Patents

Literature

80results about How to "Small thermal recession" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium carbonate whisker reinforced rubber base friction material and preparation method therefor

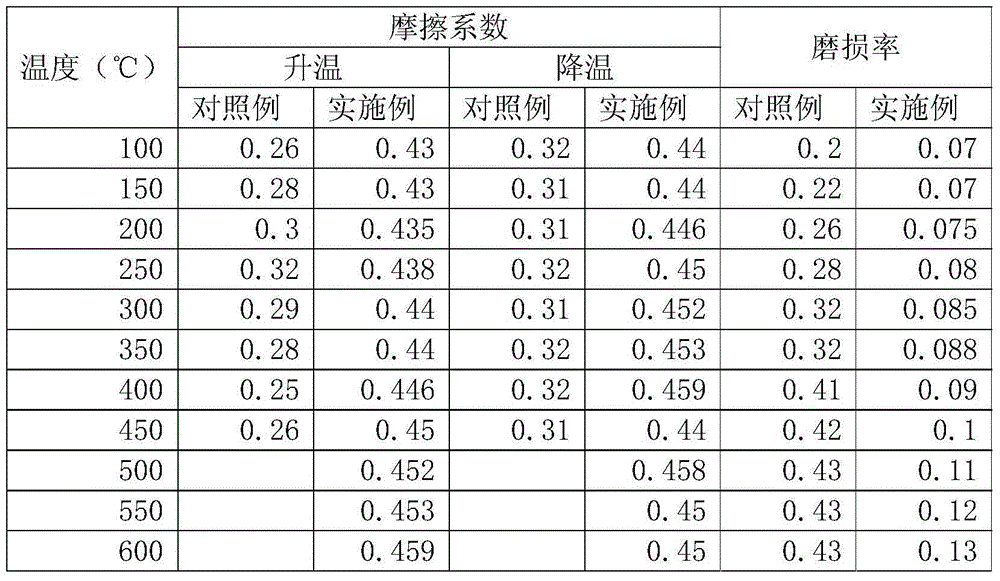

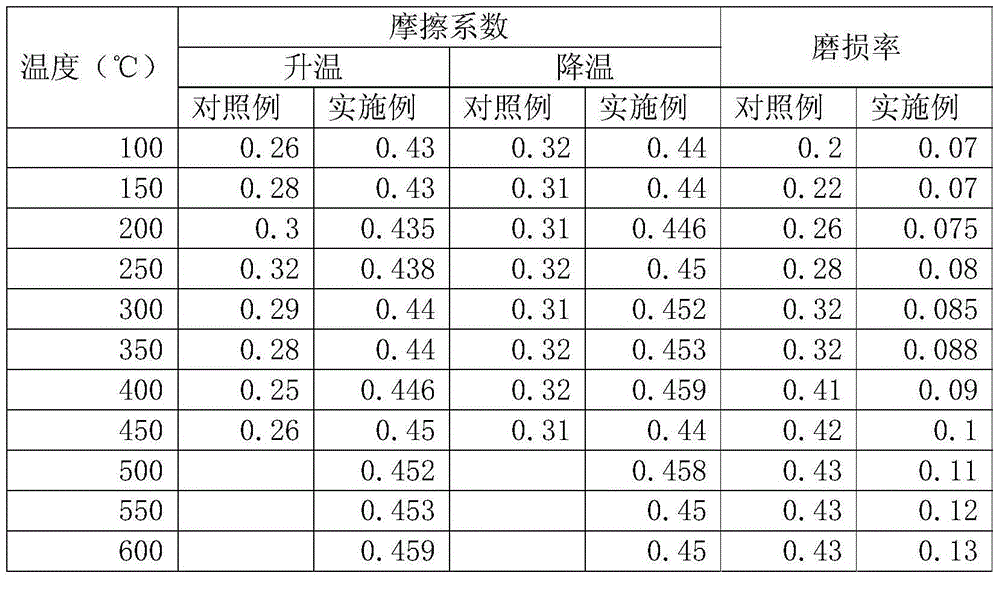

InactiveCN105111532AImprove brittlenessImprove heat resistanceOther chemical processesFriction liningButadiene-styrene rubberPetroleum coke

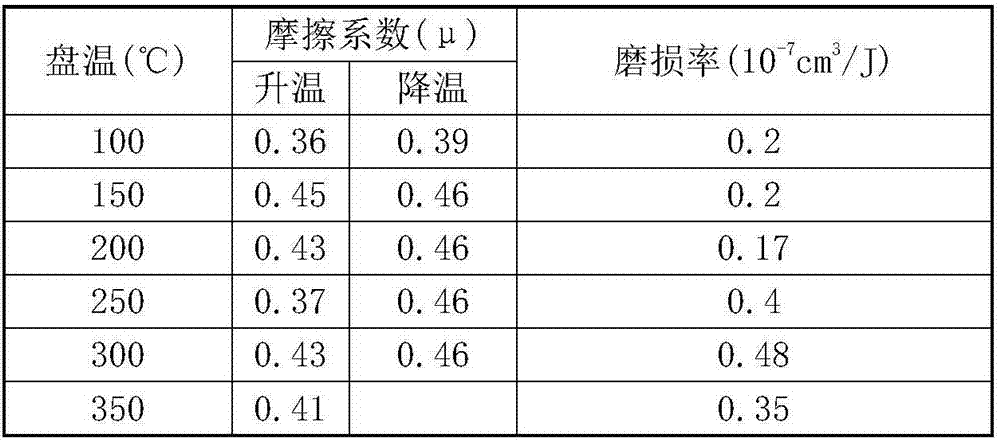

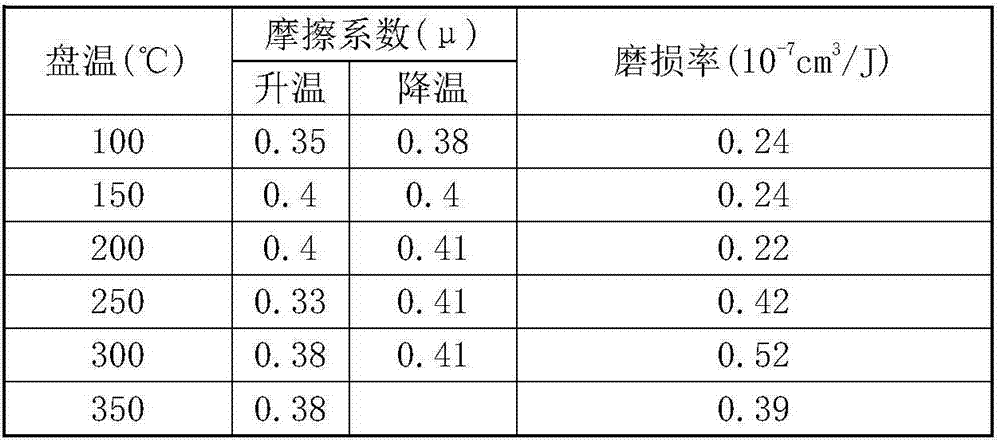

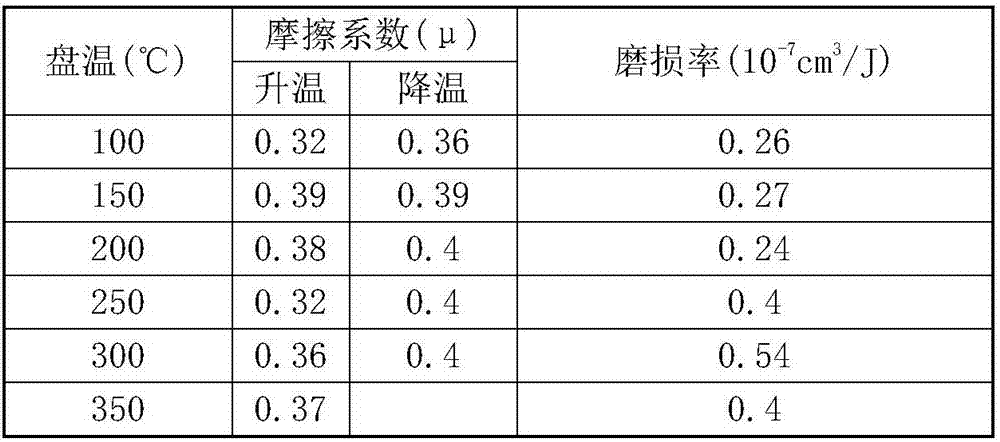

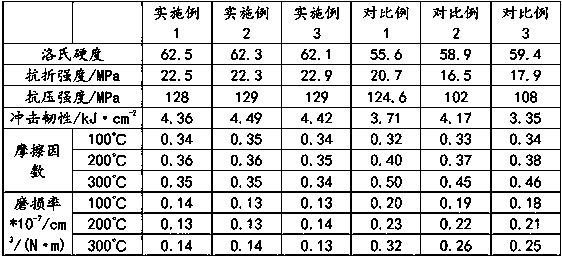

The present invention discloses a calcium carbonate whisker reinforced rubber base friction material, and a preparation method therefor. The material comprises: 8-15 parts of nitrile rubber, 10-15 parts of styrene-butadiene rubber, 5-10 parts of phenolic resin, 5-25 parts of calcium carbonate whisker, 10-20 parts of steel fiber, 2-8 parts of sepiolite fiber, 0-8 parts of mineral fiber, 0-3 parts of aramid fiber, 5-8 parts of barium sulfate, 5-10 parts of magnesium oxide, 2-3 parts of aluminum oxide, 5-10 parts of flake graphite, 1-5 parts of carbon black, 5-10 parts of petroleum coke, 3-6 parts of Cardolite cashew nut shell oil friction powder, 0.5-1 parts of sulfur, and 0.5-1 parts of accelerator. The preparation method comprises process steps of such as material collocation, mixing, pressing molding and the like. Brake pads synthesized by the method provided by the invention have the advantages including excellent friction and wear performance, stable braking performance, high heat-resistant property, safe, environmentally-friendly, and low in cost; and is suitable for braking devices for automobiles and motive power machines, thereby achieving a very wide application prospect and applying to industrial production.

Owner:GUANGXI UNIV +2

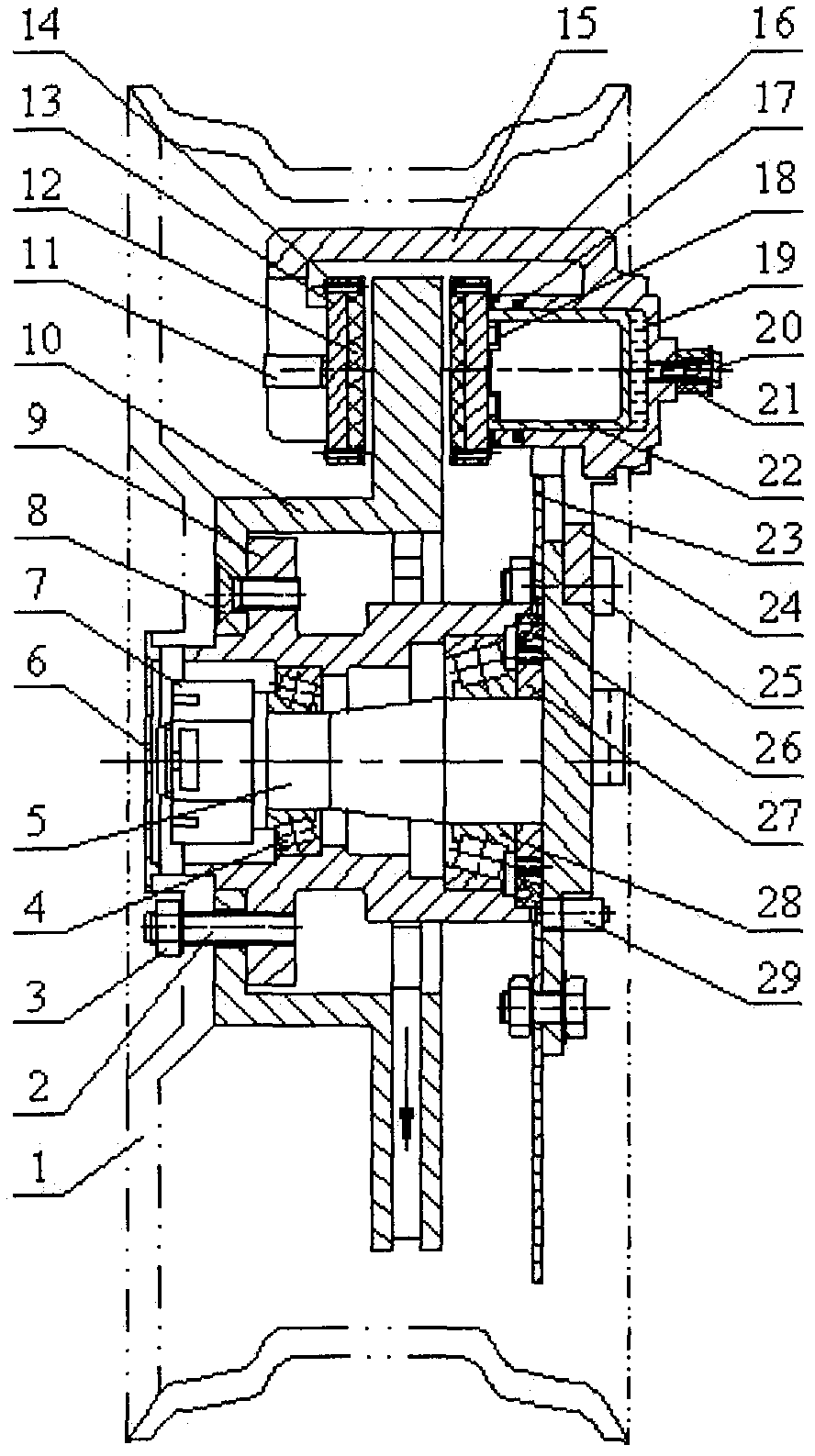

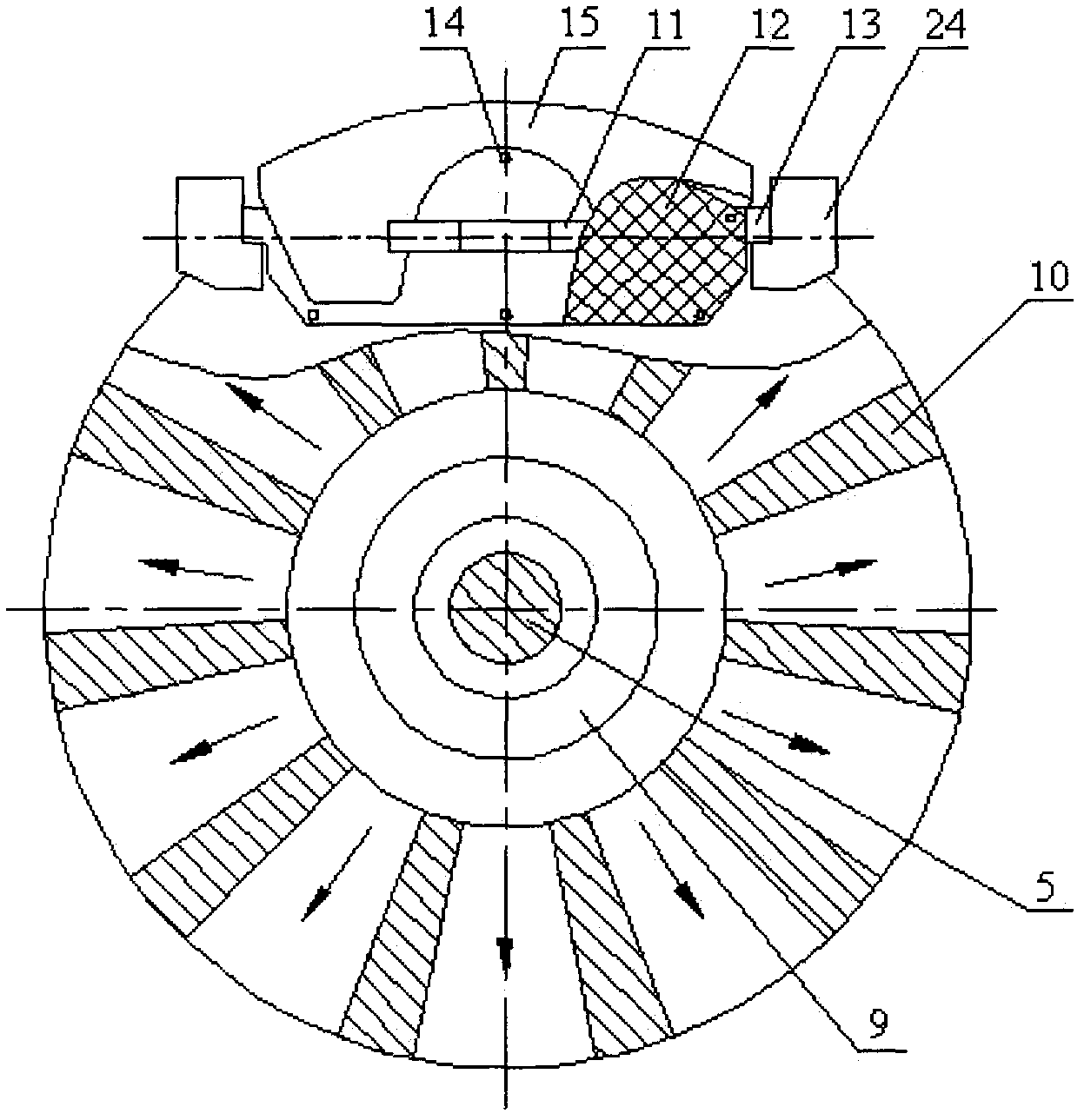

Automotive water-cooled disc brake

InactiveCN103388639AImproved thermal stability and heat dissipationSmall thermal recessionCoolant flow controlMachines/enginesDisc brakeEngineering

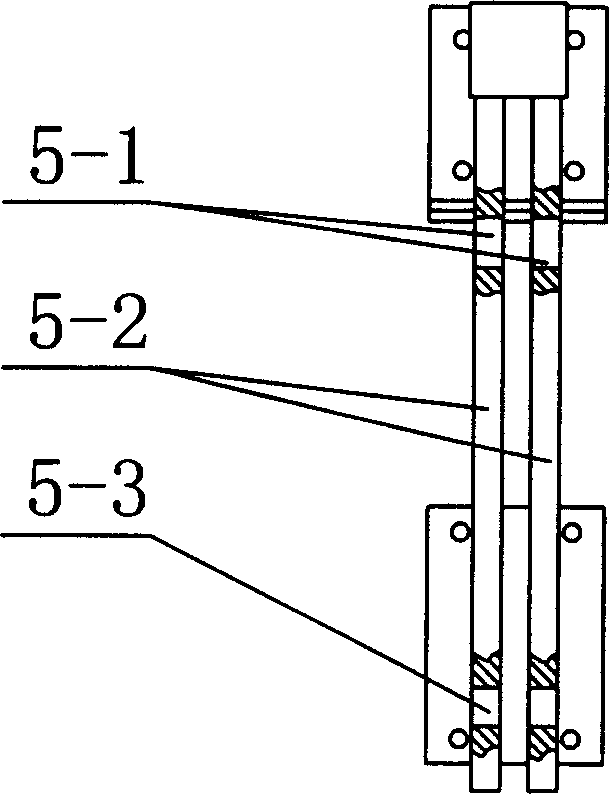

The invention discloses an automotive water-cooled disc brake, which comprises a water-cooled disc brake and a coolant circulation control system, wherein the coolant circulation control system comprises double radiators, a braking radiator and a coolant circulation control system for radiation of an engine radiator; an inner brake disc (39) and an outer brake disc (35) are connected into a split-type brake disc through a brake disc bolt (36); an outer seal spring (38) and an inner seal spring (49) are respectively welded and sealed with an outer cooling disk (37) and an inner cooling disk (40) alongin circumferences; an inner waterway baffle (50) and an outer waterway baffle (51) are respectively welded with the inner cooling disk (40) and the outer cooling disk (37) to form a waterway; a brake block friction plate (12) is fixed with a hollow brake block base plate (34) and a brake block cover plate (33) through a rivet (14); and the hollow brake block base plate (34) is provided with a waterway. The automotive water-cooled disc brake is used for replacing a common disc brake on an automobile, so that the heat stability of the disc brake is improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Modified phenolic resin, preparation process thereof and brake pad cementing agent prepared by using same

ActiveCN101838437AHigh thermal decomposition temperatureStable emergency braking performanceOther chemical processesAldehyde/ketone condensation polymer adhesivesHigh velocityBrake pad

The embodiment of the invention discloses a modified phenolic resin. Phenolic resin is modified by adopting tung oil and nano particles, wherein the tung oil accounts for 10-15 wt% of the weight of the phenolic resin, and the nano particles account for 20-45 wt% of the weight of the phenolic resin. The thermal decomposition of the phenolic resin is remarkably increased by comprehensive modification on the phenolic resin, and a brake pad including the phenolic rein has stable braking performance and less heat fading during emergent braking at high speed. The invention also discloses a preparation process of the modified phenolic resin, a brake pad cementing agent, a preparation process thereof, and a brake pad using the brake pad cementing agent as a cementing agent.

Owner:SHANDONG GOLD PHOENIX

Multielement resin base carbon compound disc-type braking pad and preparation method thereof

ActiveCN102635653AImprove wear resistanceImprove high temperature resistanceFriction liningLow noiseSulfide

The invention discloses a multielement resin base carbon compound disc-type braking pad and a preparation method thereof. The braking pad is obtained by carrying out mould pressing and forming once on the following raw materials: unmodified phenolic resin, organosilicone modified phenolic resin, polyacrylate modified phenolic resin, polyacrylonitrile carbon fiber, artificial granular graphite, natural crystalline flake graphite, granular coke, silicon carbide, aramid pulp, compound mineral fiber, steel fiber, red copper powder, ferrous sulfide and barium sulfate. The product disclosed by the invention has the advantages of high temperature resistance, ablation resistance, small heat expansion coefficient, high specific strength, high specific modulus, good abrasion resistance, low noise, excellent initial performance, short breaking-in period, small heat fade, long service life, excellent pedal comfort degree, excellent high temperature and high speed performance and stable abrasion grade under different braking conditions, the effect on considering the good abrasion resistance and low noise is achieved, no dust is generated during braking, and various materials are all environment-friendly environment-protection materials. The multielement resin base carbon compound disc-type braking pad also has the function of automatically cleaning the braking disc.

Owner:JINAN GOLD PHOENIX BRAKE SYST

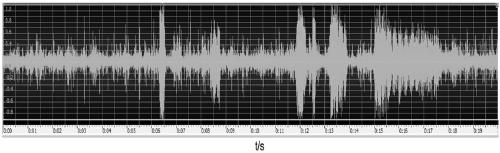

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

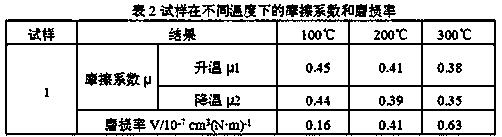

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

Friction material for brake block of heavy-duty automobile

InactiveCN106147124AImprove stress resistanceImprove impact resistanceOther chemical processesFriction liningAcrylic rubberHeat stability

The invention discloses a friction material for a brake block of a heavy-duty automobile. The friction material is prepared from, by weight, 20-35 parts of phenolic resin, 2-5 parts of acrylic rubber, 3-8 parts of amph-POSS, 2-8 parts of quartz fibers, 10-20 parts of high silica fibers, 3-10 parts of silica fibers, 3-12 parts of aluminum borate whiskers, 3-10 parts of basic magnesium sulfate whiskers, 20-35 parts of nano-palygorskite, 15-35 parts of barium carbonate, 3-10 parts of aluminum powder, 3-10 parts of nano powdered carbon, 5-15 parts of boron nitride, 3-12 parts of emery powder, 2-6 parts of vermiculite, 0.5-5 parts of mica, 3-5 parts of molybdenum trioxide, 2-6 parts of natural graphite, 2-10 parts of micron zirconia balls and 2-8 parts of graphene oxide. The friction material for the brake block of the heavy-duty automobile has excellent high temperature resistance, wear resistance and heat stability and is used for the brake block of the heavy-duty automobile, and is good in braking performance and long in service life.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

High-performance composite brake disc material

InactiveCN104893256AImprove thermal conductivityEnhanced interface bindingFriction liningMicrosphereWear resistant

The invention discloses a high-performance composite brake disc material, the wear resistant material comprises the following raw materials: bisphenol a novolac epoxy resin, diaminodiphenyl sulfone, hollow microspheres, a lubricant, a silane coupling agent, diamine, an imidazoles compound, an anti-oxidant, chloroprene rubber powder, alumina and reinforced fibers. The reinforced fibers can be a mixture of zylonite fiber, aramid fiber, cotton fiber and ramie fiber; the interface combination of fiber and particles in the materials is good, and the fiber and particles in the materials enable synergistic interaction with antimonony oxide and graphite, generation of thermal decomposition, heat attenuation and heat cracks phenomena can be effectively reduced, thermal conductivity of the materials is good, heat generated when brake friction is carried out can be timely radiated, brake disc surface temperature can be rapidly reduced, high temperature heat attenuation is reduced, hollow microspheres, the lubricant, the silane coupling agent and the enhance fiber are specific, friction coefficient of the wear resistant materials can be enhanced by intermolecular cooperation of the substances, and stability of the friction coefficient can be improved simultaneously.

Owner:CHONGQING JIAOTONG UNIVERSITY

Wear-resistant material for brake block of heavy duty automobile

InactiveCN104788906ASolve the real problemLong processOther chemical processesCross-linkCarbon fibers

The invention discloses a wear-resistant material for a brake block of a heavy duty automobile. The wear-resistant material comprises raw materials as follows: bisphenol A novolac epoxy resin, diaminodiphenyl sulfone, mineral powder, a lubricant, a cross-linking agent, chloroprene rubber powder, aluminum oxide, cotton fiber, carbon fiber, aramid fiber, sisal fiber, antimonous oxide, graphite and calcium lignosulfonate. The components are compatible, so that the overall performance of the wear-resistant material is effectively guaranteed, the components can make up for defects in performance mutually and can have high performance due to mutual restriction functions, problems of existing brake blocks are solved, high-speed decline and high-temperature decline can be well prevented, and the wear-resistant material has advantages of better stability and long service life.

Owner:CHONGQING JIAOTONG UNIVERSITY

Drum type four-ungulae pneumatic brake with gap adjusted automatically

ActiveCN1687611AExtended Decay PeriodEffective contact surfaceBraking action transmissionFluid actuated drum brakesSelf lockingCam

The invention relates to a kind of automobile brake, which changes the present symmetric brake hoofs into the brake with four brake hoofs superposing; two brake cams match with the brake hoofs; the leading screw nut device drives the two brake cams. It is characterized in that the brake air chamber connects the brake base plate through the connecting base; one end of the connecting base connects the air chamber and the other end connects the brake base plate; a inside screw thread is in one joint end of the connecting base and the brake base plate, and the screw lead angle matching with the inside screw thread is bigger than the self-locking angle; one end of the leading screw connects the push pole on the connecting base through the driving device and the other end joints the brake cam. The invention effectively ensures the stability of the contacting areas of the brake assistants and the brake moment, and improves the comprehensive stability and cooling capability of the brake system.

Owner:高自强

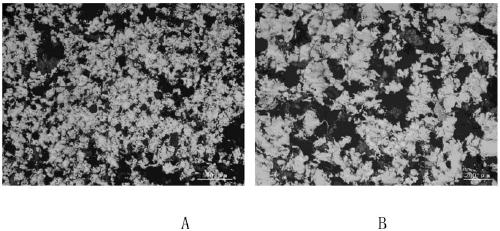

Preparation method of copper-based friction material of brake pad

ActiveCN108916277ALarge poresReduce noiseOther chemical processesFriction liningMaterials scienceDust pollution

The invention relates to a preparation method of a copper-based friction material of a brake pad. The preparation method comprises the following steps of step 1, preparing of raw materials; step 2, mixing and granulating; step 3, cold pressing and forming; step 4, preparing of steel back; step 5, cold assembly and matching; step 6, placing and charging into a furnace; step 7, hot pressing and sintering; step 8, discharging out of the furnace, and inspecting. The copper-based friction material has the advantages that by adopting the coarser flaky graphite, the dust pollution is reduced; by adding a compound anti-abrasion component, the comprehensive property of the friction material is favorably improved; by adding a certain ratio of glycerol mixed solution, rolling by hands, stirring and granulating, the uniformity and stability of each component are guaranteed, the fluidity is good, the density distribution of the press billet is uniform, and the strength of the prepared press billetis high; by adopting the high-temperature pressurizing sintering parameters, the property requirement of the friction material is guaranteed, and the connecting strength with the steel back is also guaranteed; the technology process is simple, the cost is low, the production efficiency is high, the brake noise is avoided, the heat attenuation is little, the bonding strength between the steel backand a friction block is high, and the comprehensive property is good.

Owner:滁州欧瑞斯机车部件有限公司

Preparation method of iron-copper based composite friction materials

ActiveCN109139755AStrong shear resistanceHigh strengthOther chemical processesFriction liningFiberCarbon fibers

Provided is a preparation method of iron-copper based composite friction materials. After raw materials are burdened and mixed, a mixture is obtained after being subjected to cold pressing and then subjected to high-temperature hot pressing and sintering, and the mixture is subjected to compression moulding forming through the pressure intensity of 450-550 MPa; and a pressed blank is put into a heating furnace and is subjected to pressure sintering under the nitrogen protection atmosphere, and the sintering process includes the steps that heat is preserved for 2-3 hours under the pressure of 2.5-2.8 MPa at 1000 DEG C and the billet is cooled along with the furnace. The friction materials are obtained through high-temperature hot pressing and sintering after cold pressing, the respective advantages of iron and copper are played, at the same time, carbon fibers with high specific modulus and high specific strength are applied into the iron-copper based composite friction materials, the strength of a matrix is enhanced, the impact toughness is improved, the brake noise is reduced, the friction coefficient is proper, and high-temperature abrasion resistance is good.

Owner:滁州欧瑞斯机车部件有限公司

Technology for preparing brake lining through 3D printing

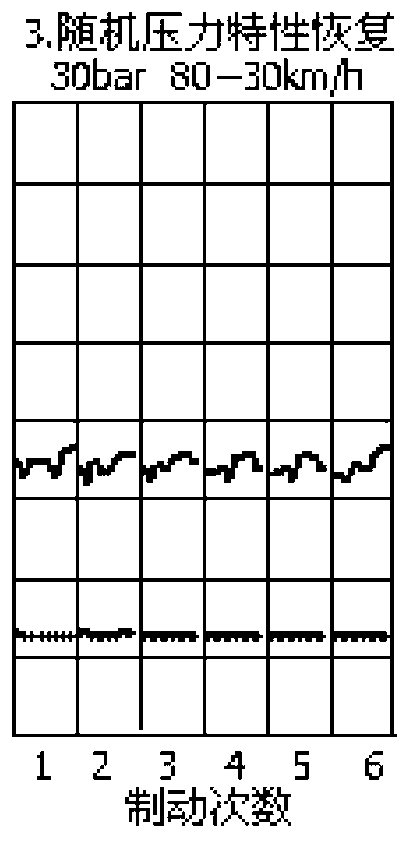

InactiveCN106286657ASmall thermal recessionFacilitates heat recoveryOther chemical processesFriction liningFrictional coefficientAdhesive

The invention discloses a technology for preparing a brake lining through 3D printing. The technology comprises the following steps: (1) materials mixing: performing evenly dry mixing to solid-state filler, preparing a liquid-state adhesive and other additives into a gel forming solution, and spraying to the solid-state filler; (2) paving powder; (3) spraying of gel: adjusting the density of a gel body to be 700kg / m<3> and the injection pressure to be 150kPa, and spraying gel; (4) quick drying with hot-air: drying for 100-130min at the temperature of 50 DEG C; then cutting materials and superposing; and (5) hydraulic molding: performing hydraulic molding at the molding temperature of 130-170 DEG C and under the forming pressure of 18-30MPa, wherein the holding time lasts 15-30min. The frictional coefficient of the brake lining prepared by adopting the technology is stabilized to range from 0.476-0.53 at 100-250 DEG C, the heat fade is small, and the brake lining has good heat restoration, wear resistance and shearing resistance properties.

Owner:WUXI MINGSHENG STRONG BLOWER

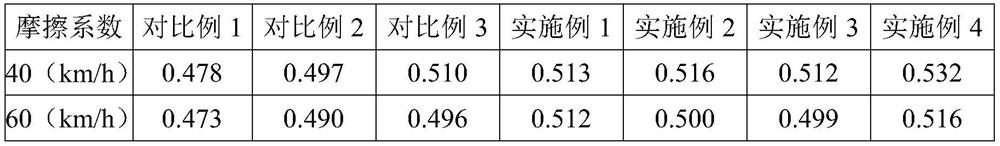

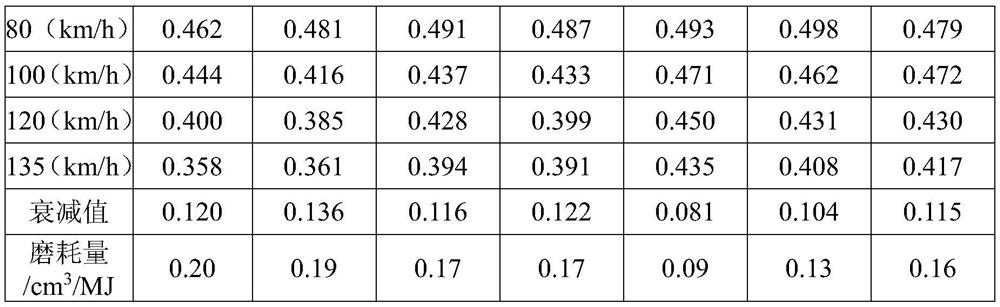

Friction material composition, high-speed train brake pad prepared from same and application of friction material composition

InactiveCN110387212AImprove reliabilityStable coefficient of frictionOther chemical processesFriction liningCopperPolymer chemistry

The invention relates to a friction material composition, a high-speed train brake pad prepared from the same and an application of the friction material composition, wherein a copper-based friction material composition is prepared by adopting a powder metallurgy technology; the friction material composition is prepared from the following raw materials: a matrix component, a lubricating component,an anti-friction component and a friction stabilizing component; and a preparation method of the high-speed train brake pad comprises: burdening, mixing, briquetting and pressurized sintering. The brake pad prepared by using the preparation method is resistant to high temperature, little in heat fading, high and stable in friction coefficient, low in wear rate, low in heat damage and wear to thesurface of a counterpart and capable of prolonging the service life of a braking system and improving the reliability and economic efficiency of the braking system.

Owner:XI AN JIAOTONG UNIV

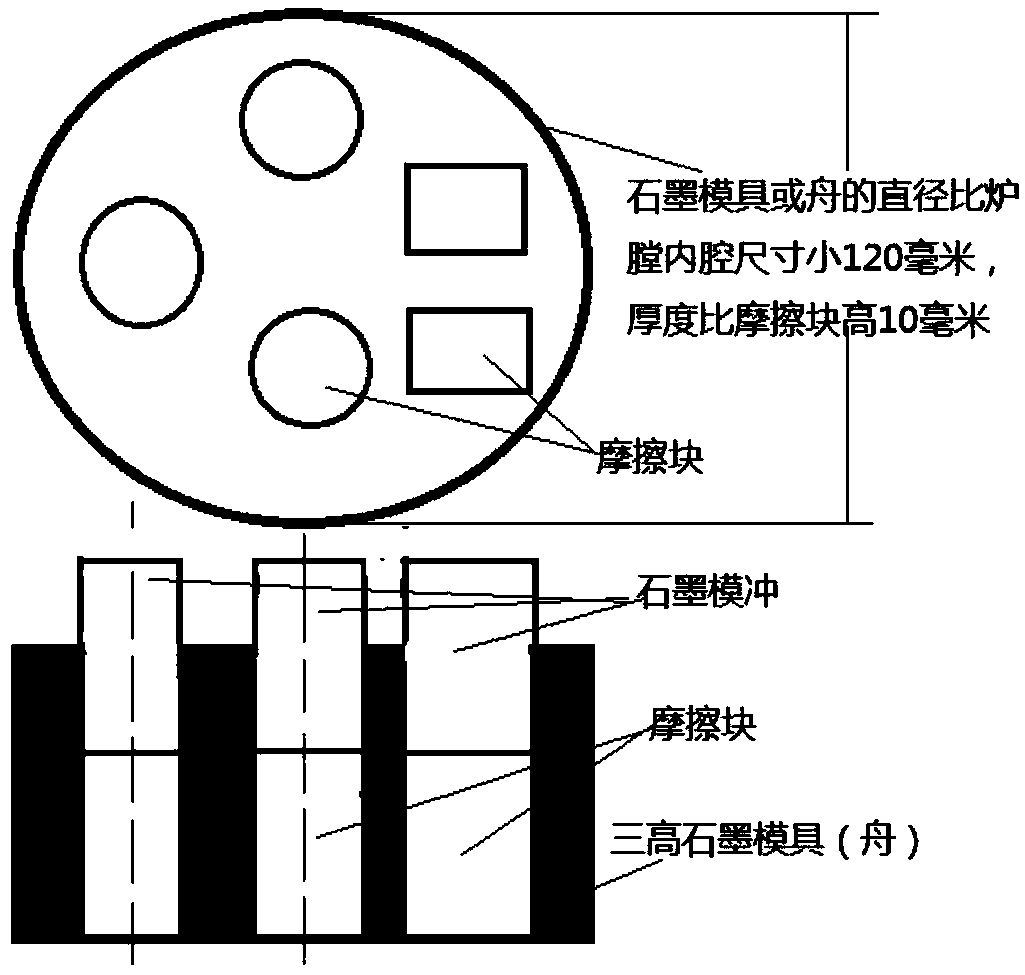

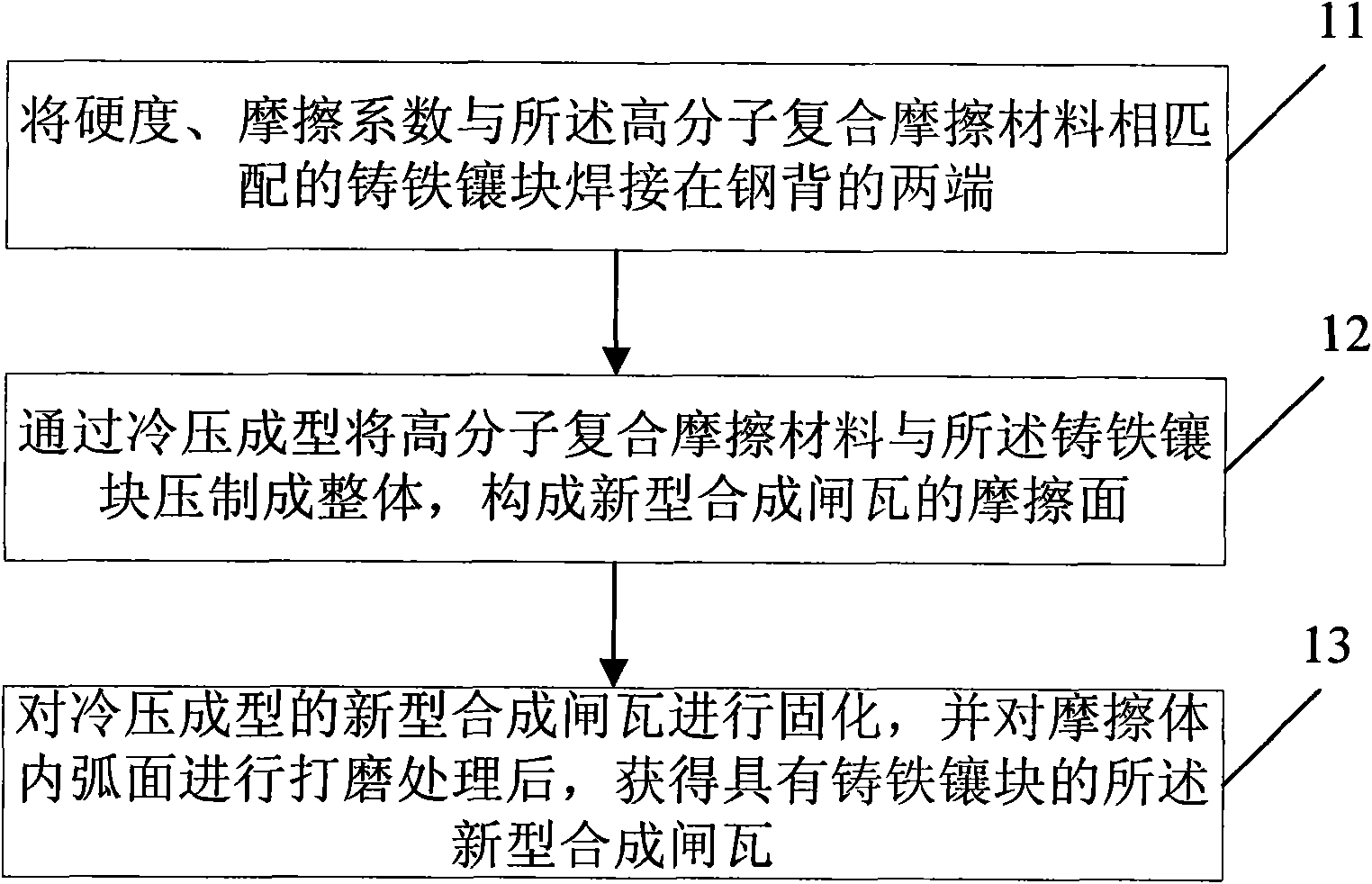

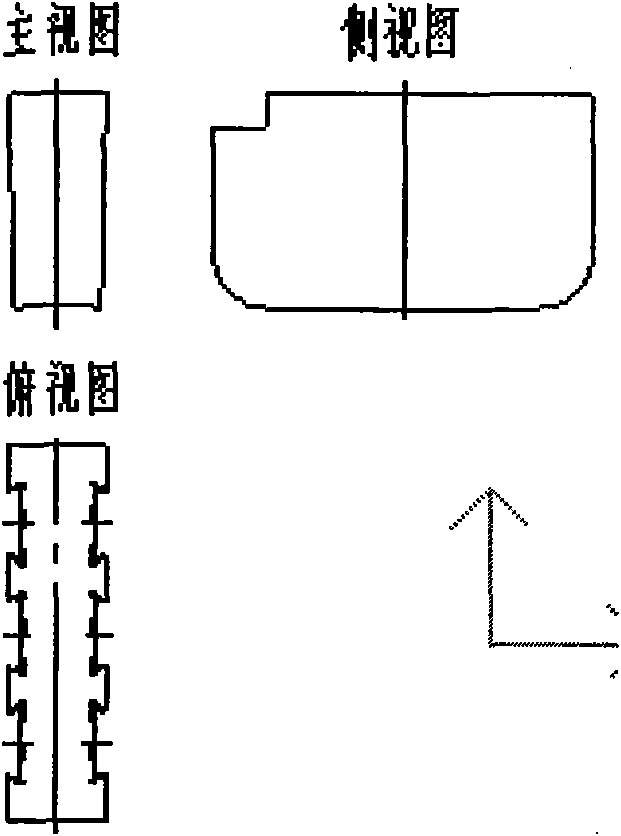

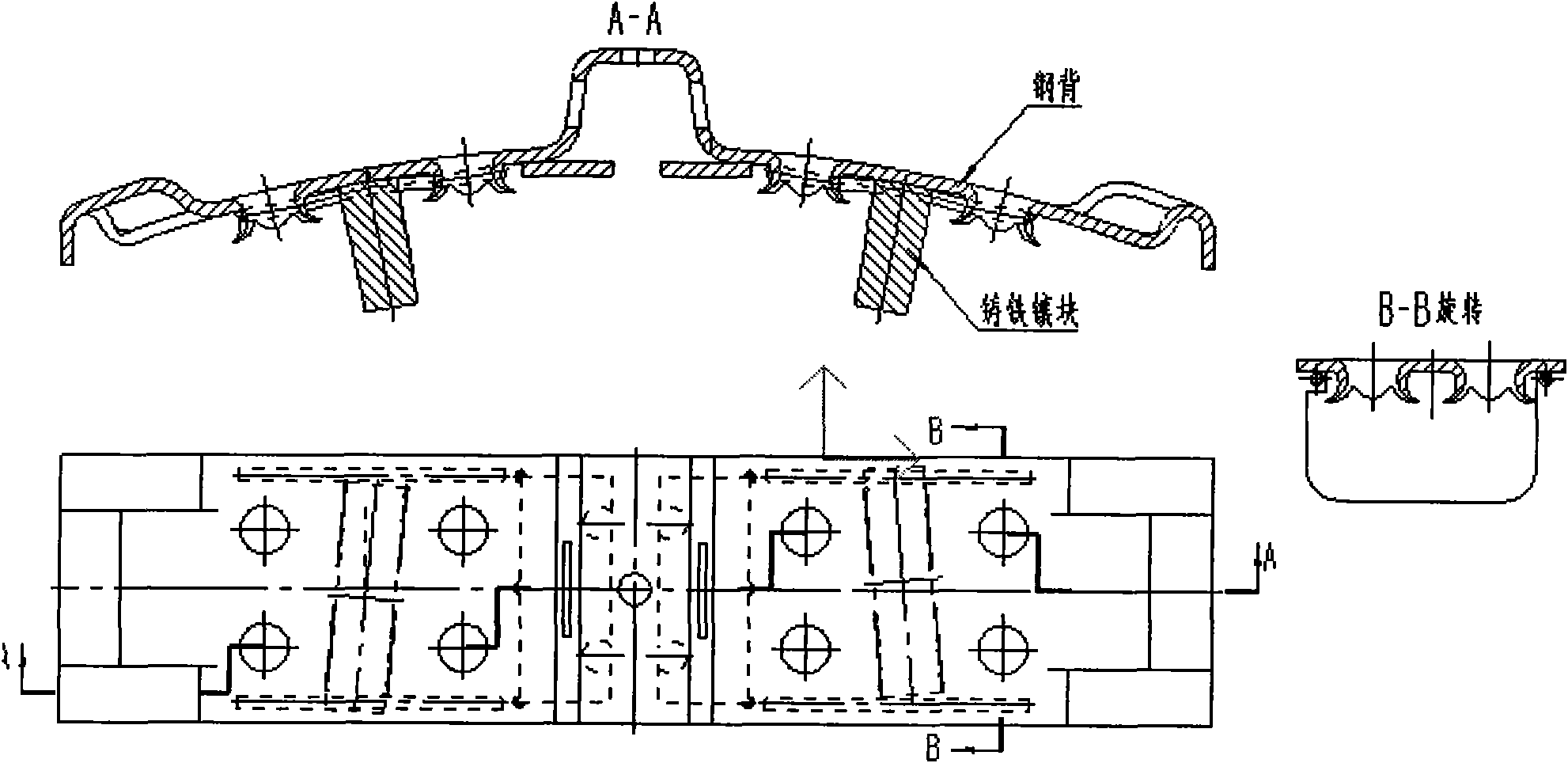

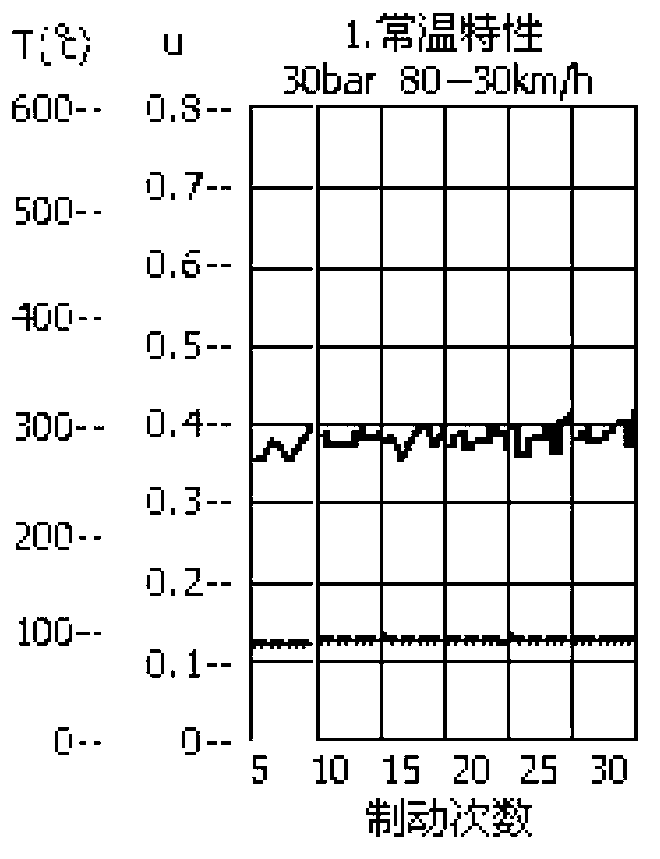

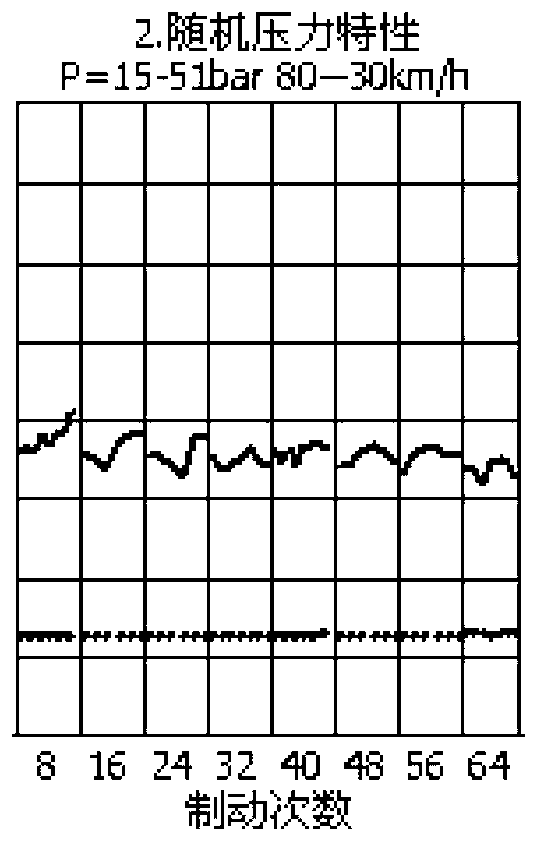

Novel mosaic composition brake shoe and manufacturing method thereof

ActiveCN101900176AImprove thermal conductivitySmall thermal recessionOther chemical processesBraking membersHardnessBrake shoe

The embodiment of the invention provides a novel mosaic composition brake shoe and a manufacturing method thereof. In the method, the novel composition brake shoe is formed by combining a high molecular composite friction material and cast iron inserts; and the method particularly comprises the following steps of: welding the cast iron inserts with hardness and friction coefficient matched with those of the high molecular composite friction material at the two ends of a steel back; pressing the high molecular composite friction material and the cast iron inserts into a whole by cold press molding to form a friction surface of the novel composition brake shoe; and curing the novel composition brake shoe formed by the cold press molding, and polishing the inner cambered surface of a friction body to obtain the novel composition brake shoe with the iron cast inserts. Thus the heat conductivity of the composition brake shoe can be obviously improved and the heat fade of the composition brake shoe can be reduced so as to ensure that the composition brake shoe has stable friction performance during the braking.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

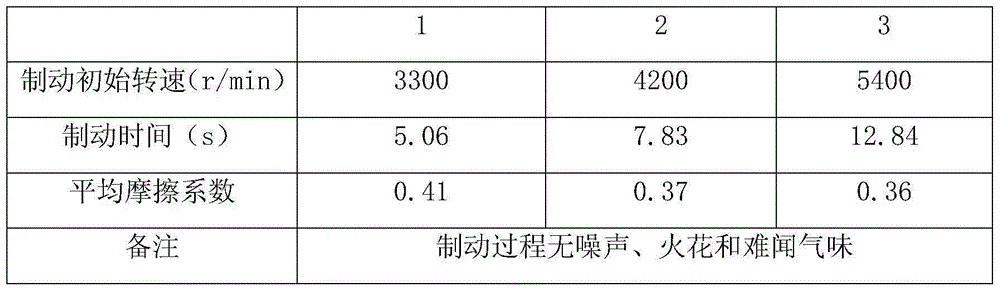

Non-asbestos drilling machine braking block material and manufacturing process therefor

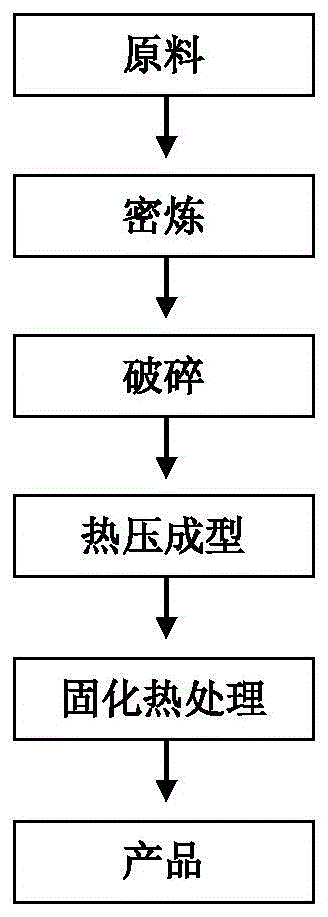

The invention relates to a manufacturing method of a friction material used on a drilling machine part and the drilling machine part, in particular to a non-asbestos brake shoe material for the drilling machine and a manufacturing method thereof. The components of the non-asbestos brake shoe material comprise a matrix material of rubber modified phenolic resin, a reinforcing fiber, a solid lubricant and a frictional behavior regulator and the like and are configured according to the following weight percentage: 10 percent to 20 percent of the modified phenolic resin, 17 percent to 50 percent of the reinforcing fiber, 3 percent to 6 percent of the solid lubricant, 40 percent to 61 percent of the frictional behavior regulator. The manufacturing method of the non-asbestos brake shoe material for the drilling machine is characterized by comprising the following steps of: (a) pre-processing the fiber, (b) stirring, (c) compressing and (d) post processing. The non-asbestos brake shoe material does not contain a high hardness abradant or steel wool, thus improving the defects of glass fiber, aramid fiber and aedelforsite fiber; and the abrasion resistance, heat fading property and other indexes of the brake shoe of the drilling machine are superior to the national standards.

Owner:长春市恒德摩擦制品有限公司 +1

Non-asbestos wet-rolled automobile drum type brake block and manufacturing method thereof

The invention provides a non-asbestos wet-rolled automobile drum type brake block and a manufacturing method thereof. According to the manufacturing method of the drum type brake block, aluminum silicate, zinc powder, blanc fixe, needle-shaped wollastonite, compound graphite, cellulosic fibers, aramid fibers, steel fibers and phenolic resin are poured into a harrow type mixer to be mixed, liquid resin is added in the mixing process, the mixed materials are pulverized by a pulverizer and then are placed in shade places to be dried for 3-4 hours, the dried materials are then put into a hopper of a roller press to be rolled and then are conveyed into a cutting forming machine, the materials are coated with glue and then are adhered to the shoe of the brake block, conventional outer arc polishing, spraying, mark printing and accessory installation, riveting and packaging are carried out after heat treatment and cooling, and finally the brake block is formed. According to the non-asbestos wet-rolled automobile drum type brake block and the manufacturing method thereof, due to the fact that the liquid resin and the wet-rolling technique are applied, the work environment of workers is greatly improved, energy consumption is greatly reduced, environmental performance is good, and the brake block manufactured with the method is free of heat fading, stable in friction coefficient, good in friction performance, stable in braking, sensitive, reliable, and long in service life.

Owner:武汉市祥龙摩擦材料有限责任公司

Nonmetal friction material for vehicle disc brake and preparation method and application thereof

ActiveCN106907414AImprove wear resistanceReduce noiseOther chemical processesFriction liningMetalCalcium

The invention relates to the technical field of friction materials, and discloses a nonmetal friction material for a vehicle disc brake and a preparation method and application thereof. The friction material comprises the following components in percentage by mass: 7-10% of binding agent, 15-25% of mineral fiber, 6-10% of inorganic fiber, 1.5-5% of organic fiber, 6-15% of calcium whisker, 12-20% of filler, 3-5% of friction powder, 6-8% of vermiculite powder, 15-26% of carbon friction reducing material, 6-15% of metal sulfide, 2-5% of tire powder, and 1-4% of molybdenum sulfide. The invention further discloses a preparation method of the friction material; and according to the method, the friction material is prepared through weighing, mixing, forming treatment and heat treatment process after formation. The friction material with higher friction coefficient, lower wear rate and excellent heat fade performance is prepared as a brake pad with high brake torque, comfortable emergent brake, short brake distance and lower heat fade.

Owner:李通

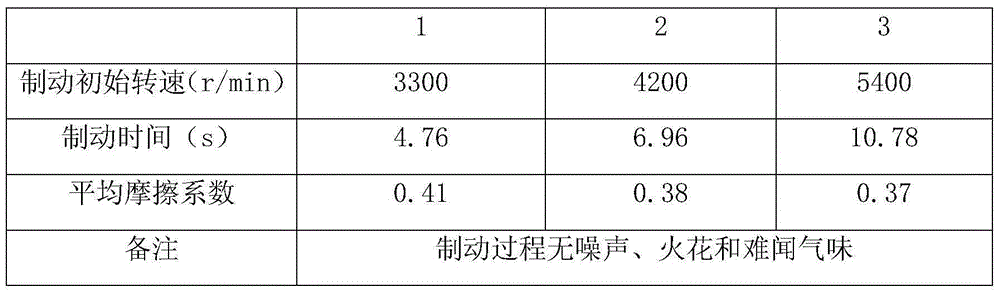

Composite friction material by using truck waste brake shoe friction material as filler and preparation method thereof

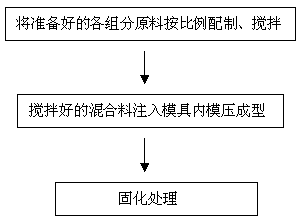

The invention discloses a composite friction material by using a truck waste brake shoe friction material as a filler, relating to the technical fields of friction materials and vehicle brake shoes. The composite friction material comprises a resin matrix, a reinforcing fiber, a filler and assistants, wherein the resin matrix is a phenol formaldehyde resin, the filler is a truck waste brake shoe friction material, and the assistants comprise iron powder, an accelerator, molybdenum disulfide, stearic acid and graphite. The preparation method comprises the following steps: material preparation, stirring, compression molding and curing treatment. By utilizing the truck waste brake shoe friction material as the filler, combining the optimal selection and proportioning of the phenol formaldehyde resin, reinforcing fiber and other assistants and optimizing various parameters of the molding technique, the prepared composite friction material has the characteristics of stable friction factor, low heat fading, favorable thermal restorability, low wear rate and high carrying capacity, can be used for manufacturing multiple friction components, has excellent frictional wear performance, favorable bending strength and favorable impact toughness, and achieves favorable use effect.

Owner:CRRC SHIJIAZHUANG CO LTD

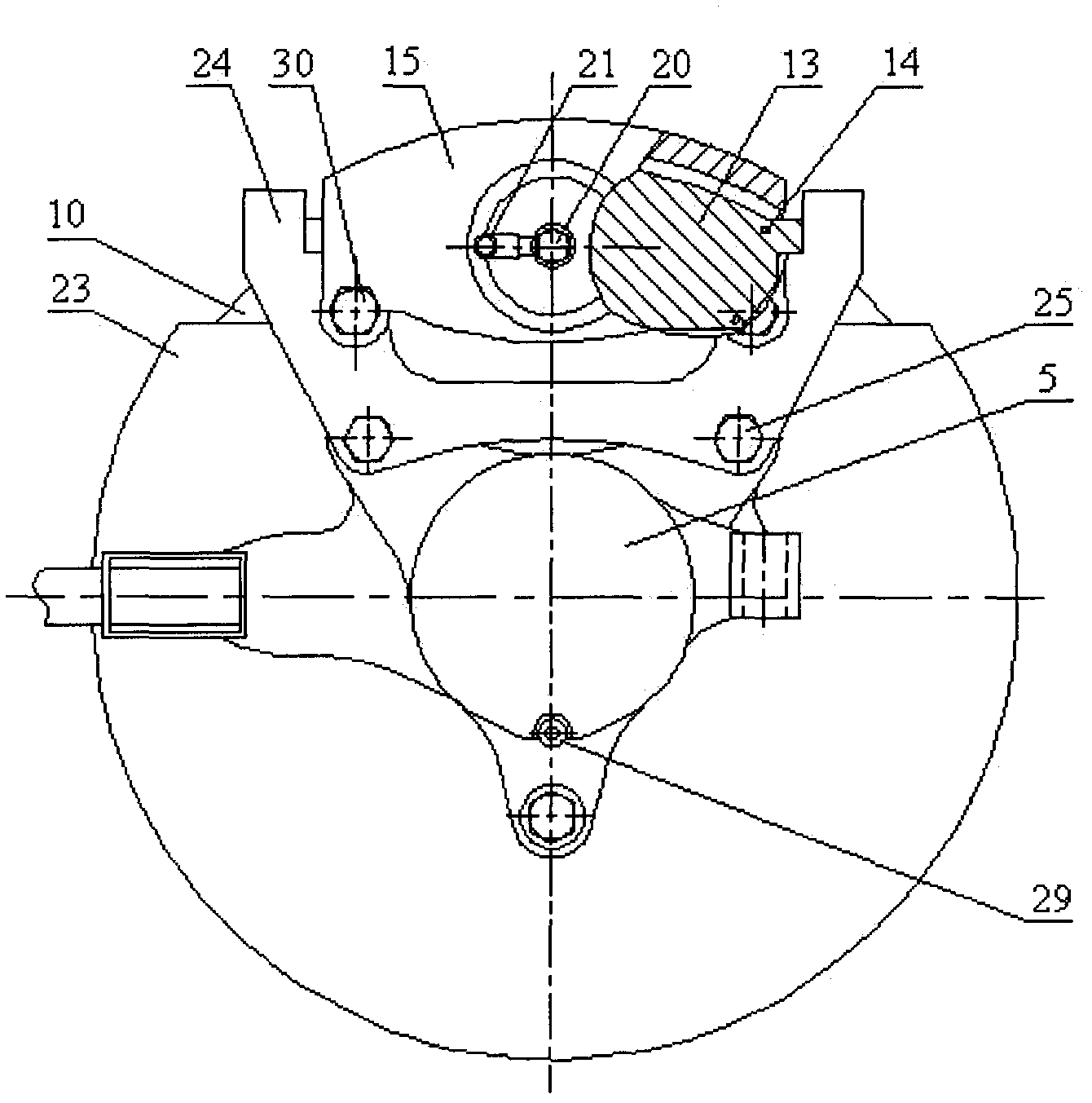

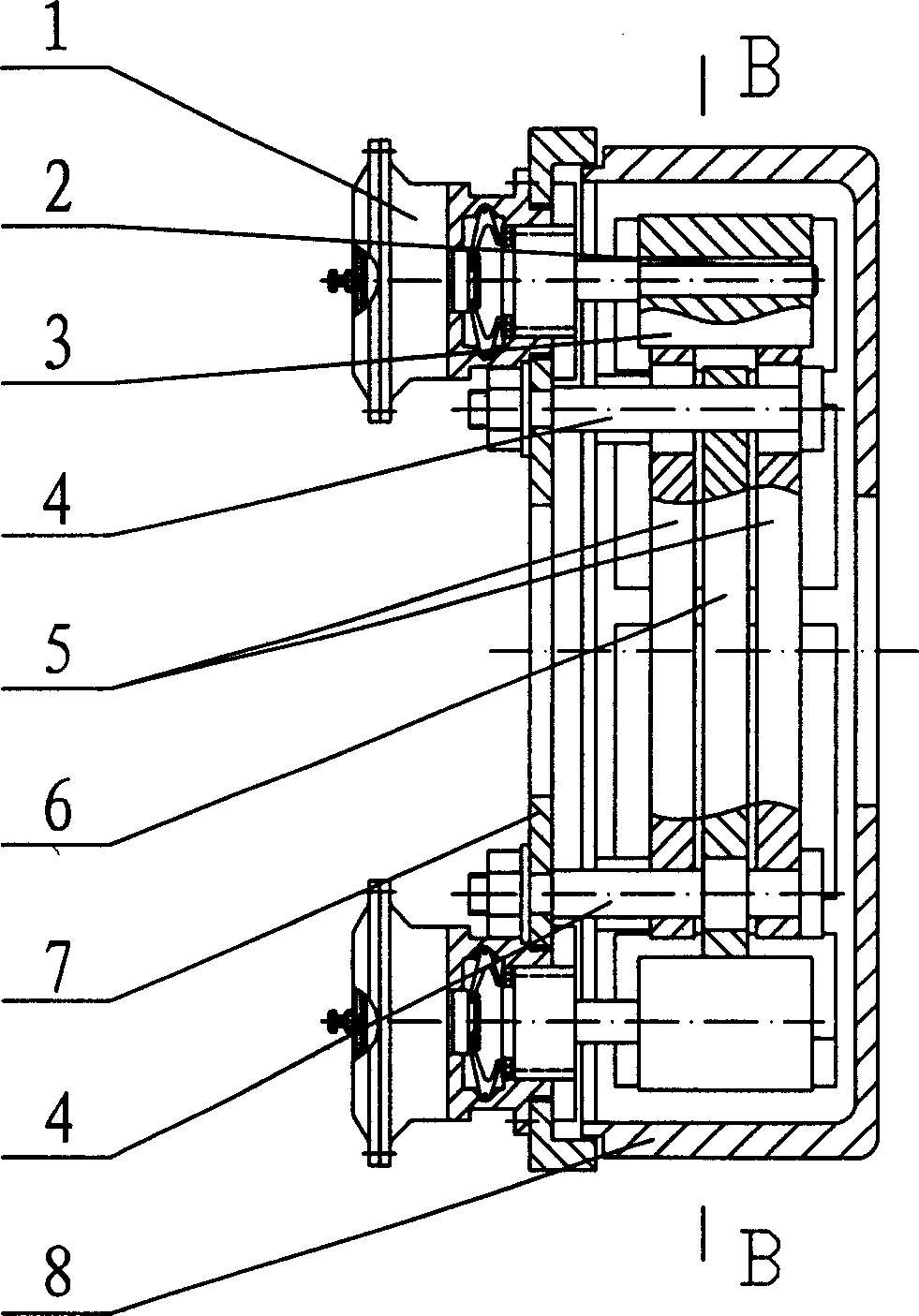

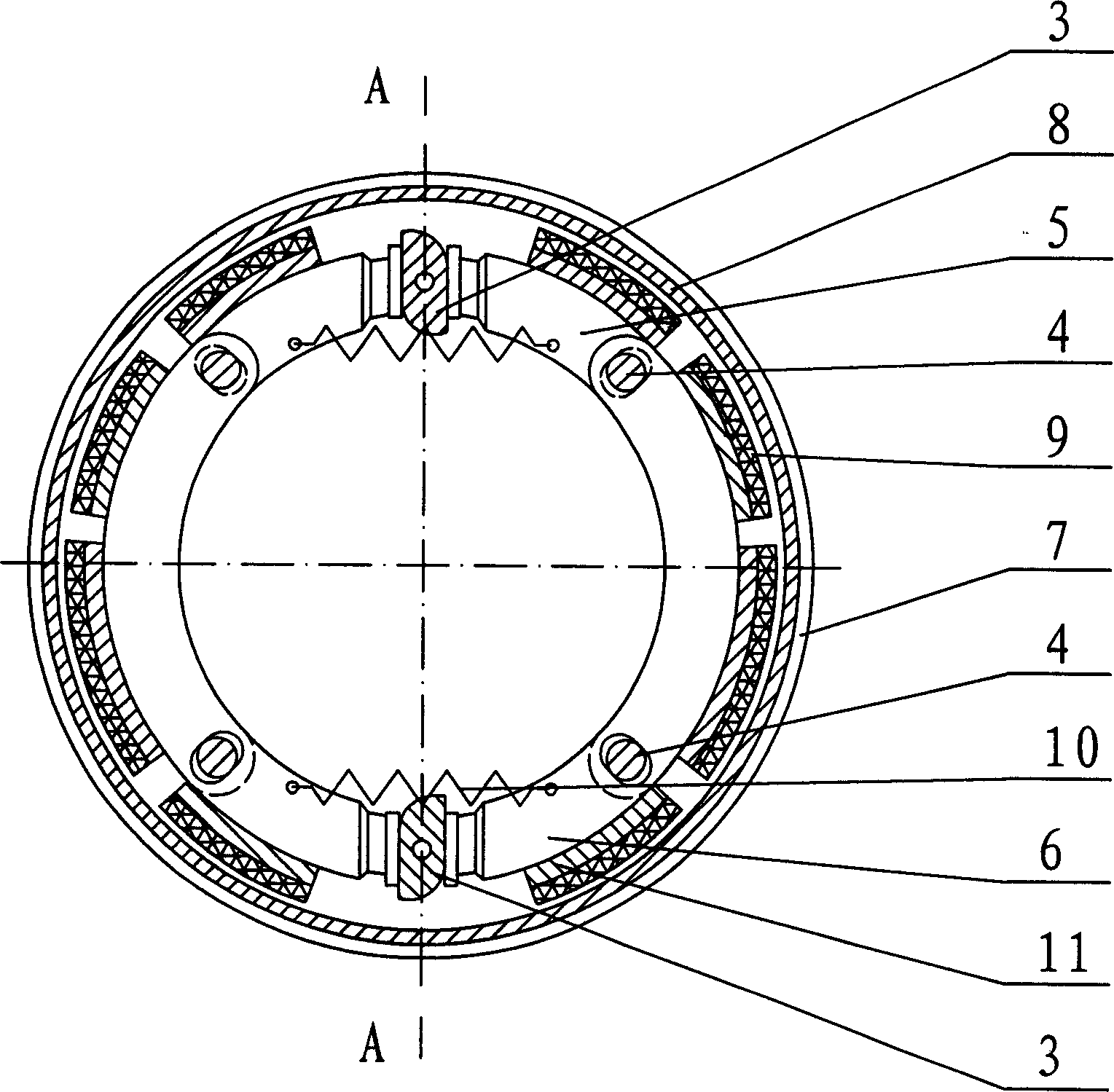

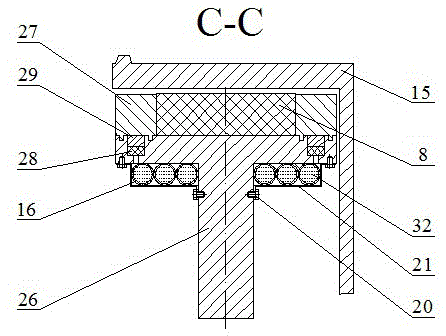

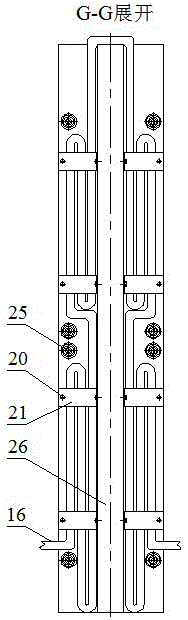

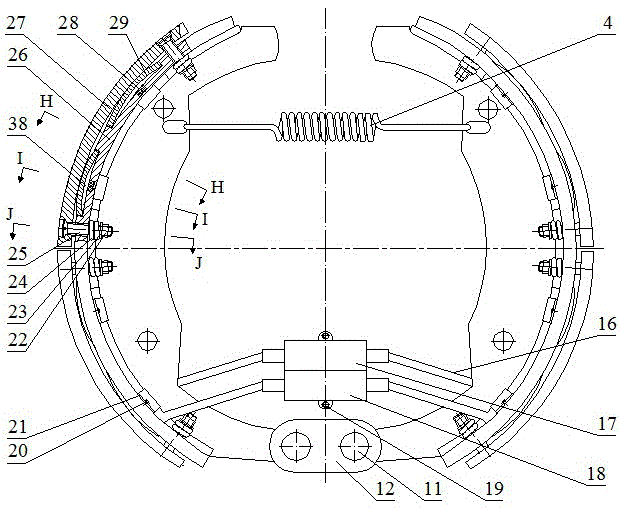

Liquid-cooling drum brake with cooling liquid circulation control system

ActiveCN105626727AImprove thermal stabilityImprove cooling effectBraking elementsControl systemHeat stability

The invention discloses a liquid-cooling drum brake with a cooling liquid circulation control system. The liquid-cooling drum brake comprises a liquid-cooling drum brake body and the cooling liquid circulation control system. On the basis of an air-cooling drum brake, a heat transfer system is mainly additionally arranged, and the liquid-cooling drum brake body is formed. Heat transfer pieces (27) are arranged on the two edges of a friction plate (8) and are connected with a liquid-cooling brake shoe (26) through heat transfer piece bolts (25). Thermosensitive pieces (29) are arranged in an arc long groove of the liquid-cooling brake shoe (26). Heating resistors (28) are arranged in holes of the liquid-cooling brake shoe (26). Cooling pipes (16) are connected with the liquid-cooling brake shoe (26). The two ends of each cooling pipe (16) are connected with a liquid inlet tee joint (17) and a liquid outlet tee joint (18), and the liquid inlet tee joint (17) and the liquid outlet tee joint (18) are connected with the cooling liquid circulation control system. The liquid-cooling drum brake with the cooling liquid circulation control system is used for replacing the air-cooling drum brake on an automobile, and the heat stability and the heat dissipation performance of the drum brake are improved.

Owner:江苏骏马压路机械有限公司

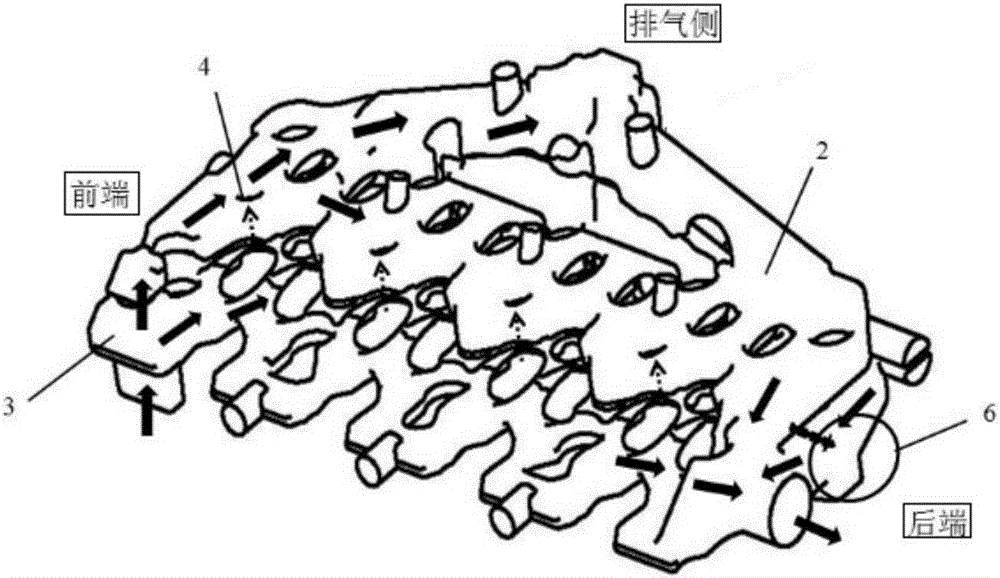

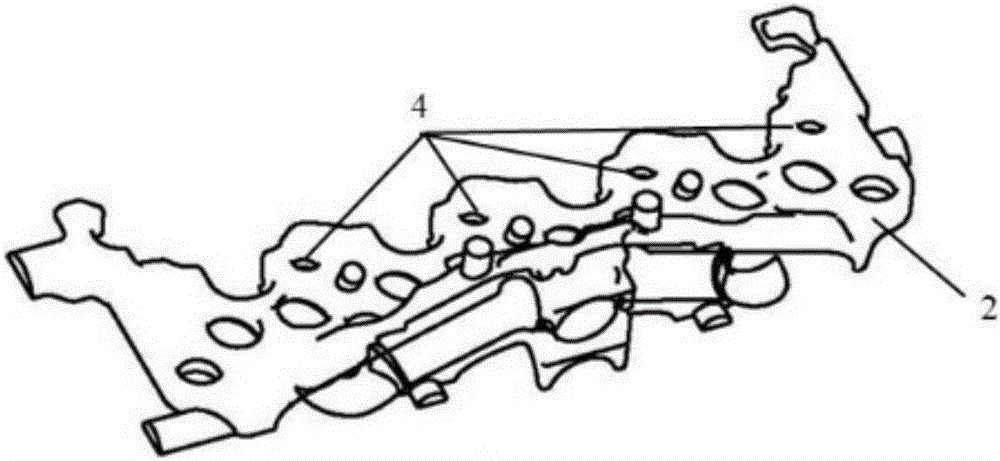

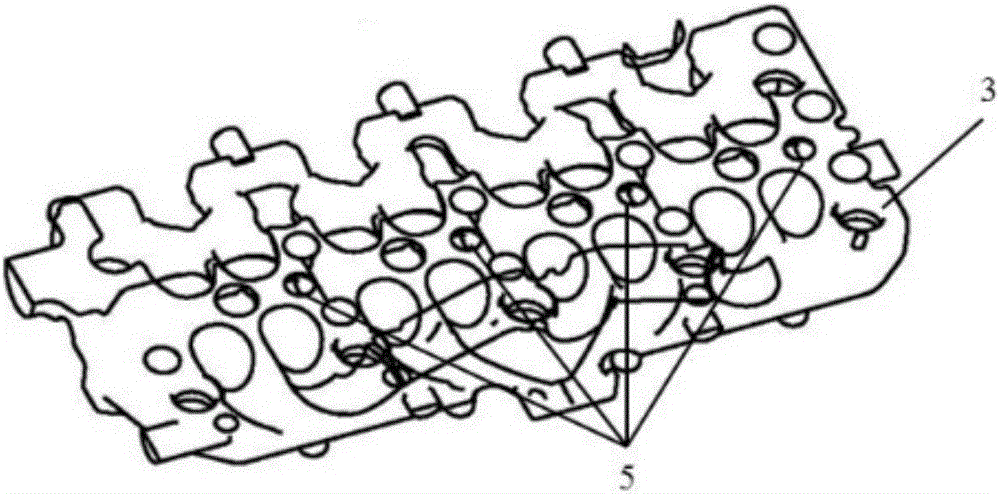

Water jacket structure of cylinder cover covering exhaust manifold

InactiveCN105971757AImprove cooling efficiencyImprove pass rateCylinder headsCylindersStructural engineeringWater jacket

The invention relates to a water jacket structure of a cylinder cover covering an exhaust manifold. The structure comprises a cylinder cover body, wherein an upper water jacket and a lower water jacket are arranged in the cylinder cover body. The structure is characterized in that four water filling holes sleeve the upper water jacket, four water inlets are formed on the lower water jacket, and the four water filling holes are in one-to-one correspondence to the four water inlets, respectively; the upper water jacket covers an exhaust duct of a first cylinder and a fourth cylinder as well as an exhaust collecting port of the first cylinder and the fourth cylinder; and the lower water jacket covers an exhaust duct of a second cylinder and a third cylinder as well as an exhaust collecting port of the second cylinder and the second cylinder. The structure provided by the invention can satisfy the cooling requirement of the cylinder cover and can inhibit gas and air retention during casting, the product yield is improved, and the structure has good manufacturability.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Preparation method of carbon fiber frictional particles

InactiveCN104449571ASmall thermal recessionAchieve decentralizationOther chemical processesHardnessFiber

The invention belongs to the technical field of frictional materials and particularly relates to a preparation method of carbon fiber frictional particles. The preparation method comprises the following steps: by adopting water, a dispersant, chopped carbon fibers, micro inorganic powder and resin powder as raw materials, dissolving the dispersant, pouring the chopped carbon fibers, micro inorganic powder and resin powder into a mixing and kneading pot with a discharge screw, stirring and uniformly dispersing to form slurry; extruding and spreading out the slurry into a sheet, heating and drying, thereby obtaining a half-dry frictional material; mixing the half-drying frictional material into a sheet; continuously drying to obtain a sheet material; rolling and pressing the sheet material into mould plastic particles; and screening, grading and curing, thereby obtaining the carbon fiber frictional particles. The preparation method can be used for lowering the wear rate of the frictional material to a great extent, obtaining a porous high-damping composite material by utilizing fluffy structures of the carbon fibers and obtaining the frictional material with low abrasion, low hardness, no noises and low heat recession; besides, the preparation method is simple in process and capable of realizing dispersing the carbon fibers and soaking the resin very well.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

Automobile brake pad

InactiveCN104776138AHigh strengthImprove high temperature resistanceOther chemical processesFriction liningFiberUltrasound attenuation

The invention discloses an automobile brake pad, and relates to the technical field of automobile accessories. The automobile brake pad is prepared from the following raw materials in parts by weight: 15-25 parts of silicon nitride ceramic powder, 20-40 parts of silicon carbide fiber, 5-10 parts of ceramic bonding agent, 3-5 parts of phenolic resin, 5-10 parts of rubber powder, 5-10 parts of frication powder, 20-30 parts of filler, 2-5 parts of nano-silica, 5-8 parts of sintering aids and 1-3 parts of defoaming agent. Compared with the prior art, the automobile brake pad is high in strength, good in high temperature resistance, small in heat attenuation, stable in friction coefficient and less in abrasion.

Owner:陈巧兰

Coconut carbon compound type brake pad and preparation method

InactiveCN103089875ALight in massSmall thermal recessionOther chemical processesFriction liningFiberCarbon fibers

A preparation method of a coconut carbon compound type brake pad is that the rate of coconut carbon, silicon oxide, carburant, barium sulfate, brown aluminum oxide, vermiculite, carbon fibers, petroleum coke, nitrile butadiene rubber copolymerization modification phenolic resin and steel fibers is 35-45 to 3-5 to 5-8 to 10-12 to 4-5 to 2-5 to 3-5 to 5-7 to 6-8 to 8-10, the carbon fibers in a formula are evenly stirred in a high speed stirring machine to be standby, other raw materials in the formula are arranged in the stirring machine to be evenly stirred, the stirred carbon fibers and other raw materials are stirred together for 5 to 10 minutes, the materials are arranged in a sheet type mould or a disk type mould of a mould machine and then are arranged in a mould pressing machine to be molded and pressed, simultaneously the materials are pressurized and heated for 16 to 19 minutes, pressure is between 14 to 14.5MPa, temperature is between 130 DEG C to 148 DEG C, pressure is released, the materials are stopped being heated, the mould is taken out, the brake pad is poured out to be ground and polished on a grinding machine to achieve a product.

Owner:DONGYING RUIZHI YOULIANG PETROLEUM EQUIP

Powder metallurgy brake pad and preparing method thereof

InactiveCN109185369AWell mixedImprove performanceOther chemical processesFriction liningSilicon oxideFading

The invention belongs to the technical field of automobile braking systems, and particularly relates to a powder metallurgy brake pad and a preparing method thereof. The powder metallurgy brake pad isprepared through the technologies of mixing, pressing and sintering. The powder metallurgy brake pad comprises friction materials and steel backing. The friction materials comprise following raw materials including, by weight, 10-50 parts of iron powder, 10-50 parts of copper powder, 1-6 parts of molybdenum trioxide, 6-20 parts of graphite, 0.5-3 parts of silicon oxide, 0.5-3 parts of aluminum oxide and 1-5 parts of nickel powder. The obvious problems that in the prior art, high-temperature heat fading exists in a brake pad, the wading recovery performance cannot meet the requirement, and theslope parking static moment is insufficient are solved. The brake pad in which components are simple, obvious heat fading is avoided, the wading recovery performance is good, the slope parking staticmoment is high is provided, and the brake pad is matched with a cast iron brake disc.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

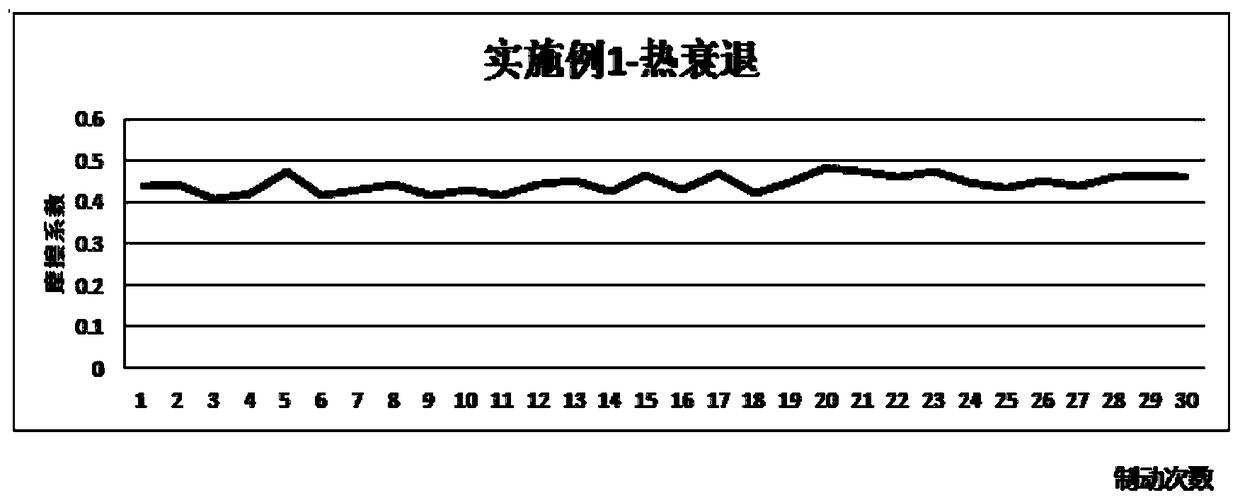

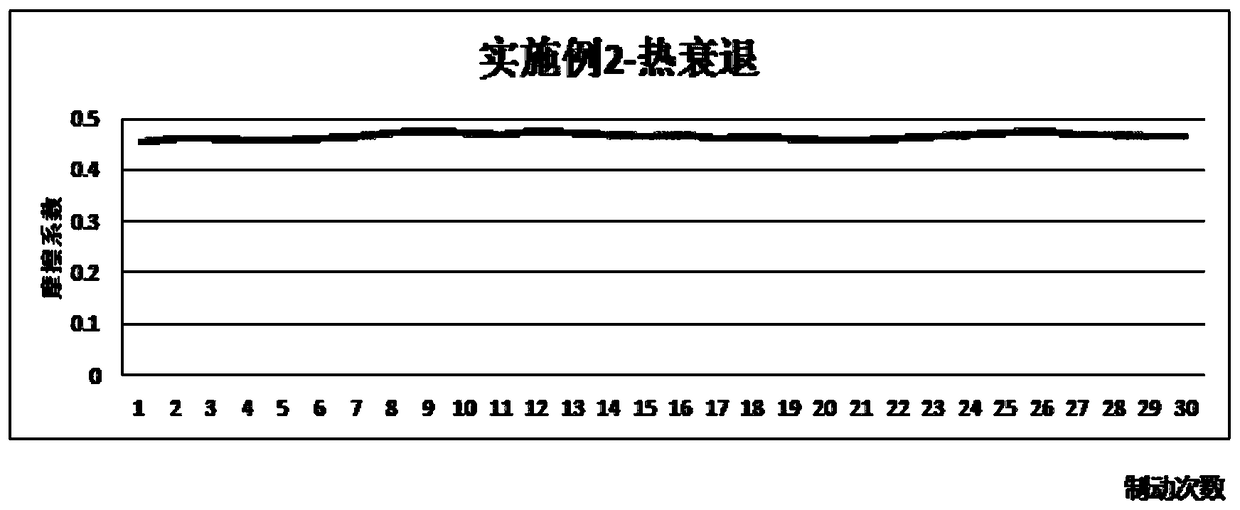

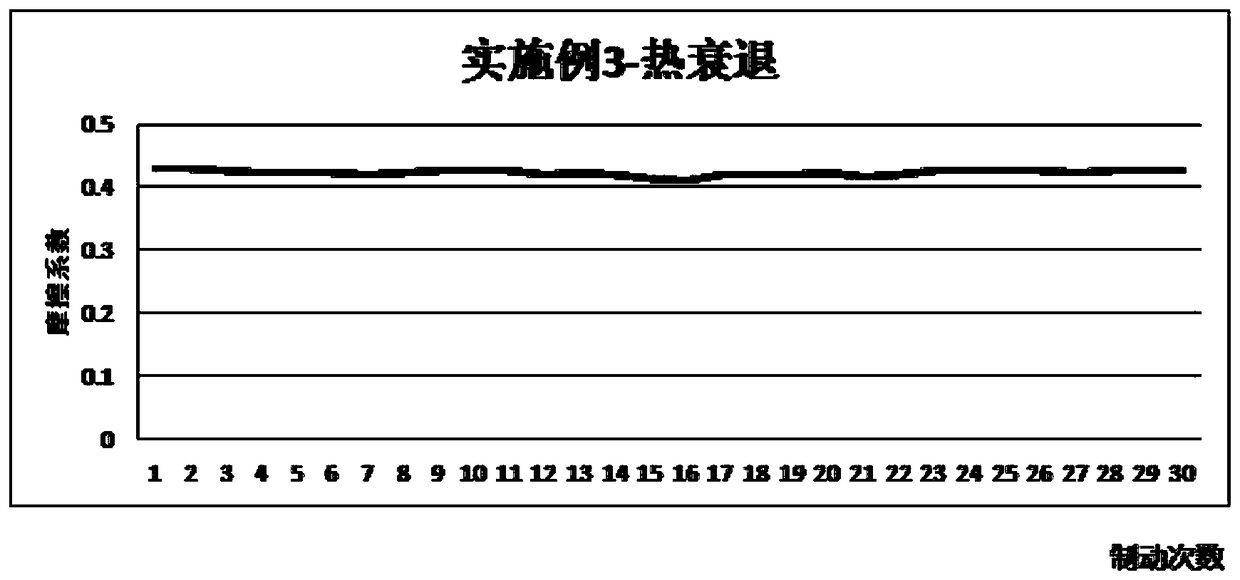

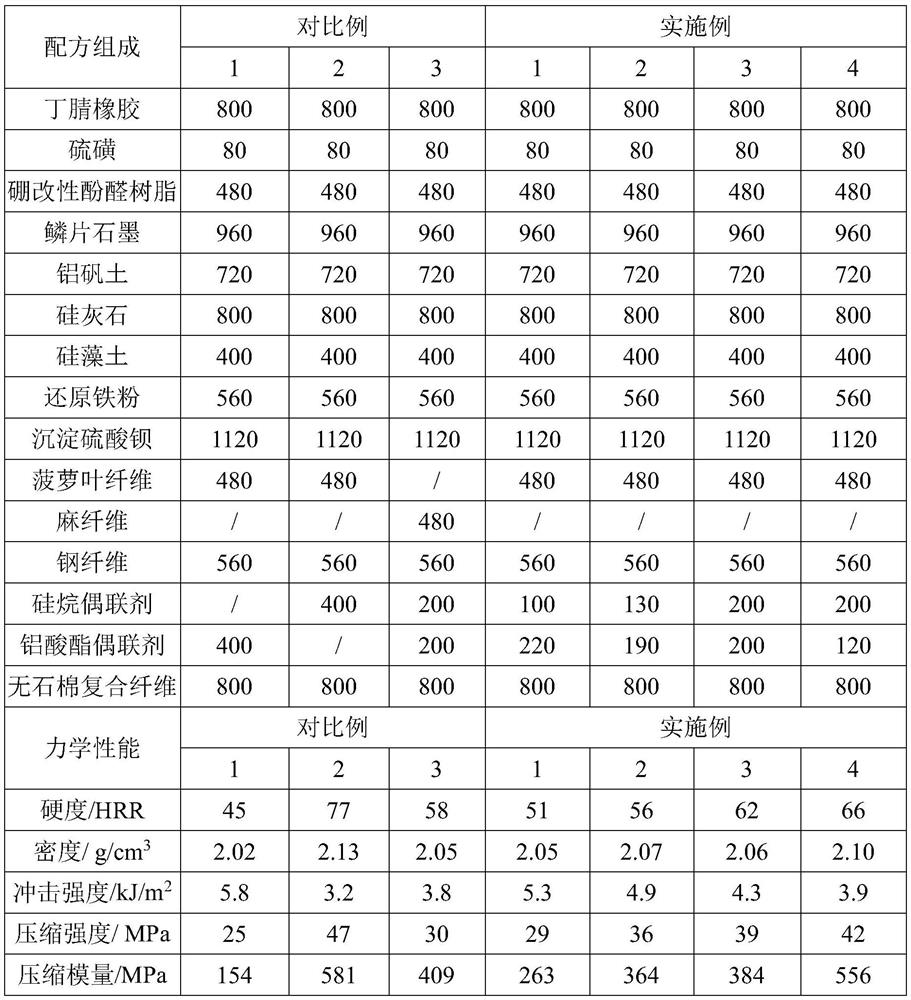

Synthetic friction material and preparation method and application thereof

ActiveCN113388173AImprove mechanical propertiesReduce coefficient of frictionNitrile rubberPhysical chemistry

The invention provides a synthetic friction material and a preparation method and application thereof. The synthetic friction material comprises the following components in percentage by mass: 8-10% of nitrile rubber, 0.9-3% of sulfur, 5-7% of boron modified phenolic resin, 10-14% of crystalline flake graphite, 8-10% of bauxite, 8-10% of wollastonite, 3-5% of diatomite, 6-7% of reduced iron powder, 12-15% of precipitated barium sulphate, 5-7% of pineapple leaf fibers, 6-8% of steel fibers, 2-4% of a coupling agent combination agent and 7-10% of inorganic mineral fibers. The sum of the mass percentages of all the components is 100%. The coupling agent combination agent comprises a silane coupling agent and an aluminate coupling agent. The invention further provides application of the synthetic friction material in synthetic friction materials for urban rail vehicles. The synthetic friction material provided by the invention has the advantages of environmental protection, high mechanical strength, low compression modulus, small dual wear, low abrasion and the like.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

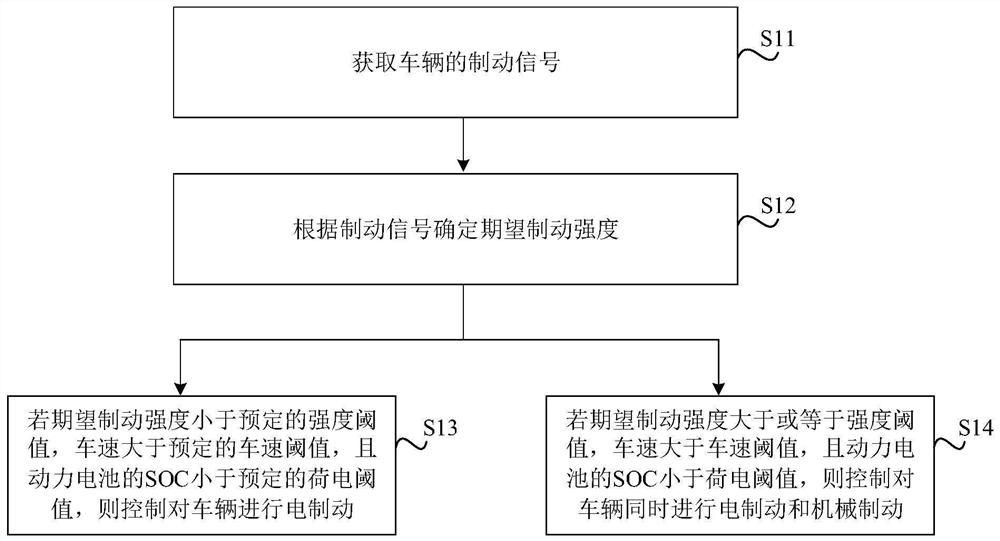

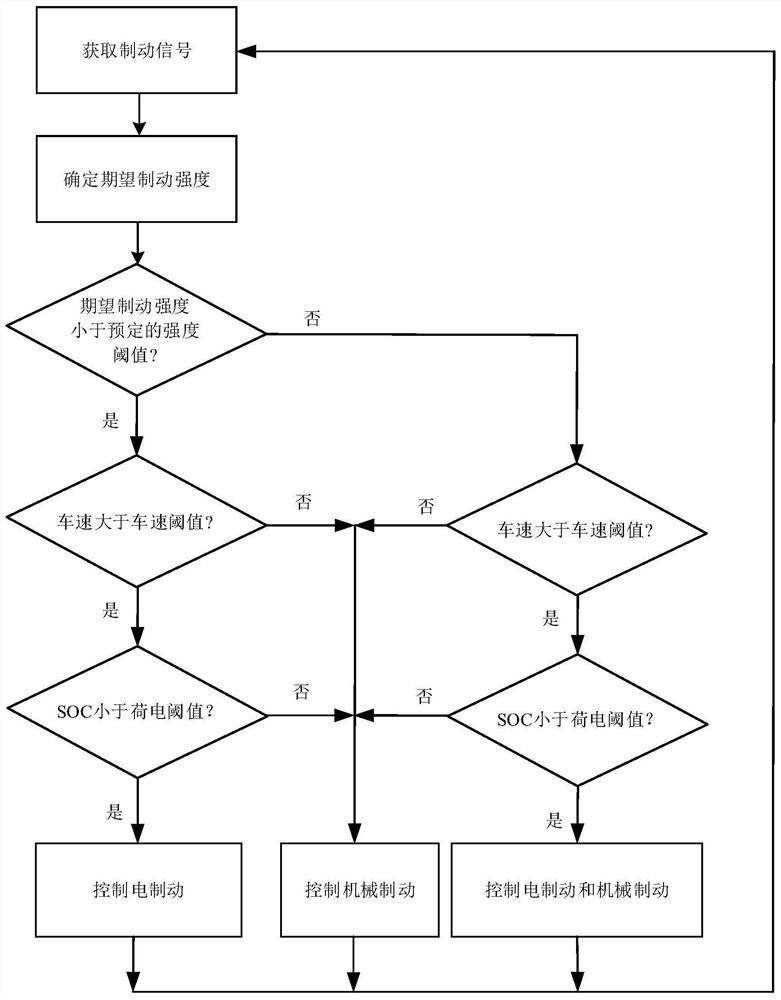

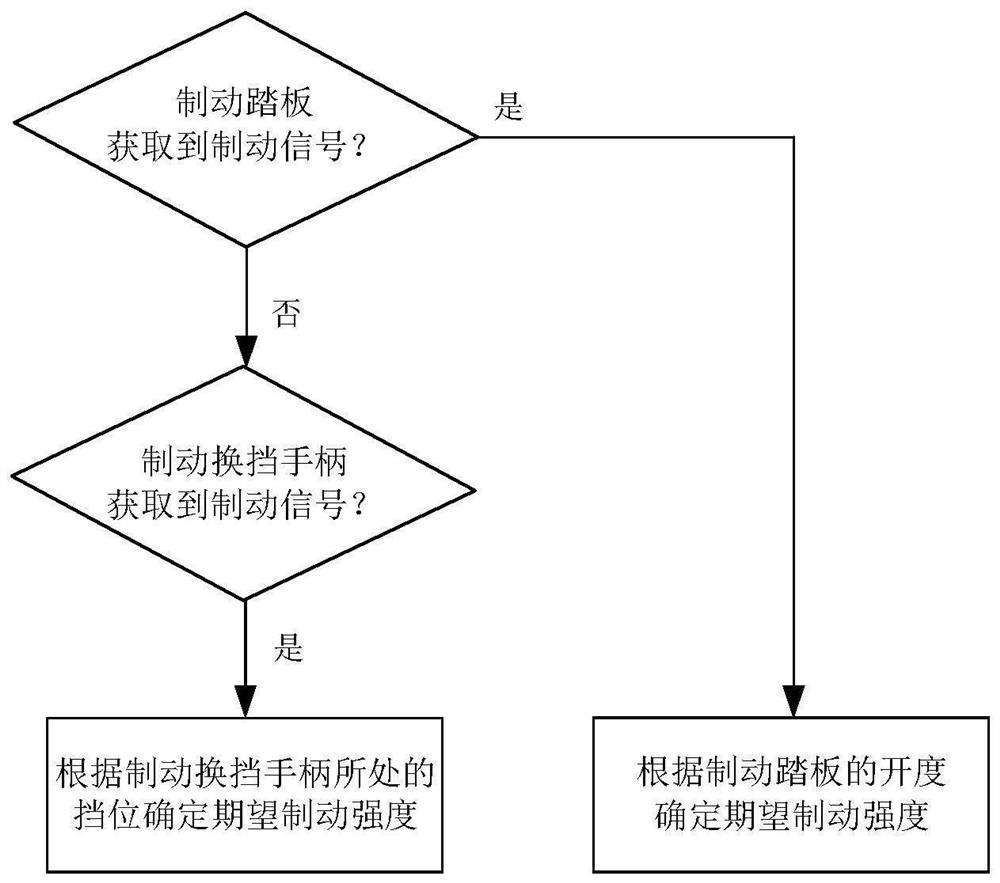

Vehicle brake control method and device, storage medium and vehicle

ActiveCN112092789AHigh recovery rateReduce frequency of useElectrodynamic brake systemsBraking systemsPower batteryNew energy

The invention relates to a vehicle brake control method and device, a storage medium and a vehicle. The method comprises the following steps: acquiring a brake signal of the vehicle; determining the expected brake strength according to the brake signal; if the expected brake strength is smaller than a preset strength threshold value, the vehicle speed is larger than a preset vehicle speed threshold value, and the SOC of a power battery is smaller than a preset charge threshold value, controlling the vehicle to be electrically braked; and if the expected brake strength is larger than or equal to the strength threshold value, the vehicle speed is larger than the vehicle speed threshold value, and the SOC of the power battery is smaller than the charge threshold value, controlling the vehicleto be subjected to electric brake and mechanical brake at the same time. Therefore, electric brake is preferential, the recovery rate of brake energy is increased, the new energy vehicle is more energy-saving, the use frequency of a mechanical braking system is reduced, and heat fade of a brake shoe is reduced.

Owner:BEIQI FOTON MOTOR CO LTD

Modified phenolic resin, preparation process thereof and brake pad cementing agent prepared by using same

ActiveCN101838437BHigh thermal decomposition temperatureStable emergency braking performanceOther chemical processesAldehyde/ketone condensation polymer adhesivesHigh velocityBrake pad

The embodiment of the invention discloses a modified phenolic resin. Phenolic resin is modified by adopting tung oil and nano particles, wherein the tung oil accounts for 10-15 wt% of the weight of the phenolic resin, and the nano particles account for 20-45 wt% of the weight of the phenolic resin. The thermal decomposition of the phenolic resin is remarkably increased by comprehensive modification on the phenolic resin, and a brake pad including the phenolic rein has stable braking performance and less heat fading during emergent braking at high speed. The invention also discloses a preparation process of the modified phenolic resin, a brake pad cementing agent, a preparation process thereof, and a brake pad using the brake pad cementing agent as a cementing agent.

Owner:SHANDONG GOLD PHOENIX

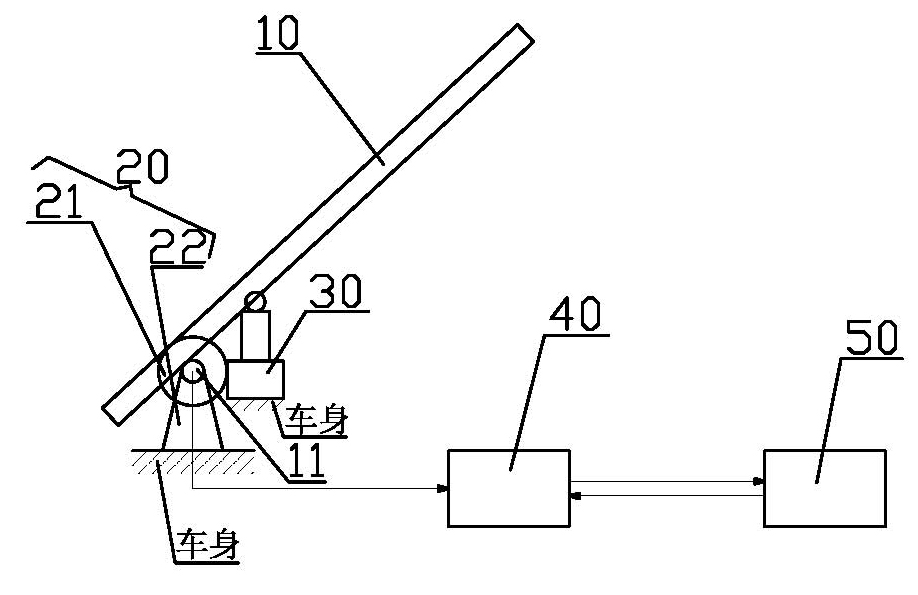

Vehicle brake control device and method

InactiveCN102029916ASmall thermal recessionExtend working lifeElectrodynamic brake systemsElectric machinesWorking lifeBrake shoe

The invention relates to a vehicle brake control device. The vehicle brake control device comprises an angle sensor and an eddy current retarder excitation winding working sequence controller which is electrically connected with the angle sensor and an eddy current retarder, wherein the angle sensor comprises a rotating shaft and a shell; the rotating shaft and the shell are provided with angle sensing components respectively; the angle sensing components are used for measuring the angle change when the rotating shaft and the shell are rotated relative to each other; and the eddy current retarder excitation winding working sequence controller is a logic control circuit and is used for controlling the working state of the original eddy current retarder excitation winding working control circuit of a vehicle according to brake angle information transmitted by the angle sensor. The vehicle brake control device exerts the effect of the eddy current retarder completely, reduces the abrasion of a brake shoe of a main brake and the heat fading of the braking efficiency as far as possible, prolongs the working life of the eddy current retarder, has a simple structure and low price, is convenient to butt, and conforms to a driving operation habit.

Owner:袁三友 +2

High-toughness fused corundum wear-resistant coating and preparation method thereof

The invention discloses a high-toughness fused corundum wear-resistant coating. The coating is prepared from the following raw materials: fused corundum 30-40 parts, a binding agent 5-8 parts, an auxiliary agent 0.2-0.3 part, activated micro-powder 2-3 parts, silicon carbide 1.6-2 parts and ethanol 7-10 parts. The invention also discloses a preparation method of the wear-resistant coating. According to the invention, fused corundum is taken as a main wear-resistant matrix and modified phenolic resin is taken as the binding agent of the wear-resistant matrix, the wear-resistant matrix be bondedand firmly attached to a substrate surface, and a dense friction layer can be formed on the substrate surface; through addition of the activated SiO2 powder into the wear-resistant coating, frictionbetween fused corundum particles is reduced, fluidity of the coating is improved, air holes of the wear-resistant coating can be filled, and thus density of the coating can be improved; and compounding of the SiC exerts an effective strengthening and toughening effect, so that the high-toughness fused corundum coating with good wear resistance is obtained, and the coating is suitable for surface protection of equipment.

Owner:YIXING GUOQIANG FURNACE IND

Multielement resin base carbon compound disc-type braking pad and preparation method thereof

ActiveCN102635653BImprove wear resistanceImprove high temperature resistanceFriction liningLow noiseTemperature resistance

The invention discloses a multielement resin base carbon compound disc-type braking pad and a preparation method thereof. The braking pad is obtained by carrying out mould pressing and forming once on the following raw materials: unmodified phenolic resin, organosilicone modified phenolic resin, polyacrylate modified phenolic resin, polyacrylonitrile carbon fiber, artificial granular graphite, natural crystalline flake graphite, granular coke, silicon carbide, aramid pulp, compound mineral fiber, steel fiber, red copper powder, ferrous sulfide and barium sulfate. The product disclosed by the invention has the advantages of high temperature resistance, ablation resistance, small heat expansion coefficient, high specific strength, high specific modulus, good abrasion resistance, low noise, excellent initial performance, short breaking-in period, small heat fade, long service life, excellent pedal comfort degree, excellent high temperature and high speed performance and stable abrasion grade under different braking conditions, the effect on considering the good abrasion resistance and low noise is achieved, no dust is generated during braking, and various materials are all environment-friendly environment-protection materials. The multielement resin base carbon compound disc-type braking pad also has the function of automatically cleaning the braking disc.

Owner:JINAN GOLD PHOENIX BRAKE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com