding with a welding parameter of between 8.156 and 24.32 KJ / cm and the interlayer temperature of energy input of between 18.9 and 24.32 KJ / cm of 300 DEG C, and selects low carbon type nickel-based welding wire. The method overcomes the problem of arc blow in welding, not only can avoid impact on 9 percent Ni steel during carbon gouging, but also can save welding materials and manpower so as to accelerate construction process and improve welding efficiency. Welding with the process can improve the cold temperature flexibility of a macrograin area of a welding zone, avoid generation of brittle tissue of a fusion area, avoid generation of cold and heat crack in welding, has excellent quality of weld joint, and effectively ensure the cold temperature flexibility of 9 percent Ni steel welding joints. The method well control the quality of the weld joint, and ensures the overall quality of the natural gas storage tank.

Owner:SHANGHAI INSTALLATION ENG GRP

Welding material for Ni-based alloy

InactiveCN102105260AGood welding performanceAvoid heat cracksTurbinesBlade accessoriesAlloySolder material

Disclosed is a welding material for a Ni-based alloy, which comprises the following components: C <= 0.05 mass%, 8 mass% <= Cr <= 25 mass%, Fe <= 4.0 mass%, W <= 15 mass%, 5 mass% <= Mo+1 / 2(W+Re) <= 20 mass%, Co <= 20 mass%, 0.01 mass% <= Al < 2.0 mass%, 0.01 mass% <= Ti < 2.0 mass%, Al+1 / 2Ti <= 3.0 mass%, Nb+1 / 2Ta <= 1.5 mass%, B <= 0.007 mass%, Zr <= 0.04 mass%, 0.01 mass% <= Si = 0.5 mass%, Mn <= 1.0 mass%, P <= 0.010 mass%, S <= 0.002 mass%, and 0 <= 0.005 mass%, with the remainder being Ni and unavoidable impurities.

Owner:MITSUBISHI HEAVY IND LTD

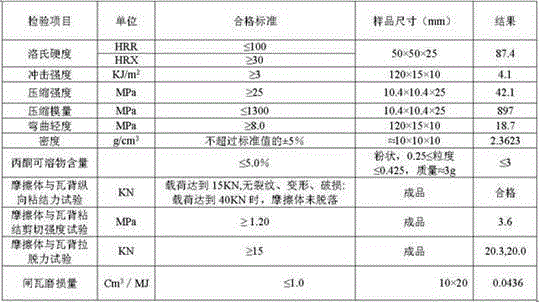

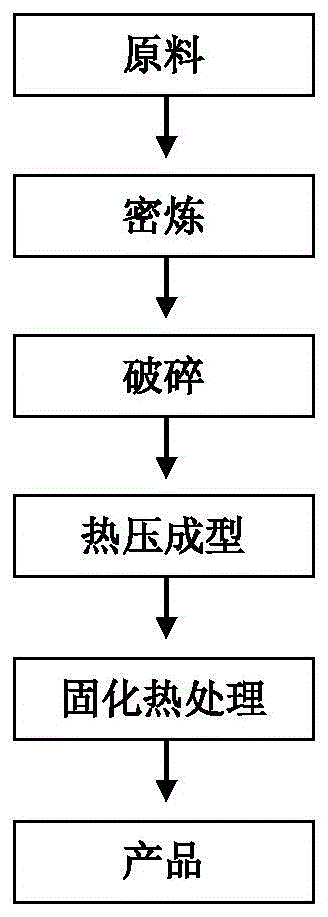

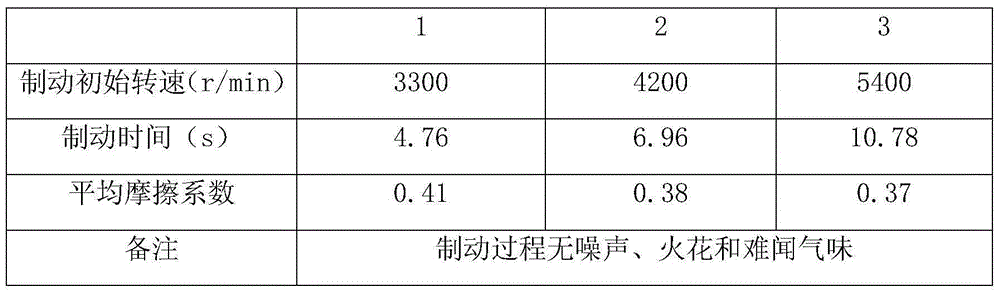

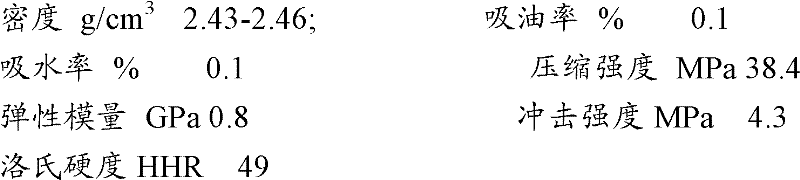

Grinder of bullet train tread cleaner and production method thereof

ActiveCN102432978AAvoid stressAvoid heat cracksOther chemical processesVehicle cleaningIron powderGraphite

The invention provides a grinder of a bullet train tread cleaner, wherein the grinder is made of a composite material; the composite materials comprises modified phenolic resin 6818, iron powder, copper fibres, steel fibres, sepiolite, potassium feldspar, graphite, cryolite and aluminium oxide; the invention further provides a production method of the grinder.

Owner:BEIJING RAILWELD NEW MATERIAL TECH CO LTD +1

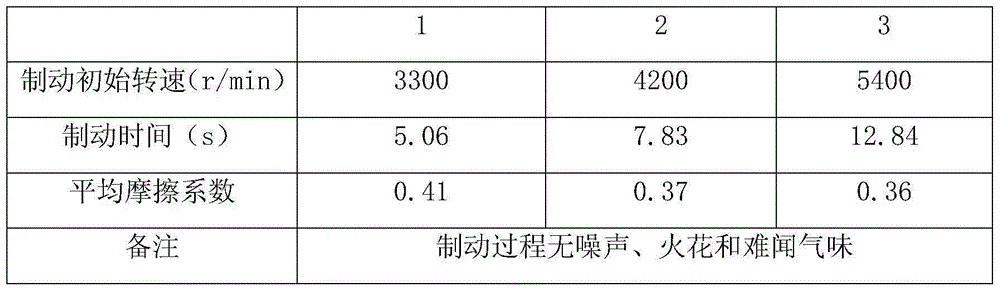

High-friction coefficient composition brake shoe and production method thereof

The invention relates to a high-friction coefficient composition brake shoe. The high-friction coefficient composition brake shoe comprises a steel backing and a friction material, the friction material comprises the following raw materials including, by weight, 1-5 parts of aramid fiber, 8-12 parts of butadiene-acrylonitrile rubber, 0.5-1 part of stearic acid, 0.3-1 part of an accelerant, 0.6-1 part of sulphur, 0.5-1 part of zinc oxide, 4-7 parts of phenolic resin, 10-20 parts of inorganic composite fiber, 8-15 parts of iron powder, 10-20 parts of barium sulfate, 7-15 parts of kibdelophane powder, 5-10 parts of steel wool fiber, 1-3 parts of bauxite, 8-15 parts of potassium feldspar powder, 2-5 parts of mica, 2-5 parts of flake graphite, 5-10 parts of sepiolite fiber and 2-5 parts of molybdenum disulfide. By means of the high-friction coefficient composition brake shoe, the change of the speed of the wear rate of the high-friction coefficient composition brake shoe can be basically identical to the change of the adhesion coefficient of a wheel track, the abrasion loss when a vehicle is braked is less, failure can not occur in braking, and the traffic safety is guaranteed. The invention provides a production method of the high-friction coefficient composition brake shoe at the same time.

Owner:HEBEI XINJI TENGYUE INDAL

Repair method of high temperature alloy vane by electron beam welding

InactiveCN101007366AShort residence time at high temperatureUniform temperature fieldWelding/cutting media/materialsWelding/soldering/cutting articlesRetention periodRetention time

The method of electron beam brazing repair high temperature alloy blades. The invention involves a brazing repair high temperature alloy blade method in order to solve the problems of complex repair art, long repair cycle, the need of integral heating when brazing repair, long retention period at high temperature when brazing work in original method of repair high temperature alloy blade. The method is realized by the following steps: (1) grinding off blade injury and polishing the injury part into trough, mixing the solder or alloy powder and acetone or general soldering bonding agent sold in market into cream status and putting it in groove; (2) setting process parameters and brazing; (3) when the solder or alloy powder are not melted completely, cooling it until room temperature and taking out high temperature alloy blade, the high temperature alloy blade is repaired. The electron beam brazing repair high temperature alloy blade method in the invention has simple repair process and short repair cycle, a cycle requires only 5 minutes to 10 minutes, it only heats the injury position, the retention time of blades when repaired is reduced to 0.1 ~ 10% of original method.

Owner:HARBIN INST OF TECH

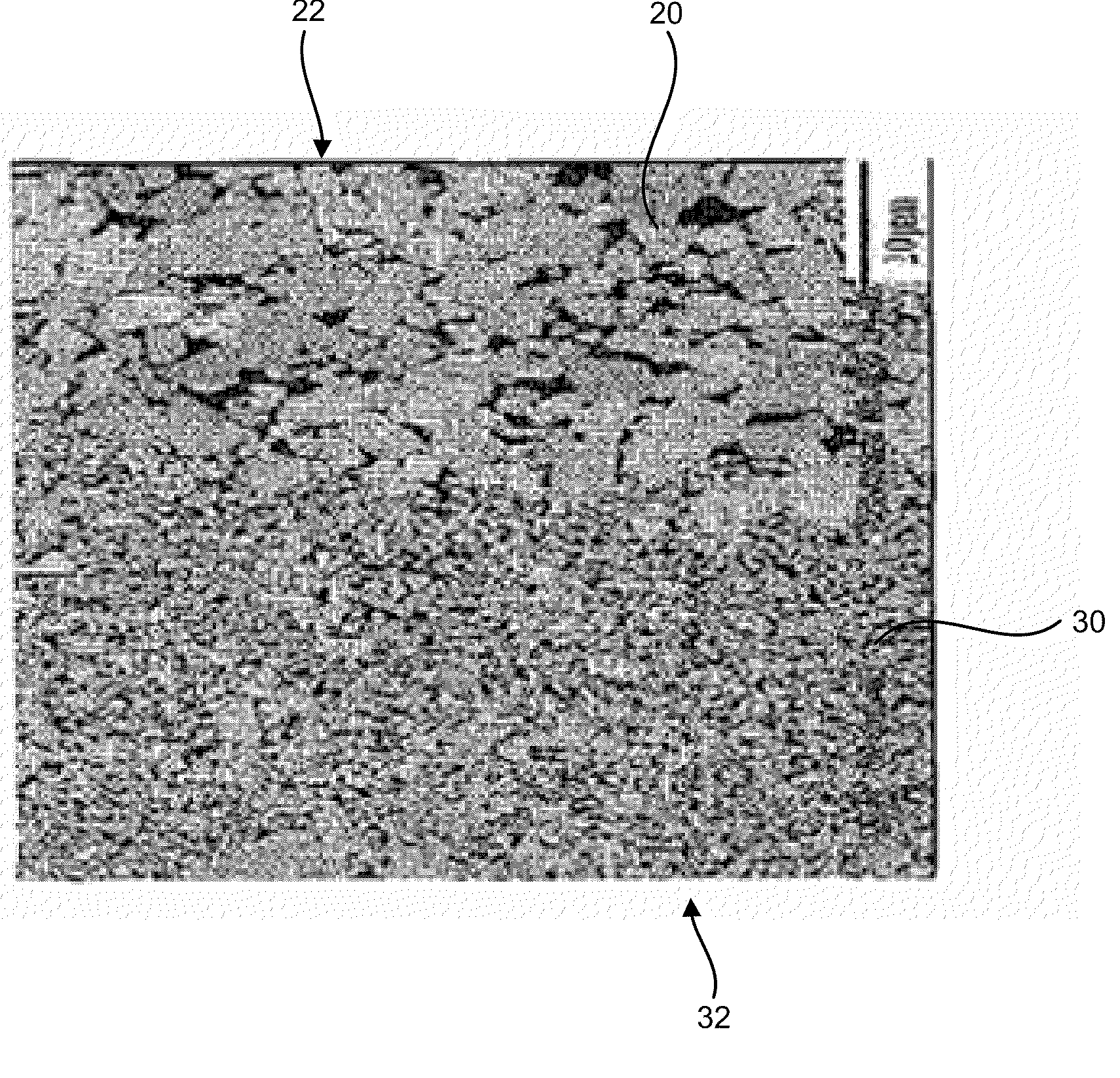

Thermal degradation and crack resistant functionally graded cemented tungsten carbide and polycrystalline diamond

InactiveUS20090226688A1Improve thermal conductivityDissipate frictional heatLamination ancillary operationsSynthetic resin layered productsPolycrystalline diamondHardness

A WC—Co material or polycrystalline diamond-Co material that has a gradient in the grain size of the particles. Specifically, the material may have a top layer that has coarse grains that is designed to dissipate the heat caused by friction (and thus prevent thermal cracking). The material will then have a bulk substrate that is made up of finer grains and provide adequate hardness for the material. The top layer is positioned on top of the bulk substrate.

Owner:UNIV OF UTAH RES FOUND

Calcium carbonate whisker reinforced rubber base friction material and preparation method therefor

InactiveCN105111532AImprove brittlenessImprove heat resistanceOther chemical processesFriction liningButadiene-styrene rubberPetroleum coke

The present invention discloses a calcium carbonate whisker reinforced rubber base friction material, and a preparation method therefor. The material comprises: 8-15 parts of nitrile rubber, 10-15 parts of styrene-butadiene rubber, 5-10 parts of phenolic resin, 5-25 parts of calcium carbonate whisker, 10-20 parts of steel fiber, 2-8 parts of sepiolite fiber, 0-8 parts of mineral fiber, 0-3 parts of aramid fiber, 5-8 parts of barium sulfate, 5-10 parts of magnesium oxide, 2-3 parts of aluminum oxide, 5-10 parts of flake graphite, 1-5 parts of carbon black, 5-10 parts of petroleum coke, 3-6 parts of Cardolite cashew nut shell oil friction powder, 0.5-1 parts of sulfur, and 0.5-1 parts of accelerator. The preparation method comprises process steps of such as material collocation, mixing, pressing molding and the like. Brake pads synthesized by the method provided by the invention have the advantages including excellent friction and wear performance, stable braking performance, high heat-resistant property, safe, environmentally-friendly, and low in cost; and is suitable for braking devices for automobiles and motive power machines, thereby achieving a very wide application prospect and applying to industrial production.

Owner:GUANGXI UNIV +2

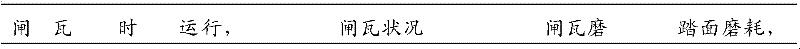

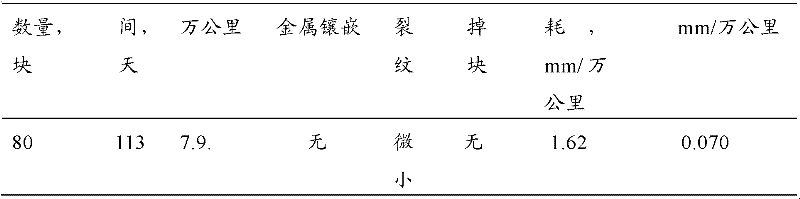

Synthetic brake shoe and preparation method thereof

The invention provides a synthetic brake shoe which comprises the following raw materials in parts by weight: 3-5 parts of phenol formaldehyde resin, 1.5-3.5 parts of nitrile-butadiene rubber, 1.5-3.5 parts of graphite, 3.5-5.5 parts of reduced iron powder, 4.5-6.5 parts of steel fiber, 1.5-3.5 parts of wollastonite, 2.5-4.5 parts of meerschaum, 3.5-5.5 parts of potash feldspar, 0.05-0.20 part ofaluminum oxide, 0.15-0.40 part of sulfur and 0.05-0.20 part of accelerator. The invention selects preferable raw materials and formula to develop the synthetic brake shoe which has the advantages of long service life, low abrasion mating plate and high friction factor. The car loading examination proves that the synthetic brake shoe satisfies the design requirements, does not generate harmful damascene, and does not generate thermal damage on the wheels; the service life is apparently longer than the currently universal synthetic brake shoe with high friction factor, reaching 0.2-0.24 millionkilometers per year; and the application and maintenance cost is lowered, the operation time for replacing the brake shoe is shortened, and the conveying efficiency is enhanced.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

Directional freezing styloid or single-crystal nickel-base high-temperature alloy repairing or coating method

InactiveCN101126143ALittle thermal impactDoes not cause recrystallizationMolten spray coatingArc welding apparatusHeat-affected zoneSingle crystal superalloy

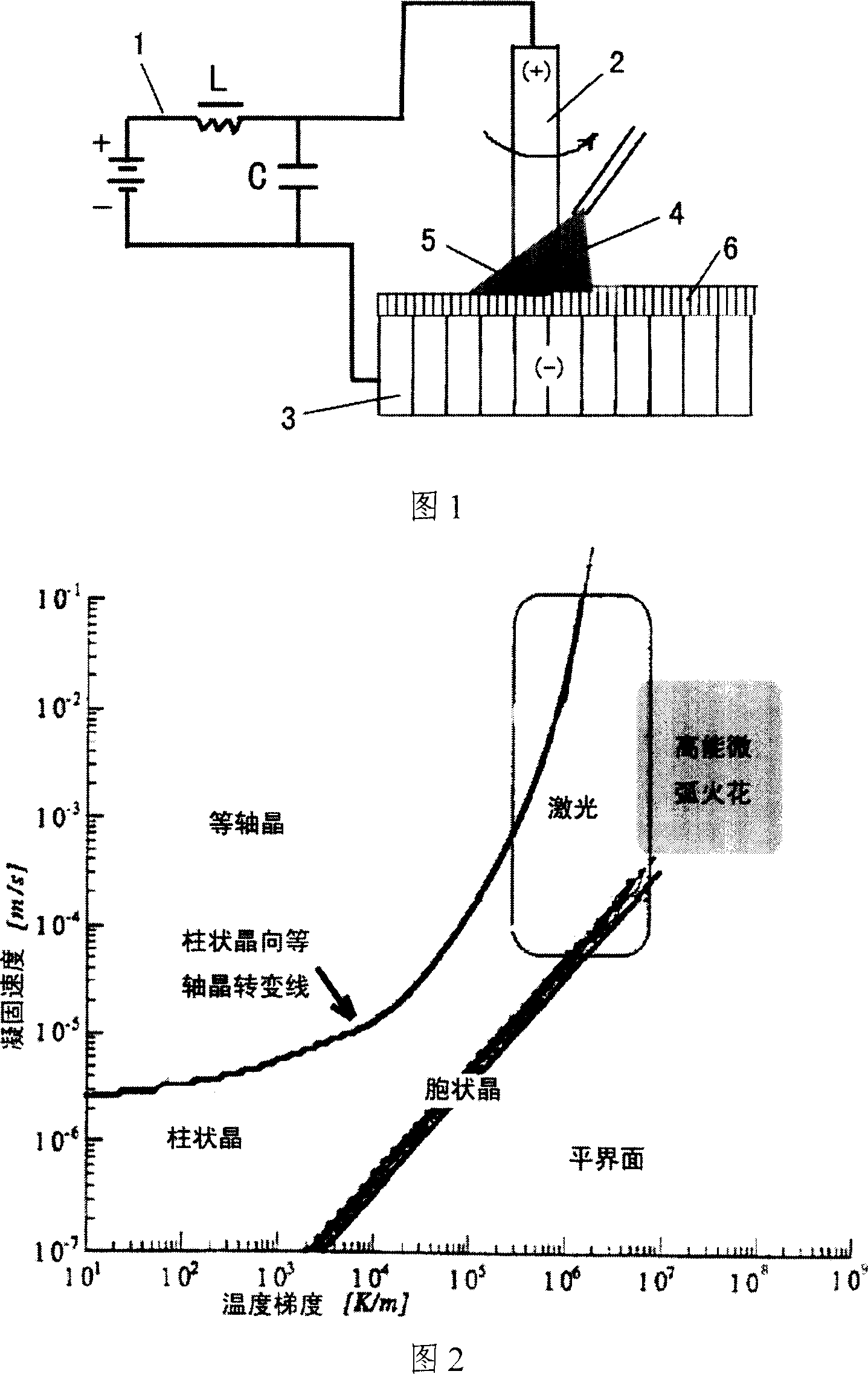

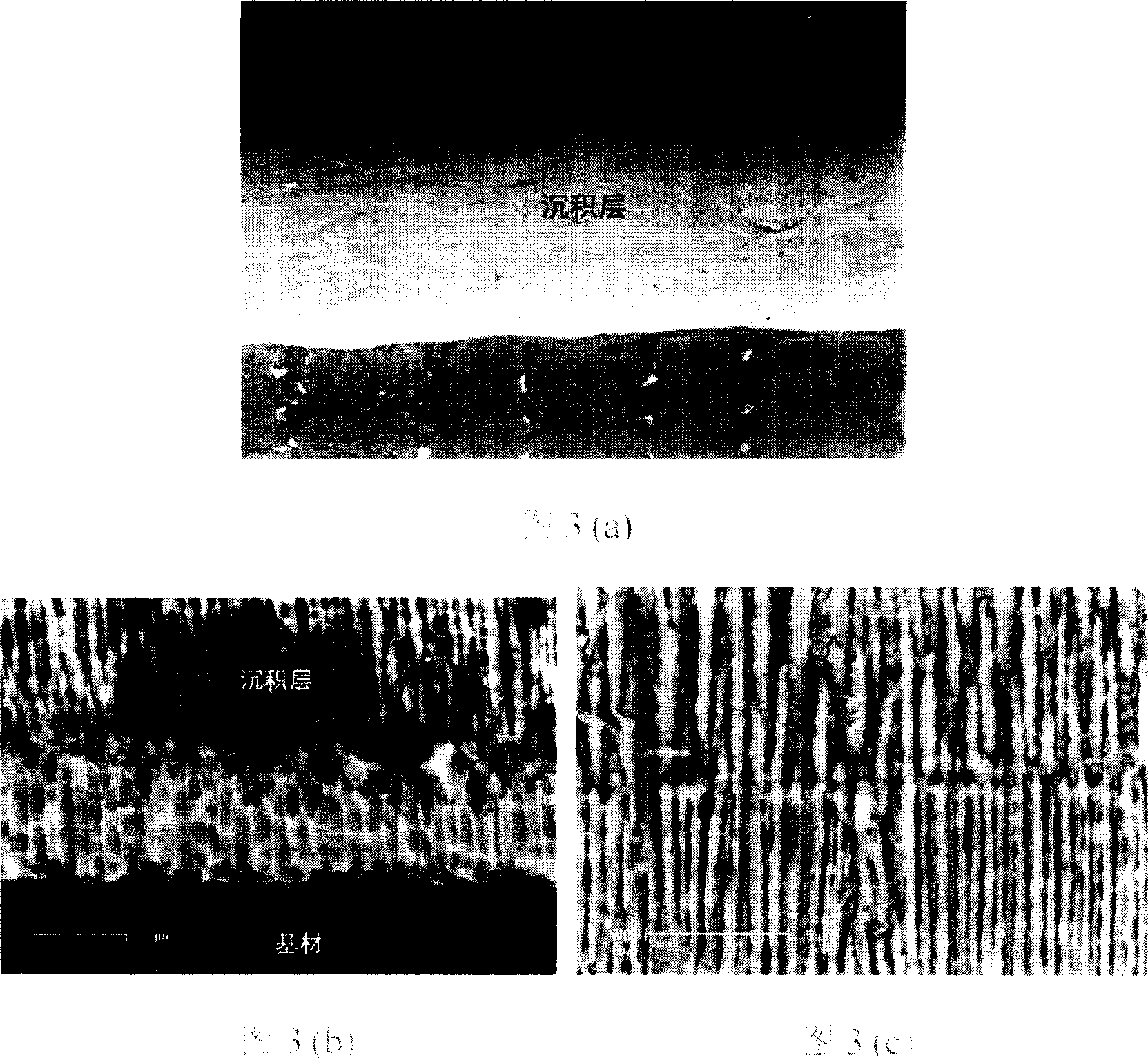

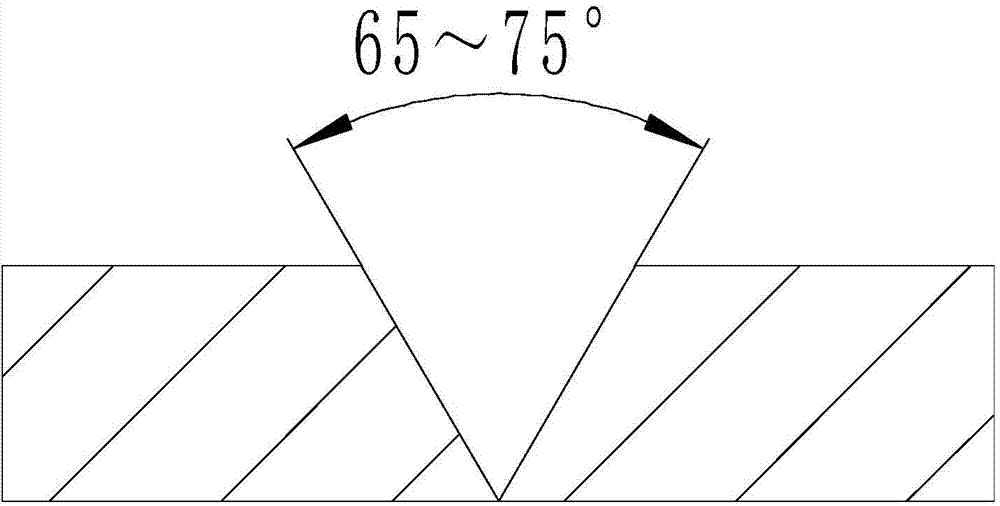

The invention belongs to a preparation technique of the metal surface settled layer, in particular to a method for preparing the directional solidification column crystal or single crystal settled layer which grows on the extension of the surface of the directional solidification column crystal or single crystal high temperature alloy. The proposal of the invention solves the problem of repairing and coating of the directional solidification column crystal or single crystal high temperature alloy; and to gain a compact and flawless directional solidification column crystal or single crystal settled layer which is matched with the directional solidification column crystal or single crystal. The invention discloses an extension high power differential arc spark metal deposition technique. The invention has the advantages of wide process window achieved by the extension high power differential arc spark metal deposition technique, no heat damage to the ferronickel high temperature alloy, narrow heat influence area or no heat influence area, being capable of effectively avoiding the phenomenon of heat flaw of the ferronickel high temperature, no complicated devices such as vacuum room needed and no preheating needed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

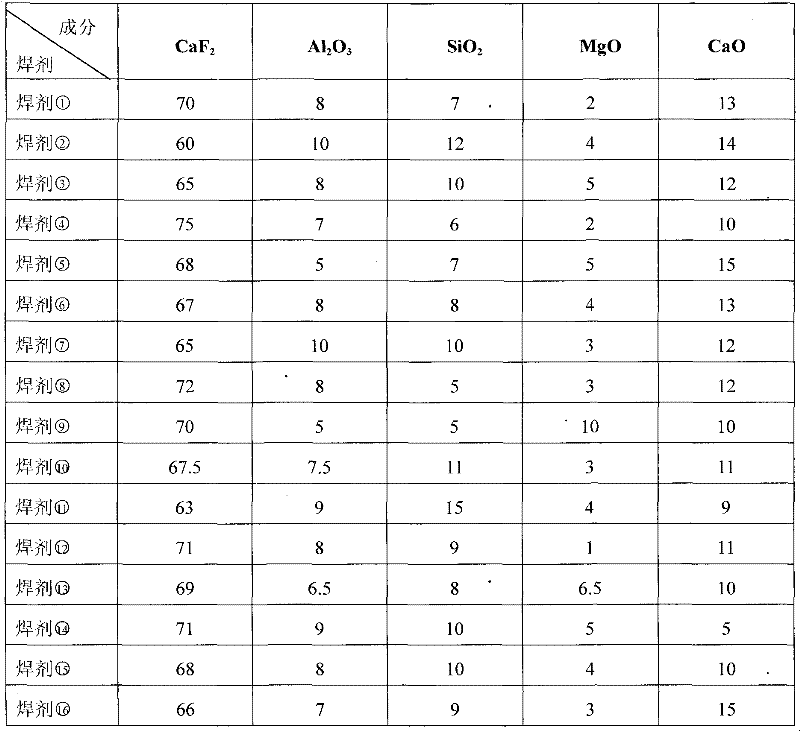

Automatic submerged arc welding method of nickel base alloy

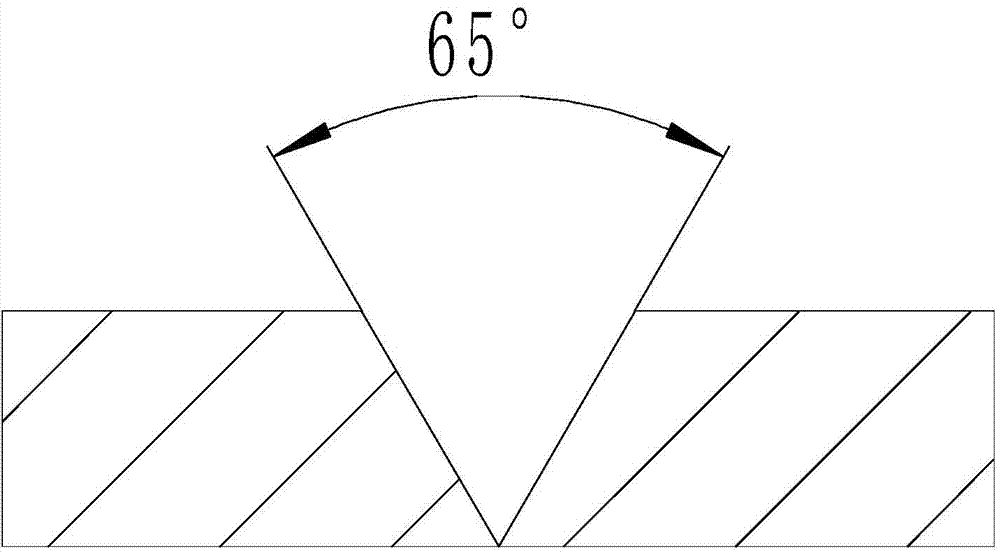

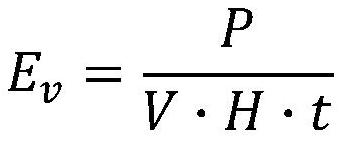

ActiveCN104722896AImprove the first pass rate of weldingPrevent unfusedArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingSurface layer

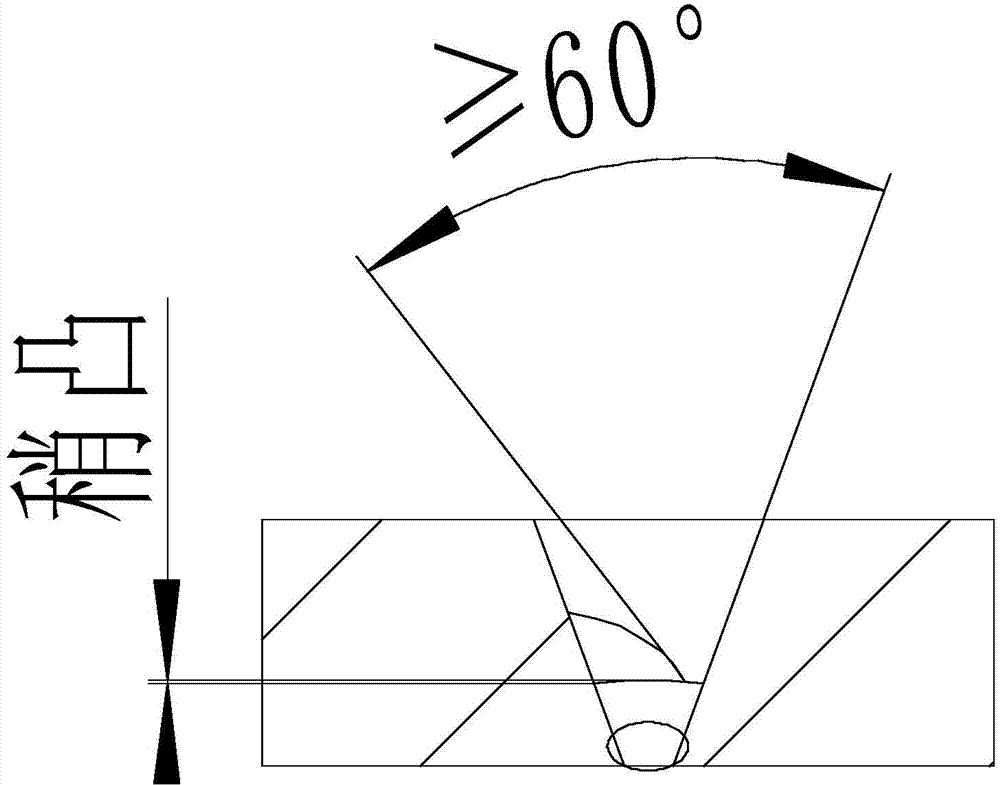

The invention discloses an automatic submerged arc welding method of nickel base alloy. The method includes the following steps that a groove is machined to be in a V shape, and the angle of the groove ranges from 65 degrees to 75 degrees; cleaning is conducted before welding; the welding parameters of a backing layer are determined; the welding parameters of packing layers and cover surface layers are determined; when packing and cover surface welding needs to be multi-layer multi-welding, each welding seam is made to be in a slightly-protruding shape; before welding is conducted on the next layer, the angle of the groove reserved in the previous welding seam and the root width are examined to guarantee that the groove angle is larger than or equal to 60 degrees. By means of the automatic submerged arc welding method, according to the welding feature of the nickel base alloy N10276, the models and specifications of welding materials are selected and matched reasonably, the optimal welding parameters are determined, the welding heat input is controlled effectively, heat cracks are prevented form being generated in the welding process, automatic submerged arc welding of the nickel base alloy is achieved, the welding efficiency of automatic submerged arc welding is 4 times to 5 times the welding efficiency of shielded metal-arc welding rod welding and 8 times to 10 times the welding efficiency of tungsten electrode argon arc welding, the welding efficiency is improved greatly, the welding labor intensity is lowered, and welding quality is improved.

Owner:LUXI IND EQUIP

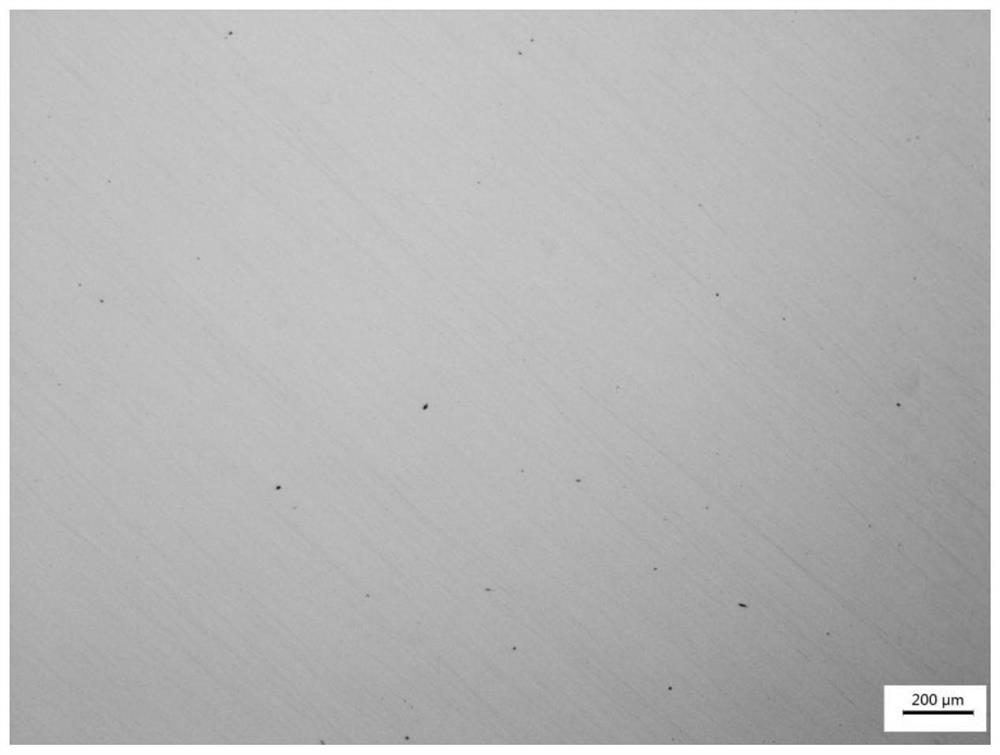

High-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing, using method therefore and nickel-based high-temperature alloy component

ActiveCN112921206AGood printabilityImprove high temperature mechanical propertiesAdditive manufacturing apparatusSelective laser meltingChemical composition

The invention provides high-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing, a using method therefore and a nickel-based high-temperature alloy component, and relates to the technical field of powder-based additive manufacturing. The high-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing comprises the following chemical components in percentage by weight: 12-14% of Cr, 8-9% of Co, 3.8-4.2% of Al, 3.8-4.2% of Ti, 2.4-2.8% of W, 1.9-2.1% of Ta, 1.6-2.0% of Mo, 1.0-1.2% of Nb, 0.1-5% of Fe, 0.1-2.0% of Hf, 0.12% or less of C, 0.1% or less of Si, 0.02% or less of n, less than 0.03% of Zr, 0.01% or less of B, and the balance Ni and impurity elements. By using the high-temperature alloy powder, compact and crack-free complex parts meeting the strength requirement in the ultrahigh-temperature environment can be printed through the selective laser melting technology.

Owner:常州钢研极光增材制造有限公司 +1

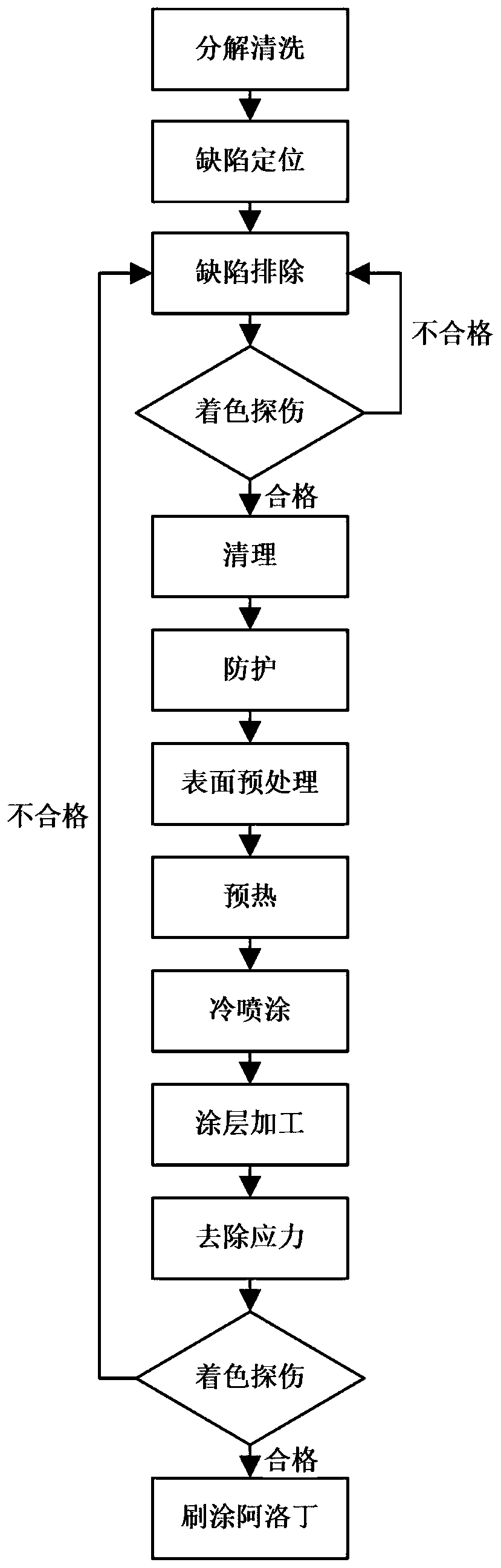

Method for repairing aircraft fuel system aluminum silicon alloy shell casting defects

ActiveCN110480254AAvoid heat cracksAvoids the problem of substrate annealing softeningAircraft componentsAircraft fuel systemDecomposition

The invention relates to the technical field of aircraft fuel system mechanical part accessory repairing, in particular to a method for repairing aircraft fuel system aluminum silicon alloy shell casting defects. The method includes the following steps of S1, decomposition cleaning; S2, defect positioning and removal; S3, dye penetration; S4, cleaning; S5, protection; S6, surface pretreatment; S7,preheating before spraying; S8, cold spraying; S9, coating processing; S10, stress relief treatment; S11, dye penetrant inspection; and S12, anti-corrosion treatment. According to the method for repairing the aircraft fuel system aluminum silicon alloy shell casting defects, the problems of a heat crack of a shell and base material annealing softening caused by large heat input of a traditional surfacing process are effectively avoided, the repairing problem of the aircraft fuel system aluminum silicon alloy shell casting defects is solved, at the same time, casting defect repairing of the shell can be realized under the operation temperature of less than 120 DEG C, the problem of scrapping of a whole part of accessories due to shell damage or secondary damage caused by repairing is avoided, and economic benefits are significant.

Owner:国营芜湖机械厂

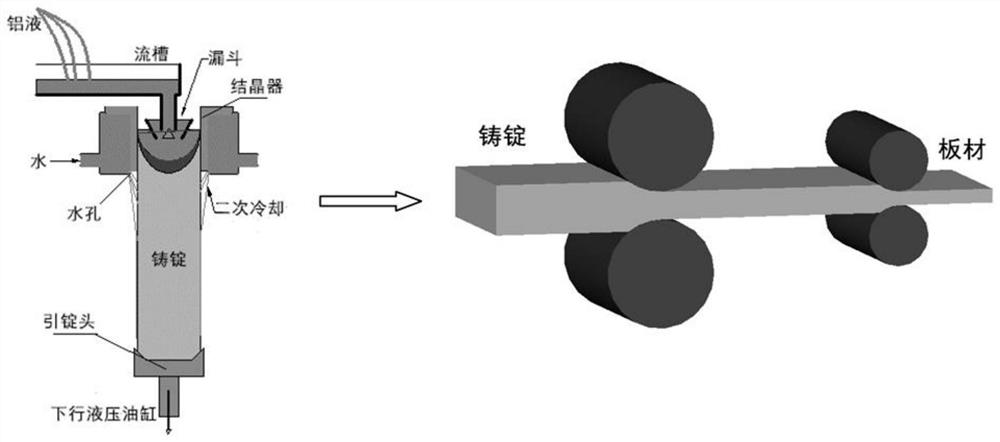

Method for improving self-feeding capacity of high and thick large-cross section casting blank

ActiveCN102161090AAchieving radial self-feedingImprove the interface heat transfer coefficientState of artDiameter ratio

The invention relates to the field of casting blank manufacturing, in particular to a method for improving the self-feeding capacity of a high and thick large-cross section casting blank, and can solve the problems that the center quality of the thick large-cross section casting blank is poor, cracks are generated on the surface of the thick large-cross section casting blank, and the rejection rate is high in the prior art. The method comprises the following steps of: controlling external cooling conditions of different solidification stages of the casting blank to quickly solidify the outer surface of the casting blank to form a shell, establish strength and prevent surface cracks from being generated; performing heat preservation and slow cooling on the surface of the casting blank to keep a large area of a core part in a pasty area, wherein a solidification layer on the outer surface of the casting blank is kept at a higher temperature so that plastic deformation is realized; and performing simultaneous solidification and solid-phase movement in the subsequent solidifying and shrinking process of the casting blank to fulfill the aim of radial self-feeding of a deformable metal at a high temperature so as to eliminate the internal shrinkage cavities and surface cracks of the casting blank and obviously improve the looseness until the internal looseness of the casting blank is eliminated. The method is applicable to the high and thick large-cross section casting blank, particularly to a thick large-cross section casting round blank and a thick large-cross section casting square blank of which the height-diameter ratio is high and the axial looseness cannot be improved through riser feeding.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

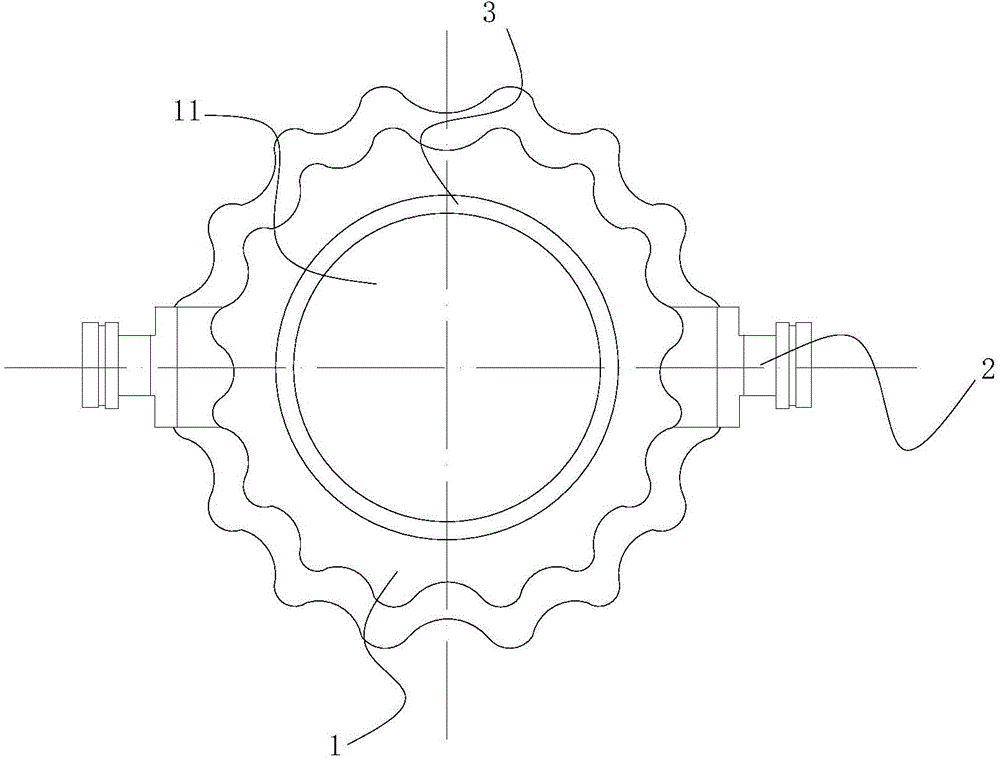

Round ingot die and round ingot manufacturing method

The invention relates to the technical field of casting of ingots, and provides a round ingot die. The round ingot die comprises a die body, a lug and an insulation board; an inner cavity is formed in the die body; the cross section of the outer side surface of the die body is polygonal wave shaped. According to the round ingot die, the radiating area of the side surface of the ingot is increased; hot melt at the outermost layer can be quickly cooled to form a chilling layer; the thickness increase of the chilling layer is sped up; therefore, static pressure in pouring of hot melt can be borne; crack can be prevented; the difficulty at pouring of the round ingot can be greatly reduced; meanwhile, the size precision of the outer side surface of the round ingot die cannot influence the size precision of the round ingot, so that the requirement on the processing precision of the outer side surface of the round ingot die is reduced, the process and working houses are decreased, and the cost can be saved. The invention further provides a round ingot manufacturing method. The method is that the degree of superheat of hot melt is 40 to 55 DEG C; the linear speed of pouring of an ingot body is 80 to 220mm / min; the linear speed of filling and pouring of a dead head of the insulation board is 35 to 90mm / min. The method can properly reduce the casting temperature and speed; the round ingot can be quickly radiated; therefore, the surface cracks can be decreased.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

7-series high-strength aluminum alloy variable polarity plasma arc welding method

InactiveCN104607779AAvoid heat cracksAvoid defects such as poresArc welding apparatusPlasma welding apparatusWelding power supplyHeat balance

The invention relates to a 7-series high-strength aluminum alloy variable polarity plasma arc welding method. The method aims at solving the problem that in the prior art, the welding quality is poor. The vertical welding process is adopted, 7-series high-strength aluminum alloy workpieces are fixed through clamps after being vertically placed, a variable polarity plasma welding gun provided with an automatic wire feed device is horizontally placed on one side of the workpieces, the gun head of the welding gun right faces a welding seam between the two workpieces to conduct variable polarity plasma arc welding, the current selection range of the positive polarity and the negative polarity of the variable polarity plasma arc welding is between 190 A and 260 A, and the current selection range of the negative polarity is between 240 A and 300 A. A variable polarity plasma arc welding power supply serves as a power supply of the plasma welding gun. The 7-series high-strength aluminum alloy variable polarity plasma arc welding method has the advantages that 7-series high-strength aluminum alloy with a thickness ranging from 6 mm to 12 mm can be welded, it can be ensured that the reasonable temperature gradient section is formed between a liquid molten pool and solid metal in the welding process, the stable hole punching effect can be obtained, hole punching molten pool force and the heat balance can be ensured, the defects of welding hot cracks, pores and the like can be overcome, the appearance of the welding seam is uniform and neat, the welding deformation is small, and the welding efficiency is high.

Owner:INNER MONGOLIA UNIV OF TECH

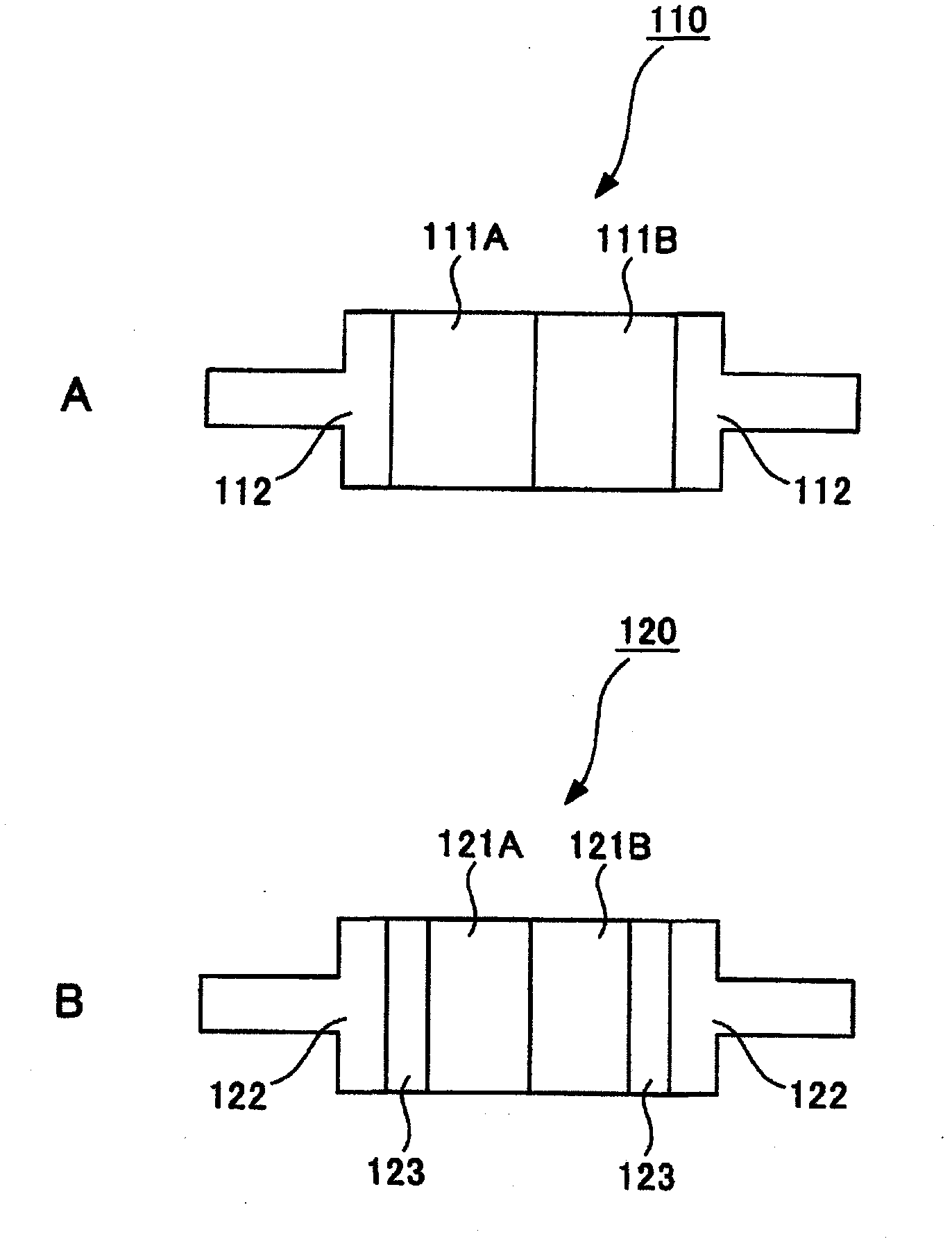

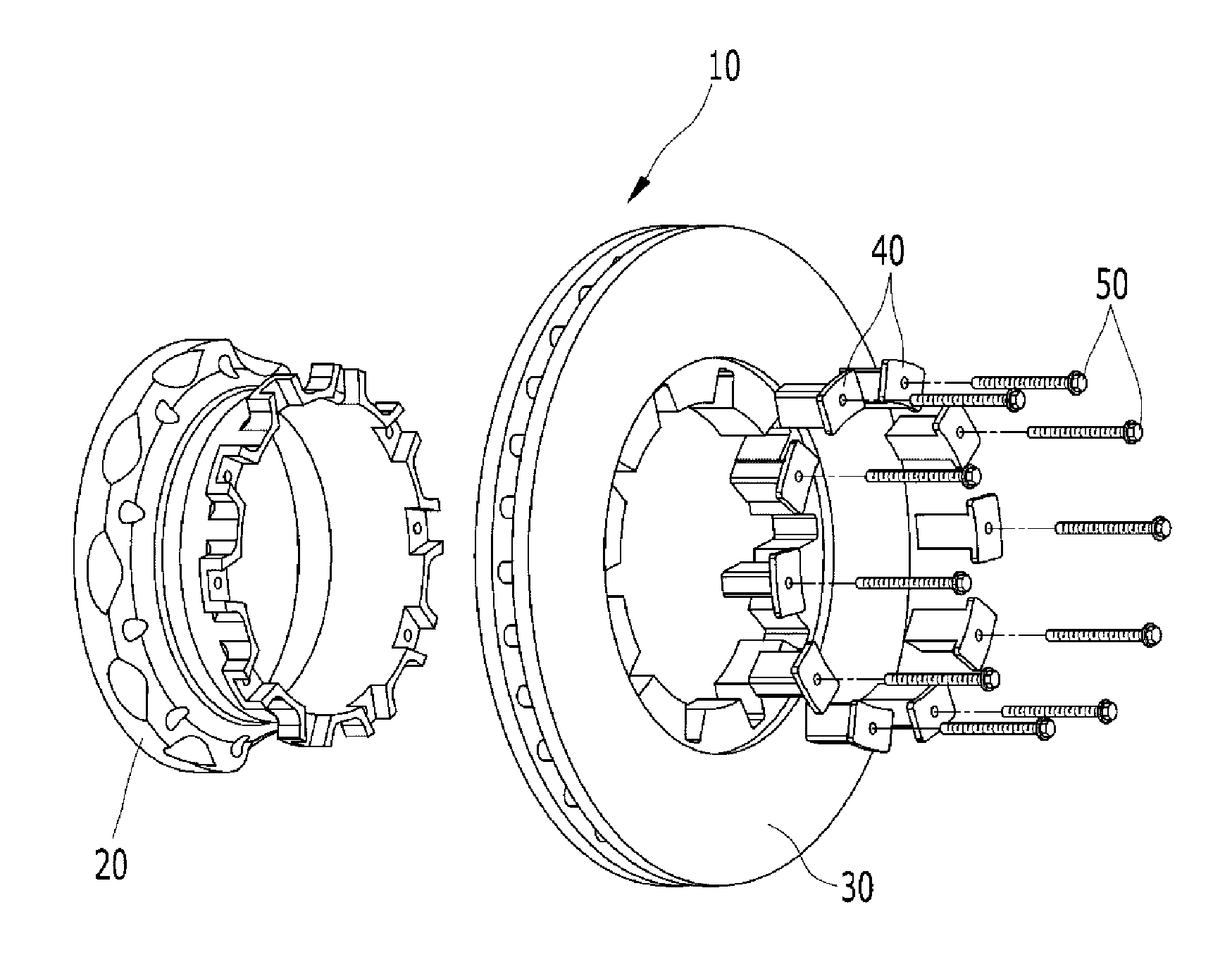

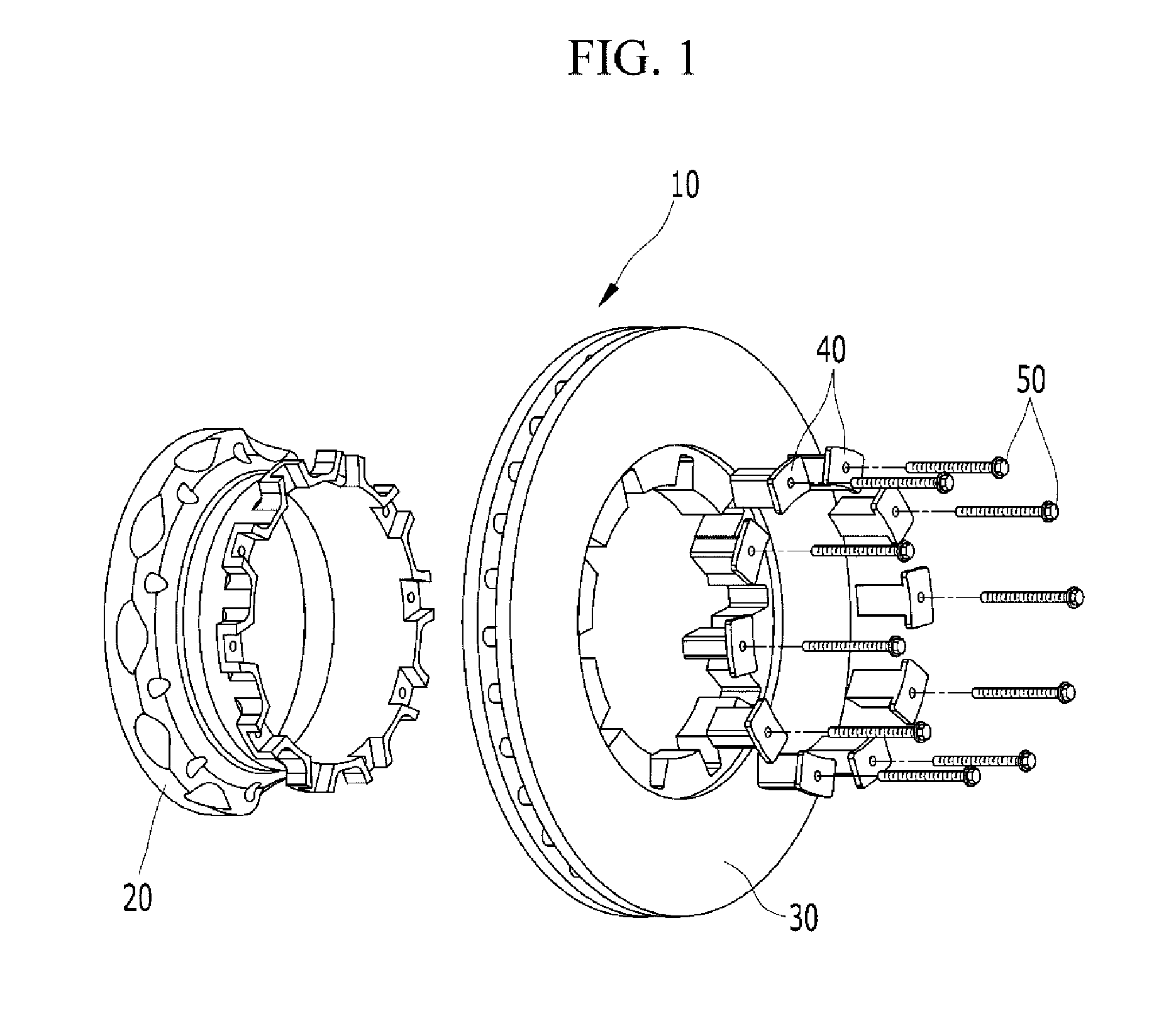

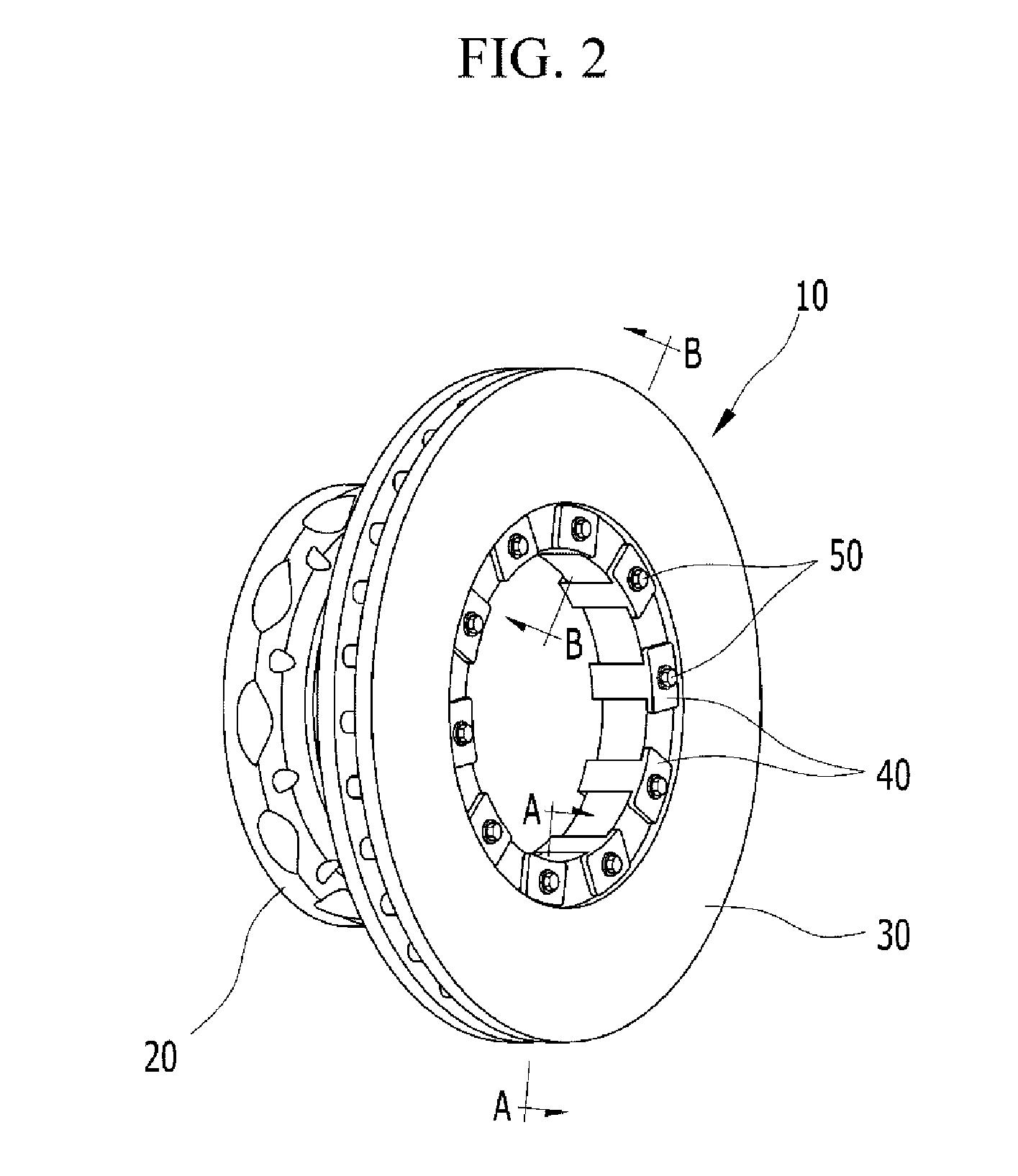

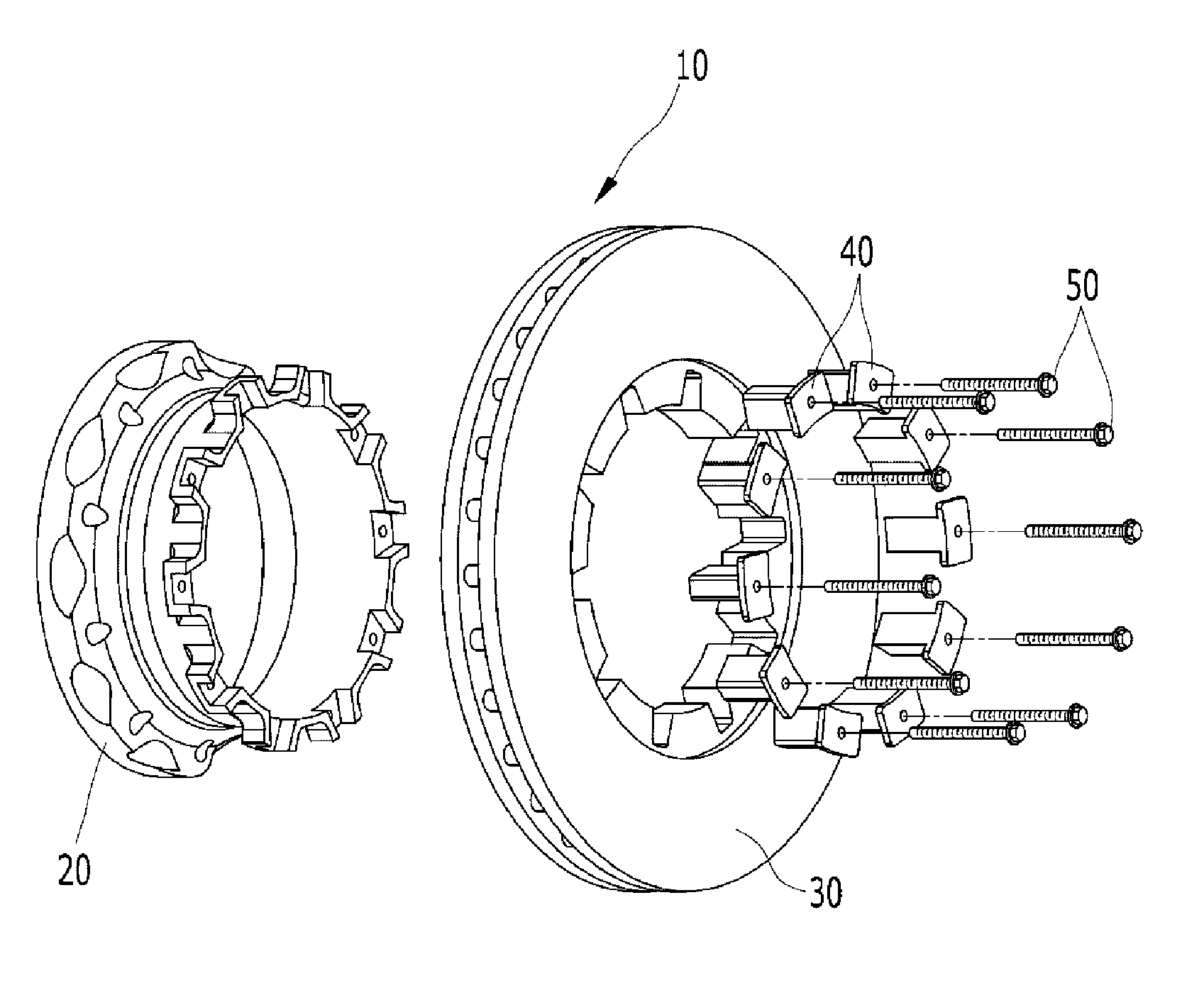

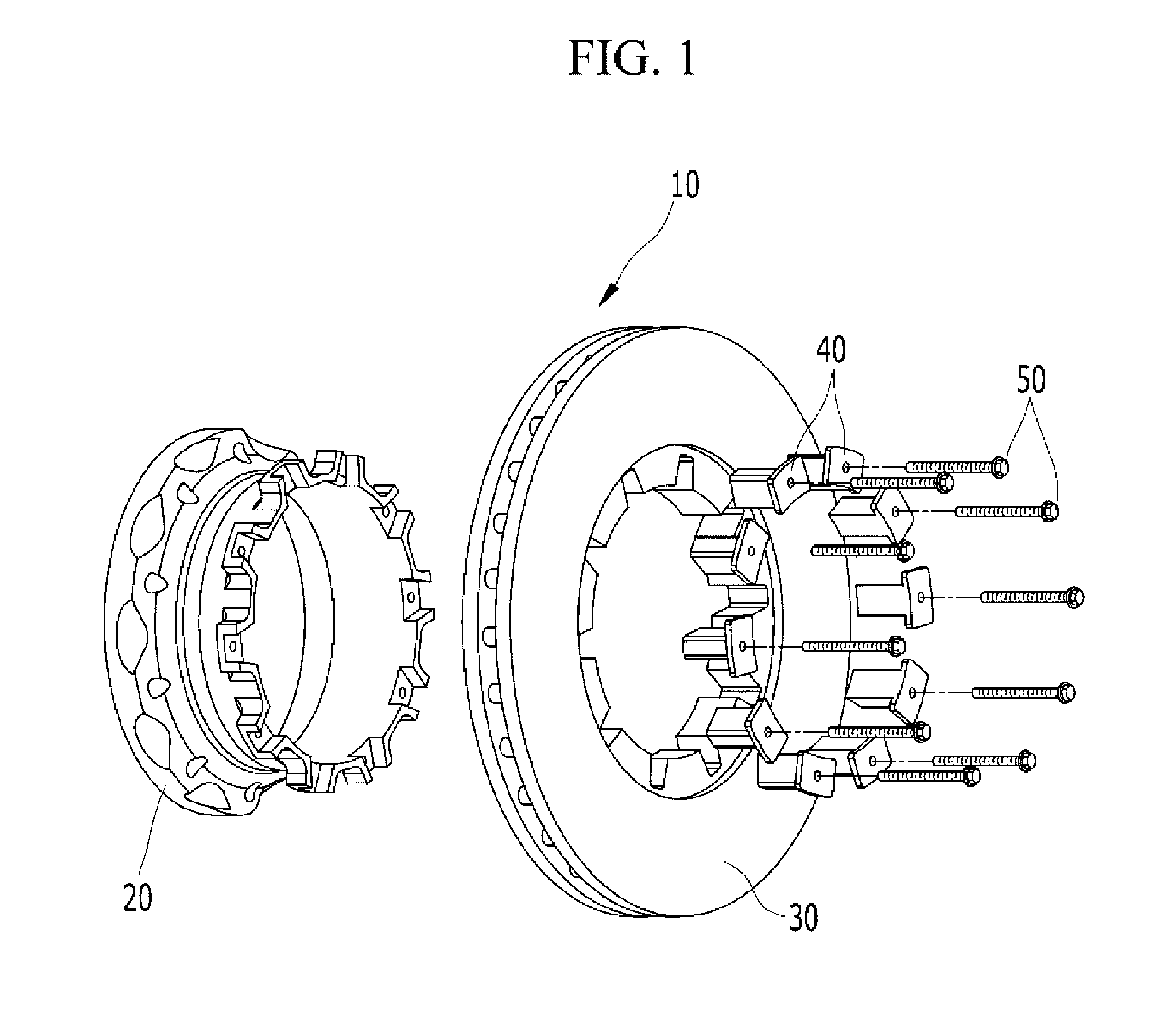

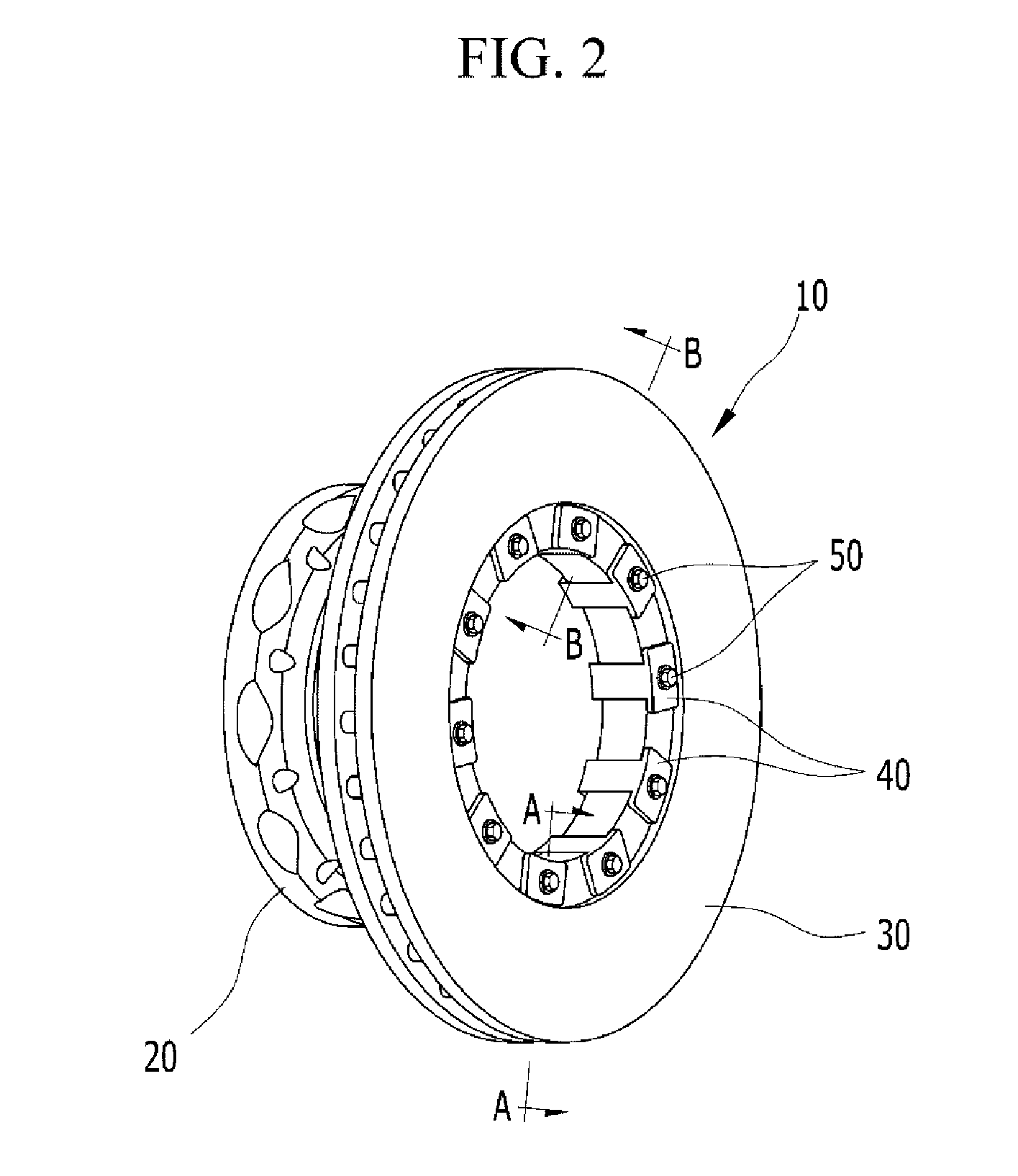

Disc rotor assembly for vehicle

ActiveUS8651249B2Avoid heat cracksIncreased durabilityBraking element arrangementsBraking discsMechanical engineeringTransmitter

A disk rotor assembly for a vehicle may include an adaptor adapted to be mounted on a hub and to receive torque of a wheel, a disk rotor generating a braking force, a transmitter engaging the adaptor with the disk rotor and adapted to transmit the torque received by the adaptor to the disk rotor or to transmit the braking force generated by the disk rotor to the adaptor, and engaging member for engaging the adaptor, the disk rotor, and the transmitter altogether.

Owner:HYUNDAI MOTOR CO LTD

SiZrCN gradient composite coating cutter and preparation method thereof

ActiveCN107177828AHigh hardnessImprove thermal stabilityVacuum evaporation coatingSputtering coatingSputteringHeat stability

The invention belongs to the field of mechanical manufacture cutting cutters, and in particular relates to a SiZrCN gradient composite coating cutter and preparation method thereof. The coating is the SiZrCN gradient composite coating prepared by adopting a composite coating method of unbalanced magnetron sputtering and electric arc plating; the surface of the coating cutter is SiZrCN gradient composite coating with gradually-changed gradient of nitrogen content, a Ti transition layer and a SiZrC transition layer are sequentially arranged between a cutter base body and the coating. By adopting the SiZrCN ultra-hard carbon-nitrogen compound coating, because two metals including Si and Zr are added in the coating at the same time, the nitrogen content of the coating structure component is gradually changed in a gradient manner, so that the cutting machining performance of the cutter can be improved. The coating has high hardness and heat stability, and also has good diffusion prevention and wear prevention performances, good plastic deformation resistance ability and excellent friction and wear resistance property. In the cutting process, the cutter can effectively prevent the occurrence of cracking of cutting edges and hot cracks, guarantee the machining surface quality of the workpieces, and prolong the service life of the cutter by more than 70%.

Owner:JINING UNIV

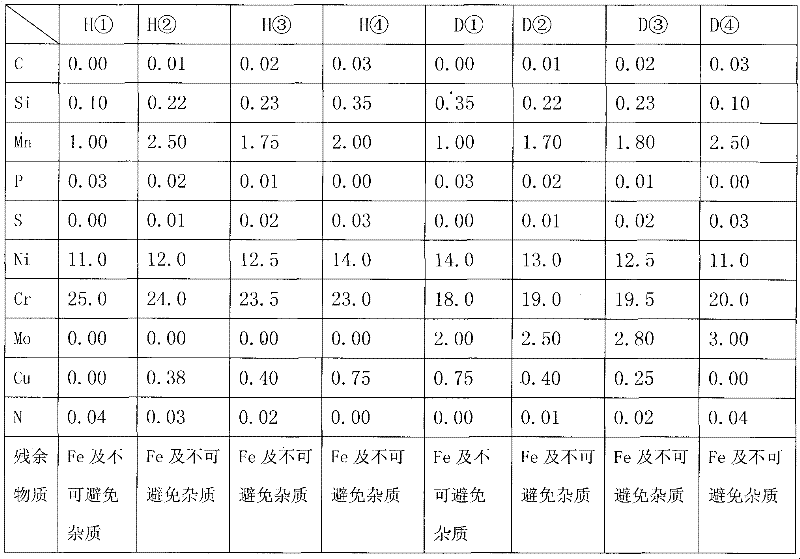

Stainless steel band electrode electroslag surfacing welding strip and welding flux

ActiveCN102233494AWeld firmlyImprove efficiencyWelding/cutting media/materialsSoldering mediaSlagCorrosion resistant

The invention discloses a stainless steel band electrode electroslag surfacing welding strip and a welding flux. The Mo element is not added into a transition layer welding strip, but the surfacing metal has sufficient Mo; and the welding strip and the welding flux can be matched to be applied to large-scale surfacing on the inner wall or the outer wall of a container and can meet corrosion-resistant and high-temperature-resistant requirements. When the welding strip and the welding flux are matched for surfacing, the dilution rate is ultralow and is 5 to 12 percent and the production efficiency is high; slag is easy to remove, a formed welding bead is attractive and welding defects do not exist; the intergranular corrosion resistance is excellent; and cracks do not exist during surfacingbending.

Owner:KUSN GINTUNE WELDING

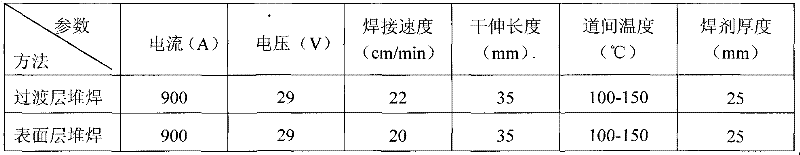

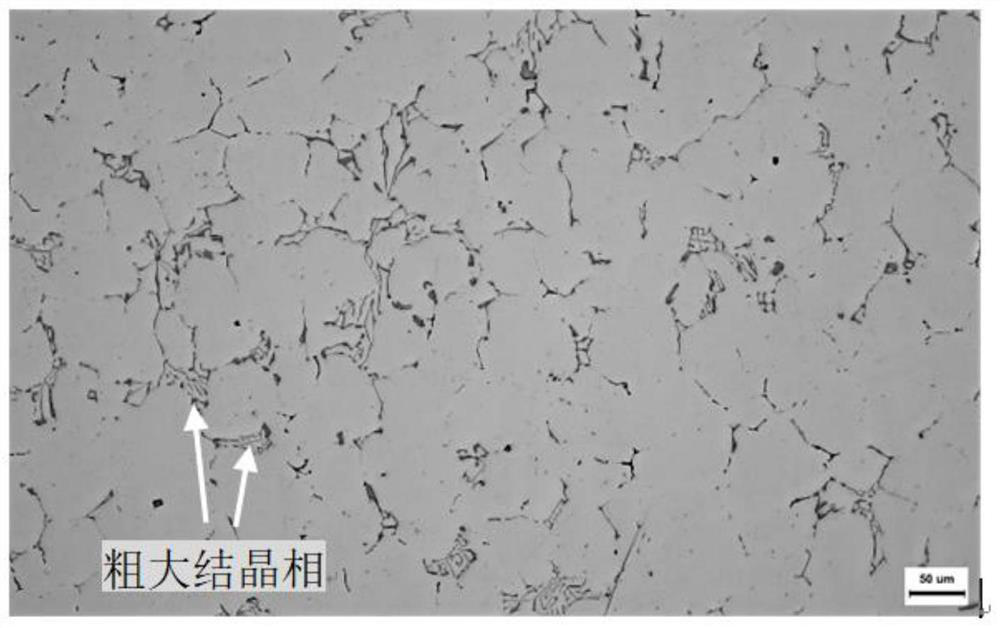

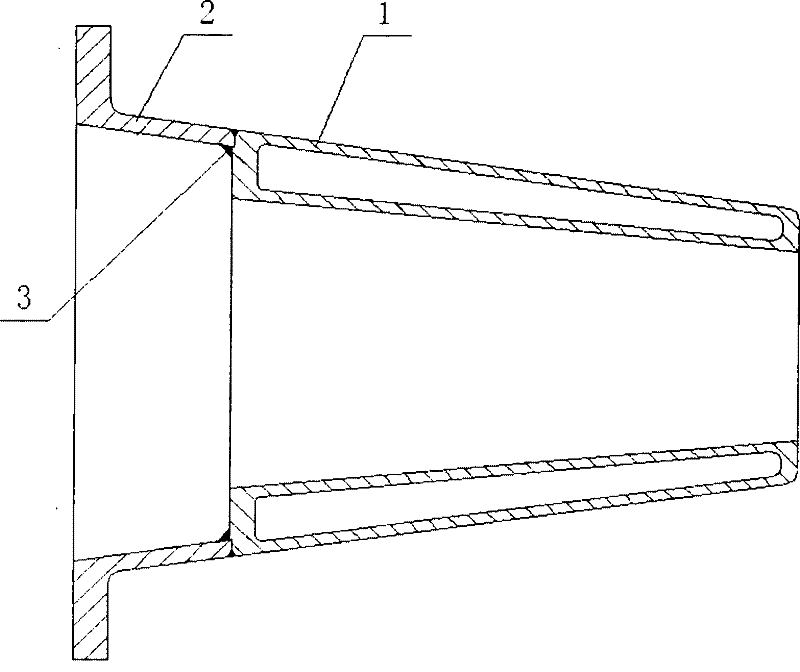

Aluminum alloy plate strip preparation method based on vacuum centrifugal casting and vacuum centrifugal casting device

The invention relates to an aluminum alloy plate strip preparation method based on vacuum centrifugal casting and a vacuum centrifugal casting device. The preparation method comprises the following steps that raw materials are prepared according to components of a target aluminum alloy; a cast pipe blank is cast in a vacuum centrifugal casting manner; the cast pipe blank prepared through vacuum centrifugal casting is split, the split cast pipe blank is leveled, and an aluminum alloy cast plate blank is obtained; and the aluminum alloy casting plate blank is rolled, and an aluminum alloy plate strip is obtained. According to the preparation method, under the action of centrifugal force, the feeding environment in the solidification process of aluminum alloy melt liquid can be obviously improved, and casting defects such as shrinkage porosity and shrinkage cavities can be effectively bridged under the action of the centrifugal force. Due to the fact that vacuum centrifugal casting is completed under the vacuum condition, a melt does not make contact with air, melt oxidation can be effectively avoided, the defect of oxide inclusion in the cast pipe blank is greatly reduced, and the quality of the pipe blank is improved.

Owner:NORTHEASTERN UNIV

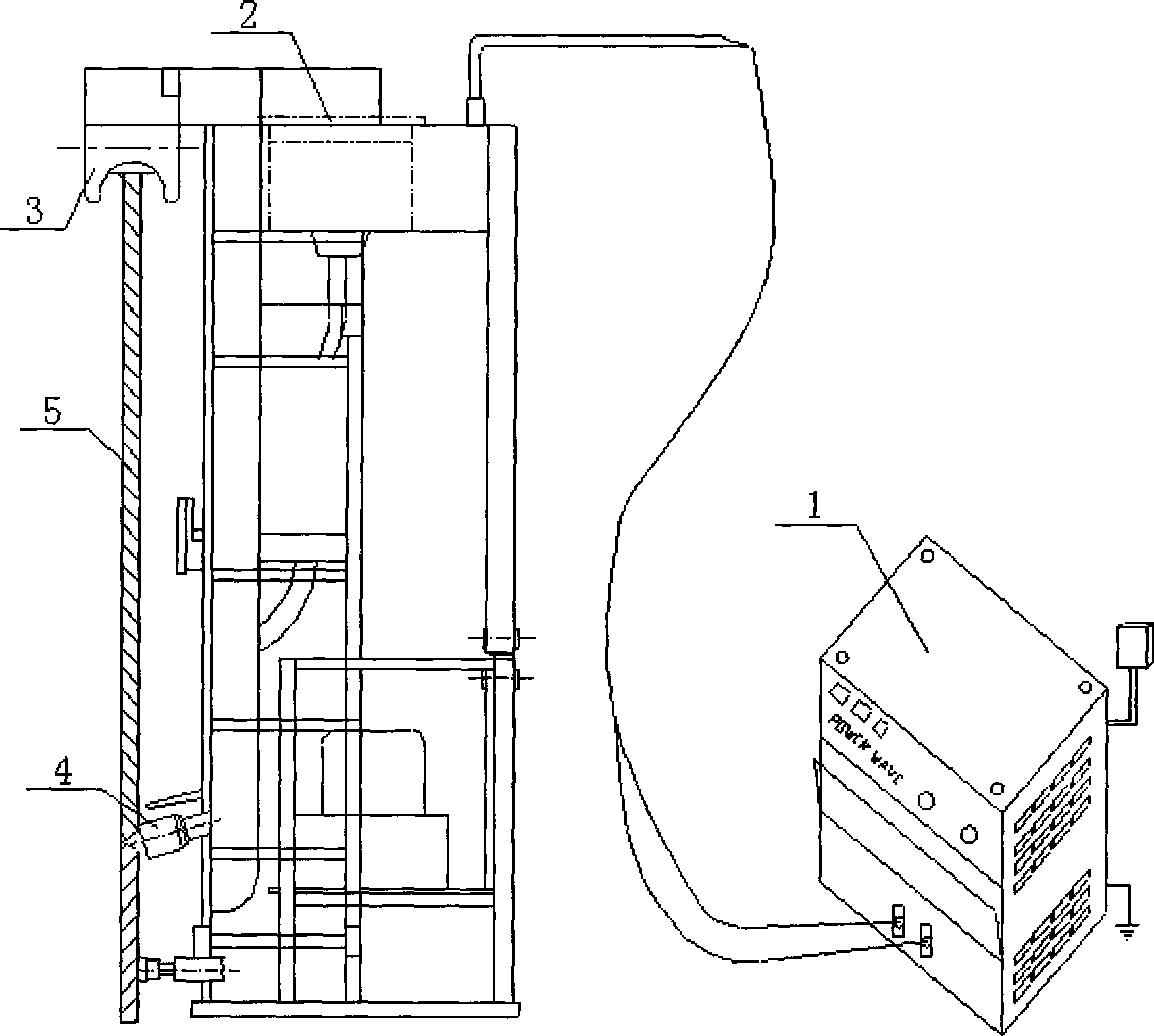

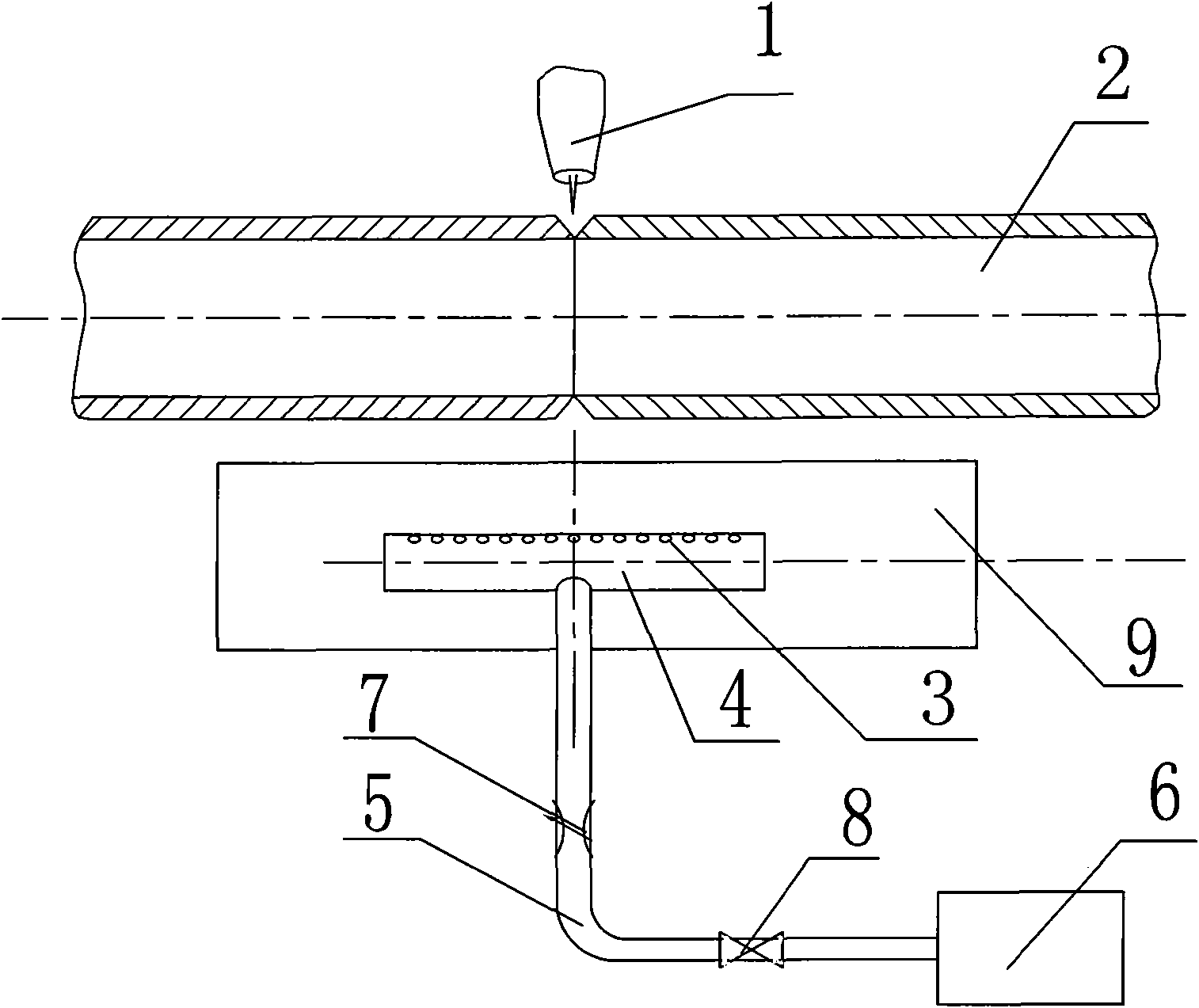

Device and method for water-cooling hot wire argon tungsten-arc welding of austenitic stainless steel tube

ActiveCN102009250ASlow altitude changeStable welding processWelding accessoriesAustenitic stainless steelTungsten

The invention relates to a device and a method for a water-cooling hot wire argon tungsten-arc welding of an austenitic stainless steel tube. If the sensitization and tendency of generating hot cracks are controlled only by reducing welding current and welding voltage and reducing welding hot input, the welding efficiency is reduced, and the welding characteristic of high-efficiency mechanical hot wire argon tungsten-arc welding cannot be fully played. In the method for the water-cooling hot wire argon tungsten-arc welding of the austenitic stainless steel tube, the prewelding preparation is performed first, namely the height and position of a welding gun are adjusted, an austenitic stainless steel straight tube is subjected to butt joint, and the water supply position of cooling water is adjusted; the welding gun and wires of welding equipment are protected by the same gas course; and when welding priming coats and the tube rotate to the position of 270 degrees, a cooling water valve is opened, and a welding joint is subjected to spray cooling by a spraying device until all priming coats, filling layers and covering layers are welded completely. The device and the method are used for the argon arc welding of the austenitic stainless steel tube.

Owner:HARBIN BOILER

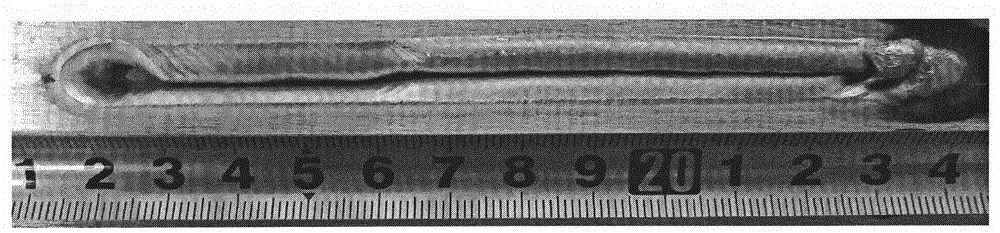

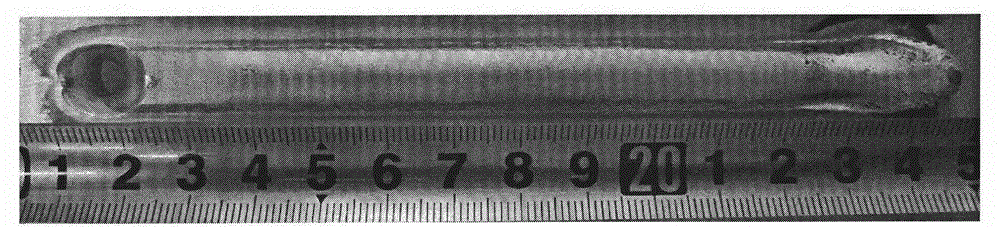

Core rod surfacing repair method and core rod surfacing layer tissue structure

InactiveCN109226935AImprove bindingHigh hardnessArc welding apparatusWelding/cutting media/materialsCrazingWear resistant

The invention discloses a core rod surfacing repair method and a core rod surfacing layer tissue structure. The core rod surfacing repair method repairs a failed core rod through flux-cored wire surfacing, improves the bonding force between a substrate and a surfacing layer, ensures that the surface of a wear layer has high hardness and excellent wear resistance, thereby obtaining a surfacing layer tissue structure of base + underlayer + wear layer mode meeting the performance requirements of the core rod. Besides, the underlayer metallographic tissue is composed of a large amount of ferrite +lower bainite + carbide, thus having good plastic toughness, being conductive to preventing the occurrence of hot cracks, being suitable for surfacing of a workpiece surface subjected to strong impact load or surfacing of a transition layer before hard surface surfacing. The wear-resistant layer tissue consists of martensite + retained austenite + carbide, thus being beneficial to the improvementof surface hardness and wear resistance, and fully meeting the comprehensive service performance requirements of the core rod from the substrate to the surface.

Owner:TIANJIN UNIV

Copper-steel dissimilar metal welding method

InactiveCN102500872AEasy to operateAvoid heat cracksArc welding apparatusDissimilar metalSpot welding

The invention discloses a copper-steel dissimilar metal welding method. A copper part and a steel part are welded together to form a copper-steel corner welding workpiece. The copper-steel dissimilar metal welding method comprises the following steps: firstly, a surfacing copper based alloy welding material is heated on one side of the copper part so as to form a copper based alloy transition layer on the welding surface of the copper part, secondly, assembling the steel part on the copper part to perform spot welding after cooling the copper part and trimming weld joints, and finally adopting a copper based welding rod to weld the copper based alloy transition layer and the steel part together, wherein the welding method is gas shield welding in a cold state. The copper-steel dissimilar metal welding method adopts a surfacing copper based alloy transition layer in a hot state so as to enable the copper based alloy welding material to be combined with the copper part well, then the copper-steel corner welding is performed in the cold state which is convenient to operate, and penetration ratio of weld metal can be controlled effectively, thereby preventing weld joint hot crack from being produced and meeting the welding requirements.

Owner:烟台鲁宝有色合金有限公司

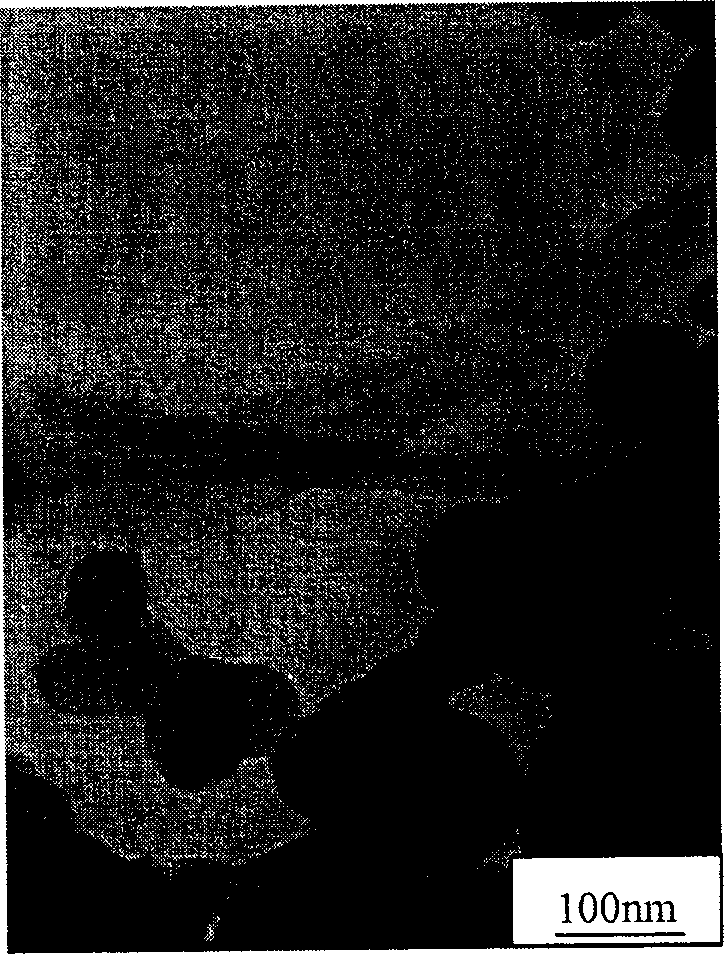

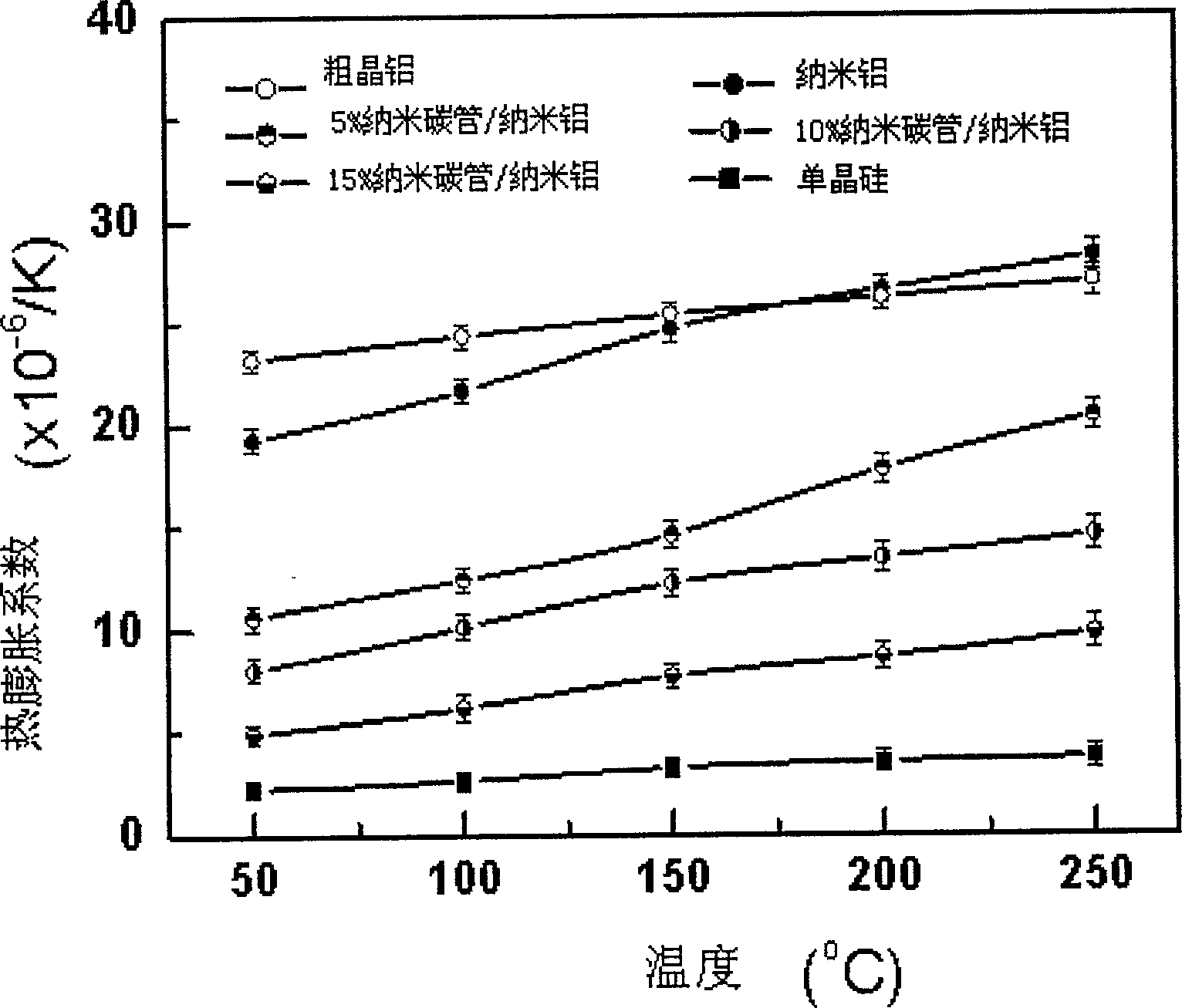

Electronic packaging material

InactiveCN1858143AImprove performanceAvoid heat stressOther chemical processesSemiconductor/solid-state device detailsCarbon nanotubeHeat stress

The electronic packaging material is prepared with nanometer metal as base material and adding carbon nanotube in 0-35 vol%. The base material may be nanometer aluminum. The present invention has the advantages of the synchronous heat expansion with silicon semiconductor to avoid heat stress and heat crack between the silicon semiconductor and packing aluminum material, excellent packaging performance, low cost and wide application.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

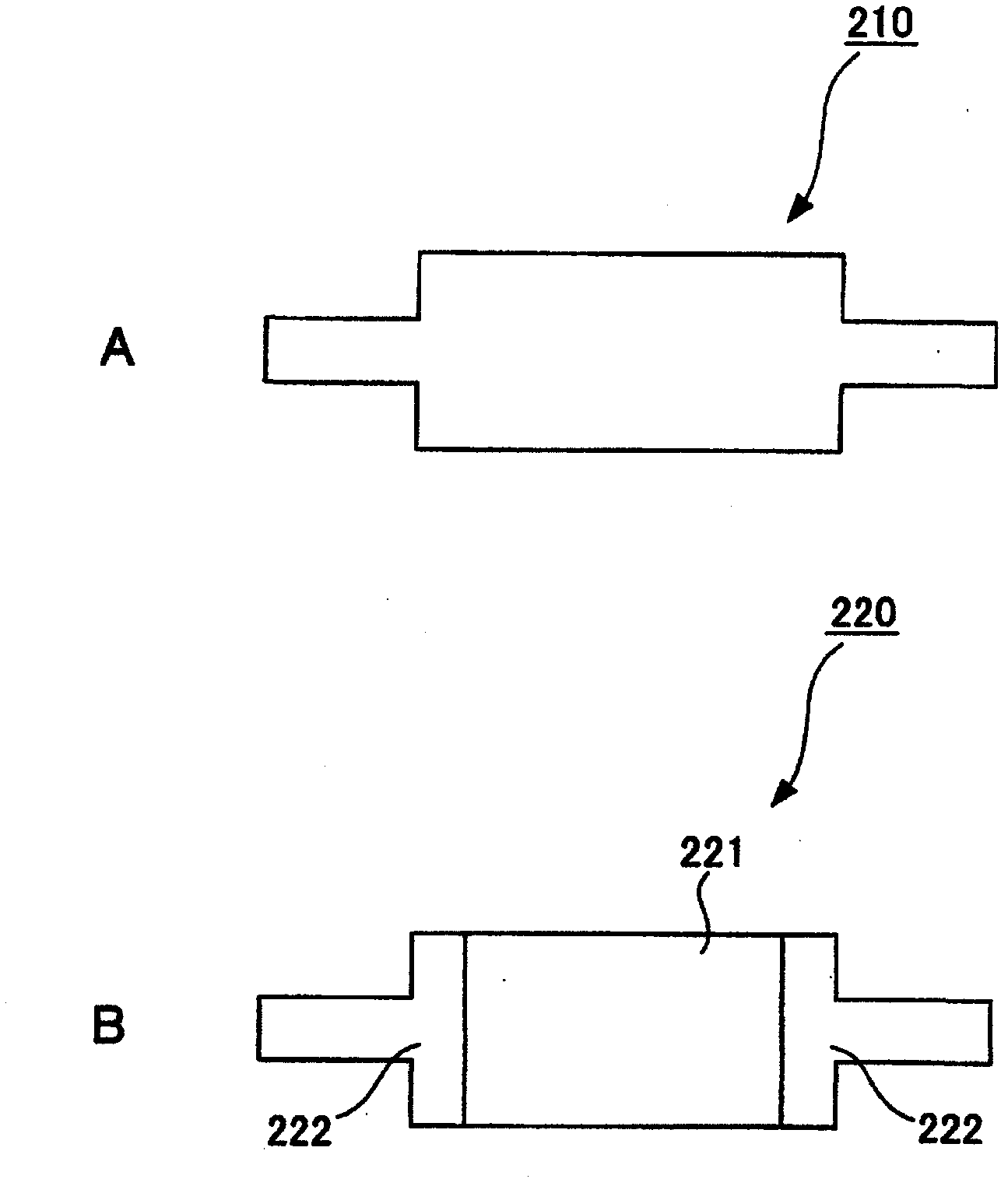

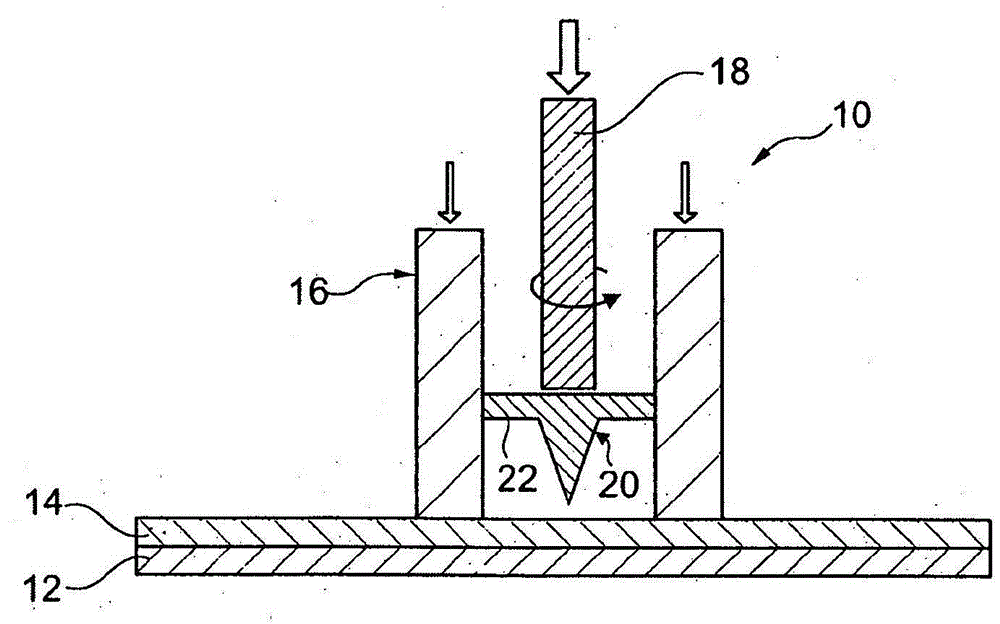

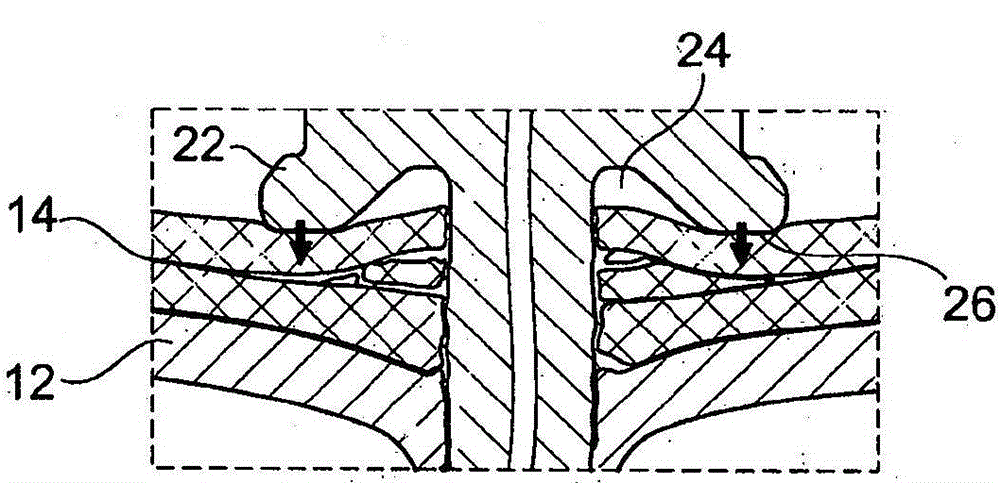

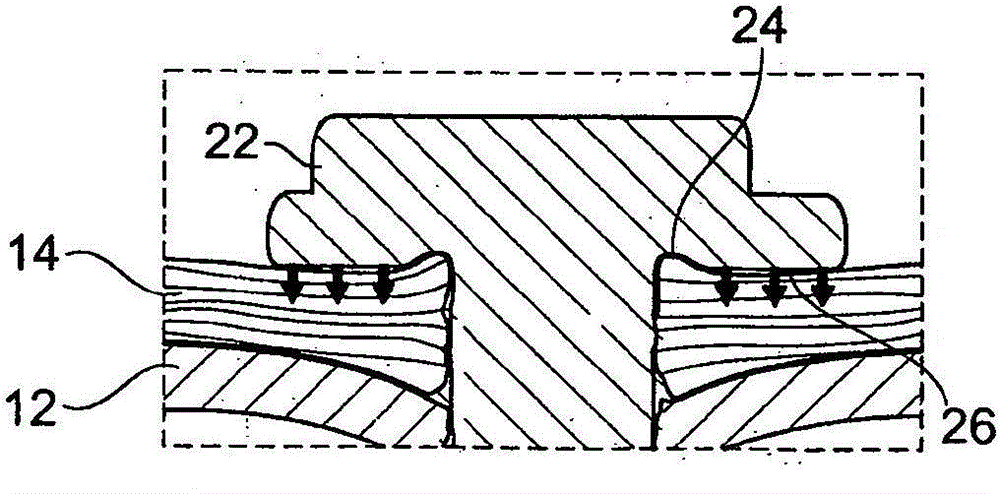

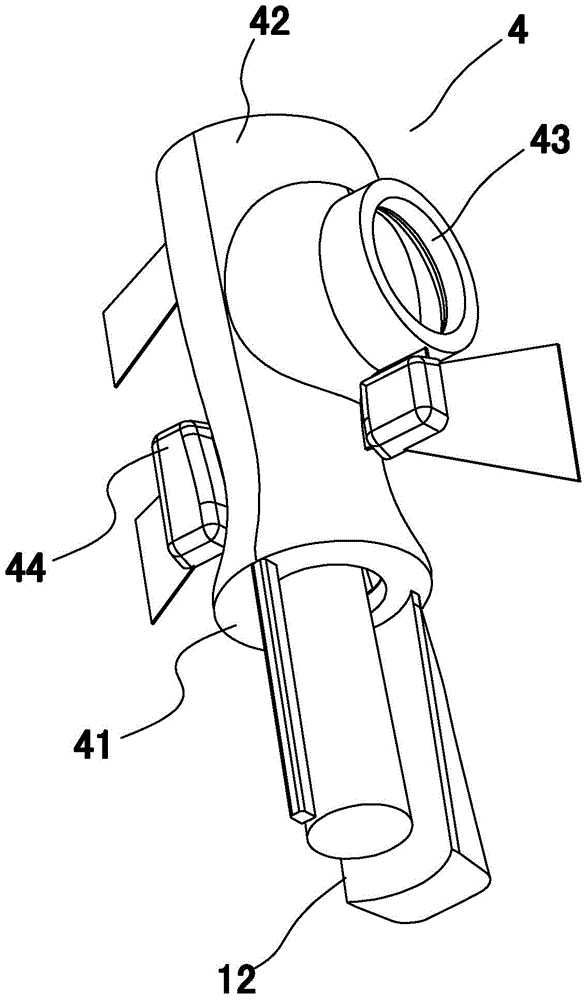

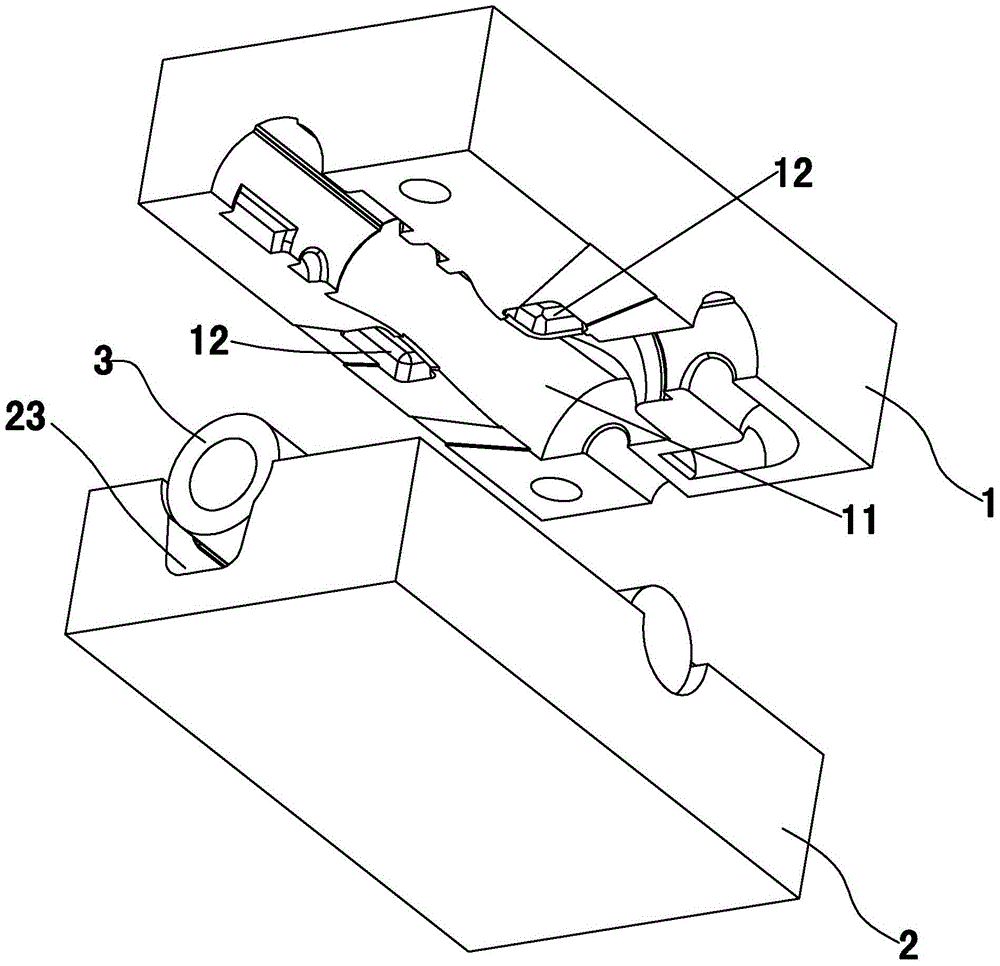

Method and device for joining members

InactiveCN104972648AWide rangeAvoiding Tolerance Chain ProblemsNon-electric welding apparatusFiberFriction welding

The invention relates to a method and device for joining members. According to the method of the invention, at least one of the members (12, 14) is made of fibre reinforced plastics, and a member complex is joined by friction welding of the members (12, 14) using an initially separate friction element (20), wherein the friction element (20) forms a fixed composition part of the member complex during the welding and friction process. The device according to the invention includes a support device (16) for fixing the members (12, 14) and a drive device (18) for rotating and pressing the friction element (20), wherein the force applied to the member (12, 14) by the support device (16) can be adjusted independent of the force applied to the friction element (20) by the drive device (18).

Owner:BAYERISCHE MOTOREN WERKE AG

Disc rotor assembly for vehicle

A disk rotor assembly for a vehicle may include an adaptor adapted to be mounted on a hub and to receive torque of a wheel, a disk rotor generating a braking force, a transmitter engaging the adaptor with the disk rotor and adapted to transmit the torque received by the adaptor to the disk rotor or to transmit the braking force generated by the disk rotor to the adaptor, and engaging member for engaging the adaptor, the disk rotor, and the transmitter altogether.

Owner:HYUNDAI MOTOR CO LTD

Submerged-arc welding wire for CO2 (Carbon Dioxide) corrosion resistant high-strength pipeline steel

InactiveCN103143856AGood crack resistanceGood impact toughnessWelding/cutting media/materialsSoldering mediaSubmerged arc weldingCorrosion resistant

The invention relates particularly to a submerged-arc welding wire for CO2 (Carbon Dioxide) corrosion resistant high-strength pipeline steel. The technical scheme is that the submerged-arc welding wire for the high-strength pipeline steel comprises the following chemical components: 0.02-0.06 wt% of C, 0.20-0.40 wt% of Si, 1.20-2.00wt% of Mn, 3.00-8.00wt% of Cr, and 0.20-0.40wt% of Cu, 0.04-0.10 wt% of (V+Ti+B), not more than 0.001 wt% of S, not more than 0.002 wt% of P, and the remain of Fe and inevitable impurities. The submerged-arc welding wire for the high-strength pipeline steel provided by the invention is matched with an SJ101-G soldering flux for use, requirements of intensity, tenacity and CO2 corrosion resistance of a welding joint formed by the welded submerged-arc welding wire for the CO2 corrosion resistant high-strength pipeline steel can be met by mechanical property and corrosion resistance of formed weld metal; moreover, the property of the welding joint is matched with base metal, so that technical requirements of oil and gas pipelines prepared by welding can be met; and the welding joint is good in CO2 corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Welding method for manufacturing jet pump by using ultra-low carbon austenitic stainless steel

InactiveCN102225487AControl deformationExtended service lifeWelding/cutting auxillary devicesArc welding apparatusRoom temperatureFiller metal

The invention provides a welding method of an ultra-low carbon austenitic stainless steel and in particular relates to a welding method for manufacturing a jet pump by using an ultra-low carbon austenitic stainless steel. The method comprises the following steps: welding a weldment by means of a welding gun through manual tungsten electrode argon arc welding, wherein a welding wire made of a material same as the ultra-low carbon austenitic stainless steel is taken as a filler metal; carrying out welding and cold-water quick cooling simultaneously, wherein the temperature of welding is below 80 DEG C, and the speed of welding is 45-50 cm / min; after extinguishing the arc, cooling the weldment is reduced to the room temperature within 2 seconds, wherein the weldment is less than or equal to 12 mm thick; and after welding, carrying out pickling and passivation treatment. The welding method has the following outstanding advantages: the welding and cooling of the weld joint by virtue of cold water are carried out simultaneously, thus reducing the welding temperature, so that the stainless steel is free of transformation of internal molecules and atoms (crystals, therefore, the service life of the weldment is greatly prolonged; and the integrated deformation of the weldment is effectively controlled.

Owner:唐山三友集团兴达化纤有限公司

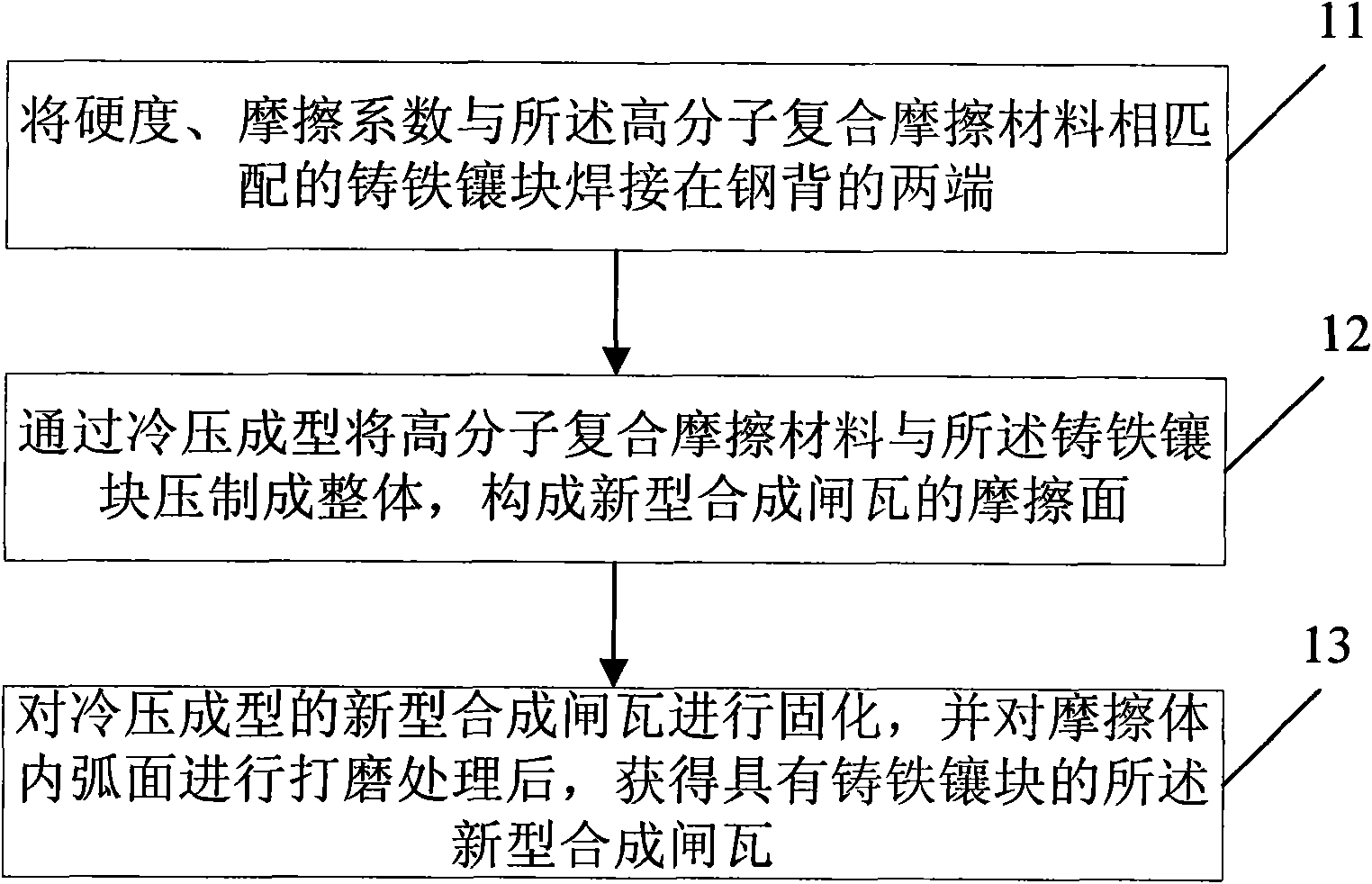

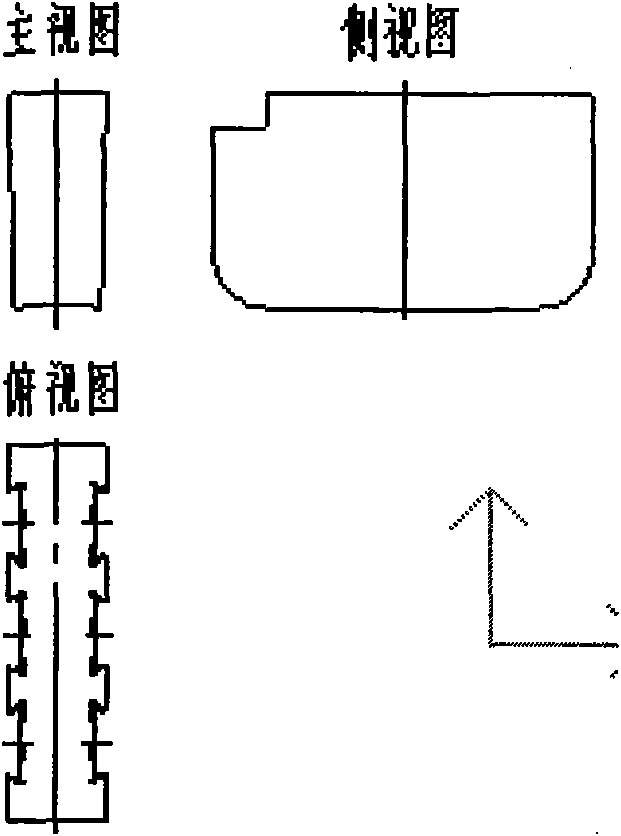

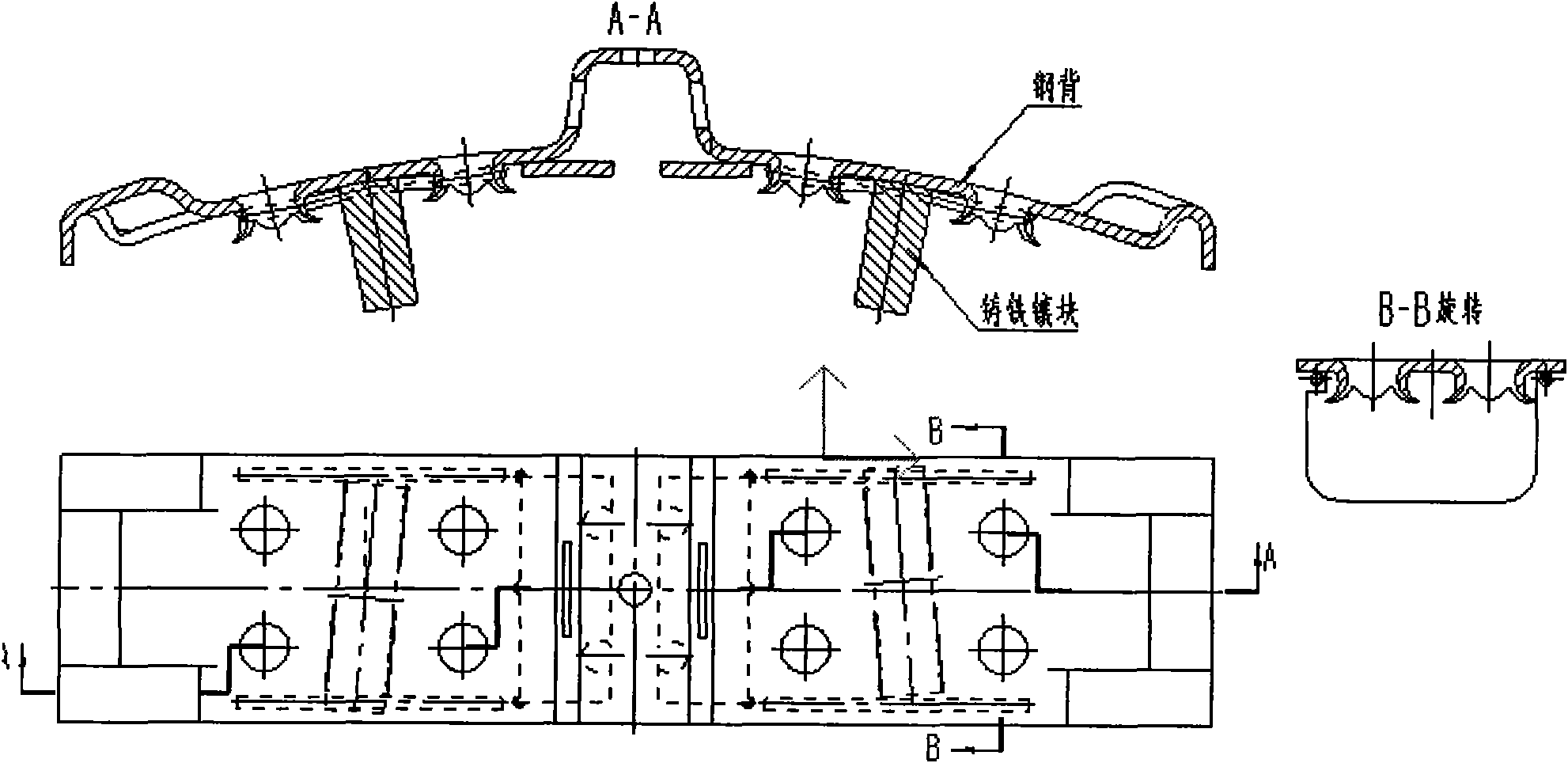

Novel mosaic composition brake shoe and manufacturing method thereof

ActiveCN101900176AImprove thermal conductivitySmall thermal recessionOther chemical processesBraking membersHardnessBrake shoe

The embodiment of the invention provides a novel mosaic composition brake shoe and a manufacturing method thereof. In the method, the novel composition brake shoe is formed by combining a high molecular composite friction material and cast iron inserts; and the method particularly comprises the following steps of: welding the cast iron inserts with hardness and friction coefficient matched with those of the high molecular composite friction material at the two ends of a steel back; pressing the high molecular composite friction material and the cast iron inserts into a whole by cold press molding to form a friction surface of the novel composition brake shoe; and curing the novel composition brake shoe formed by the cold press molding, and polishing the inner cambered surface of a friction body to obtain the novel composition brake shoe with the iron cast inserts. Thus the heat conductivity of the composition brake shoe can be obviously improved and the heat fade of the composition brake shoe can be reduced so as to ensure that the composition brake shoe has stable friction performance during the braking.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

Gravity casting process of lead-free brass tap

The invention provides a gravity casting process of a lead-free brass tap, which has the advantages that a flowing distance of a product in a casting process is short, the simultaneous solidification is achieved, hot cracks are reduced; a heat balance effect of a mould is good, so that heat balance of the product is facilitated, and the stress micro-cracks during cooling are reduced. The gravity casting process of the lead-free brass tap comprises the following step of casting and forming lead-free brass liquid through a gravity casting device, wherein the gravity casting device comprises an upper half mould, a lower half mould and a sand core, wherein mould cavities matched with a tap body in shape are respectively and correspondingly arranged between the upper half mould and the lower half mould, the sand core is arranged in the mould cavities between the upper half mould and the lower half mould, the shape of the sand core is matched with the shapes of a water inlet part and a water outlet part of the tap and an inner cavity of an installing part of a valve core, a casting cavity is formed between the sand core and the mould cavity, a sprue in which lead-free molten copper is cast is arranged in the lower half mould, the sprue is connected with the casting cavity, the sprue is provided with an internal sprue and an external sprue, and the internal sprue is correspondingly arranged at the casting cavity for forming the water inlet part of the tap body.

Owner:LONGYAN HONGHANG SANITARY WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com